Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Tidy up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

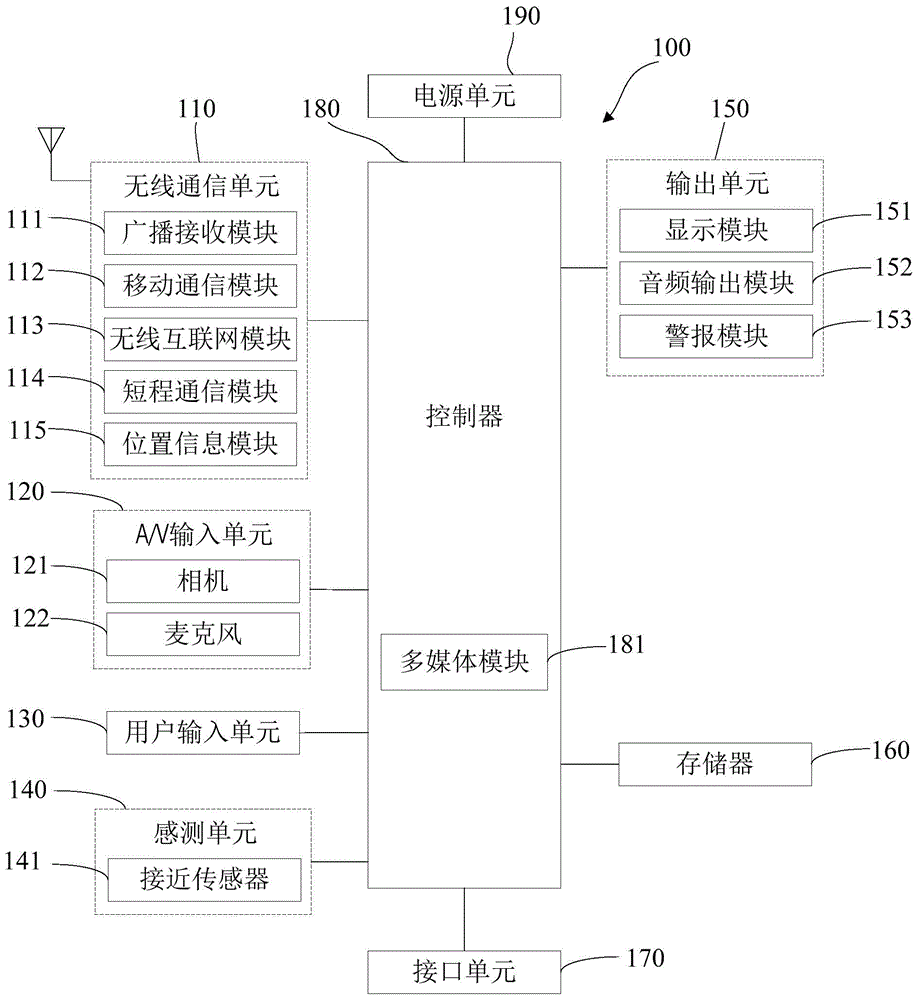

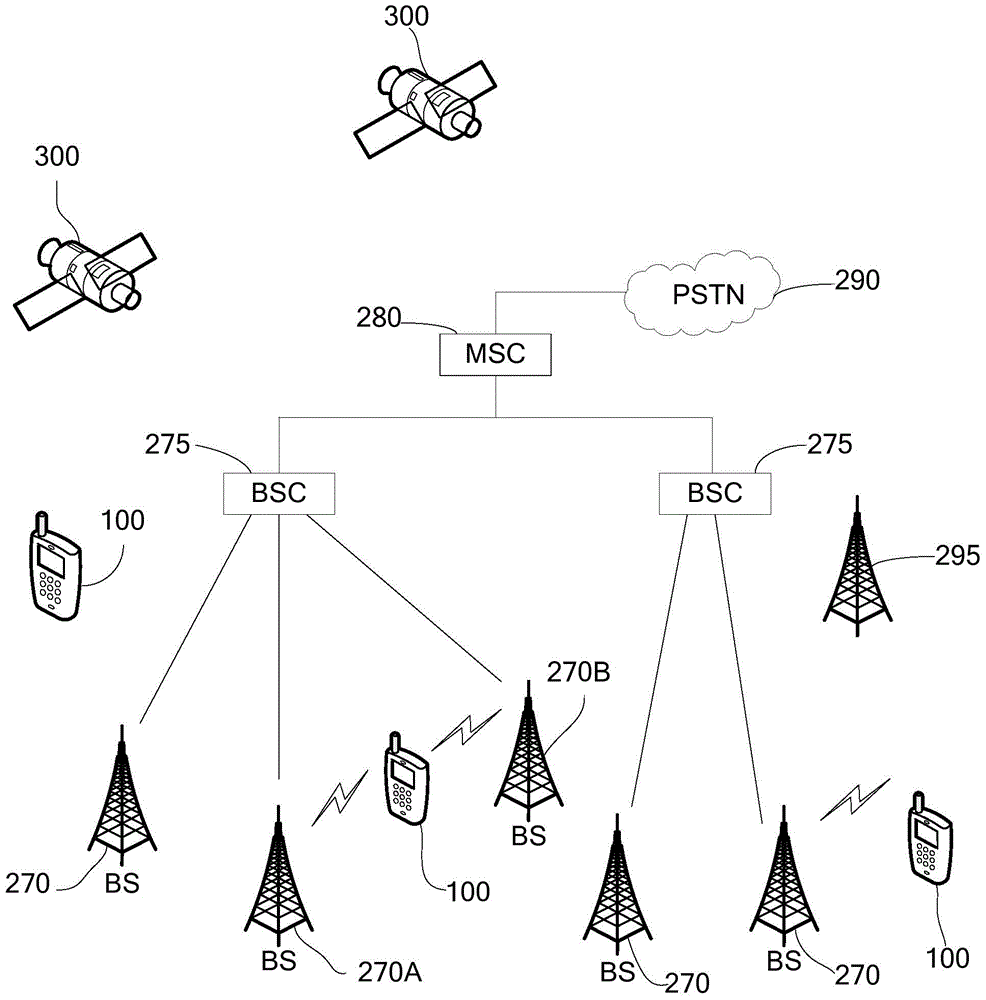

Method for managing desktop icon and mobile terminal

ActiveCN107193438ATidy upImprove user experienceInput/output processes for data processingThumbnailComputer terminal

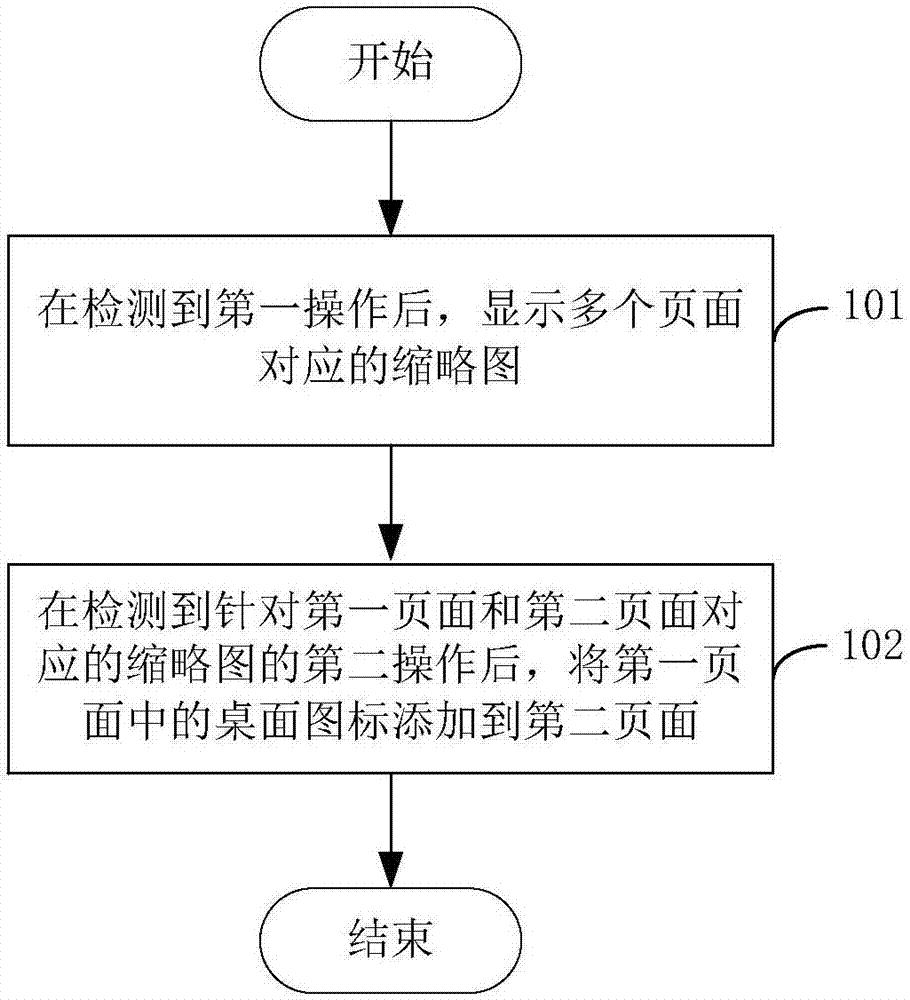

The embodiment of the invention discloses a method for managing a desktop icon and a mobile terminal. The method for managing the desktop icon comprises the steps of displaying thumbnails corresponding to a plurality of pages after detecting a first operation, wherein each page includes one or more desktop icons; after detecting a second operation for the thumbnails corresponding to the first page and the second page, adding the desktop icon in the first page to the second page, thereby facilitating a user for rapid and convenient arrangement of the desktop icons, reducing the workload of the user for moving the desktop on a certain page of the desktop to another page one by one and improving the usage experience of the user.

Owner:VIVO MOBILE COMM CO LTD

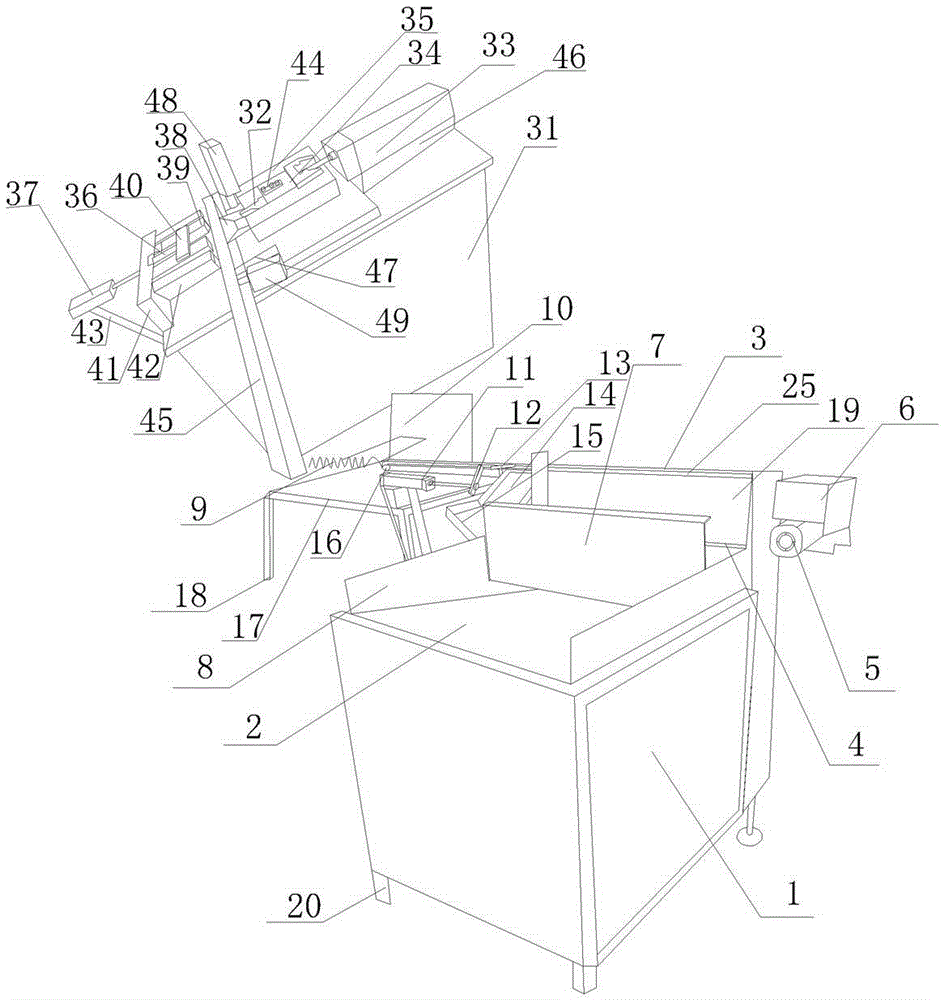

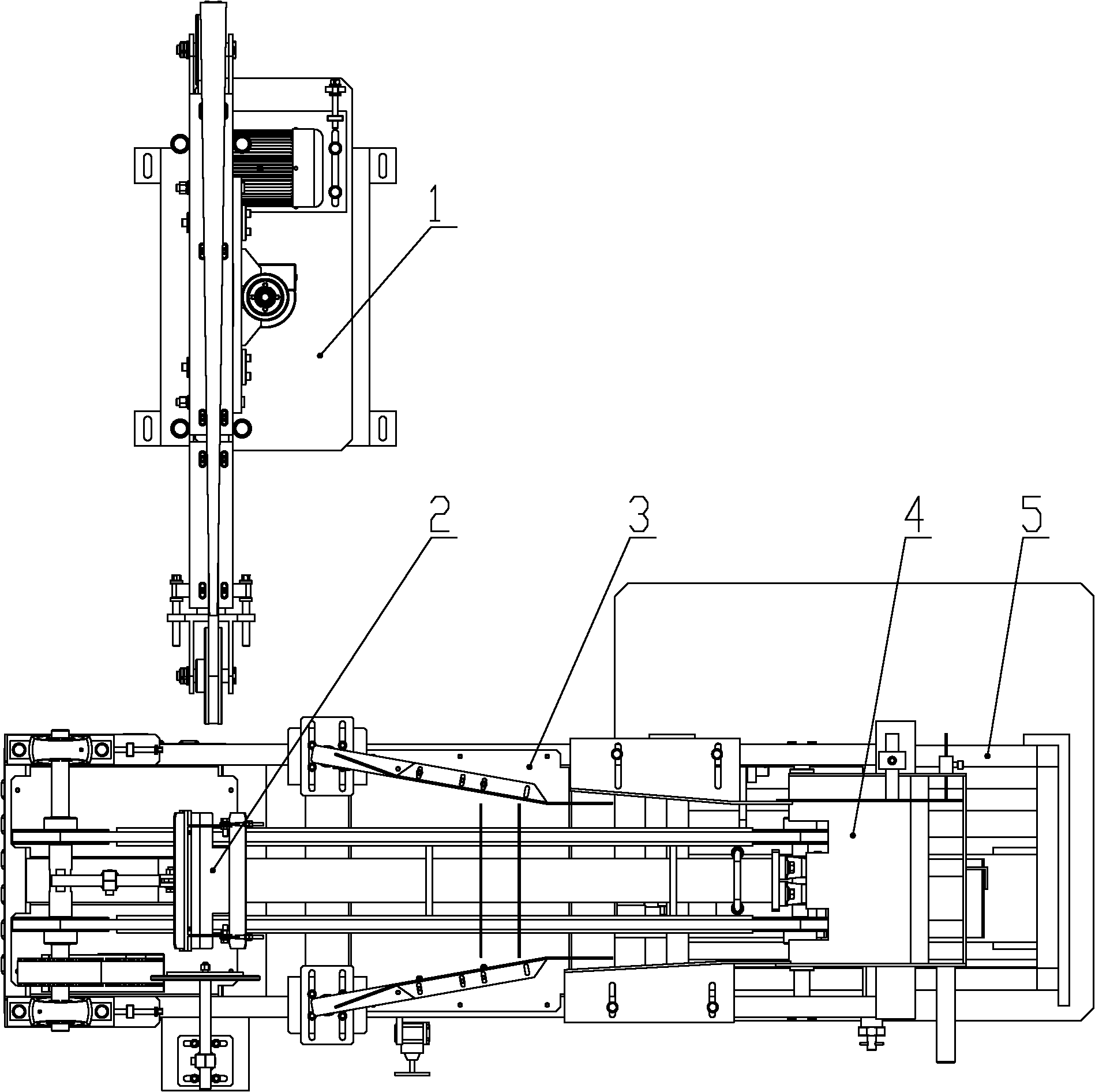

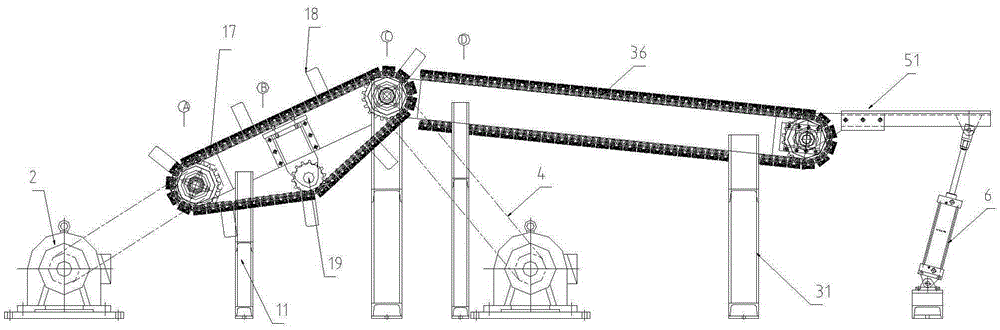

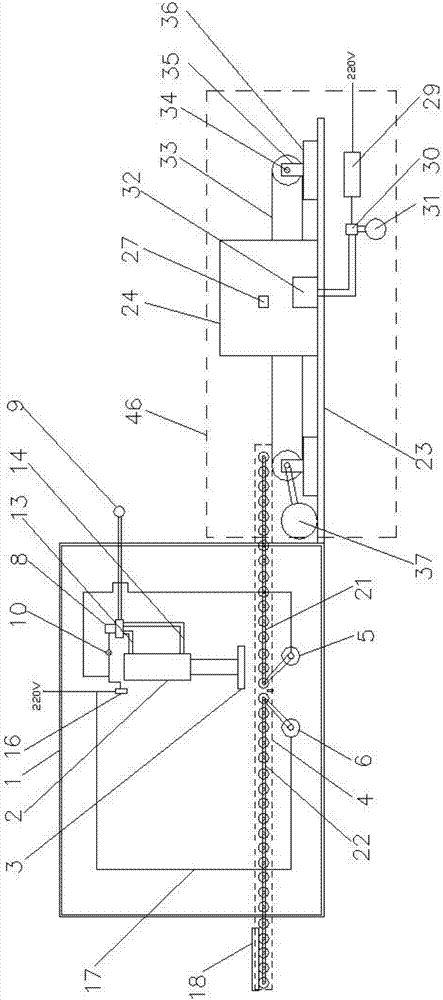

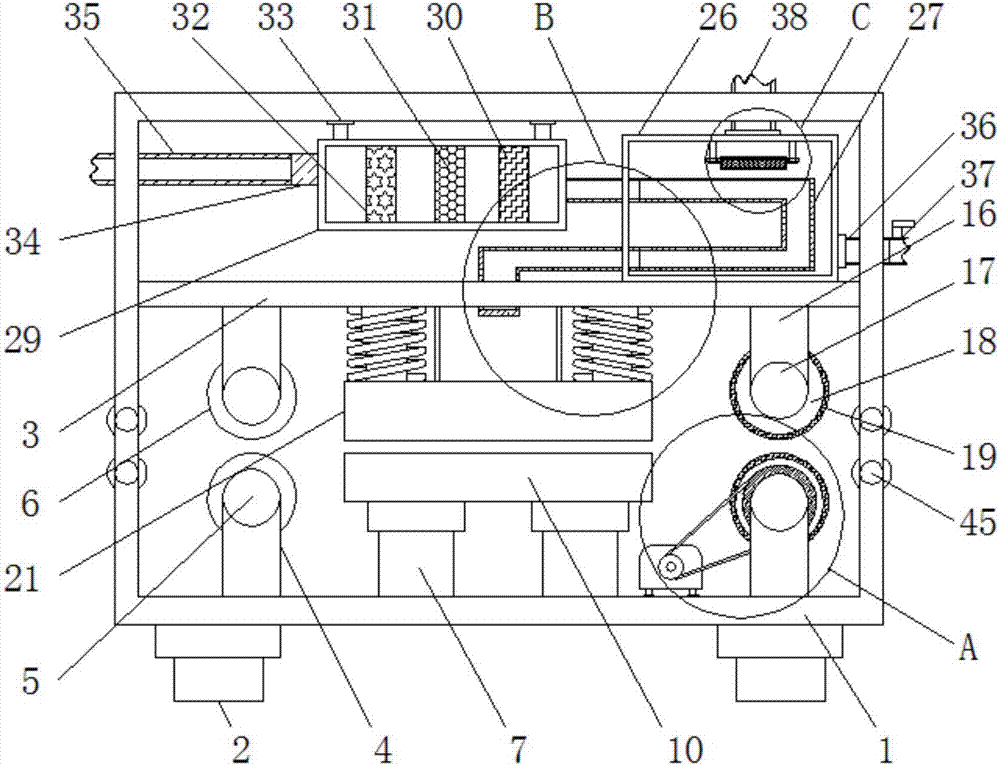

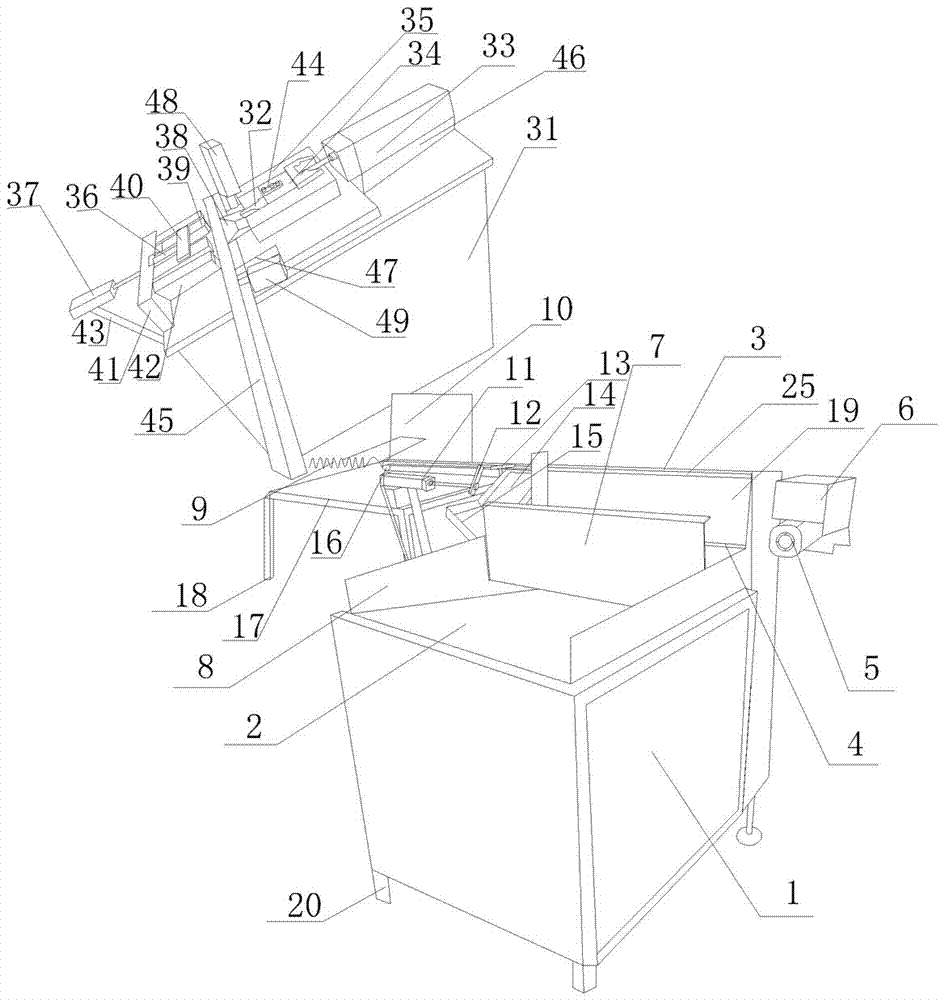

Hook production line

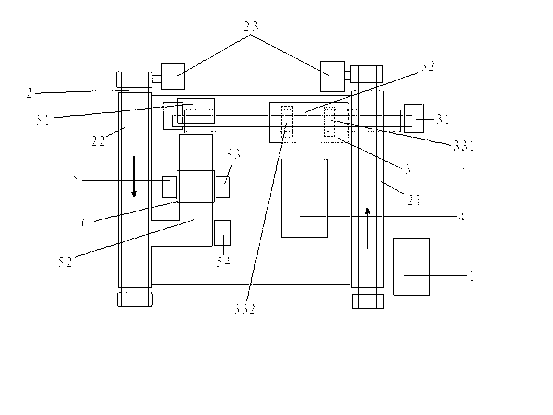

InactiveCN105383896AEnough heating timeTidy upConveyorsConveyor partsProduction lineShortest distance

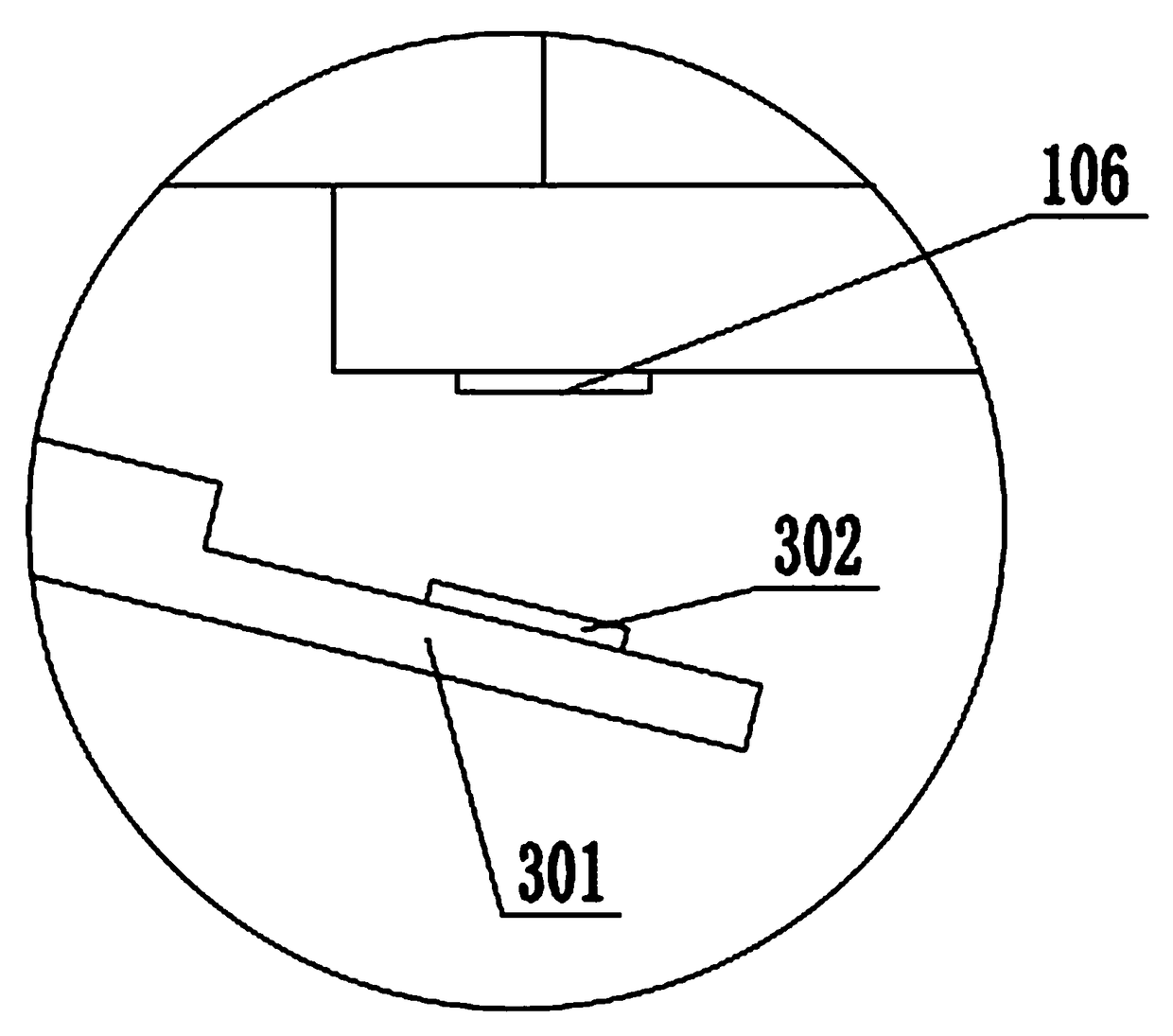

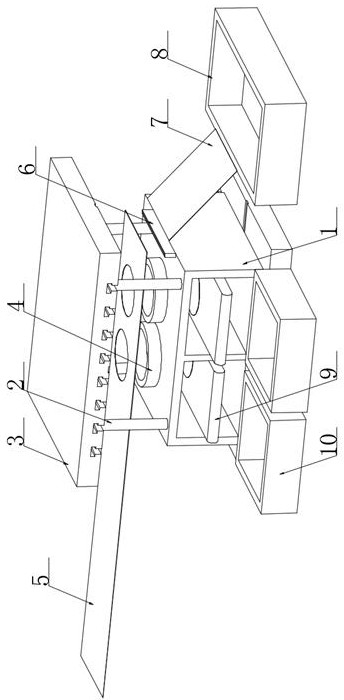

The invention discloses a hook production line. The hook production line comprises a short rod feeding conveying and heating device and a short rod bending device. The short rod feeding conveying and heating device comprises a feeding mechanism, a conveying mechanism, a material cutting mechanism and a heating mechanism. The feeding mechanism comprises a feeding bin, a feeding slope and a material supporting mechanism. The conveying mechanism comprises a conveying chain wheel, a conveying chain supporting frame, a conveying chain and a conveying motor. The heating mechanism comprises an electrical heating tube and an electric cabinet. The material cutting mechanism comprises a material cutting air cylinder, a material cutting blocking rod and a material falling slop. The electric cabinet is internally provided with a programmable logic controller (PLC) and an electrical heating tube switch controlling the operation of the electrical heating tube. The short rod bending device comprises a material collection box, a conveying track, an ejection bending mechanism and a counter-ejection discharging mechanism. According to the hook production line, the heating effect on short rods is ensured, and the operation is convenient; the efficiency is high; meanwhile, the short rods heated at high temperature automatically fall into the conveying track and can be subjected to ejection bending after a short-distance conveyance, and time and labor are saved. In addition, the discharging is convenient and the ejection bending effect is good.

Owner:建德市马目五金有限公司

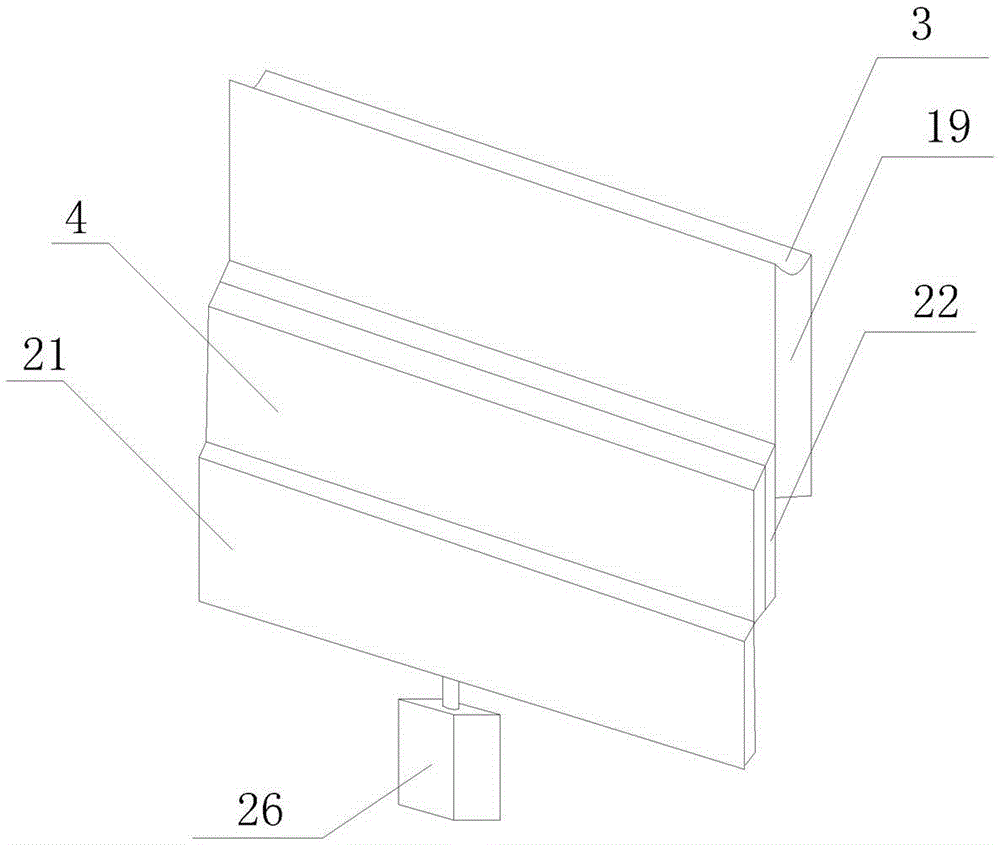

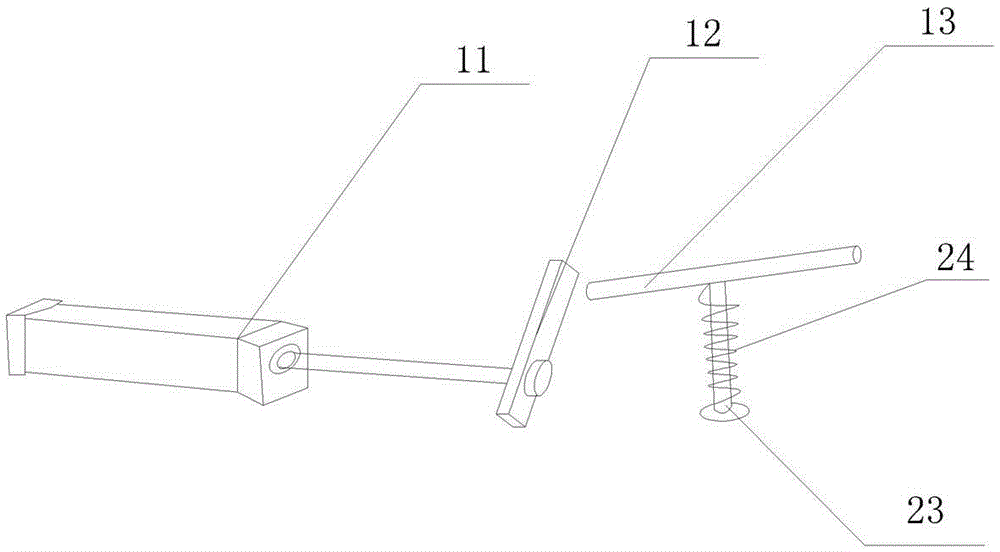

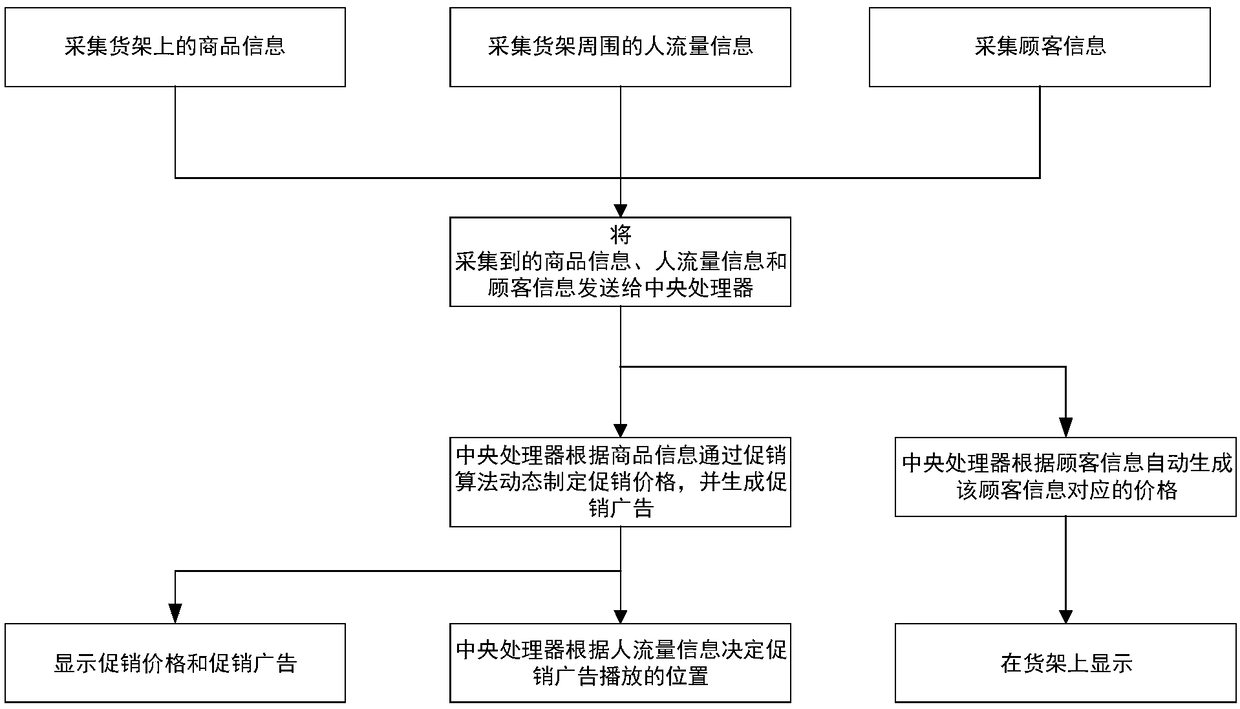

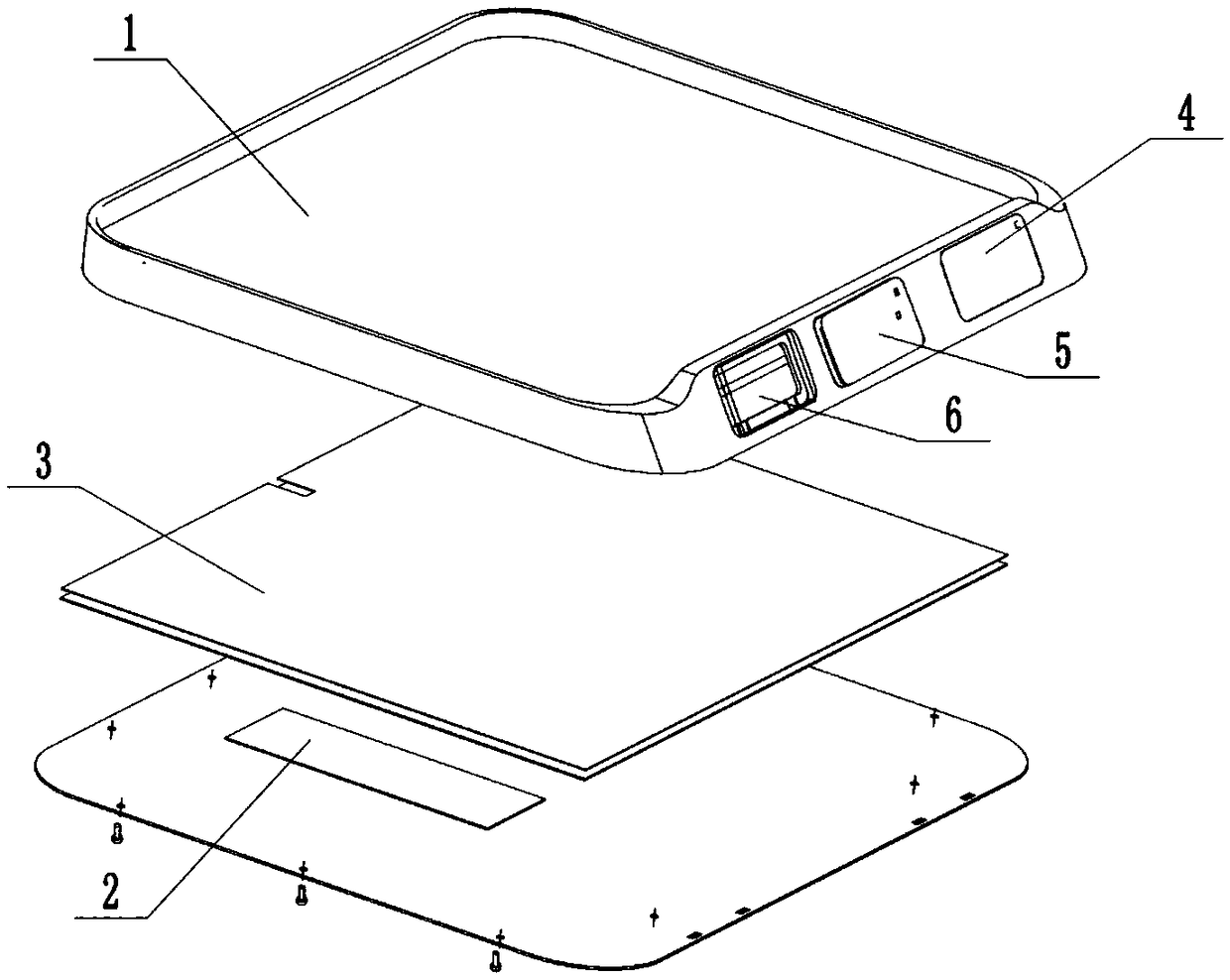

A retail promotion calculation method and device thereof

PendingCN109299965ATidy upSolve the problemCo-operative working arrangementsAdvertisingCustomer informationLibrary science

The invention relates to the field of commodity sales and discloses a retail promotion calculation method and a device thereof. The invention collects commodity information on a shelf, passenger flowinformation around the shelf and customer information through an information reading module, sends the collected the merchandise information, the passenger flow information and the customer information to the central processing unit, the CPU dynamically determines the promotional price of the commodity based on the promotional algorithm, and generate promotional ads. A promotional price is then displayed and a promotional advertisement is played in the display module. The application of the invention can accurately read the commodity information including the quantity on shelves and the commodity attributes on shelves through an information reading module, execute timely automatic price change based on the read commodity information and automatically advertise the promotion information generated by the automatic price change according to the promotion algorithm.

Owner:HANGZHOU CENTURY CO LTD

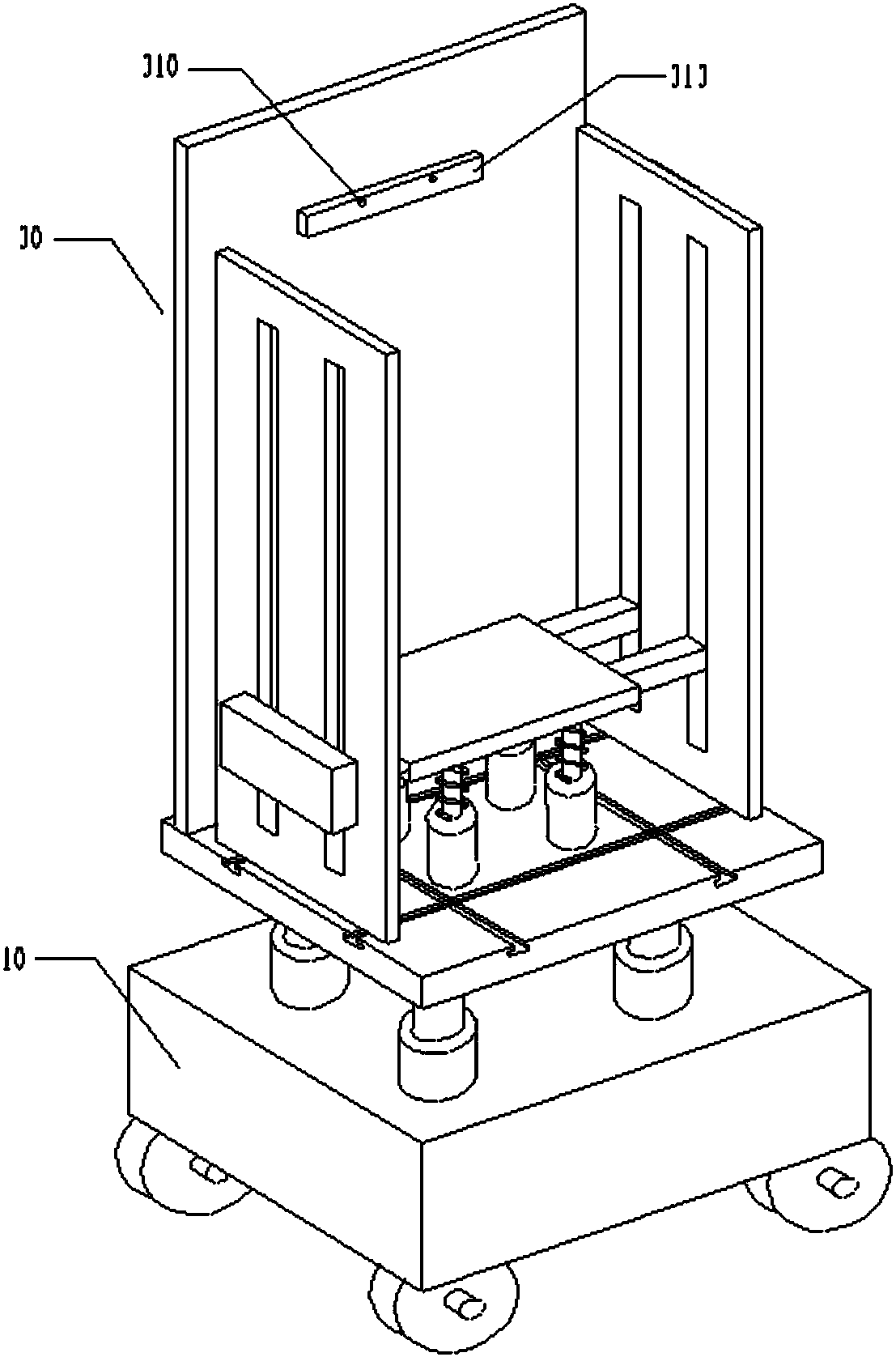

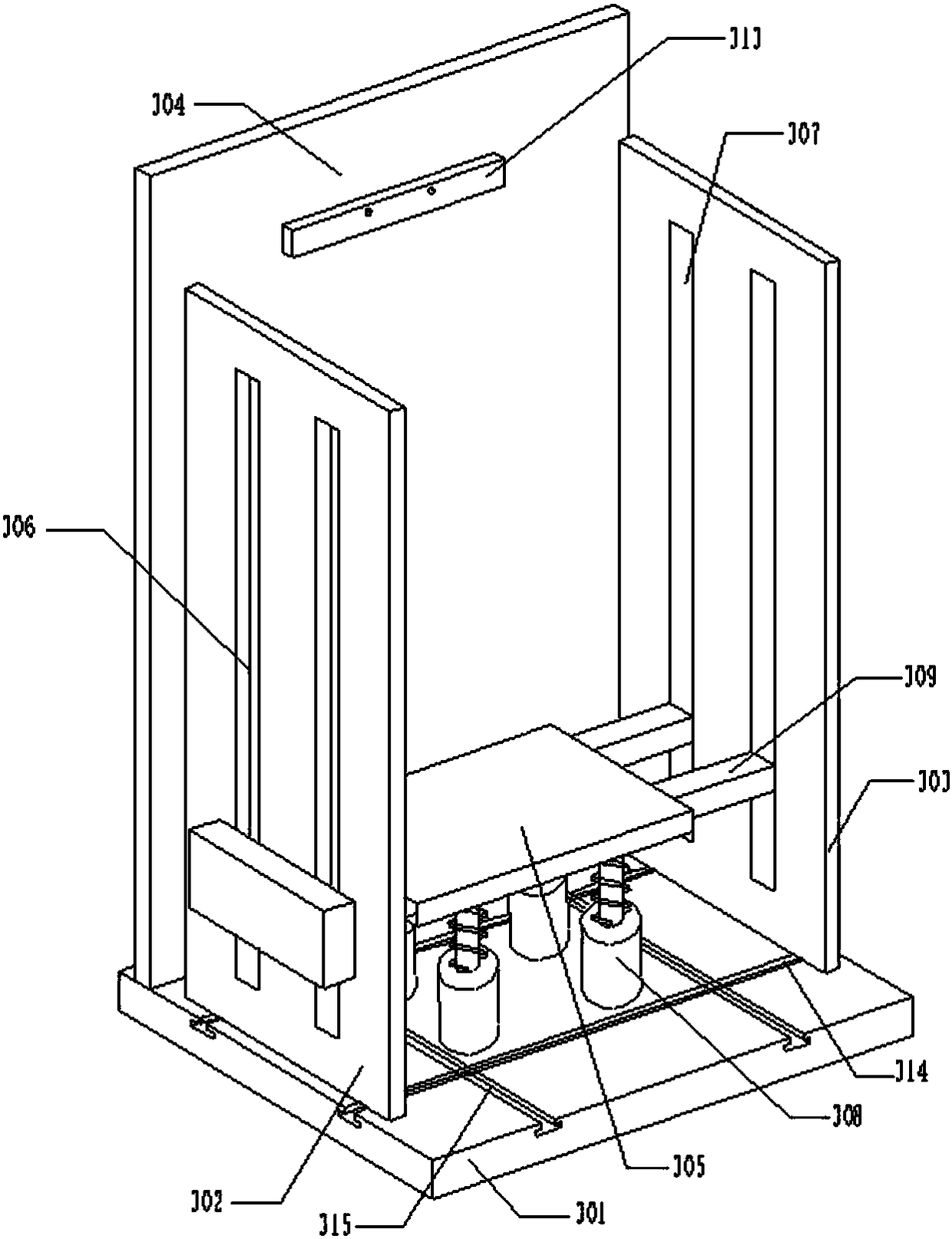

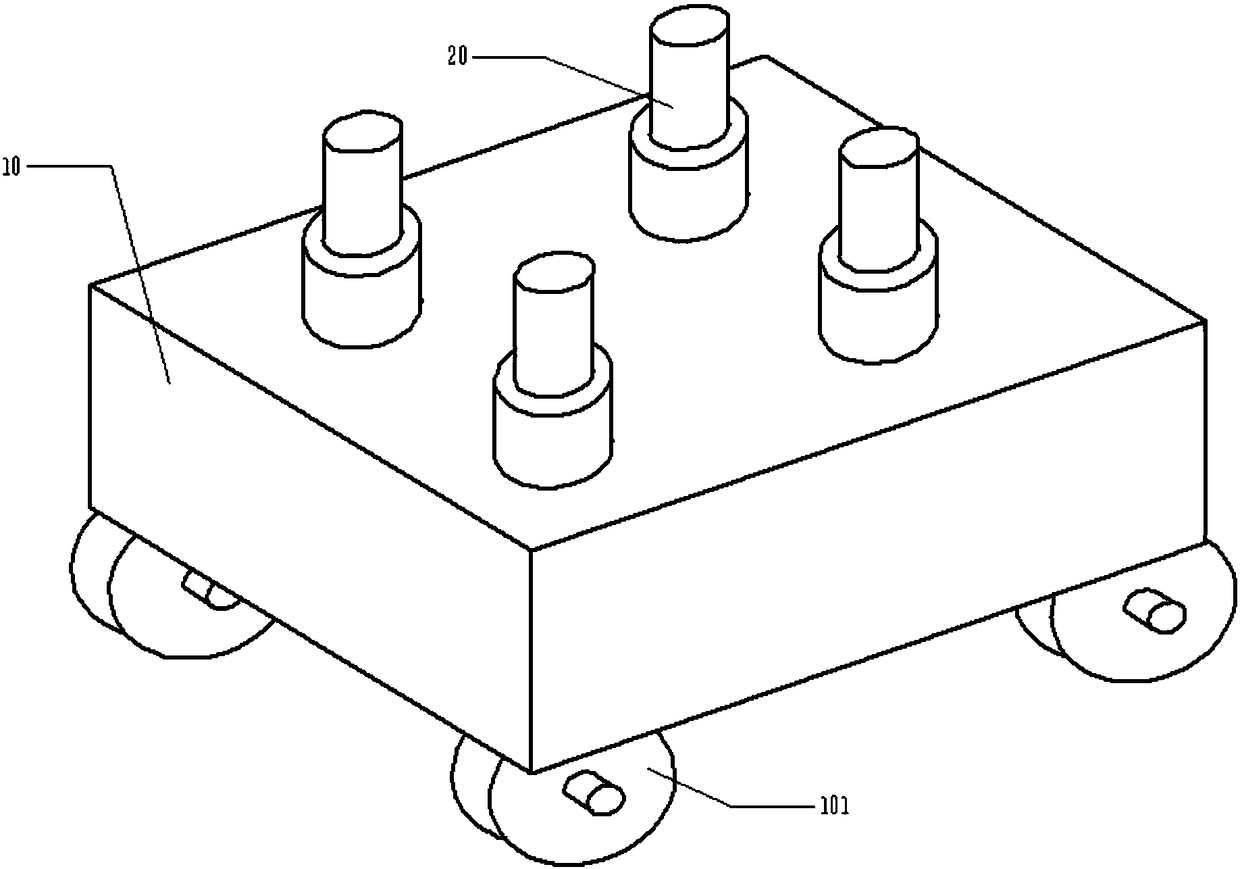

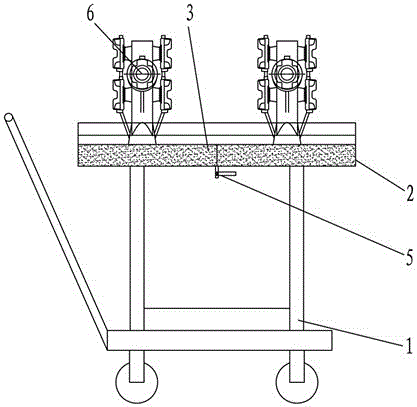

Steel plate feeding trolley in elevator production process

InactiveCN108263453AAvoid slipping problemsPrevent slippingHand carts with multiple axesSteel platesSheet steel

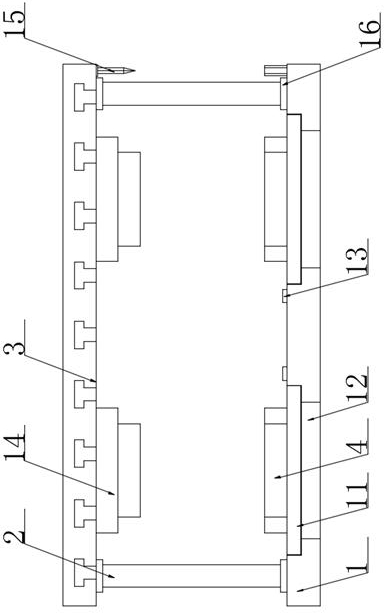

The invention provides a steel plate feeding trolley in an elevator production process. The steel plate feeding trolley comprises a trolley body base, a lifting portion, a discharge portion, and a control portion. The trolley body base is provided with the lifting portion. The top end of the lifting portion is provided with the discharge portion. The control portion is arranged on the discharge portion, and the control portion is electrically connected with the lifting portion. The lifting portion is four groups of vertical telescopic devices which are uniformly arranged. The discharge portioncomprises a bottom plate, a left baffle, a right baffle, a rear baffle, a supporting plate, and a material pushing device. The feeding trolley is simple in structure, and can coordinate good transferof steel plates in each process, and automatic material receiving and feeding of the steel plates are realized, to ensure production efficiency. The feeding trolley also effectively reduces labor intensity of workers.

Owner:TIANJIN HAOYA SCI & TECH DEV

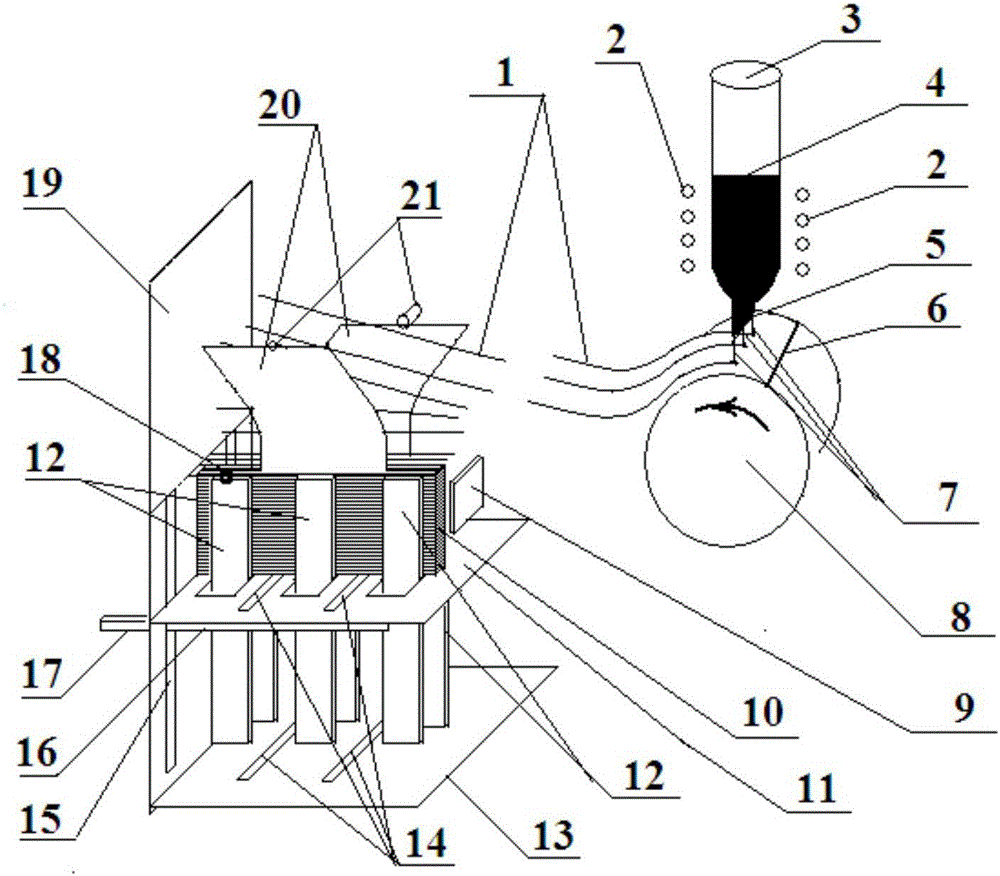

Method and system for preparing winding-free high-efficiency amorphous ribbon

The invention discloses a method and system for preparing a winding-free high-efficiency amorphous ribbon. The method comprises the steps that a plurality of small-bore small melt spraying holes are formed in a melt nozzle at certain intervals, and after a mother alloy molten mass injected out of the small-bore small spraying holes is sprayed to a rapid quenching cooling roll face, the amorphous ribbon is formed independently; the system for preparing the winding-free high-efficiency amorphous ribbon comprises a blending device, a throw-preparing device and an amorphous ribbon automatic collector. The mother alloy is heated to be molten through the high-frequency induction technology, and the alloy melt is sprayed to the cooling roll face which is provided with a transverse groove and rotates fast through the spraying holes with the diameter smaller than 1 mm, wherein the surface of the cooling roll face is polished. The alloy melt sprayed to the cooled roll face is fast cooled on the smooth roll face to form the amorphous ribbon with even thickness and width.

Owner:ZHEJIANG NORMAL UNIVERSITY

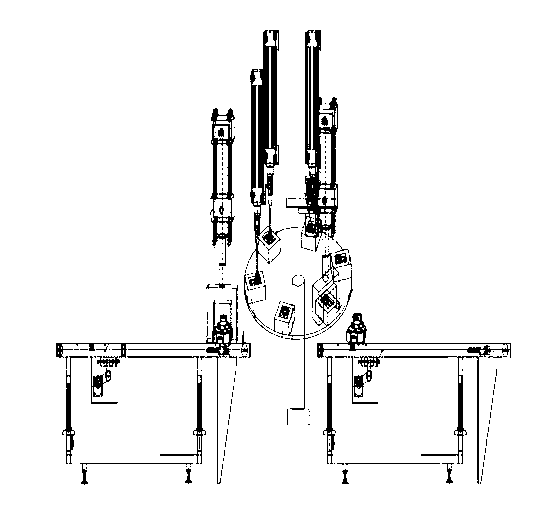

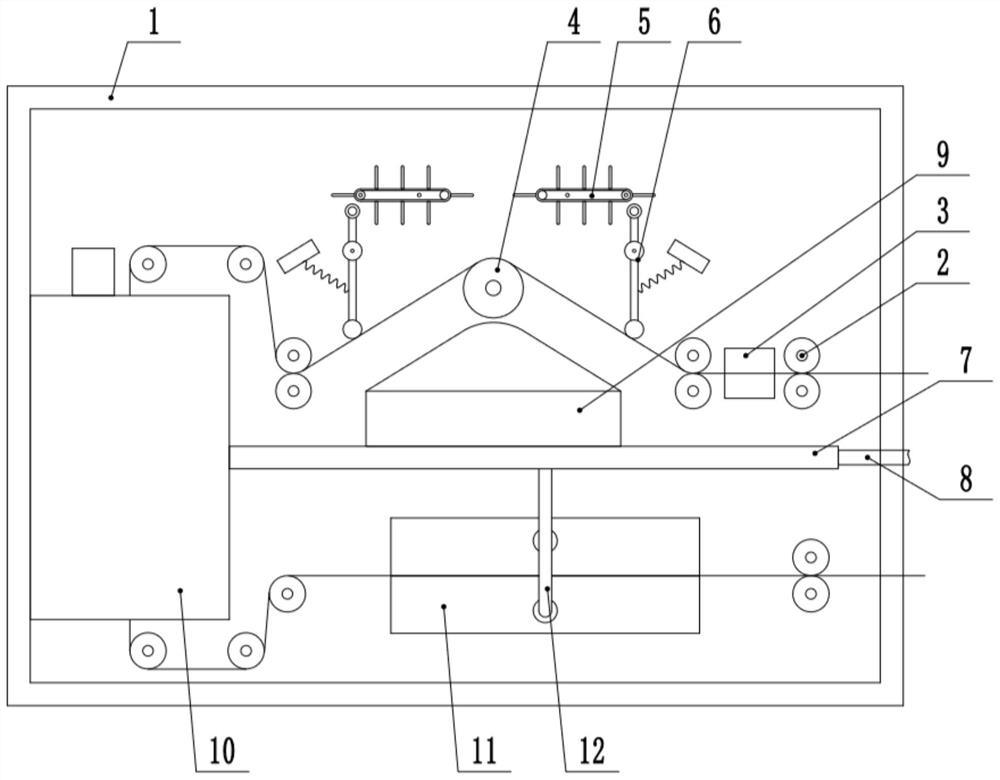

Automatic assembling machine

ActiveCN103264279AGuaranteed crawlImprove work efficiencyAssembly machinesSortingEngineeringAssembly line

The invention discloses an automatic assembling machine which comprises an electrical appliance control cabinet, a delivery mechanism, a grabbing mechanism, a rubber coating mechanism, a detection mechanism and a defective product grabbing mechanism. The delivery mechanism comprises a product input belt, a product output belt and a delivery motor, wherein the product input belt and the product output belt are respectively connected with the delivery motor. The grabbing mechanism is arranged between the product input belt and the product output belt transversely, the rubber coating mechanism is arranged on the middle portion of the grabbing mechanism, the detection mechanism is located below the grabbing mechanism and is connected with the product output belt, the defective product grabbing mechanism is arranged above the detection mechanism, and the electrical appliance control cabinet controls components of the delivery mechanism, the grabbing mechanism, the rubber coating mechanism, the detection mechanism and the defective productive grabbing mechanism to work. According to the automatic assembling machine, the electrical appliance control cabinet controls the components, the automatic assembly line work is achieved, the productivity is improved, the mechanical operation is high in stability, product quality is guaranteed, and market competitiveness is enhanced.

Owner:江苏泰昌电子有限公司

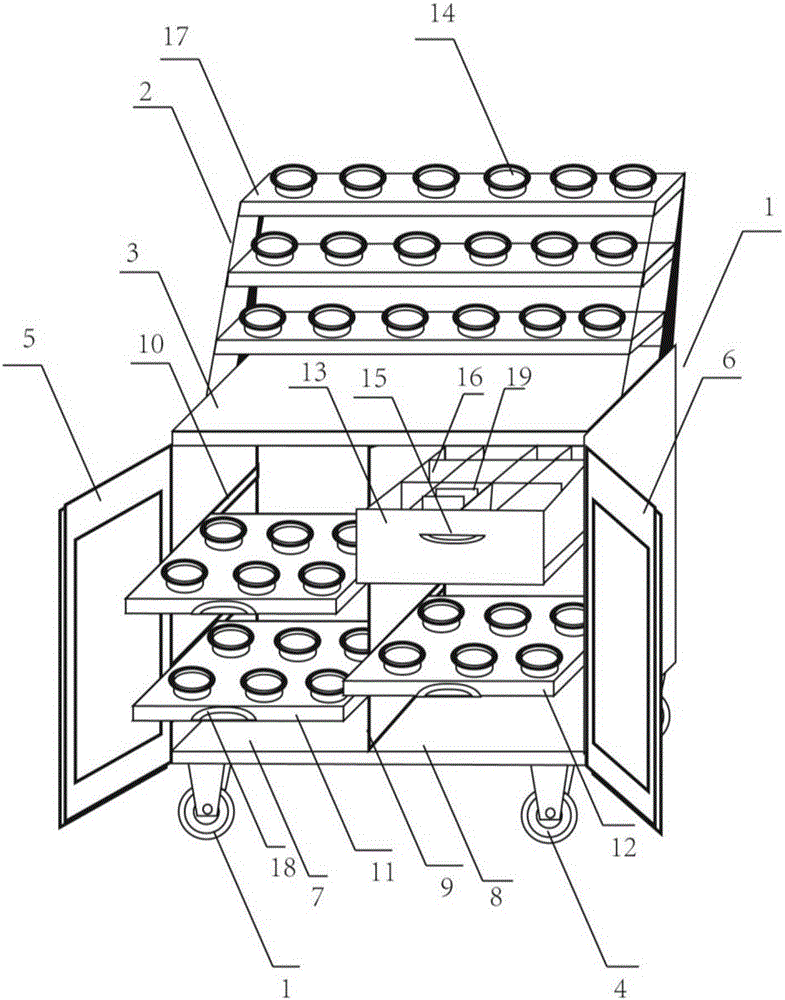

Multifunctional tool car of numerical control milling machine

InactiveCN105171706ANeatly placedTidy upWork tools storageOther workshop equipmentNumerical controlEngineering

The invention provides a multifunctional tool car of a numerical control milling machine. The multifunctional tool car is characterized in that a car body is included and comprises a support body and a cabinet; the support body and the cabinet are fixedly connected; universal wheels are arranged on the lower portion of the car body; the cabinet is provided with cabinet doors with forward openings, and the cabinet doors comprise the left cabinet door and the right cabinet door; a left cabinet body and a right cabinet body are arranged in the cabinet; first drawing type shelf boards connected through rails are arranged in the left cabinet body; a second drawing type shelf board and a drawer cabinet are arranged in the right cabinet body; the second drawing type shelf board is located on the lower portion of the right cabinet body and connected with the right cabinet body through a rail; the first drawing type shelf boards and the second drawing type shelf board are provided with a plurality of holes; a plurality of grids evenly divided are arranged in the drawer cabinet; and fixed flat plates are arranged on the support body. According to the multifunctional tool car, tools can be placed and arranged regularly, meanwhile, label plates are arranged in the drawer cabinet so that the tools can be numbered and labeled in sequence and be placed at specific positions, and workers can be effectively helped to find the tools conveniently.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

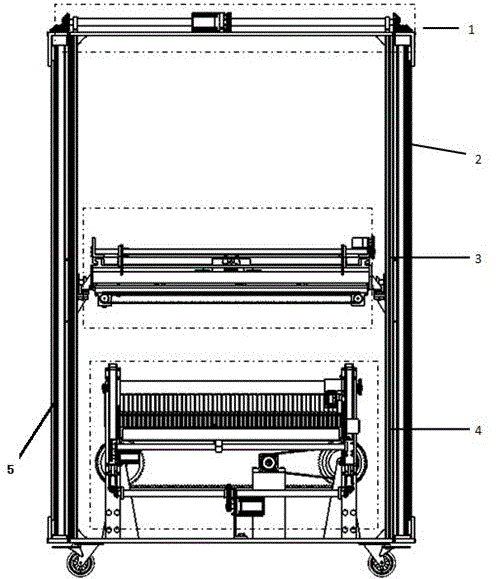

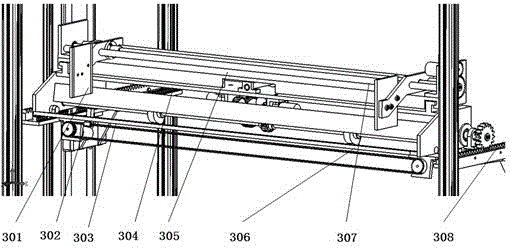

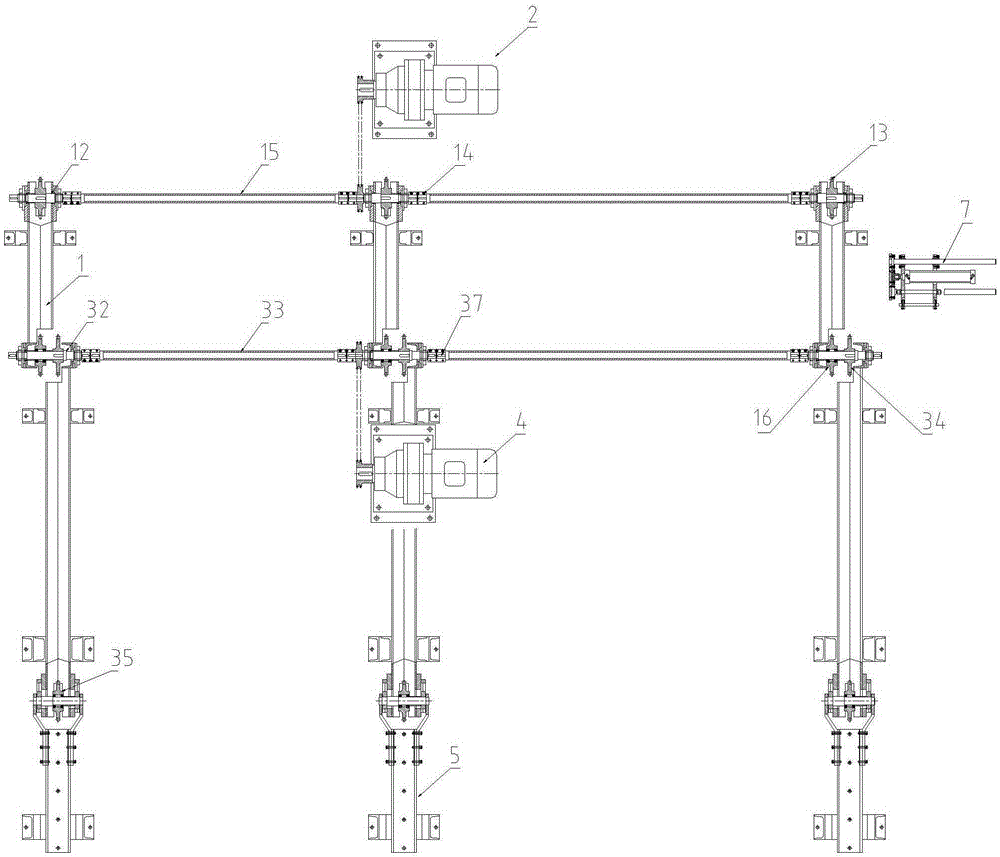

Shelving robot for library

The invention discloses a shelving robot for a library. The shelving robot comprises a first lead screw driving mechanism, first lead screws, a book taking and sorting mechanism, a sequencing mechanism and a rack, wherein the two first lead screws are symmetrically arranged on two sides of the rack in a left-right symmetric way; the first lead screw lead driving mechanism is arranged at the upper part of the rack; the book taking and sorting mechanism is arranged on the first lead screw; the sequencing mechanism is arranged at the lower part of the rack; the lead screw driving mechanism drives the first lead screws to rotate forwards and backwards, so that the book taking and sorting mechanism is driven to vertically move; the book taking and sorting mechanism is positioned on a certain layer of a bookshelf for taking books and sorting; the books are transported to the sequencing mechanism for sequencing; after sequencing, the books are transported to an original book shelf by the book taking and sorting mechanism. According to the intelligent robot working in the library, provided by the invention, the books on the certain layer in the bookshelf can be taken out and are orderly sorted; the taken books are sequenced; the books are placed back to an original layer of the bookshelf. The function of automatically sorting the books is realized under the condition that no manual intervention exists.

Owner:HUBEI UNIV OF TECH

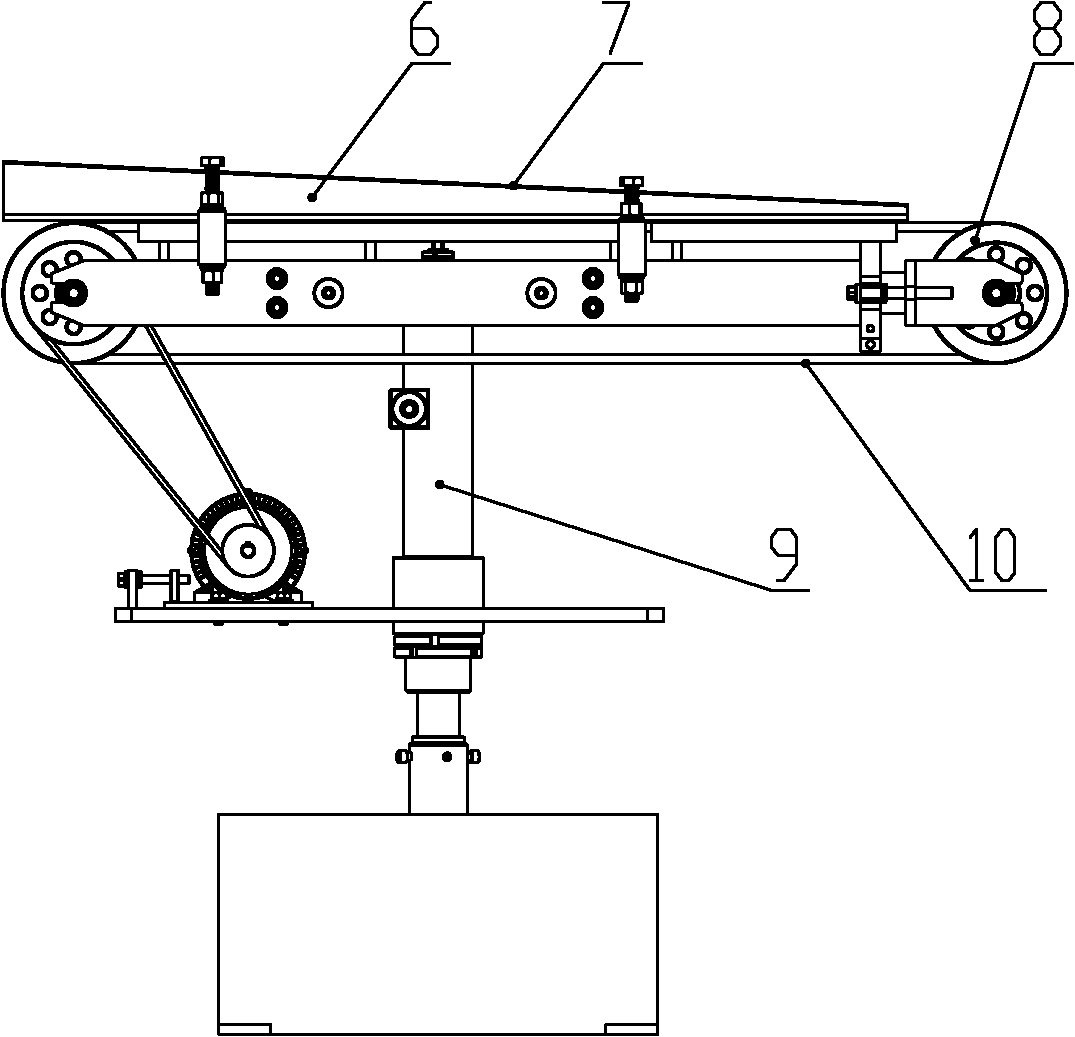

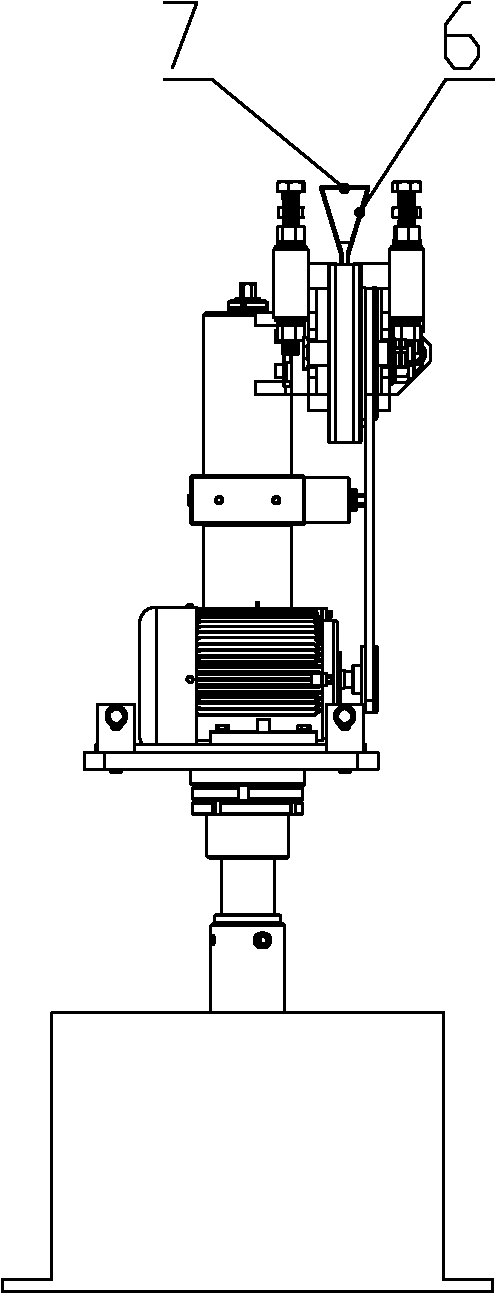

Automatic metal wire finishing device

InactiveCN102009828ATidy upNo random flyingLoading/unloadingConveyor partsControl systemWire cutting

The invention relates to an automatic metal wire finishing device. The device comprises a control system, and a wire receiving mechanism, a wire dropping mechanism, a wire adjusting mechanism, a wire feeding mechanism and a wire storing mechanism which are sequentially arranged. The automatic metal wire finishing device has high efficiency, completely meets the capacity of biaxial rotary flying shear wire cutting equipment, is easy to operate, automatically finishes metal wires without personnel intervention in the operation process, can be operated by personnel operating the biaxial rotary flying shear wire cutting equipment, does not need professional operating personnel, is safe, avoids the phenomenon of metal wire flying, ensures that the personnel do not need to contact the dangerous point of the equipment in the finishing process, has obvious effect, and ensures that the metal wires are ordered and uniform after being finished, and enter a wire storing device smoothly and quickly.

Owner:TIANJIN BRIDGE WELDING MATERIALS GROUP

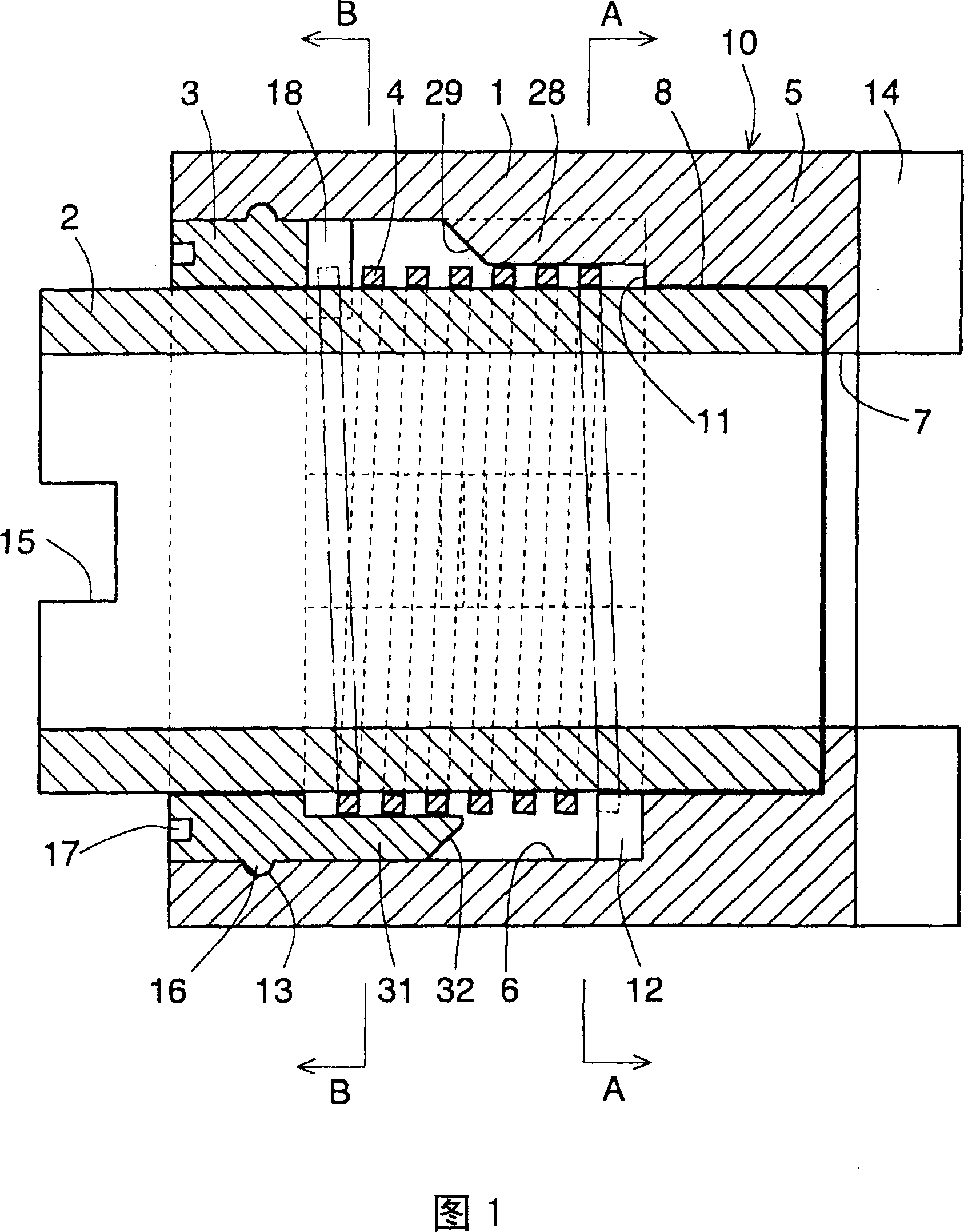

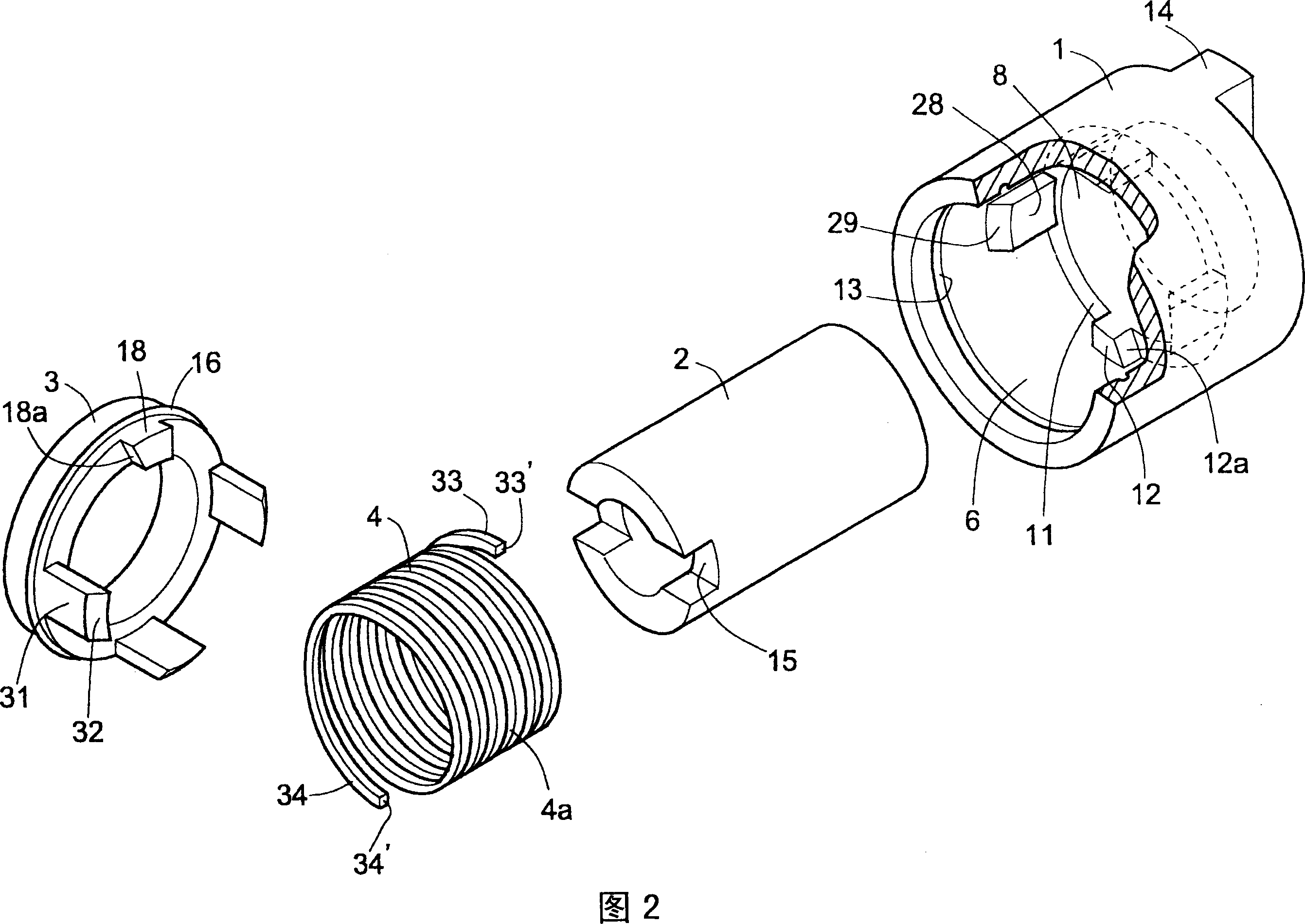

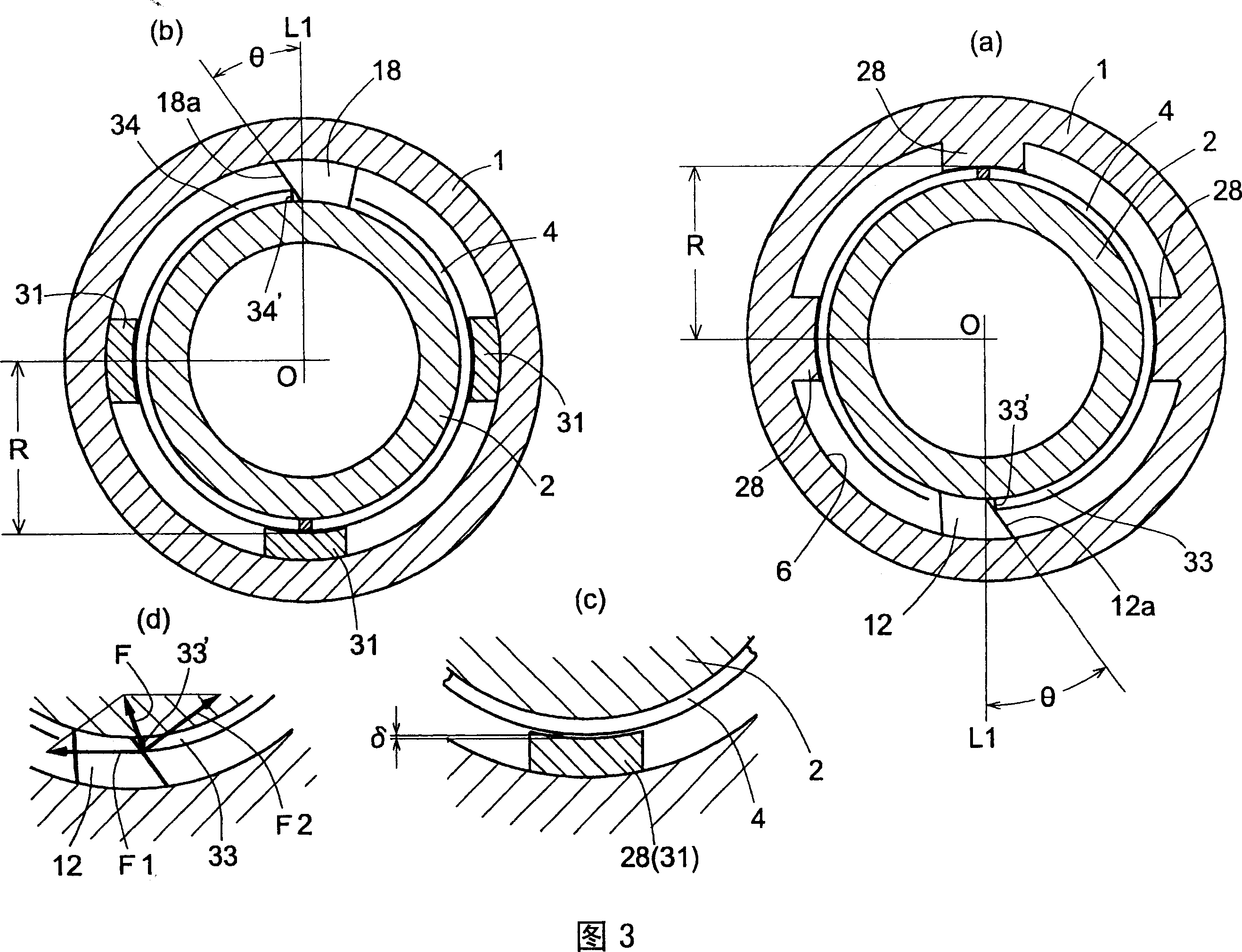

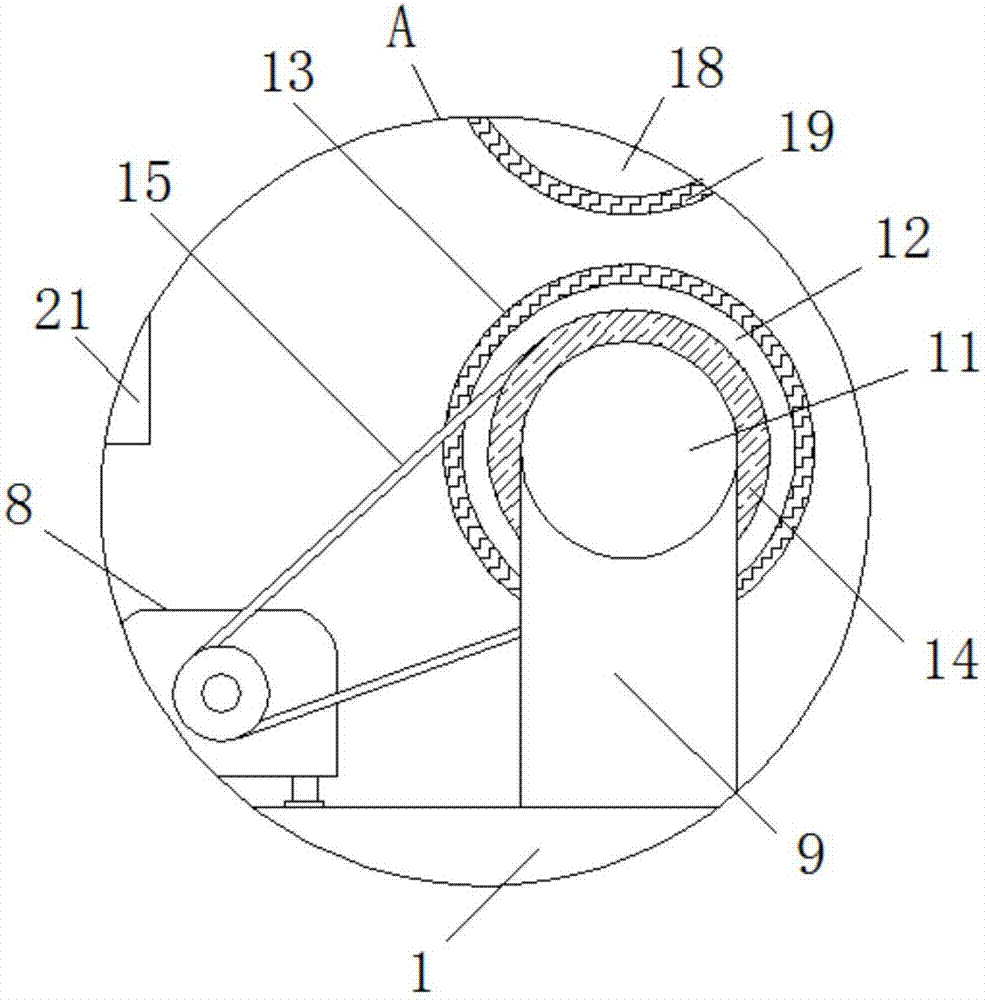

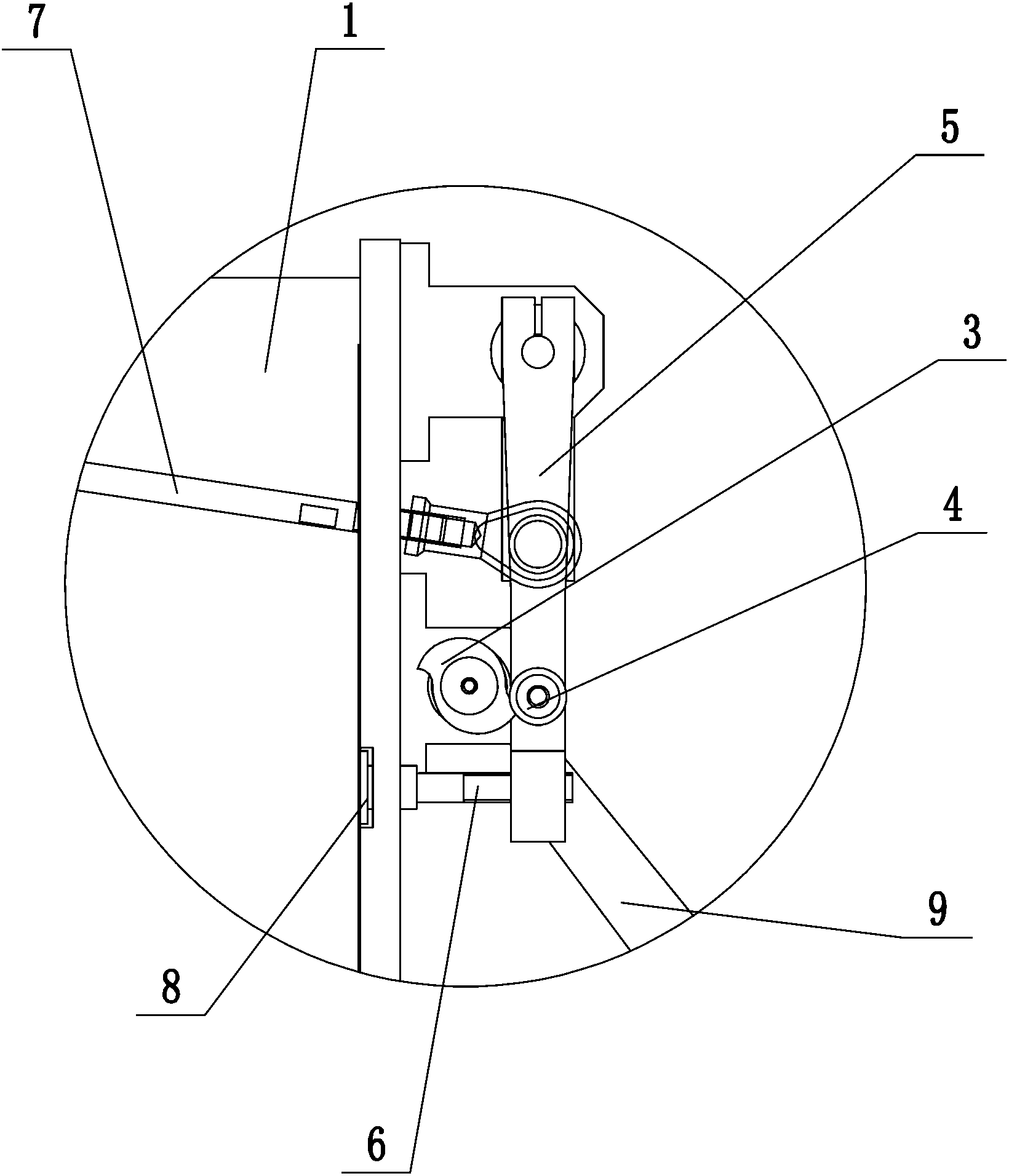

Torque restrictor

The present invention provides a spring-type torque limiter, which prevents vibration and abnormal sound during use by increasing the rigidity of both ends of a coil spring. By making the side faces of the outer ring member protrusion (12) and the cover member protrusion (18) on both ends of the coil spring (4) mounted on the outer diameter surface of the inner ring (2) have an inclination angle , the movement of the two ends in the direction of the outer diameter is restricted, thereby increasing the rigidity, and suppressing the generation of vibration and abnormal sound of the coil spring (4).

Owner:NTN CORP

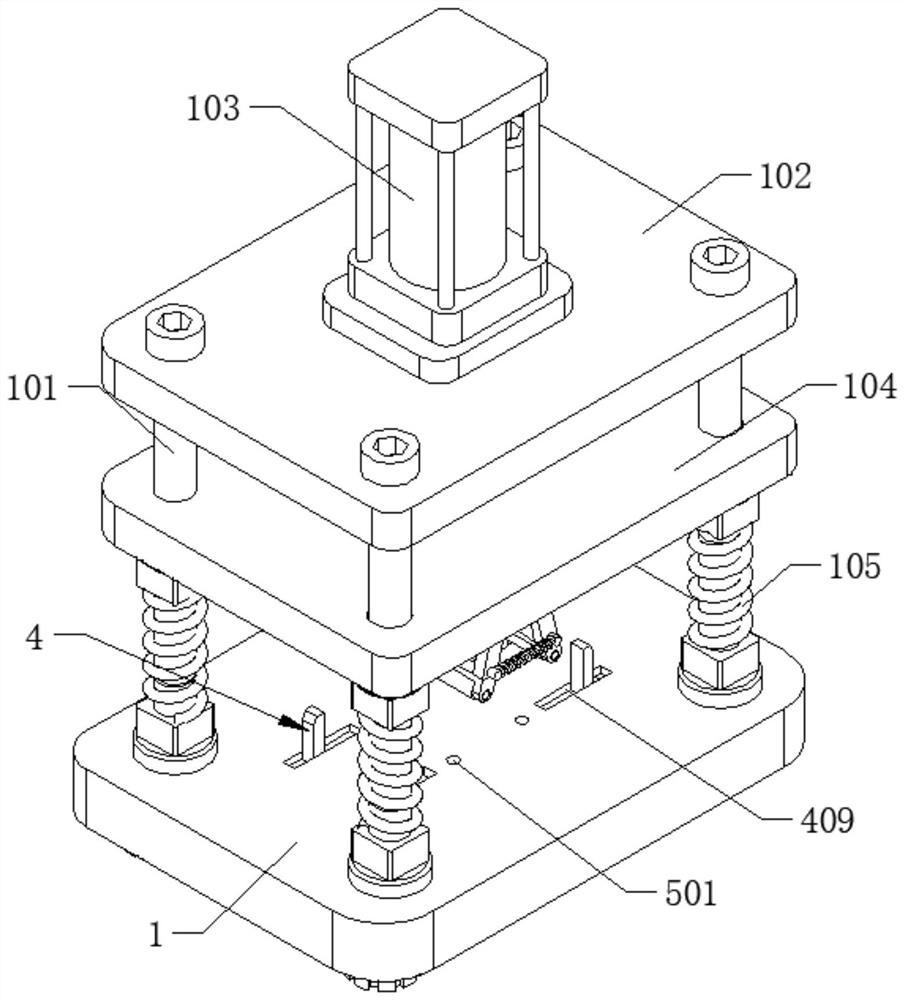

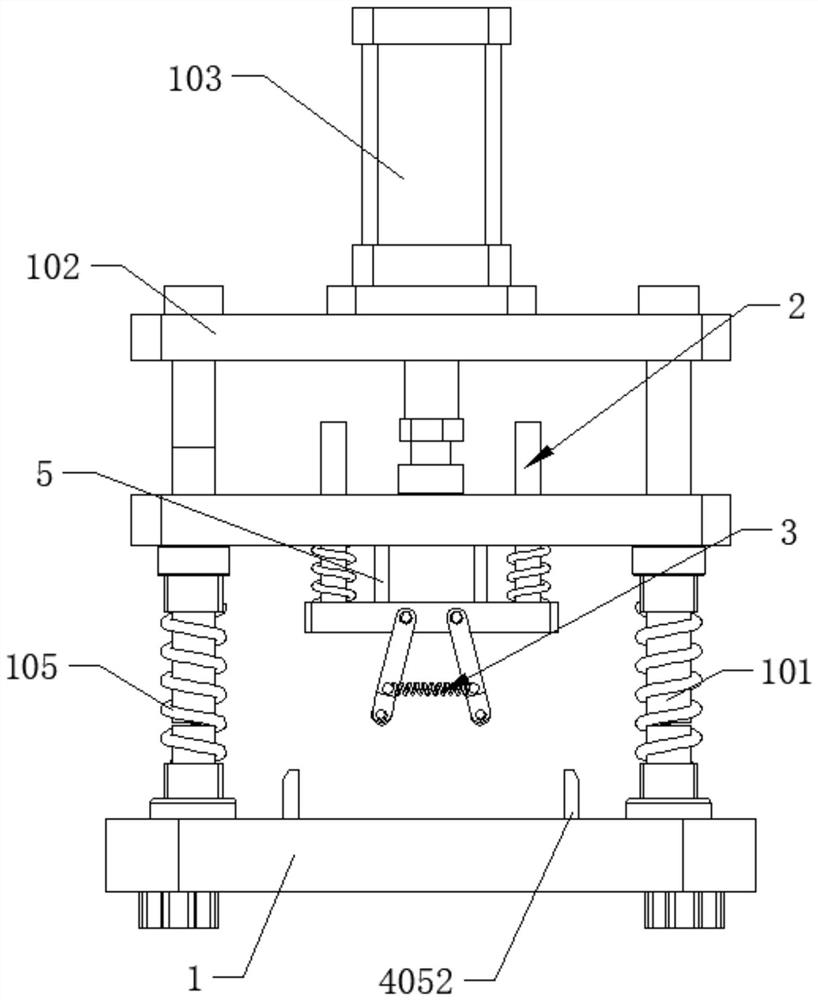

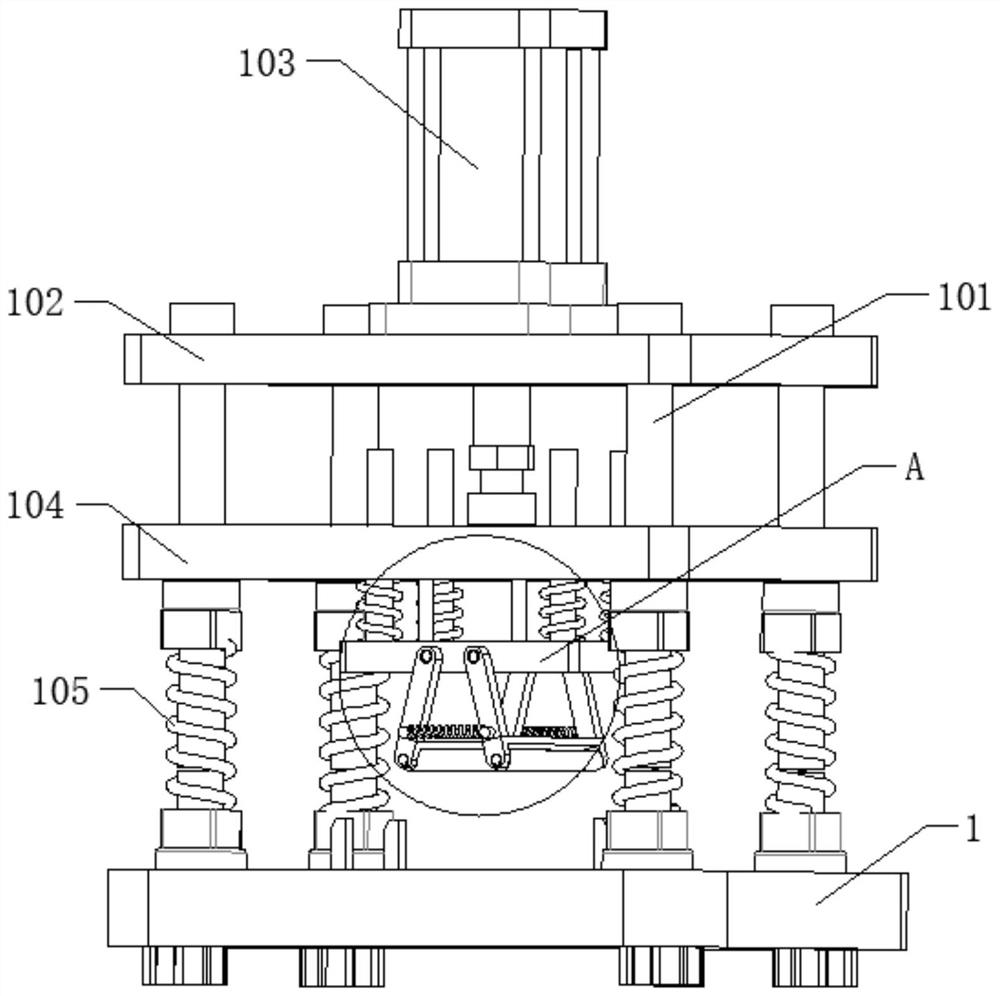

Auxiliary device for financial bill processing

InactiveCN112659778AEffective smoothing operationImprove drilling efficiencySheet bindingBookbinding pressesStructural engineeringSlide plate

The invention discloses an auxiliary device for financial bill processing, and belongs to the technical field of financial bill processing devices. The auxiliary device for financial bill processing comprises a base, a supporting column is connected to the top wall of the base, a supporting plate is connected to the top wall of the supporting column, an air cylinder is connected to the top wall of the supporting plate, the output end of the air cylinder penetrates through the supporting plate and is connected with a first sliding plate, a pressing plate assembly is connected to the bottom wall of the first sliding plate, a smoothing assembly is connected to the outer wall of the pressing plate assembly, a clamping assembly is arranged in the base, the output end of the clamping assembly penetrates through the base and extends upwards, a punching nail is further connected to the bottom wall of the first sliding plate, a sliding hole matched with the punching nail is dug in the pressing plate assembly, and a concave hole matched with the punching nail is formed in the top wall of the base. According to the device, bills needing to be perforated can be effectively and well arranged, meanwhile, the situation that the bills deviate in the perforating process can be avoided, and then the uniformity in the perforating process is effectively improved.

Owner:许嘉文

Packaging bag sorting device

The invention relates to a packaging bag sorting device comprising a workbench, a guide-in roller, a pulling force roller, an air ejecting pipe and a brush roller, wherein the air nozzle of the air ejecting pipe is aligned with the guide-in roller and used for initially blowing flat a packaging bag delivered from the workbench and guided in by the guide-in roller, and the brush roller is used for leveling and spreading the packaging bag blown flat by the air ejecting pipe. The packaging bag sorting device provided by the technical scheme of the invention can sort packaging bags flatly and regularly and is convenient to load and open bags, thereby realizing automatic filling of the packaging bags.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

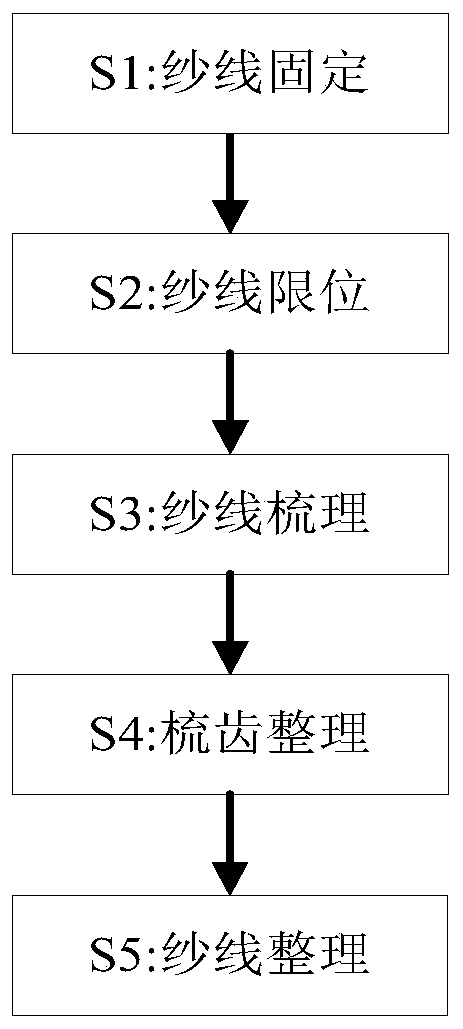

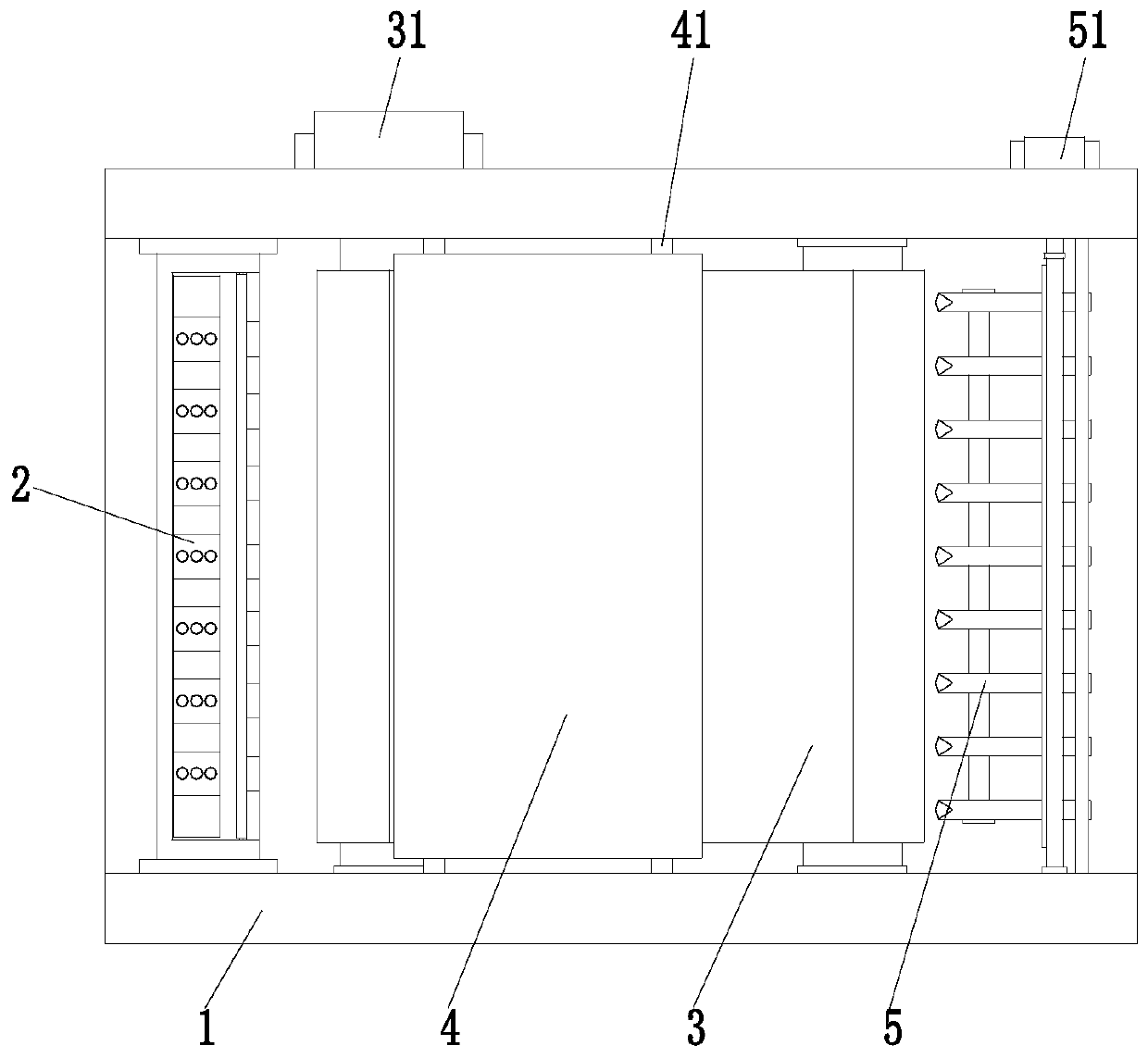

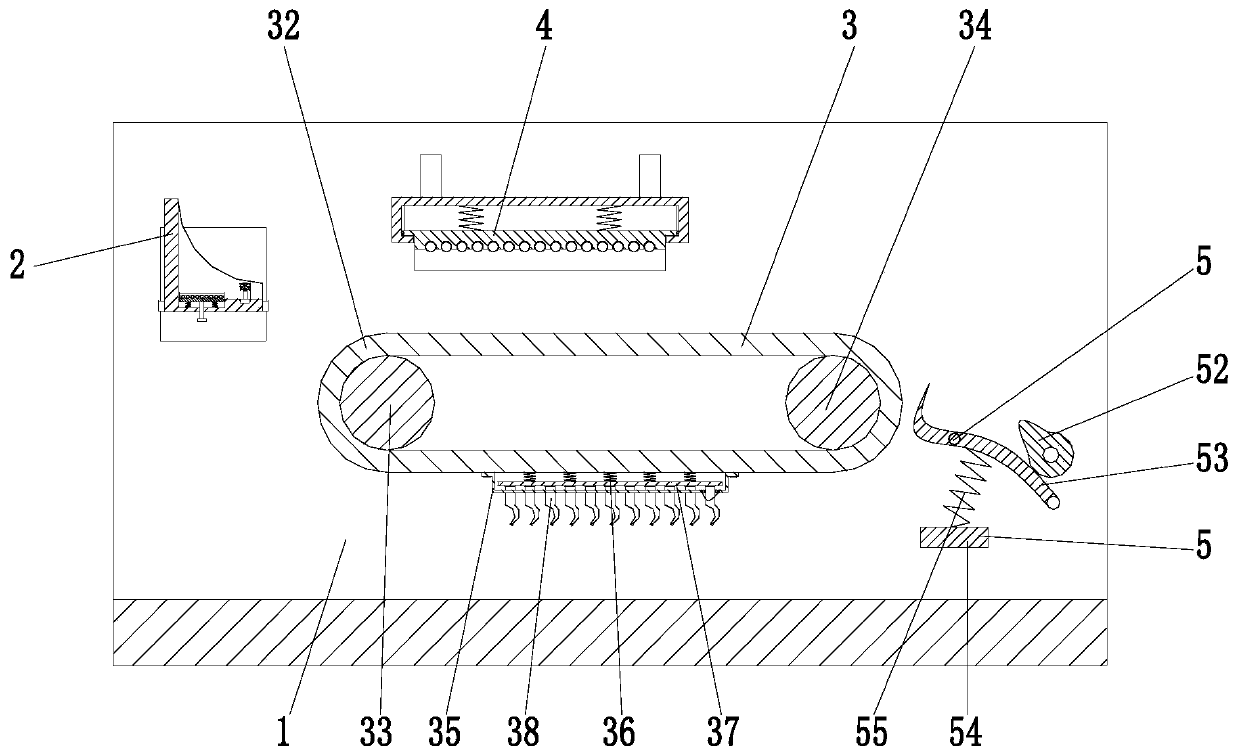

Method for quickly carding textile yarns

ActiveCN110644103AImprove combing effectImprove carding efficiencyFibre cleaning/openingTextile yarnEngineering

The invention provides a method for quickly carding textile yarns. A U-shaped frame, a fixing device, a carding device, a limiting device and an impurity removing device are matched to finish rapid carding operation of the textile yarns. The main problems that in an existing main process of carding yarns, continuous carding work in the same direction cannot be carried out for the yarns all the time, intermittent rotary carding operation is adopted, and low carding efficiency of the yarns is caused by the carding method; in the process of yarn carding, along with the lengthening of the cardingtime, a large amount of broken yarns and other impurities are wound on comb teeth, so that the carding work of the comb teeth on the yarns is influenced; and the quality of the carded yarns is low aresolved.

Owner:晋江恒升染织有限公司

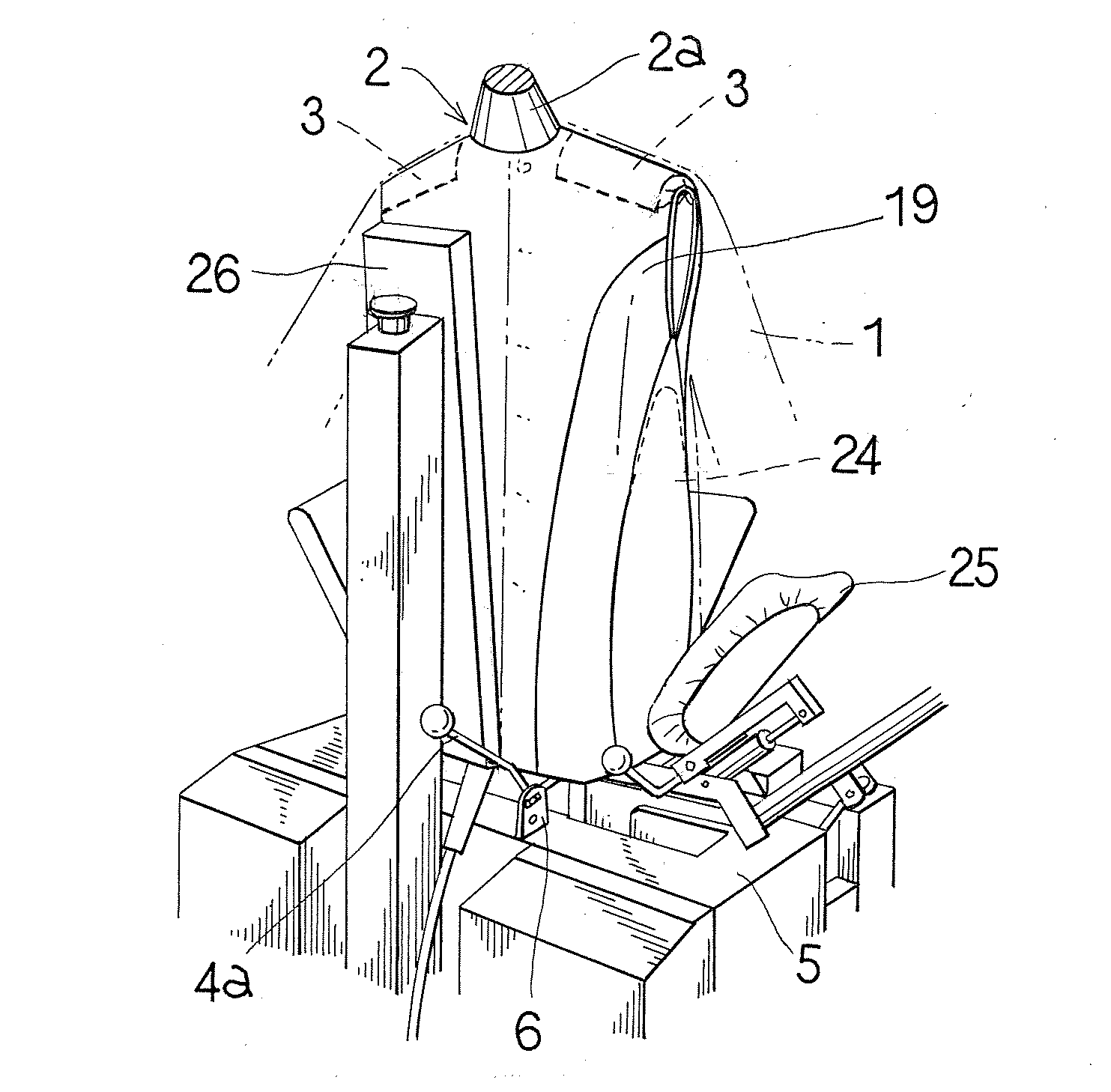

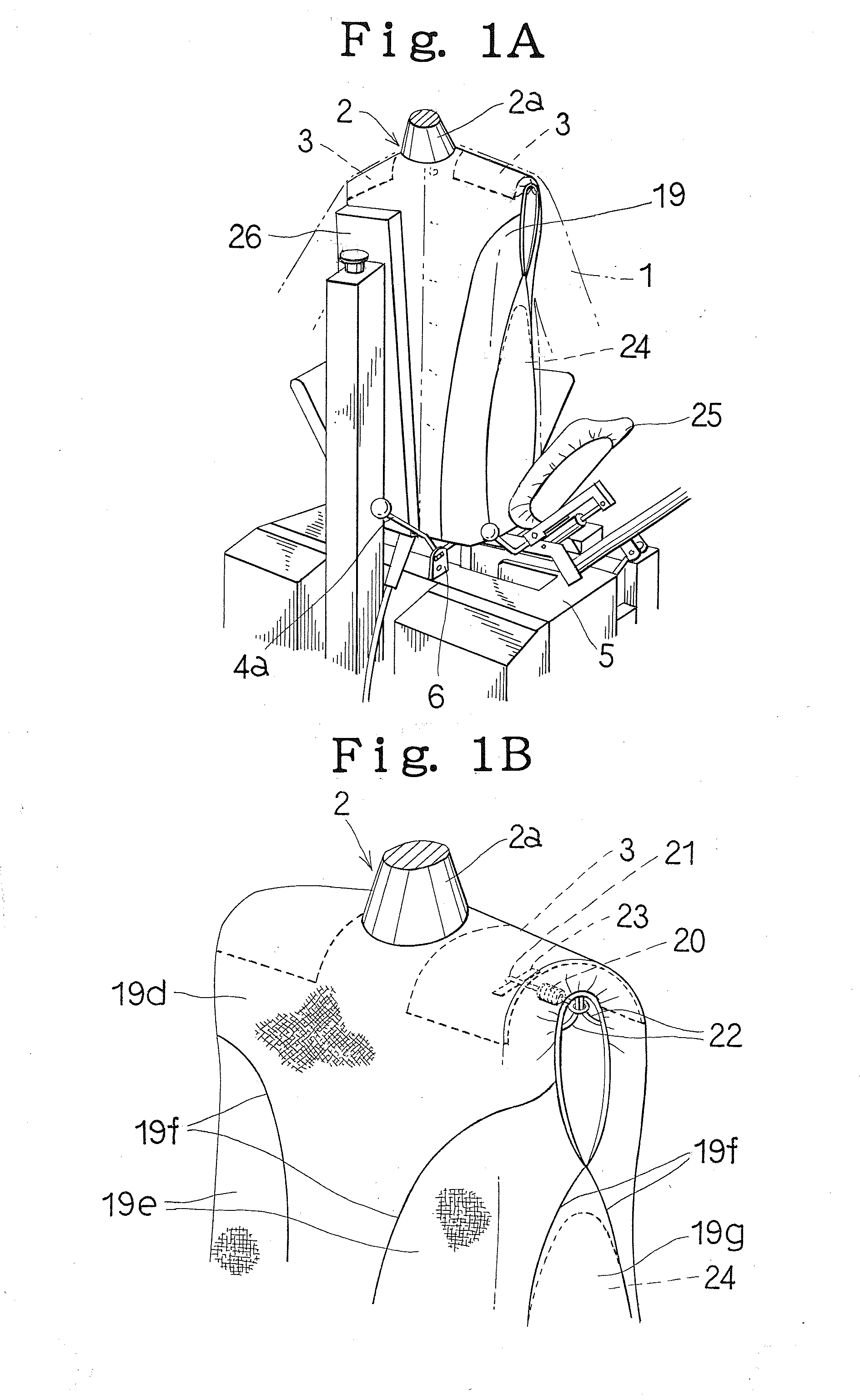

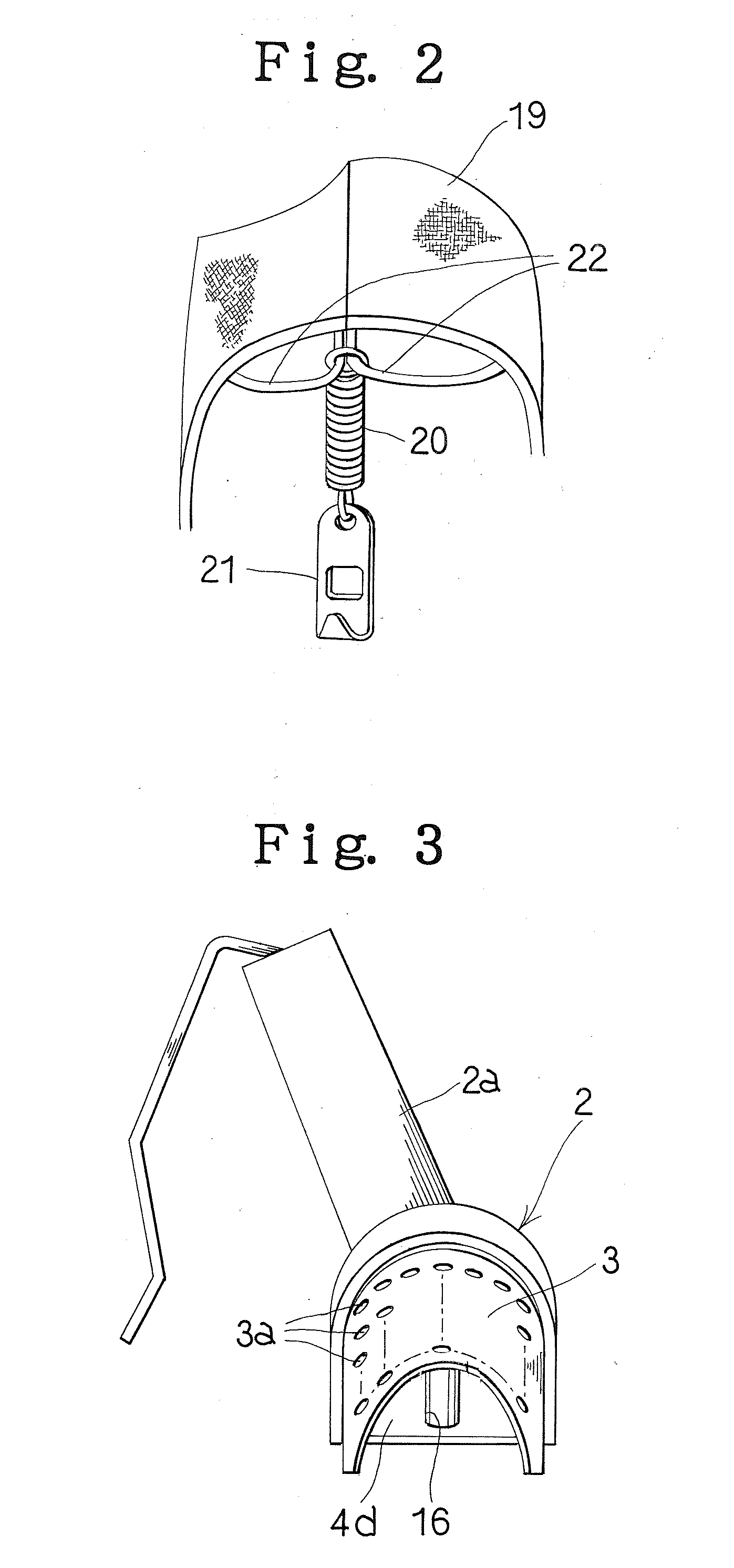

Garments Finishing Machine and Body Cover Used for Finishing Machine

InactiveUS20120006863A1Easy to adjust the widthFinished neatlyApparel holdersIroning apparatusEngineeringLaundry

This invention relates to the cleaning machine arranged to the torso 2 wearing the laundry garment 1 and finishing the garment 1 while they are kept put on the torso 2. The width across the shoulders of the torso 2 can be adjusted.This invention is constituted such that the entire shoulder part 3 of the torso 2 ranging from the positions of the shoulders of the torso 2 corresponding to the collars of the garment 1 to the shoulder ends are formed in such a way that it can be slid along the incline direction of each of the shoulder parts 3.

Owner:SANKOSHA ENGINEERING CO LTD

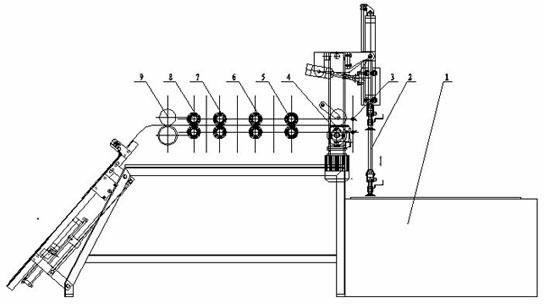

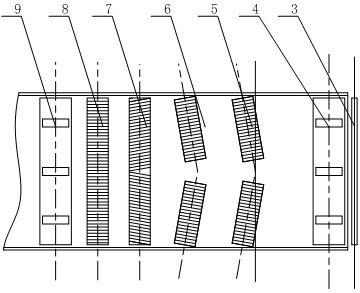

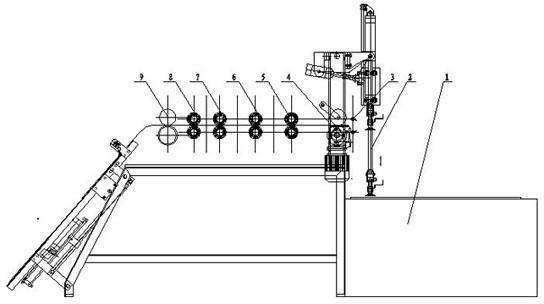

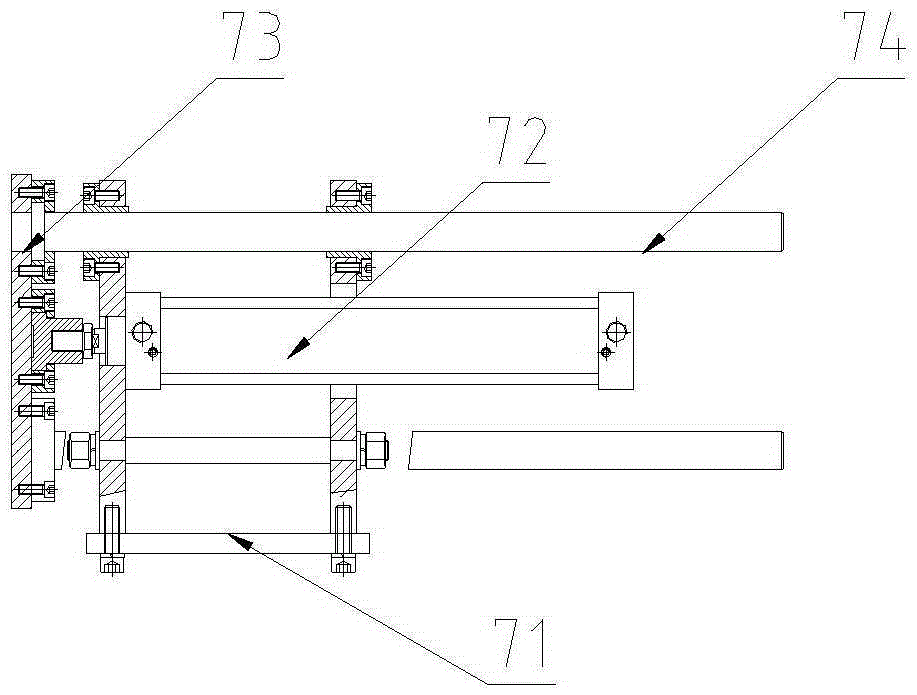

Feeding platform matched with pipe machining device

ActiveCN105235942AEase of baling operationTidy upPackagingMachiningElectrical and Electronics engineering

The invention discloses a feeding platform matched with a pipe machining device. The feeding platform comprises a feeding section obliquely arranged upwards, an upper section drive device driving the feeding section, a middle section connected with the feeding section, a middle section drive device driving the middle section, a discharging device hinged to the middle section, and a discharging air cylinder driving the discharging device to rotate. The feeding platform comprises the feeding section, the middle section and the discharging section which can be independently driven, the feeding platform can be used for ordinary continuous feeding, can also make the upper surface of the discharging device kept in a horizontal state when pipes need to be bundled, and can control the work state of the feeding section and the work state of the middle section, the pipes are stacked on the middle section and the discharging device, and therefore bundling operation is facilitated.

Owner:张家港市中悦冶金设备科技有限公司

Cloth multi-stage dust removal device for textile processing

InactiveCN113123111AImprove aestheticsTidy upMechanical cleaningPressure cleaningDust controlEngineering

The invention discloses a cloth multi-stage dust removal device for textile processing, and relates to the technical field of textile processing treatment. The cloth multi-stage dust removal device comprises a dust removal box, and a vibration dust removal assembly, a high-pressure-difference movable dust removal device and a negative pressure dust suction mechanism which are arranged in the dust removal box; the dust removal box is internally provided with a plurality of groups of conveying rollers, and the multiple groups of conveying rollers are used for conveying cloth; a fixed frame and a negative pressure pipe are arranged in the dust removal box, and the negative pressure pipe penetrates through a dust removal frame and is connected with the vibration dust removal assembly, the high-pressure-difference movable dust removal device and the negative pressure dust suction mechanism. A stirring device and a beating device are arranged to intermittently beat a textile fabric, dust in the fabric is vibrated out, and preliminary dust removal is achieved; by arranging the high-pressure-difference movable dust removal device, the dust inside and on the surface of cloth can be powerfully absorbed in the mode that high pressure difference is formed on the two sides of the cloth in a small area, efficient dust removal is achieved, by arranging a cloth carding device, the surface of the cloth can be tidied to be smooth, and the attractiveness of the cloth is improved.

Owner:吴江市潇湘纺织有限公司

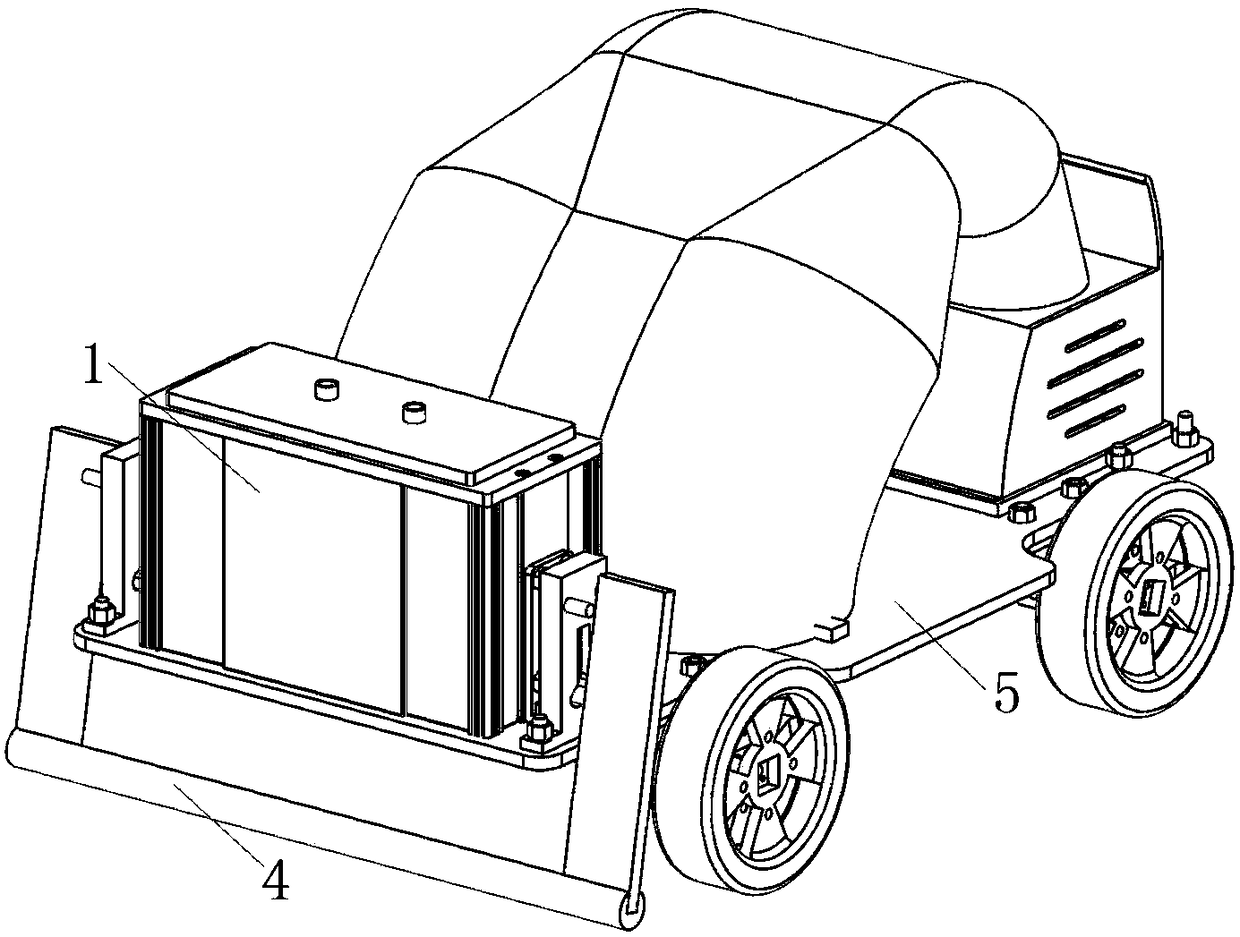

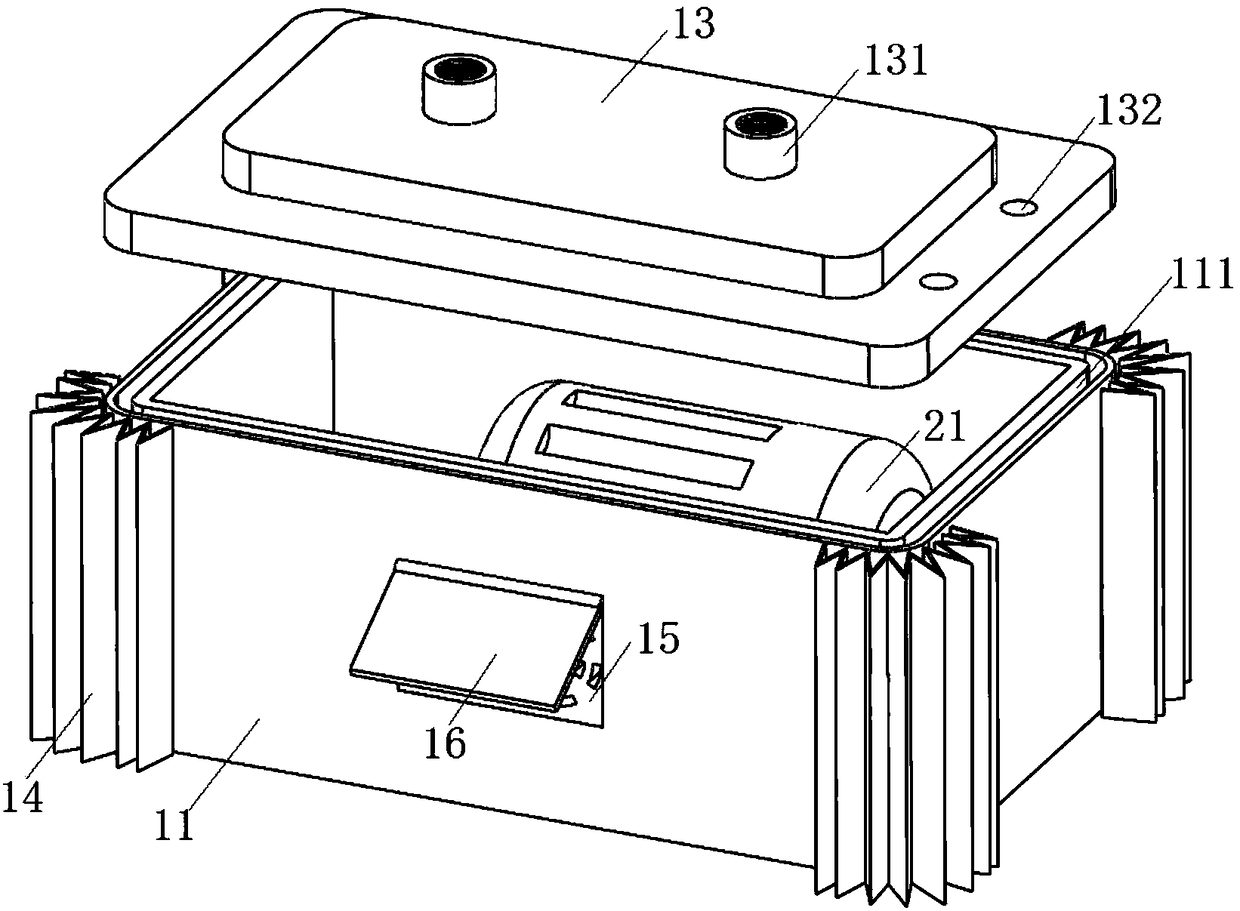

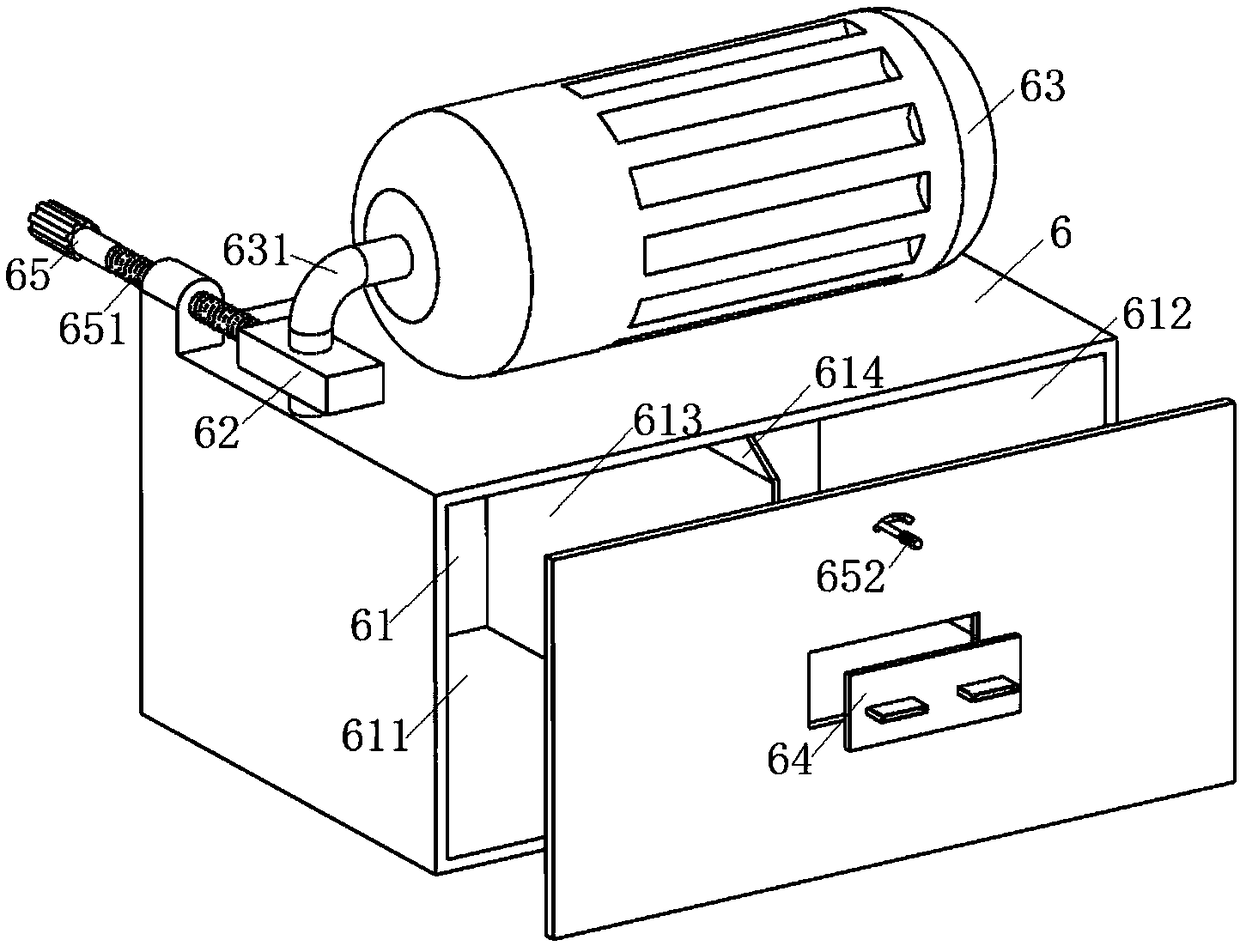

Lawn mower and operating method thereof

PendingCN108142086ATidy upImprove operational reliabilityMowersInsect catchers and killersDisease damageEngineering

The invention disclose a lawn mower, comprising a power device, a cutting device, a suction device, a rolling brush, a working platform and a spraying device; the power output end of the power deviceis connected with the power input ends of the cutting device, the suction device and the spraying device; the cutting device is mounted at the bottom of the working platform; an entry of the suction device is arranged above the cutting device; the rolling brush is mounted at the tail of the working platform. The lawn mower has the functions of moving equipment overheat / undercooling protection, rotor damping, rotor overload warning and switchable spraying of multiple liquid medicines, equipment operational stability is significantly enhanced, chances for cutting parts and a motor to damage areslimmed, liquid medicines can be sprayed during mowing so that disease damage is controlled, manpower intensity is reduced, and maintenance efficiency is improved.

Owner:XIAN TECH UNIV

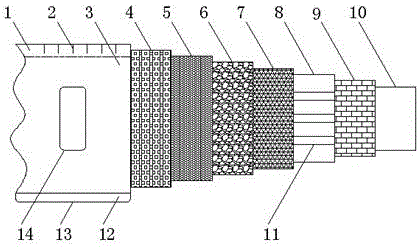

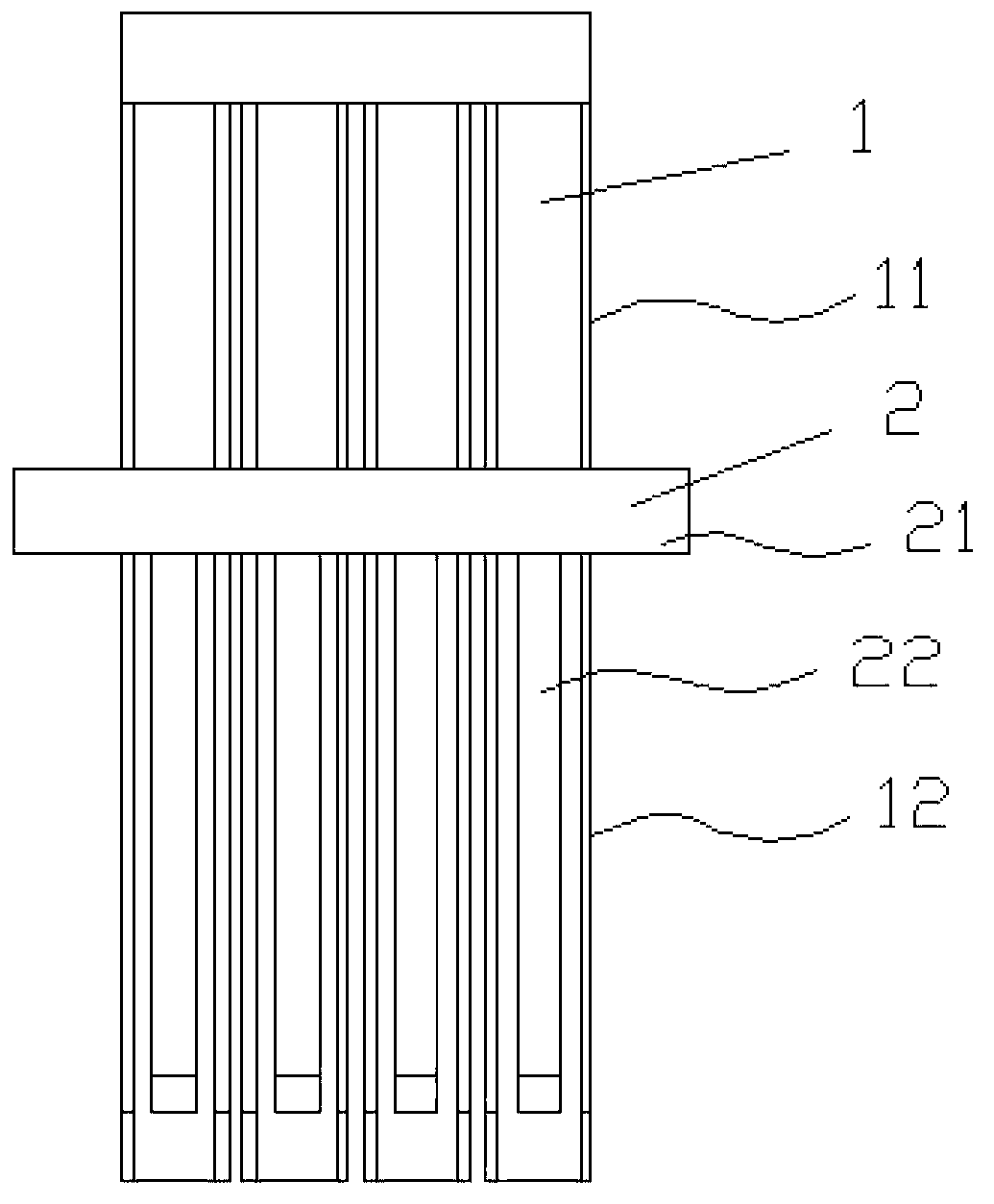

Fireproof and durable electric wire cable

InactiveCN106373654AHigh strengthExtended service lifeInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention discloses a fireproof and durable electric wire cable. The fireproof and durable electric wire cable comprises a PE protective sleeve, a fireproof layer, a fluorescent layer, a protective layer, a copper woven layer, a rubber layer, a corrosion-resistant reinforced core, a conductor and a cable body, wherein the cable body is provided with the PE protective sleeve; the PE protective sleeve is provided with a scale line; the fireproof layer is arranged on the lower surface of the PE protective sleeve; the fluorescent layer is arranged on the lower surface of the fireproof layer; the protective layer is arranged on the lower surface of the fluorescent layer; the copper woven layer is arranged on the lower surface of the protective layer; the rubber layer is arranged on the lower surface of the copper woven layer; the corrosion-resistant reinforced core is arranged on the lower surface of the rubber layer; corrosion-resistant steel bands are mounted in the rubber layer; and the conductor is arranged on the lower surface of the corrosion-resistant reinforced core. According to the fireproof and durable electric wire cable, a waterproof film is arranged in the protective layer, so that rainwater corrosion and erosion can be prevented, so that the service life of the cable can be prolonged.

Owner:LEIYANG XINGYU WIRE & CABLE CO LTD

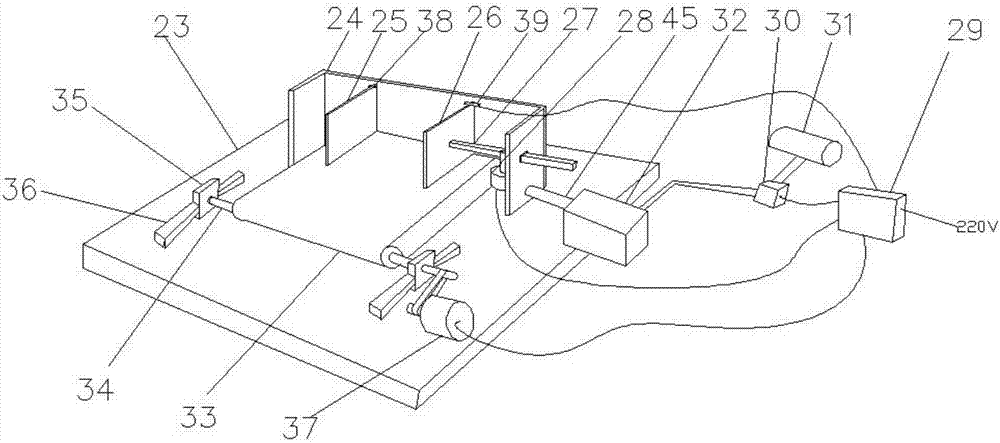

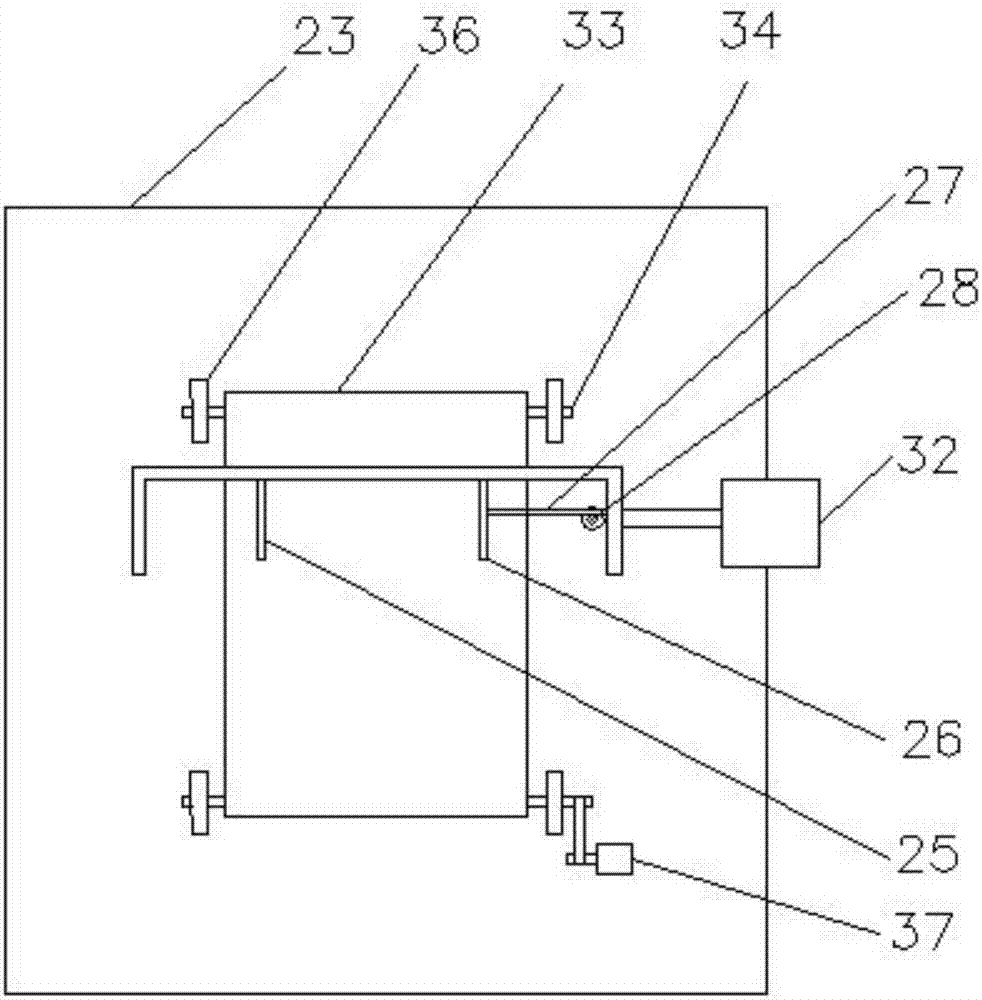

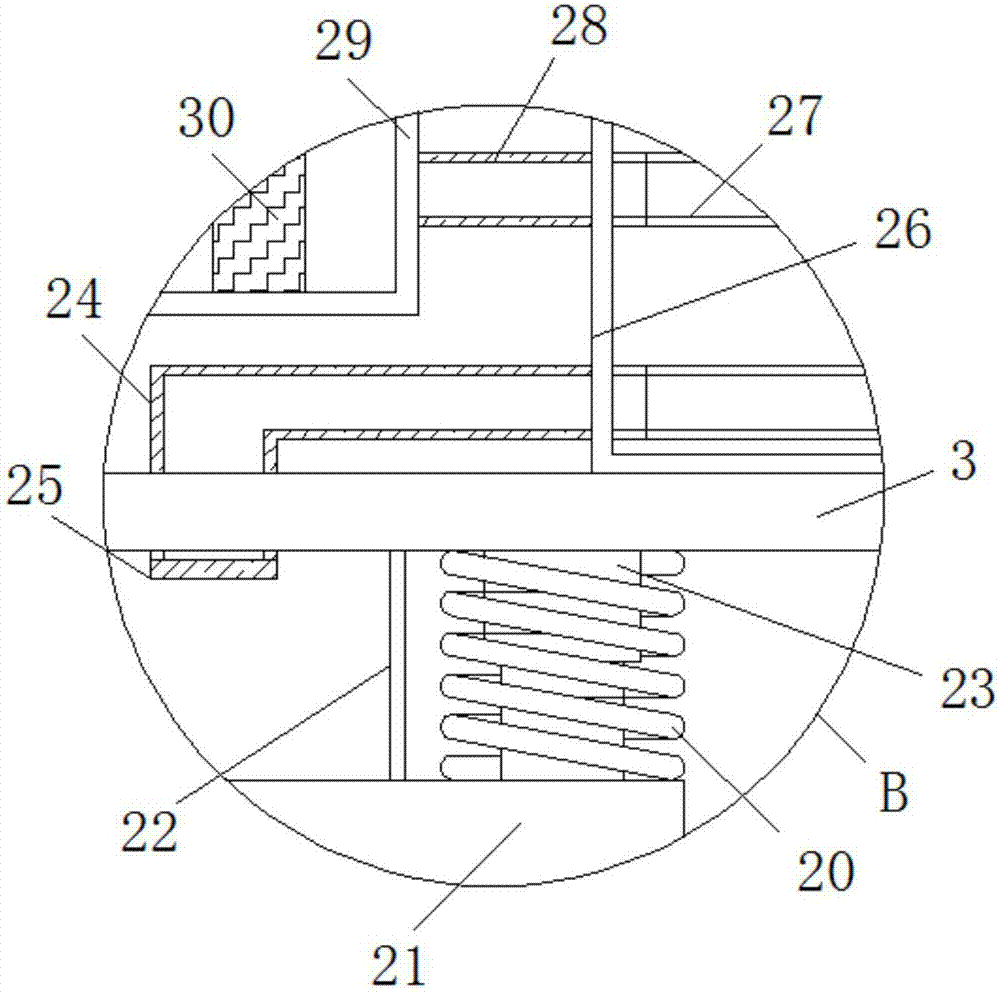

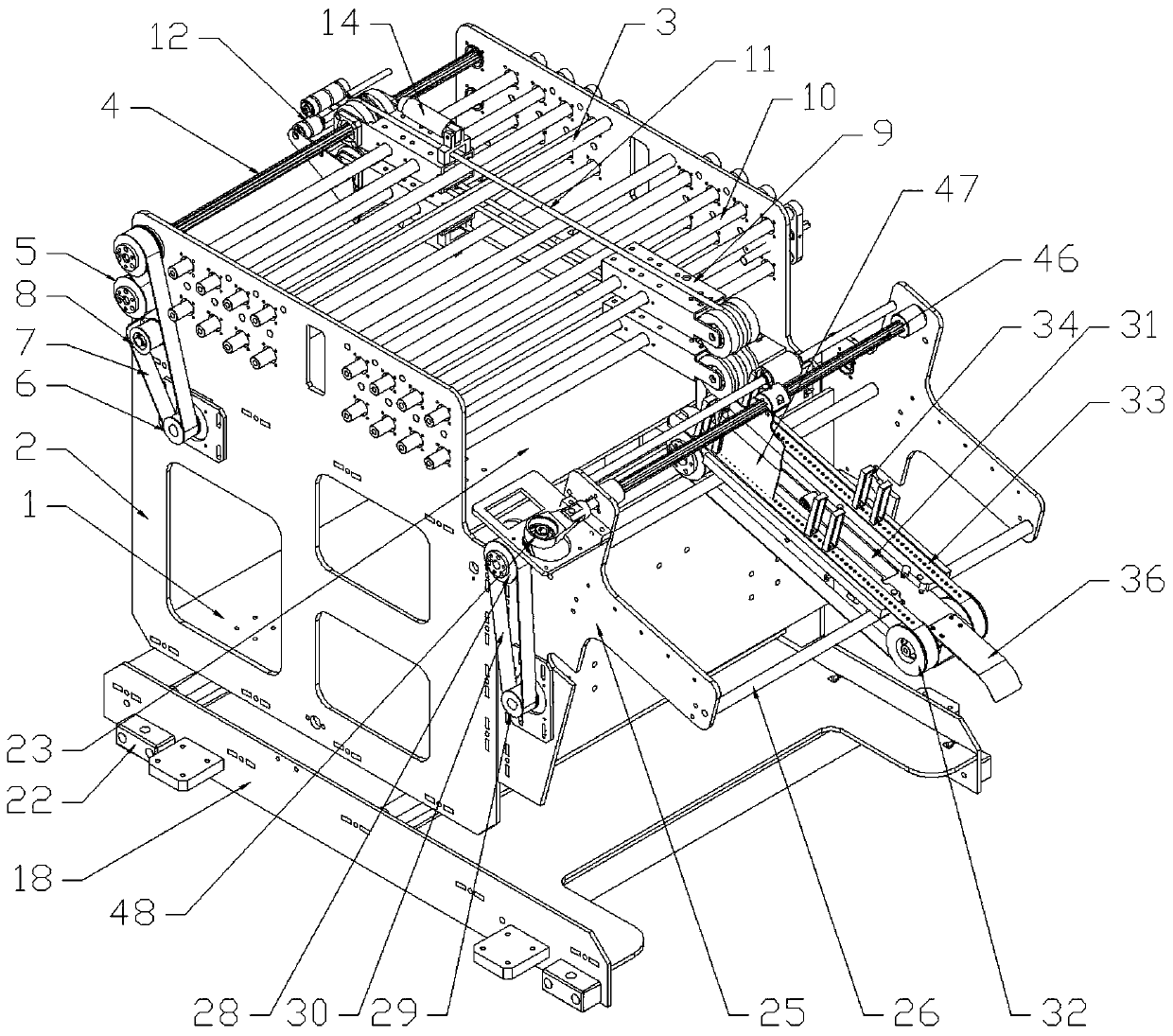

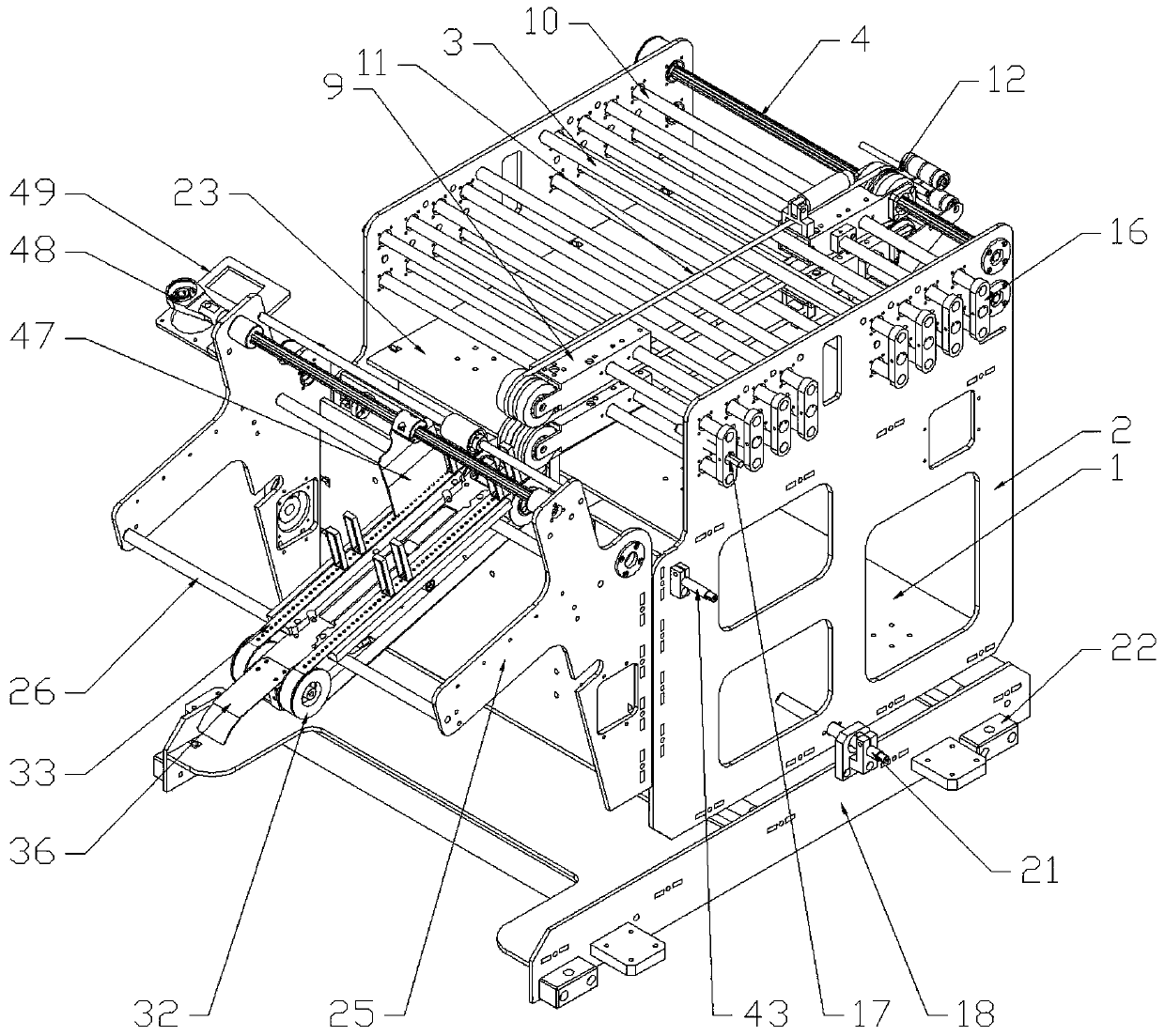

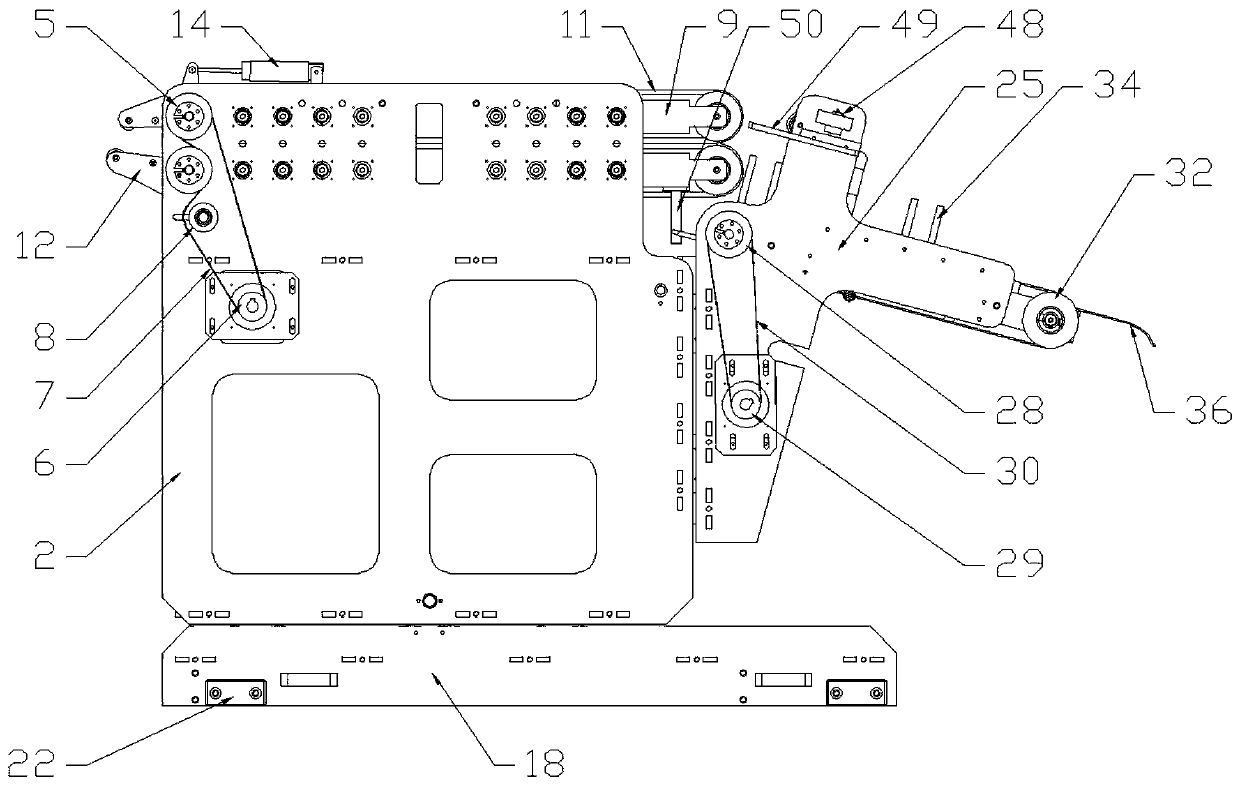

Automatic impressing paper collection type card printing machine

InactiveCN107215704ANeatly stackedTidy upPile receiversArticle deliveryTime delaysPulp and paper industry

The invention discloses an automatic embossing and receiving type card printing machine, which comprises a frame (1), a No. 1 cylinder (2) is arranged inside the frame (1), and a printing plate ( 3) and the solenoid valve (8); one end of the solenoid valve (8) is connected with a delay switch (10), and the delay switch (10) is connected with a through-beam photoelectric switch (7); the frame (1) The side is provided with a paper feeding mechanism (46), and the paper feeding mechanism (46) includes a base plate (23), the base plate (23) is connected with a rear baffle (24), and the rear baffle (24) is fixedly connected with a left baffle (25) and right baffle plate (26); On the right baffle plate (26), be connected with rack (27), be connected with rack motor (28) on the tooth bar (27), be connected with on the rack motor (28) Single-chip microcomputer controller (29). The invention can not only improve precision, pass rate, finishing effect and efficiency, but also has the advantages of stable structure, flexible adjustment, high sensitivity and wide application range.

Owner:HUZHOU JIANING PRINTING

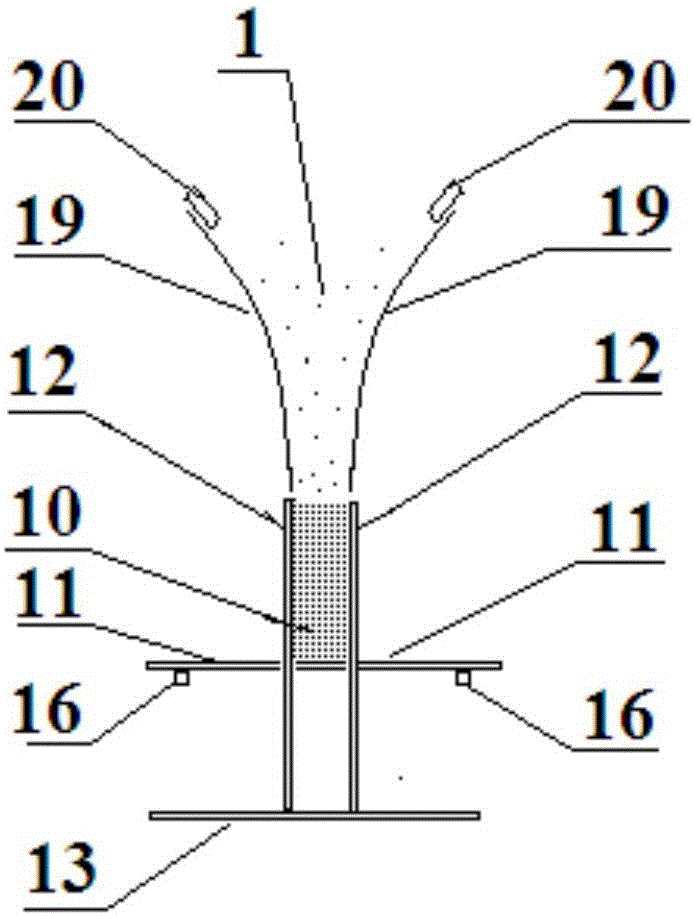

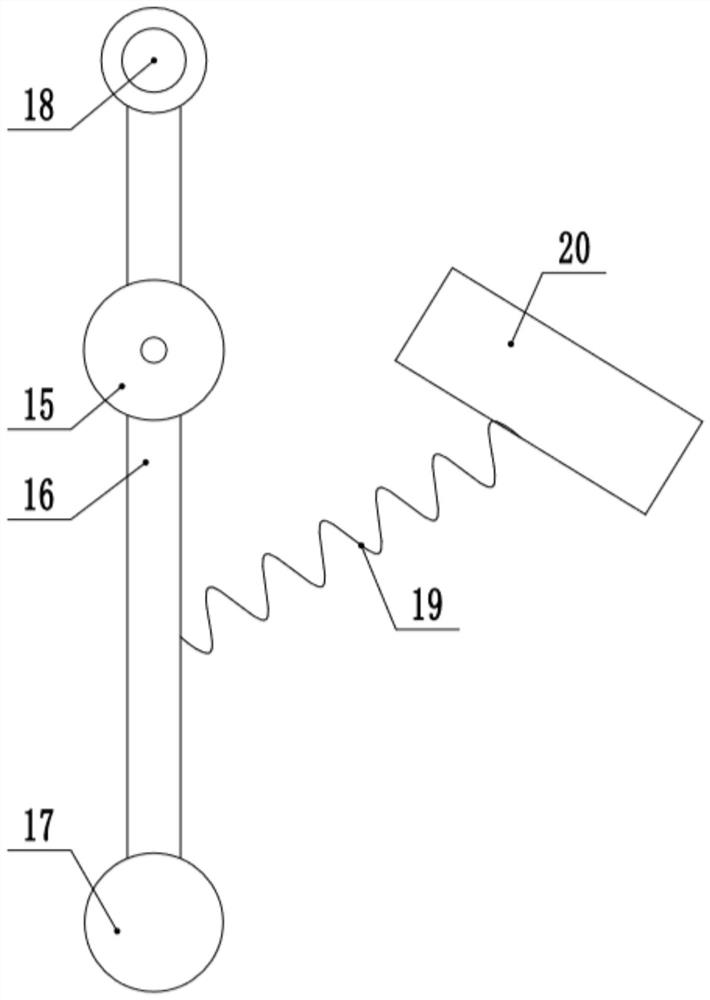

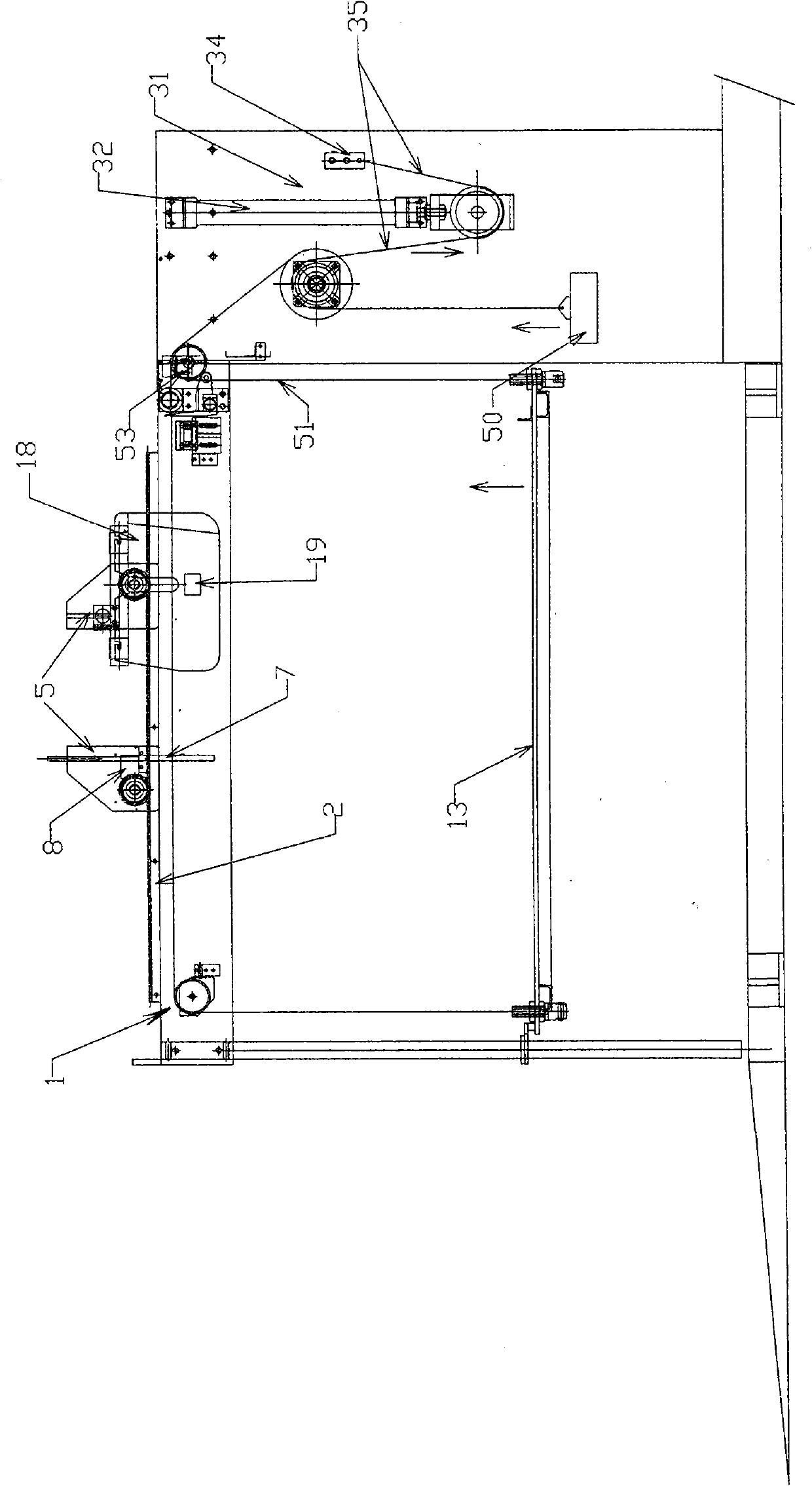

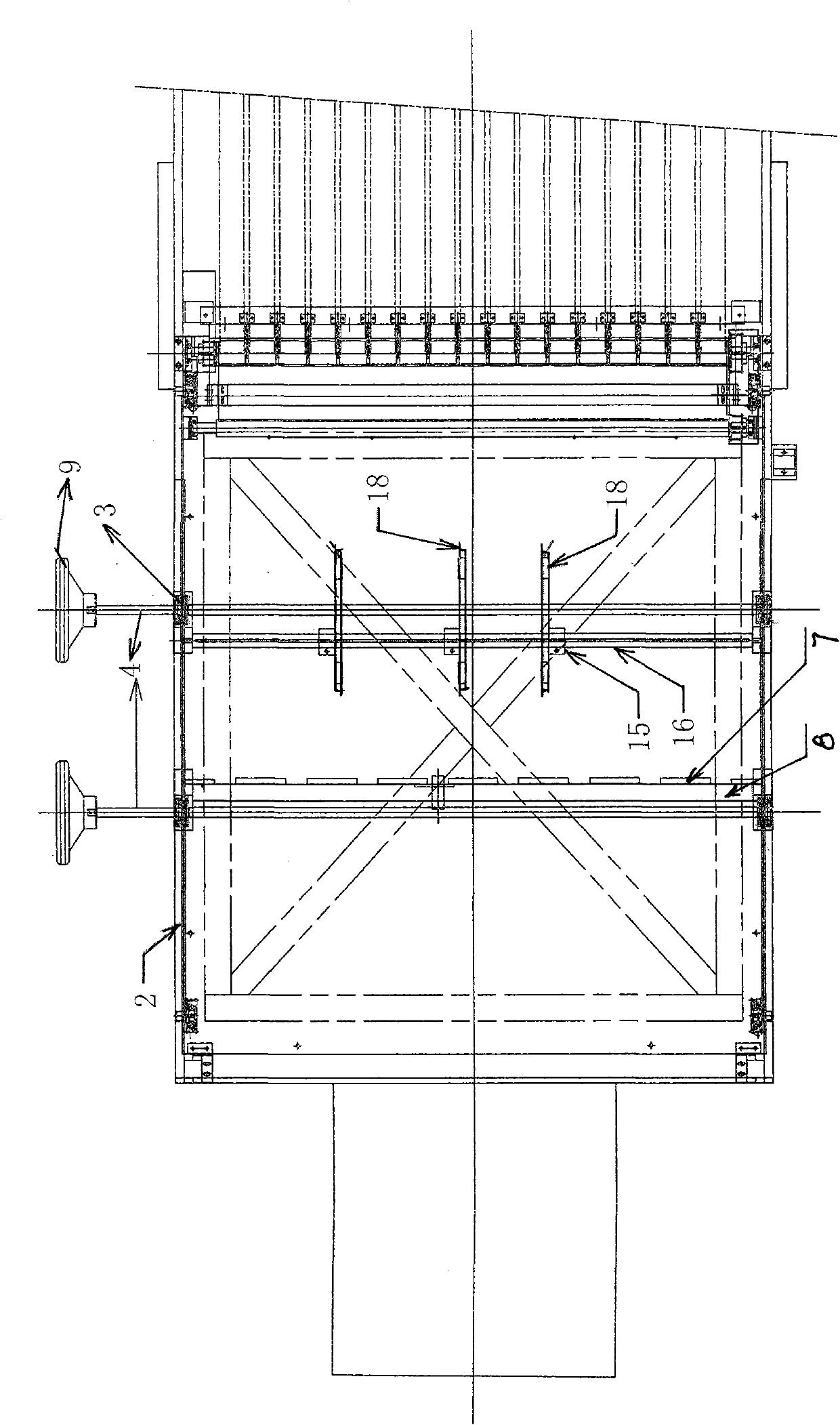

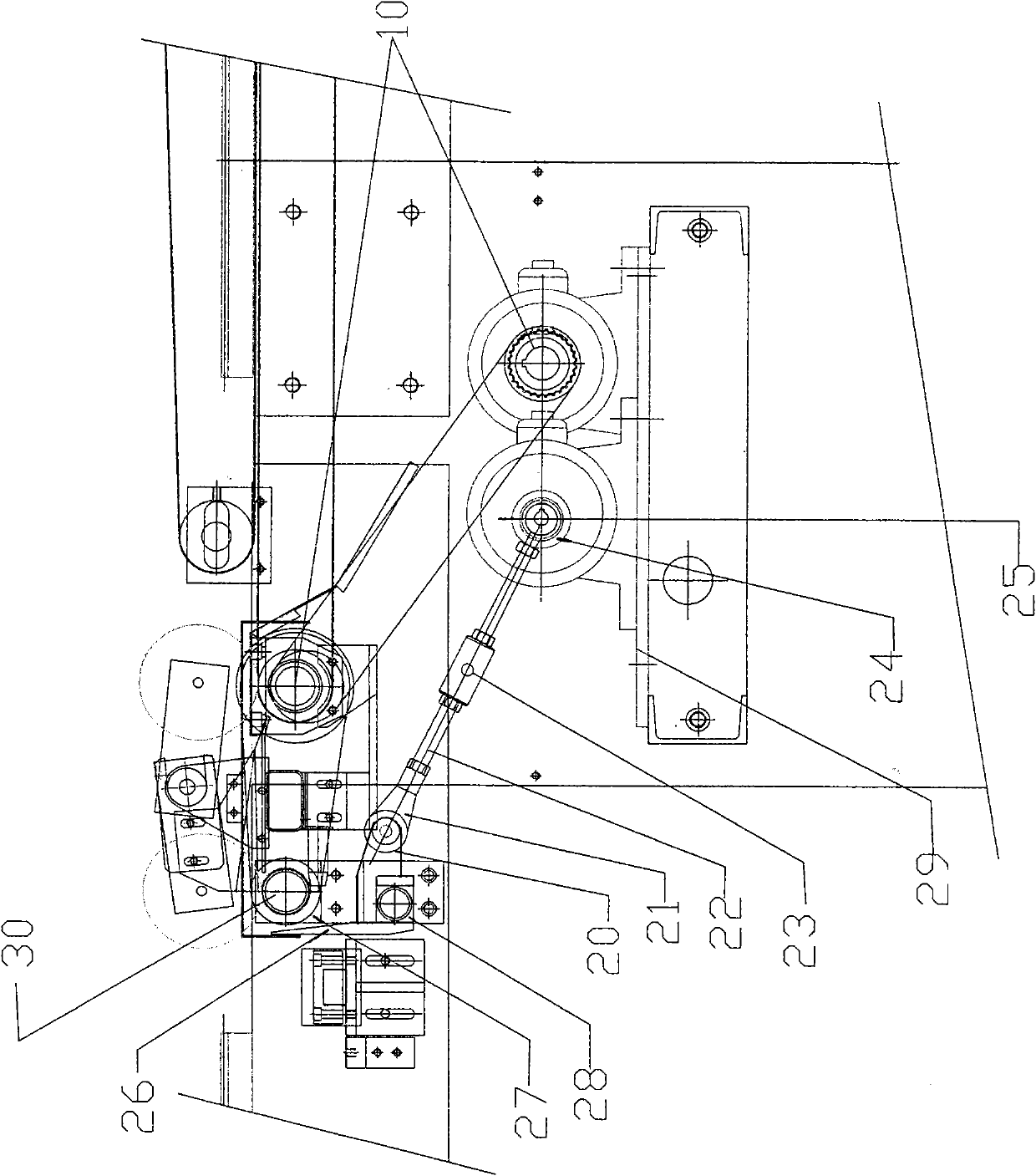

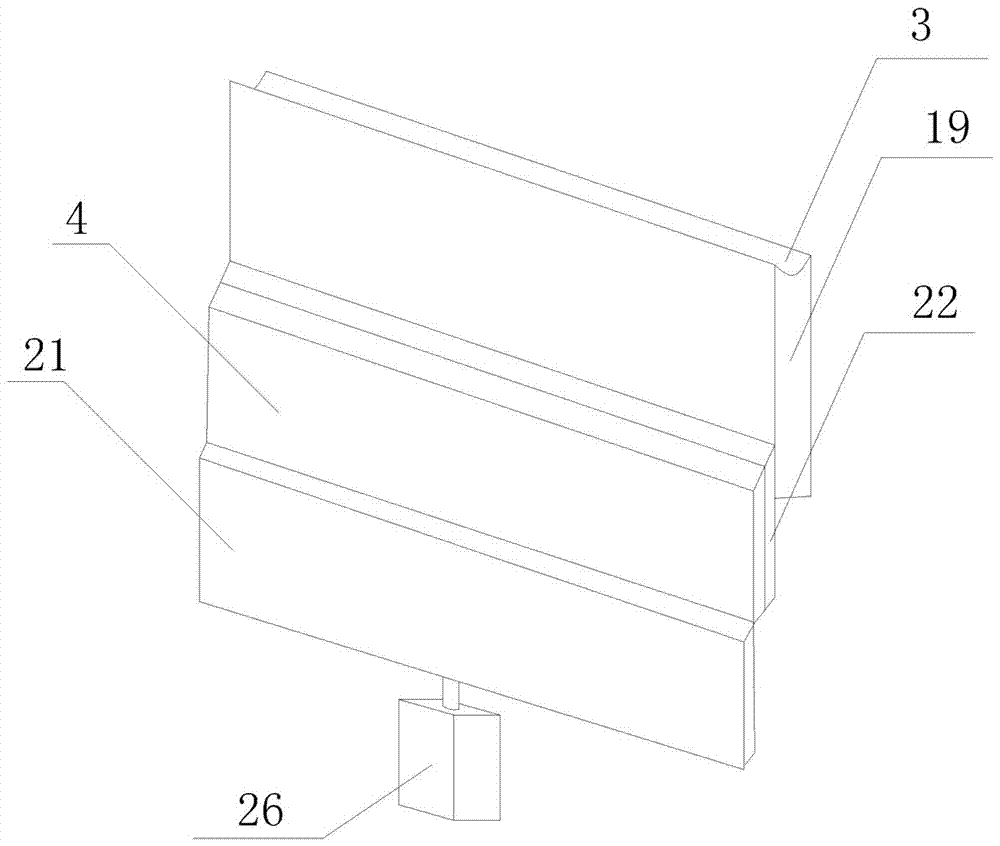

Automatic paper-gathering device of roll paper splitting machine

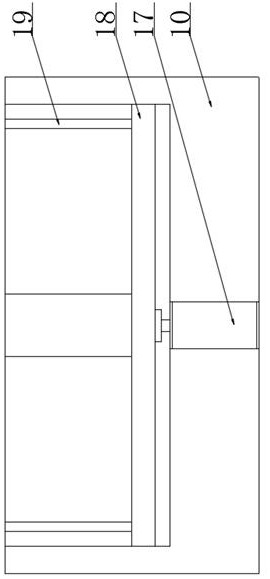

The invention discloses an automatic paper-gathering device of a roll paper splitting machine. A lifting delivery board (13) is arranged at the lower part of a rack (1) of the automatic paper-finishing device and is connected with a lifting control mechanism; the top part of the rack is provided with two sets of pressing board back seats (5), a transverse pressing board seat (8) and a transverse pressing board (7) are arranged between one set of the pressing board back seats, and a paper blocking piece shaft (16) is arranged between the other set of the pressing board back seats; and the paper blocking piece shaft is equipped with a vertical pressing board (18) provided with a vibrator (19). The transverse sides of finished product paper are gathered by the transverse pressing board while the vertical sides thereof are gathered by the vertical pressing board, and the finished product paper is placed on the lifting delivery board; and the lifting delivery board is controlled by the lifting control mechanism and can automatically descend along with the increment of the finished product paper. The automatic paper-gathering device in the invention has the advantages of high stacking quality, orderly gathered paper, high working efficiency and lowered stacking and processing cost.

Owner:瑞安市瑞阳印刷机械有限公司

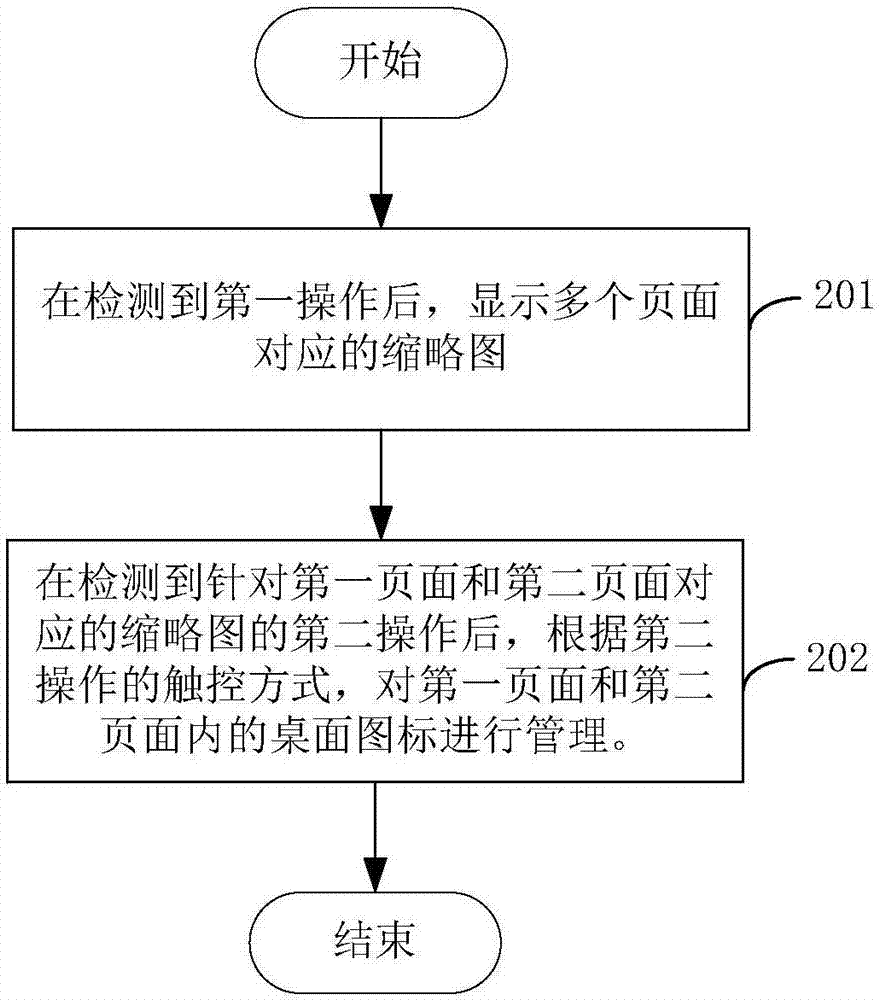

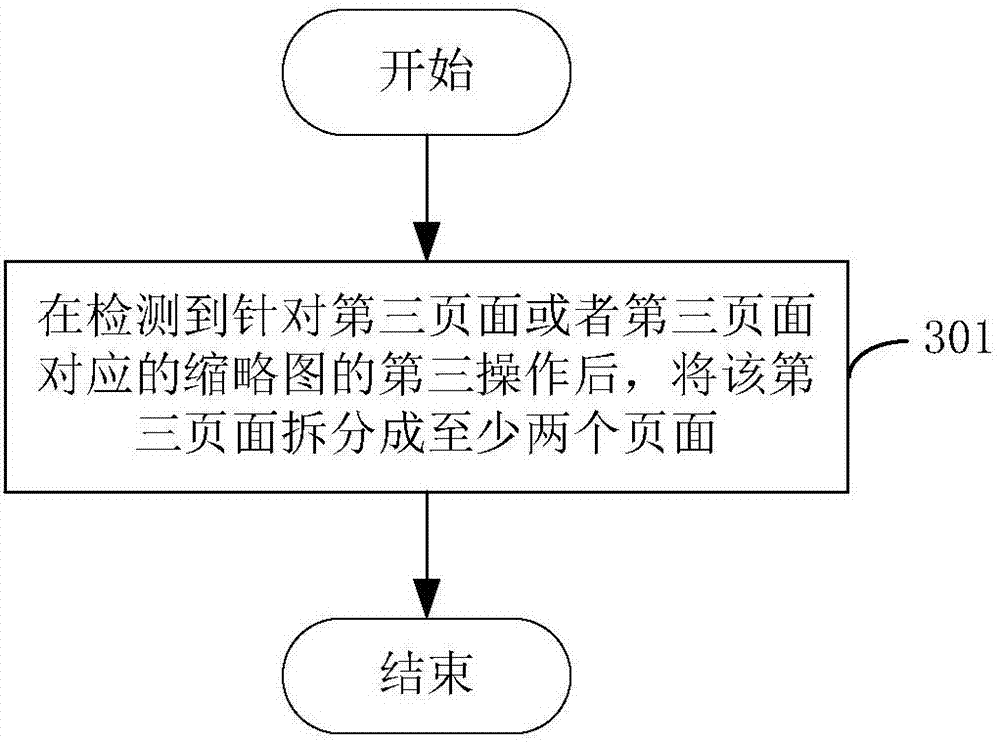

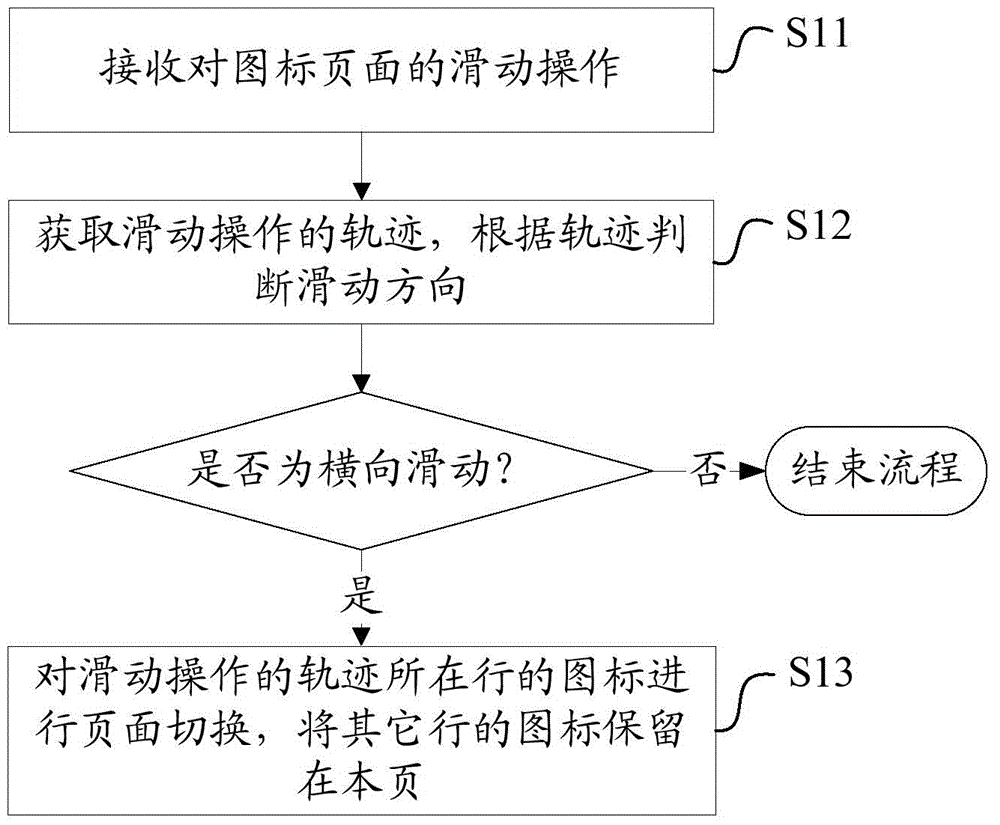

Method and device for switching icon pages

InactiveCN104991697ATidy upAdd funInput/output processes for data processingPersonalizationComputer engineering

Owner:NUBIA TECHNOLOGY CO LTD

Energy-saving and environment-friendly singeing device for printing and dyeing

InactiveCN107326597ATo achieve the purpose of energy saving and environmental protectionImprove cleanlinessCombination devicesGas treatmentToxic gasEngineering

The invention discloses an energy-saving and environment-friendly singeing device for printing and dyeing, which comprises a fixed plate, an air intake pipe is connected through the middle of the inner cavity of the fixed plate, one end of the air intake pipe is fixedly connected with a suction fan, and one end of the air intake pipe penetrates and extends to The inner cavity of the water tank, the water tank is fixed on the top of the fixed plate, one end of the air intake pipe is fixedly connected with a heat pipe, one end of the heat pipe is fixedly connected with an air pipe, and the end of the air pipe away from the heat pipe runs through the inner cavity of the water tank and extends to the water tank Externally, the end of the gas delivery pipe away from the heat pipe is fixedly connected to the air inlet on one side of the filter box. This energy-saving and environment-friendly singeing device for printing and dyeing can not only clean up all the toxic gases generated during singeing, but also remove The residual heat inside the poisonous gas produced during singeing is fully utilized, so that the singeing device for printing and dyeing can achieve the purpose of energy saving and environmental protection.

Owner:梅明会

Conveying and arranging mechanism of bag arranging machine

The invention discloses a conveying and arranging mechanism of a bag arranging machine. The conveying and arranging mechanism can be used for arranging and conveying packaging bags, and comprises twoarranging wall plates which are parallel to optical shafts and supported by the optical shafts, a transmission shaft a is erected at the front ends of the optical shafts, one end of the transmission shaft a is connected with a synchronous pulley a, and a driving wheel a connected with a motor is fixed to each arranging wall plates; and at least one arranging conveying assembly is arranged, the arranging conveying assembly comprises an aluminum tube beam, the aluminum tube beam is erected on the optical shafts a in a front-higher and rear-lower mode, the two sides of the front end and the rearend of the aluminum tube beam are provided with synchronous conveying wheels correspondingly, and the transmission shaft a passes through the two synchronous conveying wheels at the front end. An oscillating shaft is arranged, at least one pair of oscillating plates are connected with the oscillating shaft, an eccentric shaft and a shaft sleeve are arranged at one end of the oscillating shaft, andan oscillating motor is arranged on one sides of the arranging wall plates. According to the conveying and arranging mechanism, the number and height of the arranging conveying assembly body can be adjusted as needed, adjusting is very convenient, the structure is suitable for packaging bags with various sizes, the stability of conveying and arranging is guaranteed, and the packaging bags are guaranteed to be neat.

Owner:浙江创派智能科技有限公司

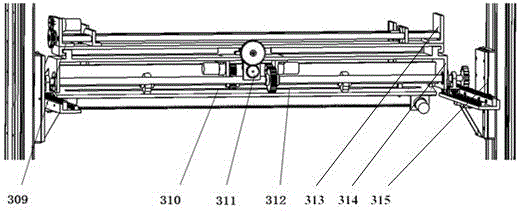

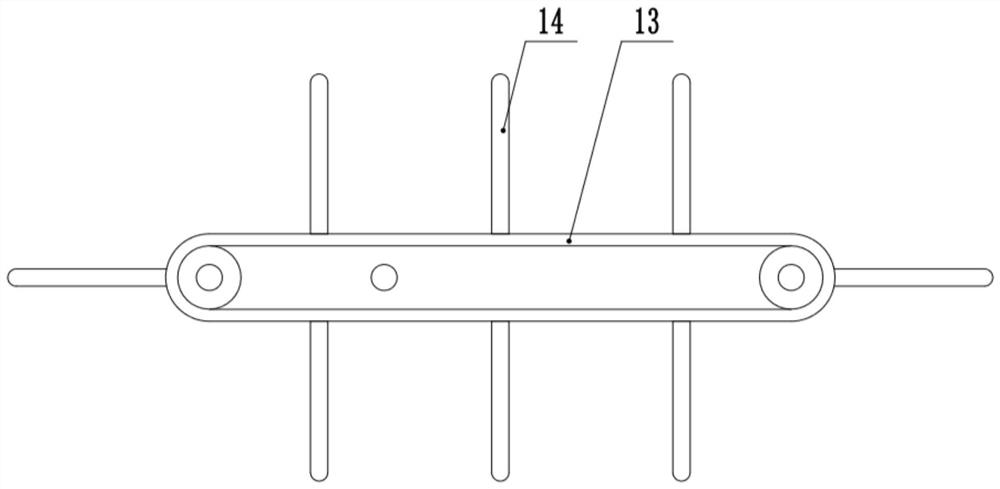

Material poking mechanism used for packing machine

The invention discloses a material poking mechanism used for a packing machine. The material poking mechanism used for the packing machine comprises a lower conveying line, four stand columns, a left installation side board, a right installation side board, a drive motor, a drive shaft and a driven tensioning shaft, wherein the left installation side board and the right installation side board are installed on the side faces of the stand columns, the drive motor, the drive shaft and the driven tensioning shaft are installed on the installation side boards, the drive shaft and the driven tensioning shaft are provided with a pair of drive chain wheels and a pair of driven chain wheels respectively, the drive chain wheels and the driven chain wheels are linked and driven by hollow chains, pin shafts of the hollow chains are provided with connecting rod material poking assemblies, and the connecting rod material poking assemblies are connected through two movable pin shafts on the hollow chains. Stress resistance of the material poking assemblies can be improved, and it is avoided that the material poking assemblies bear resistance and deform in the material poking process. Meanwhile, the multiple sets of connecting rod material poking assemblies can be arranged at equal intervals to improve the material poking efficiency, material poking rods in the connecting rod material poking assemblies are provided with cylindrical rollers which can rotate by themselves in the material poking process, and products are prevented from being poked disorderly.

Owner:SUZHOU SHENGBAIWEI PACKAGE EQUIP

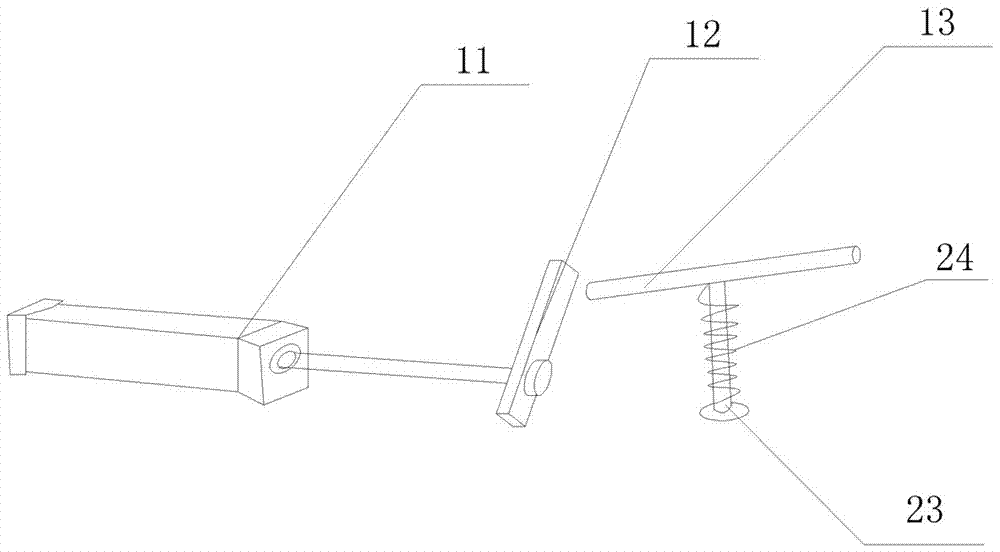

Knocking device for fiber bar stocks

The invention provides a knocking device for fiber bar stocks. The knocking device comprises a motor, a transmission gear, a cam, a driven wheel, a rocker and a knocking hammer. The motor is driven through the transmission gear, the cam is movably connected with a side plate of an arranging box through a bearing, and mutually matched with the driven wheel. The driven wheel is arranged in the middle of the rocker which is hinged to the side plate of the arranging box, and the lower end of the rocker is provided with the knocking hammer. According to the arrangement, when an arranging roller stirs and arranges the bar-shaped fibers, the arranging box is knocked continuously by the knocking device added on the knocking device for the fiber bar stocks so as to vibrate the bar-shaped fibers inside the arranging box; under the comprehensive action of vibrating and stirring arrangement, compactness of the bar-shaped fibers can be achieved, gaps among the bar-shaped fibers can be reduced as far as possible, so that the bar-shaped fibers can be arranged compactly and neatly, requirements of subsequent packing are met, and packing efficiency of the bar-shaped fibers can be effectively improved.

Owner:HENAN HAITIAN AUTOMATION SYST

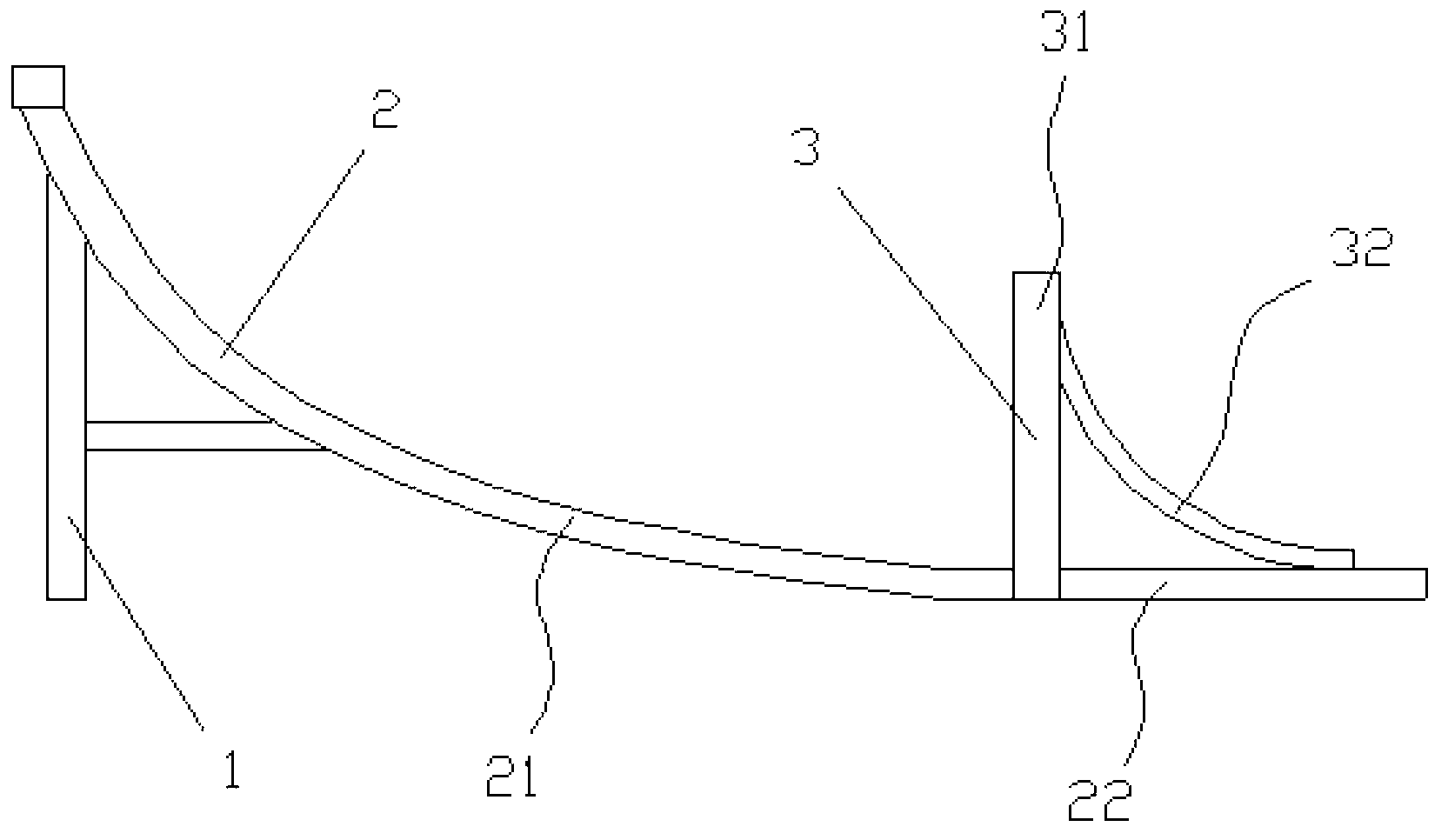

Chain plate finishing device

The invention provides a chain plate finishing device, and relates to the technical field of chain processing auxiliary tools. The chain plate finishing device comprises a support and finishing grooves arranged on the upper portion of the support. The chain plate finishing device is characterized in that the number of the finishing grooves is 3 to 5 and the finishing grooves are arranged in parallel, each finishing groove comprises an arc-shaped slipping section and a horizontal section, and an adjusting device is arranged above the joint of the horizontal section and the arc-shaped slipping section, the adjusting device comprises an adjusting support and an adjusting tableting which is arranged at the lower portion of the adjusting support and in contact with the upper portion of the horizontal section of each finishing groove. The chain plate finishing device has the advantages of being reasonable and simple in structure and design, easy to use, more orderly in finishing the chain plate and capable of better meeting the demand of feeding accuracy of subsequent processing or assembling, and capable of improving product quality.

Owner:安徽朝阳车链有限公司

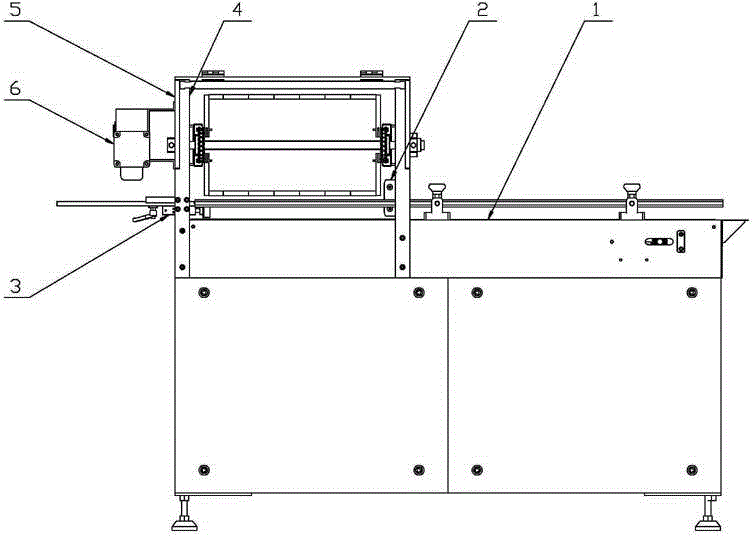

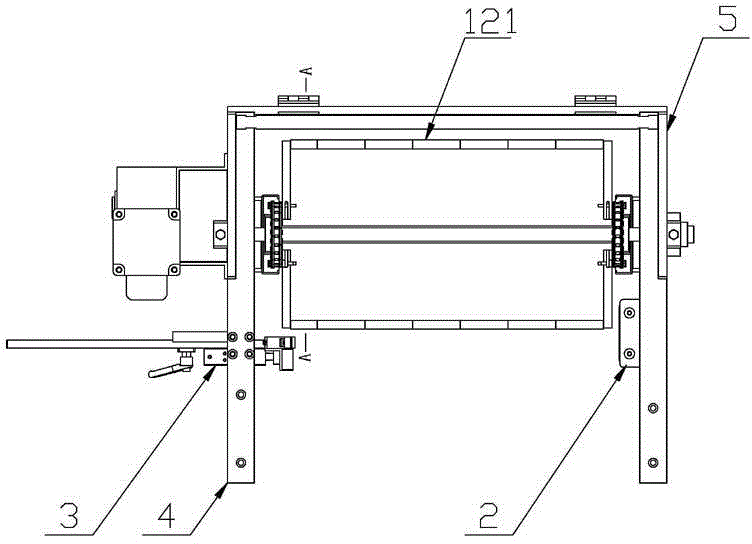

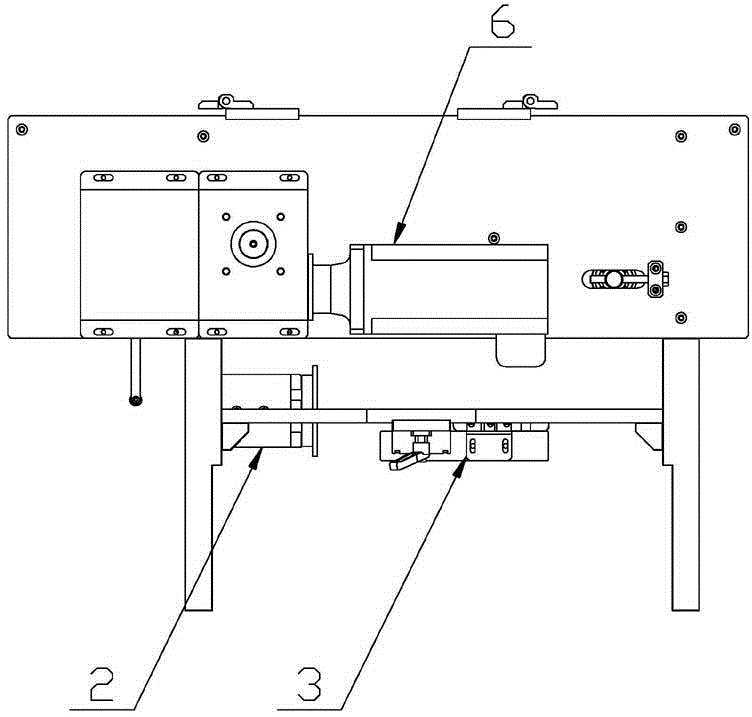

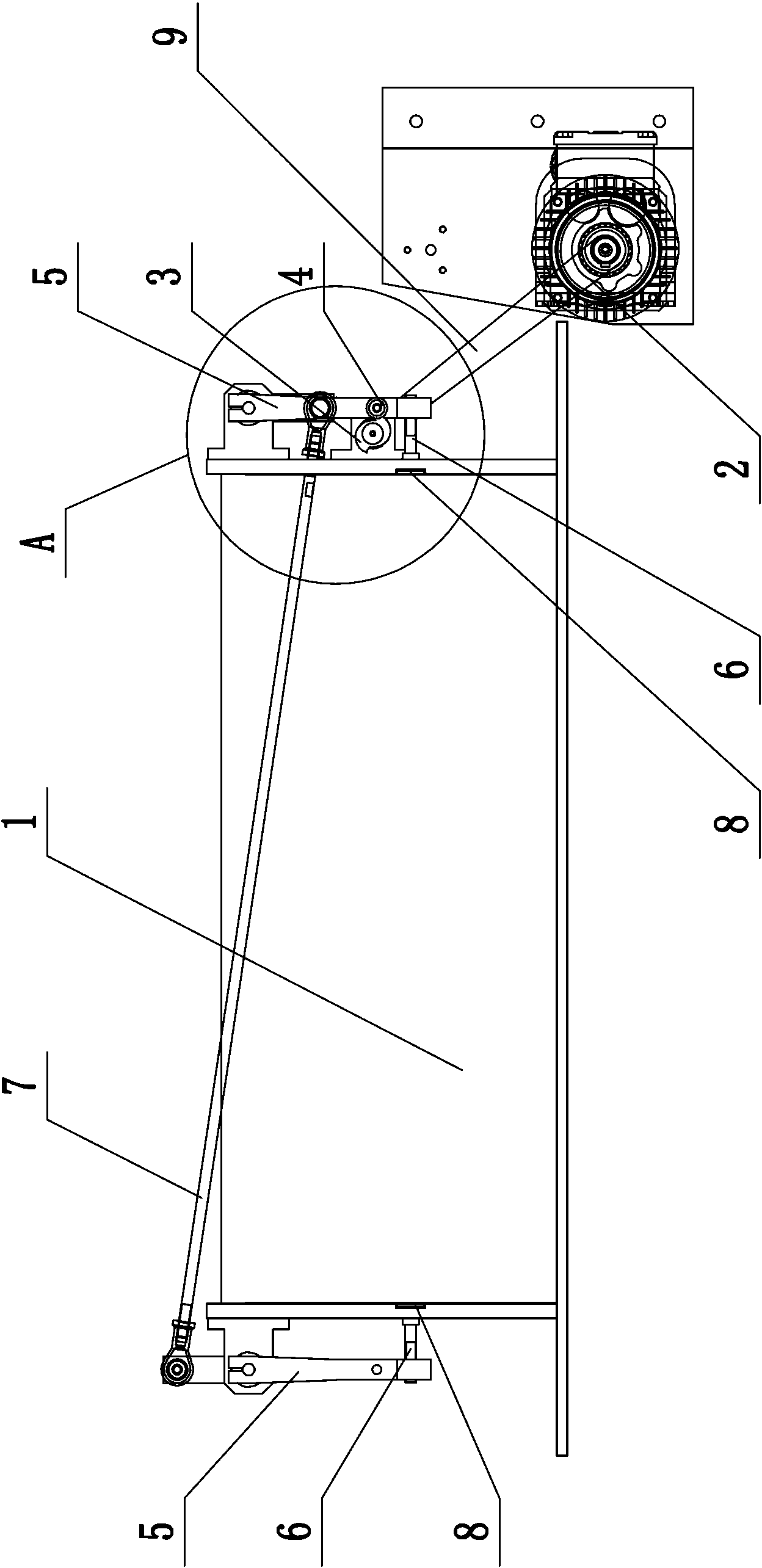

Hook Production Line

InactiveCN105383896BEnough heating timeTidy upConveyorsConveyor partsProduction lineShortest distance

The invention discloses a hook production line. The hook production line comprises a short rod feeding conveying and heating device and a short rod bending device. The short rod feeding conveying and heating device comprises a feeding mechanism, a conveying mechanism, a material cutting mechanism and a heating mechanism. The feeding mechanism comprises a feeding bin, a feeding slope and a material supporting mechanism. The conveying mechanism comprises a conveying chain wheel, a conveying chain supporting frame, a conveying chain and a conveying motor. The heating mechanism comprises an electrical heating tube and an electric cabinet. The material cutting mechanism comprises a material cutting air cylinder, a material cutting blocking rod and a material falling slop. The electric cabinet is internally provided with a programmable logic controller (PLC) and an electrical heating tube switch controlling the operation of the electrical heating tube. The short rod bending device comprises a material collection box, a conveying track, an ejection bending mechanism and a counter-ejection discharging mechanism. According to the hook production line, the heating effect on short rods is ensured, and the operation is convenient; the efficiency is high; meanwhile, the short rods heated at high temperature automatically fall into the conveying track and can be subjected to ejection bending after a short-distance conveyance, and time and labor are saved. In addition, the discharging is convenient and the ejection bending effect is good.

Owner:建德市马目五金有限公司

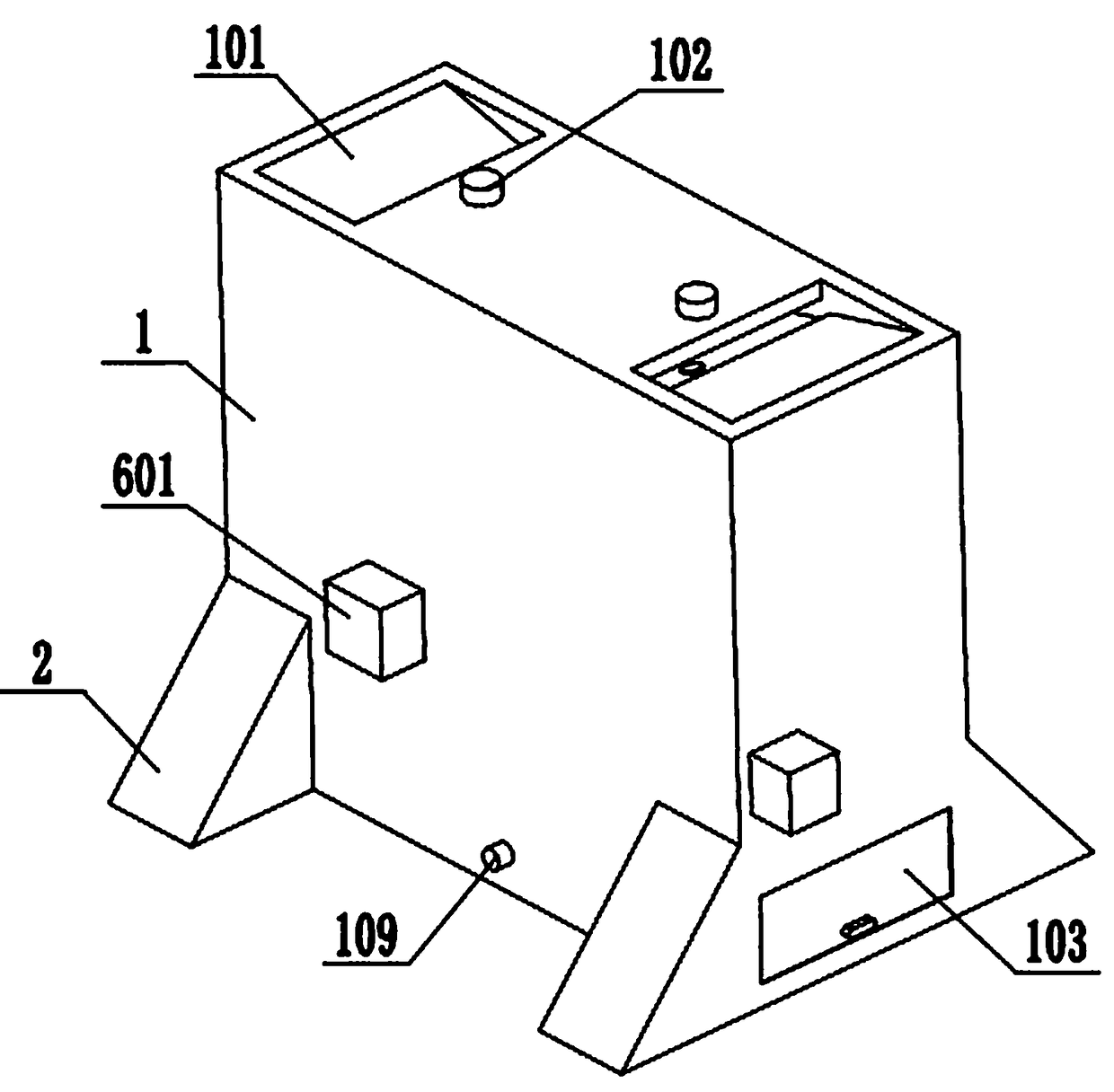

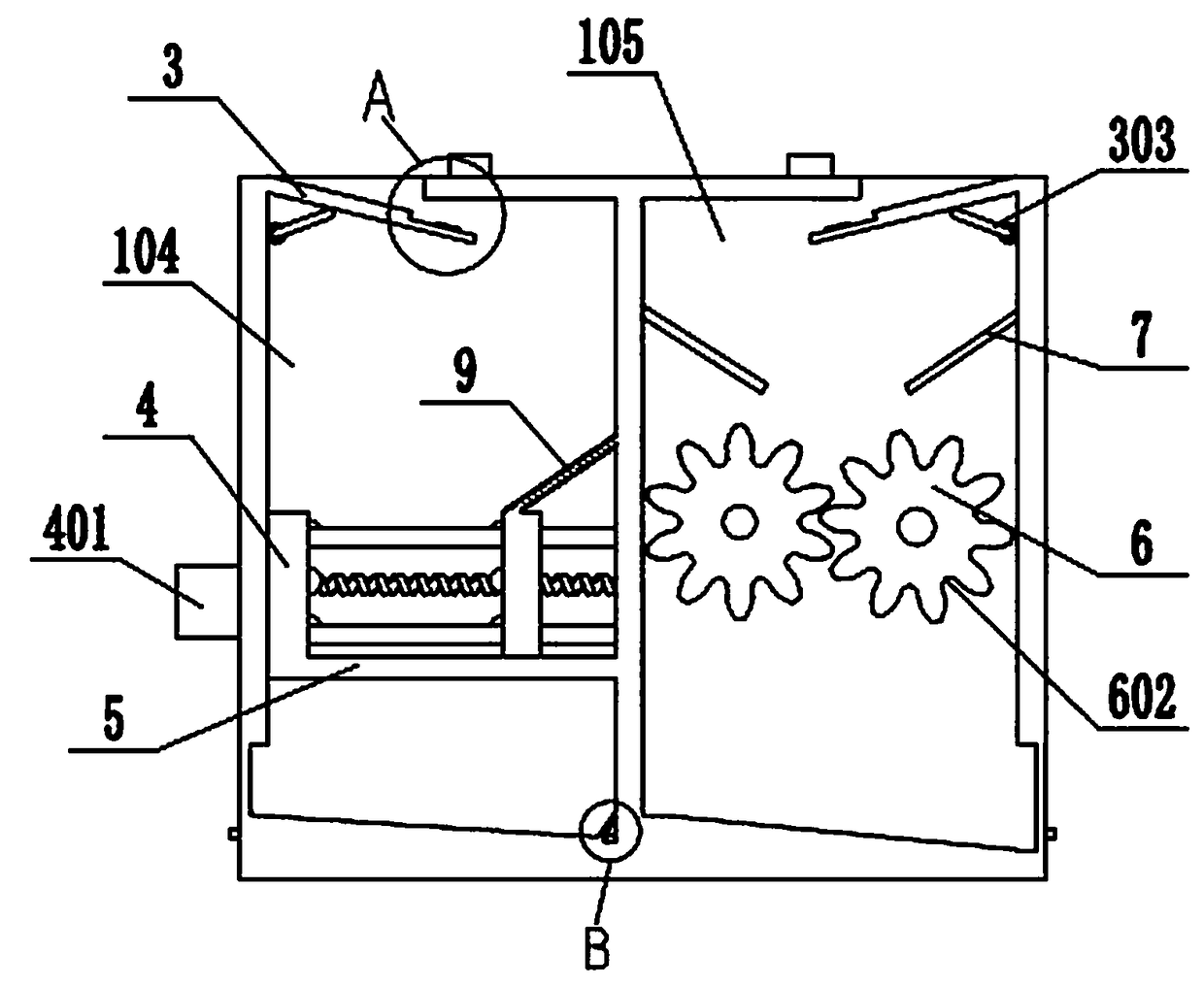

Disposal medical instrument classified treatment pulverizing device

The invention discloses a disposable medical instrument classified treatment crushing device. The device comprises a cabinet, an extrusion crushing device and a cutting wheel crushing device. A glassproduct pulverizing chamber and a non-glass product pulverizing chamber are arranged in the cabinet. Feeding inlets are formed in the upper ends of the glass product pulverizing chamber and the non-glass product pulverizing chamber correspondingly. A safety door is arranged in each feeding inlet. A switch is arranged at one side of each safety door. Discharging doors are arranged on one sides of the lower ends of the glass product pulverizing chamber and the non-glass product pulverizing chamber correspondingly. The extrusion crushing device is arranged inside the glass product pulverizing chamber. A filter plate is arranged at the lower end of the extrusion crushing device. Filter holes are uniformly formed in the filter plate. The cutting wheel crushing device is arranged inside the non-glass product pulverizing chamber. The extrusion crushing device and the cutting wheel crushing device are both electrically connected with the switches. Stabilizing bases are arranged on the two sides of the lower end of the cabinet correspondingly.

Owner:DIMENSION TECH

Automatic blanking conveying die

PendingCN112916701AFast Classification ProcessingImprove work efficiencyShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an automatic blanking conveying die, and particularly relates to the field of a die. The automatic blanking conveying die comprises a base; guide rods are arranged on four corners of the top end of the base; a top die is arranged at the top ends of the guide rods; a die holder is fixedly mounted at the top end of the base and below the top die; and a sheet is placed on the outer surface of the upper end of the die holder. According to the invention, by arranging a conveying belt, the die holder, a waste sliding plate and a finished product box, in the punching process, a formed product can fall onto the conveying belt from a through slot, then the product is conveyed into the finished product box through the conveying belt, next, waste obtained after punching is pushed out of the die holder, and during next punching, a blade at the bottom end of the top die can cut off part of the waste, part of the waste falls on the waste sliding plate and enters a waste box along the waste sliding plate, and the whole process is cycled, so that the waste and the finished products can be quickly classified and treated, the working efficiency of the die is greatly improved, and meanwhile, the risk of manual feeding is also avoided.

Owner:DALIAN TONGTAI AUTO PARTS

Device for cleaning pouring cup of investment casting mould shell

The invention discloses a device for cleaning a pouring cup of an investment casting mould shell. The device comprises a trolley, a water tank and abrasive discs, wherein the water tank is fixedly arranged on the trolley; clear water is contained in the water tank; two baffle plates which are arranged in a crossed mode are arranged on the bottom of the water tank; the two abrasive discs are separately blocked on two opposite corners in the water tank, and are pasted on the bottom of the water tank through a waterproof binder; and a water drainage control valve is mounted on the bottom of the water tank. The device for cleaning the pouring cup of the investment casting mould shell is simple in structure, is low in cost, is convenient to operate, can effectively clear the pouring cup of the mould shell to be clean and orderly, and avoids the casting defect due to the fact that impurities of the pouring cup of the mould shell drop into a mould cavity of a cast piece.

Owner:QINGDAO MELPER PRECISION CASTING & MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com