Suitable for spinning process of spinning machine with external winding device

A technology of winding device and spinning process, which is applied in the field of spinning process of new spinning machine, can solve the problems of lower product quality, lower production efficiency, lower efficiency, etc., and achieve easy maintenance and worker operation, and control of drying temperature and time, the effect of small machine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

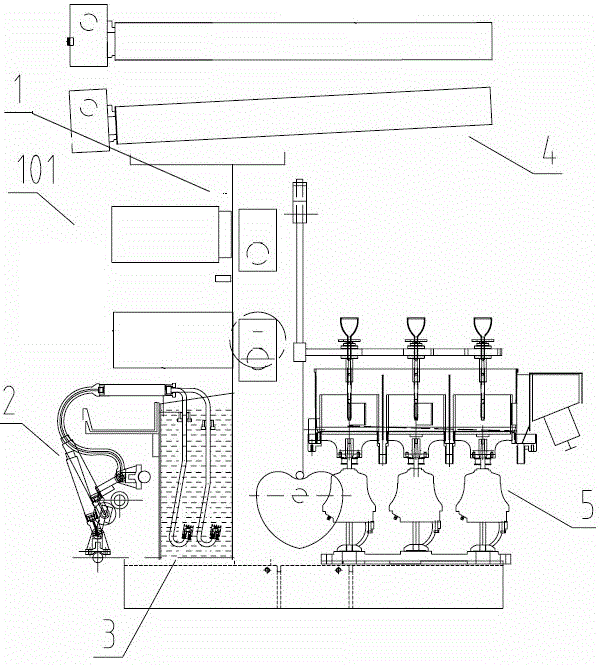

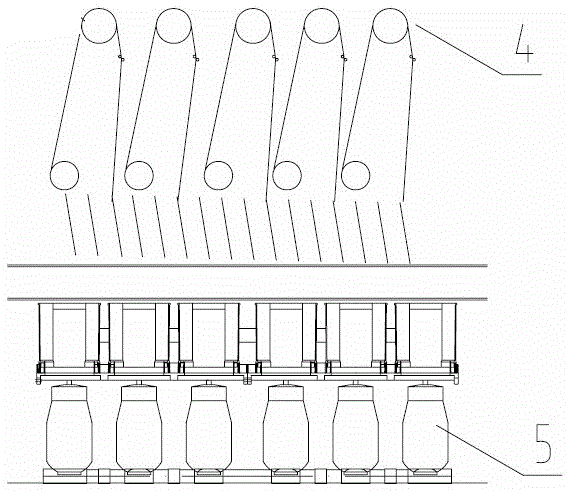

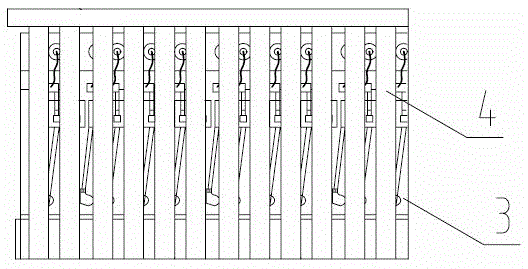

[0115] It is suitable for the spinning process of a new type of spinning machine with an external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding,

[0116] A viscose metering and glue supply

[0117] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.1MPa;

[0118] B Filtration before spinning

[0119] In the pre-spinning filtration process, viscose maturity NH 4 The Cl value is controlled at 7.0ml, the falling ball viscosity is 30mPa·s, the viscose methyl fiber content is 8.0%, the viscose contains 6.1% alkali, 500ml viscose bubbles are ≤25, the viscose surface tension is 50dyne / cm, and viscose particles below 10μm are ≤ 100 pieces / ml;

[0120] C filament forming

[0121] In the thread forming process, the composition of the acid bath is: sulfuric acid concentration 135g / L, sodium sulfate concentration 230g / L, zinc sulfate concentration 12g / L, acid ba...

Embodiment 2

[0135] It is suitable for the spinning process of a new type of spinning machine with an external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding,

[0136] A viscose metering and glue supply

[0137] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.3MPa;

[0138] B Filtration before spinning

[0139] In the pre-spinning filtration process, viscose maturity NH 4 The Cl value is controlled at 13ml, the falling ball viscosity is 38mPa·s, the viscose methyl fiber content is 8.1%, the viscose contains 5.8% alkali, 500ml viscose bubbles are ≤25, the viscose surface tension is 55dyne / cm, and viscose particles below 10μm are ≤100 a / ml;

[0140] C filament forming

[0141] In the filament forming process, the composition of the acid bath is: sulfuric acid concentration 140g / L, sodium sulfate concentration 240g / L, zinc sulfate concentration 11.0g / L, acid bath ...

Embodiment 3

[0152] It is suitable for the spinning process of a new type of spinning machine with an external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding,

[0153] A viscose metering and glue supply

[0154] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.5MPa;

[0155] B Filtration before spinning

[0156] In the pre-spinning filtration process, viscose maturity NH 4 The Cl value is controlled at 10ml, the falling ball viscosity is 28mPa·s, the viscose methyl fiber content is 8.2%, the viscose contains 5.8% alkali, 500ml viscose bubbles are ≤25, the viscose surface tension is 53dyne / cm, and viscose particles below 10μm are ≤100 a / ml;

[0157] C filament forming

[0158] In the filament forming process, the composition of the acid bath is: sulfuric acid concentration 145g / L, sodium sulfate concentration 245g / L, zinc sulfate concentration 12.5g / L, acid bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com