Spinning process of spinning machine with yarn twisting function

A spinning process and spinning machine technology, applied in the field of new spinning processes, can solve the problems of reducing product quality, increasing energy consumption, reducing efficiency, etc., to control drying temperature and time, to facilitate maintenance and worker operations, to avoid The effect of increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

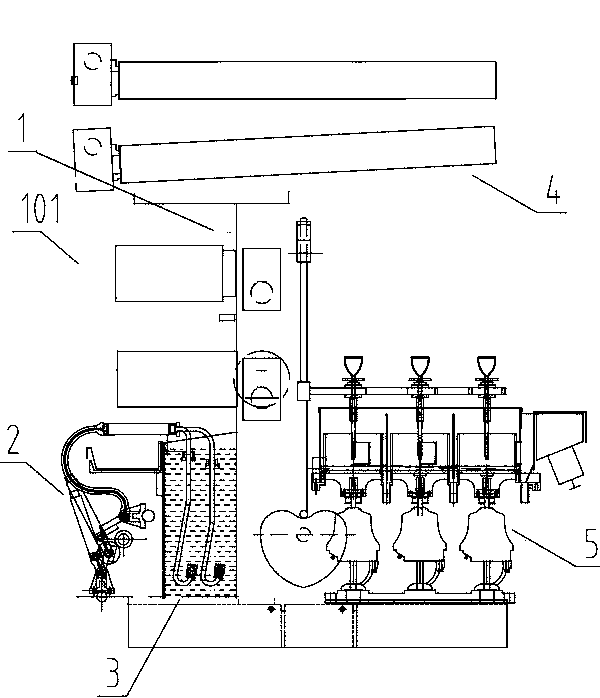

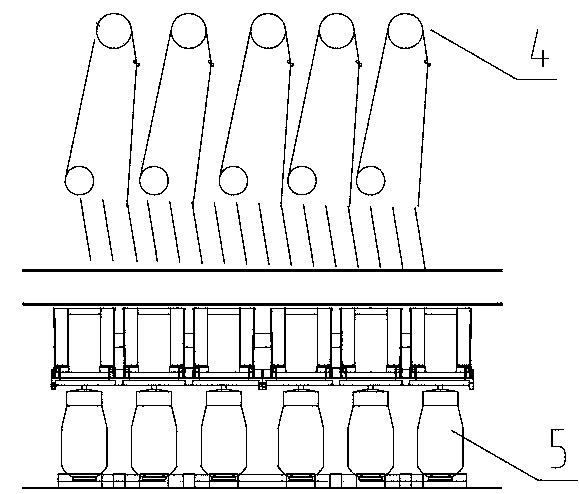

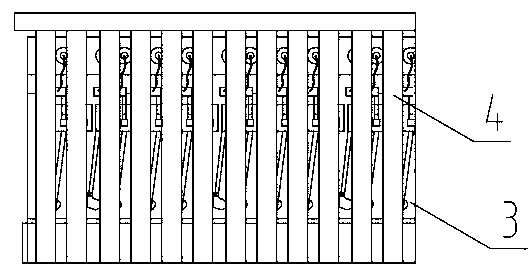

Embodiment 1

[0113] A spinning process of a spinning machine with twisting function, comprising glue supply, filament forming, spinning and twisting, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament Forming device 3 completes, and described spinning is completed by spinning device 4, and described twisting is completed by twisting device 5, and described spinning device 4 comprises many spinning rollers, and the described spinning roller Both ends are fixed, an independent drying and drafting roll 404 is arranged between the spinning rolls in the spinning device 4, and the forming part of the twisting device 5 is located between the wallboards 6 on both sides of the frame 1 The outside of the area, the other side opposite to the spinning surface 101, the spinning surface 101 refers to the outside of the frame 1 wallboard 6, the area where the filament forming device 3 is arranged, and the other side opposite to the area Referre...

Embodiment 2

[0115] A spinning process of a spinning machine with twisting function, comprising glue supply, filament forming, spinning and twisting, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament Forming device 3 completes, and described spinning is completed by spinning device 4, and described twisting is completed by twisting device 5, and described spinning device 4 comprises many spinning rollers, and the described spinning roller Both ends are fixed, an independent drying and drafting roll 404 is arranged between the spinning rolls in the spinning device 4, and the forming part of the twisting device 5 is located between the wallboards 6 on both sides of the frame 1 The outside of the area, the other side opposite to the spinning surface 101, the spinning surface 101 refers to the outside of the frame 1 wallboard 6, the area where the filament forming device 3 is arranged, and the other side opposite to the area Referre...

Embodiment 3

[0121] A spinning process of a spinning machine with twisting function, comprising glue supply, filament forming, spinning and twisting, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament Forming device 3 completes, and described spinning is completed by spinning device 4, and described twisting is completed by twisting device 5, and described spinning device 4 comprises many spinning rollers, and the described spinning roller Both ends are fixed, an independent drying and drafting roll 404 is arranged between the spinning rolls in the spinning device 4, and the forming part of the twisting device 5 is located between the wallboards 6 on both sides of the frame 1 The outside of the area, the other side opposite to the spinning surface 101, the spinning surface 101 refers to the outside of the frame 1 wallboard 6, the area where the filament forming device 3 is arranged, and the other side opposite to the area Referre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com