A rotary three-way valve

A three-way valve, rotary technology, applied in multi-way valves, valve details, valve devices, etc., can solve problems such as accurate control of unfavorable air flow, affecting the sealing performance and normal rotation of the slider, and poor spring stability. , to achieve the effect of simplifying the installation process, compact structure, and reduced speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

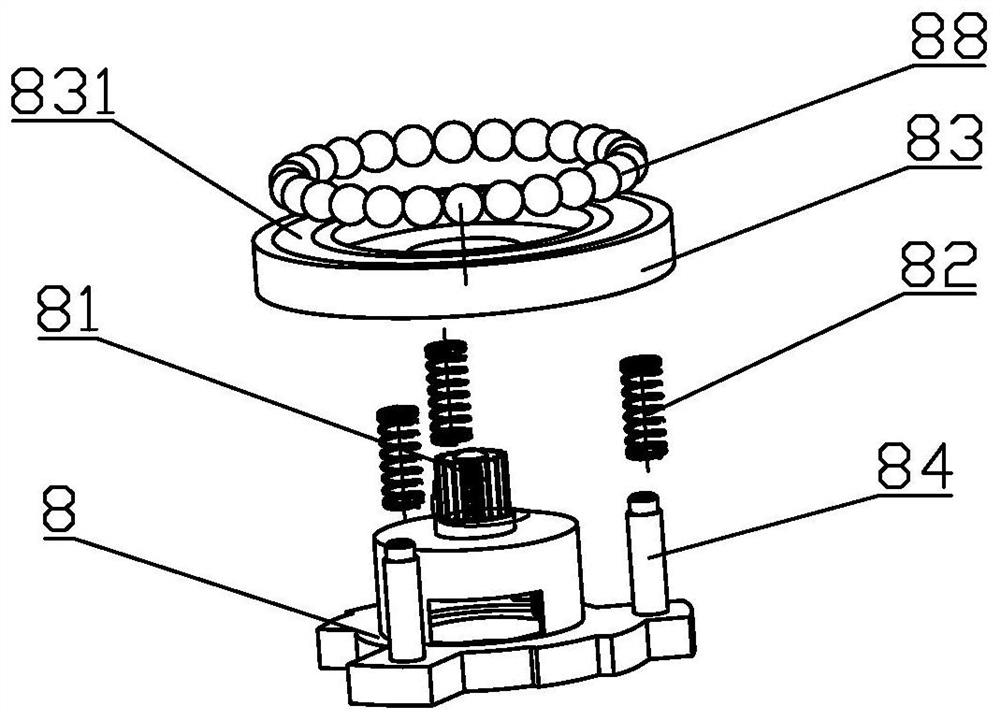

[0029] This embodiment provides a rotary three-way valve, such as Figure 1 to Figure 6 Said, including valve body 1, valve seat 2 and driving device 3, driving device 3 is connected to valve body 1, valve body 1 is connected with valve seat 2 and forms valve chamber 4, and valve seat 2 is provided with valve chamber 4 The first communication hole 21, the second communication hole 22 and the third communication hole 23 are communicated. The planetary gear mechanism and the rotary slider 8 are arranged in the valve cavity 4. The slider gear 81 is arranged on the rotary slider 8, and the slider gear 81 is arranged on the slider. The block gear 81 is meshed with the planetary gear mechanism for transmission. The side of the rotary slider 8 facing the planetary gear mechanism is provided with a pin 84. The pin 84 is covered with an elastic element, and the elastic element is against the valve body 1. The slider gear 81, pin 84 and rotary slide block 8 are integrally formed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com