Spinning technology of high-speed spinning machine provided with three-spindle passive winding device

A winding device and high-speed spinning technology, applied in the field of spinning, can solve the problems of lower product quality, lower efficiency, and higher post-processing costs, and achieve the effects of easy maintenance and worker operation, low overall machine power, and low corrosiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

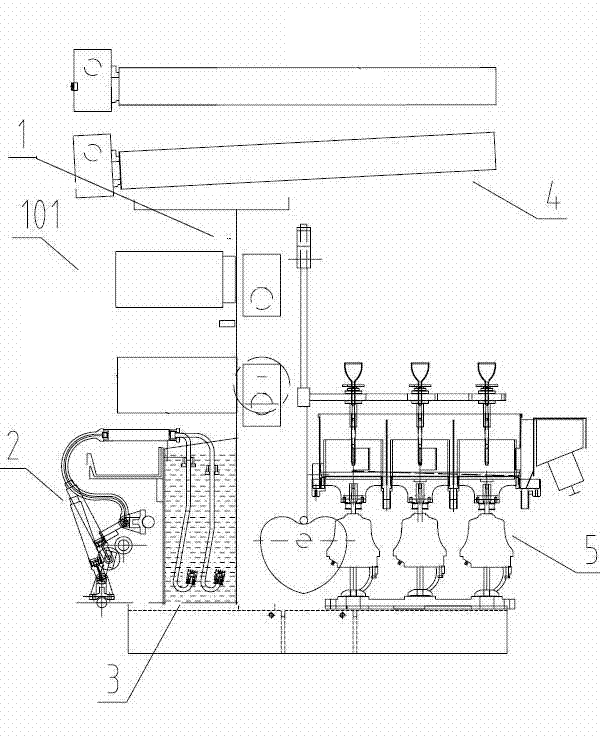

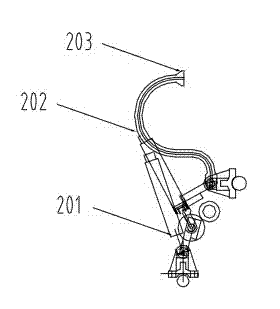

[0124] A spinning process of a high-speed spinning machine equipped with three passive winding devices, including glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament filament Shaping is completed by the filament forming device 3, the spinning is completed by the spinning device 4, the winding is completed by the winding device 5, the glue supply device 2 is connected with the filament forming device 3, and the spinning is completed by the winding device 5. The silk device 4 is installed on the frame 1, the filament forming device 3 is arranged at one end of the spinning device 4, the winding device 5 is arranged at the other end of the spinning device 4, and the spinning device 4 is provided with the winding device 5 at one end. 4 includes at least one set of spinning rolls, each set of spinning rolls includes an upper spinning roll 401 and a lower spinning roll 402 responsible for drawing, the two ends...

Embodiment 2

[0126] A spinning process of a high-speed spinning machine equipped with three passive winding devices, including glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament filament Shaping is completed by the filament forming device 3, the spinning is completed by the spinning device 4, the winding is completed by the winding device 5, the glue supply device 2 is connected with the filament forming device 3, and the spinning is completed by the winding device 5. The silk device 4 is installed on the frame 1, the filament forming device 3 is arranged at one end of the spinning device 4, the winding device 5 is arranged at the other end of the spinning device 4, and the spinning device 4 is provided with the winding device 5 at one end. 4 includes at least one set of spinning rolls, each set of spinning rolls includes an upper spinning roll 401 and a lower spinning roll 402 responsible for drawing, the two ends...

Embodiment 3

[0133] A spinning process of a high-speed spinning machine equipped with three passive winding devices, including glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament filament Shaping is completed by the filament forming device 3, the spinning is completed by the spinning device 4, the winding is completed by the winding device 5, the glue supply device 2 is connected with the filament forming device 3, and the spinning is completed by the winding device 5. The silk device 4 is installed on the frame 1, the filament forming device 3 is arranged at one end of the spinning device 4, the winding device 5 is arranged at the other end of the spinning device 4, and the spinning device 4 is provided with the winding device 5 at one end. 4 includes at least one set of spinning rolls, each set of spinning rolls includes an upper spinning roll 401 and a lower spinning roll 402 responsible for drawing, the two ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Inner diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com