Flange static seal low-dissipation system integration device and seal mounting process

A system integration and installation process technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., to achieve the effect of preventing gasket seal from being invalid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This technical solution only provides a sealed integrated structure, and the used pipe flange 1, flange pre-tightening stud 2 and flange pre-tightening bolt and nut 4 are only used to assist in explaining the accessories used in this technical solution, and should not be limited.

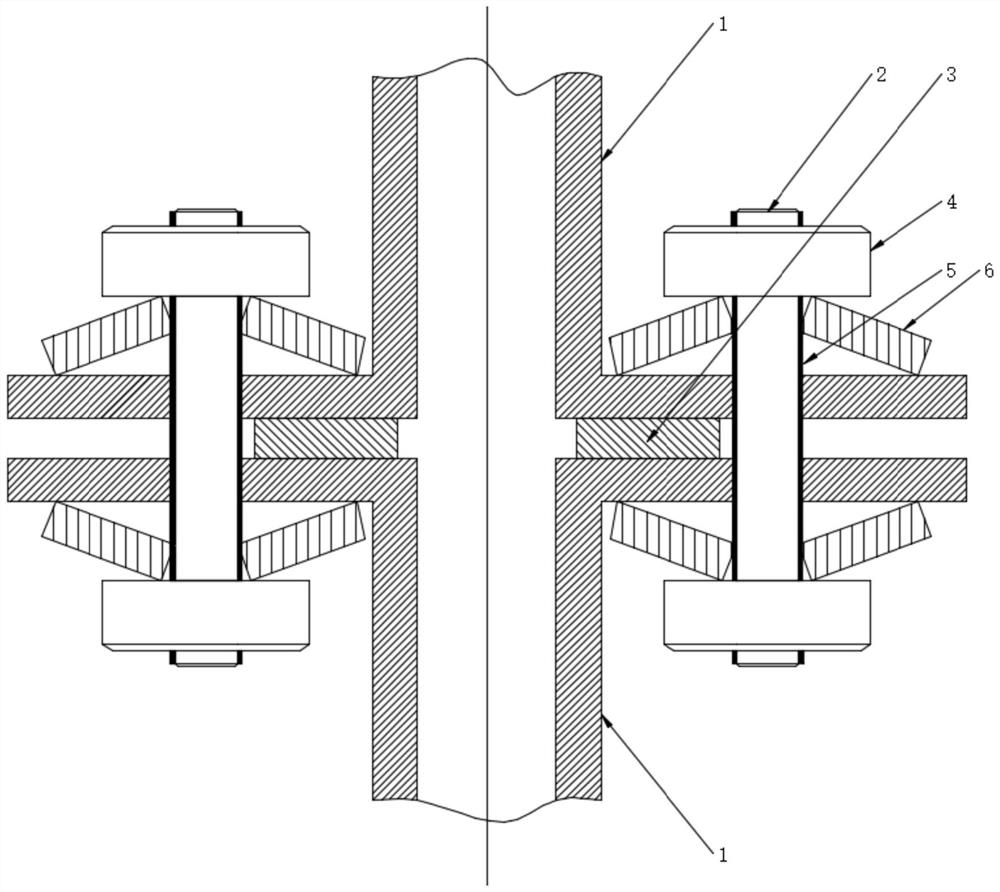

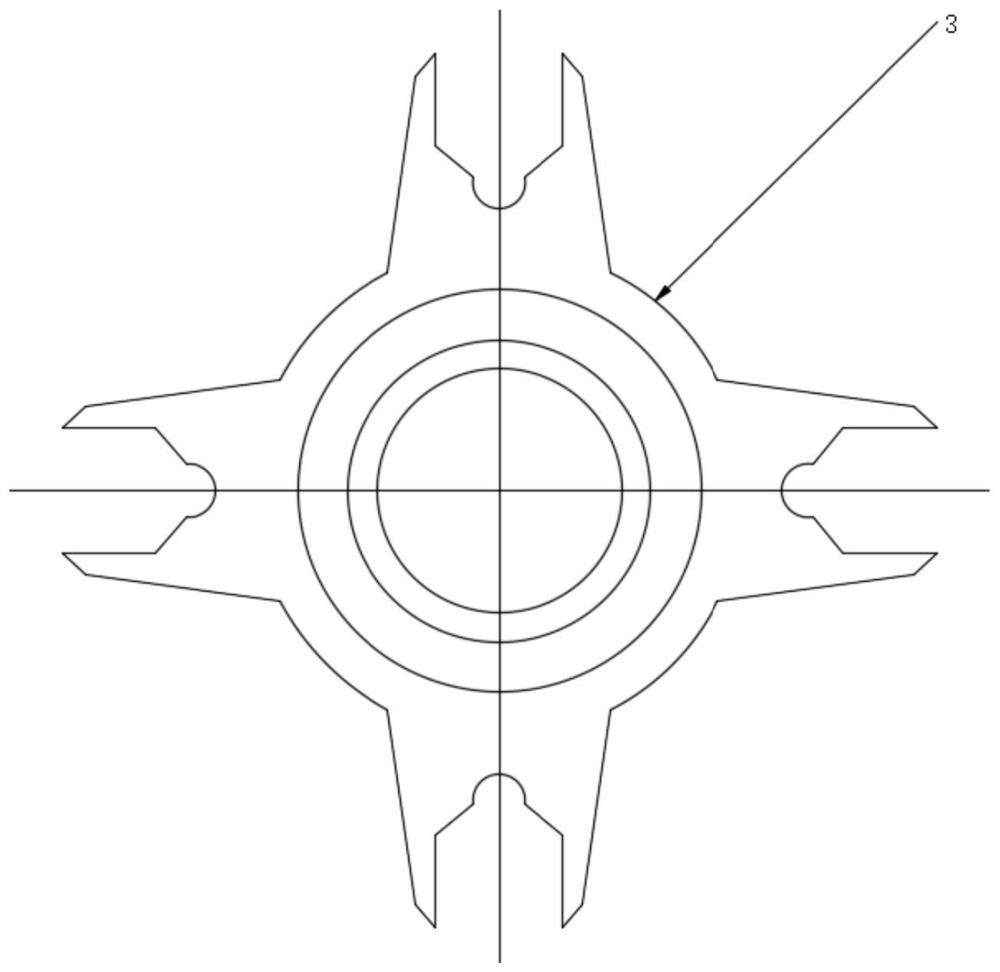

[0039] The first aspect of the present invention is to provide a flange static seal low-emission system integration device, including pipe flanges 1 and flange pre-tightening studs 2 arranged symmetrically up and down, and the flange pre-tightening studs 2 are pierced On the symmetrically arranged pipe flange 1, flange pre-tightening bolts and nuts 4 are installed at the upper and lower ends of the flange pre-tightening stud 2; it also includes: flange live pressure gasket 3, flange bolt Pre-tightening disc spring 6 and flange bolt pre-tightening force fixed value facility 5, the flange live pressure gasket 3 is installed between the symmetrically arranged pipe flanges 1, and the flange bolt p...

Embodiment 2

[0075] Based on the implementation of embodiment 1,

[0076] Further, the quantity of the flange bolt pretension disc spring 6 is two pieces, which are respectively installed between the flange pretension bolt nut 4 on the upper part and the pipe flange 1 and the flange pretension bolt nut 4 on the lower part and the pipe flange 1 respectively. between flange 1.

[0077] In this embodiment, there are two flange bolt pretension disc springs 6, which are installed between the flange pretension bolt nut 4 on the upper part and the pipe flange 1 and between the flange pretension bolt nut 4 on the lower part and the pipe flange 1. Between, up and down at the same time maintain a relatively stable bolt pre-tightening force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com