Automatic metal wire finishing device

An automatic sorting and wire technology, applied in the directions of loading/unloading, transportation and packaging, conveyor objects, etc., can solve the problems of inability to use the wire hopper to pick up materials, the wire is messy and irregular, and the personnel cannot approach it. The wire storage device is smooth and fast, the effect is remarkable, and the effect is neat and consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

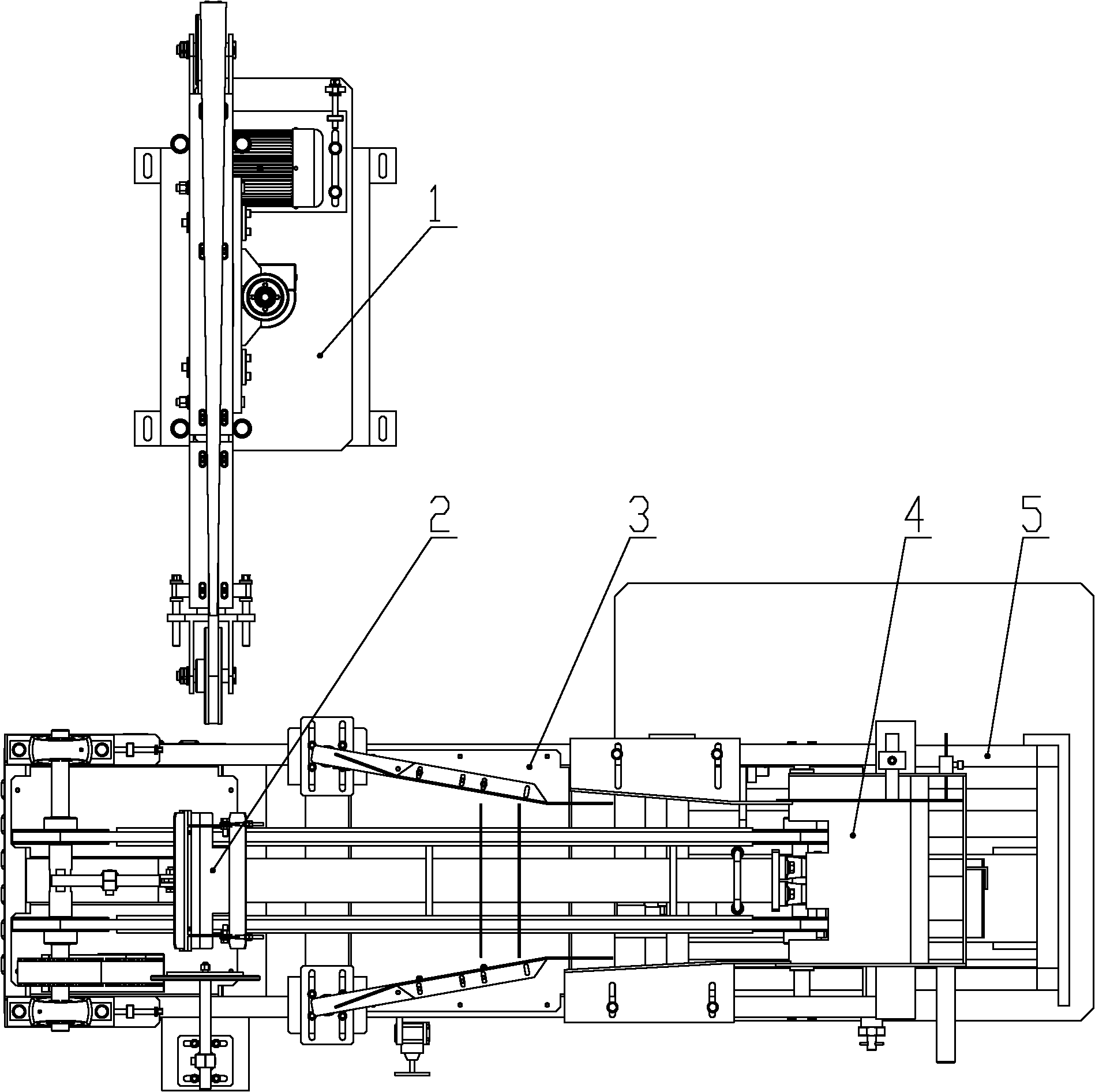

[0037] see figure 1 , a metal wire automatic finishing device of the present invention, comprising a control system, a wire connecting mechanism 1, a wire falling mechanism 2, a wire adjusting mechanism 3, a wire feeding mechanism 4 and a wire storage mechanism 5; The cut metal wire passes through the wire connecting mechanism 1, the wire falling mechanism 2, the wire adjusting mechanism 3 and the wire feeding mechanism 4 successively, and finally falls into the wire storage mechanism 5.

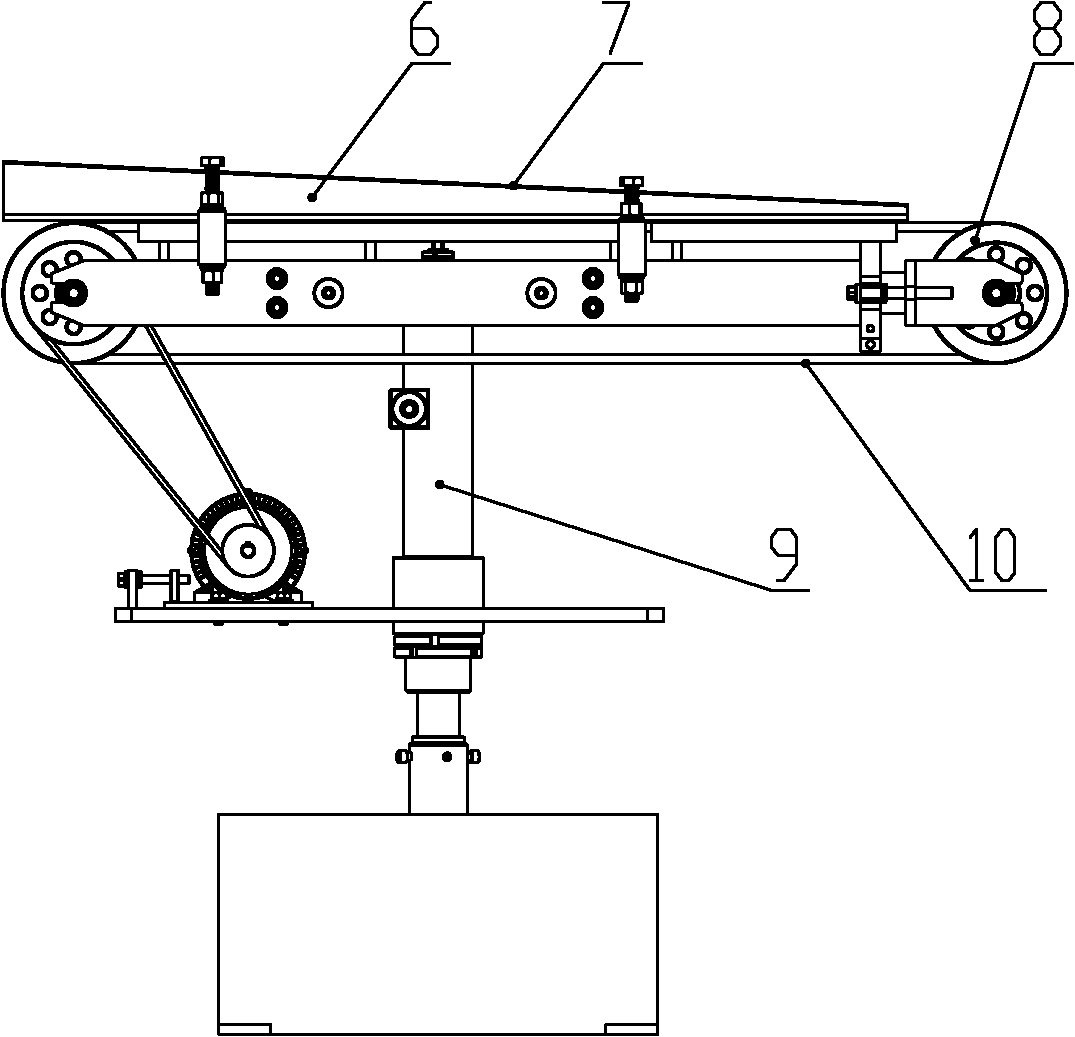

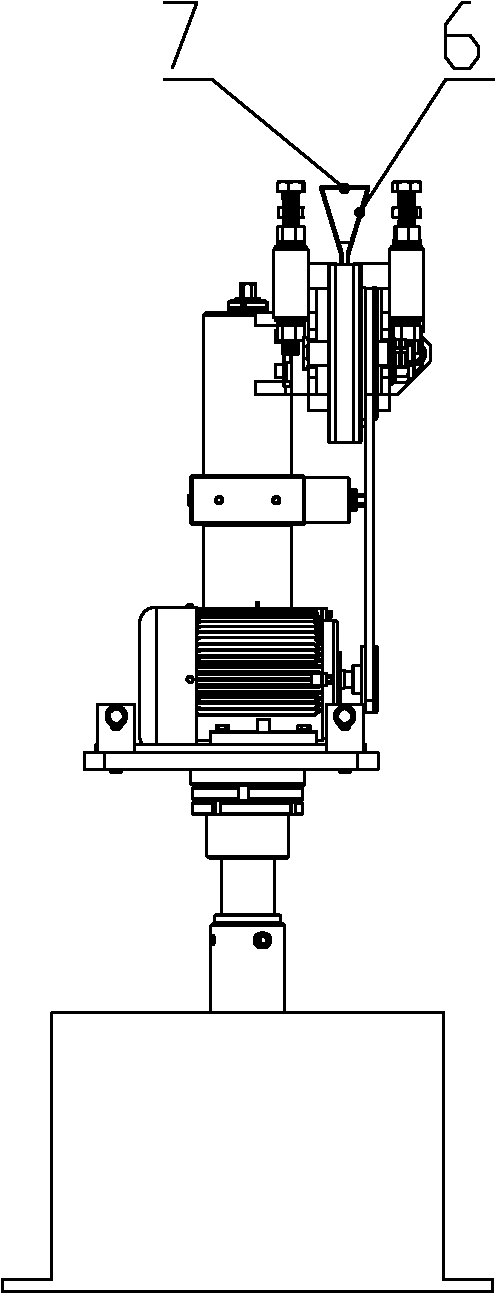

[0038] see Figure 2-1 to Figure 2-3 The wire connection mechanism 1 includes a wire reduction device 6, a first belt drive 8 and an upper horizontally rotatable wire connection frame 9, and the speed of the wire connection is higher than the maximum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com