Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "The power of the whole machine is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold control device of dual-throttle precooling and freshness preserving ice-cream machine, cold control method and ice-cream machine

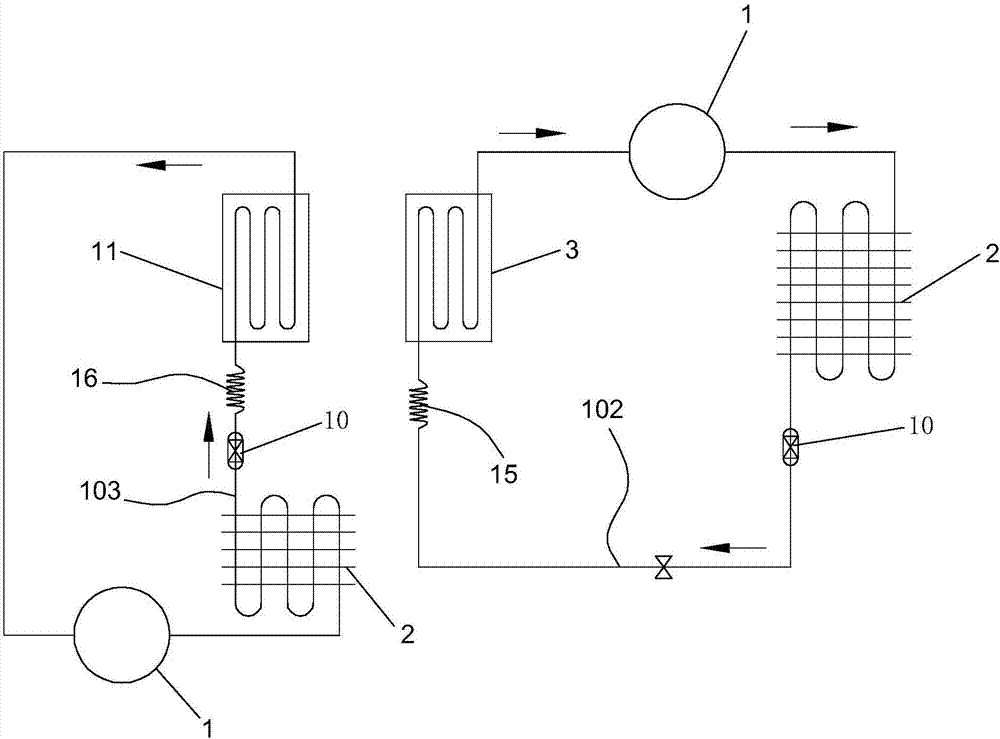

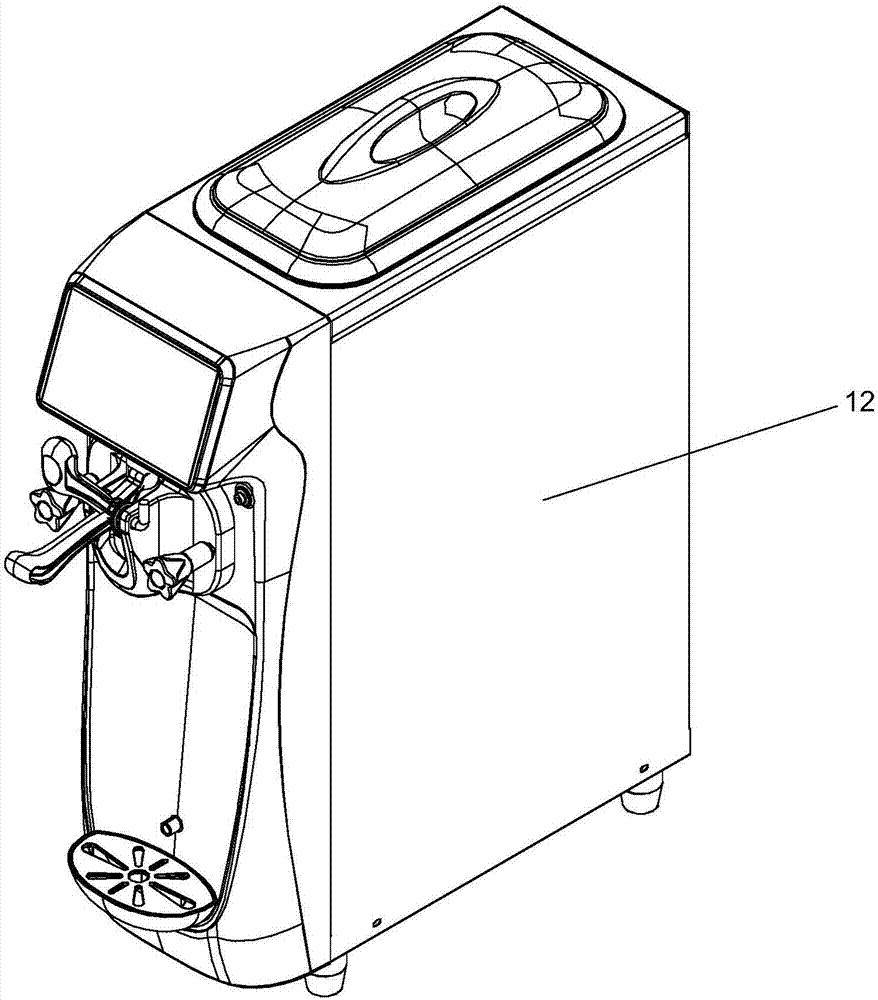

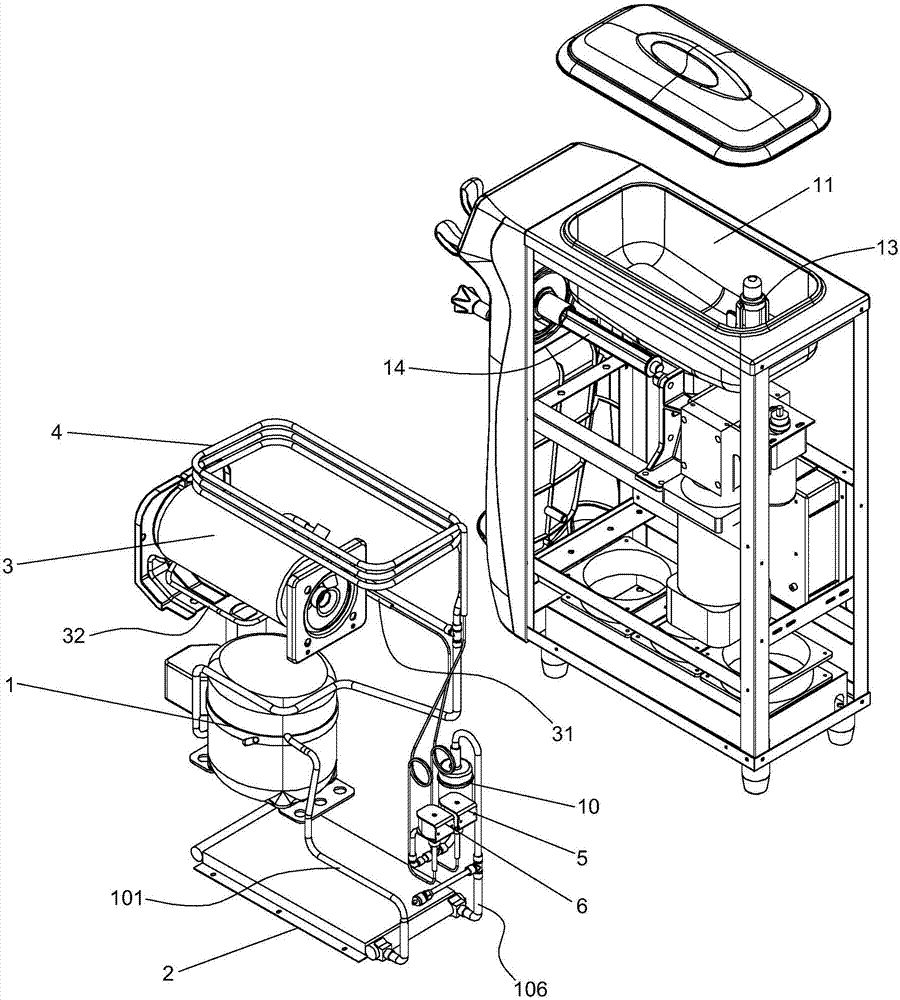

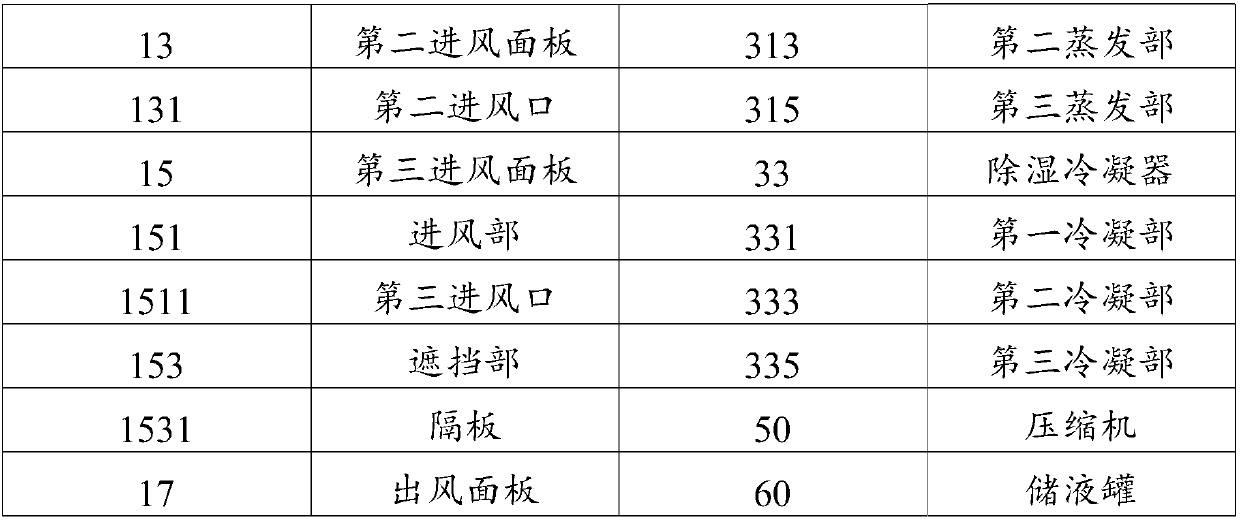

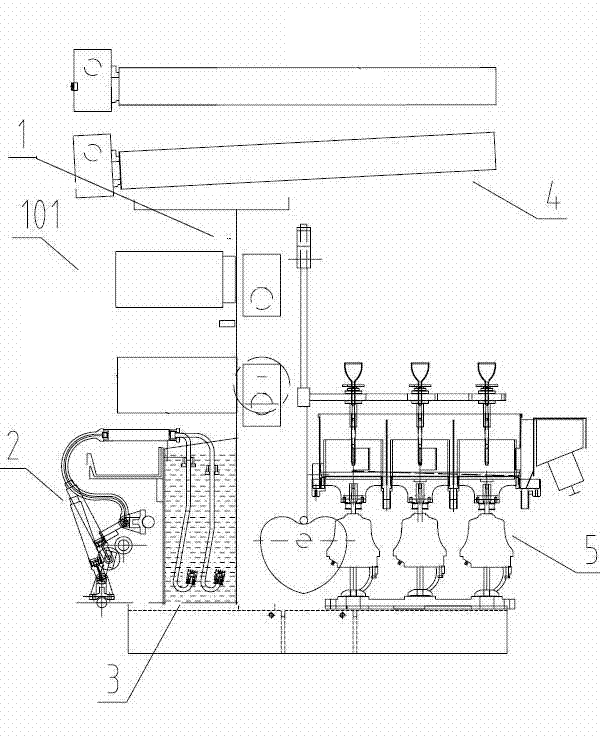

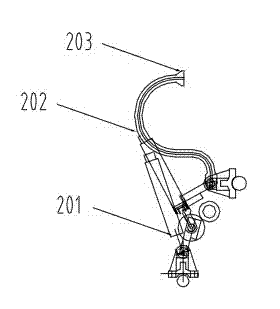

The invention discloses a cold control device of a dual-throttle precooling and freshness preserving ice-cream machine, a cold control method and an ice-cream machine. The cold control device comprises a compressor, a condenser, a bowl evaporator, a freezing cylinder refrigeration inlet pipe and a freezing cylinder refrigeration outlet pipe, wherein an outlet end of the condenser is connected with an outlet pipeline of the condenser, the outlet pipeline of the condenser communicates with three branch pipes separately, the three branch pipes comprise a freezing cylinder refrigeration pipeline, a bowl precooling pipeline and a bowl freshness preserving pipeline which are arranged in parallel, the freezing cylinder refrigeration pipeline communicates with the freezing cylinder refrigeration inlet pipe, both the bowl precooling pipeline and the bowl freshness preserving pipeline communicate with an inlet end of the bowl evaporator, and an outlet end of the bowl evaporator and the freezing cylinder refrigeration outlet pipe separately communicate with the compressor. The cold control device can truly achieve the separation of two modes, i.e., precooling and freshness preserving of a bowl. The invention simultaneously discloses the cold control method and the ice-cream machine.

Owner:ZHONGSHEN TECH (GUANGDONG) CO LTD

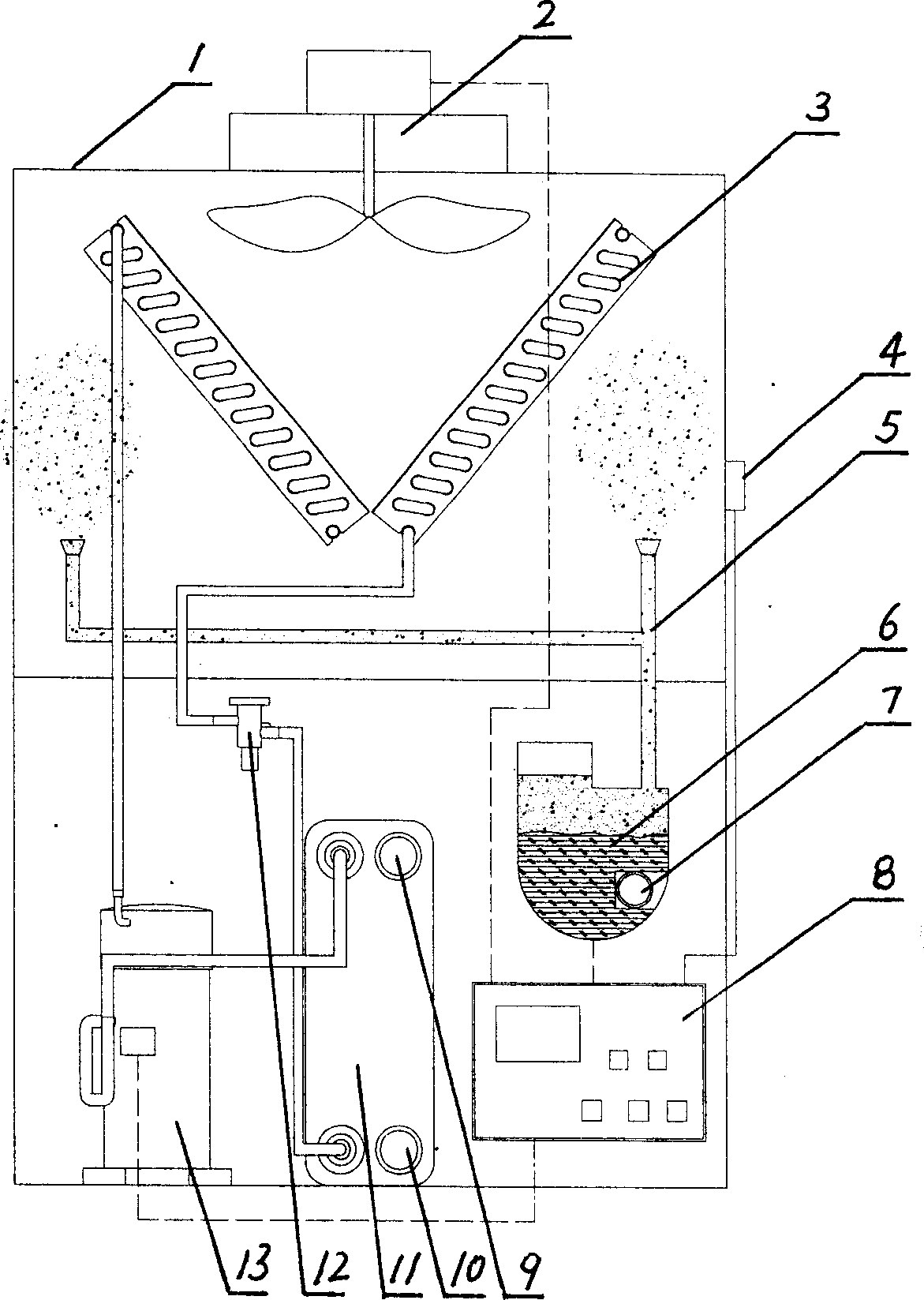

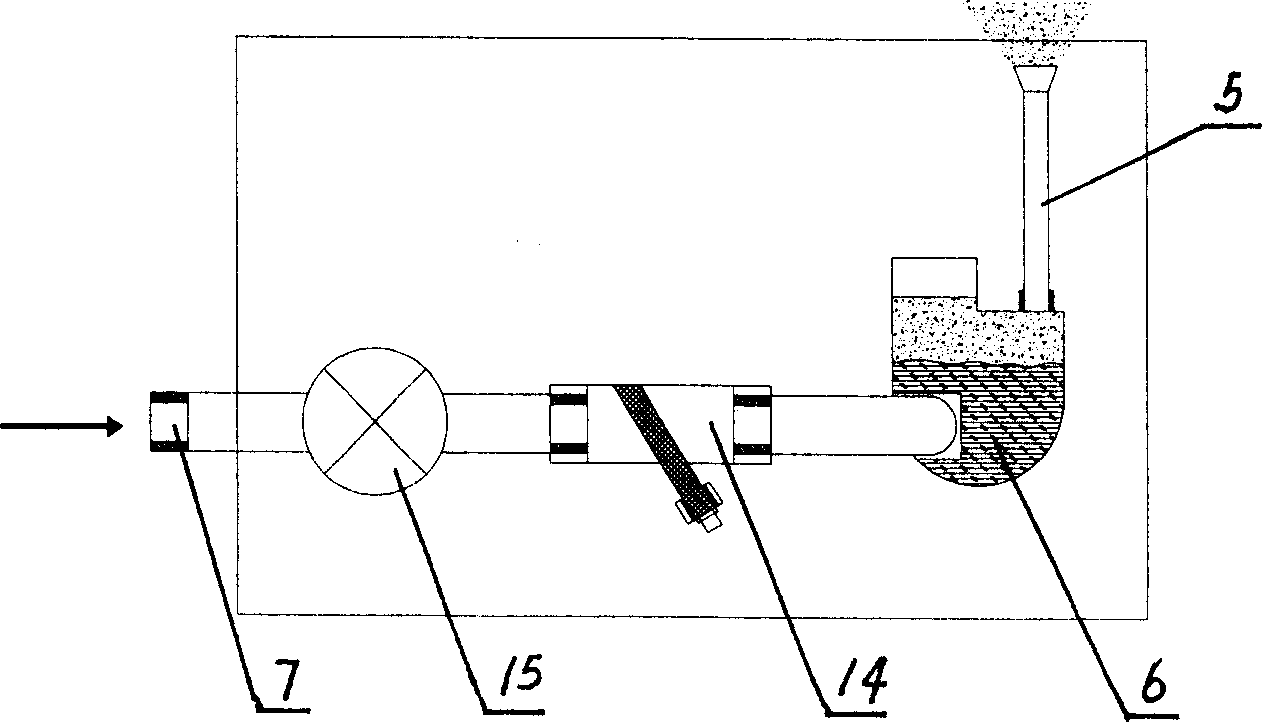

Air-cooling hot-pump water cooler set for decreasing working environment temperature

InactiveCN1818511AReduce air temperatureReduce condensing pressureCompression machines with non-reversible cycleMachines using refrigerant evaporationWater filterSprayer

The invention relates to an air-cooled heat pump water cooler set, in which is disposed a water sprayer made up of a magnetic valve, a water filter, a water atomizer and a spray-transfer device connected in order. The spray-transfer device is used as the outlet of the system and the magnetic valve is used as the inlet of the system. Outside the casing is disposed a moisture-temperature sensor connected with a electric control system. The inventive water sprayer can act for reducing the air intake temperature on the condenser side can be reduced by the spray evaporation to increase heat-exchange temperature difference between the condenser and the air, so as to improve the heat-exchange environment and effect of the condenser side.

Owner:NINGBO HICON IND

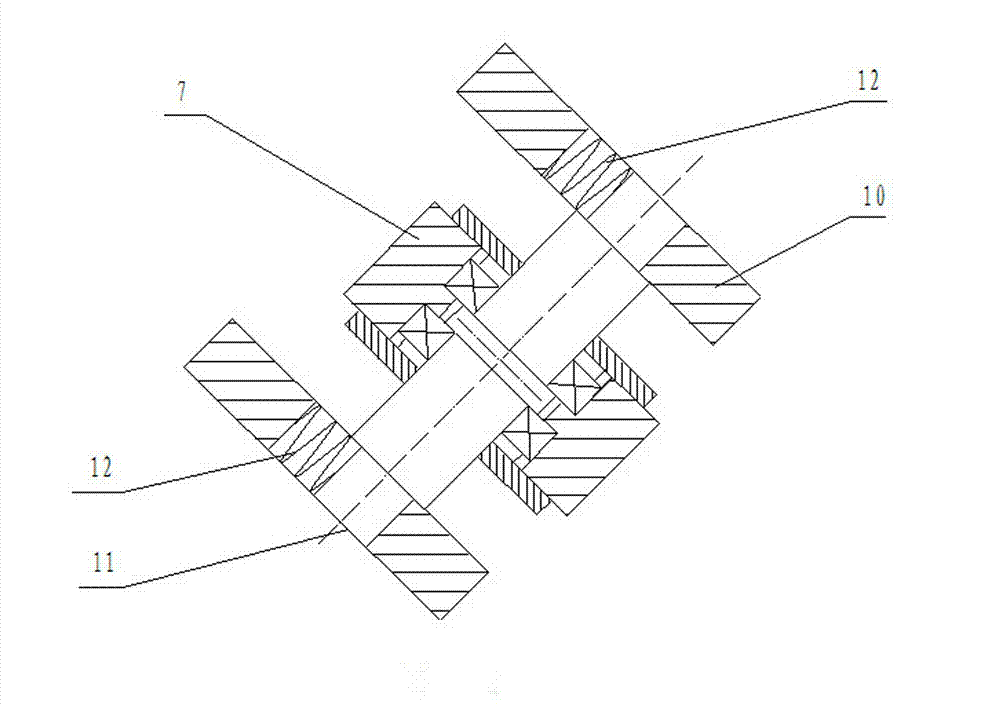

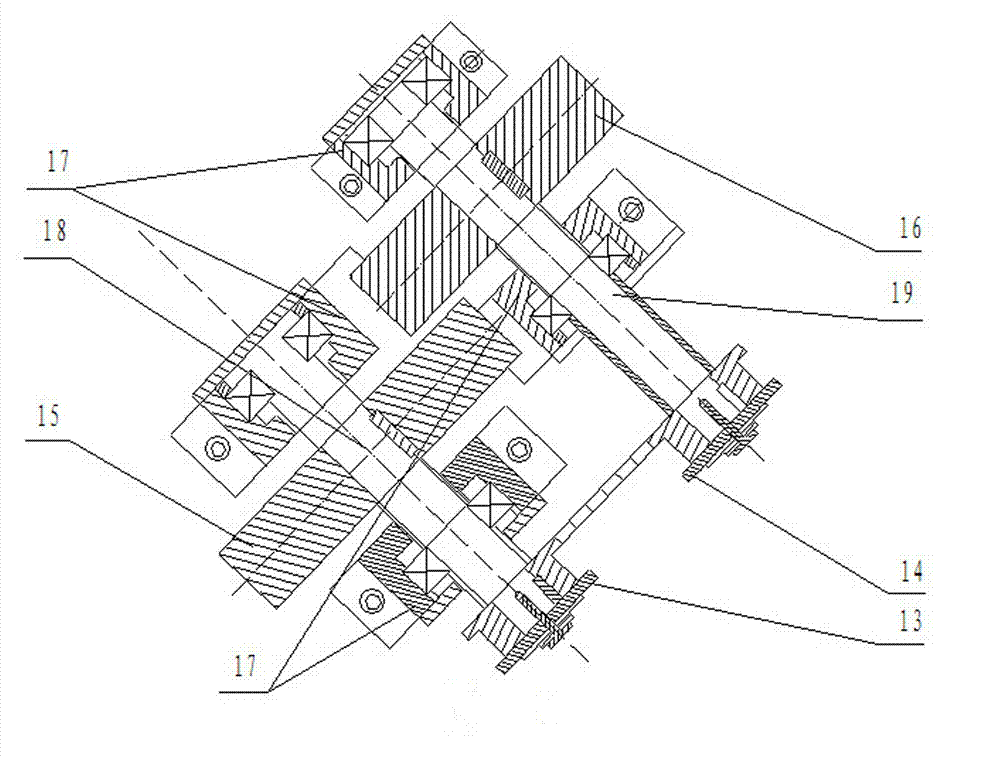

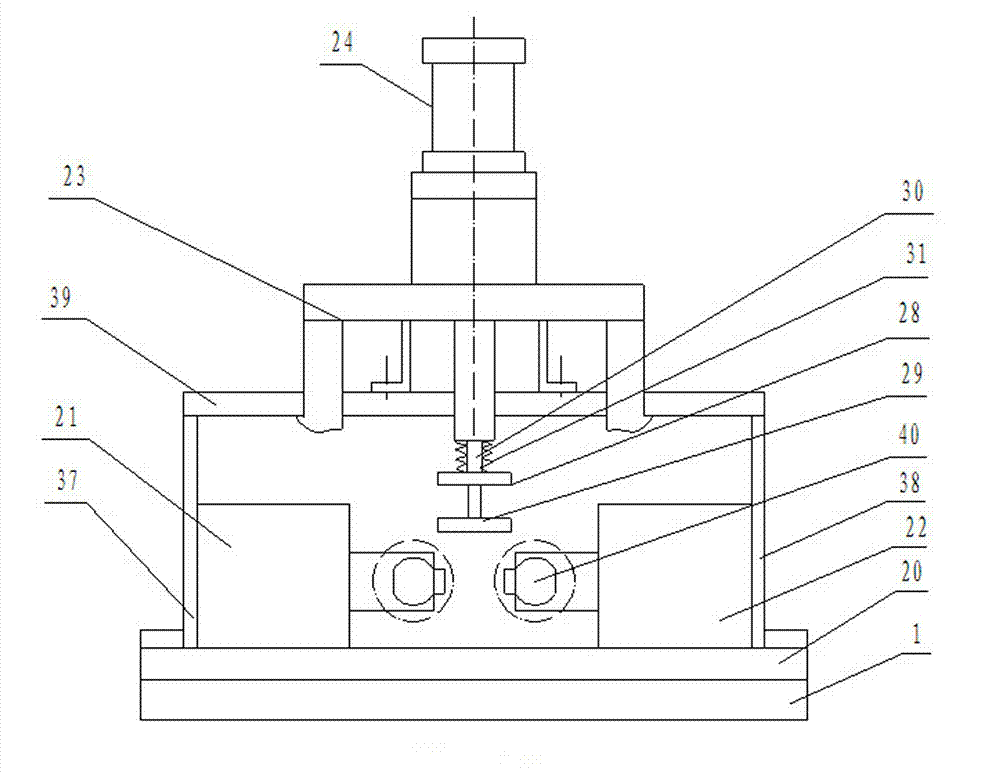

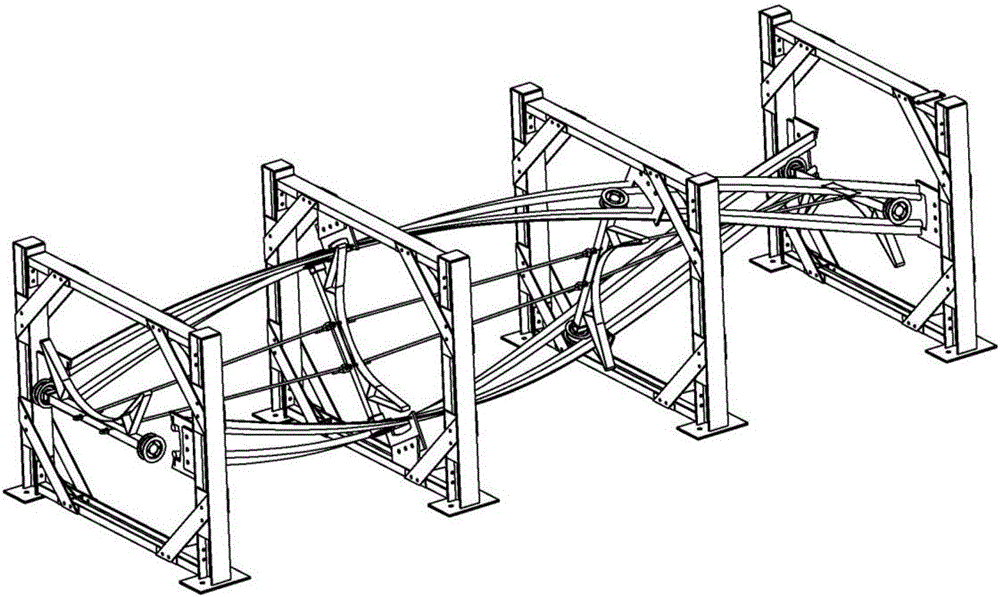

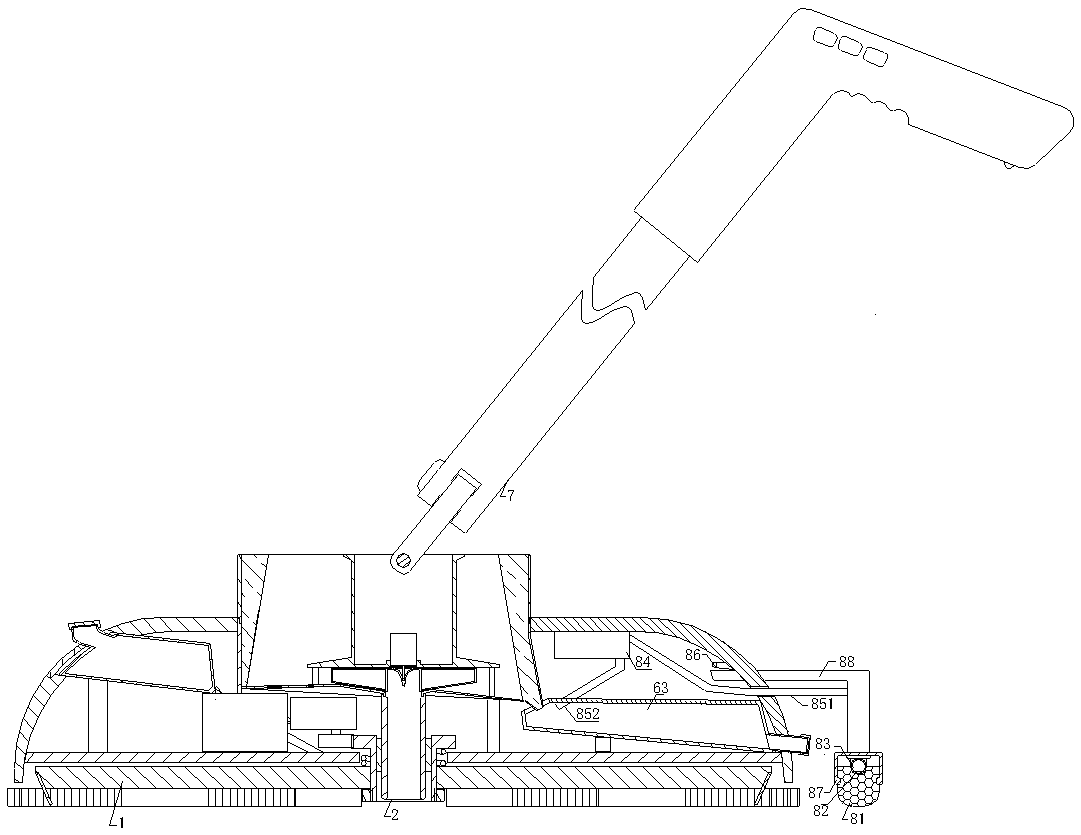

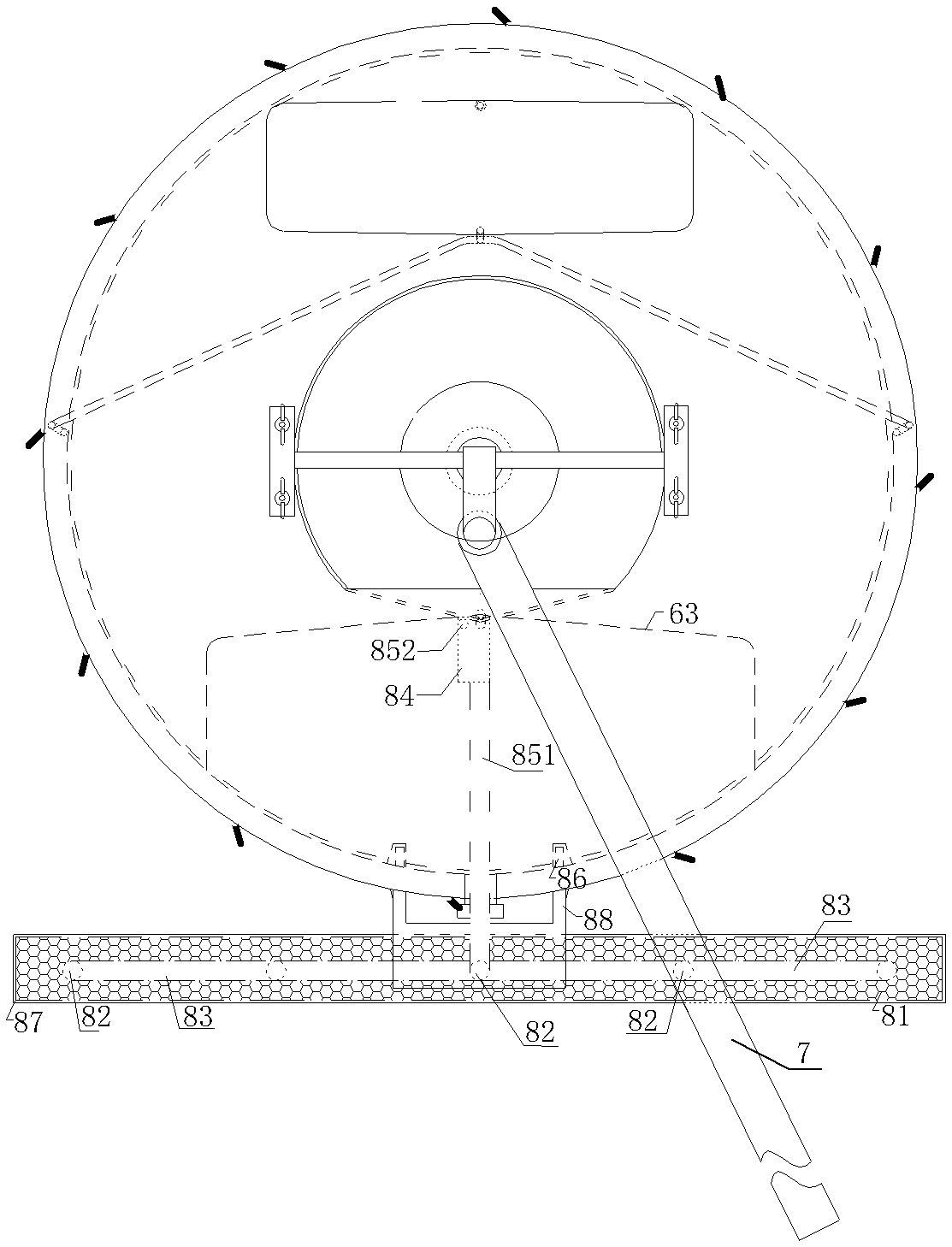

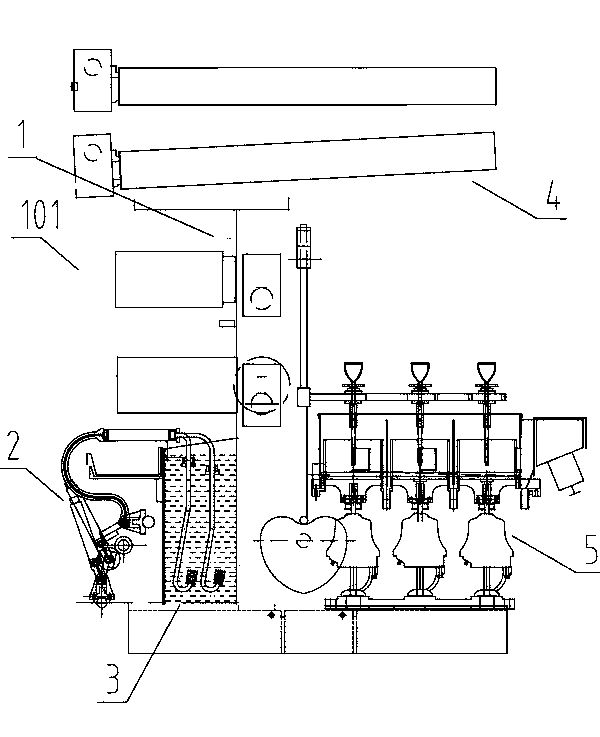

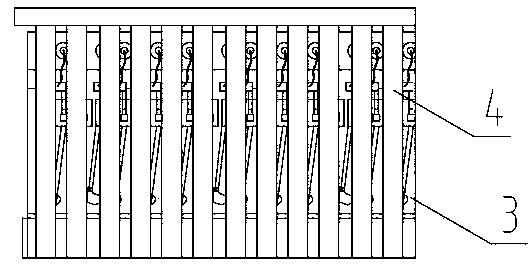

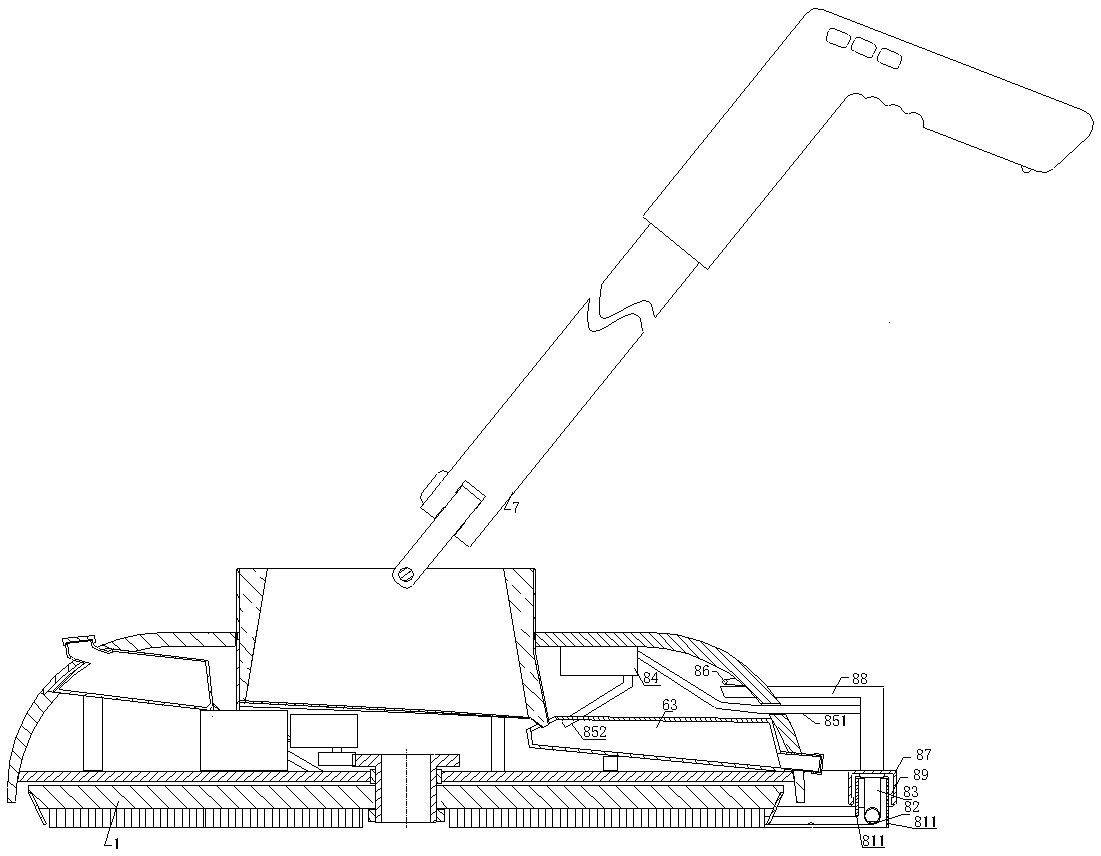

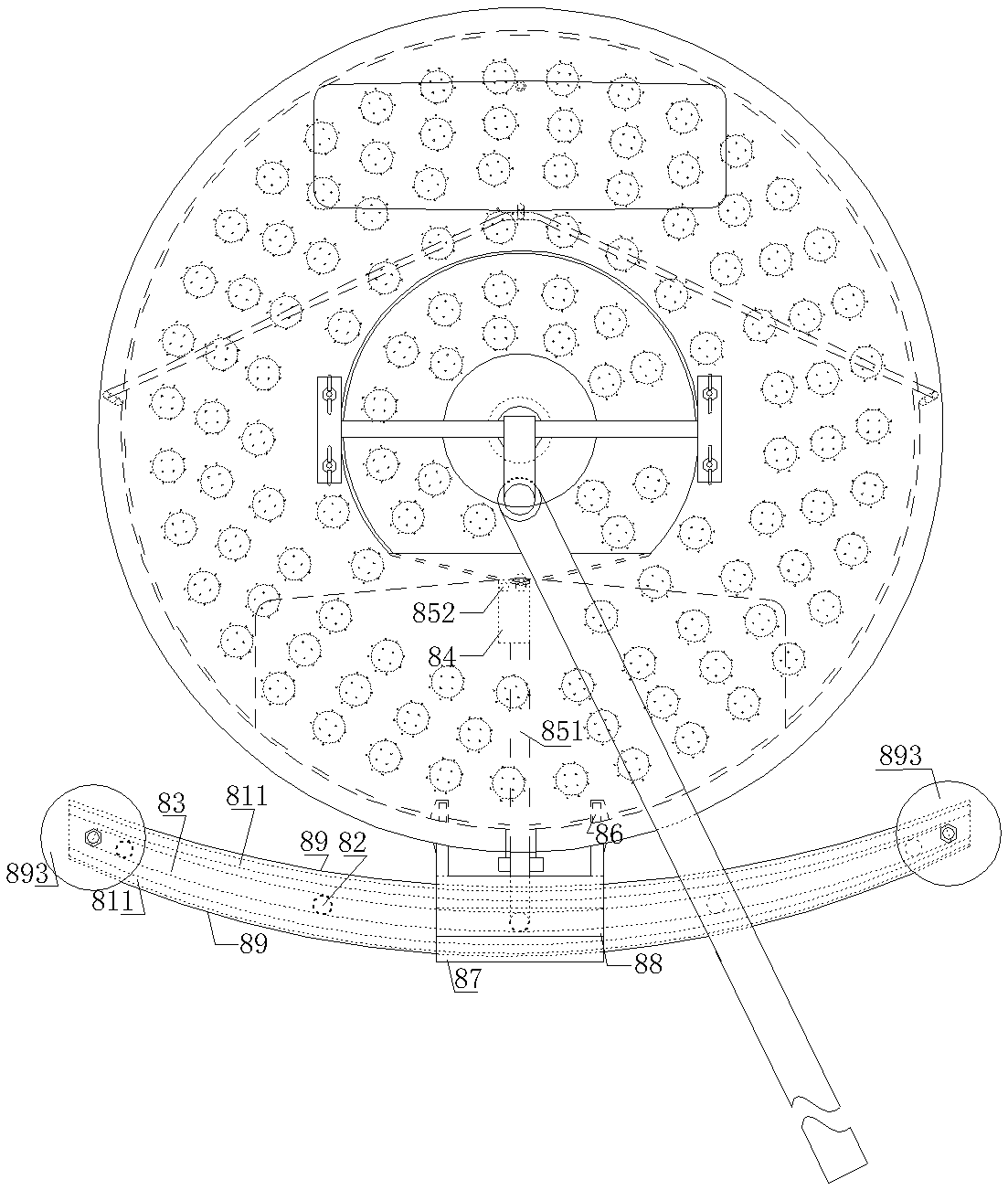

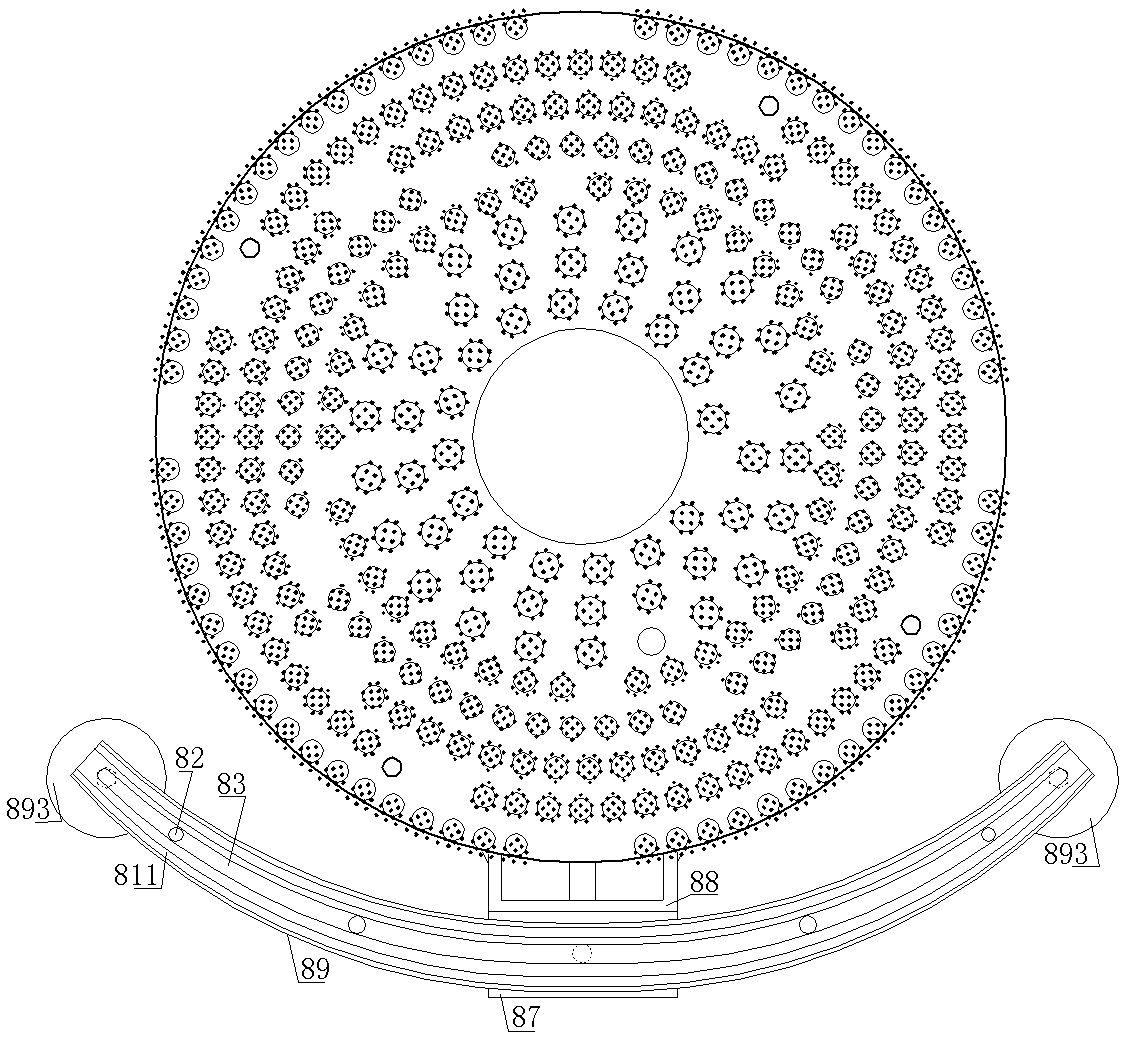

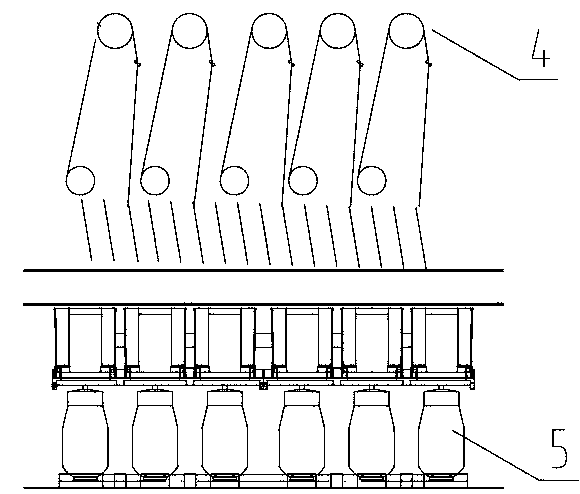

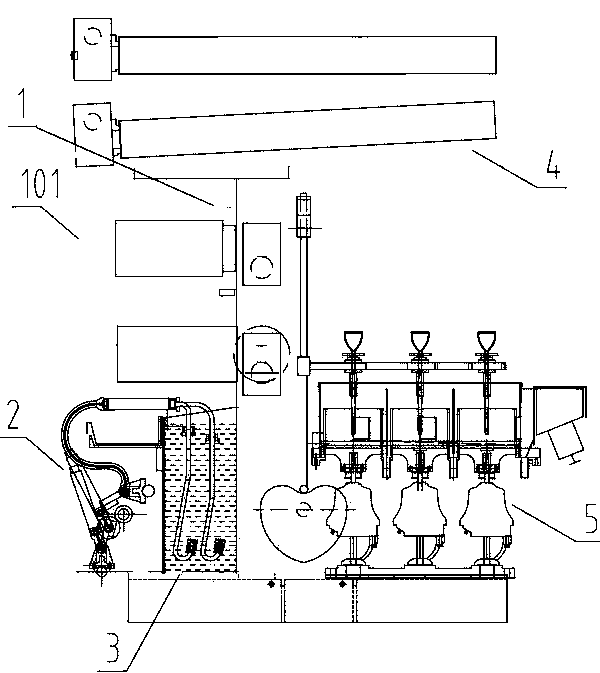

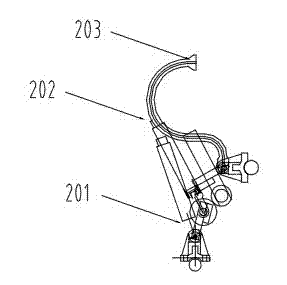

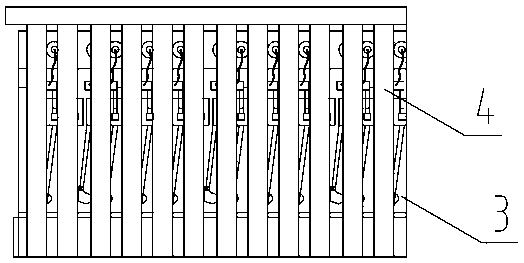

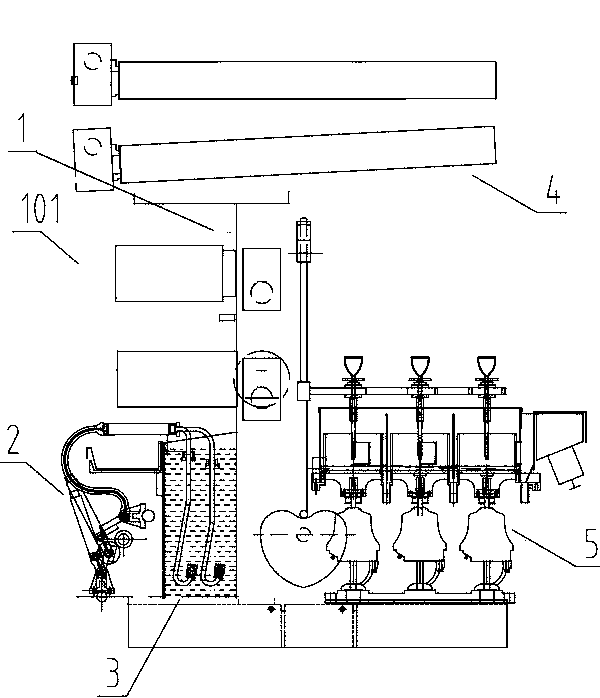

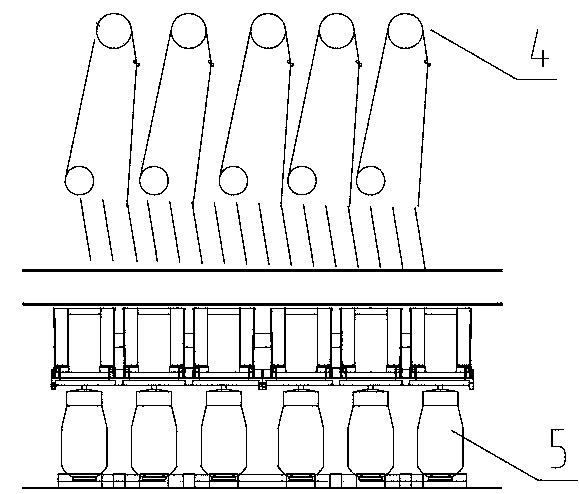

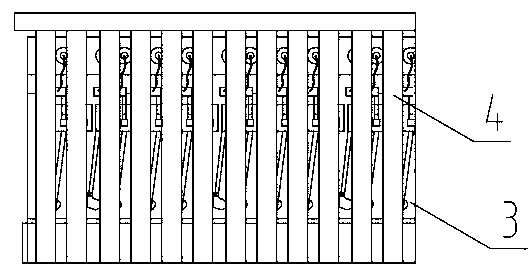

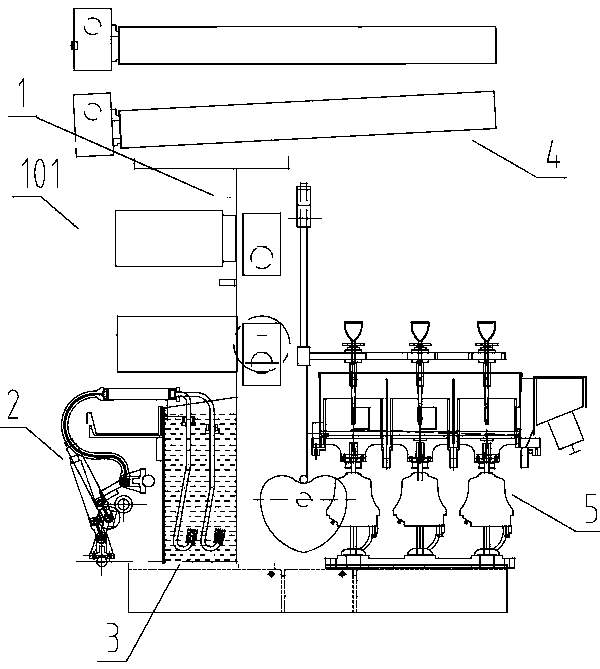

Magnetic flux leakage defection machine of oil sleeve

ActiveCN102768239AAvoid misjudgmentAvoid missed judgmentMaterial magnetic variablesHoopingProduction line

The invention discloses a magnetic flux leakage defection machine of an oil sleeve. The magnetic flux leakage defection machine comprises a control cabinet, a computer, a production line detection system and a marking machine, wherein the control cabinet is respectively connected with the computer, the production line detection system and the marking machine through a signal line; and the production line detection system comprises a plurality of clamping driving devices, a vertical defect detection device and a transverse defect detection device. Electric signals of sleeve defects, detected by an infrared monitoring sensor on the production line detection system, are processed by a signal amplification circuit and a noise cancelling circuit and are divided into two paths; in one path, defect parts are accurately sprayed with marks by a signal processing circuit through utilizing the computer to drive the marking machine; and in the other path, defect signals are mixed into a simulated signal, and defect degree is displayed on a display screen of the computer through an A / D (Analog / Digital) converting circuit. With the adoption of the technical scheme of the invention, the magnetic flux leakage defection machine disclosed by the invention can carry out defect detection on the oil sleeve in rotation process on a production line, has small power consumption amount, is energy-saving and environment-friendly and has high detection sensitivity; and a probe does not need to be replaced when sleeves with different calibers are detected, the detection efficiency is high, the hooping of the oil sleeve can be smoothly avoided, the probe can be automatically reset after being detected, the service life is long, the cost is reduced, and the detection quality and the detection effect are improved.

Owner:安庆市安科精机有限责任公司

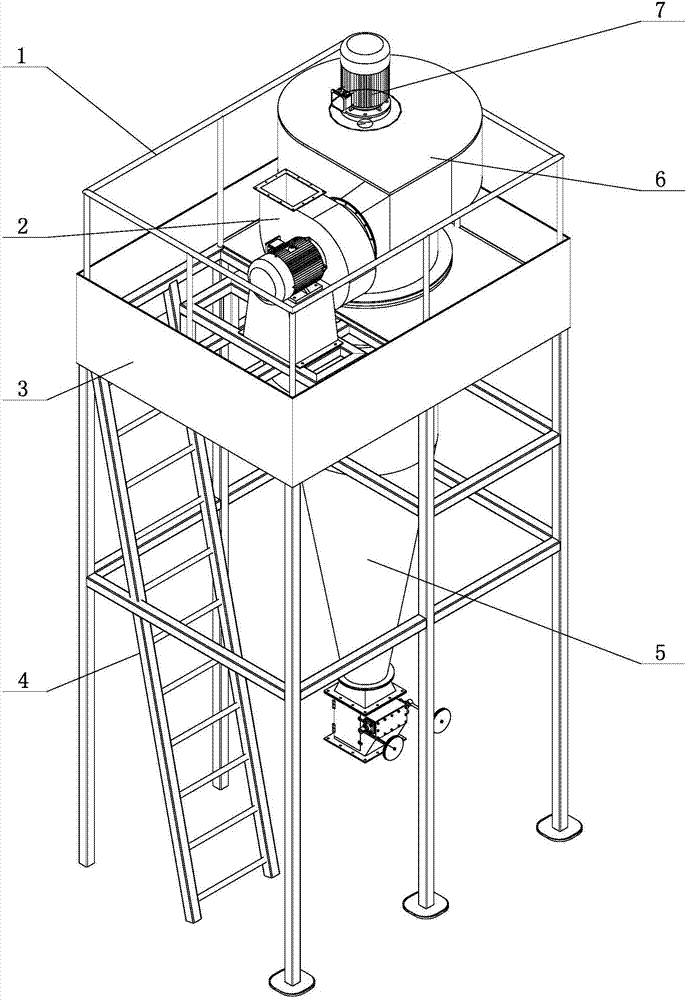

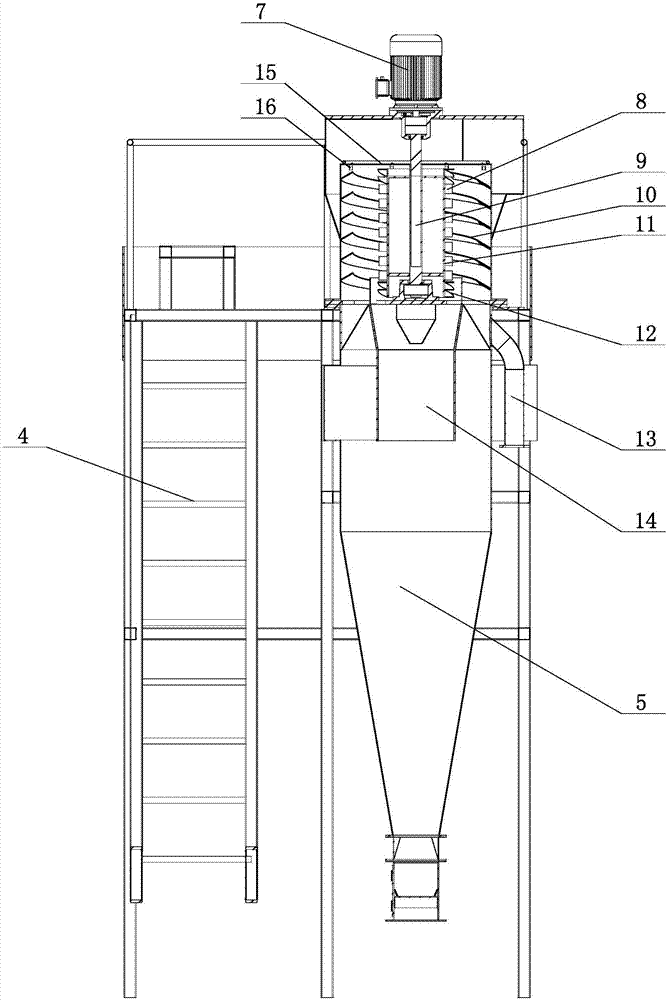

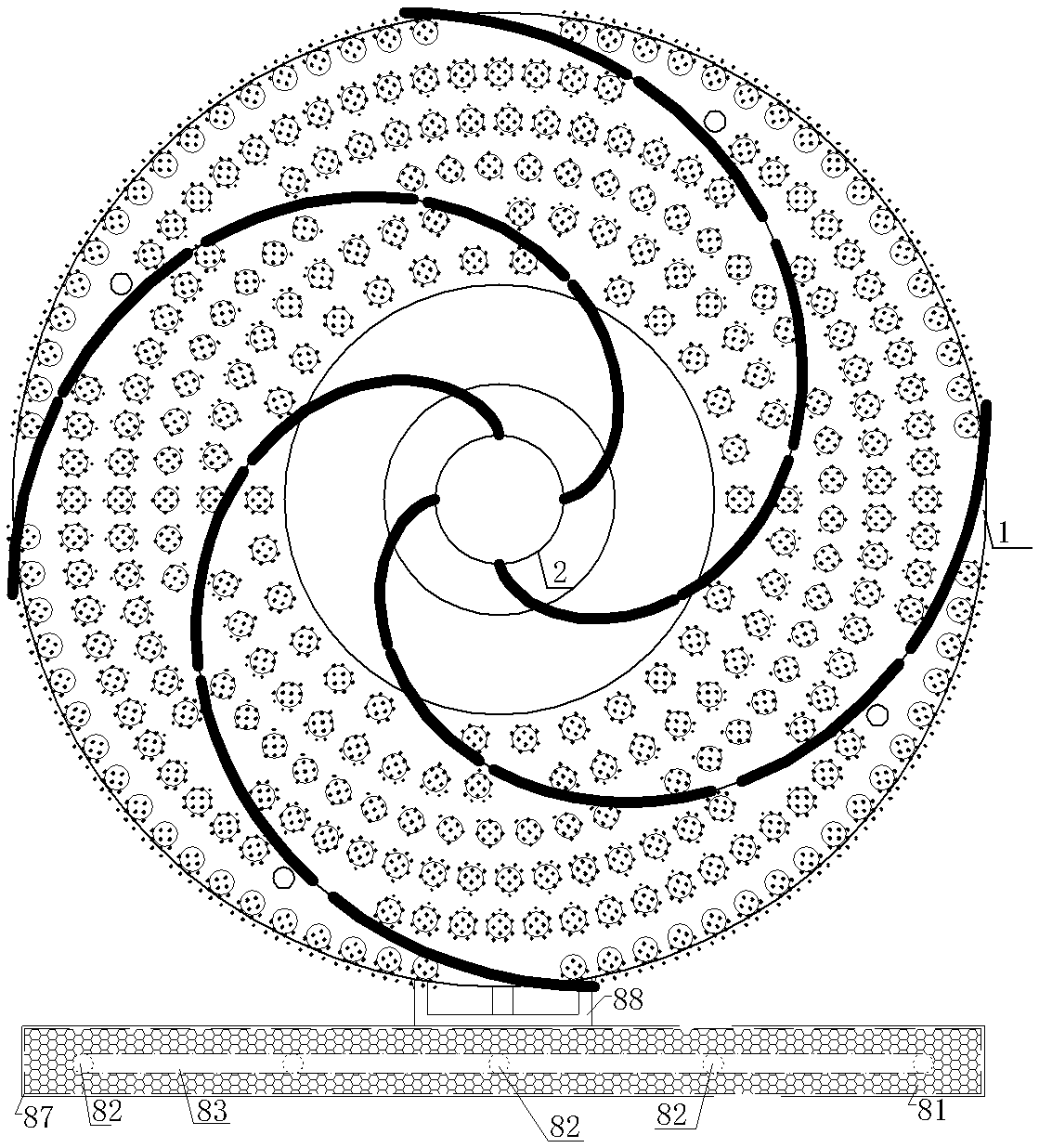

Water-mist type centrifugal dust remover

InactiveCN107174905ASmall footprintThe power of the whole machine is smallCombination devicesVortex flow apparatusWeather resistanceEngineering

The invention is mainly applied to the field of dust removal equipment and particularly relates to a water-mist type centrifugal dust remover. The water-mist type centrifugal dust remover comprises a cyclone dust remover mounted on a frame body, wherein a centrifugal machine is arranged at the top of the cyclone dust remover, a water-mist spraying structure is arranged in the centrifugal machine, and an induced draft fan is communicated to a volute at the upper end of the outer side wall; the centrifugal machine comprises a shell, an impeller and blades, the volute is arranged at the top of the shell, the impeller is mounted in the shell and is mounted on a centrifugal rotor shaft, the blades are mounted on the outer side wall of the impeller, and a driving motor is connected to the top of the centrifugal rotor shaft and is mounted at the top of the volute; and the water-mist spraying structure comprises a water injection pipe, the water injection pipe is mounted at the top of the shell, spray holes are formed in the bottom of the water injection pipe, and a sewage discharging pipe corresponding to the water-mist spraying structure is arranged outside the bottom of the shell. The water-mist type centrifugal dust remover occupies a small area, is low in complete machine power and strong in weather resistance, can be used for completely replacing existing desulfurization and denitration equipment in the industries such as boilers, desulfurization and denitration, and has a good dust removal effect.

Owner:SHANDONG ECON ENERGY SAVING TECH

Rail belt-type conveyor with rotary wheel structures

InactiveCN105692068AAchieve structural optimizationStrong complementarityConveyorsHeadframeEngineering

The invention relates to a rail belt-type conveyor with rotary wheel structures. The rail belt-type conveyor comprises a support, a headstock, a tailstock, an upper guide rail, a lower guide rail, the rotary wheel structures, spiral steering mechanisms, towing trolleys, a tape, a steel wire rope, a driving roller, steering racks and vertical racks, wherein the tape is arranged on support roll groups on two ends of the support for rotation in a surrounding manner; the towing trolleys are separated from the tape or are in contact with the tape on the middle part of the support through the rotary wheel structures and the spiral steering mechanisms; the upper guide rail and the lower guide rail are both arranged on the support through pressing plates; the headstock is arranged on the head part of the support; the tailstock is arranged on the tail part of the support; and the steering racks and the vertical racks are arranged between the tailstock and the headstock. The rail belt-type conveyor has the advantages that the structure of the conveyor is optimized, and the use cost is lowered, so that complementary advantages are realized; the operation cost is greatly lowered; a part of ordinary support rolls are replaced by the towing trolleys, so that the cost and assembly cost are lowered; and revolutionary innovation is brought to bulk material transportation.

Owner:LIBO HEAVY MACHINE TECH

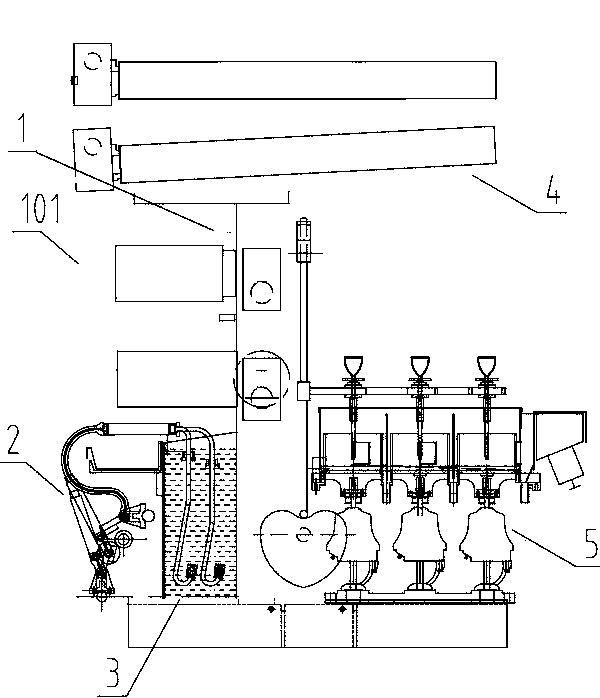

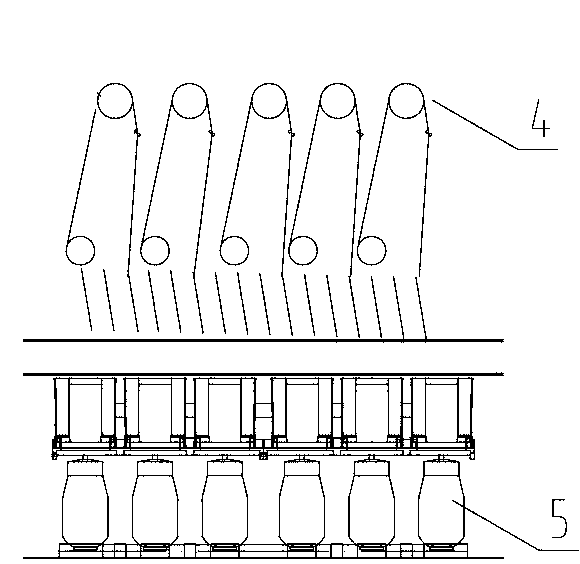

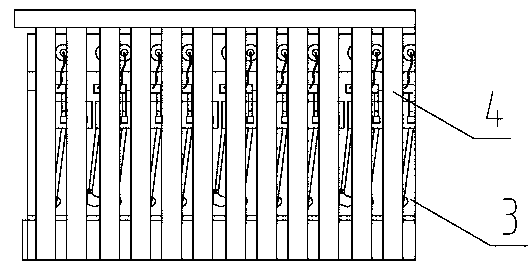

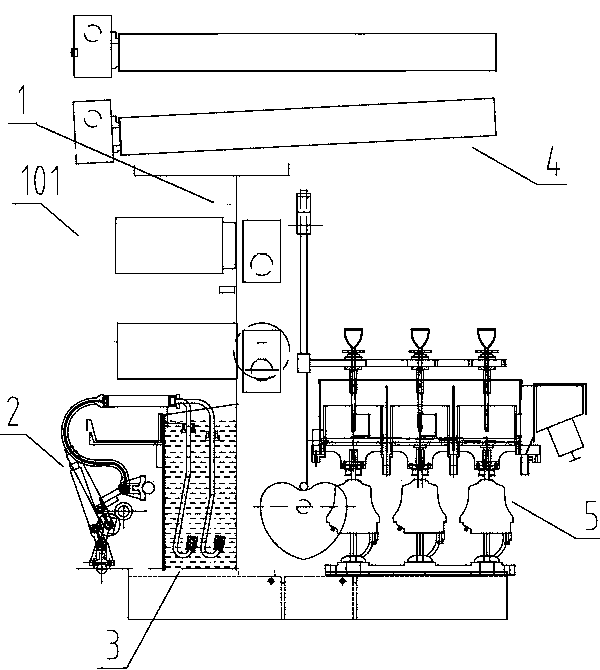

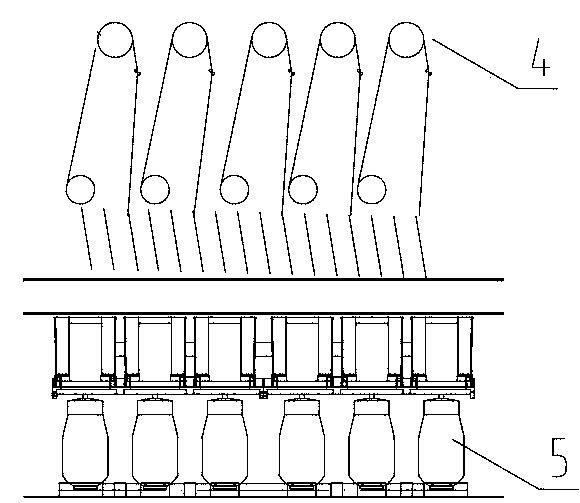

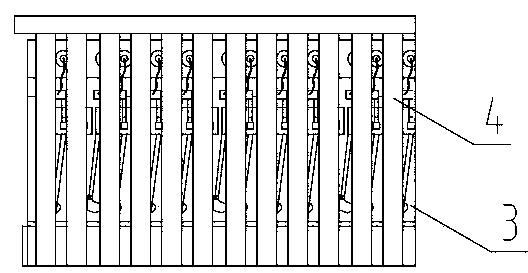

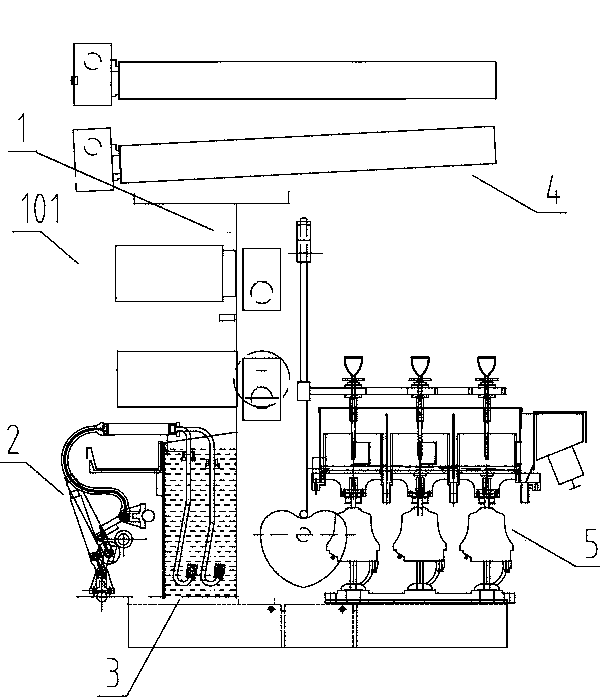

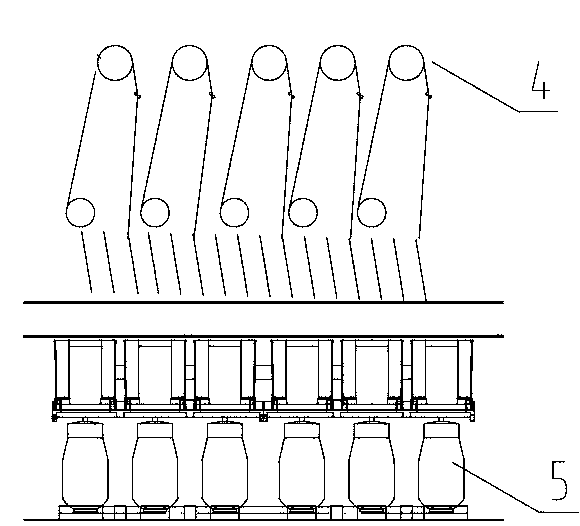

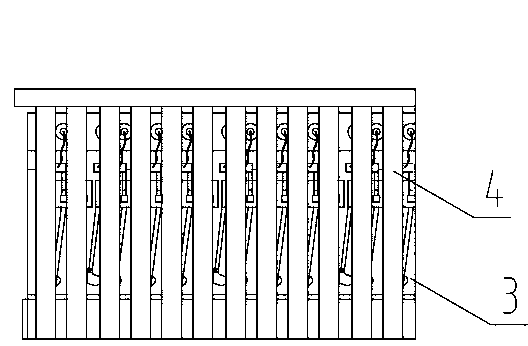

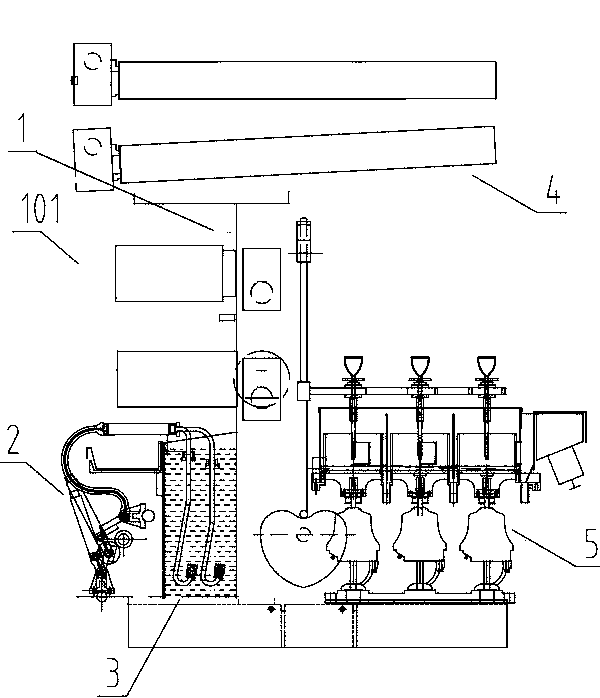

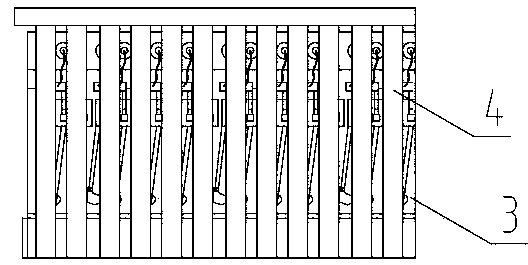

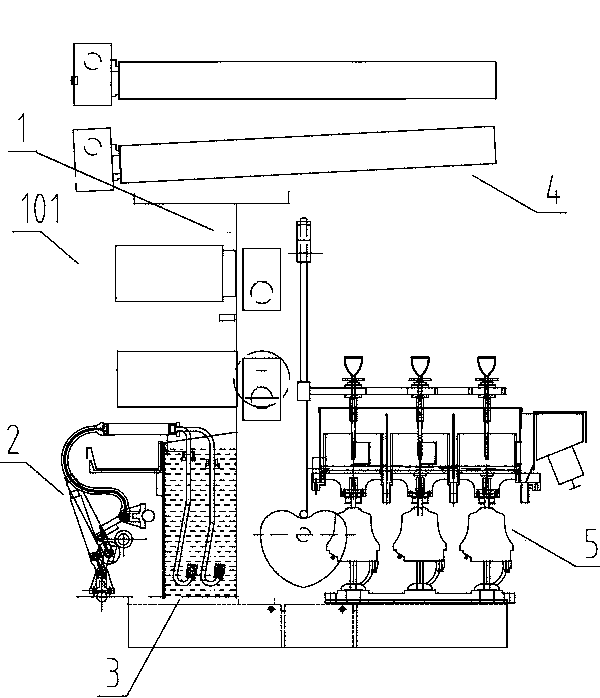

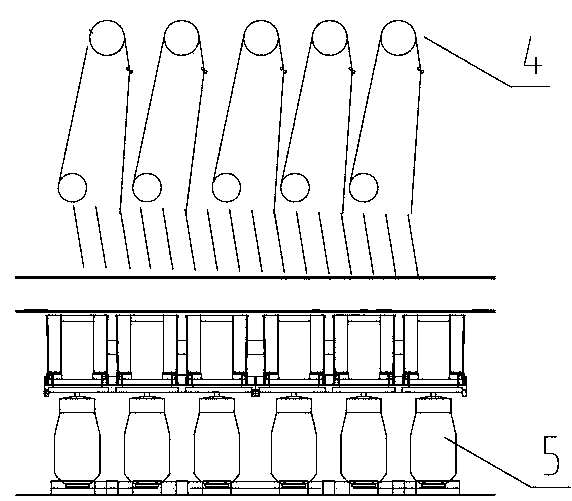

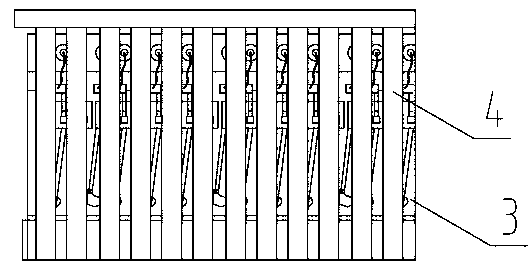

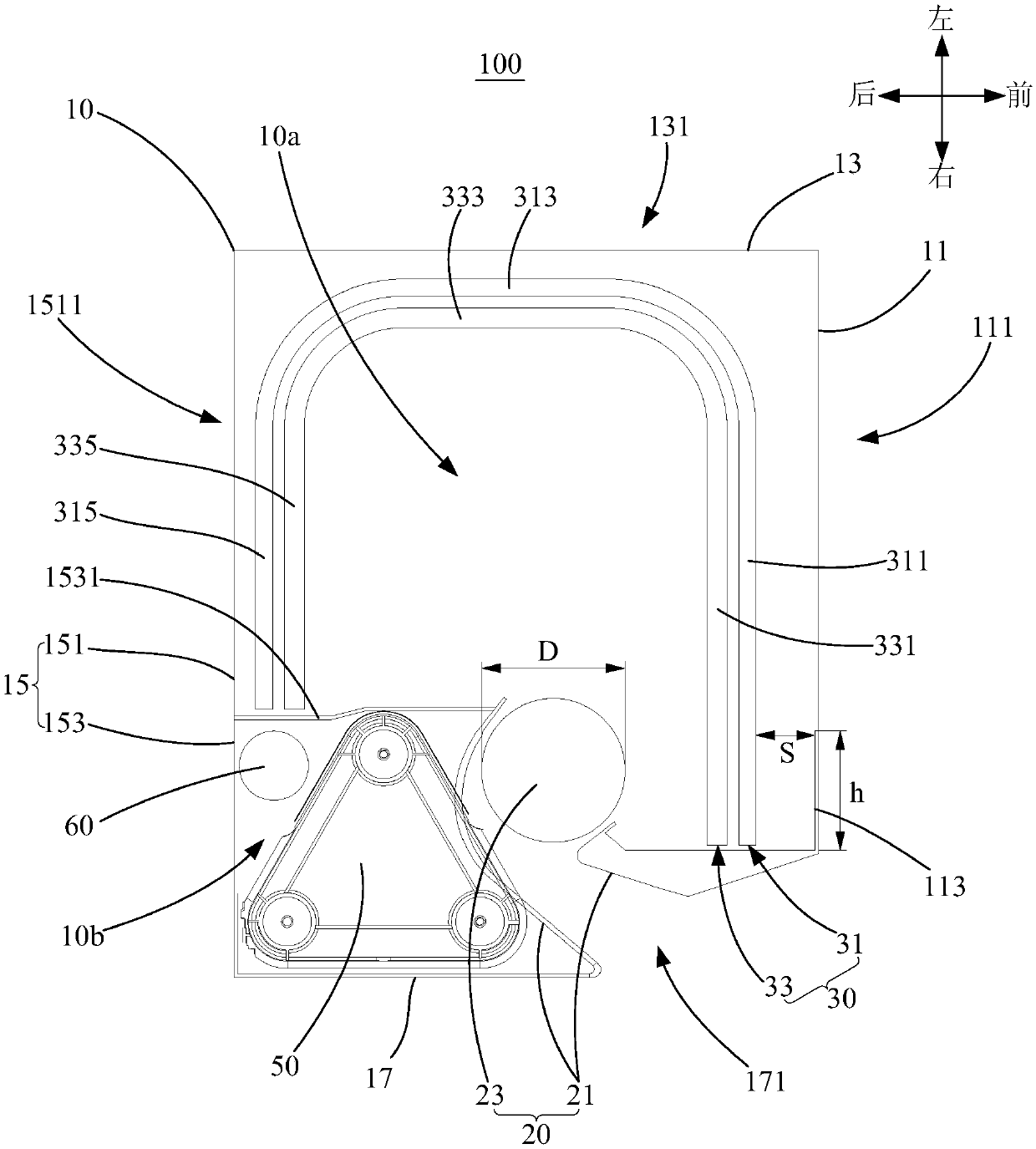

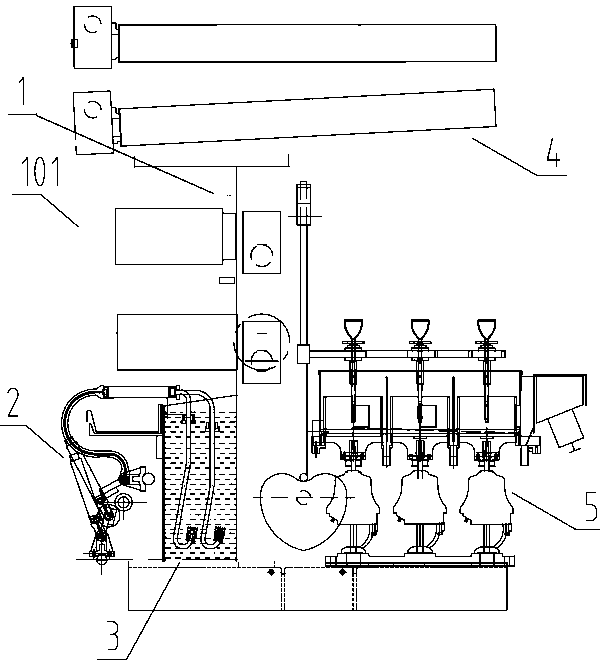

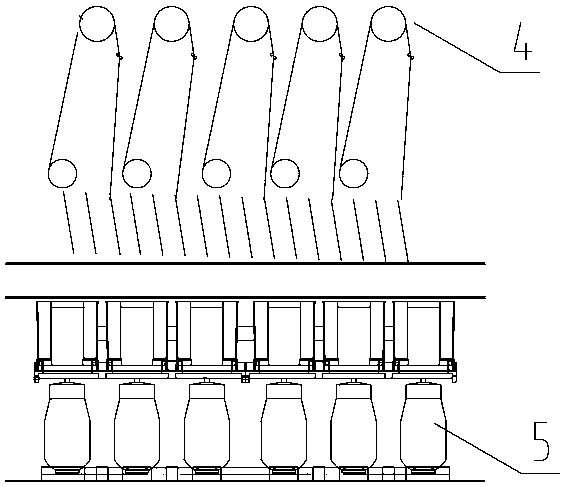

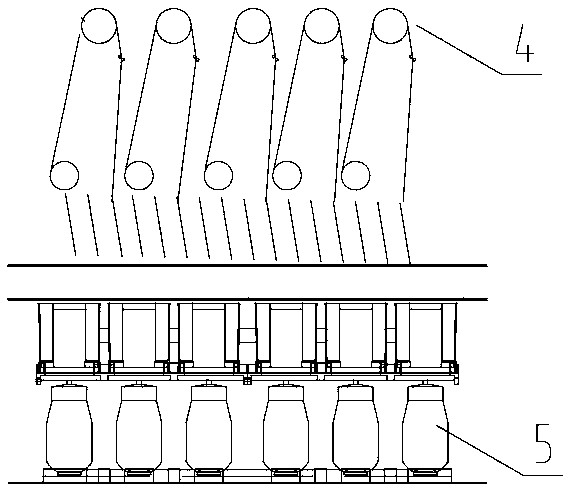

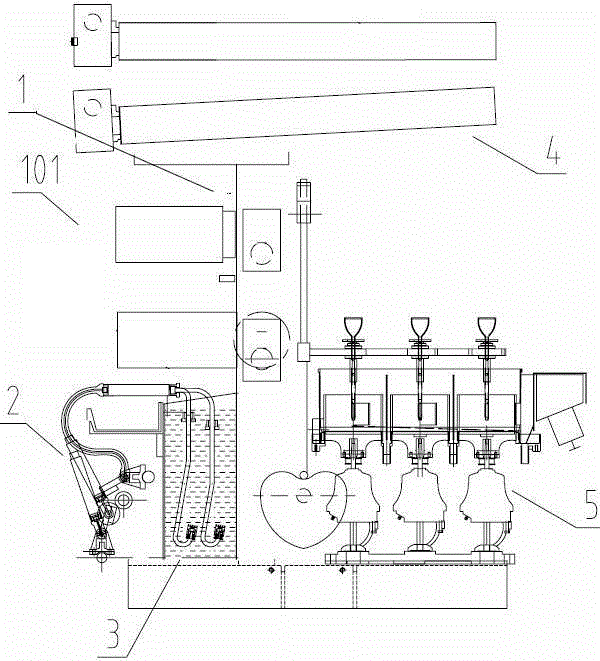

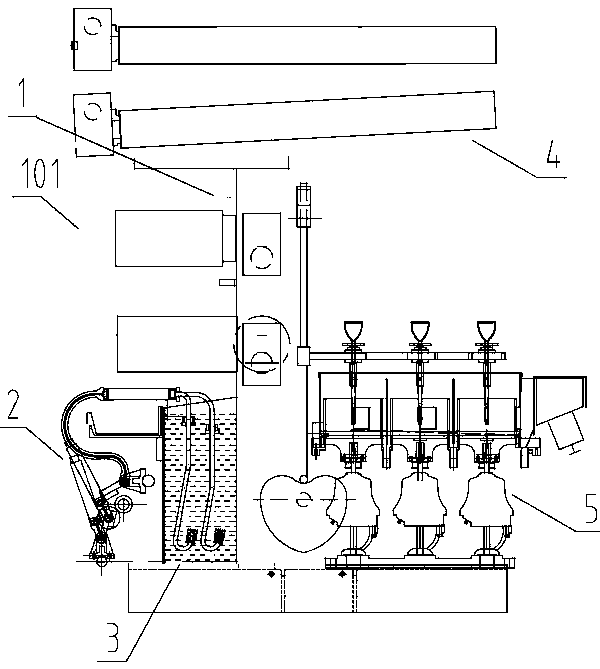

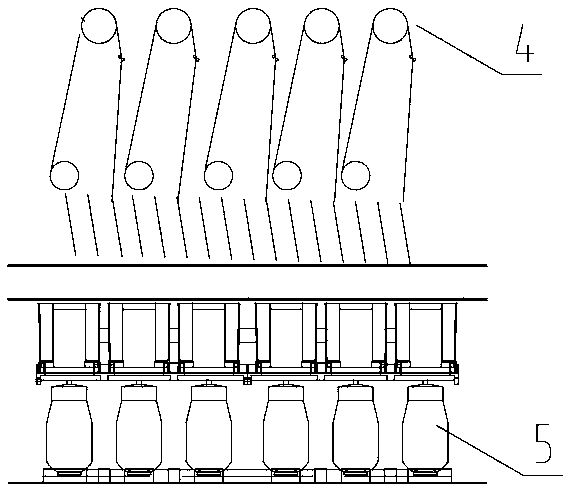

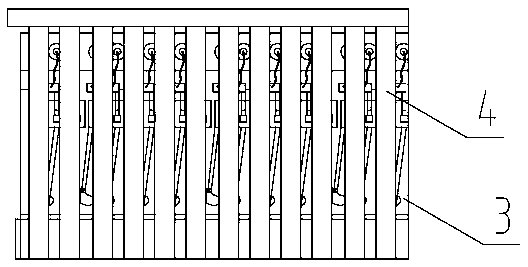

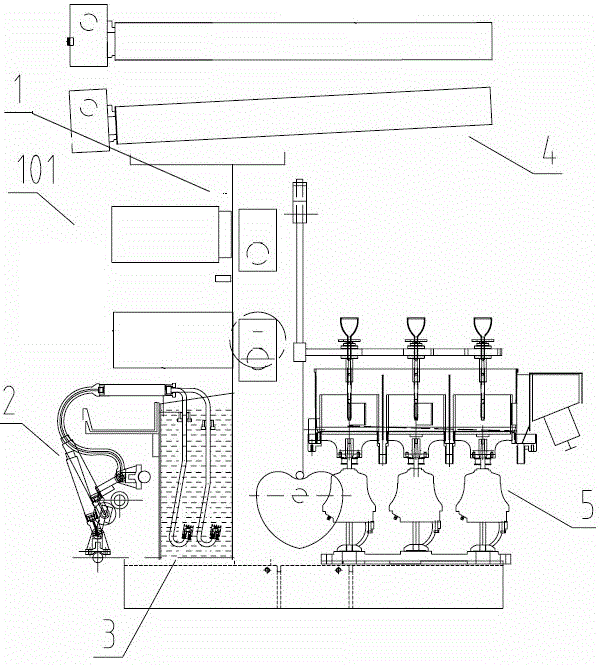

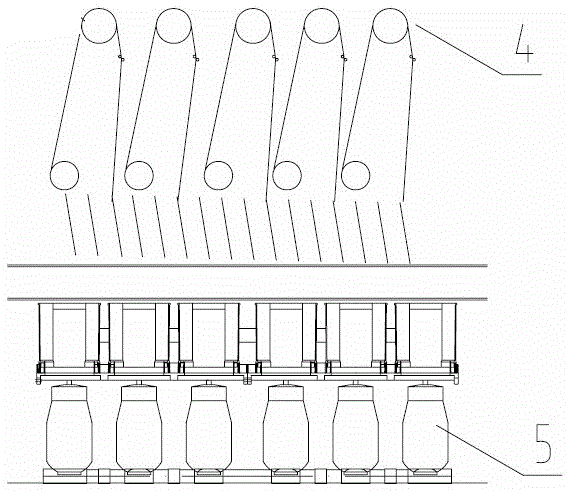

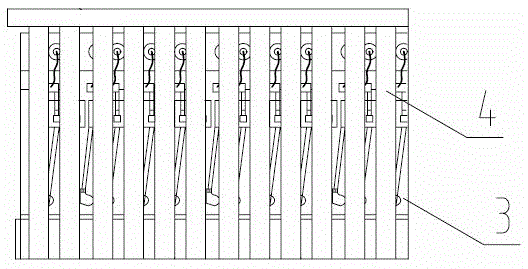

Novel high-speed spinning machine

InactiveCN103628161AAvoid unstable speedSpeed jumpNew-spun product collectionSpinning head liquid feederSpinningControl system

The invention relates to spinning equipment, in particular to a novel high-speed spinning machine. The novel high-speed spinning machine comprises a frame, adhesive supply devices, filament molding devices, spinning devices and winding devices, wherein a shaping part of each winding device is positioned on another side which is on the outer side of a region between wall plates on both sides of the frame and is opposite to a spinning surface; the adhesive supply devices and the winding devices are positioned on the outer sides of the wall plates respectively; each spinning device comprises at least one group of spinning rollers; each group of spinning rollers comprises an upper spinning roller and a lower spinning roller for drawing; the two ends of the upper spinning rollers and the lower spinning rollers are fixed; independent drying drawing rollers are arranged between the upper spinning rollers and the lower spinning rollers. According to the novel high-speed spinning machine, the winding devices are arranged externally, so that corrosion on filaments, the winding equipment and a control system of the winding equipment is low in an acid environment; the independent drying drawing rollers are arranged between the upper spinning rollers and the lower spinning rollers, so that the drying temperature and the drying time can be controlled effectively during drying of the filaments.

Owner:YIBIN GRACE GROUP CO LTD +1

Washing cleaning device

PendingCN111568302AEasy to recycleThe power of the whole machine is smallCarpet cleanersFloor cleanersSewageMechanical engineering

A washing cleaning device is provided with a water spraying mechanism, a brush and a sewage collecting mechanism. The brush is a rolling brush or a disc brush; a first sewage recovery system is arranged on a sewage collection mechanism of the washing cleaning device; the first sewage recovery system comprises a sponge strip, a water suction pipe, a water suction hole, a micro water pump, a sewageconveying pipeline and a sewage tank; the sponge strip is arranged on one side of the disc brush or a chassis or the rolling brush of the washing cleaning device; at least one sponge strip, at least one water suction hole is formed in the water suction pipe; the water suction pipe is inserted into the sponge strip; or the side, provided with the water suction holes, of the water suction pipe facesoutwards and abuts against the top end or the front side or the rear side of the sponge strip; the micro water pump is positioned between the water suction pipe and the sewage tank, and two ends of at least one sewage conveying pipeline are respectively connected with the water suction pipe and a water inlet of the micro water pump or are respectively connected with the sewage tank and a water outlet of the micro water pump.

Owner:SUZHOU DANAOTIANGONG ROBOT TECH CO LTD

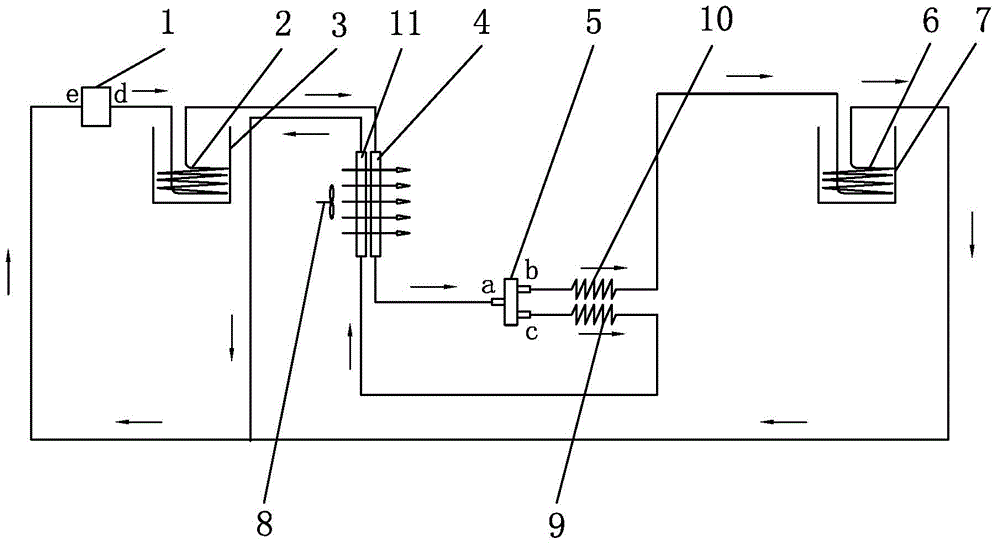

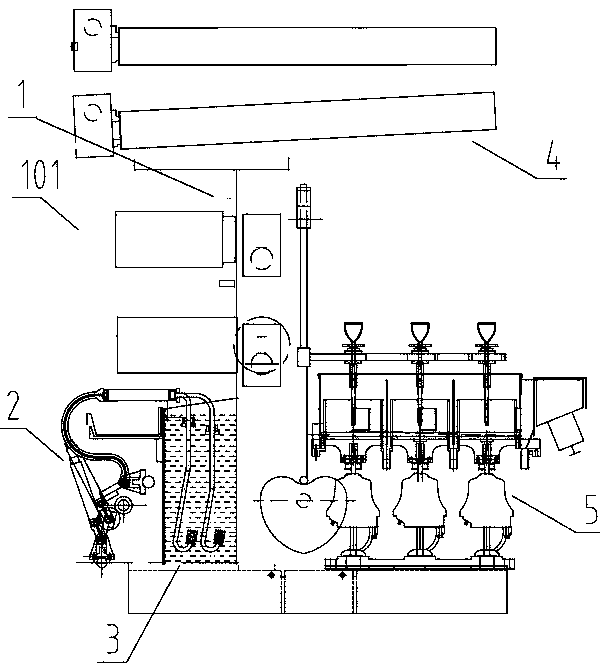

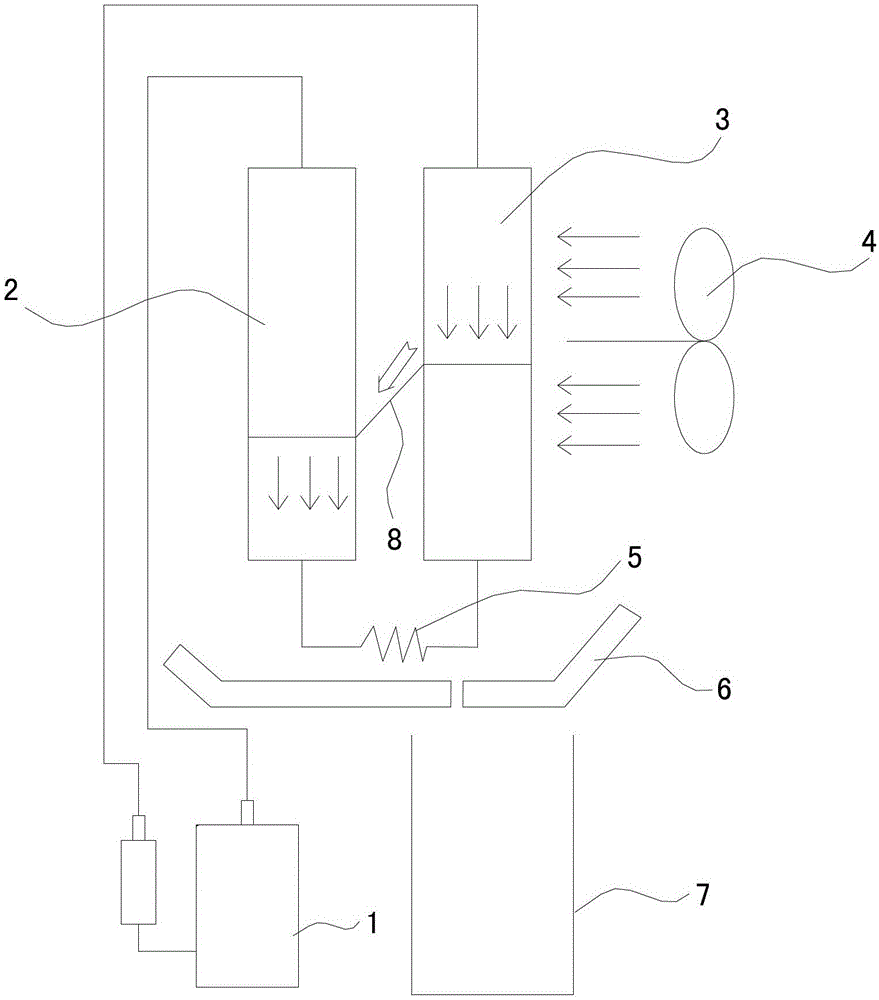

Low-energy-consumption environmental-friendly multifunctional air water maker

InactiveCN106320446ALow powerMeet the needs of useWater conservationDrinking water installationFresh airEngineering

The invention relates to a low-energy-consumption environmental-friendly multifunctional air water maker which comprises a machine body. A compressor, a hot water coil pipe, a hot water tank, a condenser, a refrigerant three-way valve, a cold water coil pipe, a cold water tank, a fan, an evaporator, a water collection system and a water supply system are arranged in the machine body; a d end of the compressor, the hot water coil pipe, the condenser, an a end of the refrigerant three-way valve are sequentially connected by refrigerant pipelines; a b end of the refrigerant three-way valve, the cold water coil pipe and an e end of the compressor are sequentially connected by refrigerant pipelines; a c end of the refrigerant three-way valve, the evaporator and the e end of the compressor are sequentially connected by refrigerant pipelines. The low-energy-consumption environmental-friendly multifunctional air water maker disclosed by the invention is low in total power, high in energy utilization rate, low in temperature of exhaust air and fresh air, can keep direct drinking water always according with the advanced drinking water standard, and is more suitable for home use; consumers are more crazy about the product; commercial value is high.

Owner:温镇霆

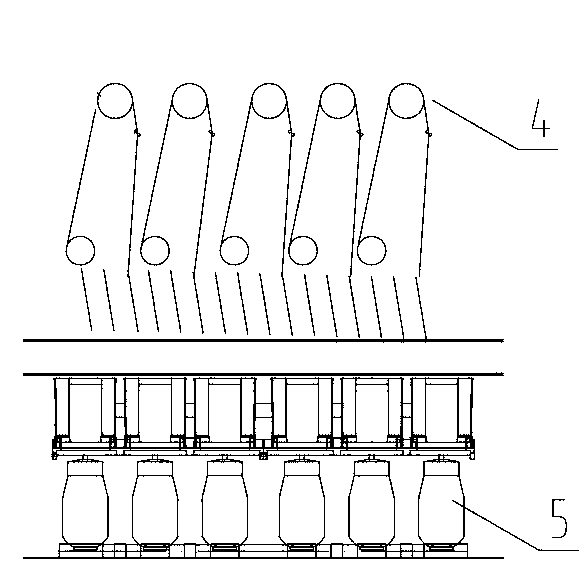

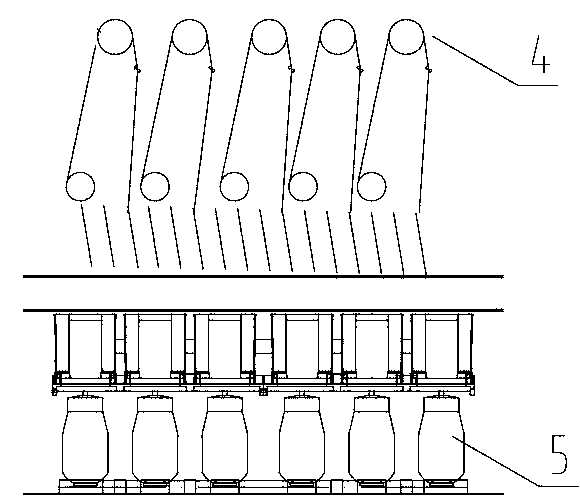

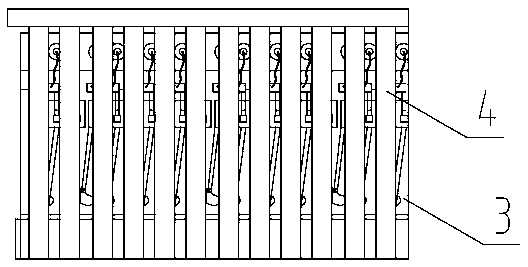

Spinning technology of high-speed spinning machine provided with active winding device

InactiveCN103643331AEfficient use ofSmall footprintArtificial thread manufacturing machinesFilament handlingSpinningControl system

The invention relates to a spinning technology of a high-speed spinning machine provided with an active winding device. The spinning technology comprises the steps of glue supplying, strand molding, spinning and winding. The spinning device used in the spinning step comprises at least one group of spinning rollers; each group of spinning rollers comprises an upper spinning roller and a lower spinning roller for drafting; a forming part of the active winding device is positioned on the outer side of an area between wallboards on two sides of the frame and on the other side opposite to a spinning surface. With the external winding device, the corrosion on strands, winding equipment and a control system is low in an acid environment, and the maintenance and manual operation are convenient. Because a conventional centrifugal cylinder needs to rotate at a high speed, the energy consumption is high. However, only the speed of the spinning rollers needs to be guaranteed according to the winding device, and other energy consumption is not needed, so that the whole machine power is low.

Owner:YIBIN GRACE GROUP CO LTD +1

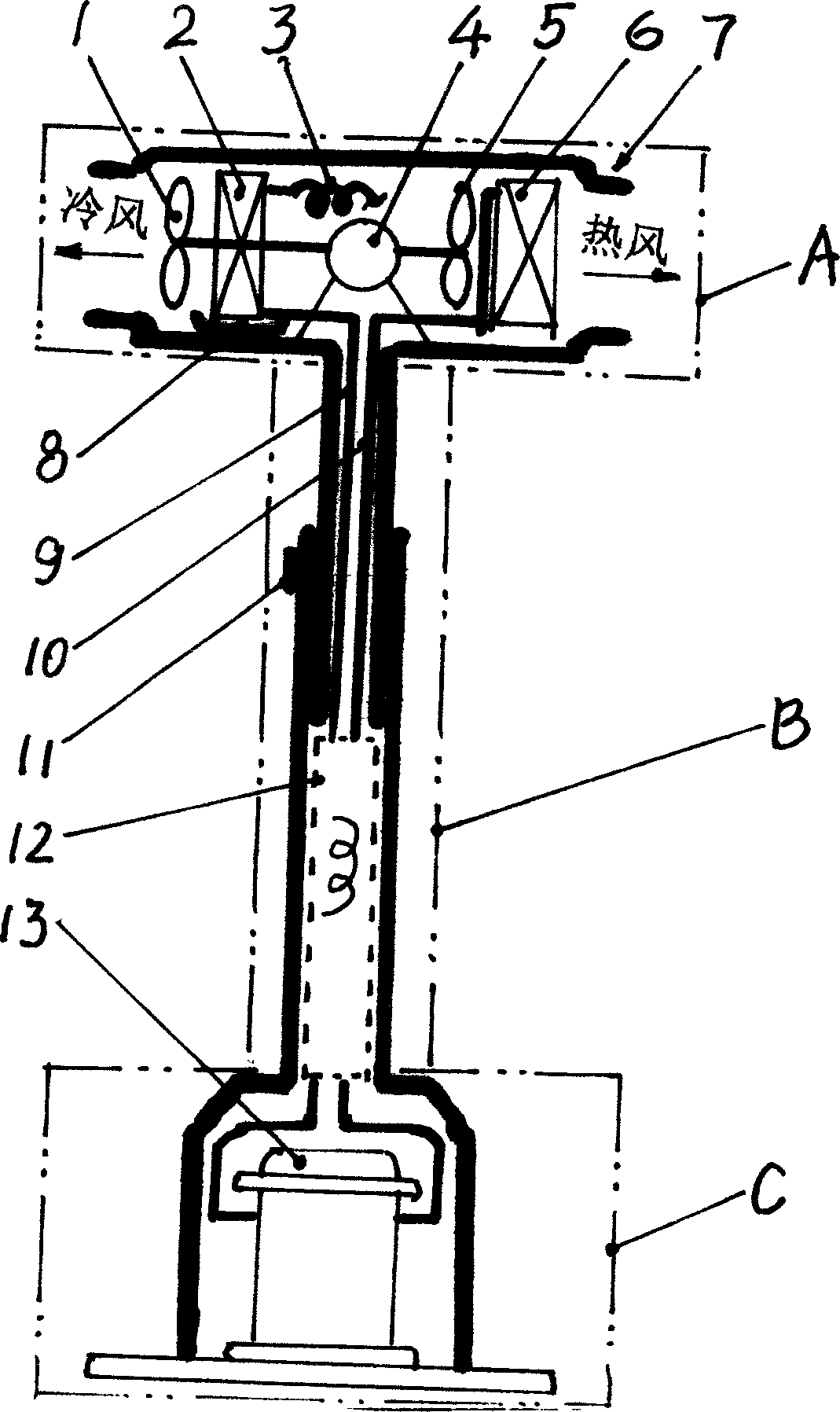

Console super small power cold and warm fan supported by refrigeration system and its using method

InactiveCN1749664AThe power of the whole machine is smallLow costLighting and heating apparatusAir conditioning systemsEvaporatorFresh air

The standard super small power cooling and heating fan supported with steam compressing refrigerating system consists of cooling and heating fan device with evaporator, condenser and fan; telescopic upright device with coiled air returning pipe and coiled air exhaust pipe; and pedestal with compressor. It can blow disposable cold wind or warming wind via switching its operation mode. It has nothing to do in replacing fresh air. The present invention is suitable for household and other places.

Owner:CHINA JILIANG UNIV

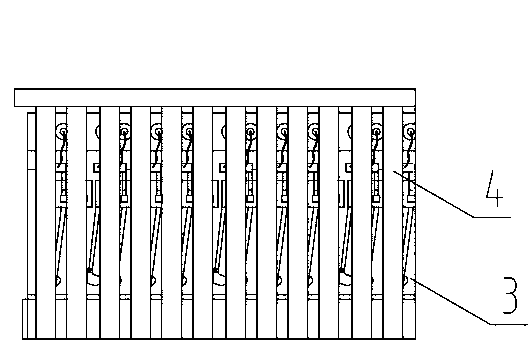

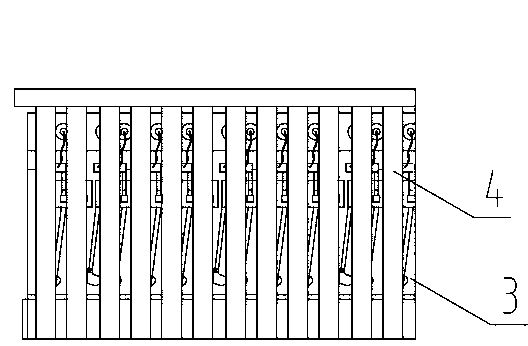

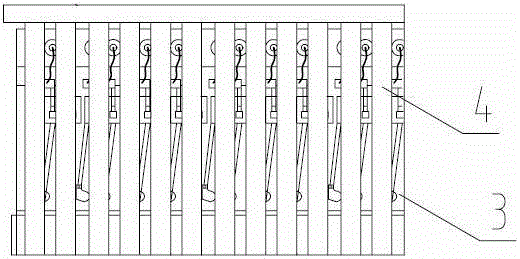

Spinning process of high-speed spinning machine

InactiveCN103603067AWill not affect normal workLess corrosiveArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention relates to a spinning process of a high-speed spinning machine. The spinning process includes the steps of glue supplying, strand forming, spinning and winding. In the winding step, forming portions of winding devices are located on the other side, opposite to a spinning surface, outside the area between wallboards on the two sides of a machine frame, glue supplying devices and the winding devices are located outside the wall boards, and the winding devices include the wet-state cake assembling winding devices and / or the wet-state cylinder assembling winding devices and / or the wet-state hinge assembling winding devices. A spinning device comprises at least one set of spinning rollers, each set of spinning rollers comprise the upper spinning roller and the lower spinning roller, and each upper spinning roller and the corresponding lower spinning roller are responsible for drafting. Due to the fact that the winding devices are externally arranged, corrosion caused to strands, the winding devices and a control system of the winding devices is small under the acid environment. Due to the fact that the glue supplying devices and the winding devices are located outside the wall boards, the number of the glue supplying devices and the number of the winding devices can be increased according to different production requirements, and the yield of the spinning machine is greatly improved.

Owner:YIBIN GRACE GROUP CO LTD +1

Spinning technology of high-speed spinning machine provided with single spindle passive winding device

InactiveCN103643321APlay the role of drawing filamentsWind evenlyNew-spun product collectionArtificial thread manufacturing machinesControl systemMachine

The invention relates to a spinning technology of a high-speed spinning machine provided with a single spindle passive winding device. The spinning technology comprises the steps of glue feeding, strand forming, spinning and winding. A spinning device in the spinning step comprises at least one set of spinning rollers, and each set of spinning rollers comprise an upper spinning roller and a lower spinning roller, wherein the upper spinning roller and the lower spinning roller are used for drafting. A forming part of the winding device is located on the outer side of the area between the two side wall plates of a rack and the other side opposite to a spinning surface, and the winding device is the single spindle passive winding device. Due to the fact that the winding device is arranged externally, corrosivity on strands, on the winding device and on a control system thereof is small under an acid environment, and maintenance and worker operation are convenient to carry out; due to the fact that an existing centrifugal cylinder needs to rotate at a high speed, energy consumption is high, the winding device only needs to meet the speed of the spinning rollers, no other energy consumption is needed, and therefore the total power is small.

Owner:YIBIN GRACE GROUP CO LTD +1

Spinning technology of high-speed spinning machine provided with through going shaft passive winding device

InactiveCN103643319AWon't cause wobbleLow failure rateNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The invention relates to a spinning technology of a high-speed spinning machine provided with a through going shaft passive winding device. The spinning technology comprises the steps of glue feeding, strand forming, spinning and winding. A spinning device in the spinning step comprises at least one set of spinning rollers, each set of spinning rollers comprise an upper spinning roller and a lower spinning roller, wherein the upper spinning roller and the lower spinning roller are used for drafting. A forming part of the winding device is located on the outer side of the area between the two side wall plates of a rack and the other side opposite to a spinning surface, and the winding device is the through going shaft passive winding device. Due to the fact that the winding device is arranged externally, corrosivity on strands, on the winding device and on a control system thereof is small under an acid environment, and maintenance and worker operation are convenient to carry out; due to the fact that an existing centrifugal cylinder needs to rotate at a high speed, energy consumption is high, the winding device only needs to meet the speed of the spinning rollers, no other energy consumption is needed, and therefore the total power is small.

Owner:YIBIN GRACE GROUP CO LTD +1

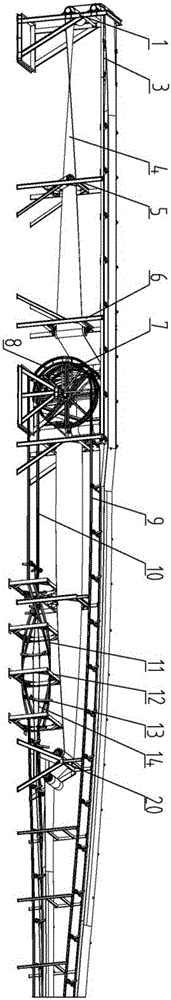

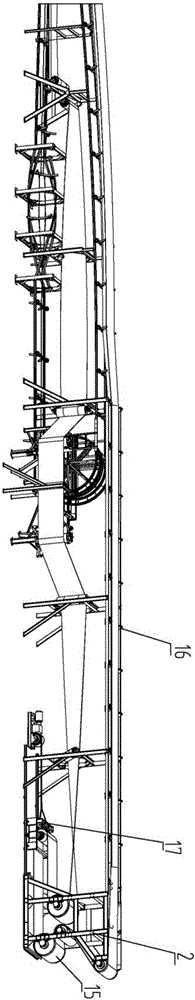

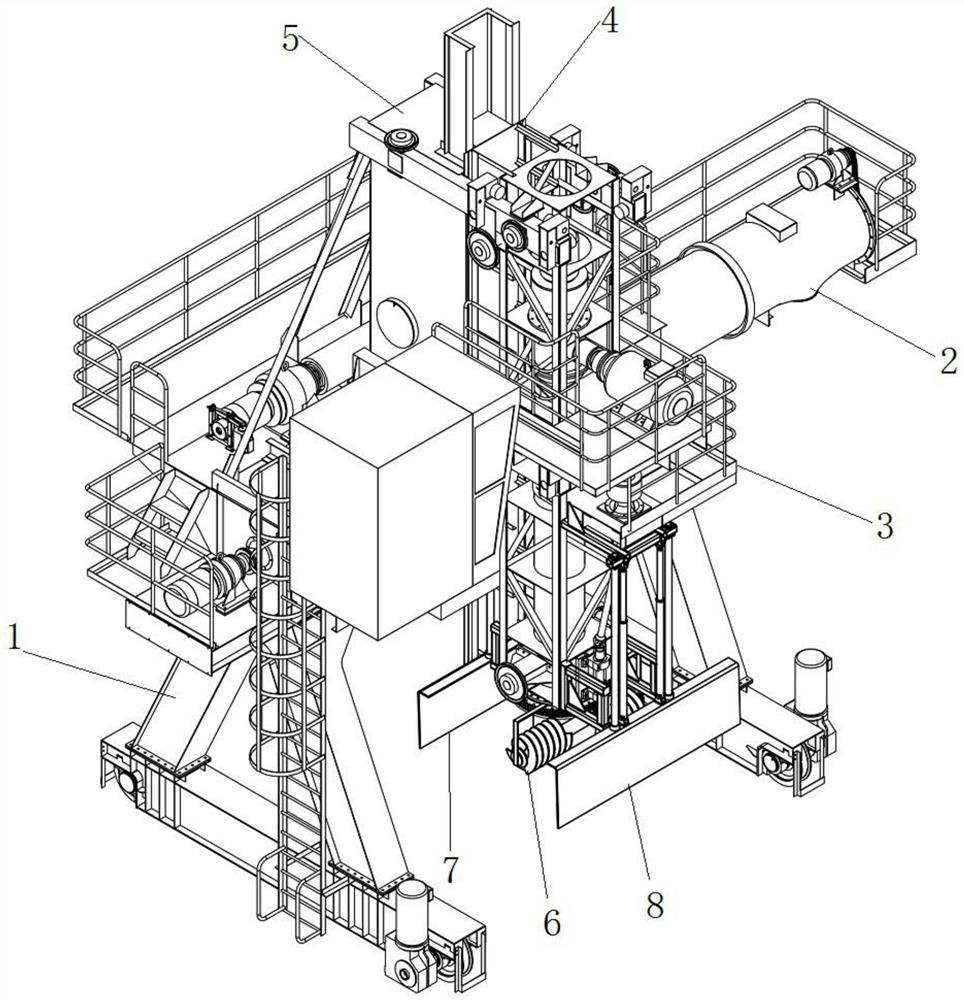

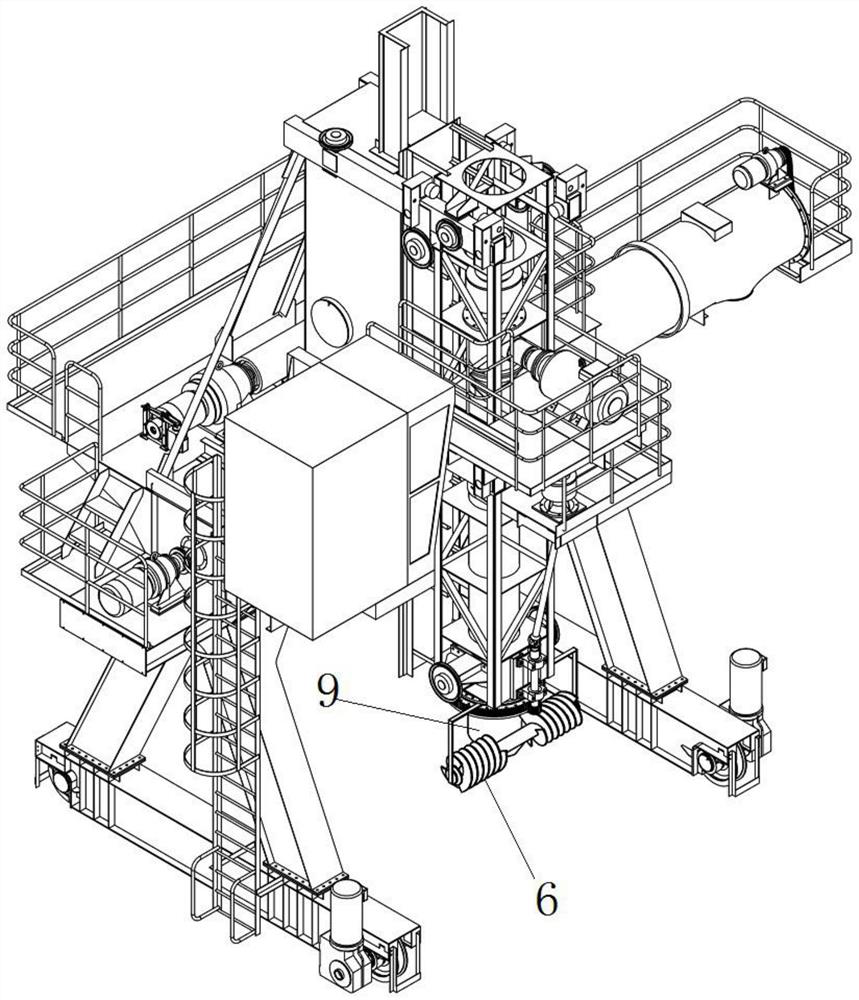

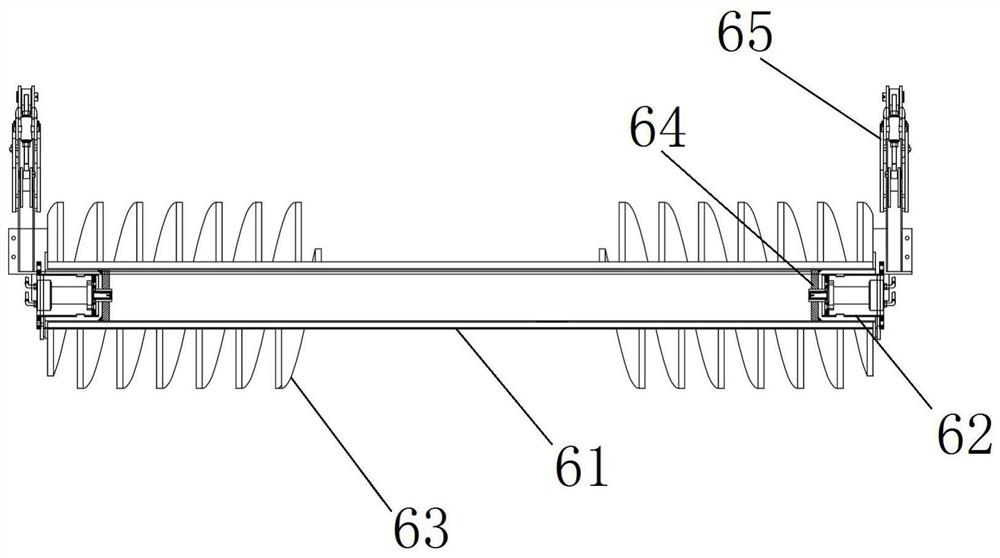

Horizontal spiral material collecting type vertical spiral car unloader

PendingCN113044605AImprove stabilityThe power of the whole machine is smallPackagingLoading/unloadingMachineCarriage

The invention discloses a horizontal spiral material collecting type vertical spiral car unloader which comprises a movable portal, a horizontal spiral mechanism, a vertical spiral mechanism, a lifting mechanism and a sealing bin, a horizontal spiral material collector is installed on one side of the bottom end of the vertical spiral mechanism, and a fixed scraper blade is installed on the other side of the bottom end of the vertical spiral mechanism; and the bottom end of the vertical spiral mechanism is further provided with a movable scraper device, and the movable scraper device is located on the side, away from the vertical spiral mechanism, of the horizontal spiral material collector. The invention provides the horizontal spiral material collecting type vertical spiral car unloader which is high in stability, the power of the whole machine is reduced, the working reliability is improved, residual materials in a carriage are reduced to the minimum, and therefore materials at corners in the carriage can be thoroughly cleaned.

Owner:TIANFU HEAVY IND

Washing cleaning device

InactiveCN111035316AEasy to recycleThe power of the whole machine is smallCarpet cleanersFloor cleanersSewageMechanical engineering

A washing cleaning device is disclosed. The washing cleaning device is provided with a water spraying mechanism, a brush and a sewage collecting mechanism, wherein the brush is a rolling brush or a disc brush; a first sewage recovery system is arranged on the sewage collecting mechanism; the first sewage recovery system comprises adhesive tapes, a water suction pipe, water suction holes, a micro water pump, sewage conveying pipelines and a sewage tank; the adhesive tapes are arranged on one side of the disc brush or a chassis or the rolling brush of the washing cleaning device; one or two groups of adhesive tapes are arranged; each group of adhesive tapes at least comprises one adhesive tape; one group of adhesive tapes are in contact with a cleaning surface; the water suction pipe is arranged beside the adhesive tapes in contact with the cleaning surface; the distance between the water suction pipe and the cleaning surface is small; at least one water suction hole is formed in the water suction pipe; a certain distance is formed between the water suction hole and the adhesive tape; the micro water pump is located between the water suction pipe and the sewage tank; there is at least one sewage conveying pipeline; two ends of one sewage conveying pipeline are connected with the water suction pipe and a water inlet of the micro water pump respectively, or the two ends are connected with the sewage tank and a water outlet of the micro water pump respectively.

Owner:SUZHOU DANAOTIANGONG ROBOT TECH CO LTD

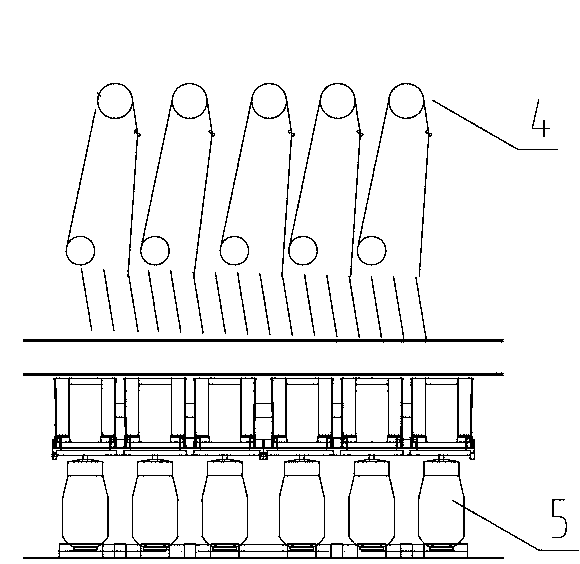

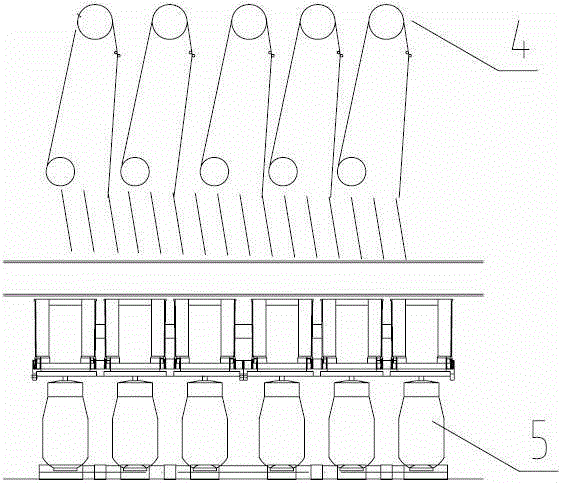

High speed spinning machine

InactiveCN103603076AWill not affect normal workLess corrosiveNew-spun product collectionSpinning head liquid feederControl systemEngineering

The invention relates to a spinning device, in particular to a high speed spinning machine. The high speed spinning machine comprises a machine frame, a viscose supplying device, a sliver forming device, a spinning device and winding devices. The forming parts of the winding devices are located on the two sides of the area between two lateral wall plates of the machine frame and on the other side opposite to a spinning face, and the viscose supplying device and the winding devices are located on the outer sides of the wall plates respectively, the winding devices comprise a wet state cake winding device, and / or a wet state cylinder winding device and / or a wet state twist winding device. The winding devices at least comprise a set of spinning rolls, and each set of spinning roll comprises an upper spinning roll and a lower spinning roll responsible for drafting. Due to the fact that the winding devices are arranged outside, in an acid environment, corrosion to sliver forming device, the winding devices and a control system of the sliver forming device and the winding devices is small. The viscose device and the winding devices are located on the outer sides of the wall plates, so that the quantity of the viscose device and the winding devices can be expanded according to different production requirements, and the production capacity of the spinning machine is greatly improved.

Owner:YIBIN GRACE GROUP CO LTD +1

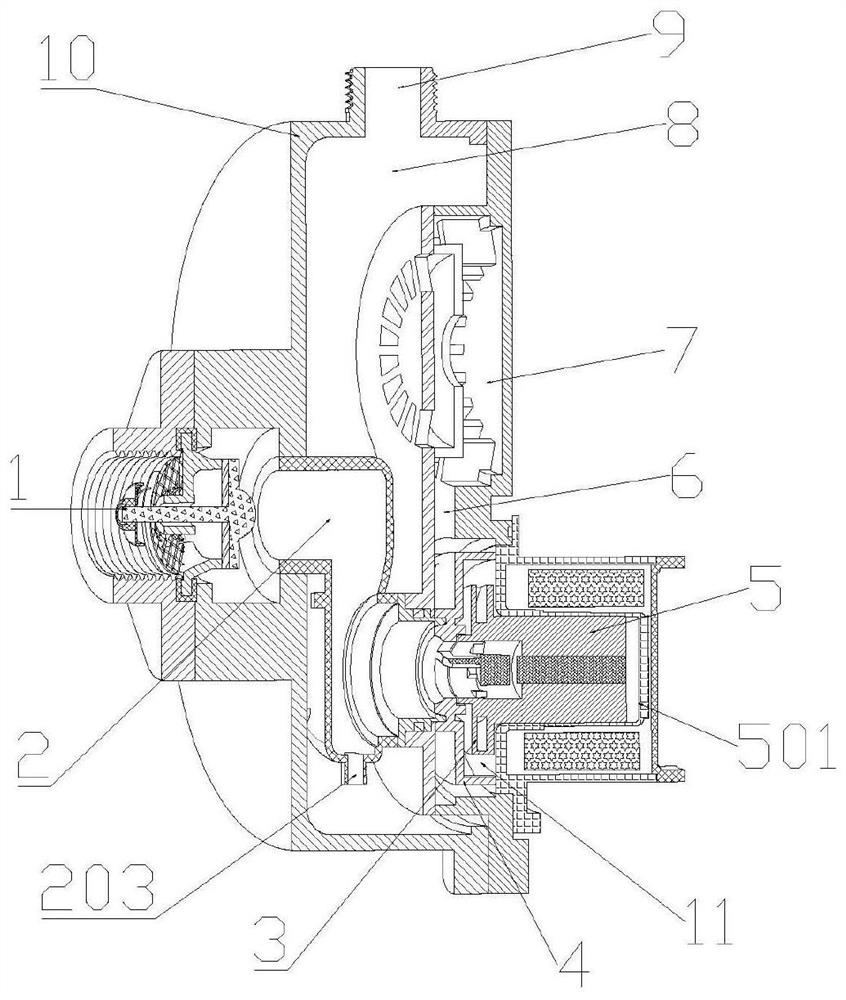

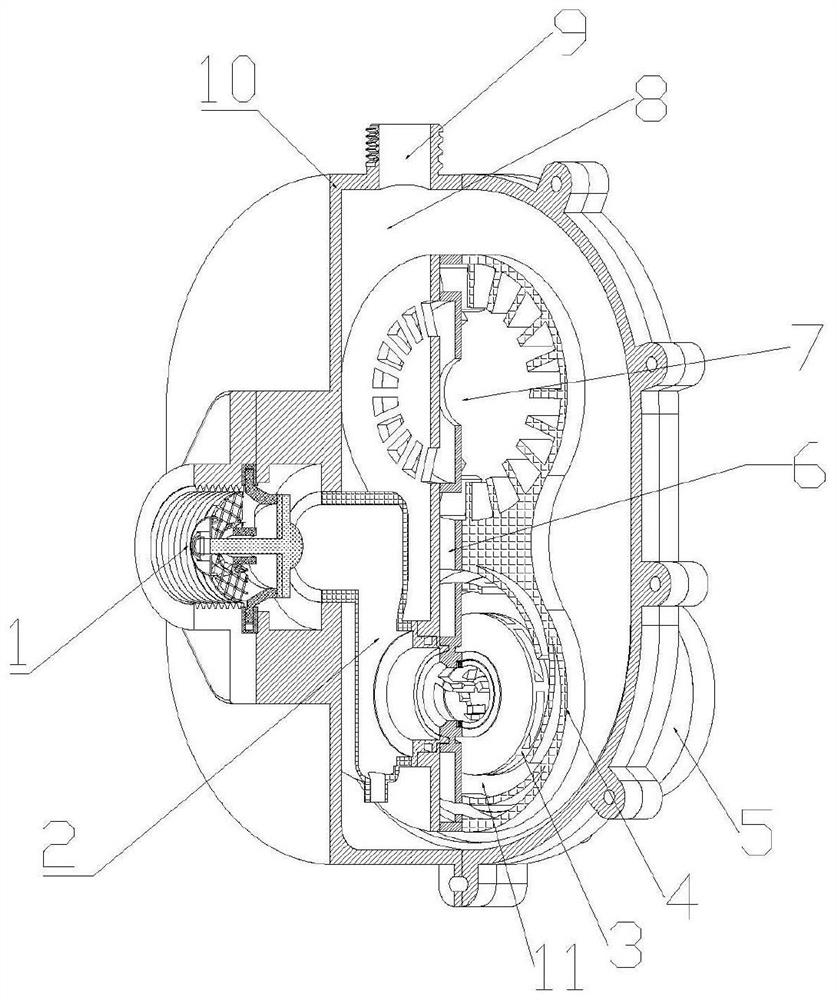

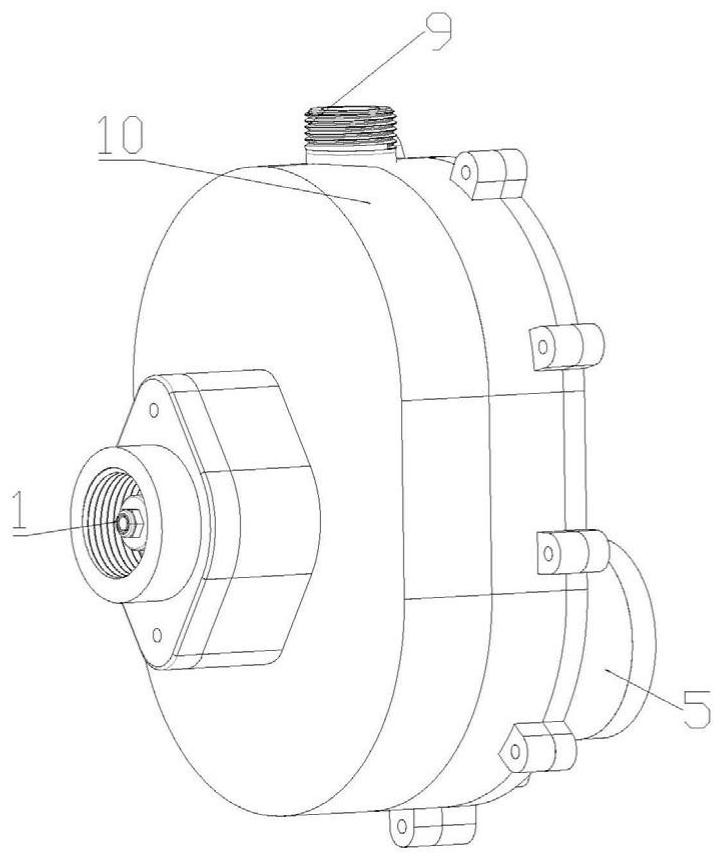

Direct-current permanent magnet type self-absorption composite shield pump with gas-liquid mixing cavity

ActiveCN113389739AEasy to control intelligentlyImprove energy efficiencyPump componentsPriming pumpElectric machineryPermanent magnet motor

The invention discloses a direct-current permanent magnet type self-absorption composite shield pump with a gas-liquid mixing cavity. The direct-current permanent magnet type self-absorption composite shield pump comprises a pump inlet, a gas-liquid mixing cavity, a centrifugal end, a buffer booster cavity, a gas-liquid separation chamber and a pump outlet, wherein the pump inlet is connected with an inlet of the gas-liquid mixing cavity, an outlet of the gas-liquid mixing cavity is connected with an inlet of the centrifugal end, an outlet of the centrifugal end is communicated with an inlet of the buffer booster cavity, an outlet of the buffer booster cavity is communicated with the gas-liquid separation chamber, and the gas-liquid separation chamber is communicated with the pump outlet; the buffer booster cavity is used for rapidly reducing the speed of high-speed pressure fluid at the outlet of the centrifugal end and boosting the high-speed pressure fluid; in the exhaust self-suction stage, the flow speed of gas-liquid mixed fluid is reduced, and meanwhile bubble breakage is reduced; and in the non-exhaust stage, flow resistance is reduced, pressure loss is reduced, and meanwhile buffer boosting of the fluid at the outlet of the centrifugal end is achieved. A direct-current permanent magnet motor is combined with the gas-liquid mixing cavity and the shield pump, so that the shield pump has the characteristics of strong self-absorption and good hydraulic characteristic, the spatial position and the internal structure of the buffer booster cavity are ingeniously arranged, and the technical problem that gas-liquid separation is difficult due to the fact that bubbles in the composite shield pump are seriously broken at a high rotating speed is effectively solved.

Owner:陈荣国

Spinning technology of novel spinning machine

InactiveCN103628158AStable strengthStable transmissionNew-spun product collectionArtificial thread manufacturing machinesEngineeringControl system

The invention relates to a spinning technology of a novel spinning machine. The spinning technology comprises the steps of supplying glue, molding threads, spinning and winding, wherein during spinning, independent drying drawing rollers are arranged among spinning rollers; a molding part of a winding device is arranged at the outer side of the area between wall boards at the two sides of a stand and at the other side opposite to the spun surfaced; after the steps of supplying glue, molding the threads and spinning, the obtained threads pass through the drying drawing rollers and are wound by the winding device, so that the wound threads can be obtained. According to the spinning technology of the novel spinning machine, the winding device is externally arranged, so that the corrosivity to the threads, the winding device and a control system of the winding device is low in the acid environment, and the winding device is convenient to maintain and operate by a worker; the independent drying drawing rollers are arranged among the spinning rollers, so that the threads pass through the drying drawing rollers when walking at the rear sections of the spinning rollers; at the moment, the drying drawing rollers are independent of the spinning rollers, so that the drying temperature and the drying time can be effectively controlled when the threads are dried.

Owner:YIBIN GRACE GROUP CO LTD +1

Spinning process of high-speed spinning machine with novel single-spindle passive winding device

InactiveCN103628155AWill not affect normal workLess corrosiveNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The invention relates to a spinning process of a high-speed spinning machine with a novel single-spindle passive winding device, and the process comprises the steps of adhesive feeding, filament forming, spinning and winding. A spinning device comprises at least one group of spinning rolls, and each group of spinning rolls comprise an upper spinning roll and a lower spinning roll which are used for drawing. The forming parts of the winding device are arranged on the outer side of an area between wall panels on both sides of a frame and on the other side which is opposite to a spinning surface; the winding device is the novel single-spindle passive winding device; due to the external winding device, the corrosion to filaments, the winding equipment and a control system thereof is low in an acid environment, so that the repair and the operation of a worker are convenient; due to the fact an existing centrifugal cylinder rotates at high speed, the energy consumption is high, while the winding device only needs to reach the speed of the spinning rolls, no other energy is consumed, so the power of the whole machine is low.

Owner:YIBIN GRACE GROUP CO LTD +1

Dehumidifier

PendingCN107940602AIncrease air volumeImprove energy efficiencyLighting and heating apparatusHeating and ventilation casings/coversThermodynamicsEngineering

The invention discloses a dehumidifier. The dehumidifier comprises a shell, a cross-flow fan and a dehumidifying component, wherein the shell comprises a first air charging panel, a second air charging panel, a third air charging panel and an air discharging panel which are connected in sequence; the first air charging panel is provided with a first air inlet; the second air charging panel is provided with a second air inlet; the third air charging panel is provided with a third air inlet; the air discharging panel is provided with an air outlet; an air channel communicating with the first airinlet, the second air inlet, the third air inlet and the air outlet is formed inside the shell; the cross-flow fan is arranged inside the air channel and is used for guiding air flow into the air channel via the first air inlet, the second air inlet and the third air inlet and blowing the air flow inside the air channel out of the air outlet; the dehumidifying component is arranged inside the airchannel; and the dehumidifying component is arranged corresponding to the first air inlet, the second air inlet and the third air inlet by means of extending along the arrangement direction of the first air charging panel, the second air charging panel and the third air charging panel. The dehumidifier disclosed by the invention can improve the energy efficiency level.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Spinning technology of high-speed spinning machine provided with three-spindle passive winding device

InactiveCN103643320AEfficient use ofSmall footprintNew-spun product collectionArtificial thread manufacturing machinesControl systemEngineering

The invention relates to a spinning technology of a high-speed spinning machine provided with a three-spindle passive winding device. The spinning technology comprises the steps of glue feeding, strand forming, spinning and winding. A spinning device in the spinning step comprises at least one set of spinning rollers, each set of spinning rollers comprise an upper spinning roller and a lower spinning roller, wherein the upper spinning roller and the lower spinning roller are used for drafting. A forming part of the winding device is located on the outer side of the area between the two side wall plates of a rack and the other side opposite to a spinning surface, and the winding device is the three-spindle passive winding device. Due to the fact that the winding device is arranged externally, corrosivity on strands, on the winding device and on a control system thereof is small under an acid environment, and maintenance and worker operation are convenient to carry out; due to the fact that an existing centrifugal cylinder needs to rotate at a high speed, energy consumption is high, the winding device only needs to meet the speed of the spinning rollers, no other energy consumption is needed, and therefore the total power is small.

Owner:YIBIN GRACE GROUP CO LTD +1

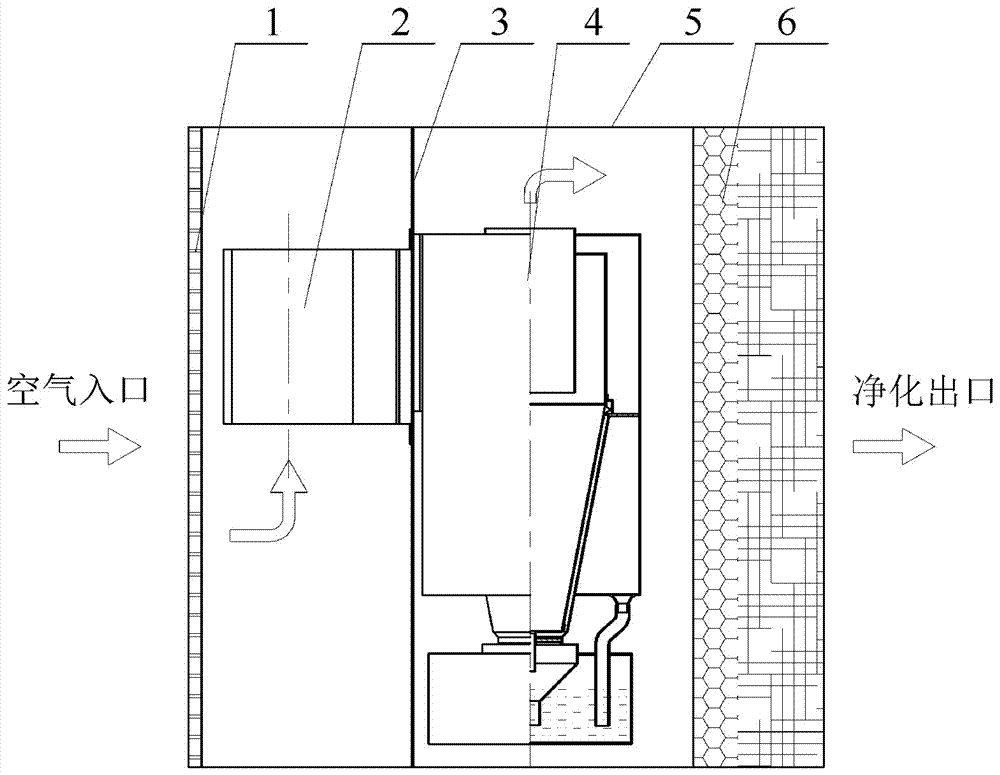

Air purifying system

InactiveCN107185349AReduce cleaning frequencyReduce replacement frequencyHuman health protectionCombination devicesParticulatesAir purification

An air purifying system comprises an air purifying device composed of a meshed plate, an air fan, a cyclone dust collector, a shell and a fine filter. A physical de-dusting mode is adopted, after the air containing dust is sucked into the purifying device, a lot of particles in the air are removed through the cyclone dust collector first, then the particles remaining in the air are collected through the fine filter, and finally clean air goes out from an air outlet. By means of the device, the frequency of cleaning or replacement of the fine filter can be reduced, the wind resistance is low, the de-dusting efficiency is high, the whole machine power is low, and the device is healthy and environmentally friendly and suitable for families, shops, hospitals and occasions where the requirements for the air cleanliness are high in industrial production.

Owner:CHANGSHA UNIVERSITY

Spinning process of a spinning machine with twisting function

InactiveCN103643328BLess corrosiveEasy to operateSpinning head liquid feederArtificial thread manufacturing machinesSpinningIndustrial engineering

Owner:YIBIN GRACE GROUP CO LTD +1

Spinning process of spinning machine with yarn twisting function

InactiveCN103643328APrevent splashEasy to cleanSpinning head liquid feederArtificial thread manufacturing machinesYarnSpinning

The invention relates to a spinning process of a spinning machine with a yarn twisting function. The spinning process comprises glue feeding, strand forming, spinning and yarn twisting. Independent drying traction rollers are arranged between spinning rollers during spinning, forming portions of yarn twisting devices are located on the outer side of the area between wallboards on the two sides of a machine frame and the side opposite to the spinning face, strands obtained after glue feeding, strand forming and spinning pass through the drying traction rollers and then pass through the yarn twisting devices, yarn twisting is finished and embroidery threads are obtained. The spinning machine is provided with the yarn twisting devices, the strands pass through the drying traction rollers of a spinning device for heating and drying and then enter the yarn twisting devices, the strands are processed through the yarn twisting devices, and finished products of the embroidery threads are obtained. High integration of the processes from glue feeding to forming of the embroidery threads is achieved, complication caused by the fact that multiple independent devices are used is avoided, the structure of the whole device is simplified, energy consumption of the device is reduced, production time is saved, and the production efficiency of the embroidery threads is improved.

Owner:YIBIN GRACE GROUP CO LTD +1

New high-speed spinning machine

InactiveCN103628161BWill not affect normal workLess corrosiveNew-spun product collectionSpinning head liquid feederPolymer scienceSpinning

The present invention relates to a spinning equipment, in particular to a novel high-speed spinning machine, comprising a frame, a glue supply device, a filament forming device, a spinning device and a winding device, the forming part of the winding device Located on the outside of the area between the wallboards on both sides of the frame, on the other side opposite to the spinning surface, and the glue supply device and winding device are respectively located on the outside of the wallboard, the spinning device includes at least one set of spinning Spinning rolls, each set of spinning rolls includes an upper spinning roll and a lower spinning roll responsible for drafting, the two ends of the upper spinning roll and the lower spinning roll are fixed, and the gap between the upper spinning roll and the lower spinning roll It is equipped with independent drying and drafting rollers. The winding device is installed outside, so it is less corrosive to the filaments, winding equipment and its control system in an acidic environment. There is an independent drying and drafting roller between the upper spinning roller and the lower spinning roller. When drying silk strips, it can effectively control the drying temperature and time.

Owner:YIBIN GRACE GROUP CO LTD +1

Cooling method of dehumidifier and dehumidifier condenser

ActiveCN103453586BThe power of the whole machine is smallImprove energy efficiency ratioCondensate preventionEvaporators/condensersBusiness efficiencyEngineering

The invention discloses a dehumidifier which comprises an evaporator, a condenser and a water pan. The evaporator and the condenser are arranged side by side, the water pan is arranged below the evaporator, and a flow guide part is arranged between the evaporator and the condenser. Besides, the invention further discloses a cooling method for the condenser of the dehumidifier. Part of low-temperature condensed water generated by the evaporator is guided onto the condenser through the flow guide part, the condenser is cooled, so that water cooling and air cooling of the condenser of the dehumidifier are combined, the total power of the dehumidifier can be effectively reduced, the energy efficiency ratio of the dehumidifier is increased, energy is saved, and emission is reduced. Moreover, the arrangement form of an original dehumidifier does not need to be changed, and the transformation cost is low.

Owner:GREE ELECTRIC APPLIANCES INC

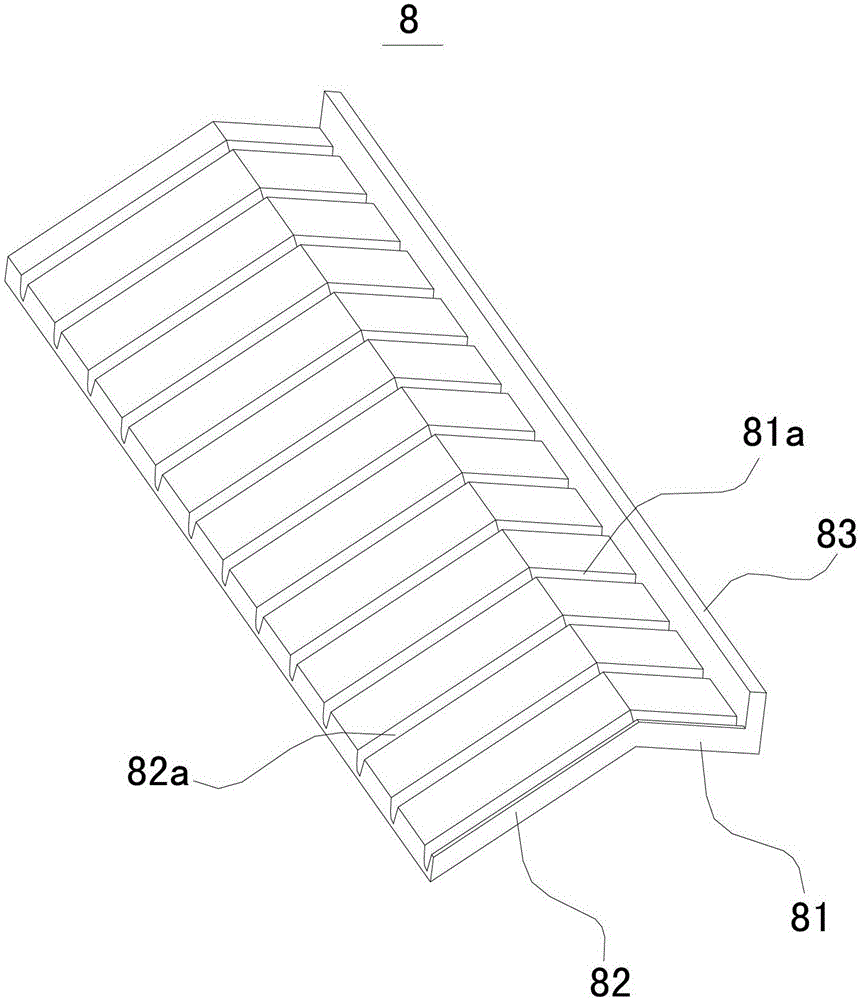

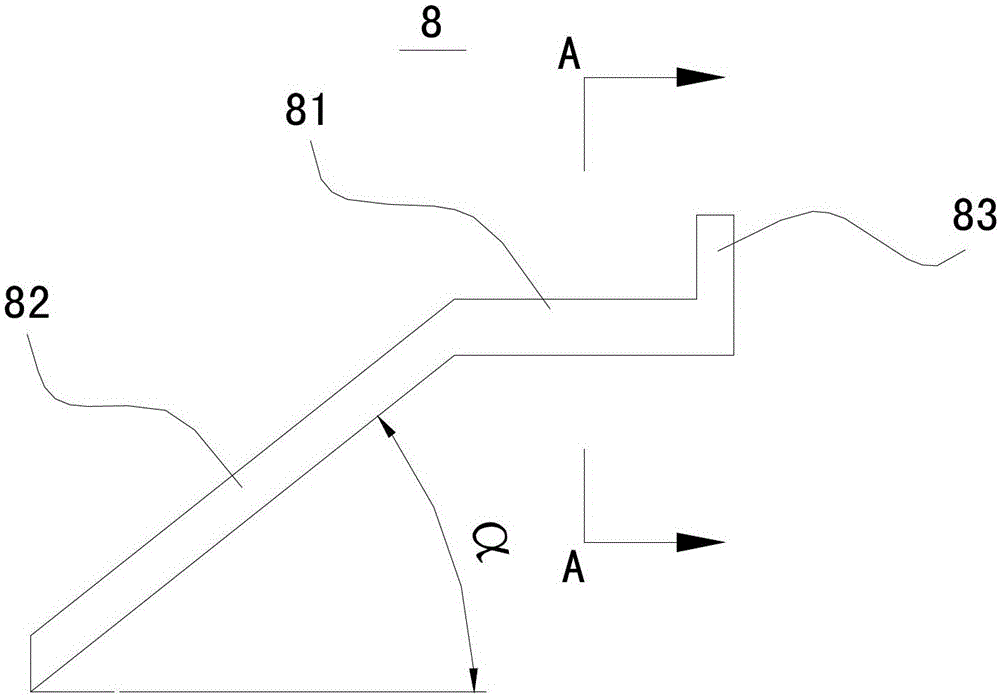

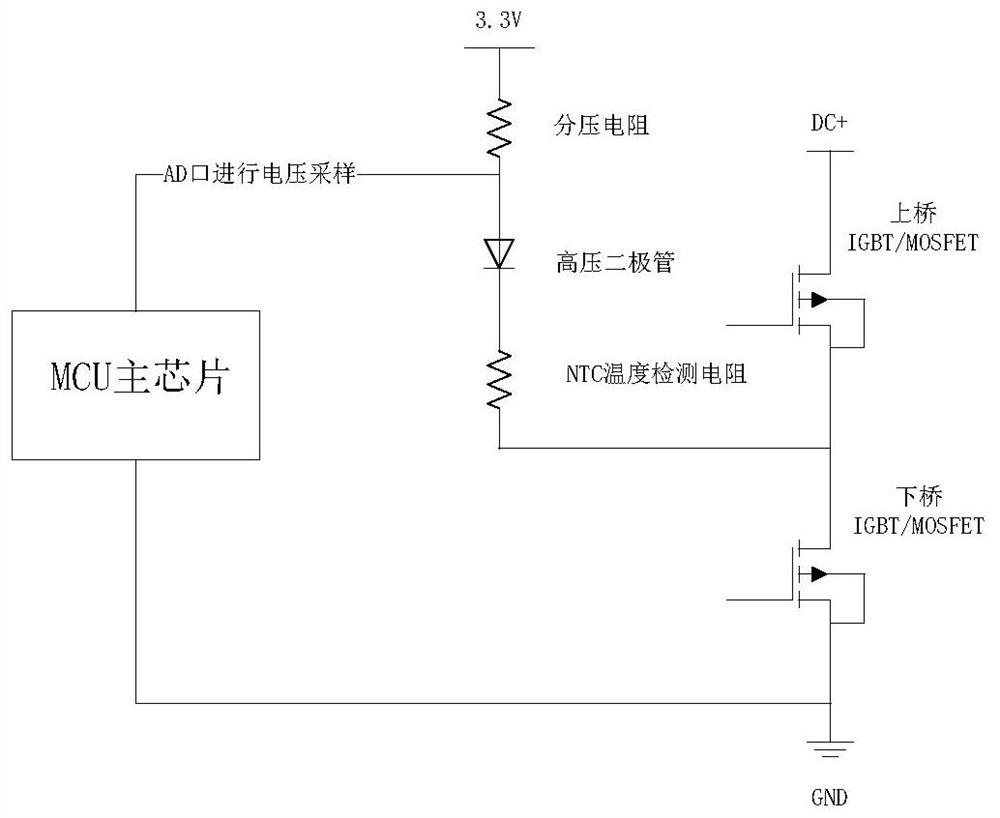

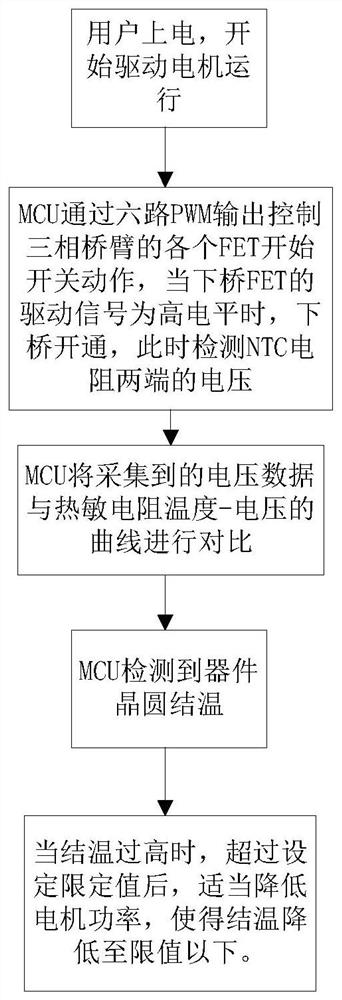

A bridge arm junction temperature detection device, method and air conditioner

ActiveCN113551796BReal-time monitoring of internal wafer junction temperatureExtend your lifeThermometers using electric/magnetic elementsUsing electrical meansThermodynamicsJunction temperature

A bridge arm junction temperature detection device is provided, each bridge arm includes an upper bridge arm and a lower bridge arm, the drain of the lower bridge arm is connected to the source of the upper bridge arm, and the device includes: an NTC resistor, a high voltage diode, a branch Piezoresistor and control module, wherein the drain of the lower bridge arm is connected to one end of the NTC resistor, the other end of the NTC resistor is connected to the cathode of the high voltage diode, and the anode of the high voltage diode is connected to the voltage dividing resistor The first end of the voltage dividing resistor is connected to the source voltage; wherein the device also includes a control module, the voltage sampling positive end of the control module is connected to the anode of the high voltage diode and the first end of the voltage dividing resistor Between, used to detect the junction temperature of the bridge arm. The scheme of the present invention can realize the real-time detection of the junction temperature of all devices in the IPM or three-phase bridge arm circuit, and intelligently adjust the power of the whole machine when the junction temperature is too high, so as to avoid damage to the devices.

Owner:GREE ELECTRIC APPLIANCES INC

Spinning process of a high-speed spinning machine

InactiveCN103603067BWill not affect normal workLess corrosiveArtificial thread manufacturing machinesArtificial filaments from viscoseSpinningWall plate

The invention relates to a spinning process of a high-speed spinning machine. Including glue supply, filament forming, spinning and winding, the forming part of the winding device in winding is located outside the area between the wall panels on both sides of the frame, on the other side opposite to the spinning surface, and the glue supply device The winding device is respectively located on the outside of the wallboard, and the winding device includes a wet cake winding device, and / or a wet drum winding device, and / or a wet skein winding device; the spinning device includes at least A set of spinning rolls, each set of spinning rolls includes the upper spinning roll and the lower spinning roll responsible for drafting. Due to the external winding device, the filaments, winding equipment and their control are in acidic environment. The system is less corrosive, and the glue supply device and winding device are located on the outside of the wallboard, so the number of glue supply devices and winding devices can be expanded according to different production needs, which greatly improves the production capacity of the spinning machine.

Owner:YIBIN GRACE GROUP CO LTD +1

A spinning process of a high-speed spinning machine equipped with a through-shaft passive winding device

InactiveCN103643319BWill not affect normal workLess corrosiveNew-spun product collectionArtificial thread manufacturing machinesSpinningControl system

The invention relates to a spinning process of a high-speed spinning machine provided with a through-shaft passive winding device. Including glue supply, filament forming, spinning and winding, the spinning device in spinning includes at least one set of spinning rolls, and each set of spinning rolls includes an upper spinning roll and a lower spinning roll responsible for drafting, so The forming part of the winding device is located on the outside of the area between the wall panels on both sides of the frame, on the other side opposite to the spinning surface. The winding device is a passive winding device through the shaft. Since the winding device of the present invention The external winding device, so in the acidic environment, the corrosion to the filament, winding equipment and its control system is small, and it is convenient for maintenance and worker operation. Since the existing centrifugal cylinder needs to rotate at a high speed, the energy consumption is high, and the The winding device of the present invention only needs to meet the speed of the spinning roller, and has no other energy consumption, so the power of the whole machine is small.

Owner:YIBIN GRACE GROUP CO LTD +1

Suitable for spinning process of spinning machine with external winding device

InactiveCN103643313BLess corrosiveEasy to operateNew-spun product collectionArtificial thread manufacturing machinesYarnAcid washing

Owner:YIBIN GRACE GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com