Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Stable preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

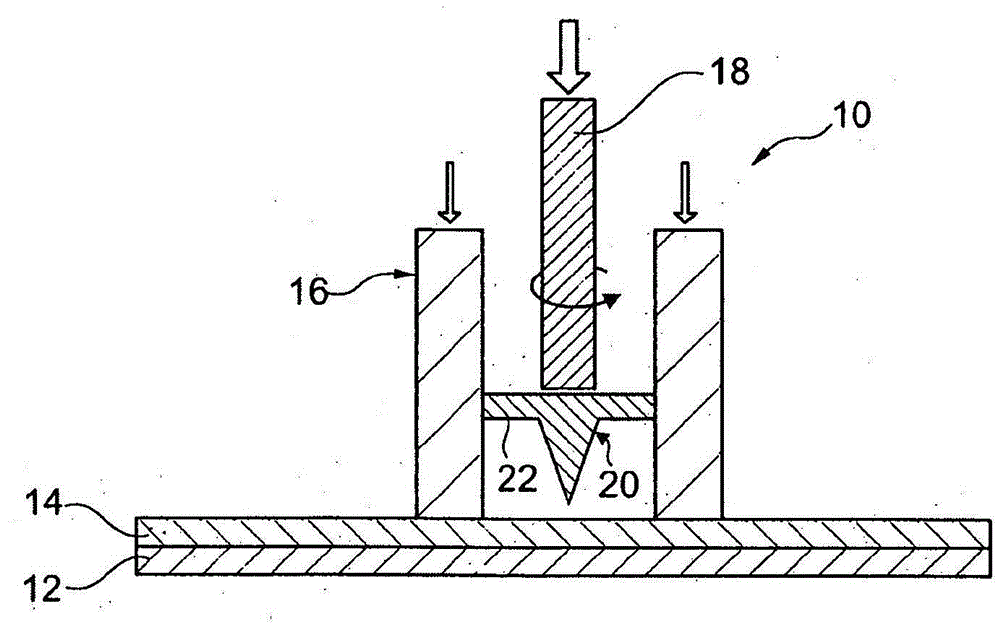

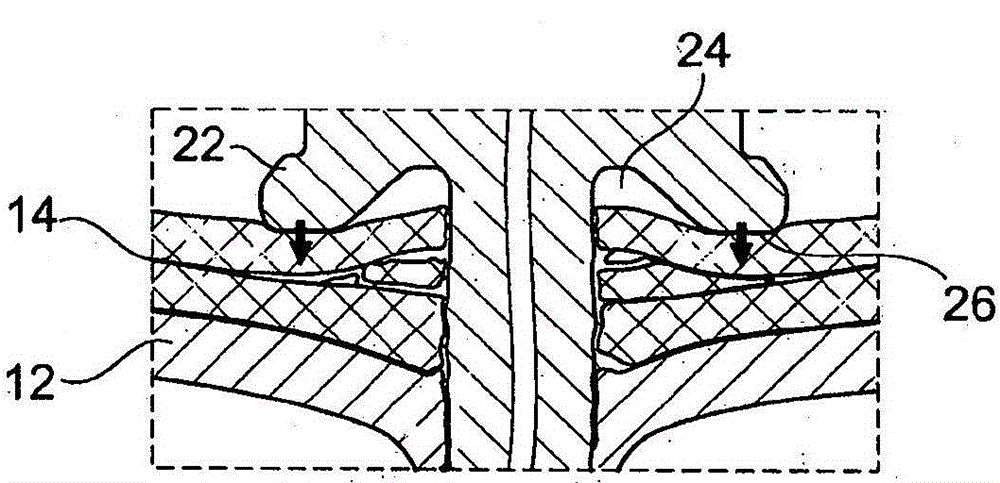

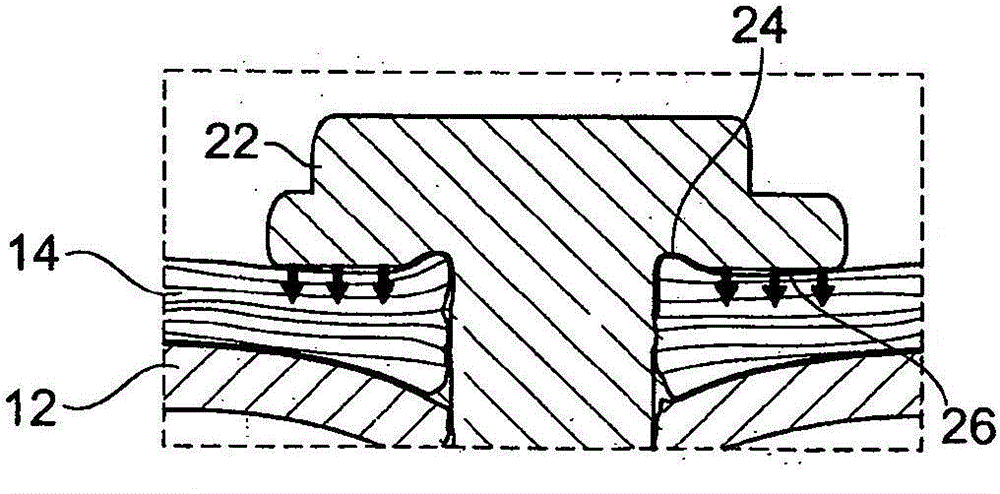

Method and device for joining members

InactiveCN104972648AWide rangeAvoiding Tolerance Chain ProblemsNon-electric welding apparatusFiberFriction welding

The invention relates to a method and device for joining members. According to the method of the invention, at least one of the members (12, 14) is made of fibre reinforced plastics, and a member complex is joined by friction welding of the members (12, 14) using an initially separate friction element (20), wherein the friction element (20) forms a fixed composition part of the member complex during the welding and friction process. The device according to the invention includes a support device (16) for fixing the members (12, 14) and a drive device (18) for rotating and pressing the friction element (20), wherein the force applied to the member (12, 14) by the support device (16) can be adjusted independent of the force applied to the friction element (20) by the drive device (18).

Owner:BAYERISCHE MOTOREN WERKE AG

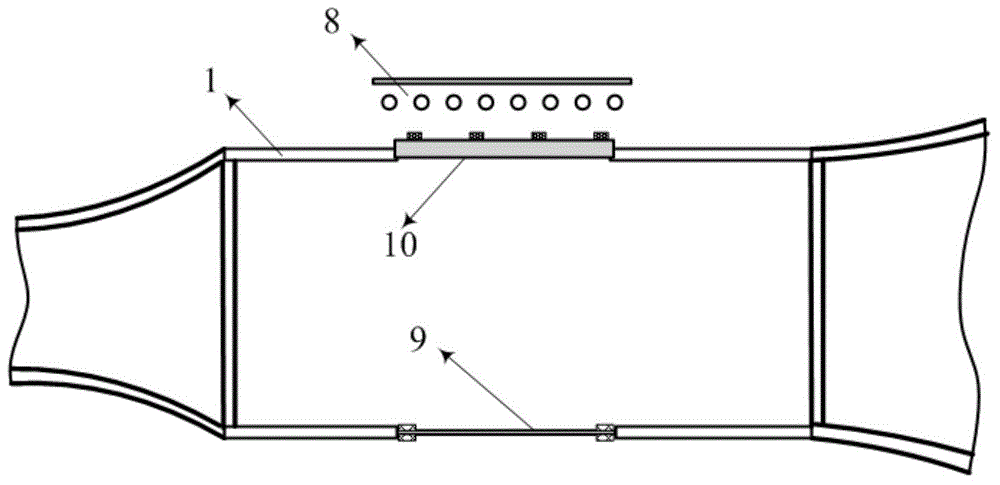

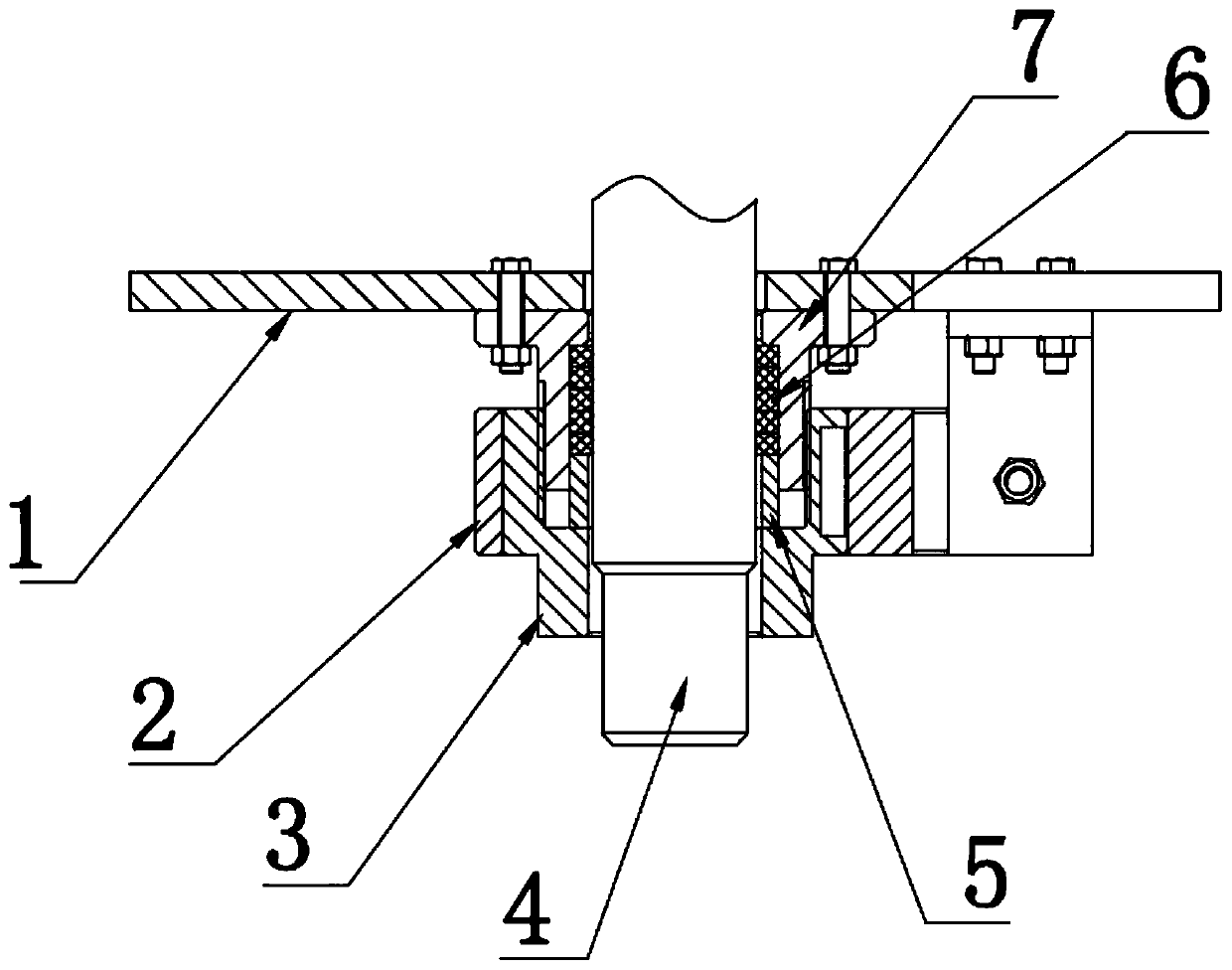

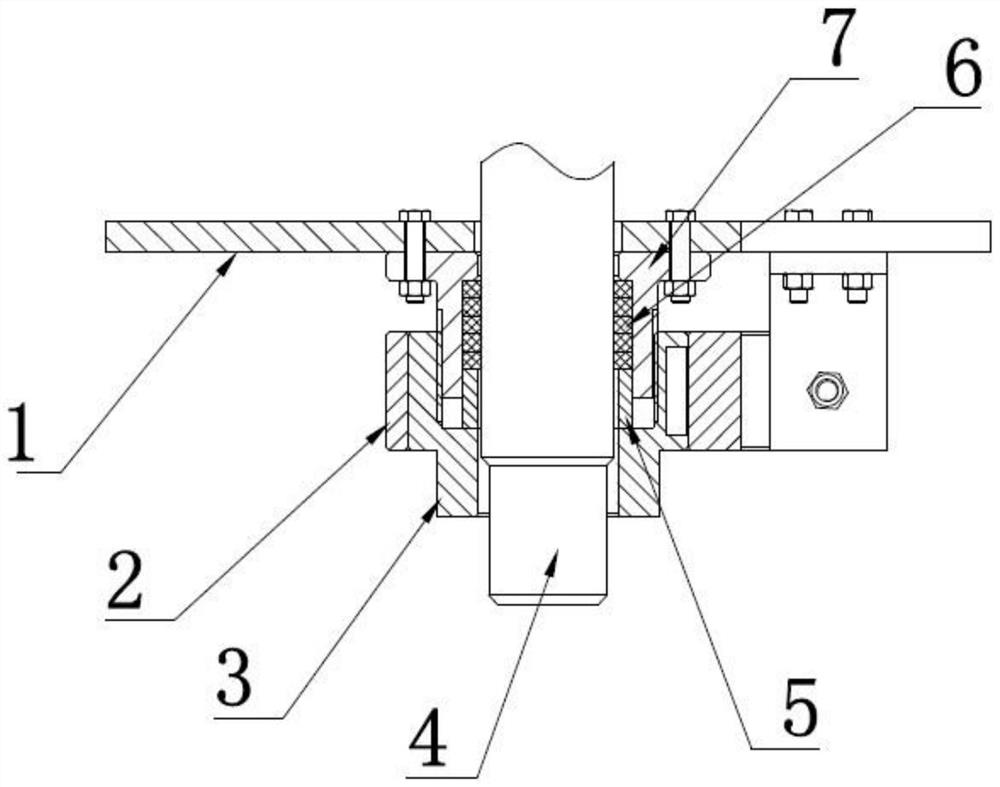

Device and method for mounting high noise resistance quartz window under high temperature environment

ActiveCN104594769AIntegrity guaranteedRelieve installation stressMaterial thermal analysisGlass pane fixingThermal insulationThermal deformation

The invention relates to the technical field of structural thermal noise composite environment tests, in particular to a device and method for mounting a high noise resistance quartz window under a high temperature environment. The mounting device comprises brackets (3), thermal insulation felt (4), metal shock pads (5), fastening bolts (6) and gland nuts (7). The brackets (3) are U-shaped groove components and are arranged on the upper side and the lower side of the window of a mounted object (1), and the two brackets (3) with opposite openings are mounted to be used for constraining the quartz window (2). The thermal insulation felt (4) is arranged between the quartz window (2) and the brackets (3) in a cushioned mode. In the horizontal direction, the metal shock pads (5), the fastening bolts (6) and the gland nuts (7) are used for fixing the quartz window (2). By the adoption of the device and method, the mounting stress caused by thermal deformation of a traveling-wave tube can be relieved, meanwhile, stable pretightening force can be provided under the high temperature environment, and the integrity of the thermal noise test system is guaranteed.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

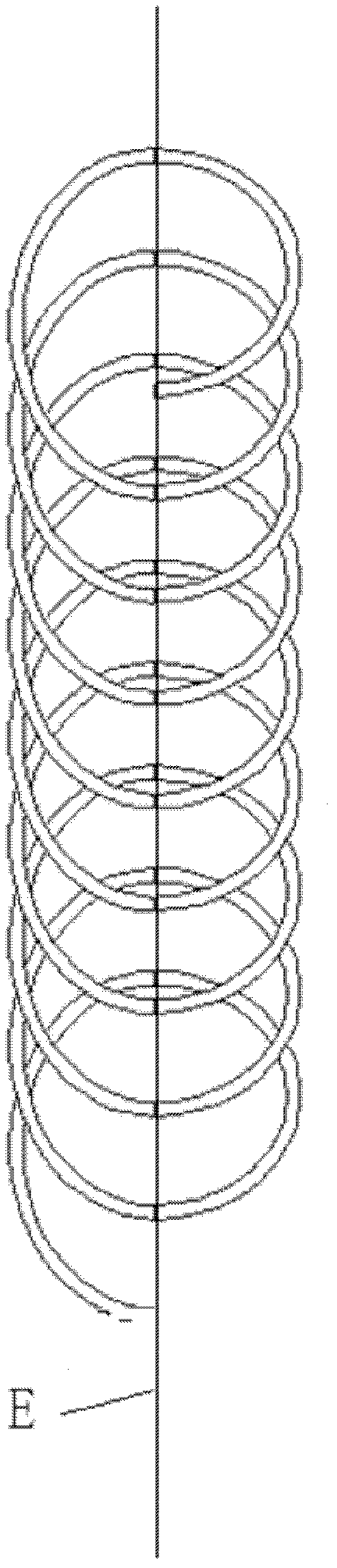

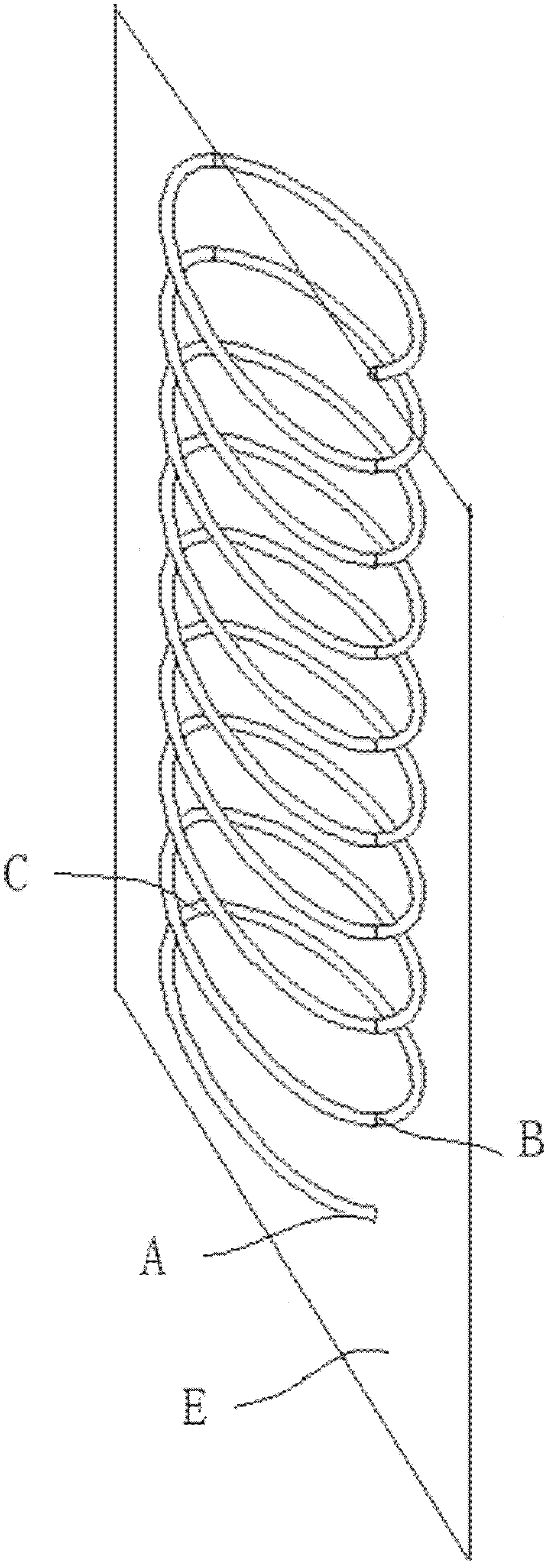

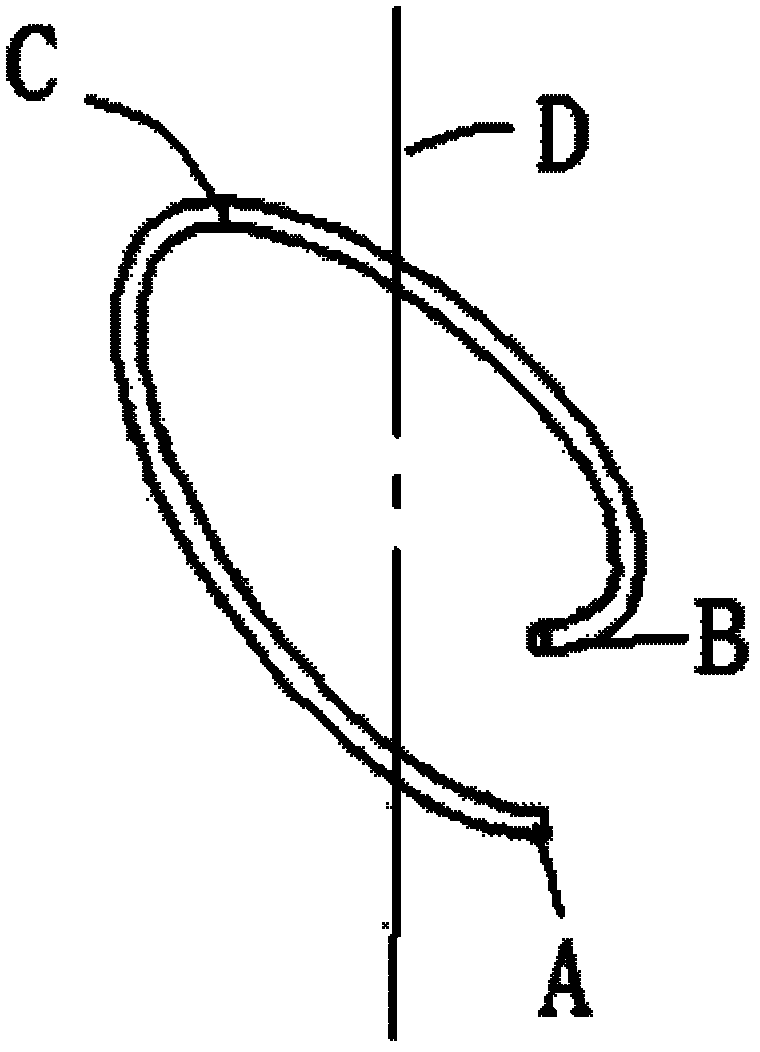

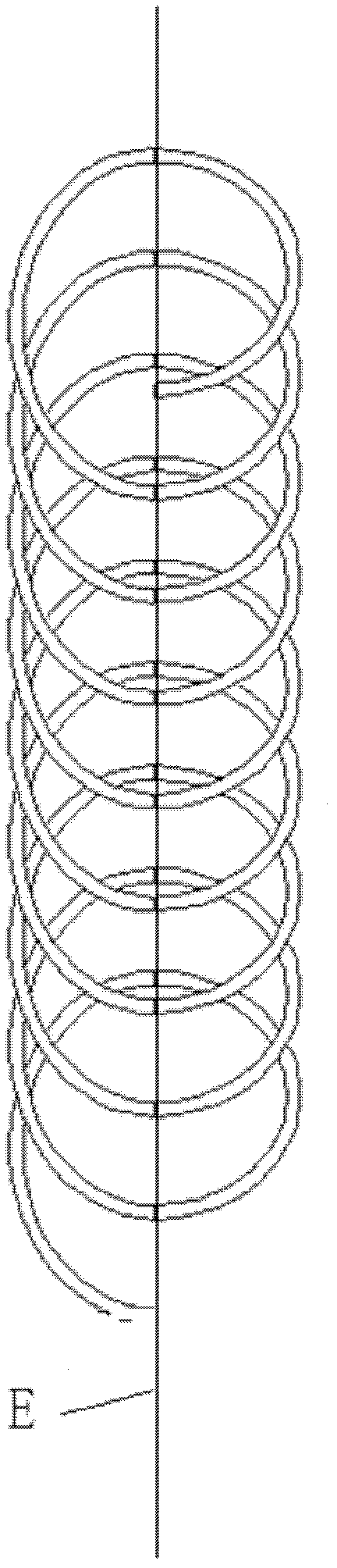

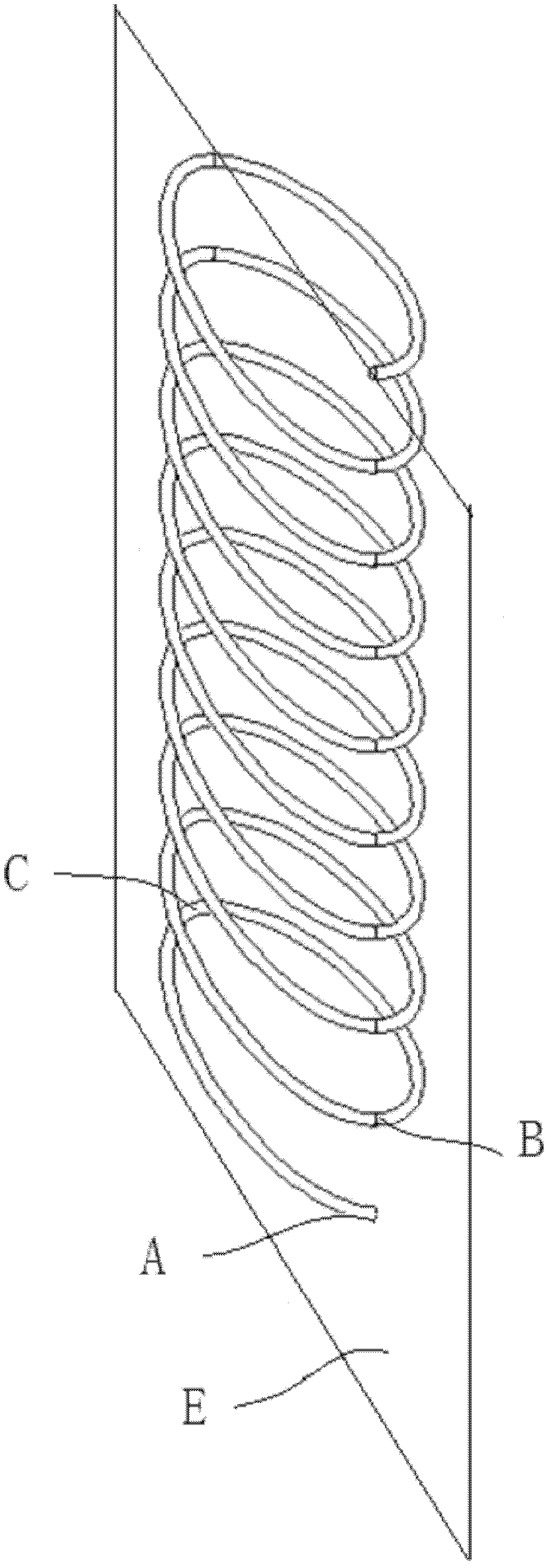

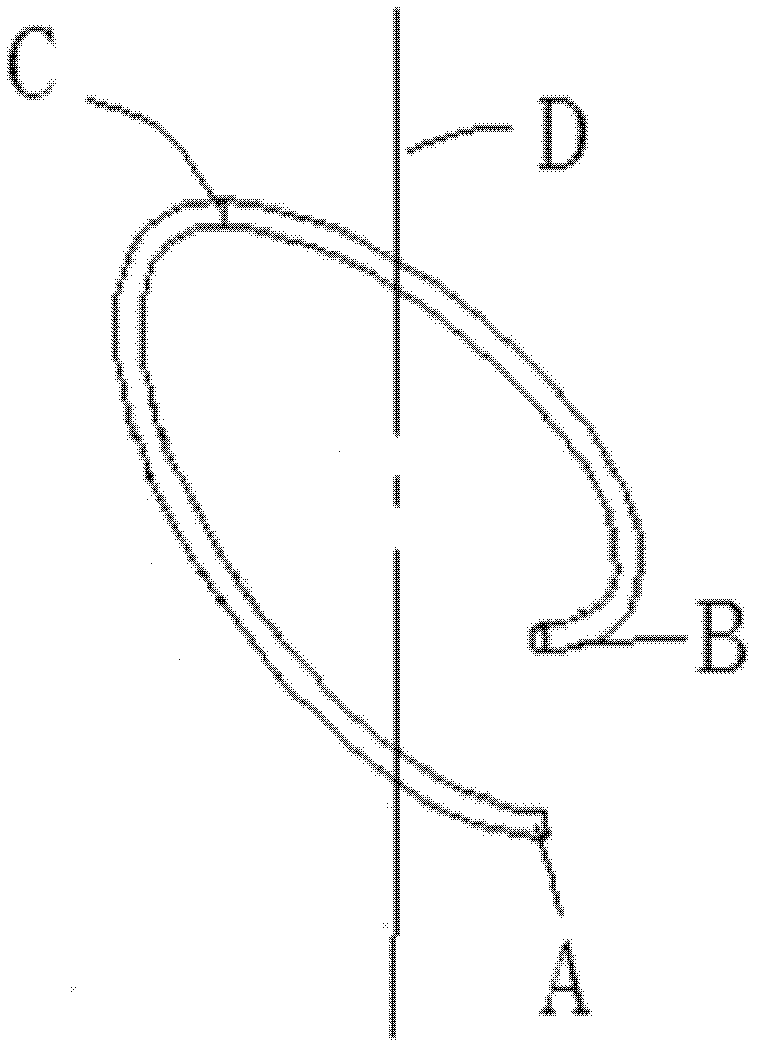

Lateral pressure spiral spring and sealing ring with same

InactiveCN102494067AStable preloadEffective stress compensationEngine sealsSpringsEngineeringBreaking point

The invention provides a lateral pressure spiral spring which is formed by rotating and bending a cylindrical body wound by using linear materials, wherein the axis of the cylindrical body is a central line of the spring, and basic parameters include a material linear diameter, an external diameter of the spring and a spiral angle; and the cylindrical body can be wounded into a cylinder or a ring shape connected end to end. The lateral pressure spiral spring is characterized in that the spiral angle is a variable. The front half circle of the spiral angle is a positive spiral angle, and the rear half circle of the spiral angle is a negative spiral angle; a transitional surface of break points of the spiral angle is formed between the front half circle and the rear half circle, and the absolute value of the positive spiral angle is larger than that of the negative spiral angle; and the spring is in a spiral raising structure as a whole. The spring can be applied to various mechanical application fields and particularly to the sealing field, is wide in stress range and can provide multidirectional stress compensation for elements, the stress compensation direction can be adjusted at any time along with the change of an external acting direction, and the spring can still provide enough stress compensation when pressure stress is not on the same horizontal surface but forms a certain angle with the horizontal surface.

Owner:上海大亚密封技术有限公司

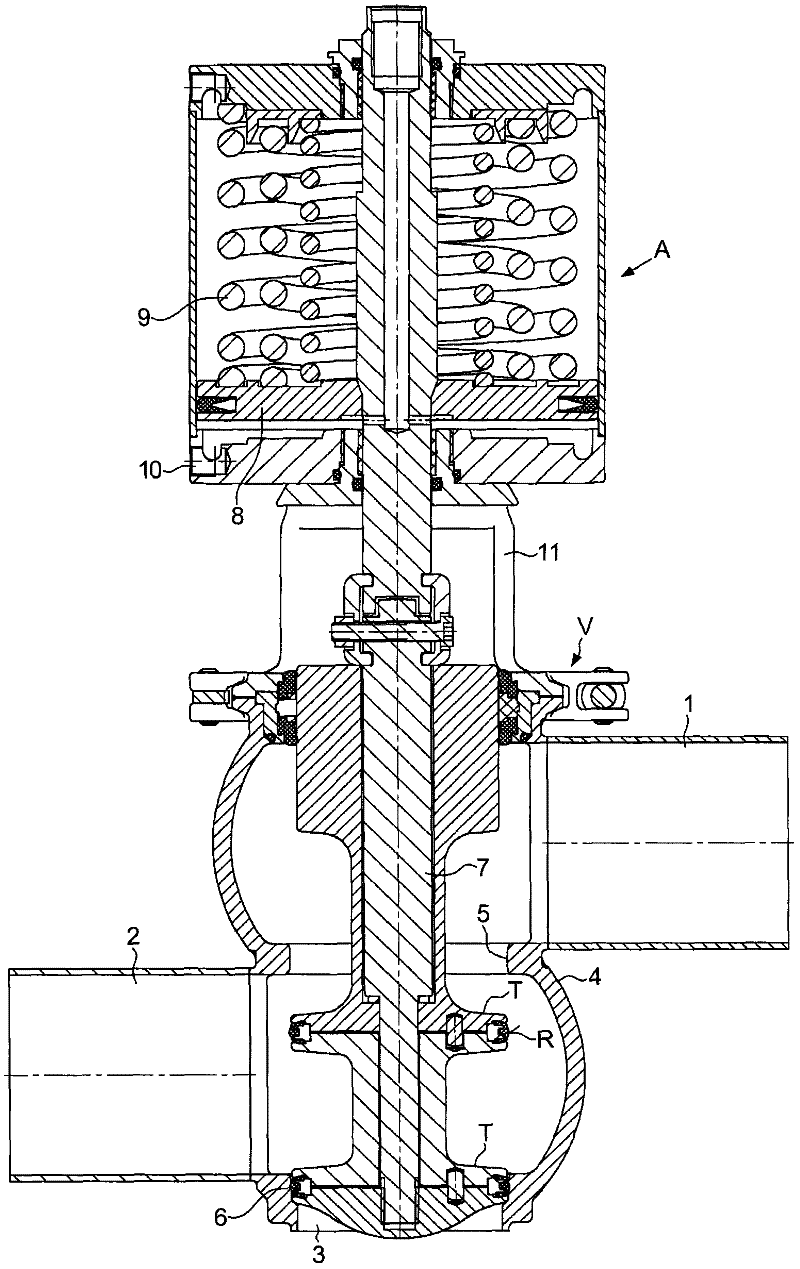

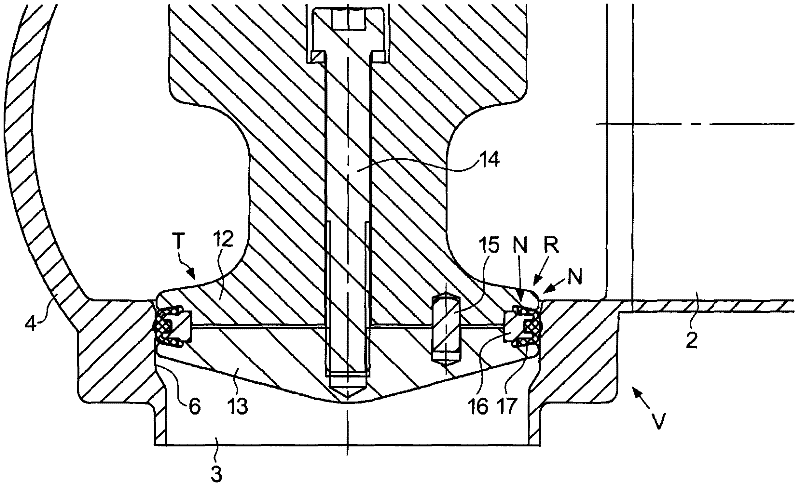

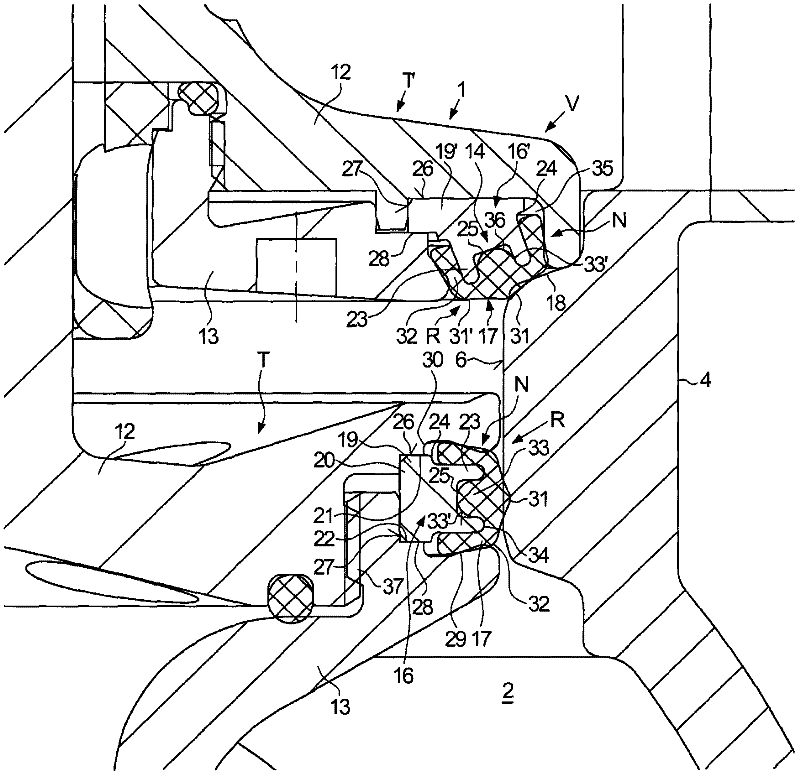

Multi-piece valve disk

ActiveCN102401143ACheap manufacturingEasy to assembleEngine sealsMultiple way valvesEngineeringMechanical engineering

The invention discloses a multi-piece valve disk (T, T'), in particular a multi-piece valve disk (T, T') of a sliding and / or seat valve (V). In the multi-piece valve disk (T, T'), a ring seal (R, R') with an elastic sealing ring (17) with an external sealing zone (31) is placed in a ring groove (N) of the valve disk (T, T') onto a dimensionally stable backup ring (16, 16'), and where an elastic restoring region (33) effectively positioned between the backup ring (16, 16') and the external sealing zone (31) is arranged in the backup ring (16, 16'), the restoring region (33) being embodied in one piece with the sealing ring (17) of its material adjacent to the external sealing zone (31) of the sealing ring (17).

Owner:KRONES AG

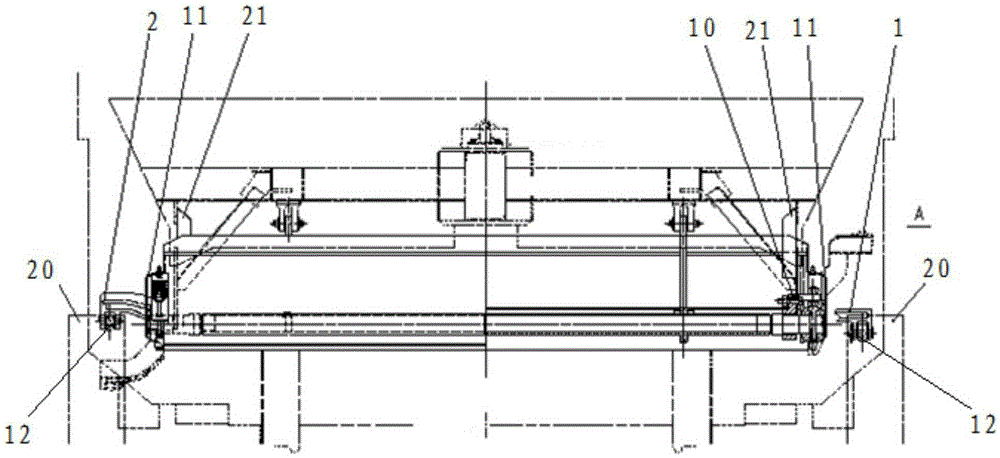

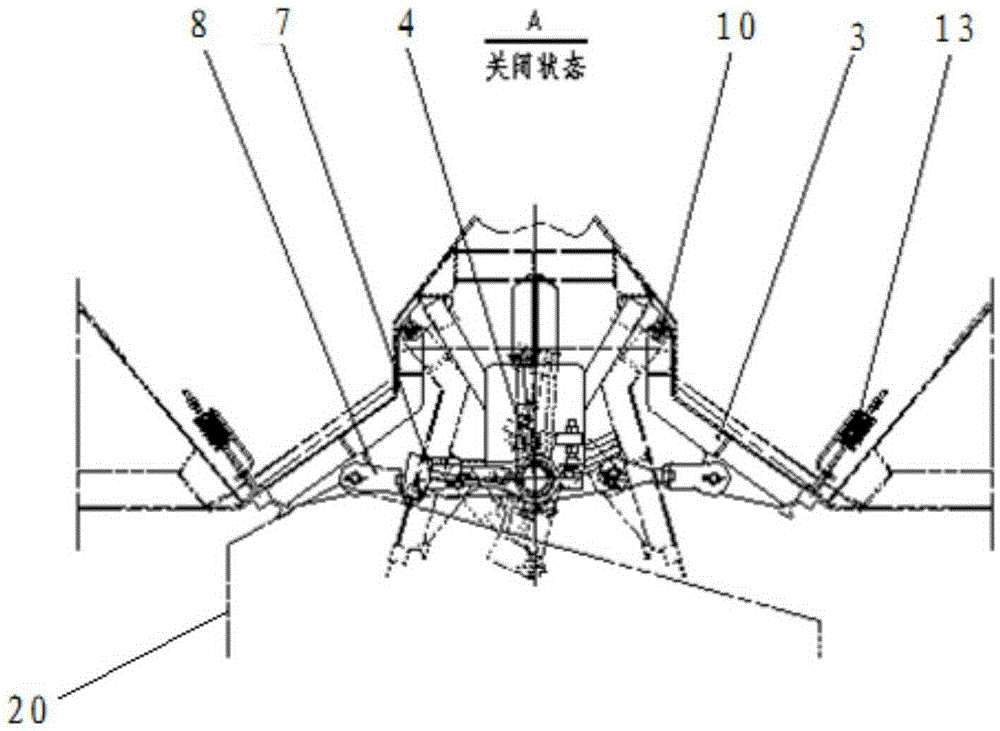

Bottom door opening and closing mechanism with adjustable door opening space

InactiveCN105329246ALarge openingGuaranteed normal opening and closingHopper carsEngineeringMechanical engineering

The invention discloses a bottom door opening and closing mechanism with adjustable door opening space. The bottom door opening and closing mechanism with the adjustable door opening space comprises a door opening arm, a door closing arm, a main shaft and an adjustable connecting rod, wherein the main shaft is connected with the door opening arm and the door closing arm; the main shaft is also connected with the adjustable connecting rod; the adjustable connecting rod is connected with a bottom door; and when the door opening arm touches a door opening touch table, impact force is transmitted to the adjustable connecting rod by virtue of the main shaft to enable the adjustable connecting rod to move, so as to close the bottom door. The bottom door opening and closing mechanism with the adjustable door opening space has the advantages that space between the bottom door and a hopper opening is adjusted by adjusting the length of the adjustable connecting rod, so that opening of the bottom door can not be too large, change of a force produced by collision between the door opening arm and the door closing arm of the bottom door and the touch table is prevented, normal opening and closing of the bottom door is guaranteed, and leakage rate of cargo is reduced.

Owner:CRRC YANGTZE CO LTD

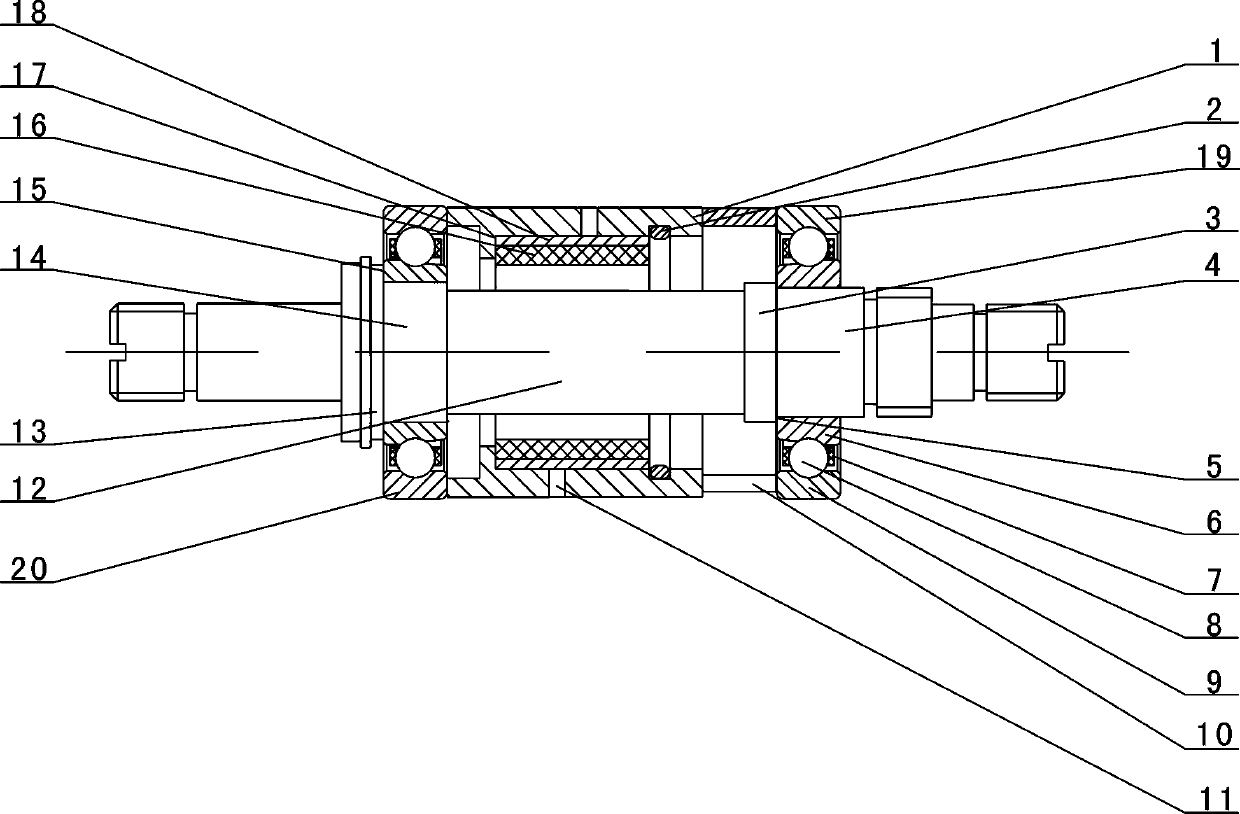

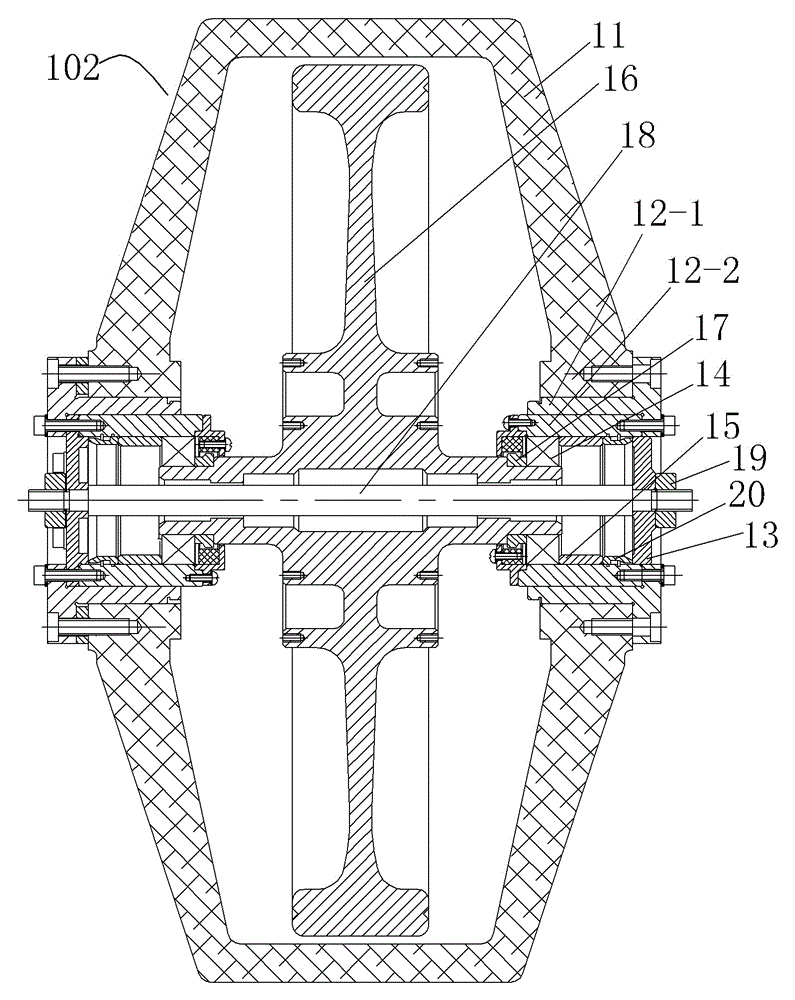

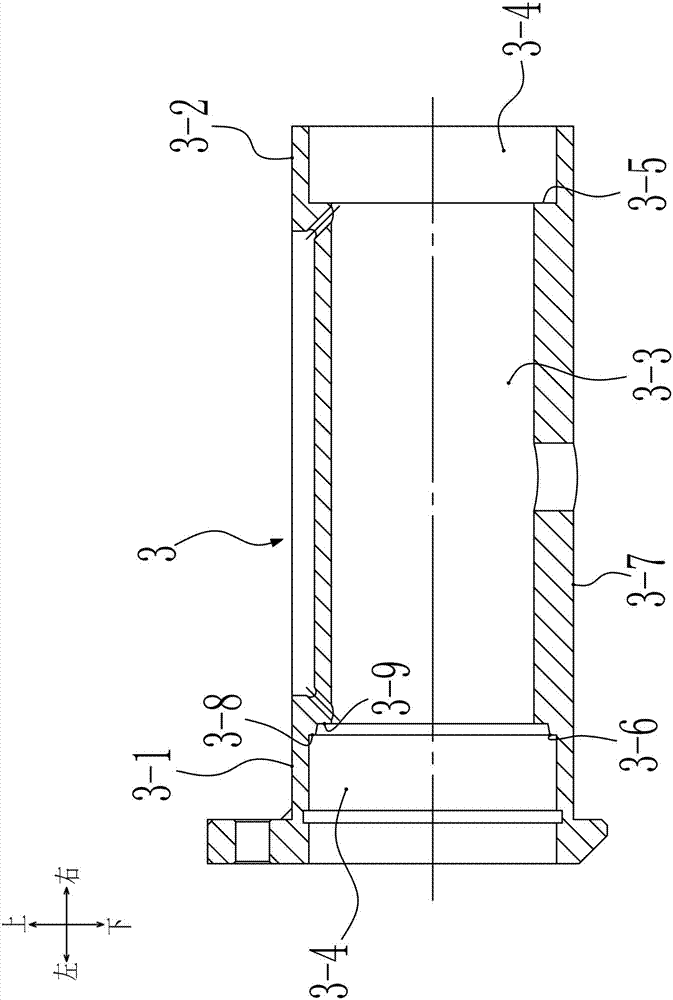

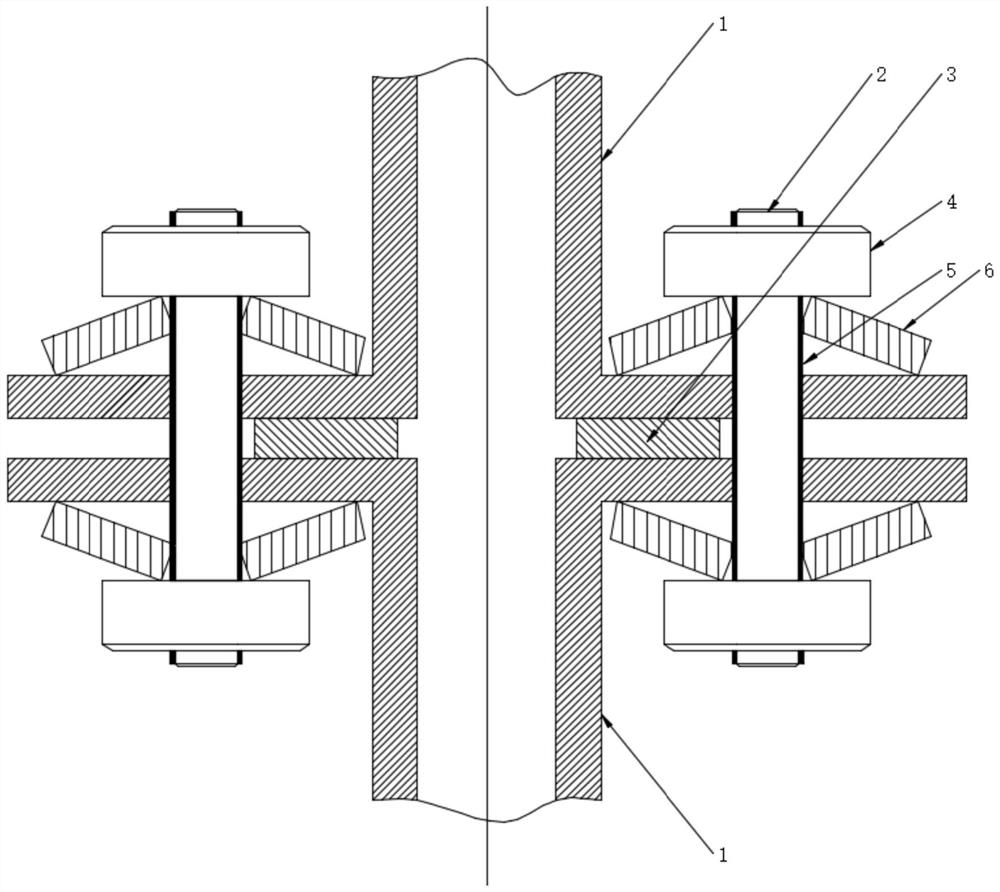

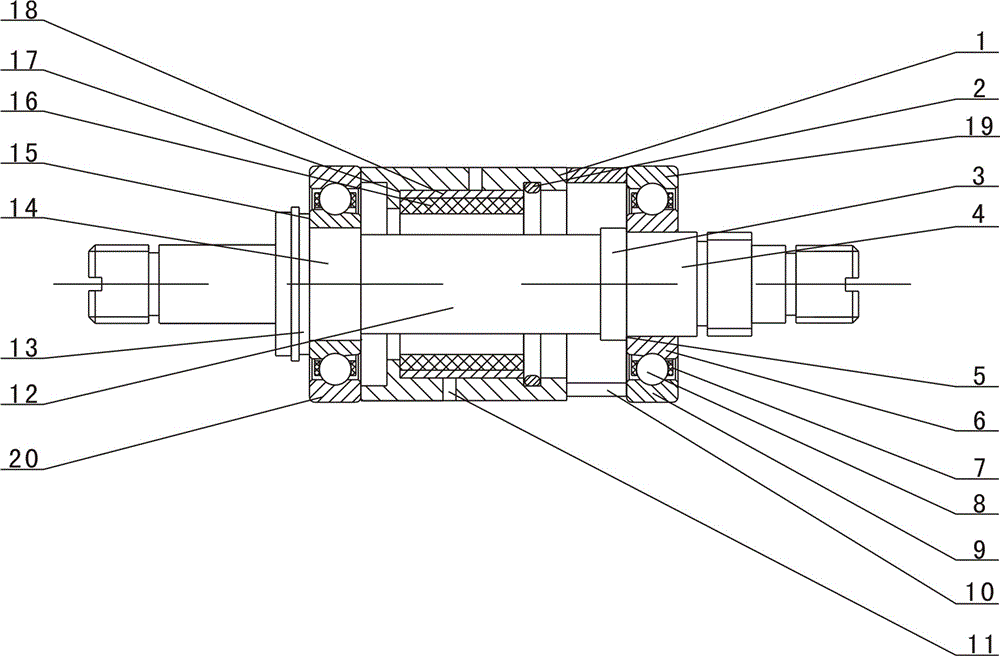

Gyro motor bearing unit

ActiveCN103742526AQuick installationImprove the qualified rate of installationBall bearingsBearing componentsDesign technologyOil storage

The invention discloses a gyro motor bearing unit and relates to the field of the design technologies of the bearings. The gyro motor bearing unit comprises a step shaft (12), a bearing A (19), a bearing B (20), an oil storage ring (16), an oil storage ring lining (18), an elastic lining (1) and a U-shaped clamping ring (10), wherein the bearing A and the bearing B are arranged on two sides of the middle part of the step shaft (12); the elastic lining and the U-shaped clamping ring are arranged between the bearings A and B; the U-shaped clamping ring is arranged between the elastic lining and the bearing A; the oil storage ring is arranged in a groove body which is formed in the middle part of the inner surface of the elastic lining; an oil storage ring lining is arranged between the oil storage ring and the groove body of the elastic lining. The gyro motor bearing unit overcomes such defects of the conventional gyro motor bearing unit as low rotation precision, short service life, low reliability and poor installation qualified rate; and the performance of the gyro motor bearing unit can be effectively improved.

Owner:LUOYANG BEARING RES INST CO LTD

Tensioning device for MPCVD

PendingCN110684961AAdjustable tensionTimely measurementPolycrystalline material growthChemical vapor deposition coatingClassical mechanicsDisplay device

The invention relates to the technical field of MPCVD equipment, in particular to a tensioning device for an MPCVD, and solves the problems of incapacity of timely measuring and adjusting of tensioning force of a connecting rod in MPCVD equipment in the prior art. The tensioning device comprises a reaction cavity, a waveguide cavity and a connecting rod, a tensioning device body located below thewaveguide cavity is further mounted on the connecting rod, the tensioning device body comprises a tensioning assembly, an elastic element, a pallet, a pre-tightened piece, a tensioning piece and a weighing sensor, and the weighing sensor is electrically connected to a display. According to the tensioning device for the MPCVD, as the change of the tensioning force of the elastic element is caused by the change of the tensioning force of the connecting rod, the expected force of the elastic element can be measured at any time through the weighing sensor in the tensioning device body and displayed on the display, the change of the tensioning force of the connecting rod can be viewed at any time through the display, and the change of the tensioning force of the connecting rod can be measured timely, so that the tensioning force of the connecting rod can be adjusted timely.

Owner:四川三三零半导体有限公司

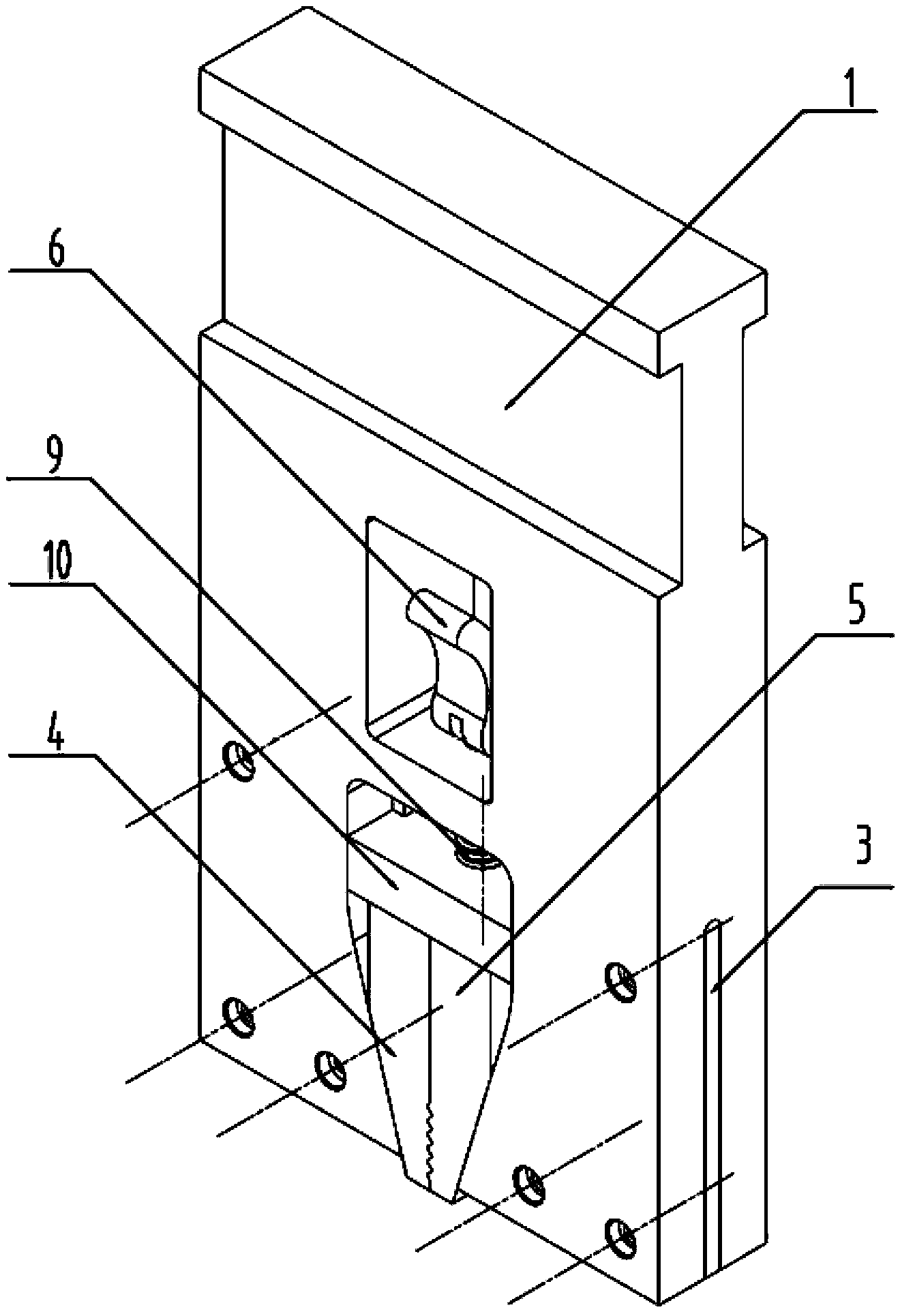

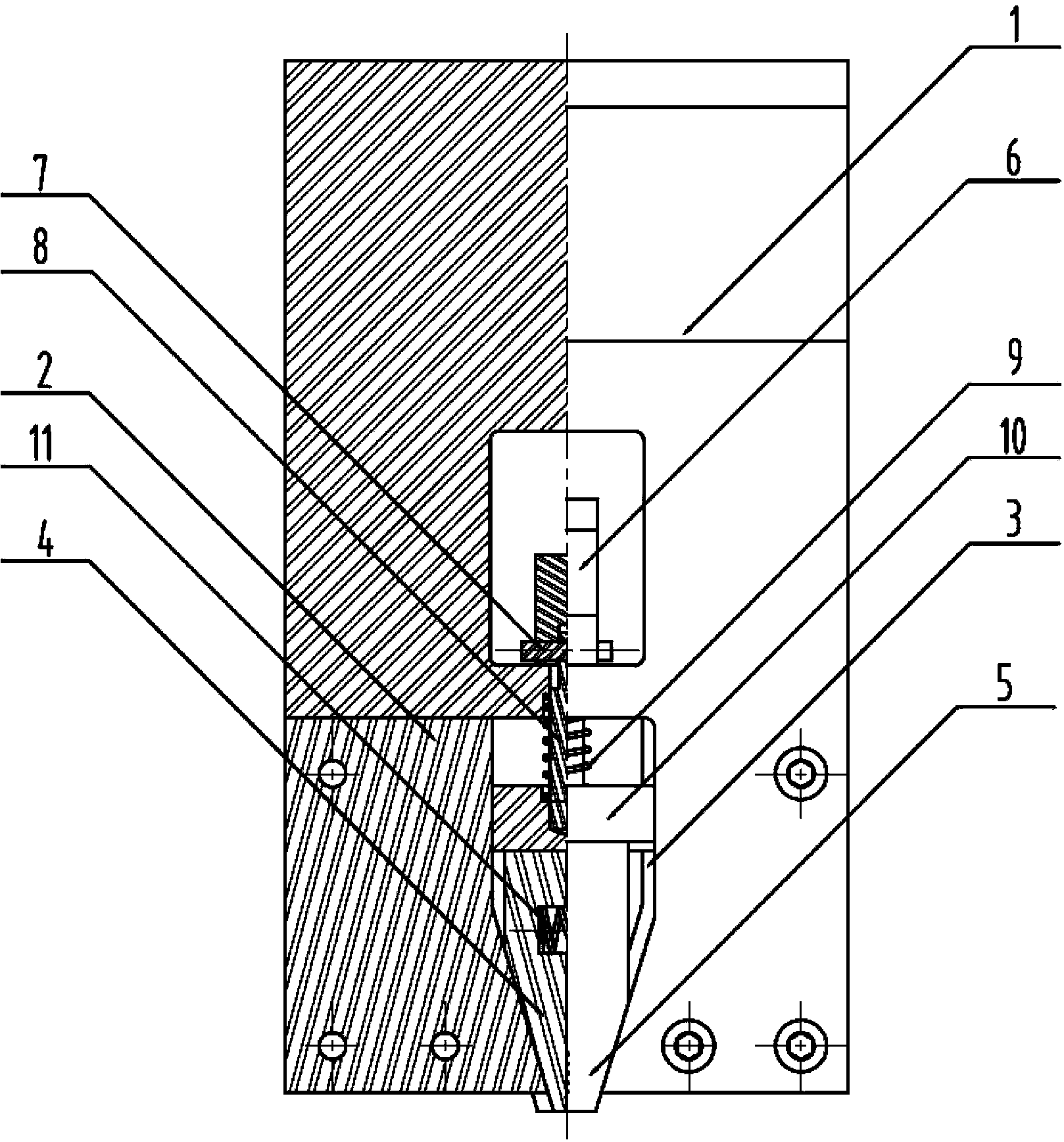

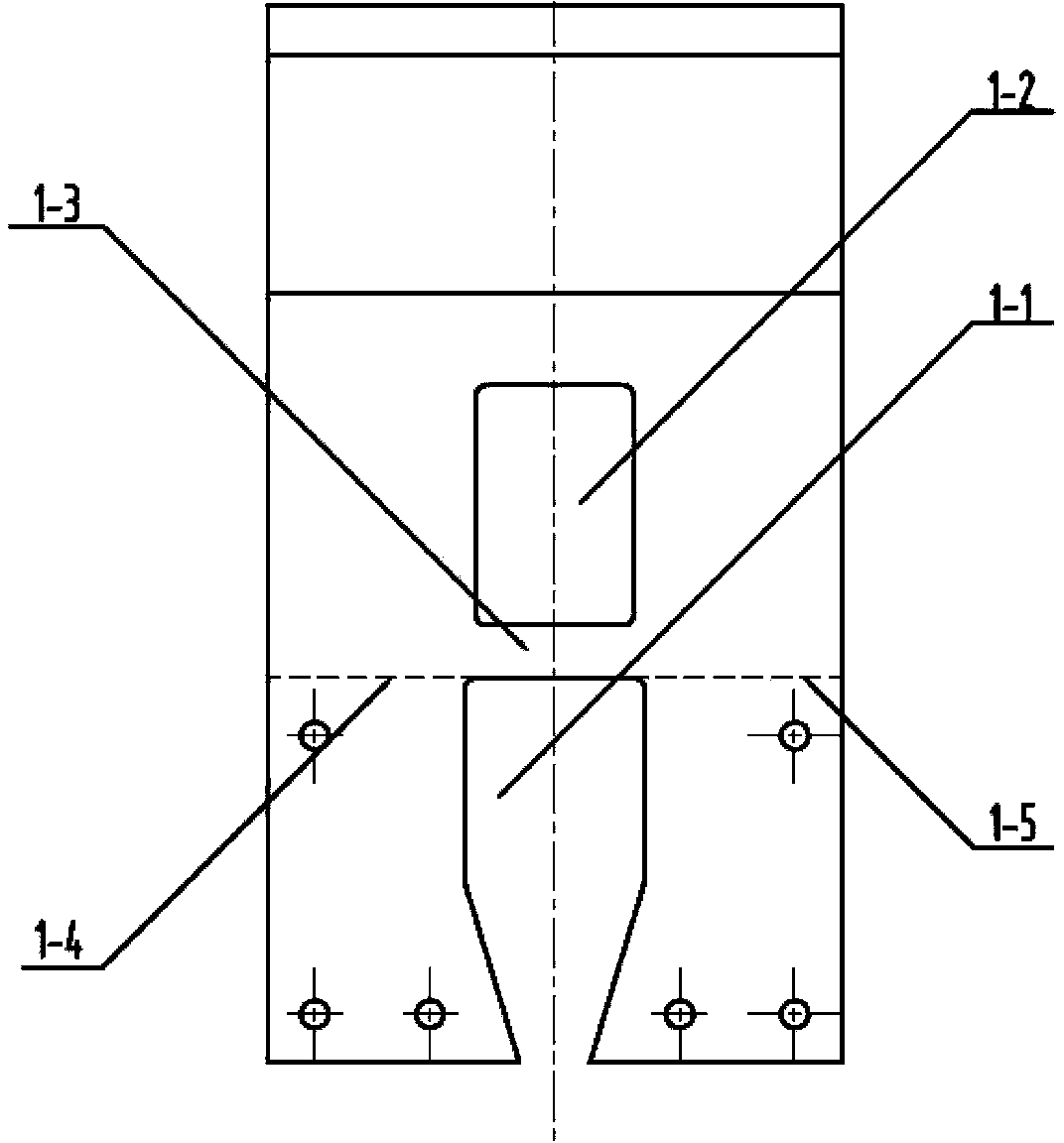

Tensile fixture

ActiveCN103293055BRealize unloadingContinuous preloadStrength propertiesThermal expansionEngineering

The invention provides a tensile fixture, which belongs to the field of fixtures. The tensile fixture overcomes the problems that a conventional fixture cannot reliably clamp a tiny sample and becomes slack at high temperature and is especially applicable to tensile test of tiny samples under the conditions of normal temperature and high temperature. According to the invention, an elastic force released by a longitudinal spring exerts a continuous pretightening effect on a sample, the pretightening effect is more continuous and stable compared with a pretightening effect of a screw, and operation in the invention is simpler; in the process of drawing, the clamp force of a chuck increases with increase of a tensile force, a pretightening force can be continuously maintained at the same time, so relaxation of a material caused by thermal expansion can be effectively compensated, which guarantees that the sample is stably clamped and prevented from slipping in the process of drawing; and thus, the problems of slipping of a tiny sample caused by thermal expansion, a small size and the like in the process of drawing, inconvenient clamping and the like are effectively overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

Mining self-pressurization intelligent wireless anchor cable dynamometer and using method thereof

PendingCN111982359AAvoid layingAvoid holesHydraulic/pneumatic force measurementWireless transmissionData acquisition

The invention discloses a mining self-pressurization intelligent wireless anchor cable dynamometer and a use method thereof, and aims to solve the problems existing in the use of an existing anchor cable dynamometer. The wireless anchor cable dynamometer comprises an oil cylinder outer body, a telescopic body, a first sealing ring, a three-way joint, a gauge outfit, an intelligent tray and a high-pressure oil pipe. The pressure release valve is arranged on the oil cylinder outer body, and the pressure release function can be achieved under the action of blasting impact; the manual pump pressurizes the interior of the oil storage cavity of the oil cylinder outer body through the three-way joint, and when the designed pre-tightening force is reached, the oil tightening valve can be rotated to seal oil into the oil storage cavity; a plurality of modules are arranged in the meter head, so that data acquisition, conversion and recording can be realized, and wireless transmission can be realized. The wireless anchor cable dynamometer is suitable for long-term monitoring and early warning of the axial force of the anchor cable in the coal mine tunnel, has the advantages of impact resistance, the stable test result, convenient data recording and transmission and convenient pressurization, and can analyze the stress conditions of the tray in different directions so as to better guide supporting construction and evaluate and check the supporting effect.

Owner:山东省邱集煤矿有限公司

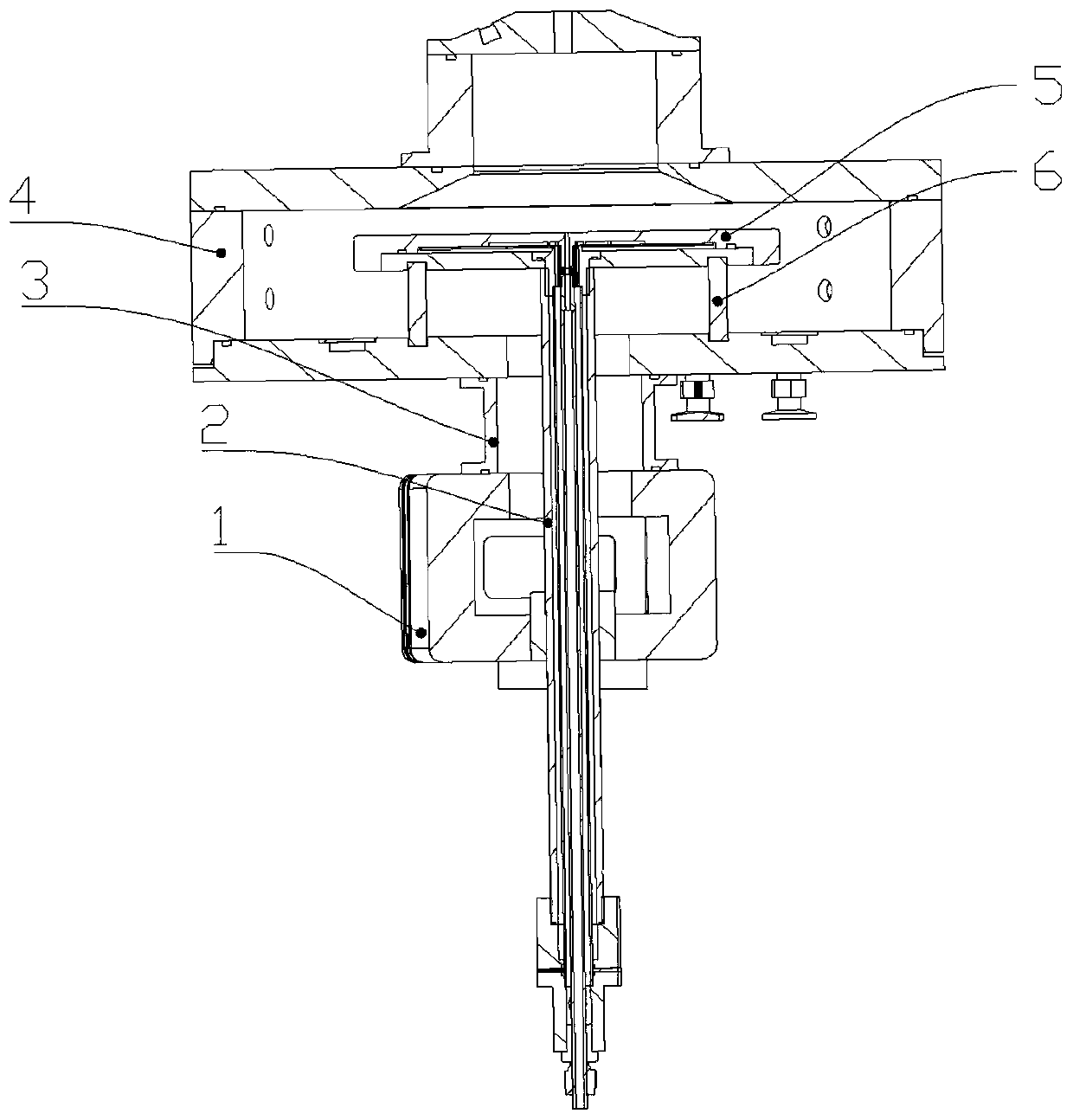

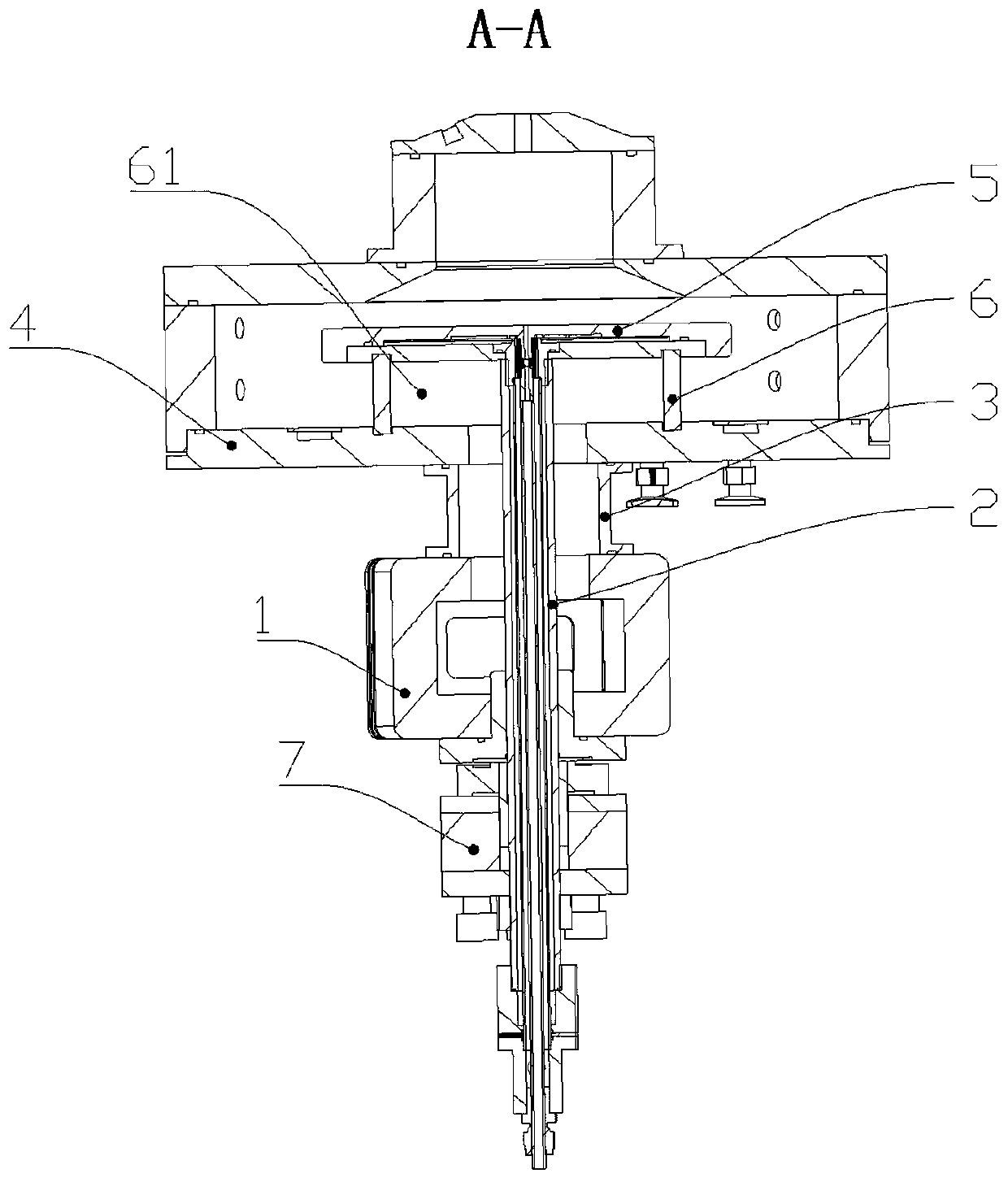

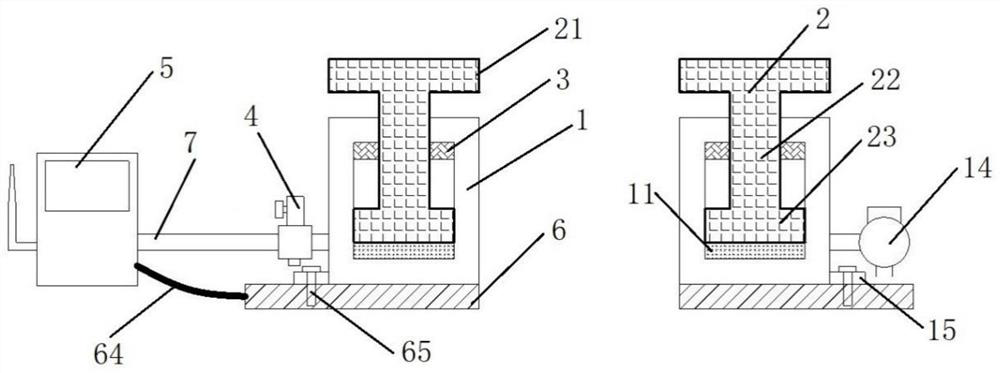

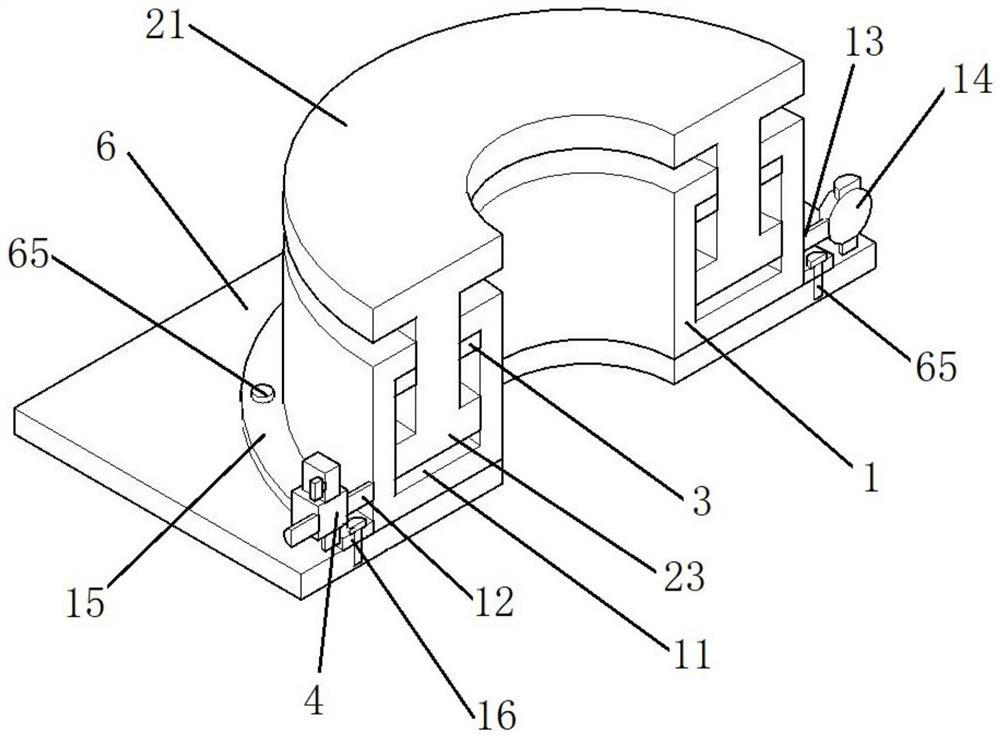

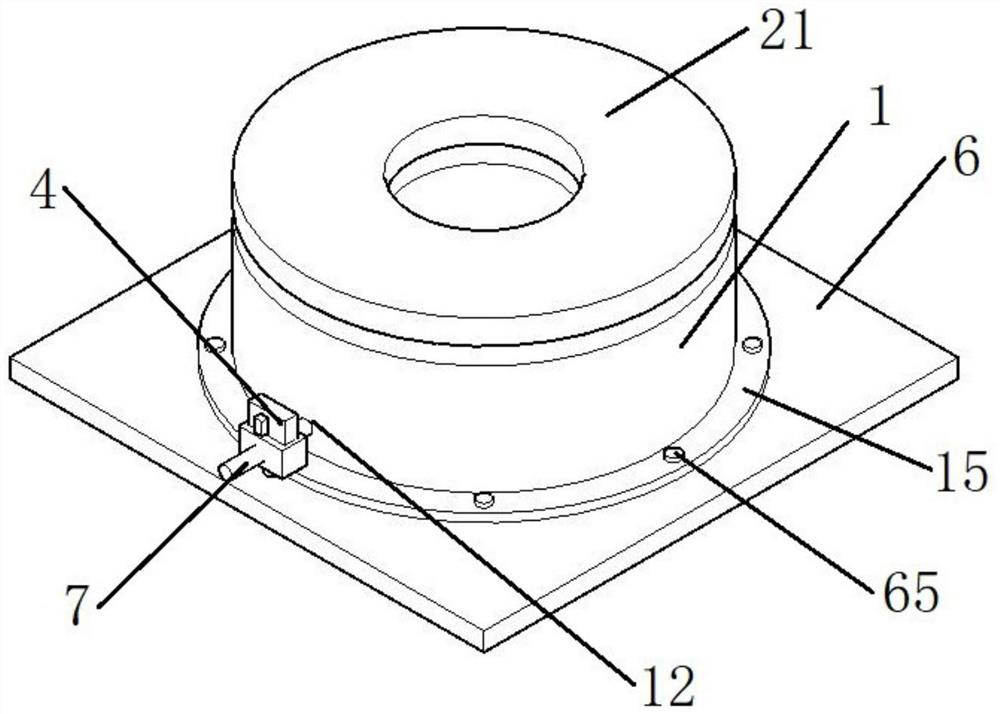

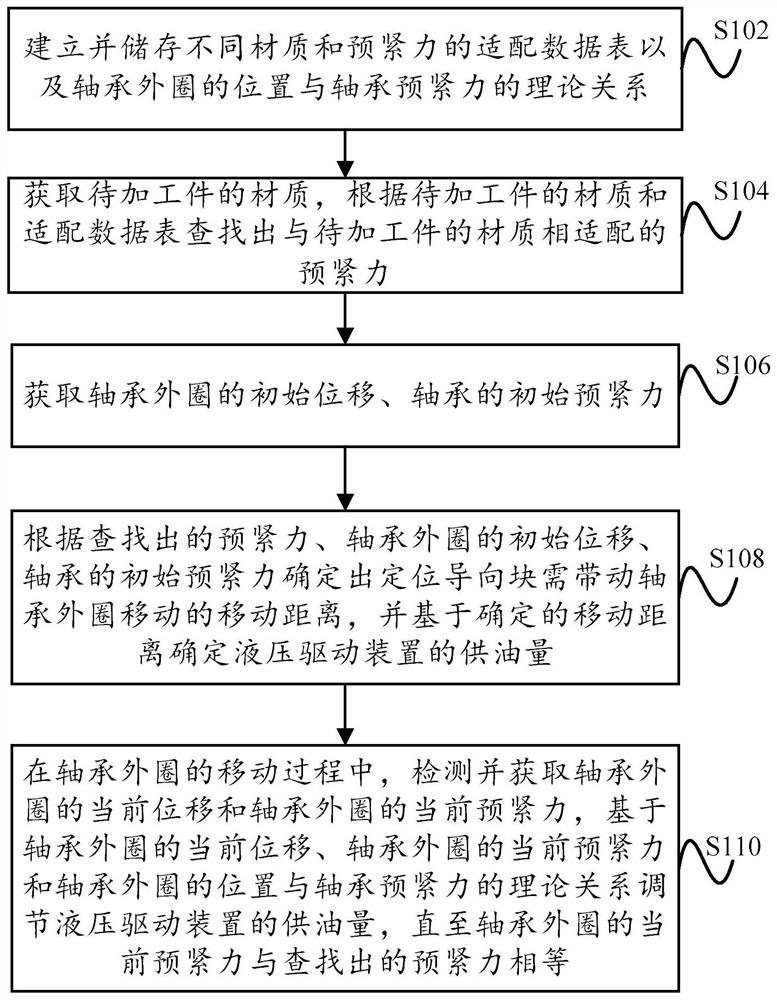

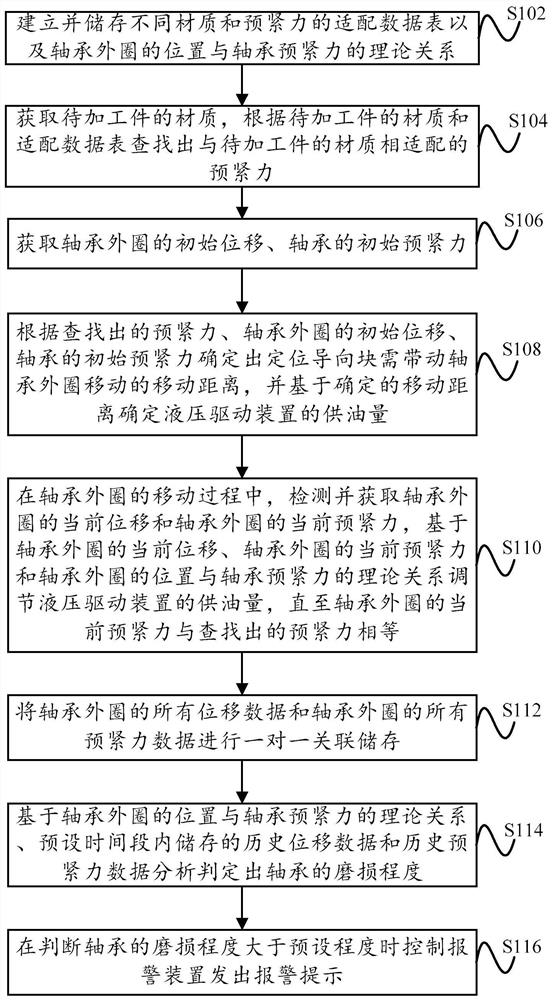

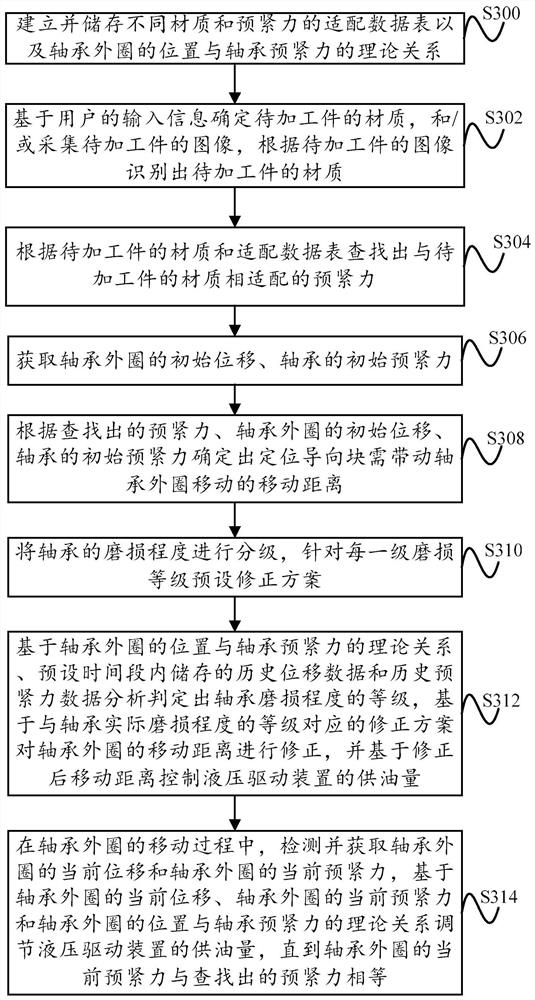

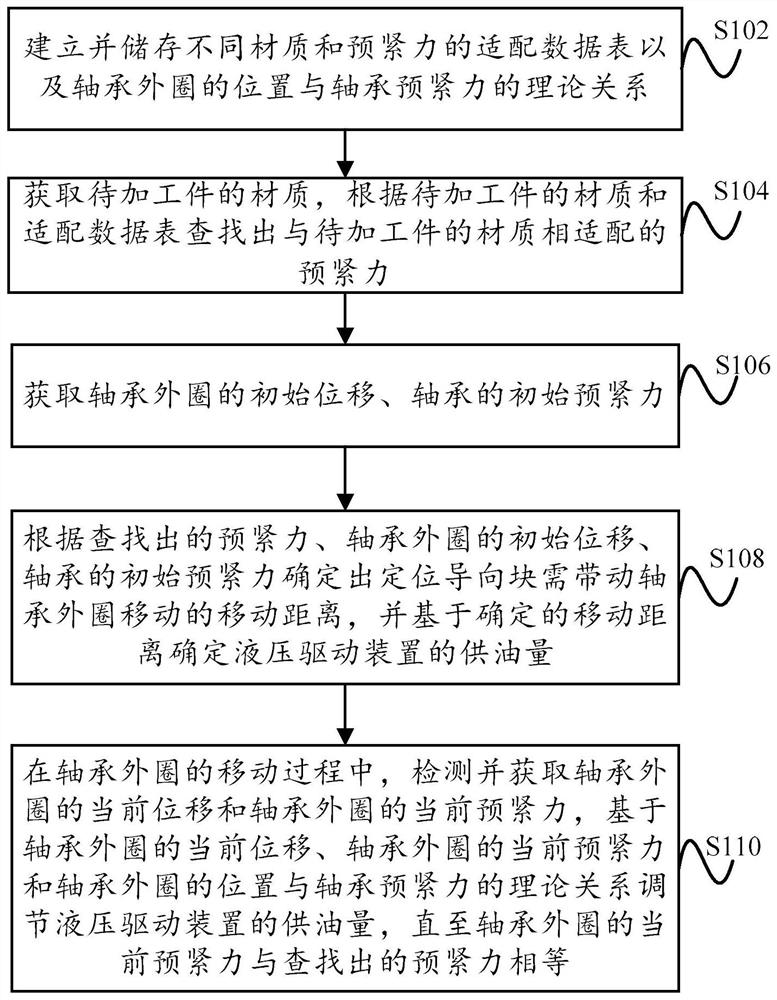

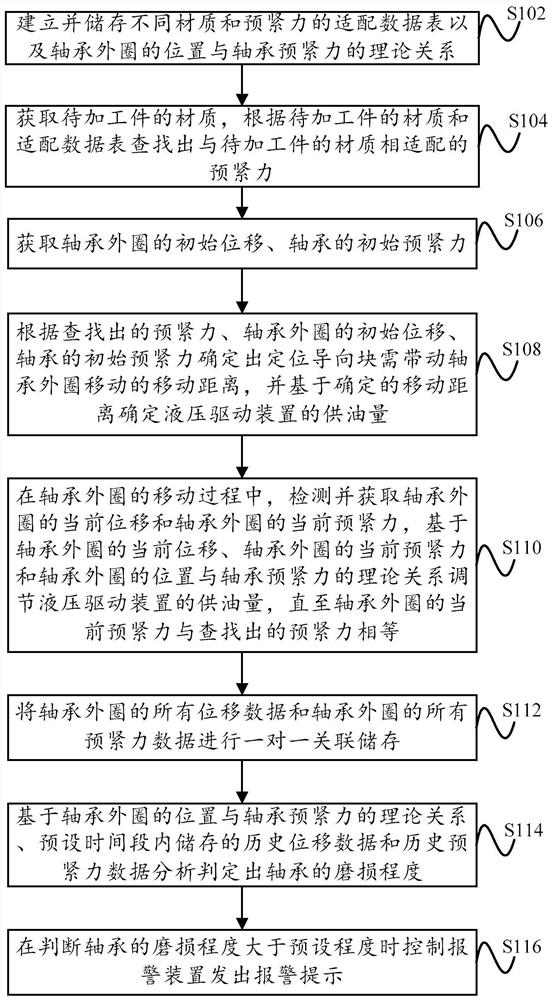

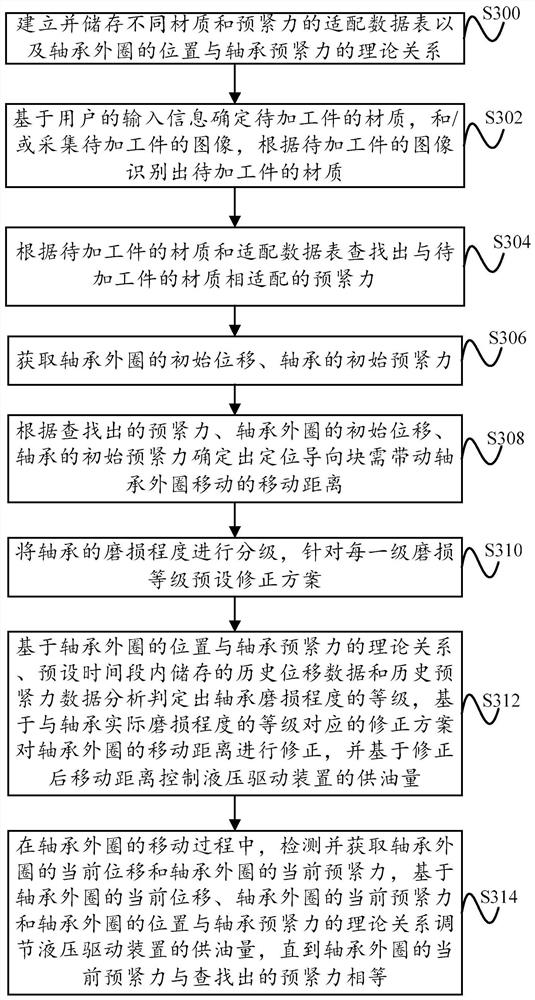

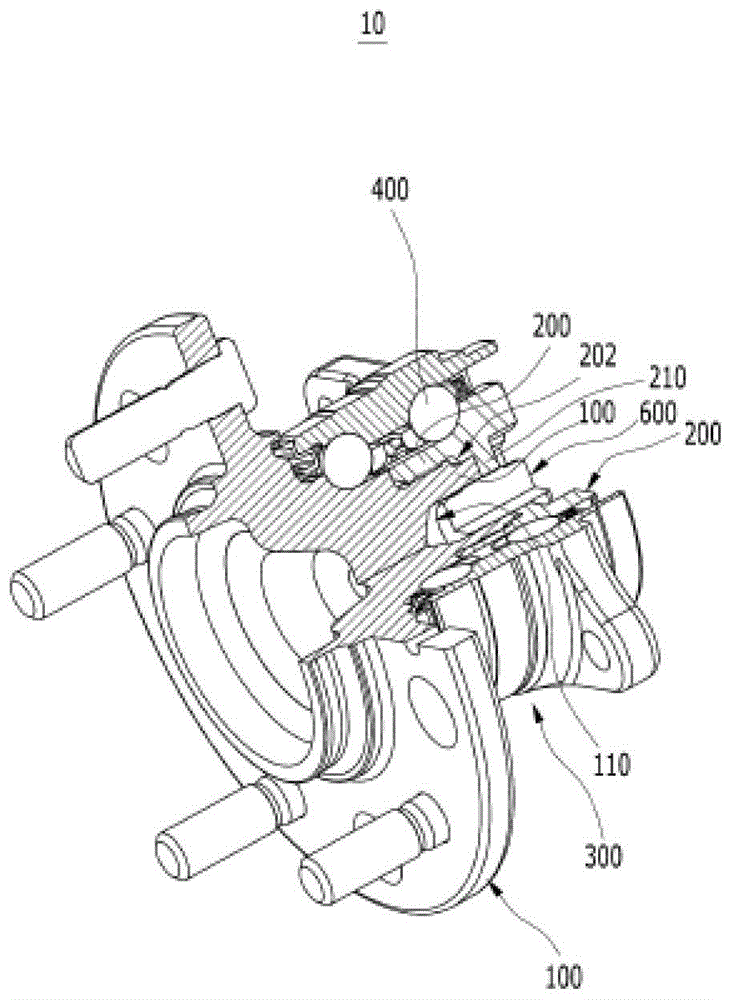

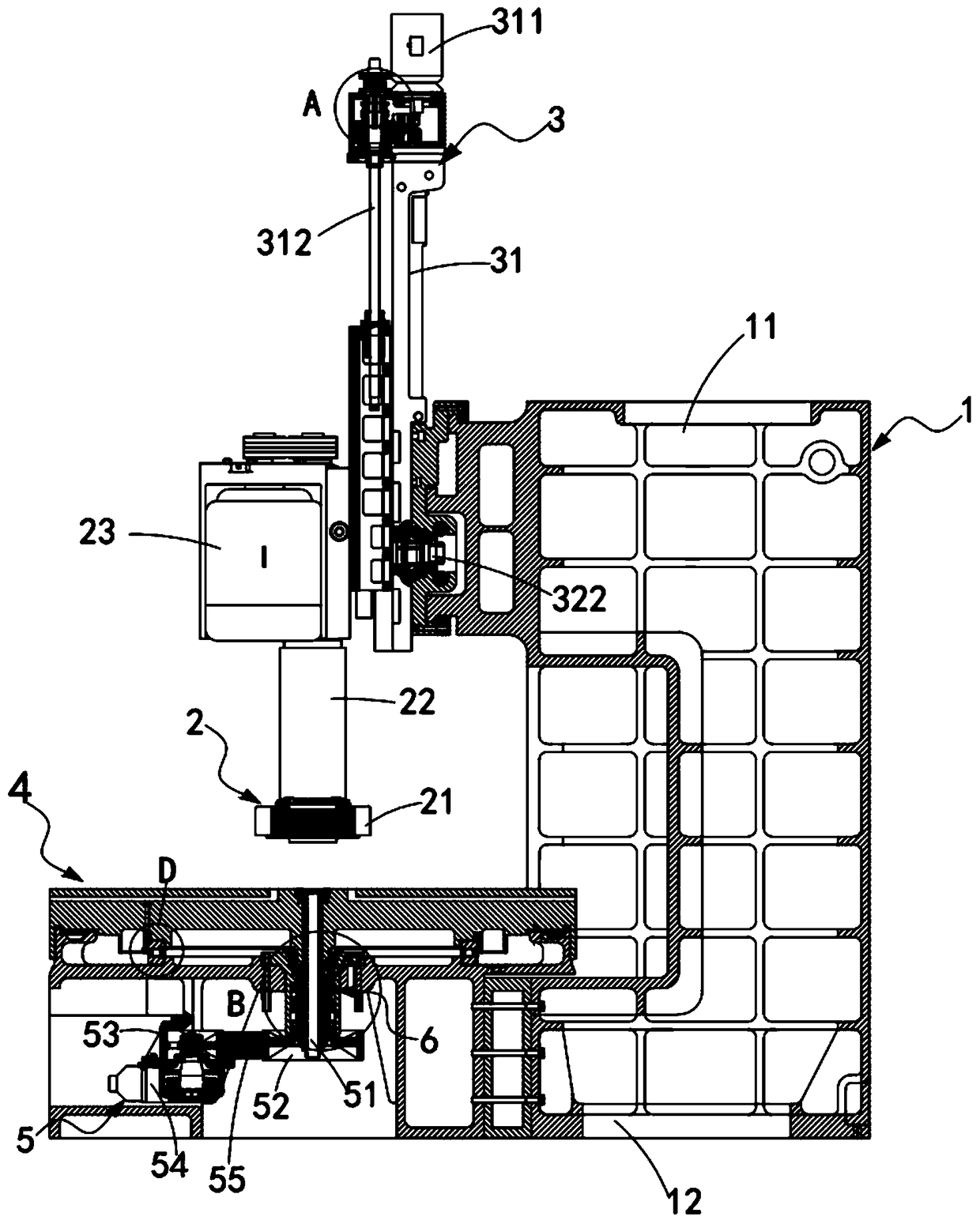

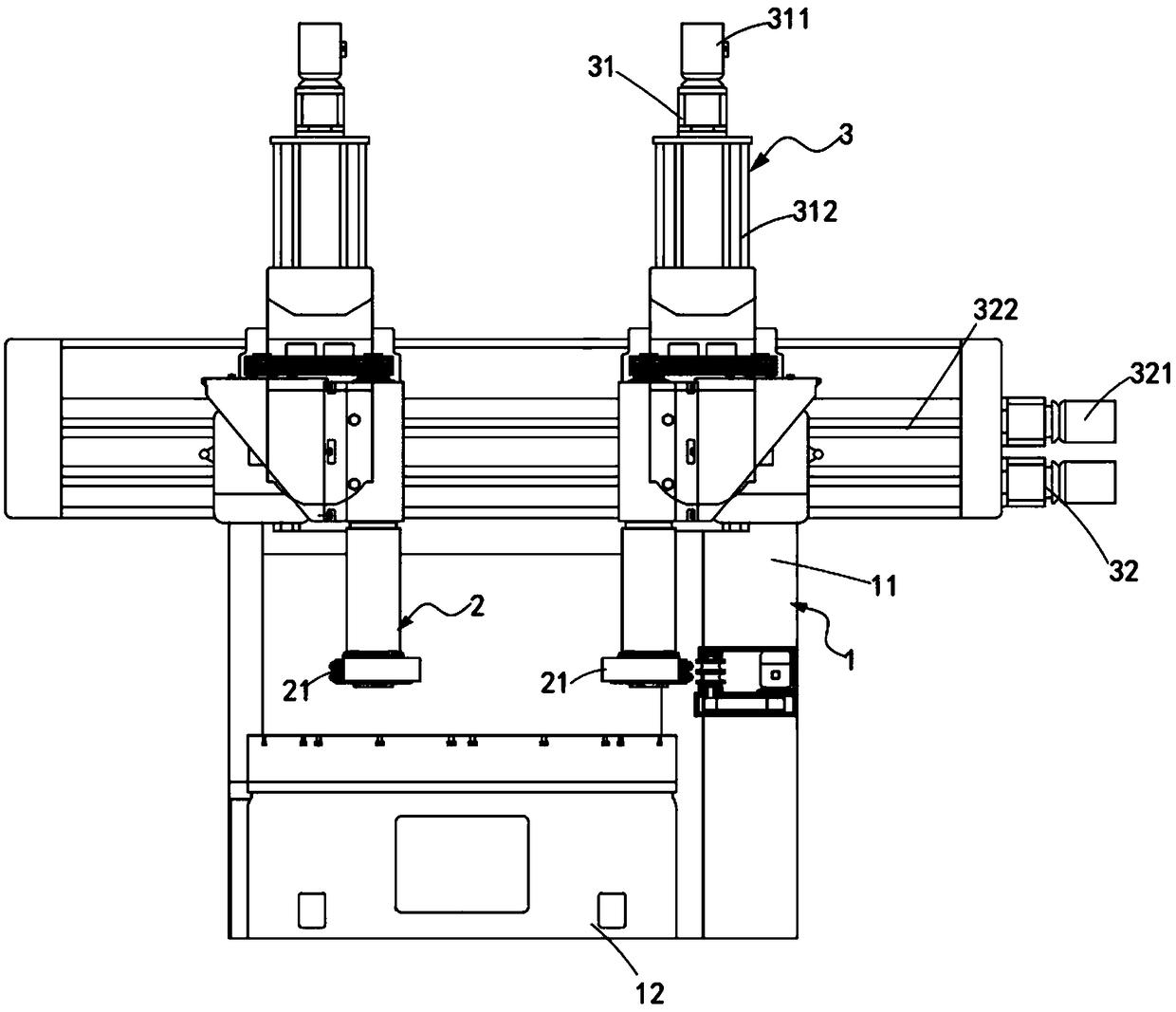

Method and system for intelligently adjusting pre-tightening force of bearing of electric spindle

ActiveCN112059213AGuaranteed processing effectGuaranteed preloadAuxillary equipmentLarge fixed membersControl engineeringControl theory

The invention provides a method and a system for intelligently adjusting the pre-tightening force of a bearing of an electric spindle. According to the method and the system, a positioning guide blockis arranged in a spindle device and is hydraulically driven to move and drive a bearing outer ring to move, and therefore the contact angle of the bearing inner ring and the bearing outer ring can beadjusted, and the effect of adjusting the pre-tightening force of the bearing is achieved. Meanwhile, an optimal adaptation data table of different materials and pre-tightening force is established in advance, the pre-tightening force which most adapts to the material can be automatically selected based on the material of a to-be-machined workpiece, and the pre-tightening operation of the bearingis automatically completed, and thus the magnitude of the pre-tightening force of the bearing can be matched with the type of a machined plate. Besides, the method and the system provided by the invention can judge the actual abrasion condition of the bearing by detection of the movement distance of the bearing outer ring and the current pre-tightening force of the bearing and combination with the theoretical relation between the position of the bearing outer ring and the pre-tightening force of the bearing; and the oil supply amount can be properly corrected based on the abrasion condition of the bearing so as to make up the influence caused by long-term abrasion of the bearing.

Owner:SHENYANG JIANZHU UNIVERSITY

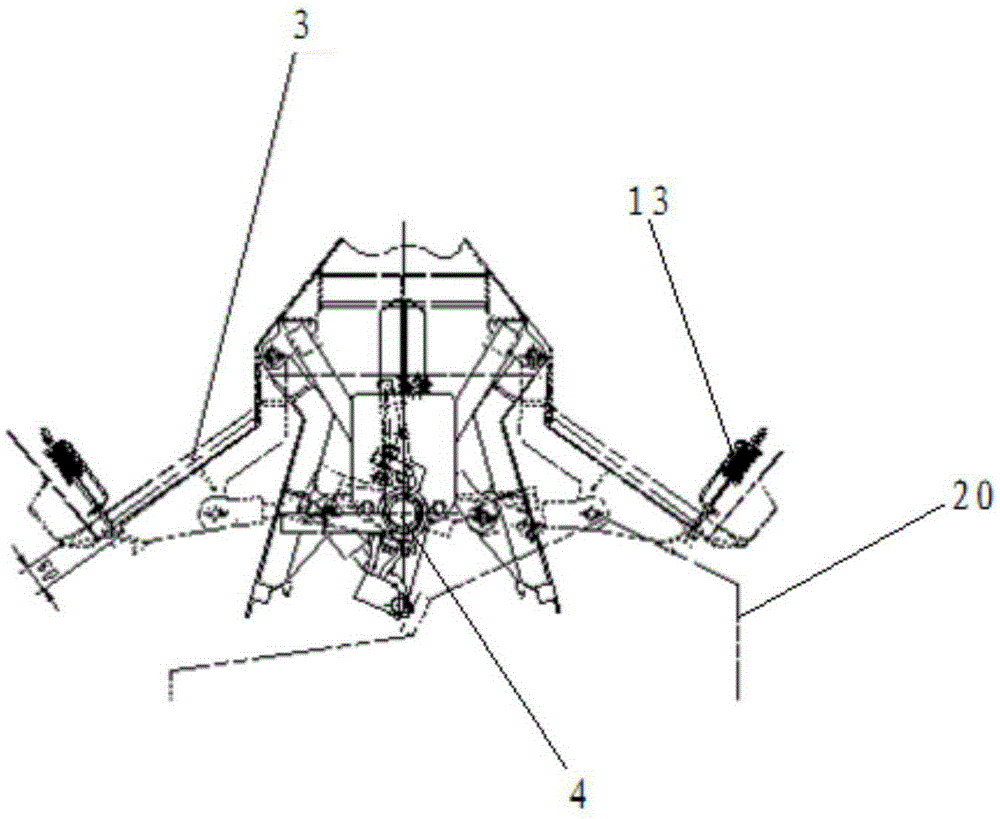

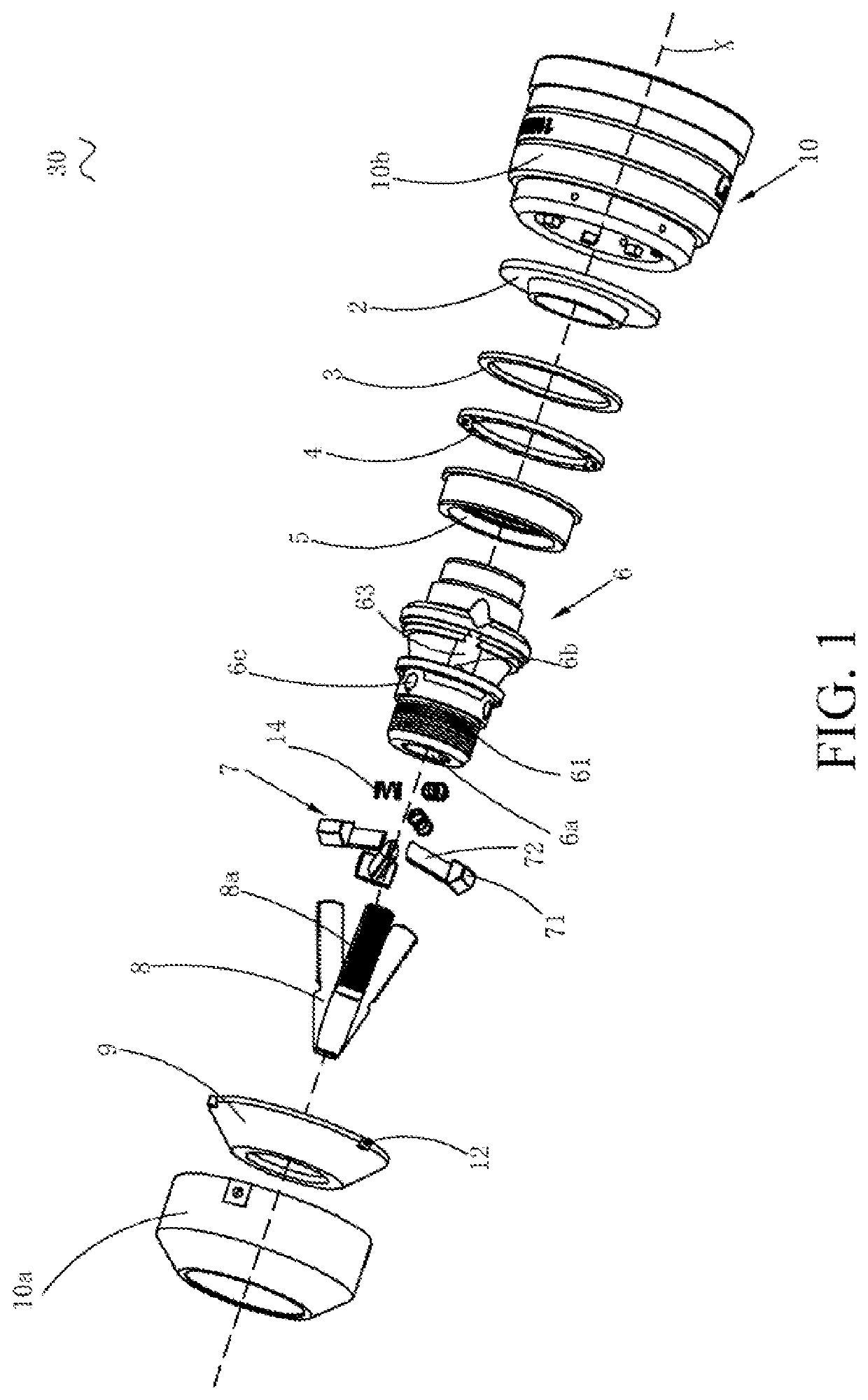

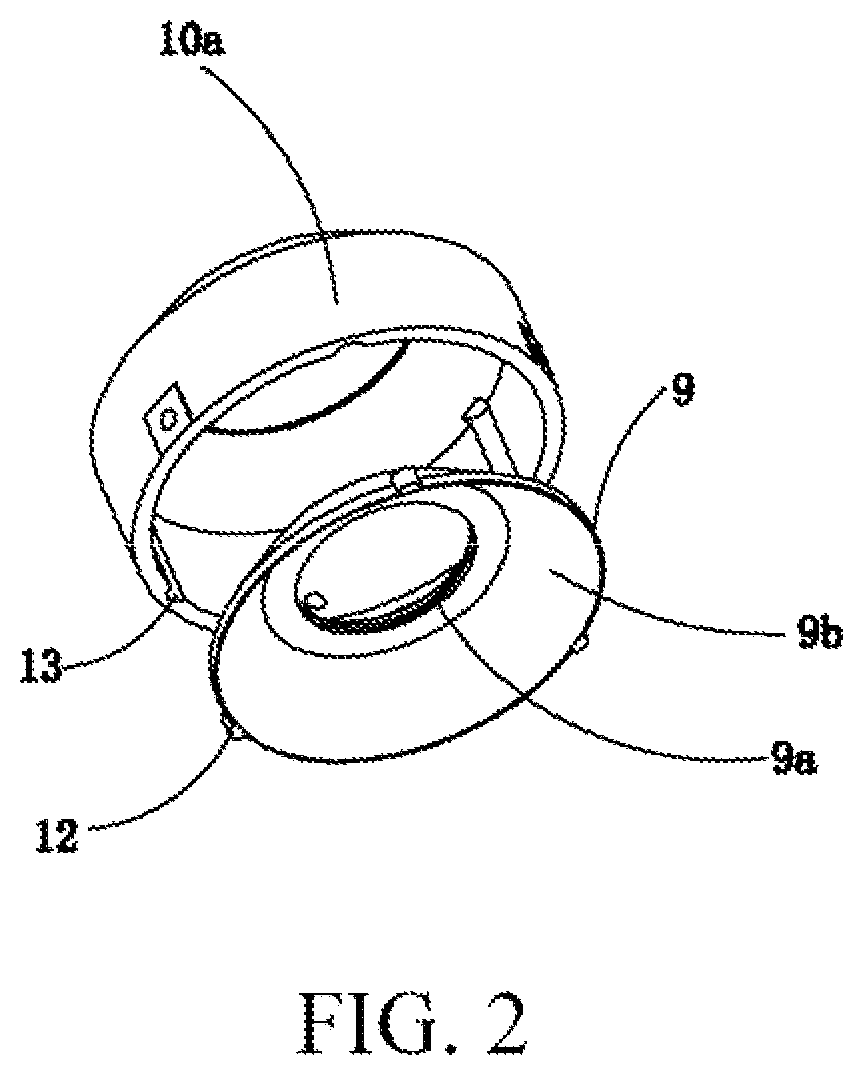

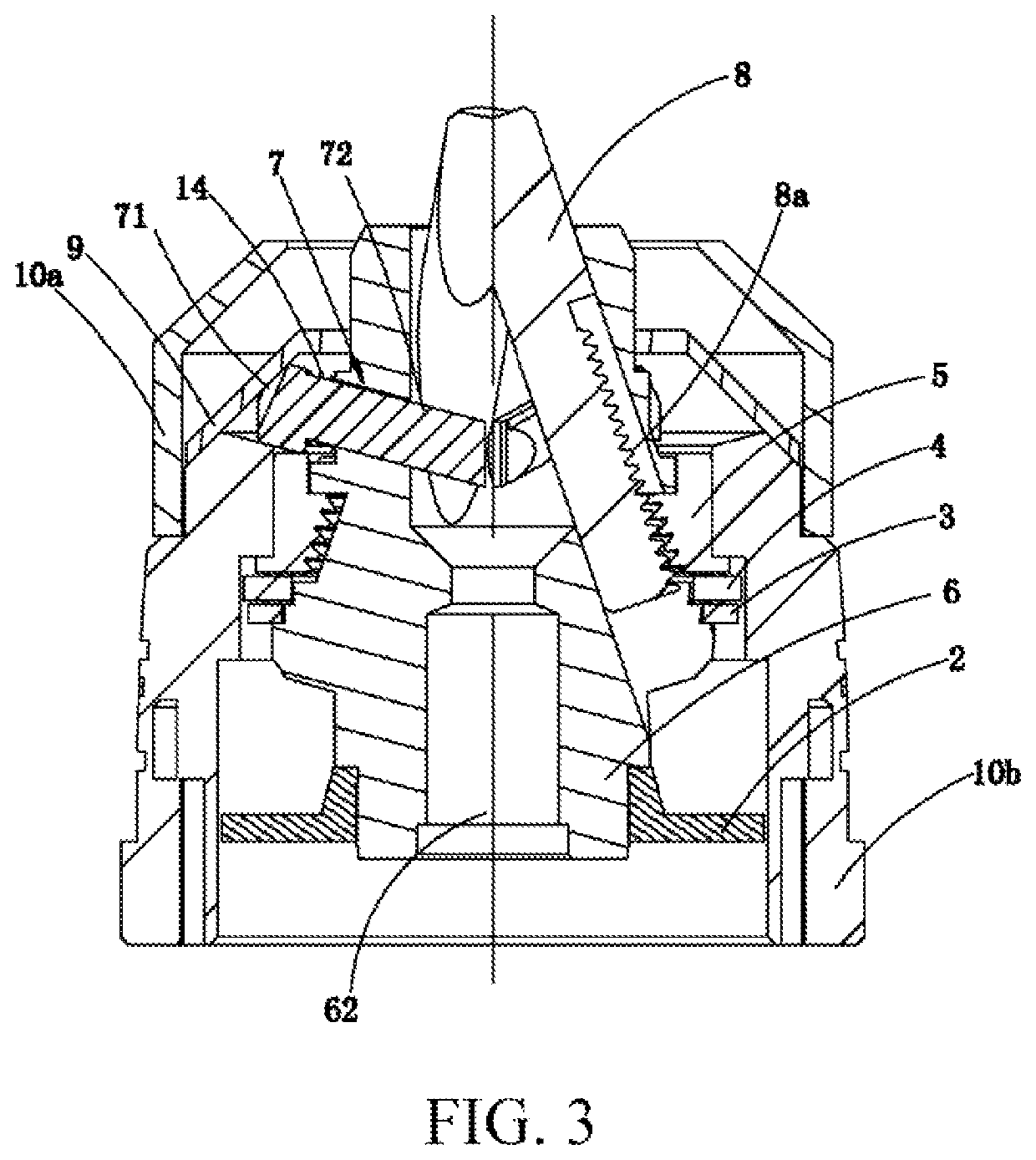

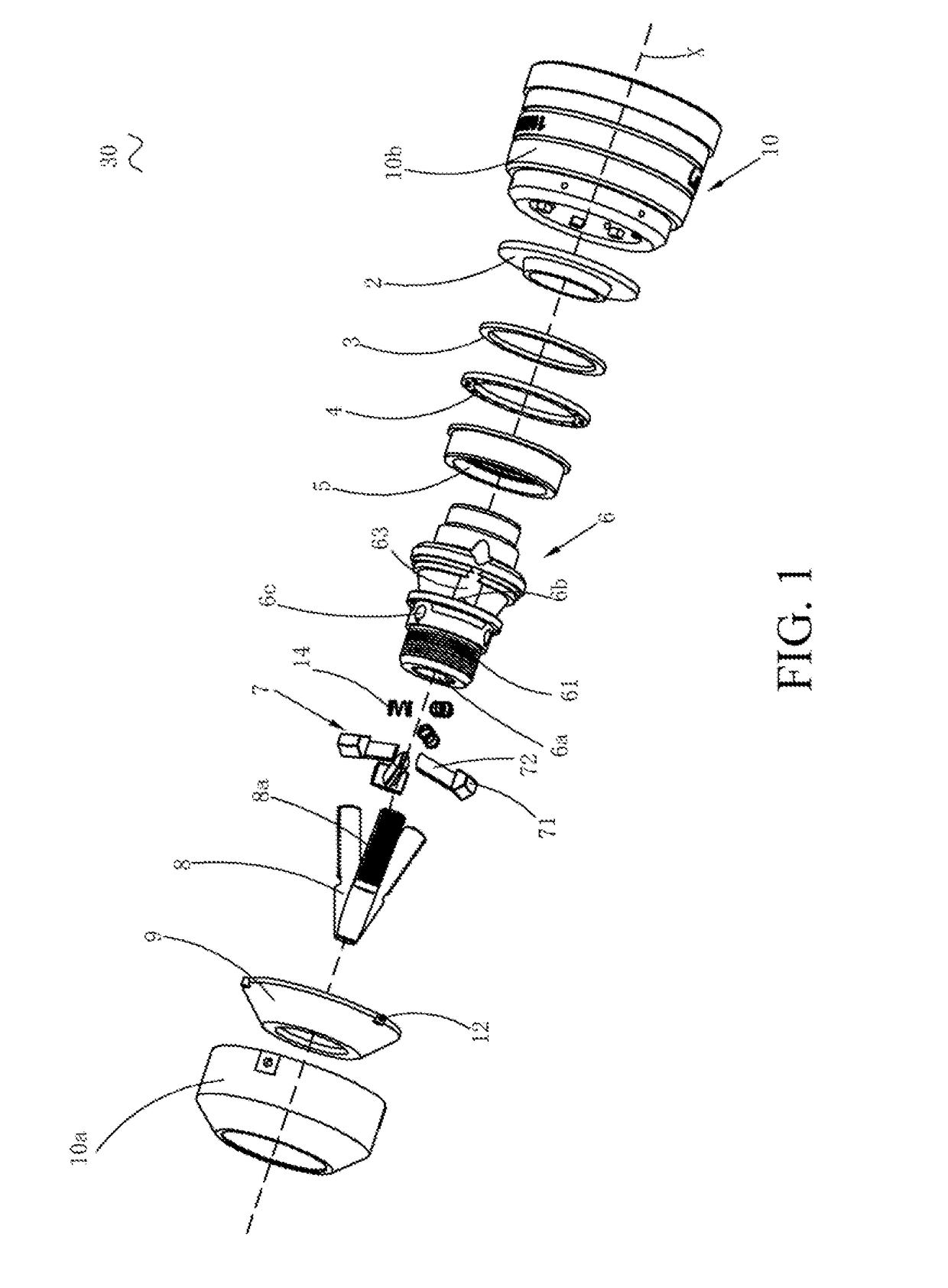

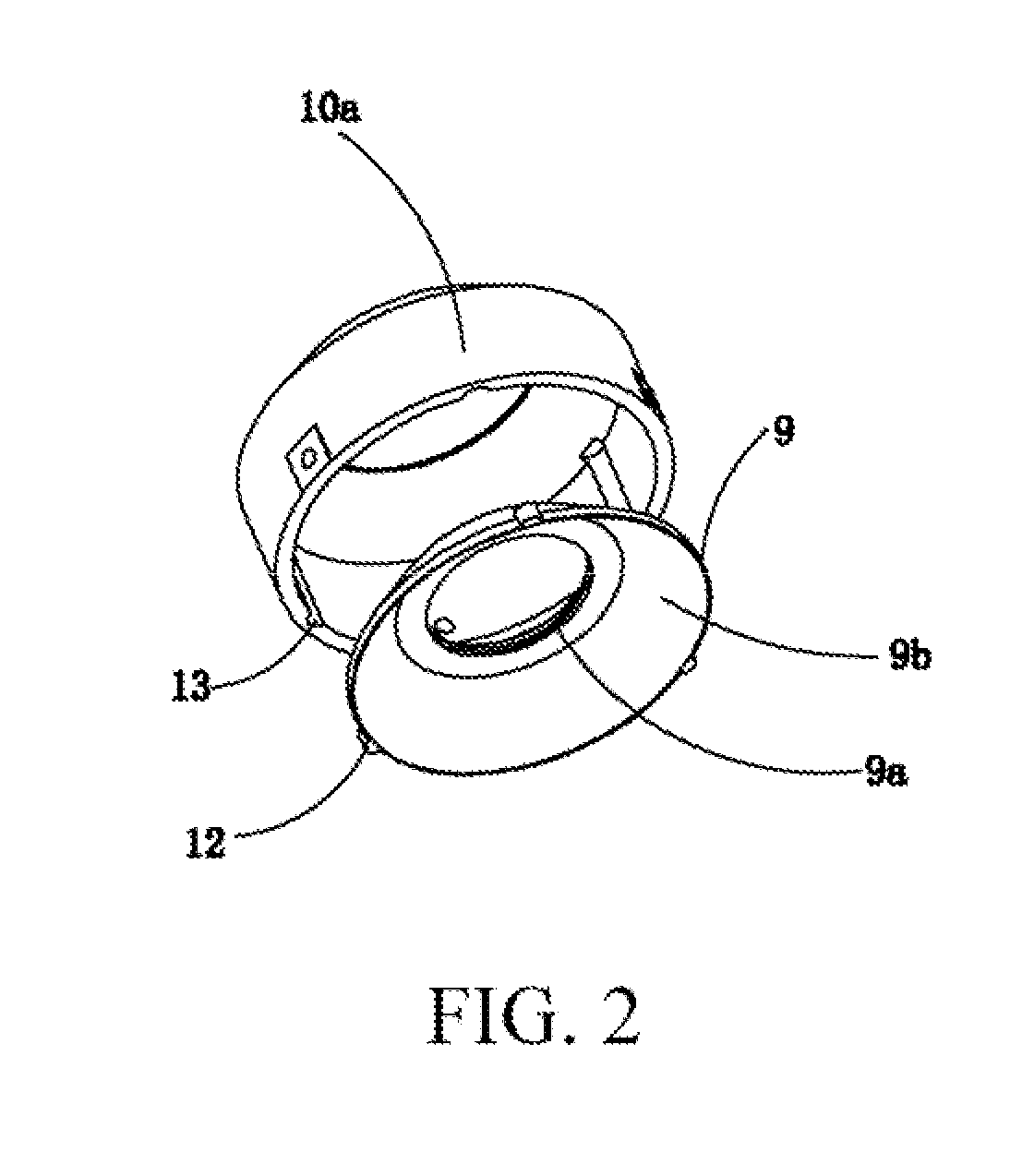

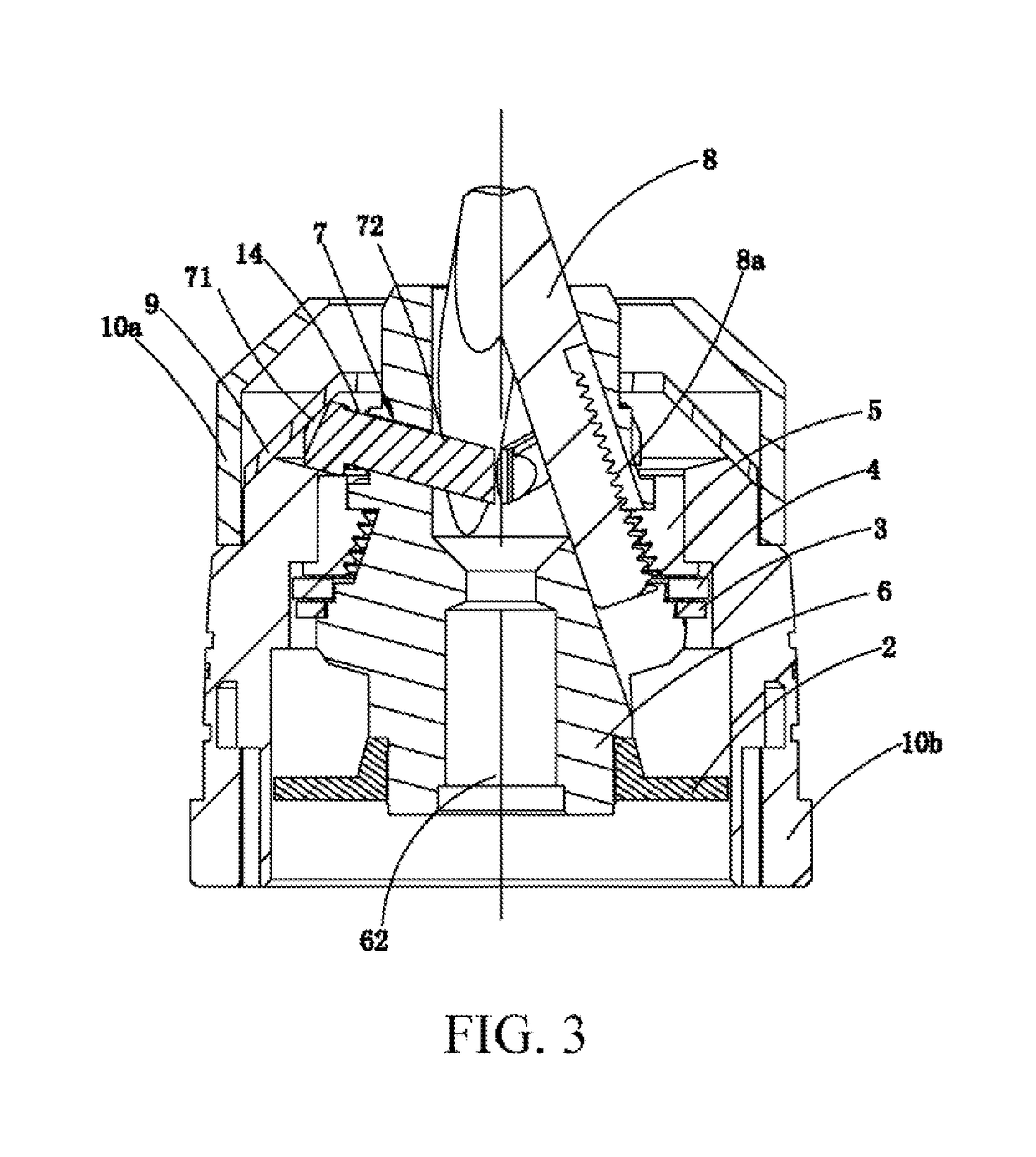

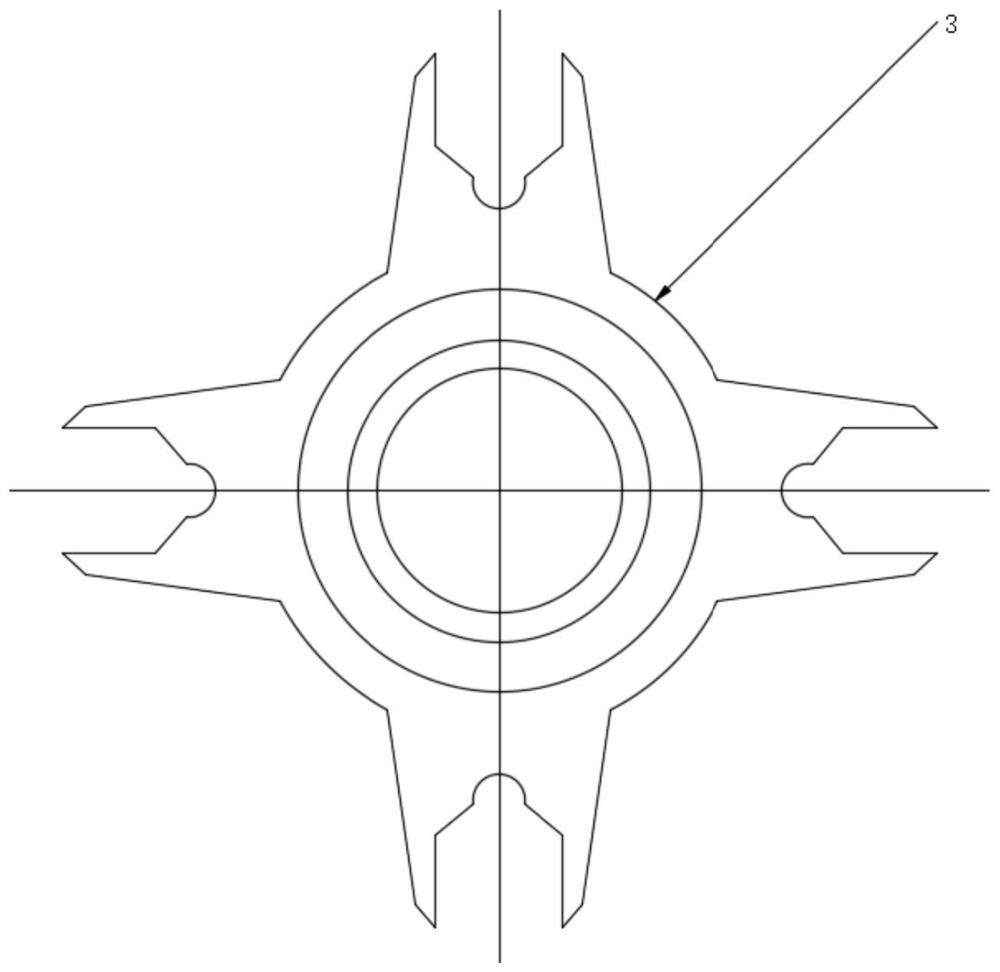

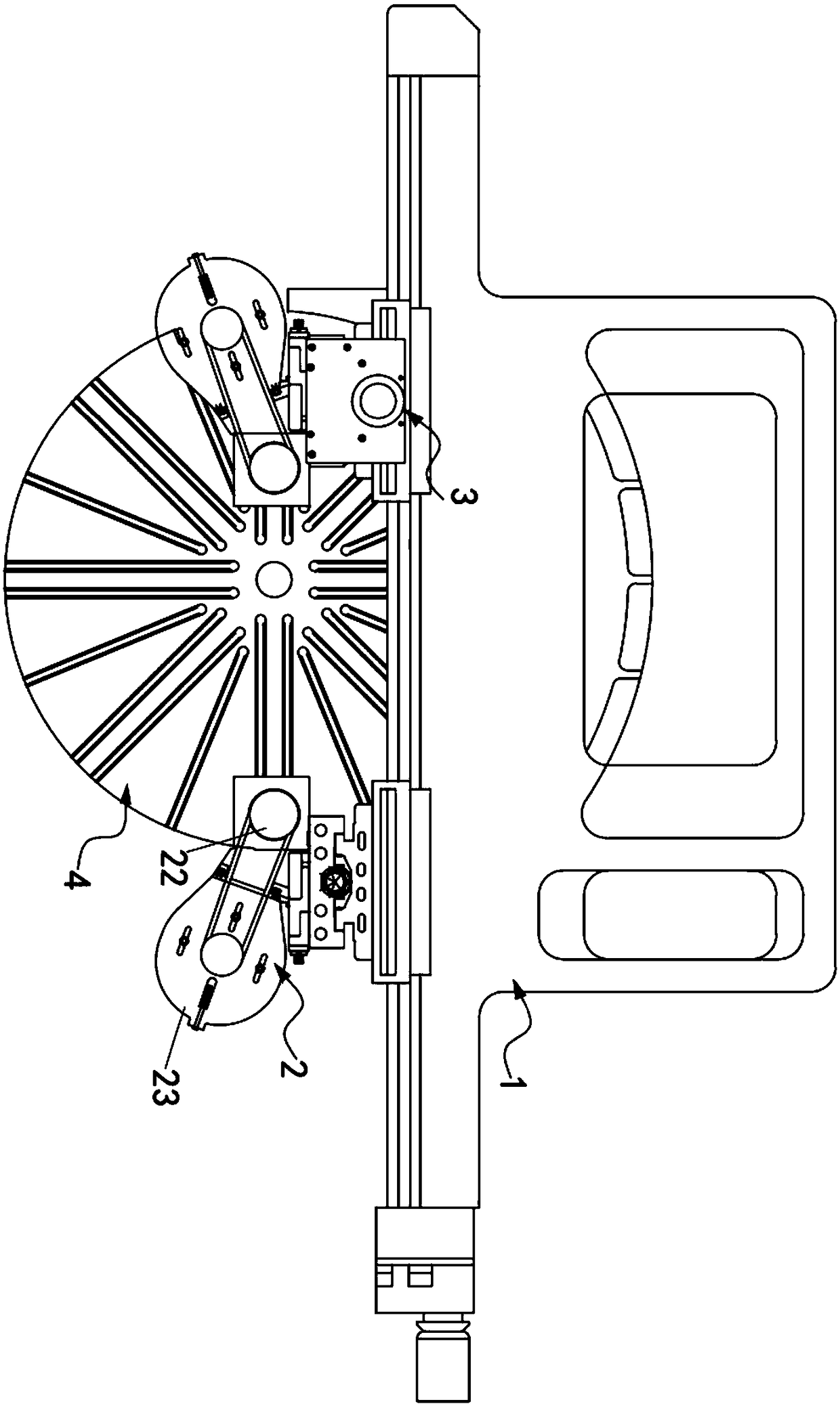

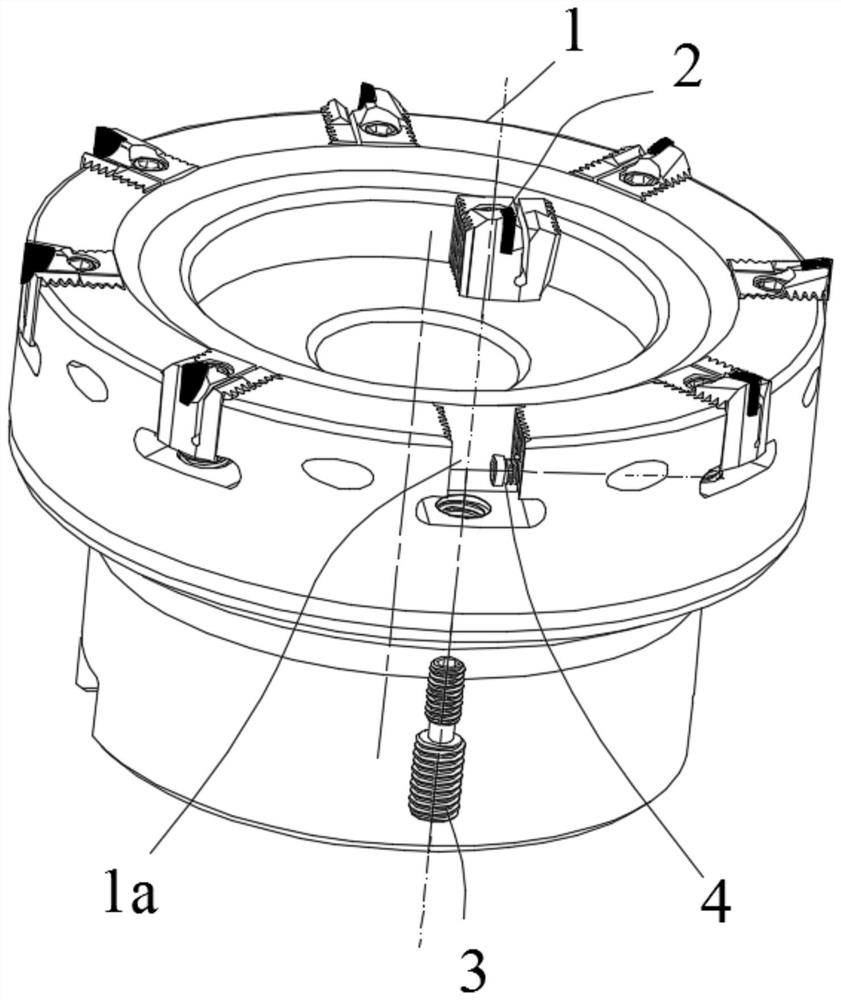

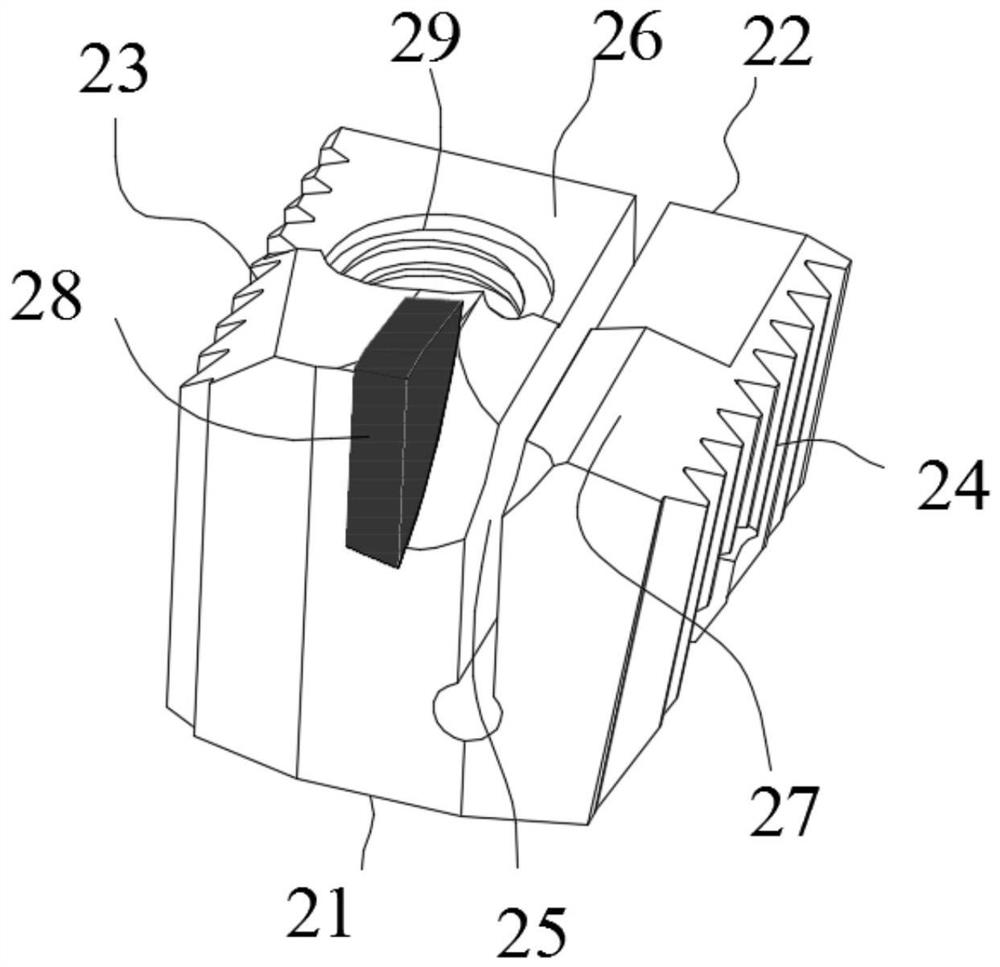

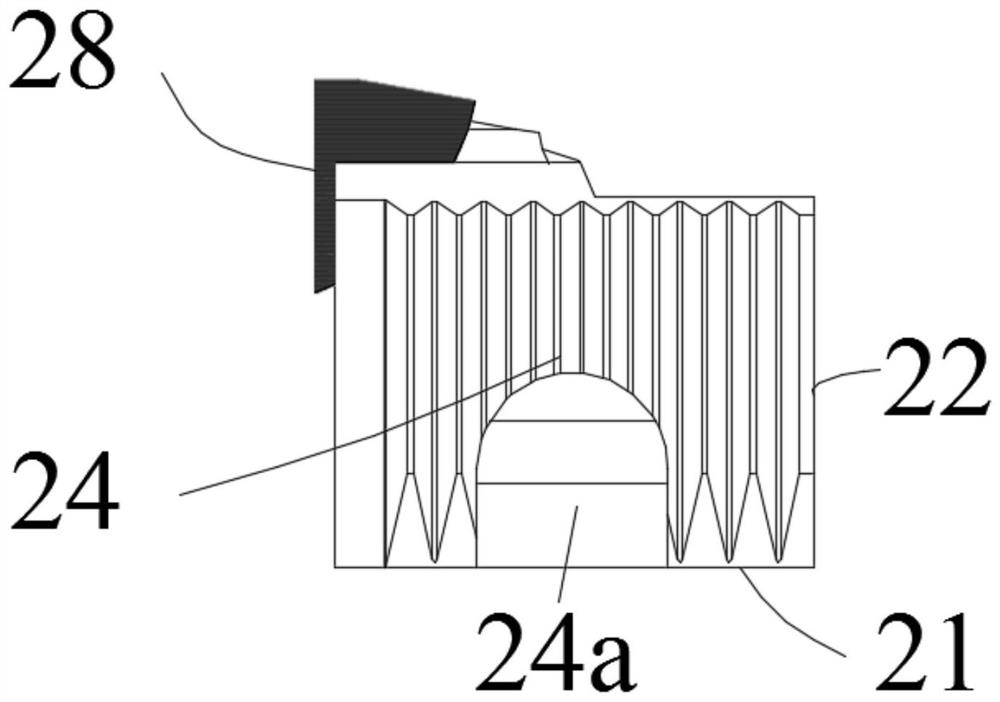

Chuck

ActiveUS10632544B2Simple and safe operationEffect is precise and reliableSleeve/socket jointsChucksEngineeringRelative motion

The invention relates to a chuck having a sleeve, a chuck body, a plurality of chuck jaws, an adjusting mechanism configured to adjust relative movement between the chuck jaws and the chuck body, at least one locating member and a pushing mechanism. The locating member is disposed on the chuck body between the adjacent chuck jaws. When the adjusting mechanism drives the chuck jaws to approach to each other relative to the longitudinal axis, the pushing mechanism pushes the locating member to move towards the longitudinal axis. When the adjusting mechanism drives the chuck jaws to move away from each other relative to the longitudinal axis, the pushing mechanism pushes the locating member to move away from the longitudinal axis. Therefore, the operation is more convenient and safer; the aligning effect is precise and reliable, and the pre-tightening force is stable.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

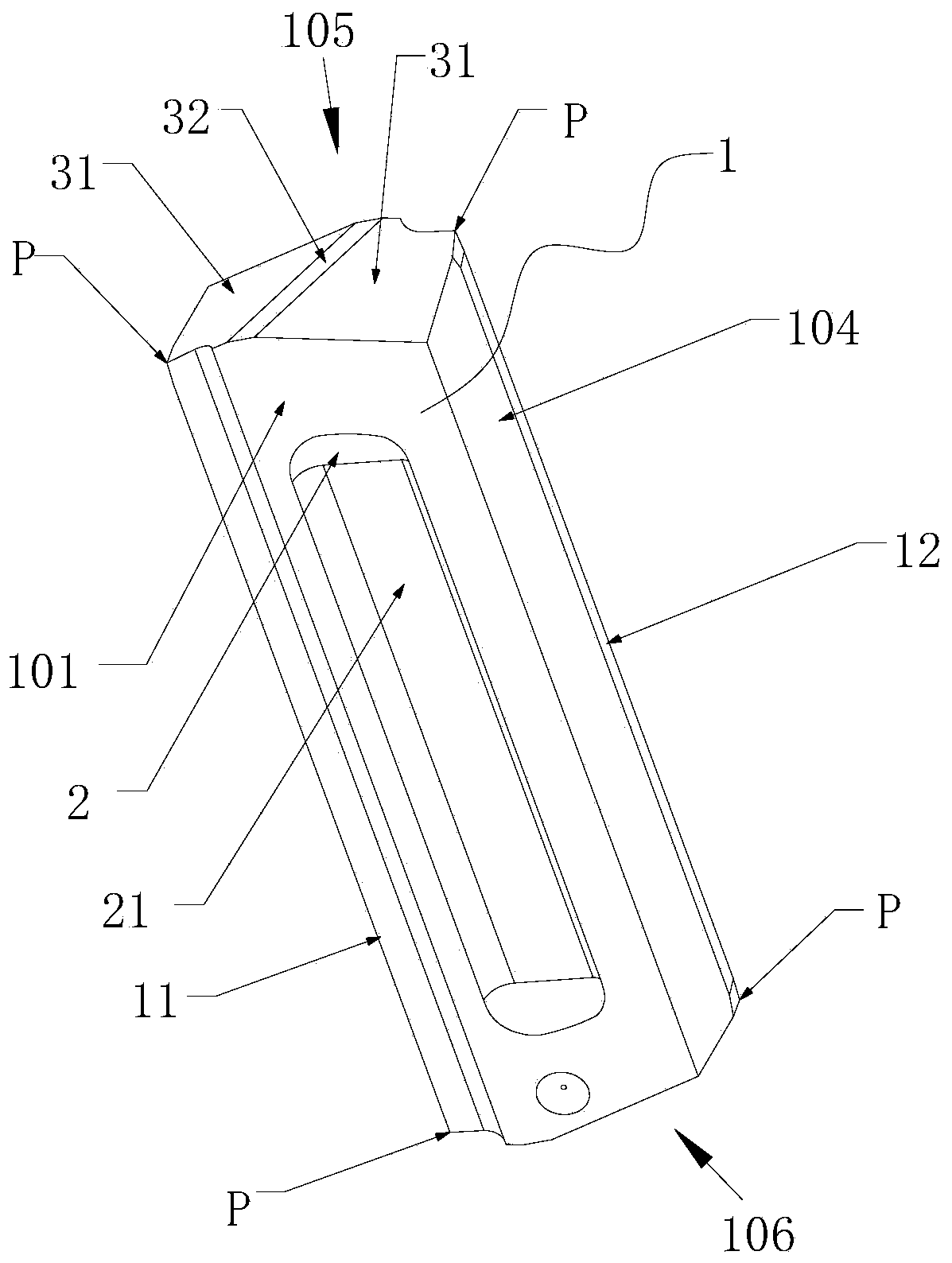

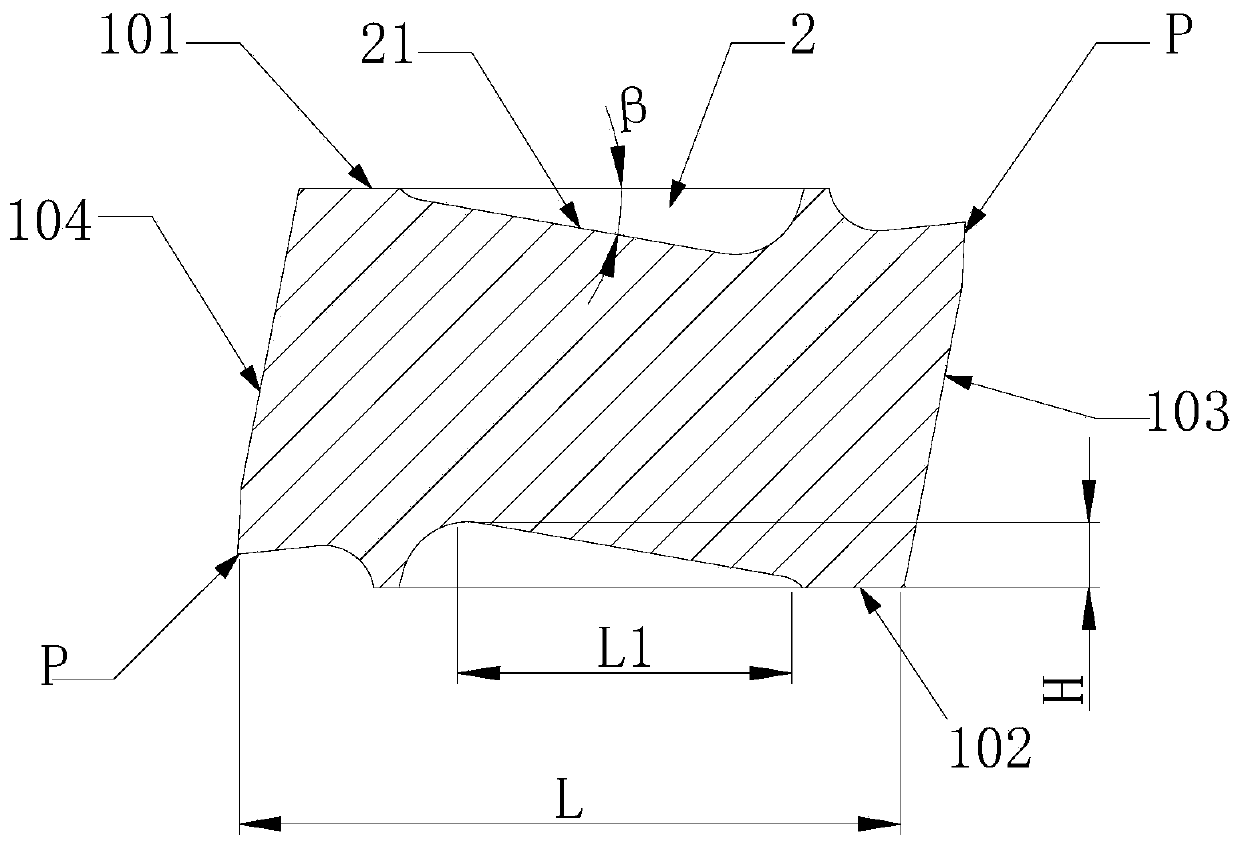

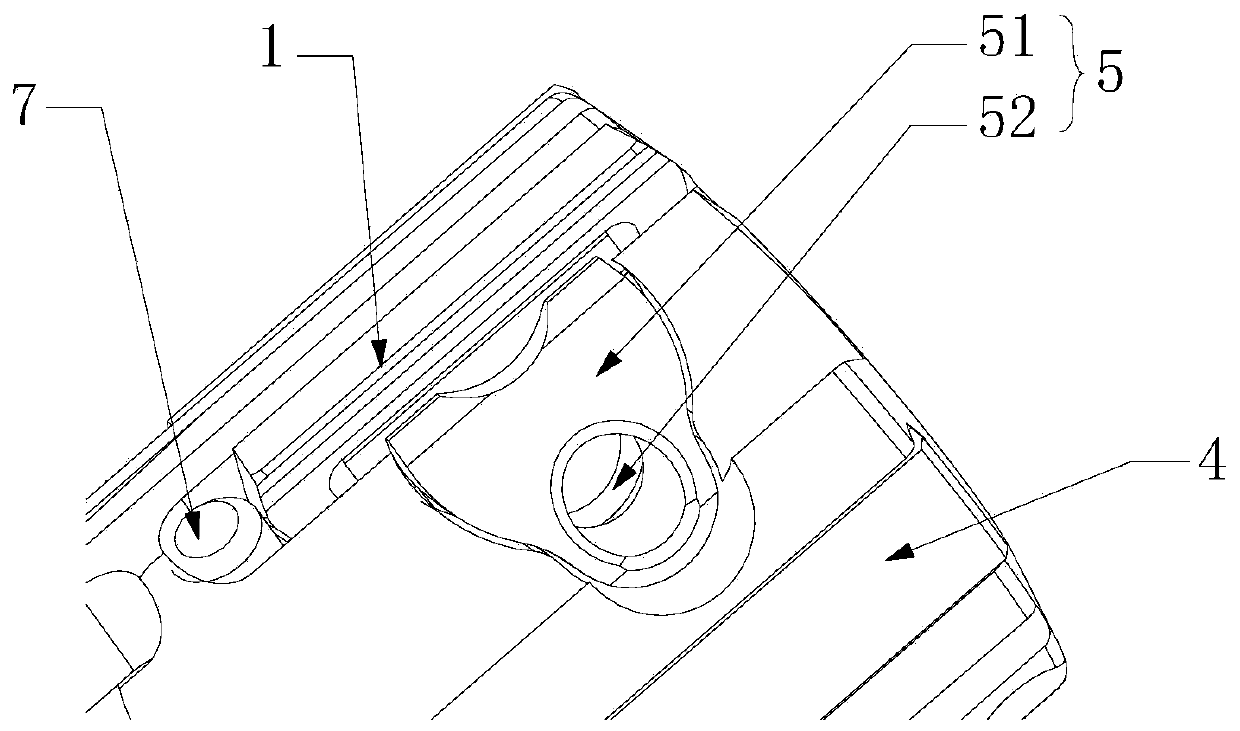

Cutting insert and cutting tool with adjustable structure

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Lateral pressure spiral spring and sealing ring with same

InactiveCN102494067BStable preloadEffective stress compensationEngine sealsSpringsEngineeringBreaking point

The invention provides a lateral pressure spiral spring which is formed by rotating and bending a cylindrical body wound by using linear materials, wherein the axis of the cylindrical body is a central line of the spring, and basic parameters include a material linear diameter, an external diameter of the spring and a spiral angle; and the cylindrical body can be wounded into a cylinder or a ring shape connected end to end. The lateral pressure spiral spring is characterized in that the spiral angle is a variable. The front half circle of the spiral angle is a positive spiral angle, and the rear half circle of the spiral angle is a negative spiral angle; a transitional surface of break points of the spiral angle is formed between the front half circle and the rear half circle, and the absolute value of the positive spiral angle is larger than that of the negative spiral angle; and the spring is in a spiral raising structure as a whole. The spring can be applied to various mechanical application fields and particularly to the sealing field, is wide in stress range and can provide multidirectional stress compensation for elements, the stress compensation direction can be adjusted at any time along with the change of an external acting direction, and the spring can still provide enough stress compensation when pressure stress is not on the same horizontal surface but forms a certain angle with the horizontal surface.

Owner:上海大亚密封技术有限公司

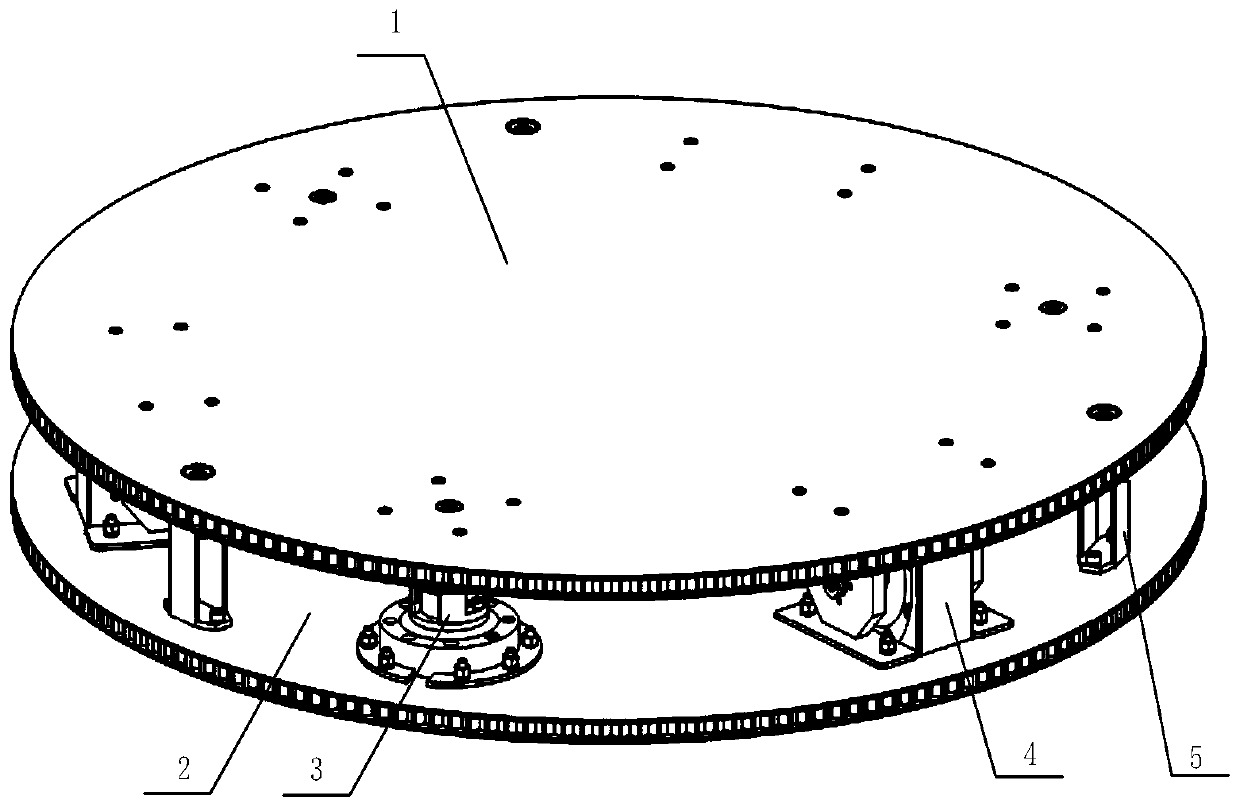

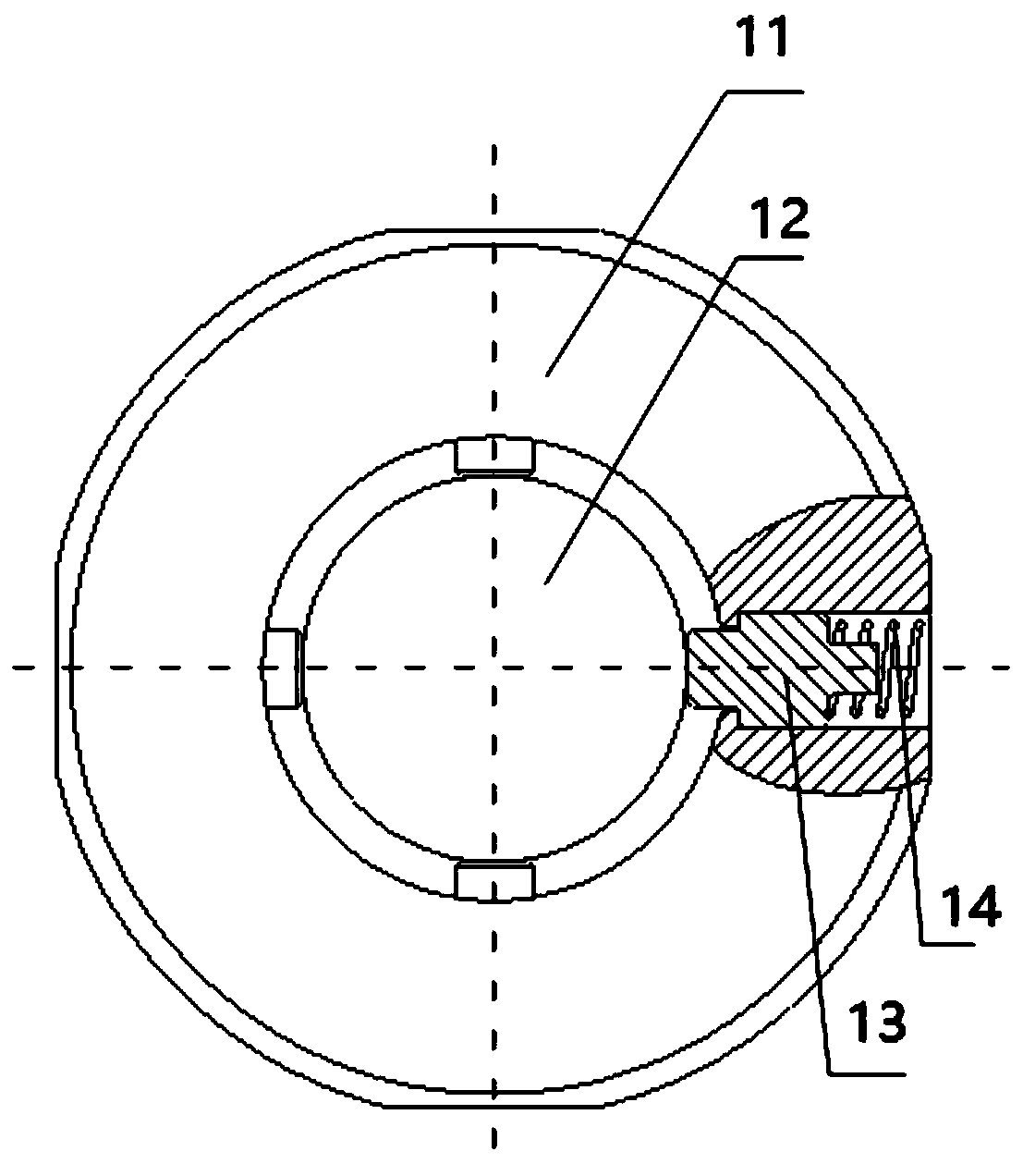

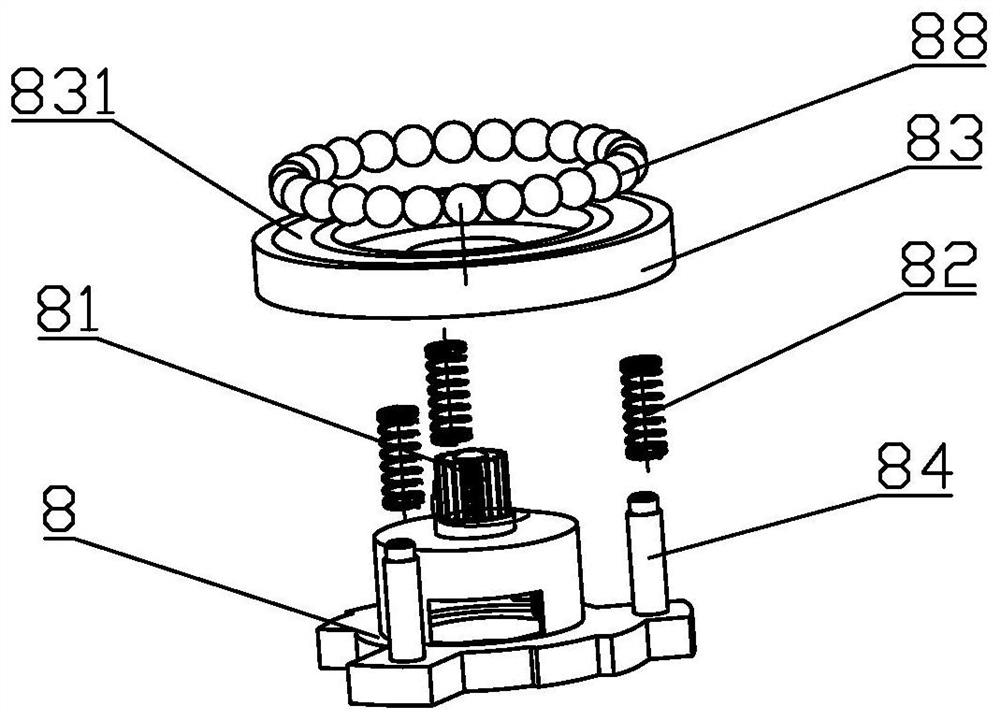

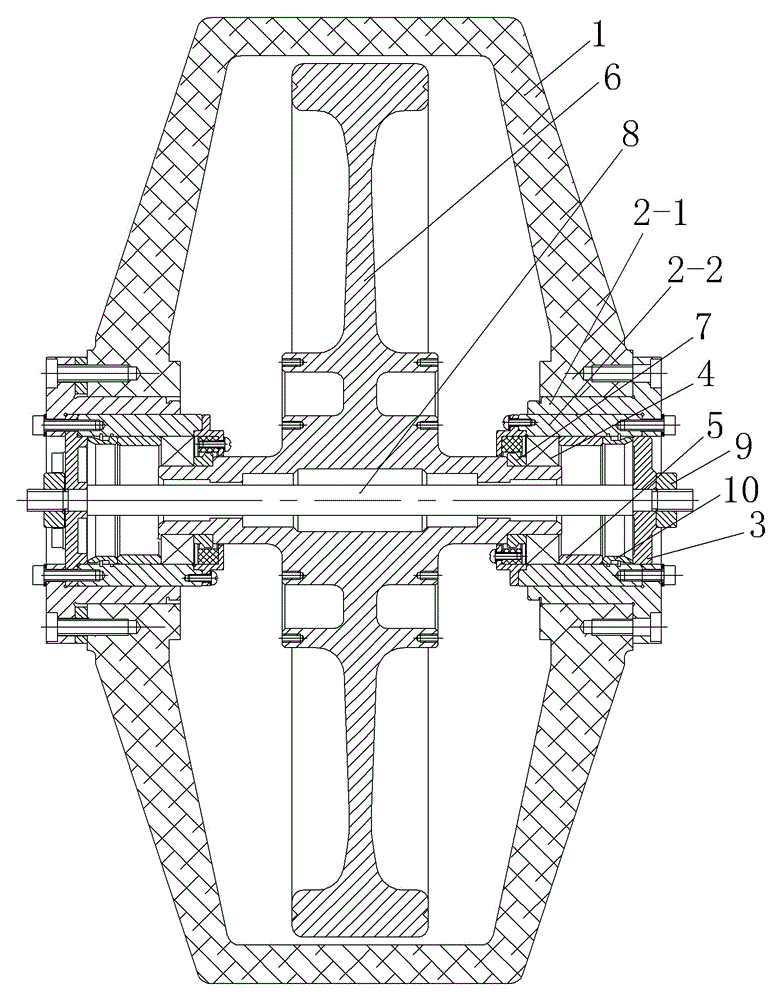

Six-dimensional force measuring platform with mosaic self-centering decoupled force measuring branches

ActiveCN109029818BThe difficulty of processing and manufacturing process is reducedLow costMeasurement of force componentsEngineeringSteel ball

The invention discloses a six-dimensional dynamometry platform with an embedded self-aligning decoupling dynamometry branch. The six-dimensional dynamometry platform comprises a first platform, a second platform, three embedded self-aligning vertical decoupling dynamometry branches, three embedded self-aligning horizontal decoupling dynamometry branches and three support frames. The first platformand the second platform are circular and are made by processing honeycomb aluminium plates. The embedded self-aligning vertical decoupling dynamometry branches, the embedded self-aligning horizontaldecoupling dynamometry branches and the support frames are mounted between the first platform and the second platform in a staggered mode. According to the six-dimensional dynamometry platform, aligning positioning of upper and lower steel balls and side dynamometry decoupling of tension-compression bidirectional dynamometry are realized; difficulty of a processing technology of the dynamometry branches is reduced; mounting and debugging are simple; cost is low; tension-compression pretightening force is adjusted through adjustment of gasket thickness; and continuous measurement precision of the dynamometry platform is ensured.

Owner:YANSHAN UNIV

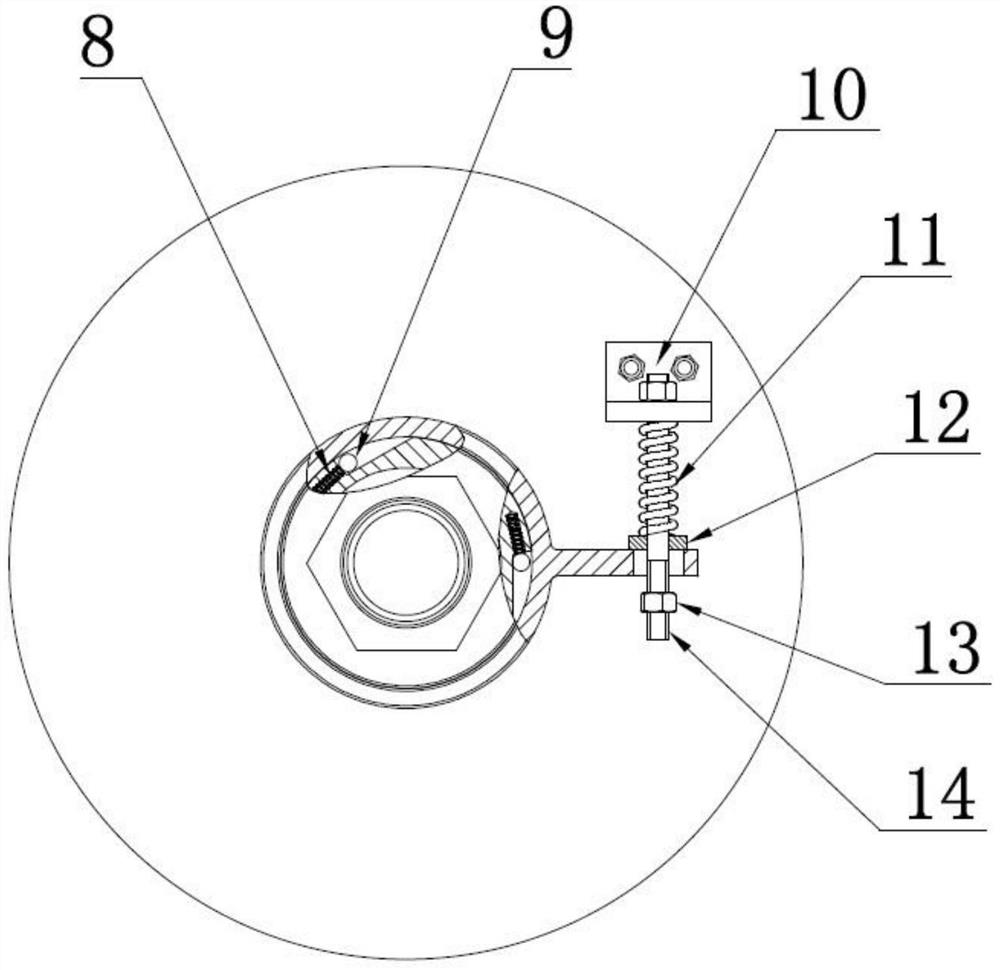

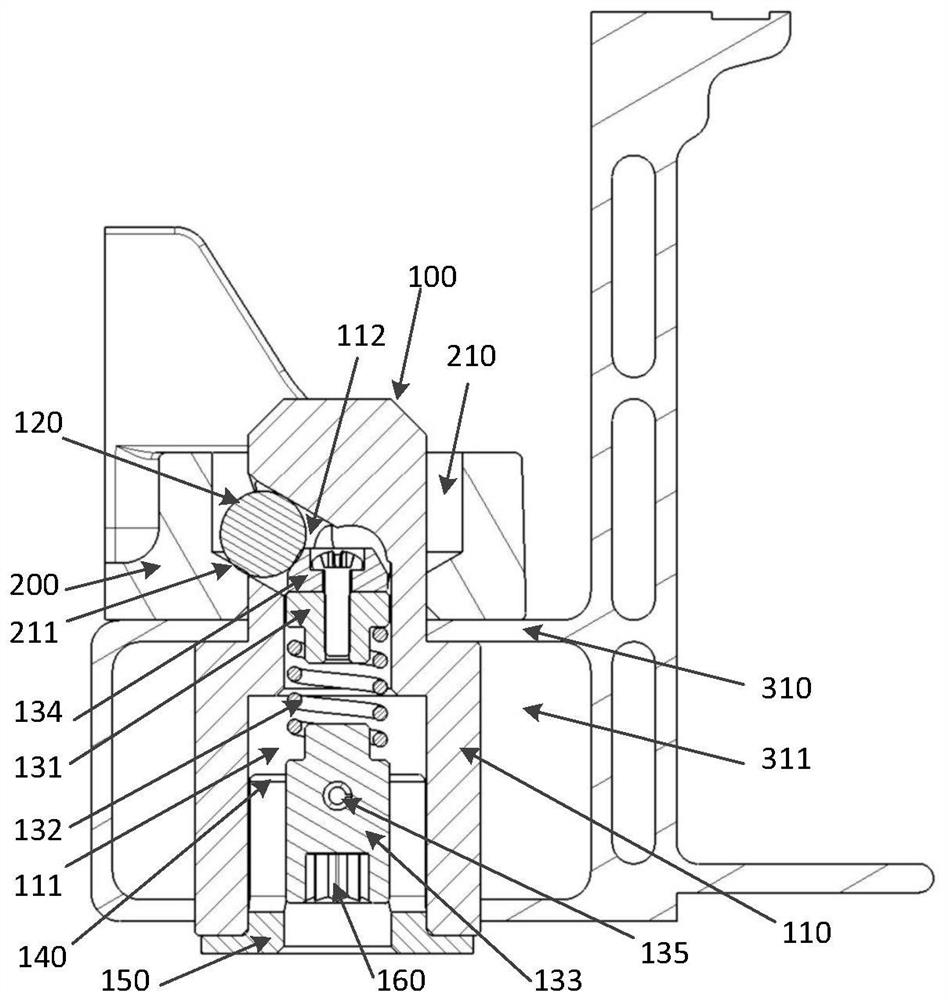

Shaft end sealing mechanism

ActiveCN111237463AImprove sealingExtended service lifeEngine sealsStructural engineeringMechanical engineering

The invention discloses a shaft end sealing mechanism. The shaft end sealing mechanism comprises an equipment end plate, a sealing base, a lock nut and a compression sleeve, wherein the sealing base is arranged on the equipment end plate; a rotating shaft is arranged inside the sealing base in a matching way; a sealing material is arranged between the inner cavity of the sealing base and the rotating shaft; the lock nut is arranged on the sealing base; the compression sleeve is arranged on the rotating shaft and is positioned between the sealing material and the lock nut; the lock nut is rotated to drive the rotating shaft to move upwards along the sealing base; and the sealing material is extruded and tensioned by the compression sleeve to realize a shaft end sealing function. According to the shaft end sealing mechanism, an integral spiral pre-tightening structure is adopted together with a ball-type one-way non-return structure, so that rapid pre-tightening and timely locking can berealized by only rotating the lock nut. The tensioning system can keep stable pre-tightening force, and has an automatic compensation function, so that the service life of the sealing material is prolonged greatly.

Owner:FAMSUN CO LTD

A shaft end sealing mechanism

Owner:FAMSUN CO LTD

Chuck

ActiveUS20180369928A1Simple and safe operationEffect is precise and reliableSleeve/socket jointsChucksEngineeringMechanical engineering

The invention relates to a chuck having a sleeve, a chuck body, a plurality of chuck jaws, an adjusting mechanism configured to adjust relative movement between the chuck jaws and the chuck body, at least one locating member and a pushing mechanism. The locating member is disposed on the chuck body between the adjacent chuck jaws. When the adjusting mechanism drives the chuck jaws to approach to each other relative to the longitudinal axis, the pushing mechanism pushes the locating member to move towards the longitudinal axis. When the adjusting mechanism drives the chuck jaws to move away from each other relative to the longitudinal axis, the pushing mechanism pushes the locating member to move away from the longitudinal axis. Therefore, the operation is more convenient and safer; the aligning effect is precise and reliable, and the pre-tightening force is stable.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

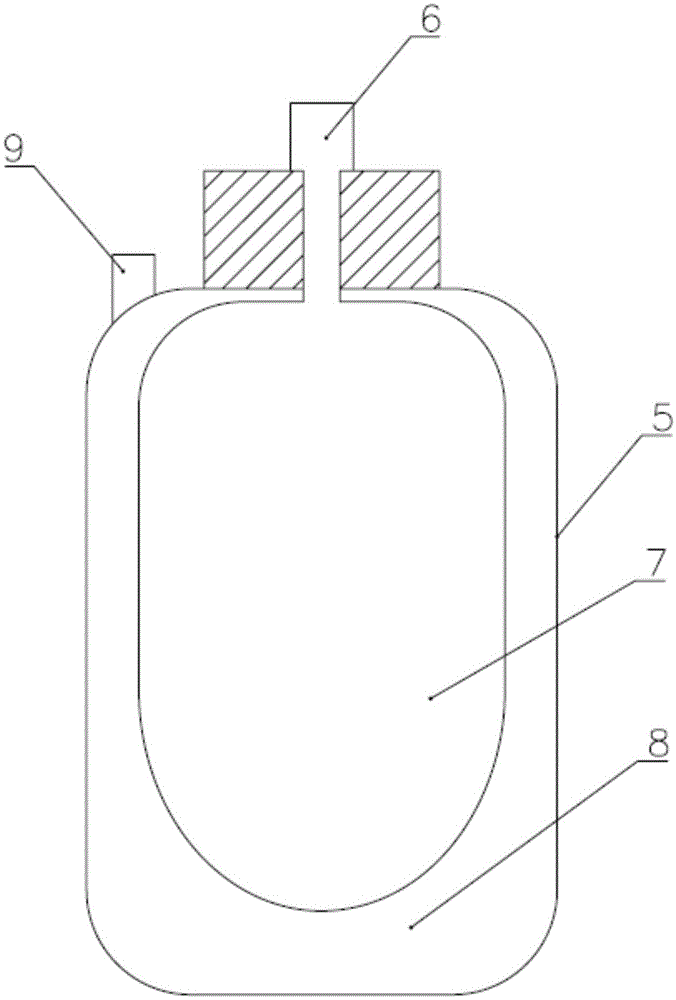

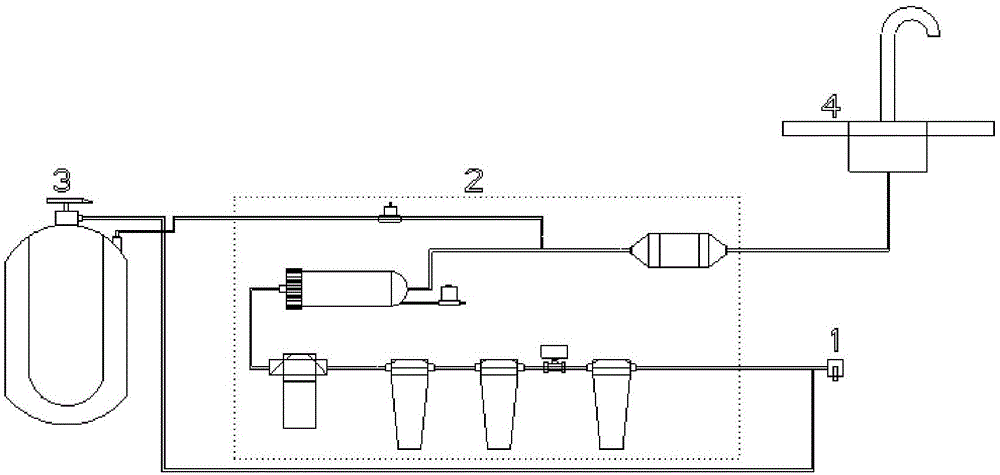

Water purifier

InactiveCN105060370ASimple structureIncrease usable volumeWater/sewage treatmentTap waterFilter system

The invention provides a water purifier. The water purifier comprises a pressure stabilizing valve, a filter system, a safe pressure barrel and a water faucet, wherein the pressure stabilizing valve, the safe pressure barrel and the filter system are sequentially communicated, and the filter system is further communicated with the water faucet; the safe pressure barrel comprises a casing, a water inlet and outlet joint, a water storage liner, a prepressing cavity and a tap water outlet and inlet joint, the water inlet and outlet joint is arranged at the upper end of the casing, the tap water outlet and inlet joint is arranged on one side of the casing, the water storage liner is arranged in the casing, the water inlet and outlet joint is connected with the water storage liner, the prepressing cavity is formed between the inner wall of the casing and the outer wall of the water storage liner and communicated with the tap water outlet and inlet joint, the water inlet and outlet joint is communicated with the filter system, and the tap water outlet and inlet joint is communicated with the pressure stabilizing valve. According to the water purifier, the potential safety hazards caused by air leakage, air addition and compressed air explosion in complex technology of a production process as well as in the use process are avoided, and the available volume of water storage of the pressure barrel is greatly increased.

Owner:NINGBO PUER WATER PURIFICATION TECH CO LTD

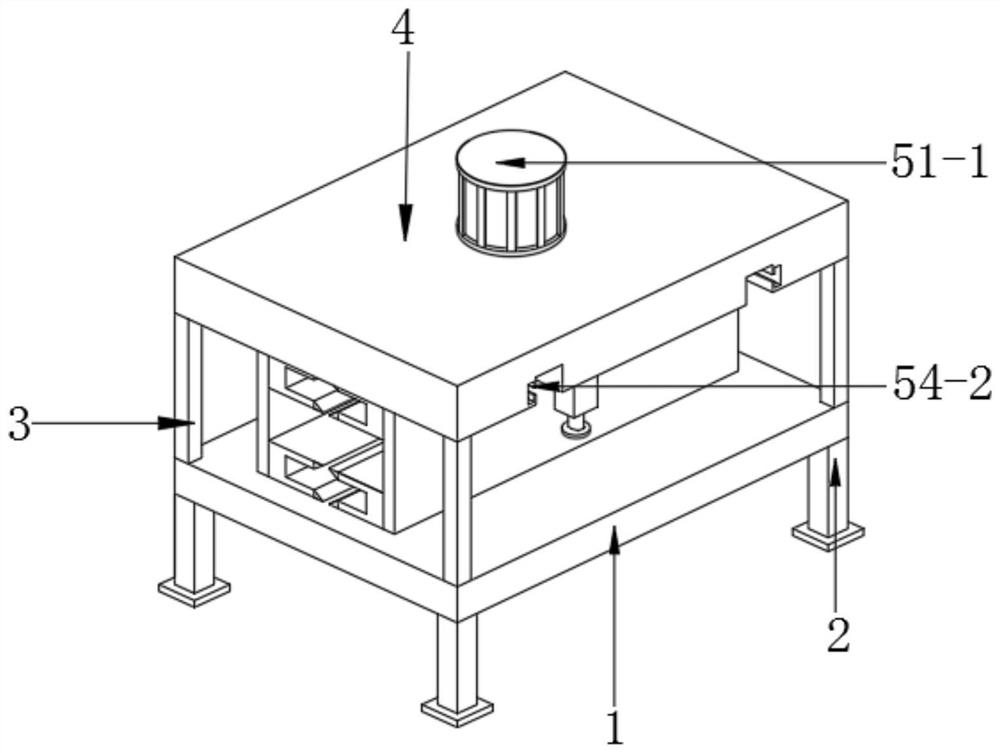

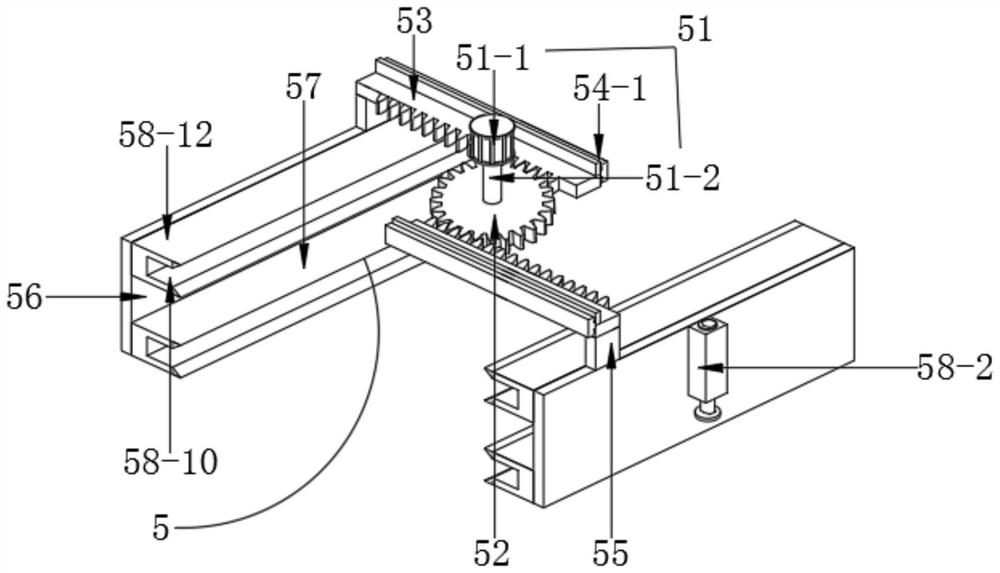

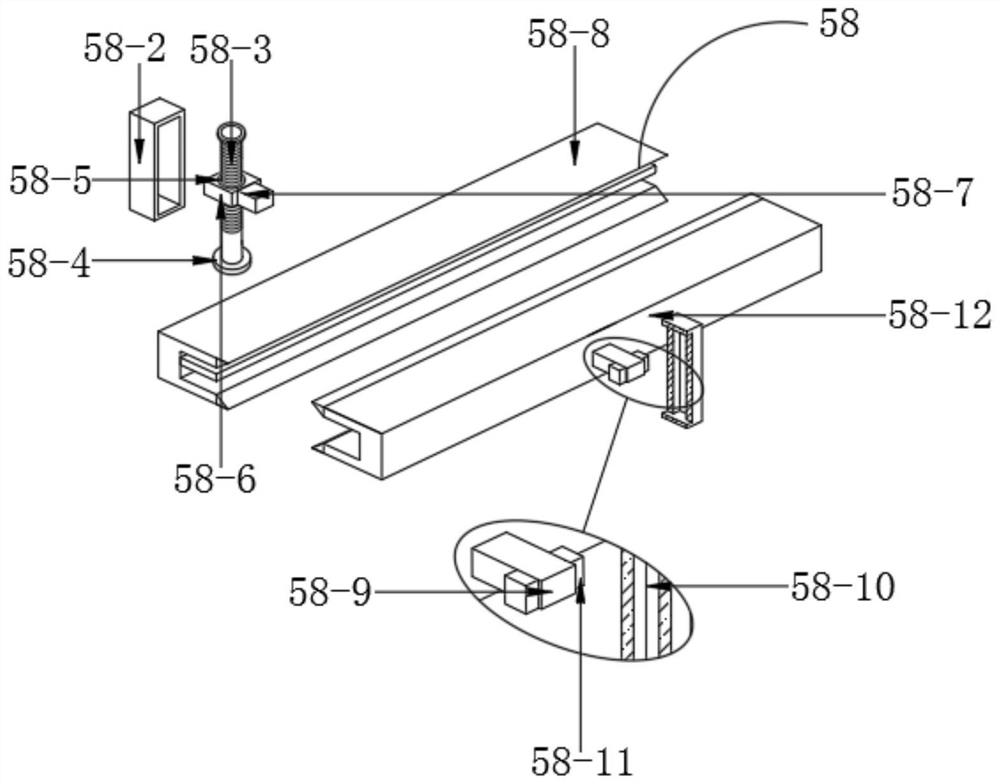

Hollow glass processing assembly line and processing technology thereof

PendingCN114856384APrecise positioningImprove stabilityDoors/windowsClimate change adaptationGear wheelElectric machinery

The hollow glass processing assembly line comprises a workbench, a base is fixedly connected to the bottom of the workbench, supporting frames are fixedly connected to the opposite angles of the top of the workbench, a control box is fixedly connected between the top ends of the supporting frames, and a pre-assembling mechanism is arranged in the control box; the preassembling mechanism comprises a transmission gear and a transmission rack which are driven by a driving assembly. The invention relates to the technical field of glass processing. According to the hollow glass processing assembly line and the processing technology thereof, the preassembling mechanism is arranged, and a driving motor in a driving assembly is used for driving a transmission gear and a driving rotating shaft to rotate, so that a transmission rack drives a first prepressing plate, a second prepressing plate and a third prepressing plate on a supporting plate to move, and glass needing to be assembled is prepressed; and therefore, the edge mounting operation is more convenient and accurate, and the machining efficiency is improved.

Owner:襄阳鑫军威玻璃有限公司

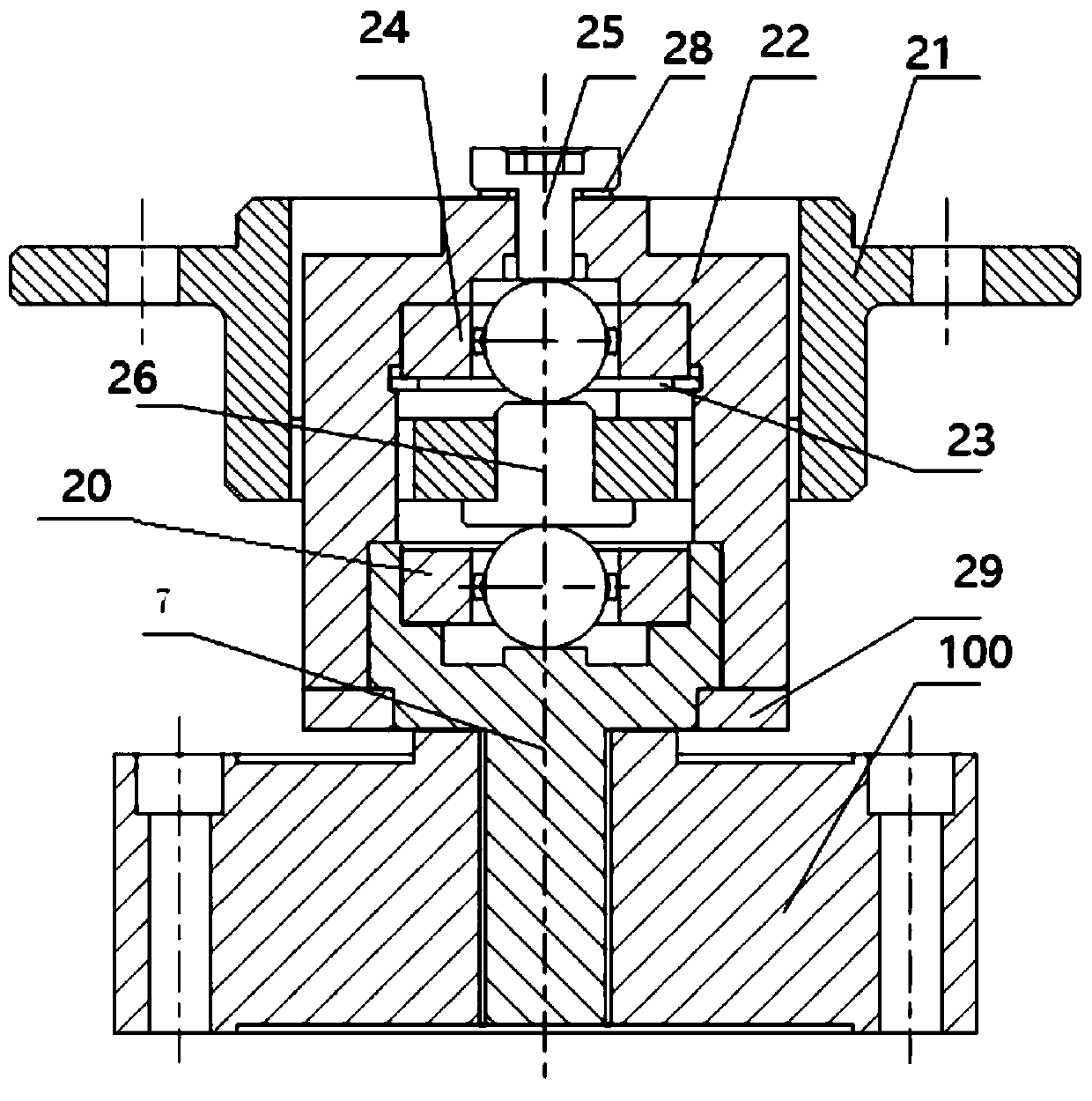

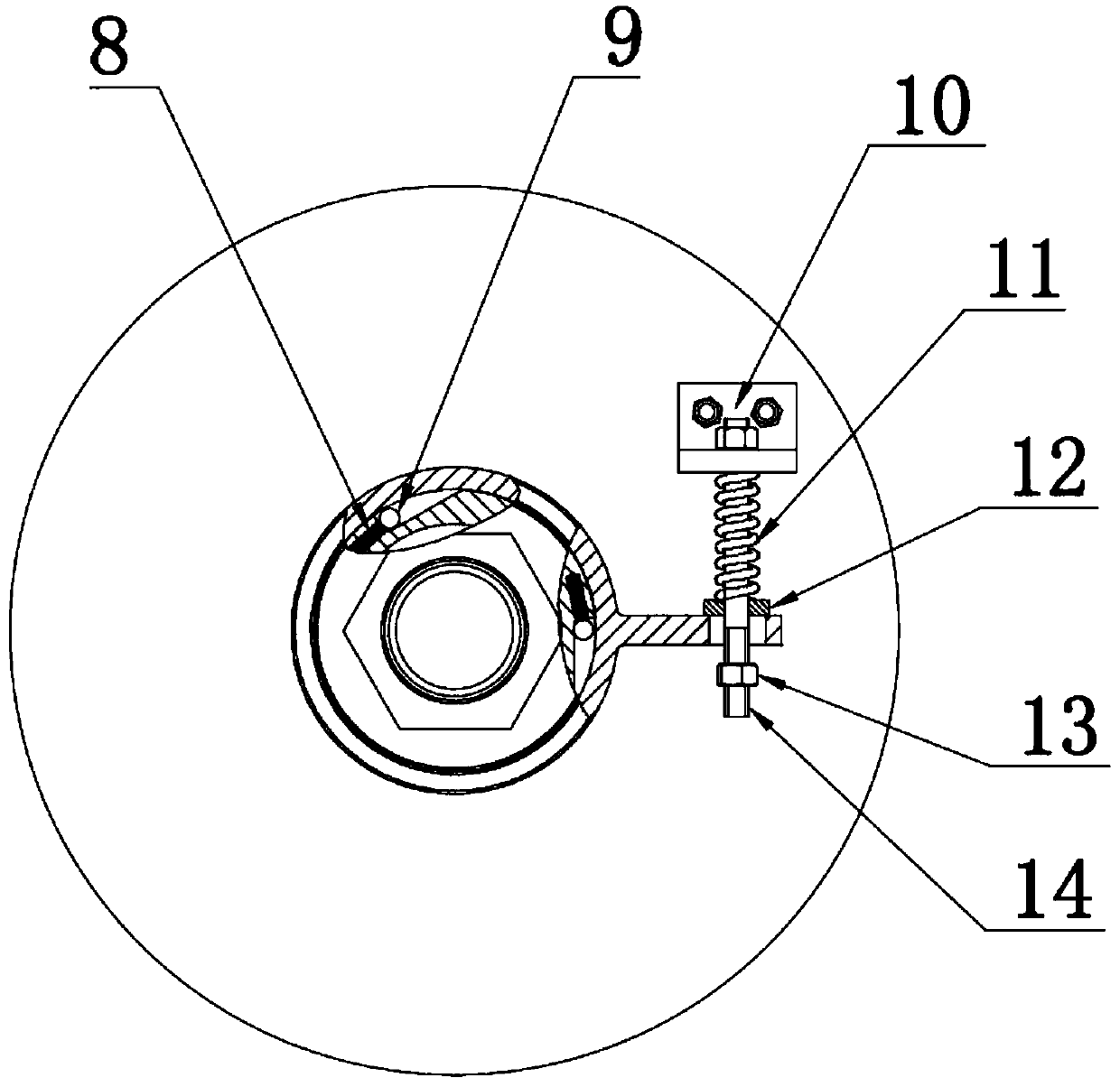

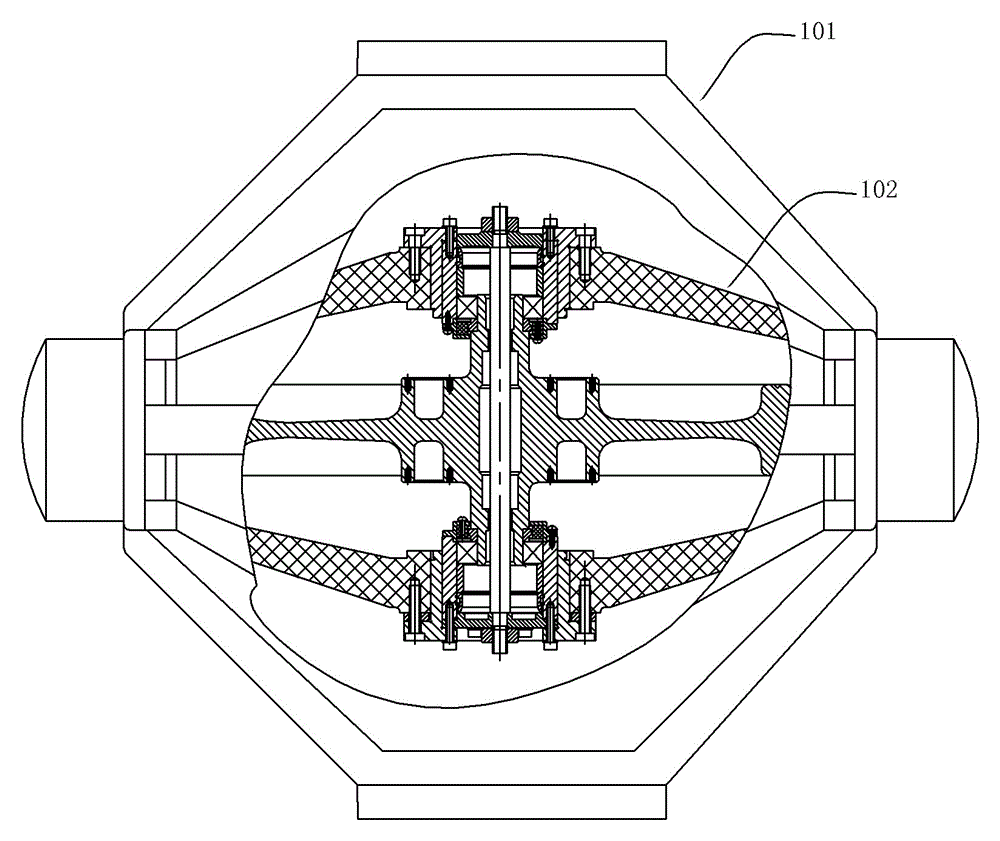

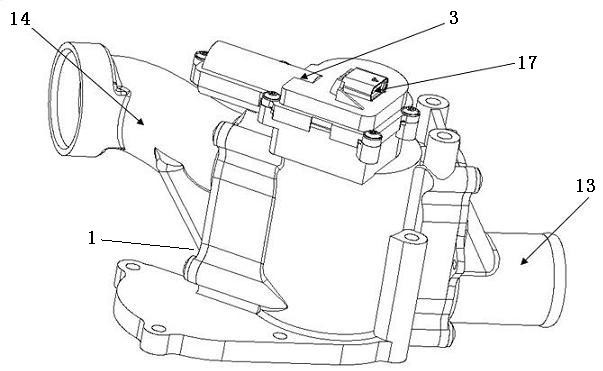

A rotary three-way valve

ActiveCN107917243BInfluence motion trajectoryReduce speedOperating means/releasing devices for valvesMultiple way valvesGear wheelEngineering

The invention discloses a rotary three-way valve, which belongs to the field of control valves and solves the problems of inconvenient processing and installation of the rotary three-way valve and low accuracy of flow control. device, the driving device is connected to the valve body, and the valve body is connected to the valve seat to form a valve chamber. There is a planetary gear mechanism and a rotary slider. A slider gear is provided on the rotary slider, and the slider gear is meshed with the planetary gear mechanism for transmission. The side of the rotary slider facing the planetary gear mechanism is provided with a pin, which is fitted on the pin There is an elastic element, the elastic element is against the valve body, and the slider gear, the pin and the rotary slider are integrally formed. In the present invention, the rotary slider, the pin and the slider gear are connected as a whole, which reduces the difficulty of assembling the rotary slider and the slider gear, and ensures that the elastic element provides a stable pre-tightening force for the rotary slider.

Owner:ZHEJIANG DUNAN MASCH CO LTD

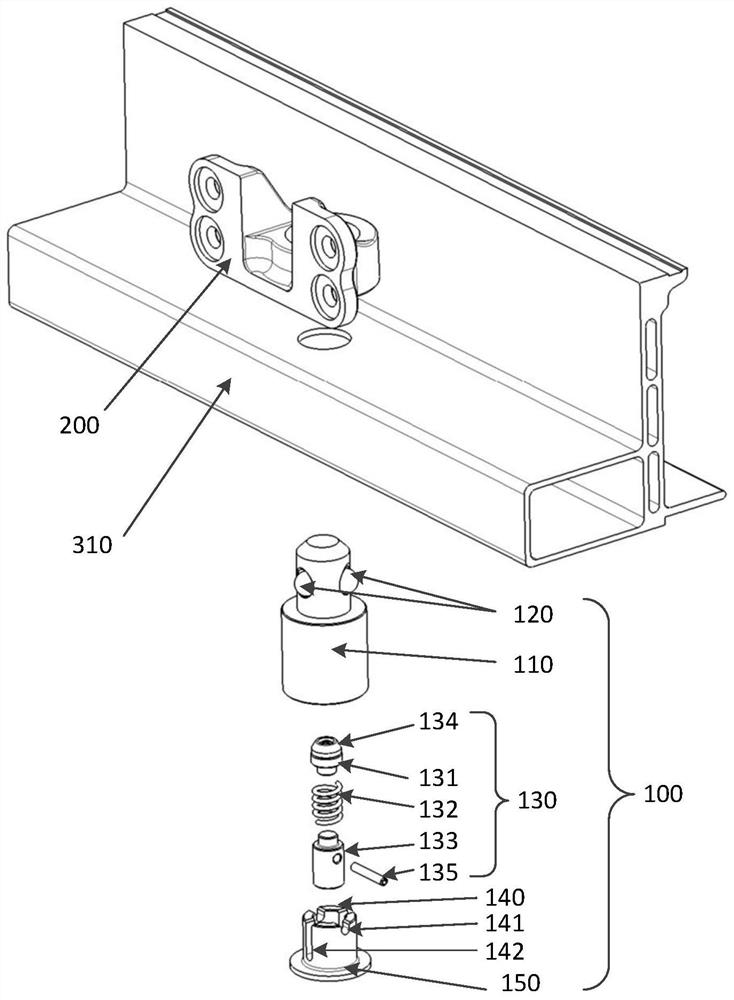

Battery pack locking mechanism, battery pack and vehicle

ActiveCN109501569BSave disassembly timeLock firmlyElectric propulsion mountingVehicle sub-unit featuresMechanical engineeringBattery cell

The invention relates to a battery pack locking mechanism, comprising: a locking member and a locking fitting, the locking member includes a shell and an engaging portion; one of the shell and the locking fitting is fixed on The other battery pack is fixed at the fixed position of the battery pack; the engaging part can move between a first position and a second position relative to the casing; when in the first position, the engaging part A part of the engaging portion protrudes out of the housing to interlock with the locking fitting; in the second position, the engaging portion retreats into the housing to engage with the locking file is unlocked. The battery pack locking mechanism of the present invention enables the battery pack to be stably locked on the vehicle, and facilitates quick loading and unloading of the battery pack.

Owner:NIO ANHUI HLDG CO LTD

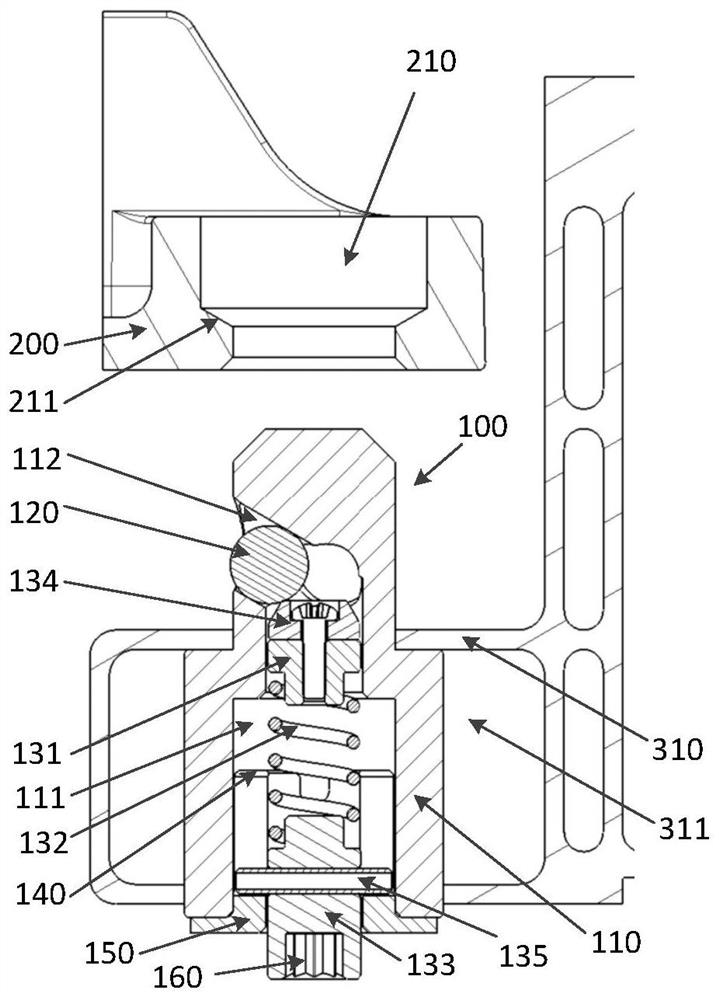

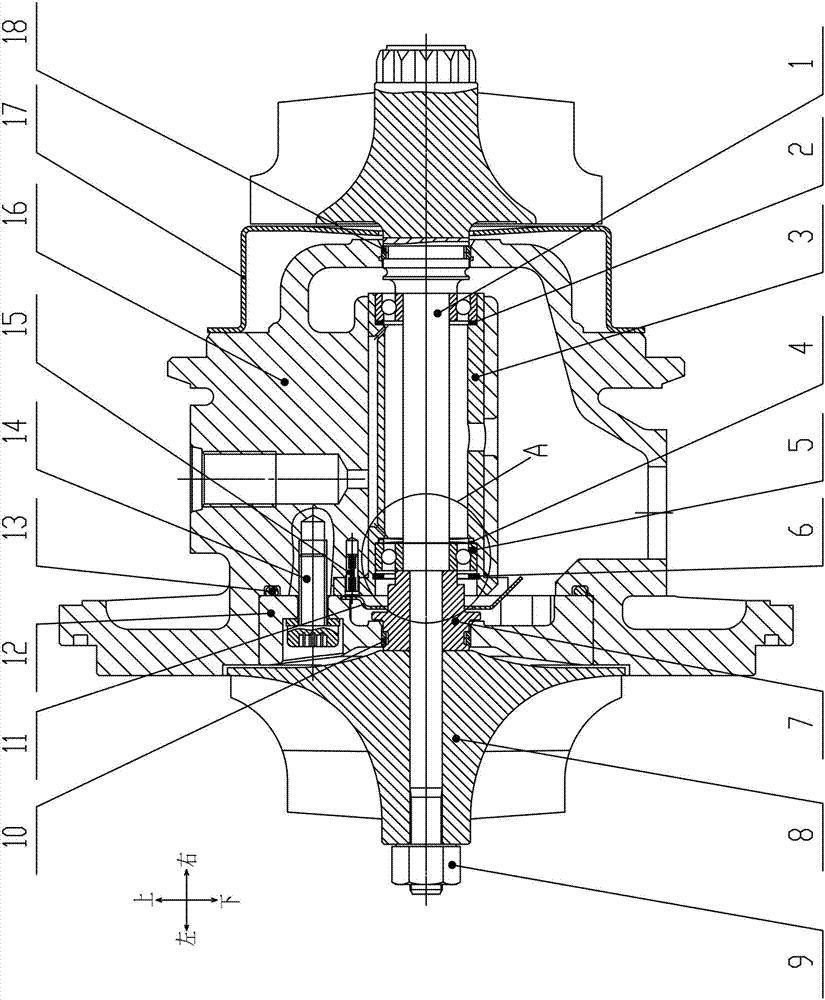

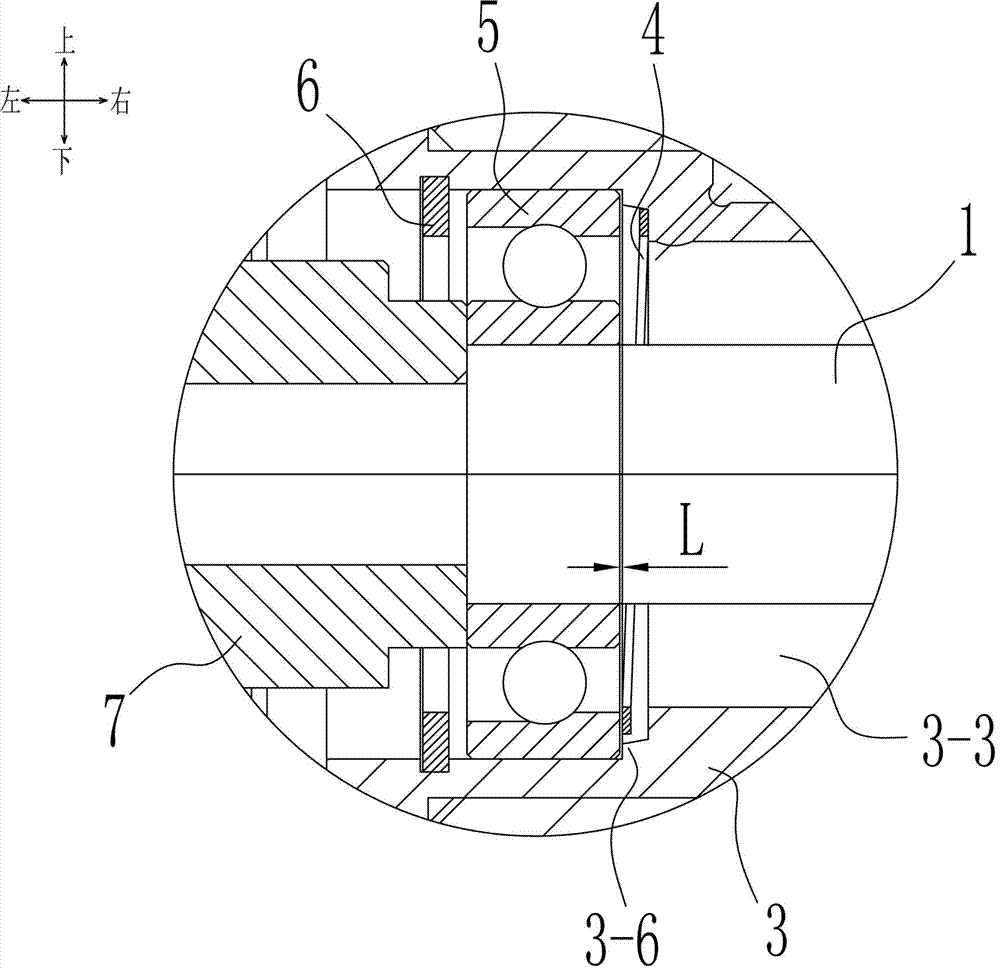

A high-speed rotor and a control moment gyroscope using the rotor

ActiveCN102435182BSolve the problem of narrow temperature rangeStable preloadRotary gyroscopesNarrow rangeBall bearing

The invention relates to a high-speed rotor and a control moment gyro using the same. The high-speed rotor comprises a shell and a wheel body arranged in the shell, wherein the wheel body is rotatably assembled on the shell by utilizing two angular contact ball bearings as a support; bearing covers are respectively arranged at the axial outer sides of the two angular contact ball bearings; a drawbar penetrates through the wheel body coaxially and rotatably; the two bearing covers are respectively fixedly assembled on corresponding ends of the drawbar; and one of the bearing covers is in stationary fit with the shell, and the other one of the bearing covers is in pilot clearance fit with the shell along the axial direction of the wheel body. When the temperature in the working environment of the control moment gyro rises or falls, the cover in pilot fit with the shell can compensate for the difference of linear expansion values between the shell and the wheel body through the movement relative to the shell, thus the stability of the anticipated load of the two angular contact ball bearings can be ensured, and further the control moment gyro can be adapted to working environments with a relatively wide range of temperature difference, therefore the problem of a narrow range of applicable temperature of the high-speed rotor of the existing control moment gyro is solved.

Owner:LUOYANG BEARING RES INST CO LTD

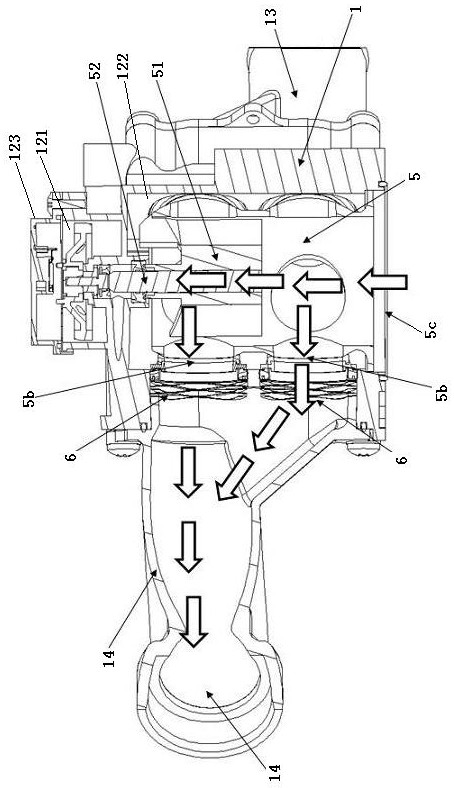

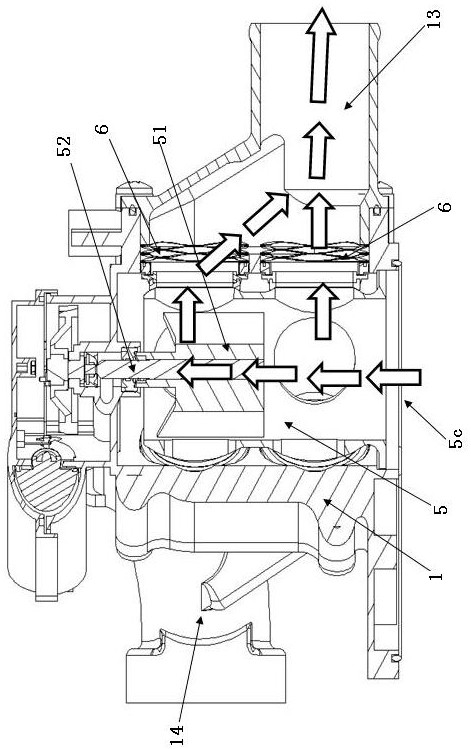

Sealing structure of valve and electric control throttle valve with same

PendingCN112228569AThe elastic coefficient K value is smallSmall force value fluctuationOperating means/releasing devices for valvesLeaf springsAxial pressureEngineering

A sealing structure of a valve comprises a valve body, a valve element, a sealing ring, an installation support, an elastic ring, a wave spring and a pressure applying part. The valve element is rotationally arranged on the valve body. The sealing ring is installed on the installation support, and the installation support is provided with a fluid through hole in the axial direction. The elastic ring is arranged between the installation support and the wave spring, the front end surface of the elastic ring is in sealed contact with the rear end of the installation support, and the outer peripheral surface of the elastic ring is in sealed contact with the inner surface of the valve body. The wave spring is in a corrugated pipe shape, and the front end of the wave spring abuts against the rear end of the elastic ring. The pressure applying part abuts against the rear end of the wave spring so as to apply axial pressure to the wave spring, and the axial pressure is transmitted to the sealing ring through the elastic ring and the installation support so that the sealing ring can be tightly attached to the surface of the valve element. A good sealing effect can also be maintained in a high-low temperature environment and under the condition that assembly and part size accumulative deviation exists.

Owner:ZHEJIANG KEBODA IND

A method and system for intelligently adjusting the bearing pretightening force of the main shaft

ActiveCN112059213BGuaranteed processing effectGuaranteed preloadAuxillary equipmentLarge fixed membersClassical mechanicsControl theory

The invention provides a method and system for intelligently adjusting the bearing pretightening force of the main shaft. The method and system are provided with a positioning guide block in the main shaft device, and the positioning guide block is driven by hydraulic pressure to move and drive the outer ring of the bearing to move, so that The contact angle of the inner and outer rings of the bearing can be adjusted to play the role of adjusting the preload of the bearing. At the same time, the application has established the best matching data table for different materials and preload in advance, and can automatically select the most suitable preload based on the material of the workpiece to be processed and automatically complete the preload operation of the bearing, so that The size of the bearing preload can be matched with the type of plate to be processed. In addition, the present application can also judge the actual wear condition of the bearing by detecting the moving distance of the outer ring of the bearing and the current preload of the bearing, and combining the theoretical relationship between the position of the outer ring of the bearing and the preload of the bearing. The amount of oil supply should be properly corrected in order to compensate for the impact caused by long-term wear of the bearing.

Owner:SHENYANG JIANZHU UNIVERSITY

A turbocharger bearing sleeve and turbocharger

ActiveCN106014501BSimple structureStable preloadMachines/enginesEngine componentsTurbochargerEngineering

Owner:张运波

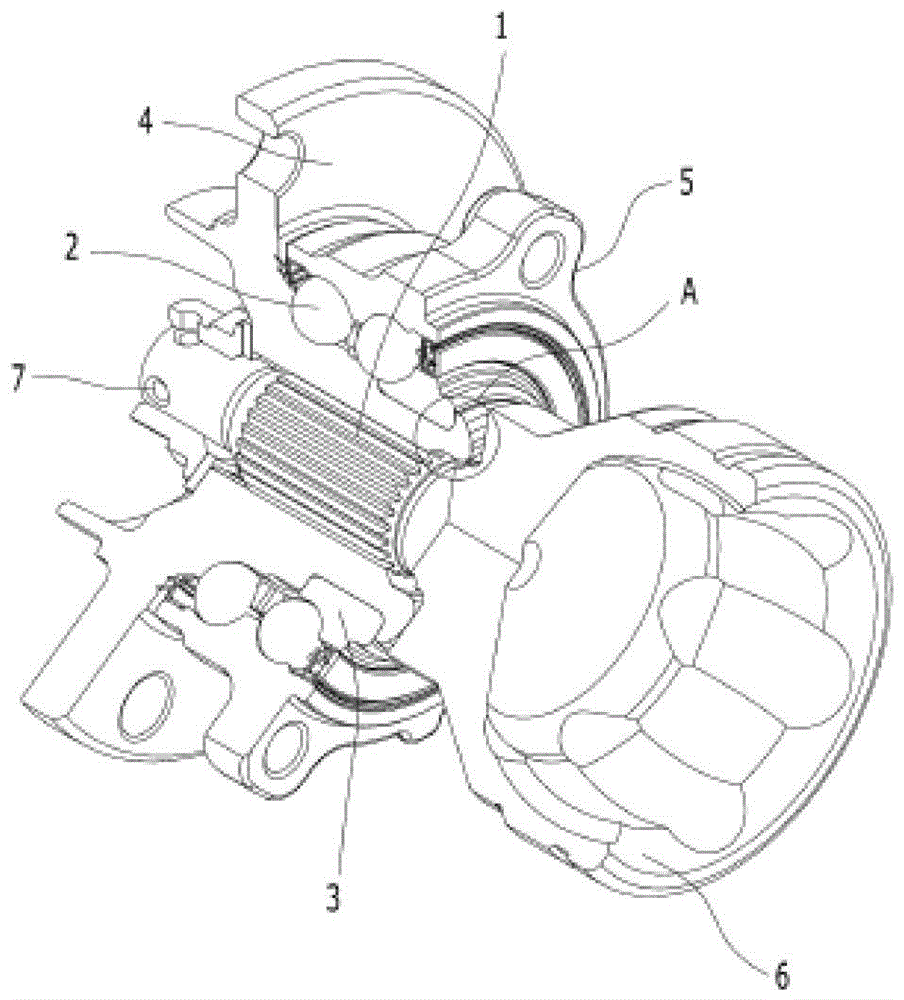

Wheel bearing connection structure

InactiveCN103144496BOmit molding processSmall amount of workHubsBearing unit rigid supportEngineeringTrack formation

The invention provides a wheel bearing connecting structure. The wheel bearing connecting structure comprises a wheel hub which is rotationally fixed onto a vehicle suspension device, a ring-shaped inner wheel which is arranged on the outer peripheral surface of the wheel hub, a ring-shaped outer wheel which is arranged on the outer side of the inner wheel, and a wheel bearing which is provided with bearing ball beads which are arranged between the inner wheel and the outer wheel; and in addition, the inner peripheral surface on one side of the inner wheel and the outer peripheral surface of the wheel hub are integrated through a bolt structure. According to the wheel bearing connecting structure, an engineering step of track formation can be omitted, the durability and quality are improved, and a manufacturing project is simplified.

Owner:天津日进汽车系统有限公司

Flange static seal low-dissipation system integration device and seal mounting process

The invention discloses a flange static seal low-dissipation system integration device and seal mounting process. The device comprises pipe flanges, flange pre-tightening studs, and flange pre-tightening bolt nuts, and further comprises flange movable pressing gaskets, flange bolt pre-tightening disc springs and flange bolt pre-tightening force fixed-value facilities, wherein the flange movable pressing gasket is arranged between the symmetrically-arranged pipe flanges; the flange bolt pre-tightening disc spring is located between the flange pre-tightening bolt nut and the pipe flange; and theflange bolt pre-tightening force fixed-value facility is arranged on the flange pre-tightening stud. The low-dissipation system integration device is composed of three parts; the flange movable pressing gasket technology can comprehensively replace a non-metal gasket, a metal winding gasket, a wave tooth composite gasket, a metal coating gasket and the like; the flange bolt pre-tightening disc springs can solve the problem that the bolt pre-tightening force of the flange pre-tightening bolt nuts is lost due to temperature difference, pressure difference, vibration and the like, and maintain the relatively stable bolt pre-tightening force; and fixed-value anti-blocking lubricating grease is beneficial to high-temperature meshing prevention and low-temperature freezing corrosion preventionof bolts and nuts.

Owner:江苏嘉洛德低逸散工程技术有限公司

Super-large numerical control vertical mill machine

ActiveCN108655915AResolve technical issues that ariseEliminate floatGrinding carriagesGrinding drivesNumerical controlEngineering

The invention provides a super-large numerical control vertical mill machine. The super-large numerical control vertical mill machine comprises a rack, a grinding head mechanism, an adjusting mechanism, a machining platform, a driving mechanism and a hydraulic mechanism. According to the super-large numerical control vertical mill machine, the hydraulic mechanism is arranged on a machining platform of a traditional numerical control vertical mill machine. During operation, the super-large numerical control vertical mill machine drives a spindle to drop through pressure of the hydraulic mechanism and then drives an operating platform to drop to pre-tighten bearings mounted on the operating platform and the spindle. However, during non-operation, the hydraulic mechanism discharges hydraulicoil to release the bearings. The technical problems that the bearings are pre-tightened in place and the operating platform floats up in the operating process are solved. The floating amount of the operating platform is eliminated. The bearing capacity, shock absorption and stability of the operating platform are improved, and the service life of the bearings is prolonged.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

High-speed milling tool

The invention provides a high-speed milling tool which comprises a tool body, tool grooves, a tool clamp, a driving screw and auxiliary pressing screws. Each tool groove is provided with a tool grooveaxial surface, a tool groove radial surface, a tool groove first tangential surface and a tool groove second tangential surface. The tool clamp is provided with a tool clamp axial surface, a tool clamp radial surface, a tool clamp first tangential surface and a tool clamp second tangential surface. The tool clamp first tangential surface and the tool clamp second tangential surface are oppositelydisposed and tilted to each other at an acute angle a. The tool clamp is divided by at least one seam into a fixed part and an elastic part. The fixed part is provided with a cutting part. A drivingscrew hole is formed in the fixed part. The tool clamp moves in the tool grooves when the driving screw is matched with the driving screw hole. The high-speed milling tool is reasonable in structuraldesign, convenient to adjust and stable in structure and cannot fly out under force, meanwhile the elastic part of the tool clamp can provide a similar 'damping' effect, microvibration of the tool clamp during cutting is reduced, and the service life of the tool is prolonged.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

A gyro motor bearing unit

ActiveCN103742526BQuick installationImprove the qualified rate of installationBall bearingsBearing componentsEngineeringMechanical engineering

The invention discloses a gyro motor bearing unit and relates to the field of the design technologies of the bearings. The gyro motor bearing unit comprises a step shaft (12), a bearing A (19), a bearing B (20), an oil storage ring (16), an oil storage ring lining (18), an elastic lining (1) and a U-shaped clamping ring (10), wherein the bearing A and the bearing B are arranged on two sides of the middle part of the step shaft (12); the elastic lining and the U-shaped clamping ring are arranged between the bearings A and B; the U-shaped clamping ring is arranged between the elastic lining and the bearing A; the oil storage ring is arranged in a groove body which is formed in the middle part of the inner surface of the elastic lining; an oil storage ring lining is arranged between the oil storage ring and the groove body of the elastic lining. The gyro motor bearing unit overcomes such defects of the conventional gyro motor bearing unit as low rotation precision, short service life, low reliability and poor installation qualified rate; and the performance of the gyro motor bearing unit can be effectively improved.

Owner:LUOYANG BEARING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com