Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Squeeze thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

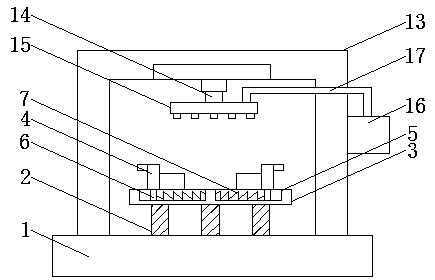

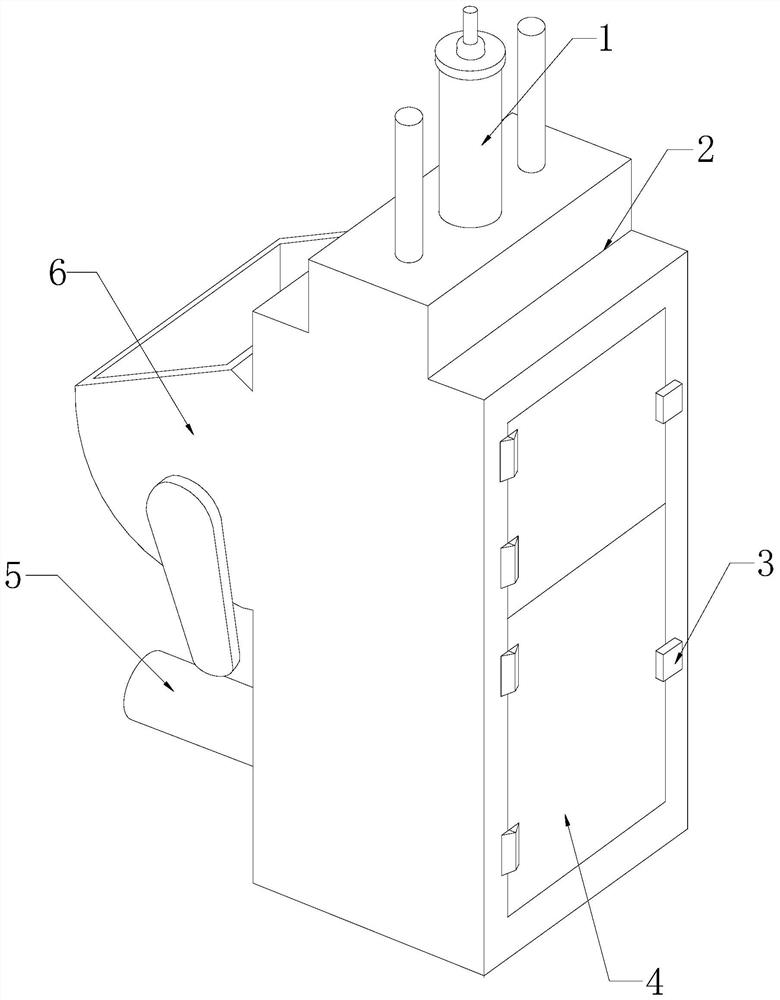

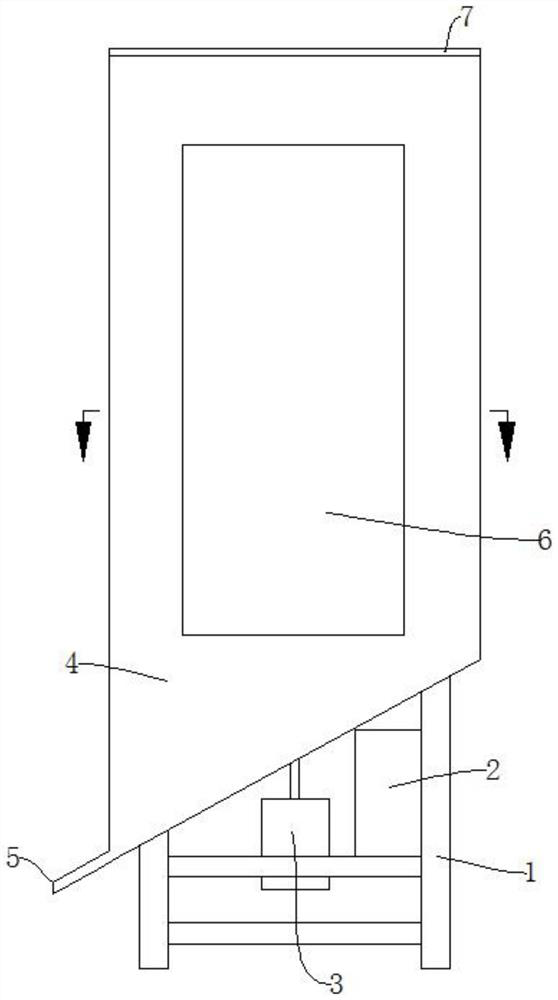

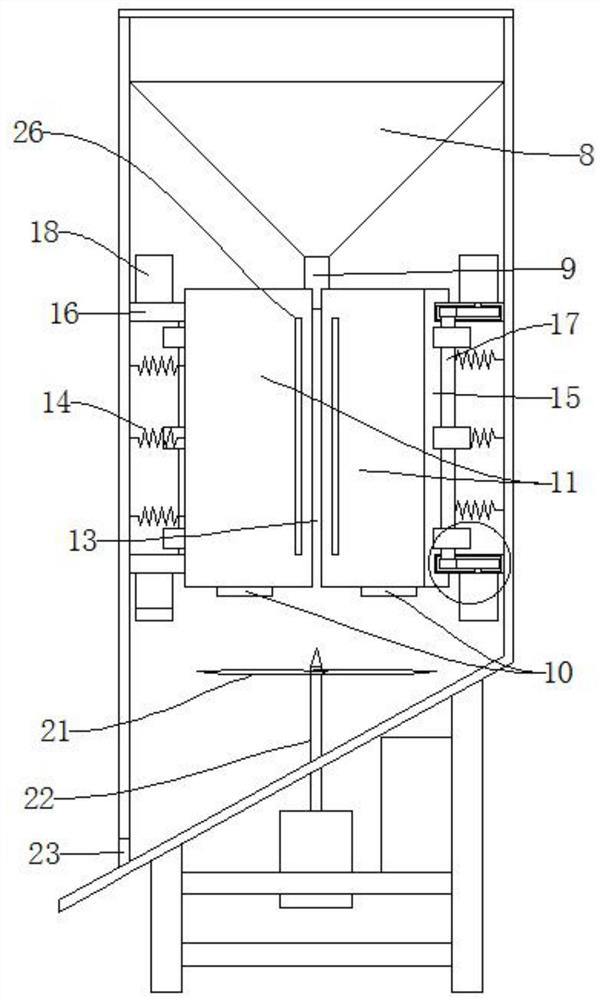

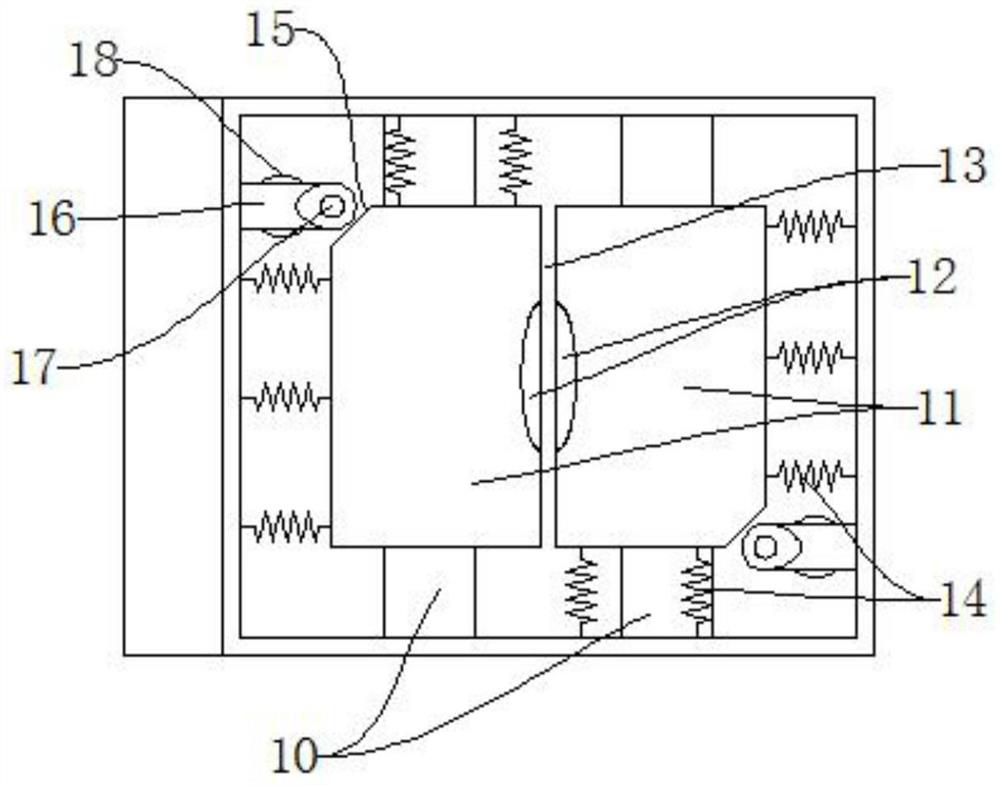

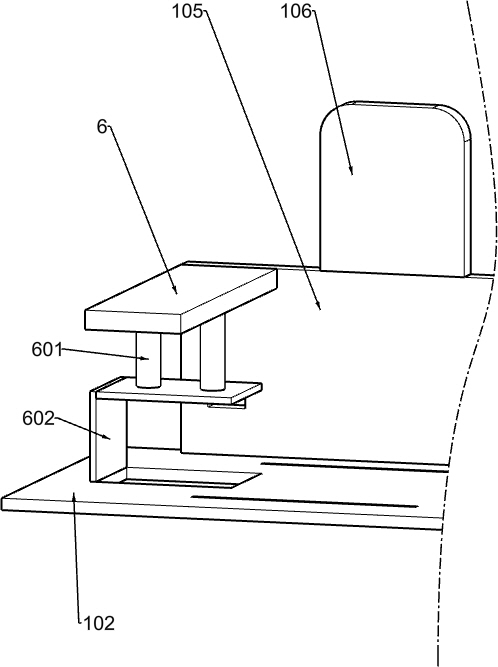

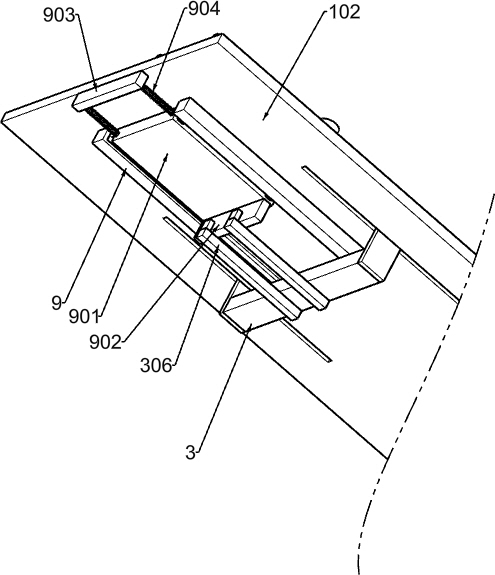

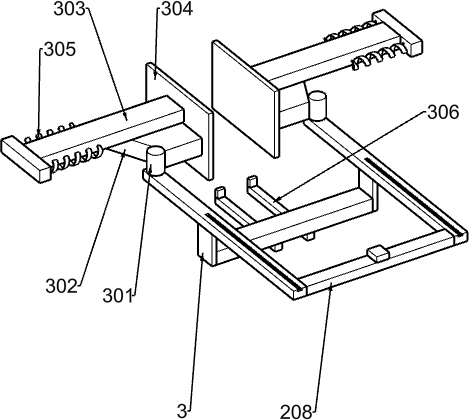

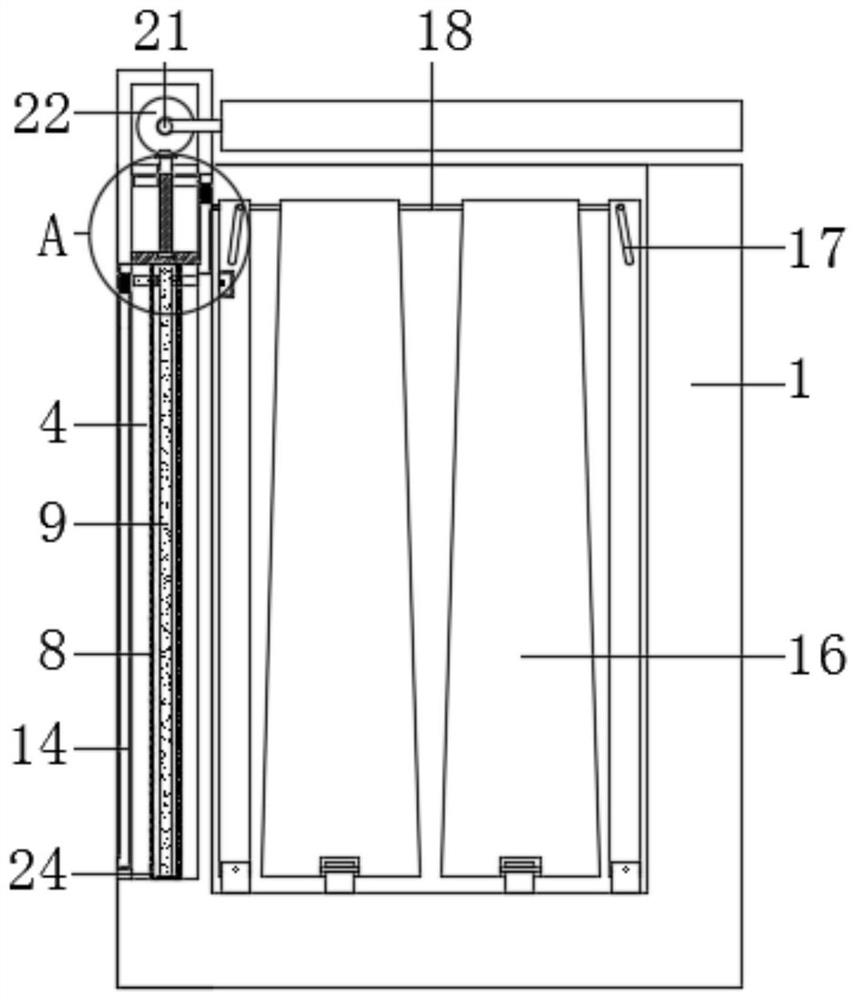

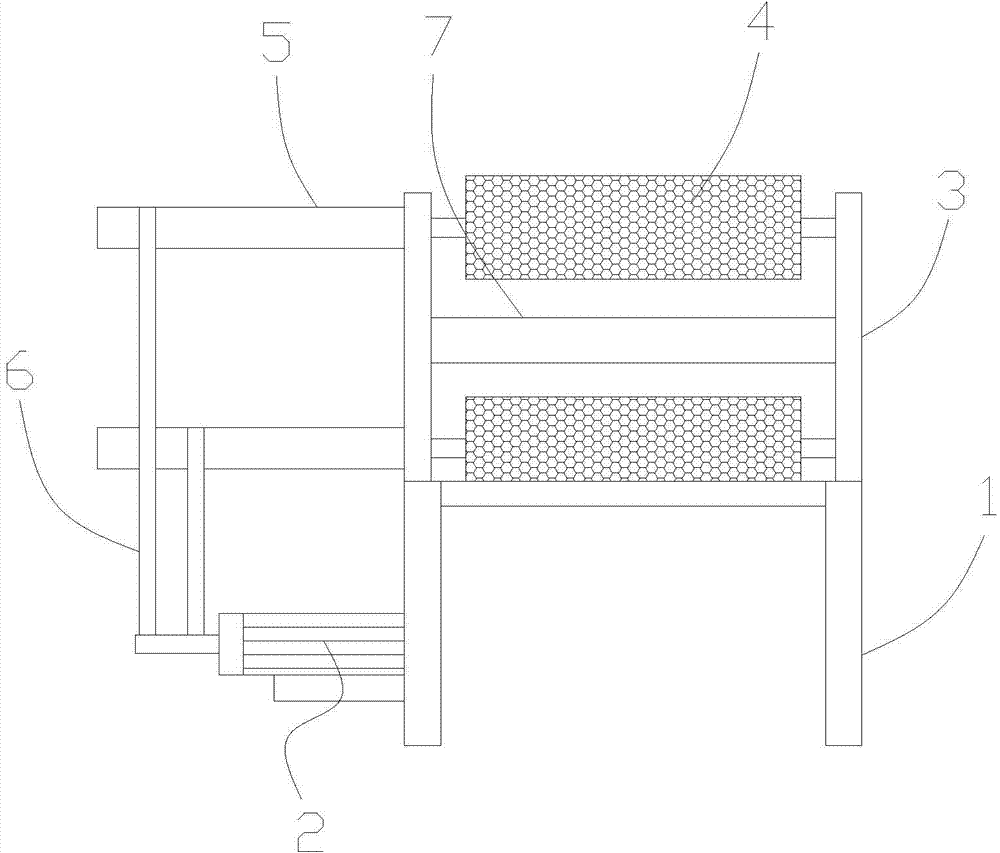

Wood board extruding device and method with positioning function

ActiveCN108908534APrevent movementImprove stabilityWood veneer joiningPulp and paper industryWood panel

The invention discloses a wood board extruding device with a positioning function in the technical field of wood board processing. The wood board extruding device comprises a base. A buffering deviceis arranged on the outer wall of the top of the base. The top end of the buffering device is movably connected with an extruding platform. Fixing plates are arranged on the left side and the right side of the top of the extruding platform. Moving grooves are formed in the left side and the right side of the top of the extruding platform. The adjacent ends of two adjusting springs are connected with the inner walls of the adjacent sides of the two moving grooves. In the device, through contraction of the adjusting springs, the two fixing plates fix a wood board from the left side and the rightside, and the wood board is prevented from moving during machining; meanwhile, supporting springs contract, limiting plates fix the wood board from the upper portion, the wood board fixing stability is further improved, and the wood board is prevented from moving during machining; and through changing of the distance between the two fixing plates and the distance between a baffle and a pressing device, the device can fix wood boards different in size.

Owner:XINCHANG LUHENG MASCH CO LTD

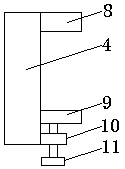

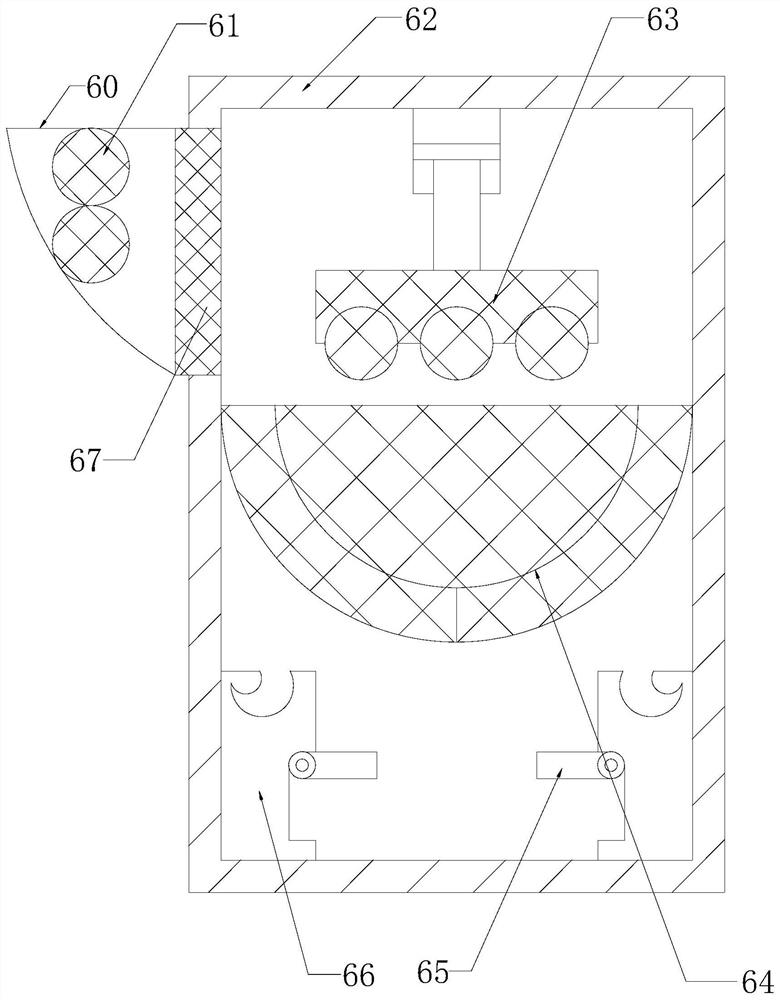

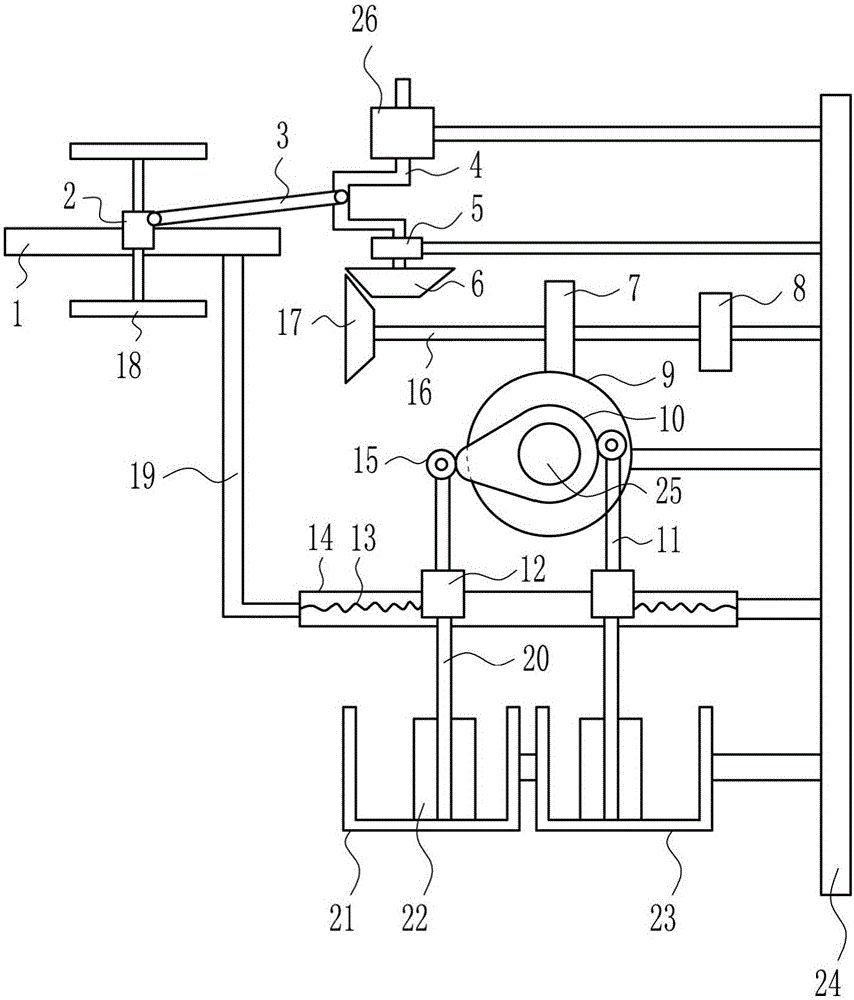

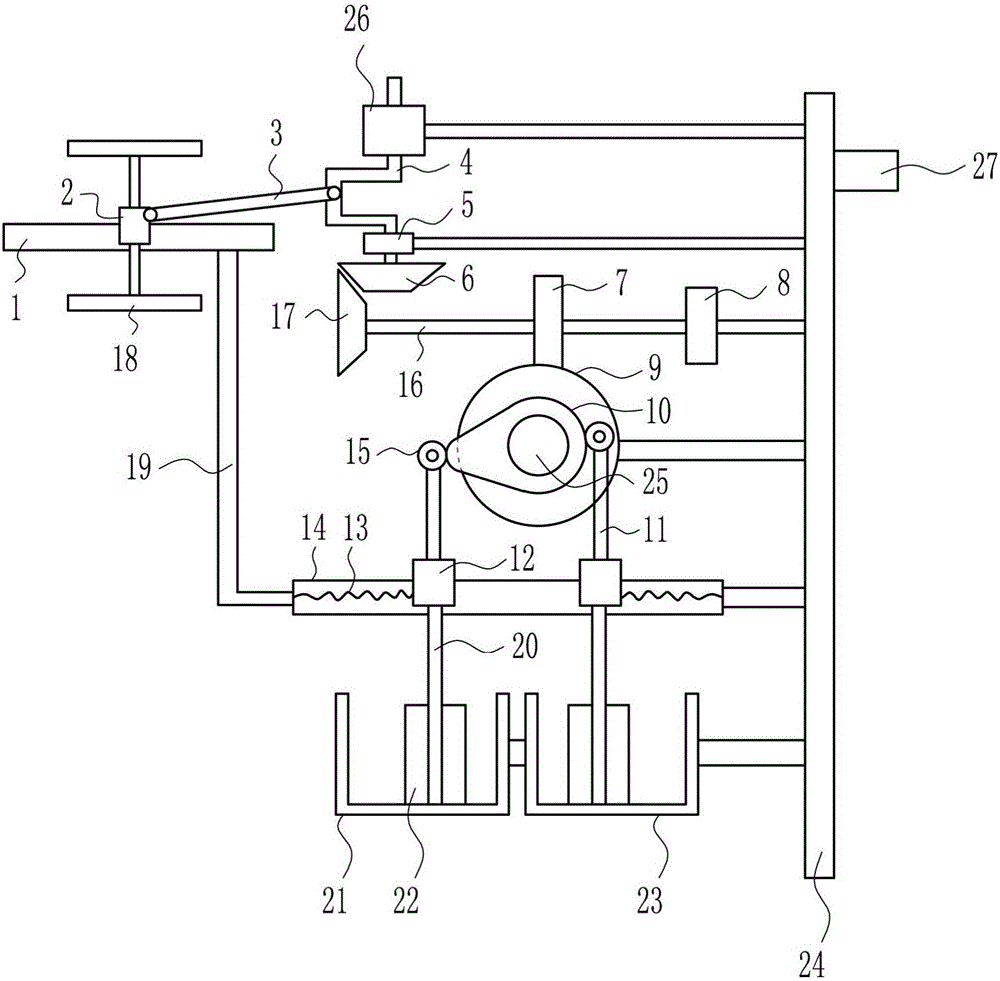

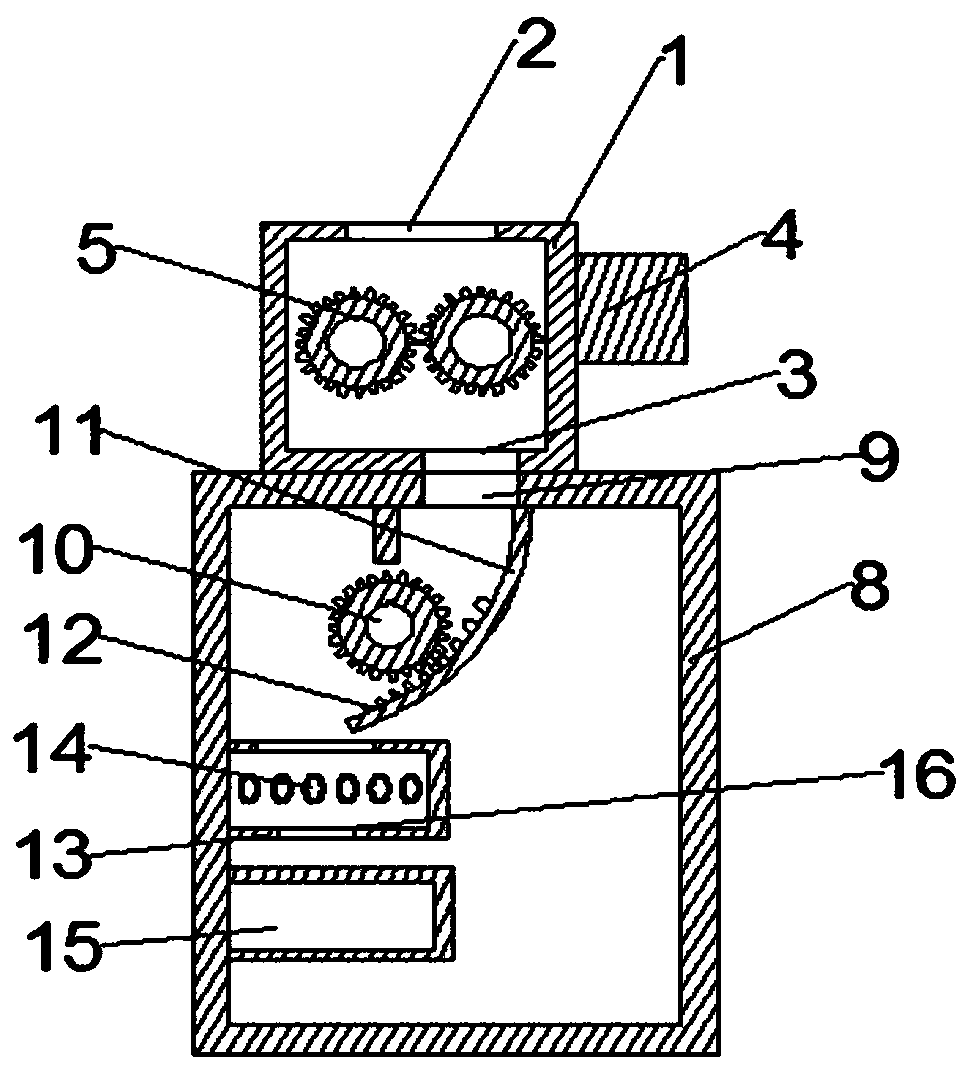

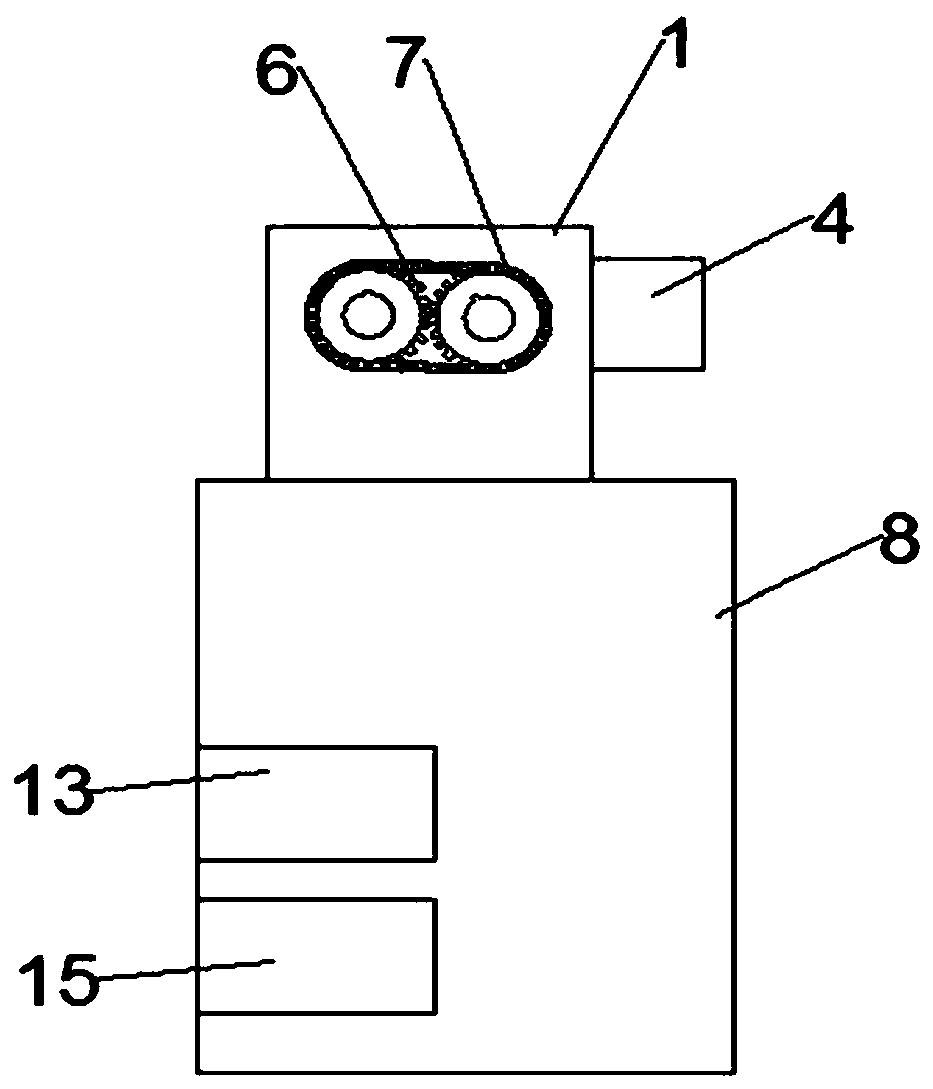

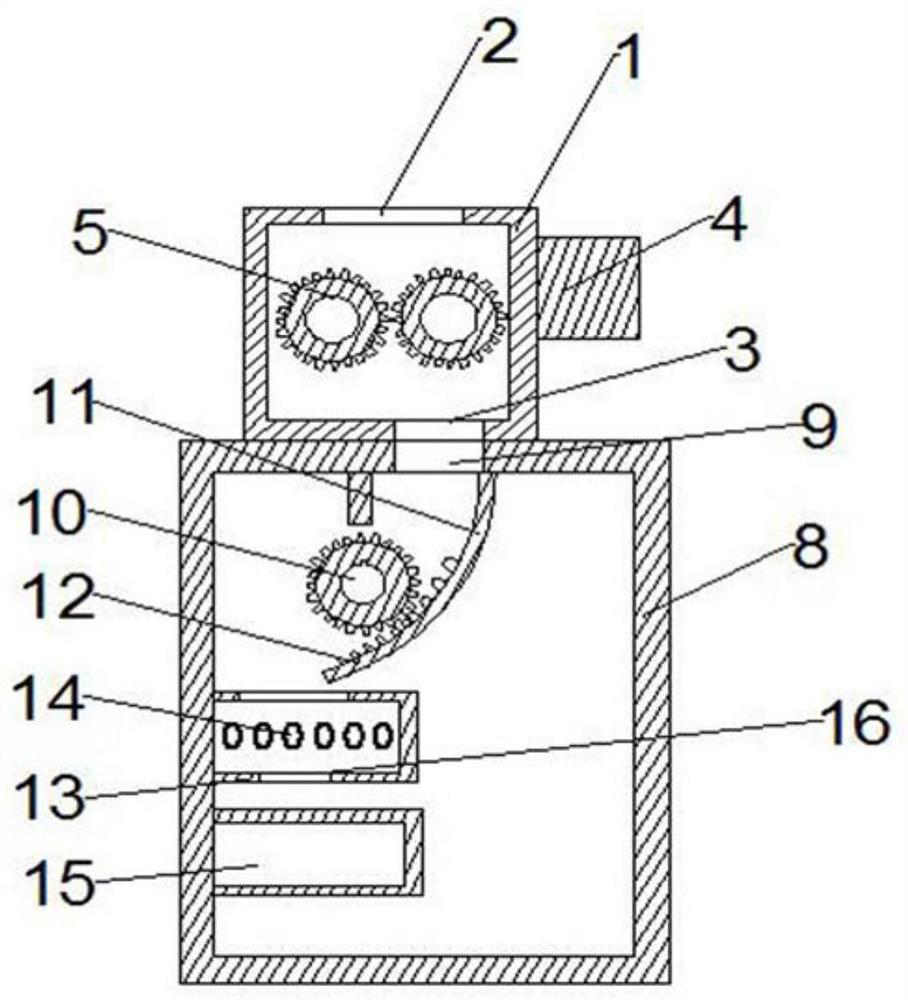

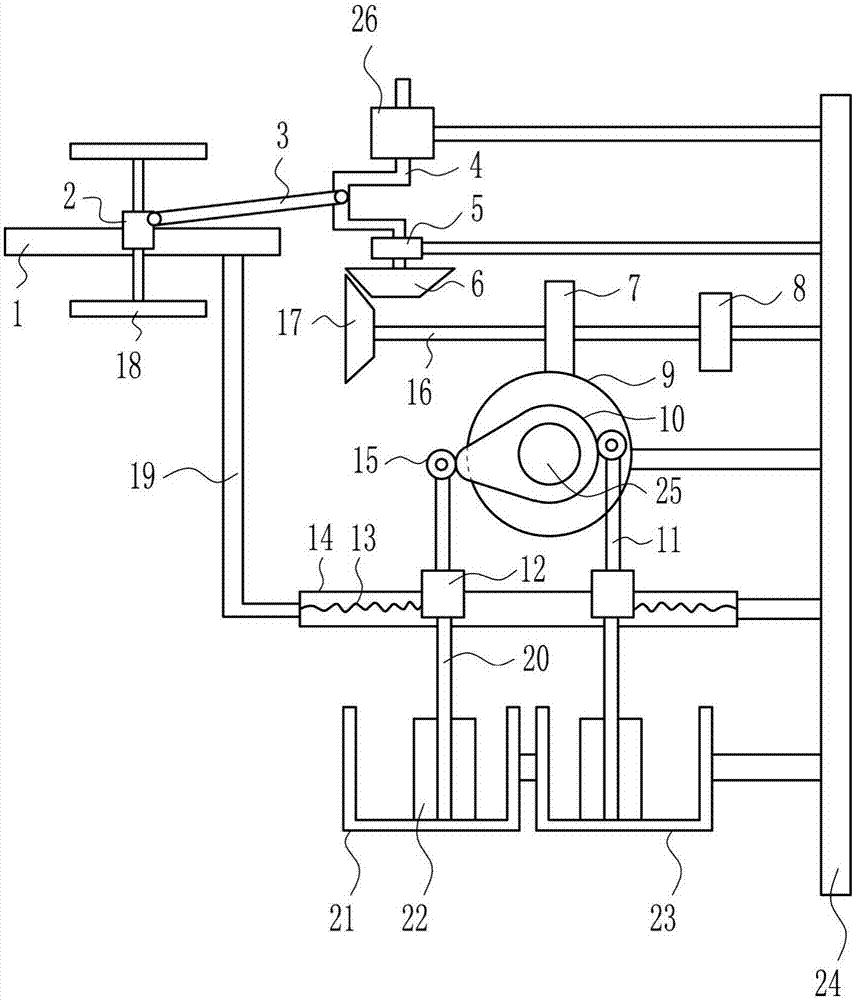

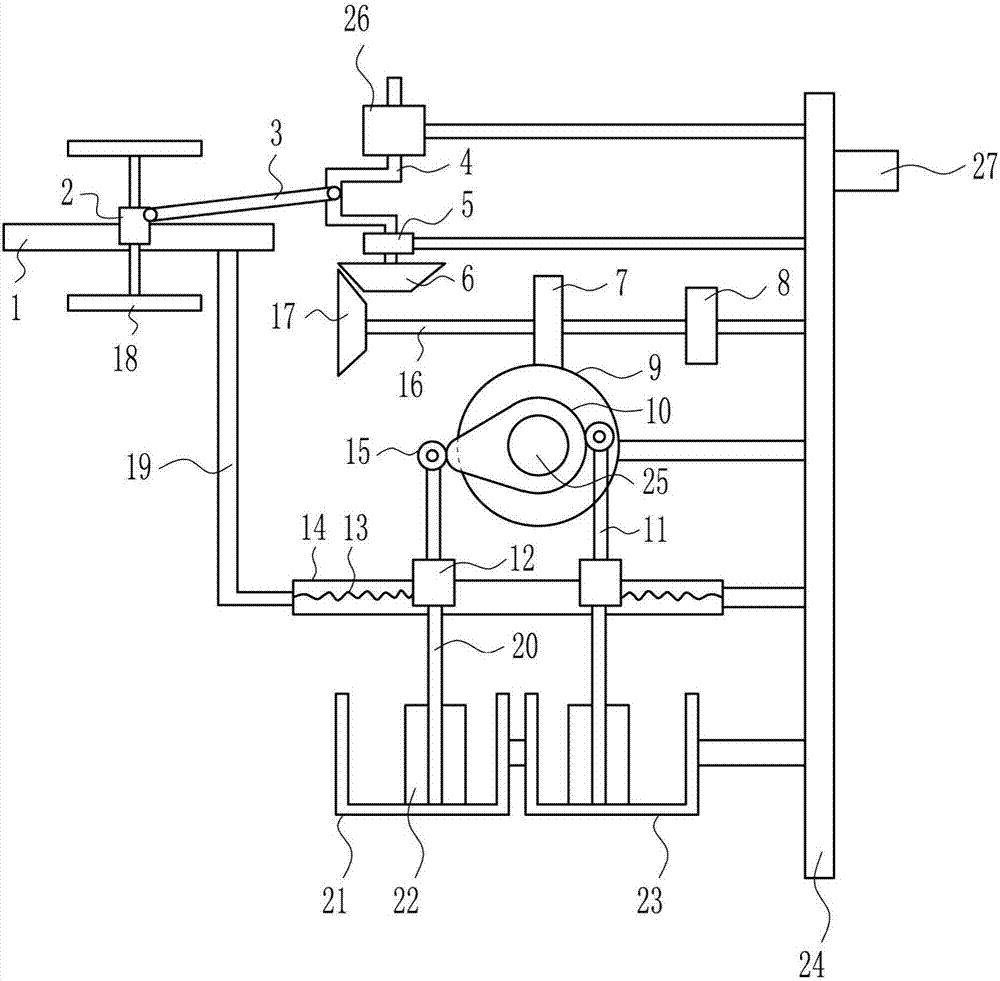

Strip mop with mechanical wiping device

InactiveCN101779941AEasy squeezeSqueeze thoroughlyCarpet cleanersFloor cleanersReciprocating motionEngineering

The invention relates to a strip mop with a mechanical wiping device, which is characterized in that the mechanical wiping device is additionally arranged on the common cloth strip or wire mop; the mechanical wiping device is driven by utilizing up-and-down movement of slide blocks of a connecting rod mechanism on a mop rod. The pressing modes comprise a roll mode, a pressure plate mode and a pressure claw mode, wherein the roll mode transforms linear movement of the slide blocks to rotation of a roll through a rack, a gear and a synchronous belt transmission mechanism, a mop head is towed by the rack and is pressed by the roll at the same time, the speed of pressing a mop head transfer strip belt by the roll is the same as the speed of towing the mop head strip belt by the rack, both of the speeds keep synchronous, and the mop head is wiped and reset by the reciprocating movement of the slide blocks; and the pressure plate mode and the pressure claw mode are both characterized in that driving force of the slide blocks acts on a power arm of a lever through a top block and a pressure wheel so as to drive a pressure plate or a pressure claw on a resistance arm of the lever to extrude the mop head; the slide blocks tow the mop head to move up and down through drive rods at the same time; and the mop head is wiped in a framework and is reset when leaving the framework.

Owner:周现华

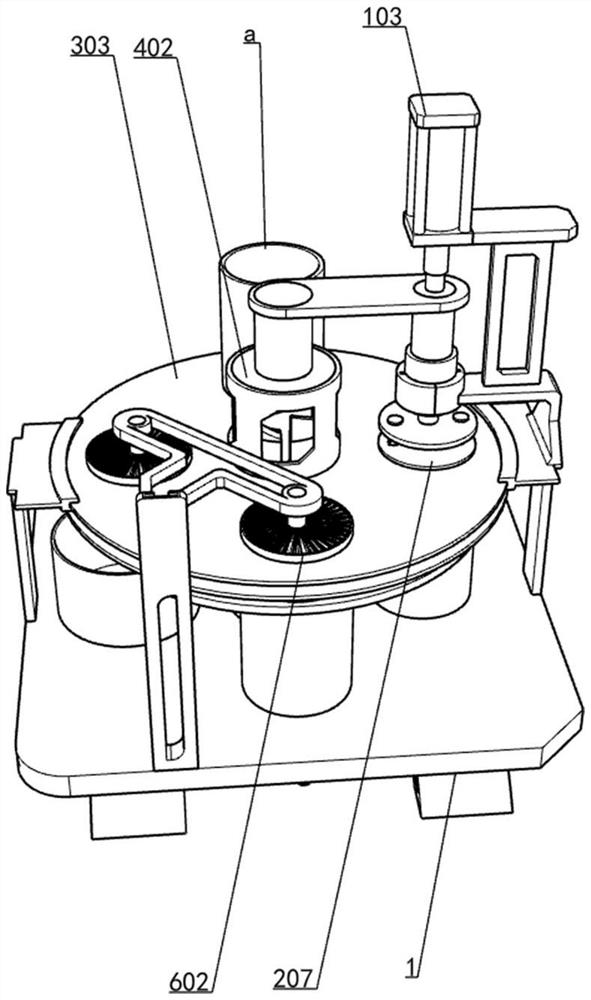

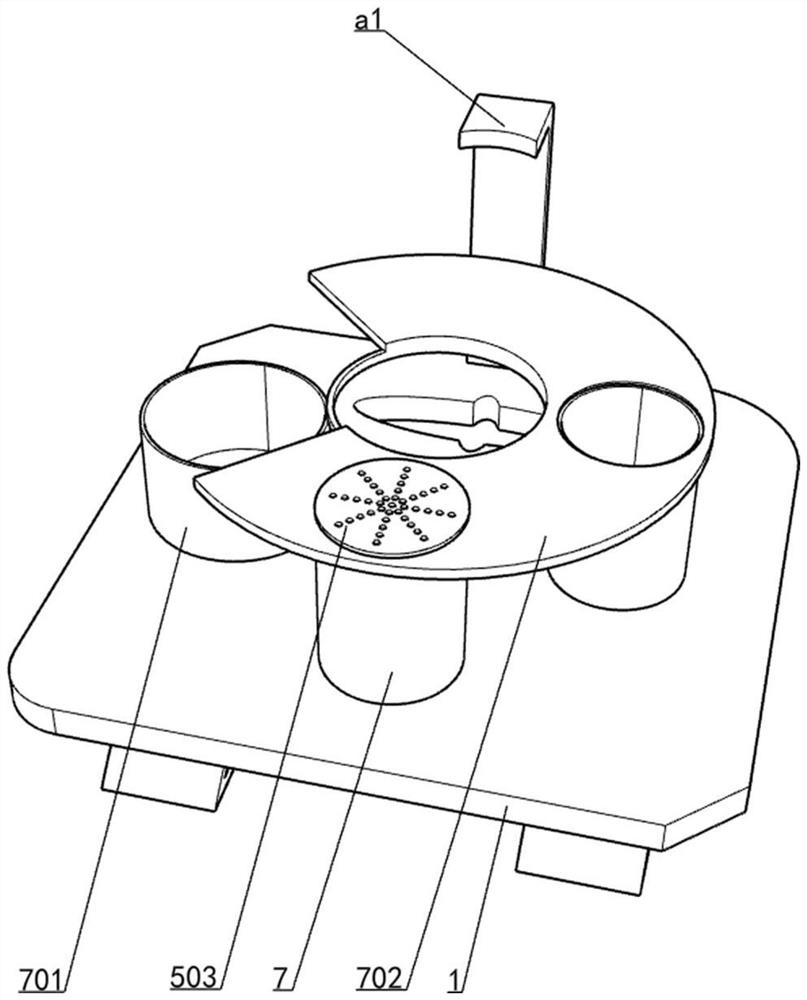

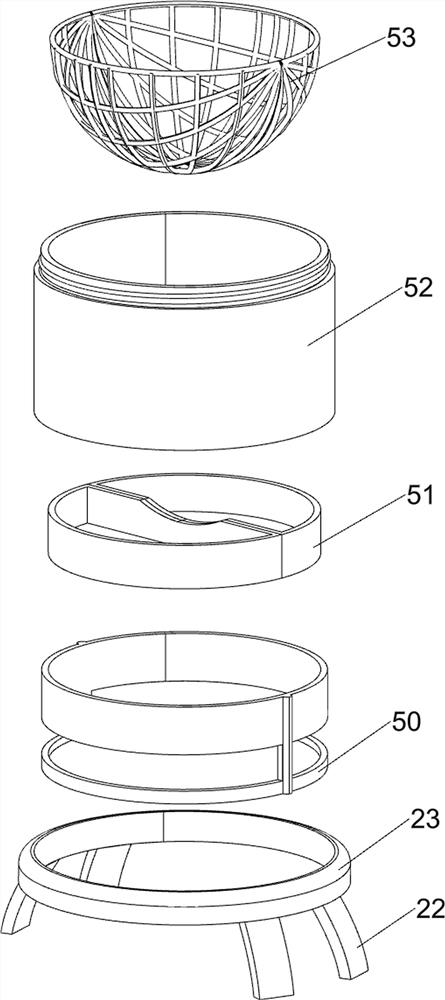

Dry chili powder manufacturing equipment for workshops

ActiveCN112403567AMake fastPrecise rotationGrain treatmentsFood scienceManufacturing engineeringChili pepper

The invention relates to dry chili powder manufacturing equipment, in particular to dry chili powder manufacturing equipment for workshops. The dry chili powder manufacturing equipment for the workshops can thoroughly crush dry chilies and can screen the dry chilies. The dry chili powder manufacturing equipment for the workshops comprises a bottom plate and a beating mechanism, wherein a supporting mechanism is arranged on the bottom plate; and the beating mechanism is arranged on the bottom plate. The equipment is supported by the supporting mechanism, and then the dried chilies are extrudedunder the cooperation of the beating mechanism, so that the chili powder is quickly prepared; and through cooperation of the beating mechanism and a rotating mechanism, vertical movement of the rotating mechanism is achieved, then automatic overturning of a chassis is achieved, and therefore the chassis does not need to be overturned manually by people.

Owner:乐陵市益民调味食品有限公司

Paper garbage recycling device

InactiveCN111874485ADoes not block squeeze movementIncrease the areaRefuse receptaclesStructural engineeringGarbage collection

The invention discloses a paper garbage recycling device which structurally comprises a sliding rod, a machine body, a closing buckle, a closing door, a push plate sliding block and a treatment box. The sliding rod is arranged above the machine body, the closing door is connected with the machine body in a clamped manner, the closing door is connected with the closing buckle in a buckled manner, the machine body is mechanically connected with the treatment box, and the push plate sliding block is connected with the machine body in a sliding manner; and the treatment box is provided with a feeding cavity, a pressure transfer device, a box body, a pressing device, a rolling device, an air suction block, a side wall and an extruder, and the feeding cavity is formed in the side face of the boxbody. According to the paper garbage recycling device, a cleaning block is a spring arc-shaped strip, a spring is arranged in the cleaning block, and the cleaning block can conduct clamping along with the radian of a protruding block on a rotating wall during cleaning and sweeping; and during rotating, spines on the cleaning block can pick up paper garbage attached to the equipment by correspondingly compressing the equipment, the front ends of the spines are sharp, and the paper garbage at cracks can be picked up when the spines rotate.

Owner:林宇

Pressing and polishing device of high-voltage side extension line of capacitor for electric power dynamic reactive compensation

ActiveCN106158432ASqueeze thoroughlyImprove smoothing effectReactive power adjustment/elimination/compensationCapacitor manufactureEngineeringHigh pressure

The invention relates to a pressing and polishing device and in particular relates to a pressing and polishing device of a high-voltage side extension line of a capacitor for electric power dynamic reactive compensation. Aiming at solving the technical problems, the invention provides the pressing and polishing device of the high-voltage side extension line of the capacitor for the electric power dynamic reactive compensation, which has the advantages of complete extrusion, good polishing-flattening effect and high practicability. In order to solve the technical problems, the pressing and polishing device of the high-voltage side extension line of the capacitor for the electric power dynamic reactive compensation, provided by the invention, comprises a second sliding rail, a second sliding block, a first connecting rod, a first rotary rod, a first bearing seat, a first bevel gear, a first inclined gear, a second bearing seat, a second inclined gear and the like; the first bearing seat is connected with the first rotary rod, and the middle part of the first rotary rod is in rotary connection with the first connecting rod; the lower end of the first rotary rod is connected with the first bevel gear. The pressing and polishing device has the effects of complete extrusion, good polishing effect and high practicability when pressing and polishing- flattening work of the high-voltage side extension line of the capacitor is carried out.

Owner:南通日精电子有限公司

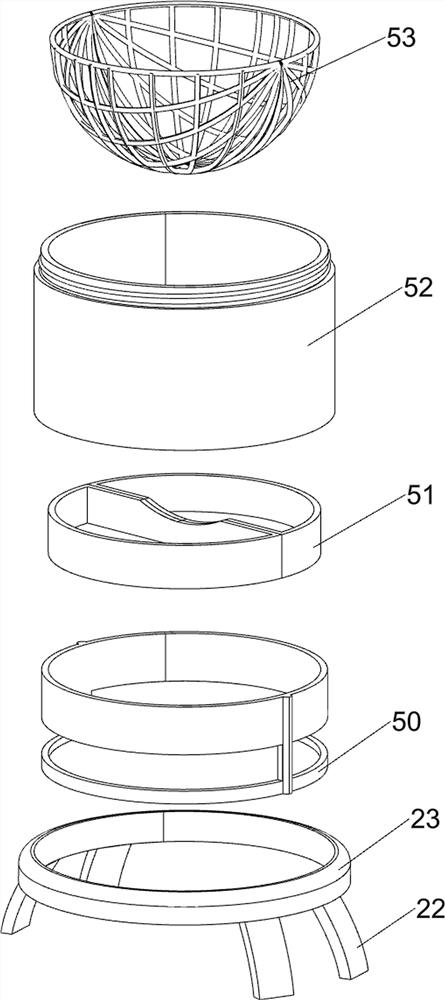

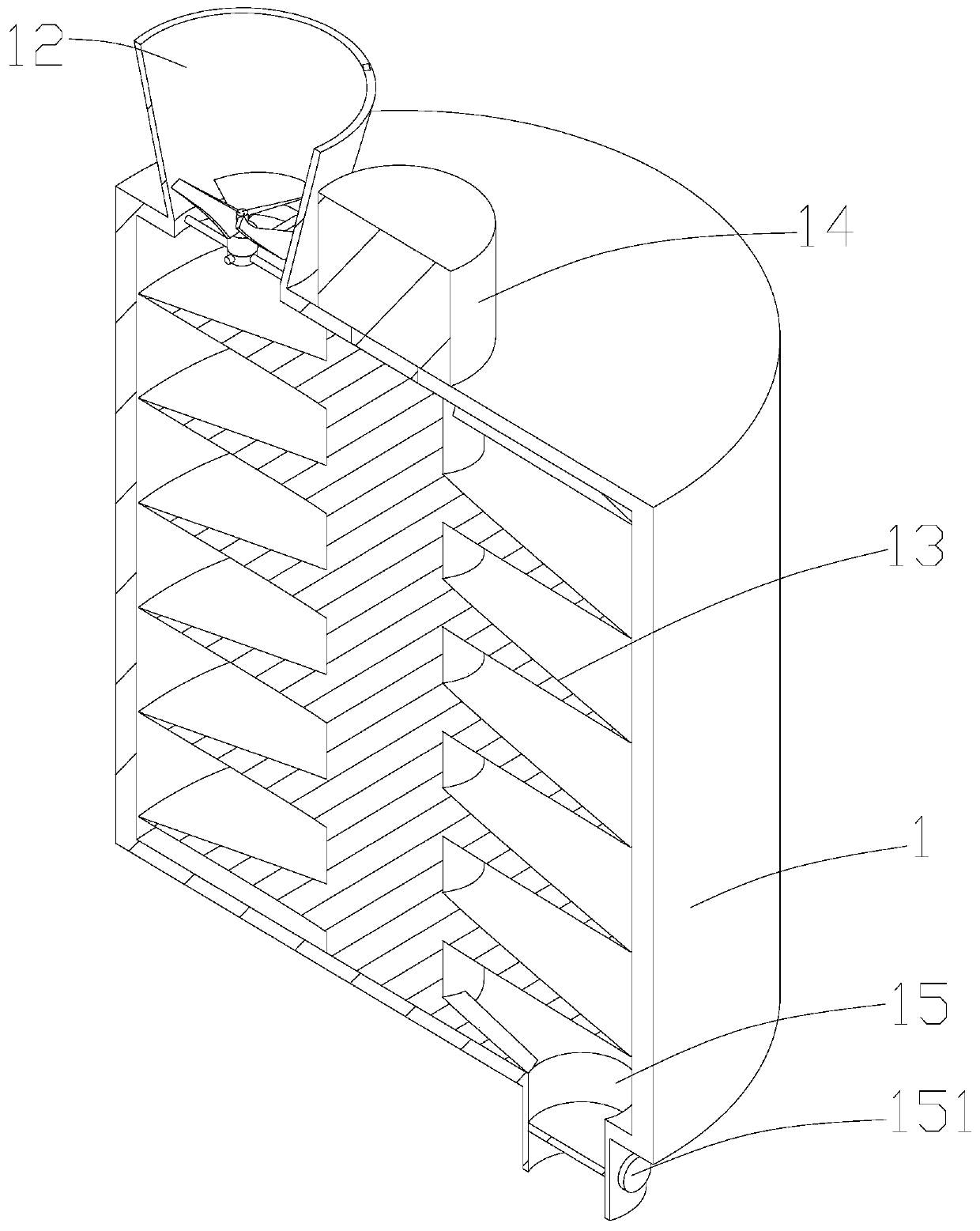

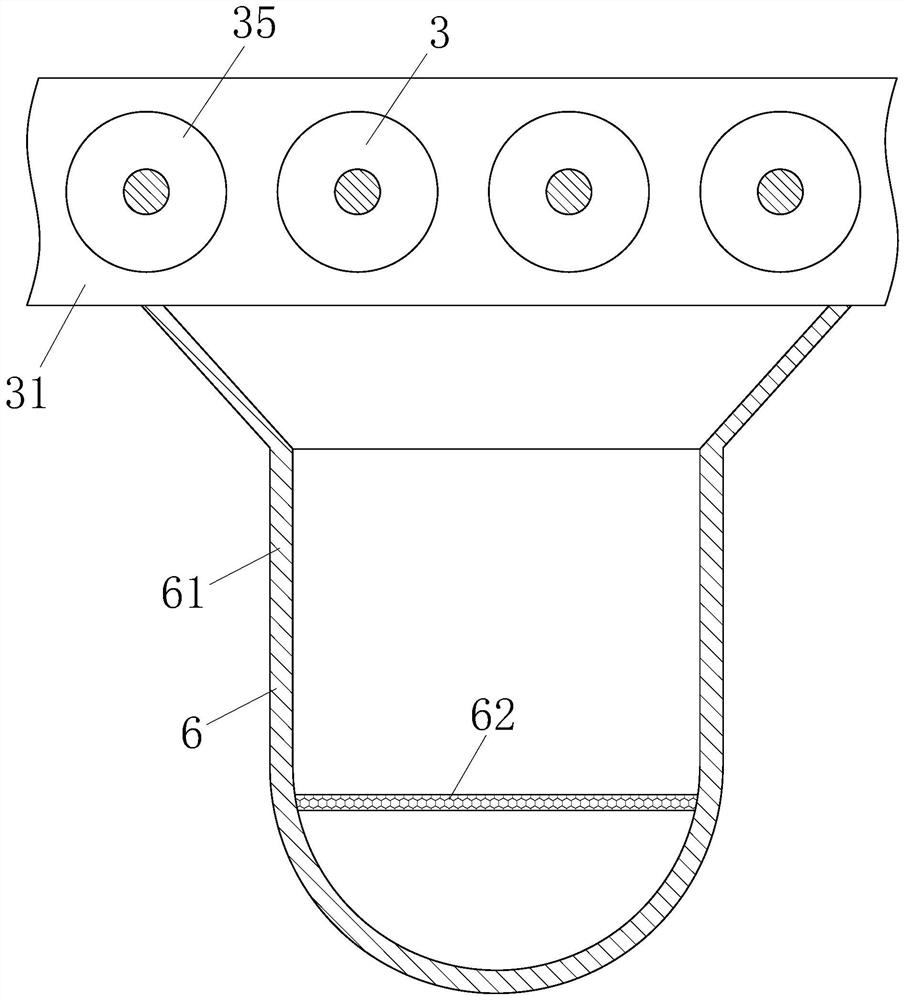

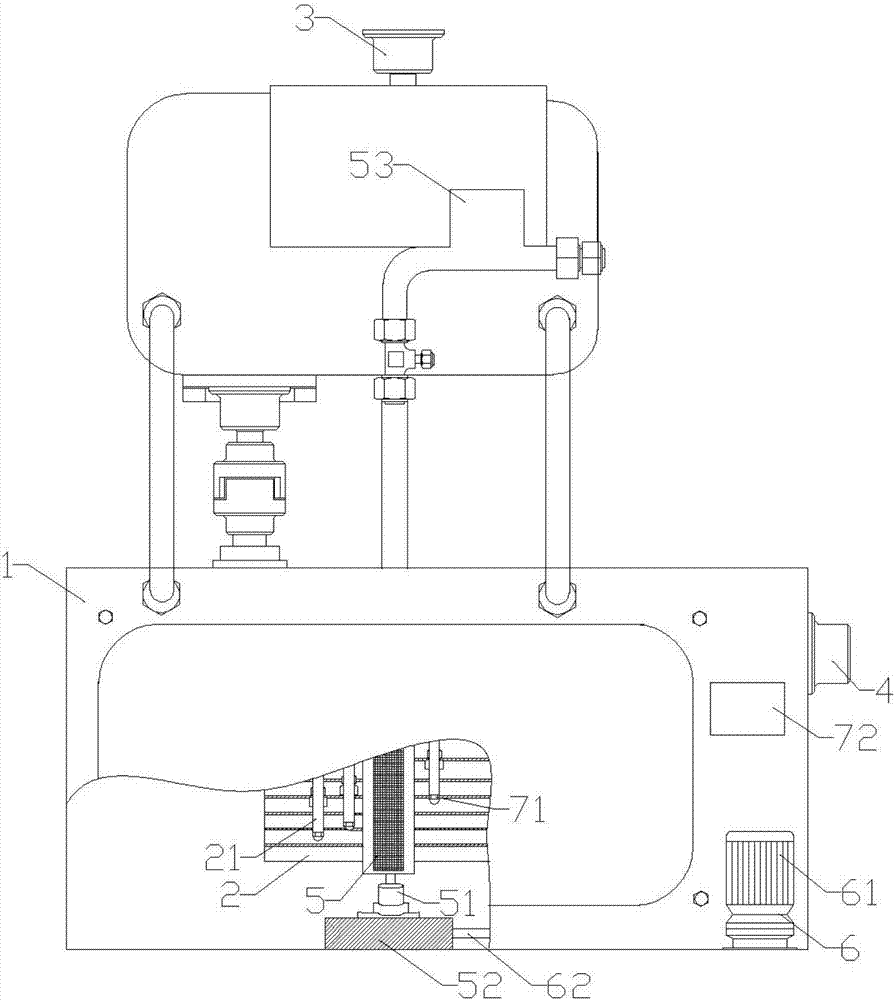

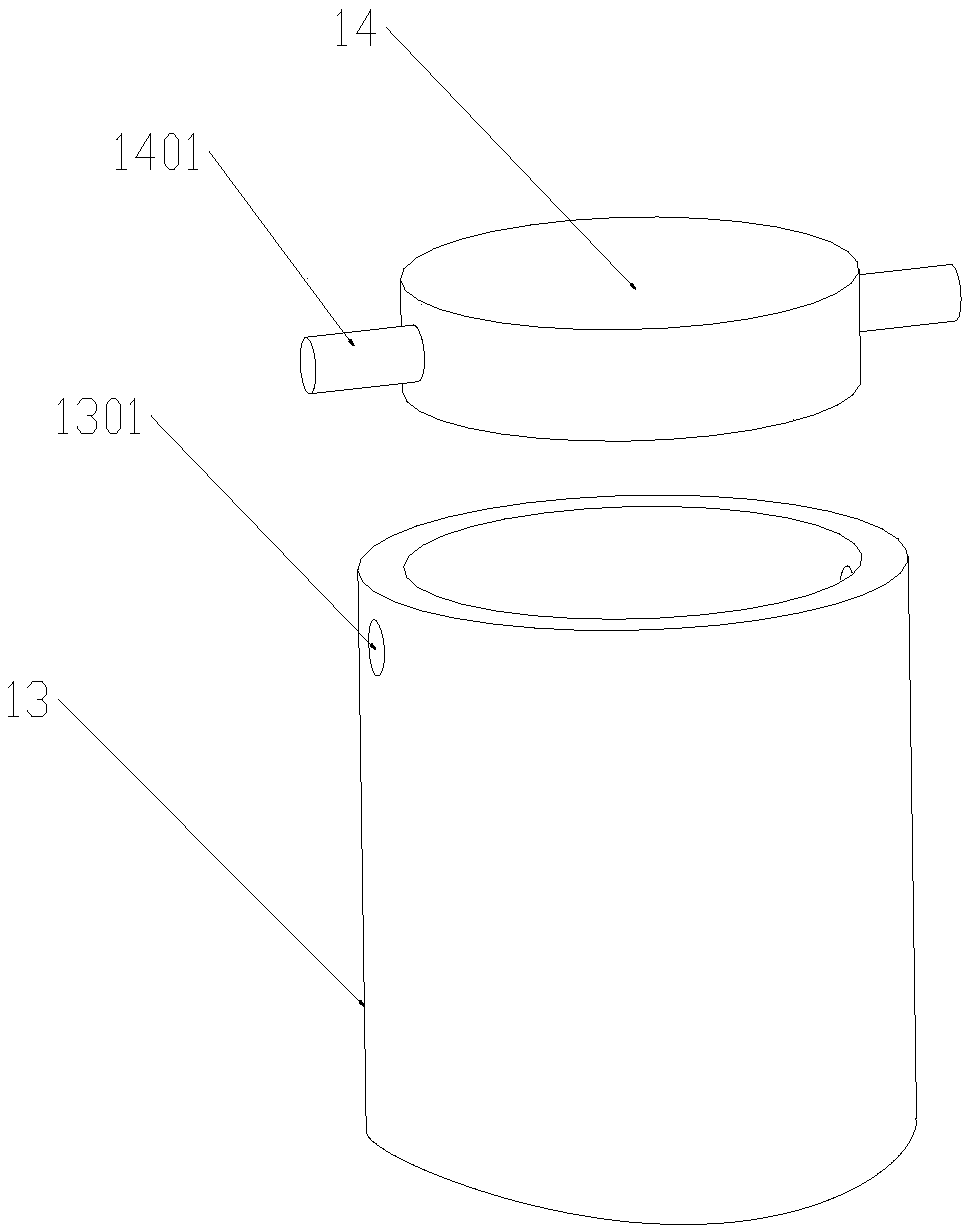

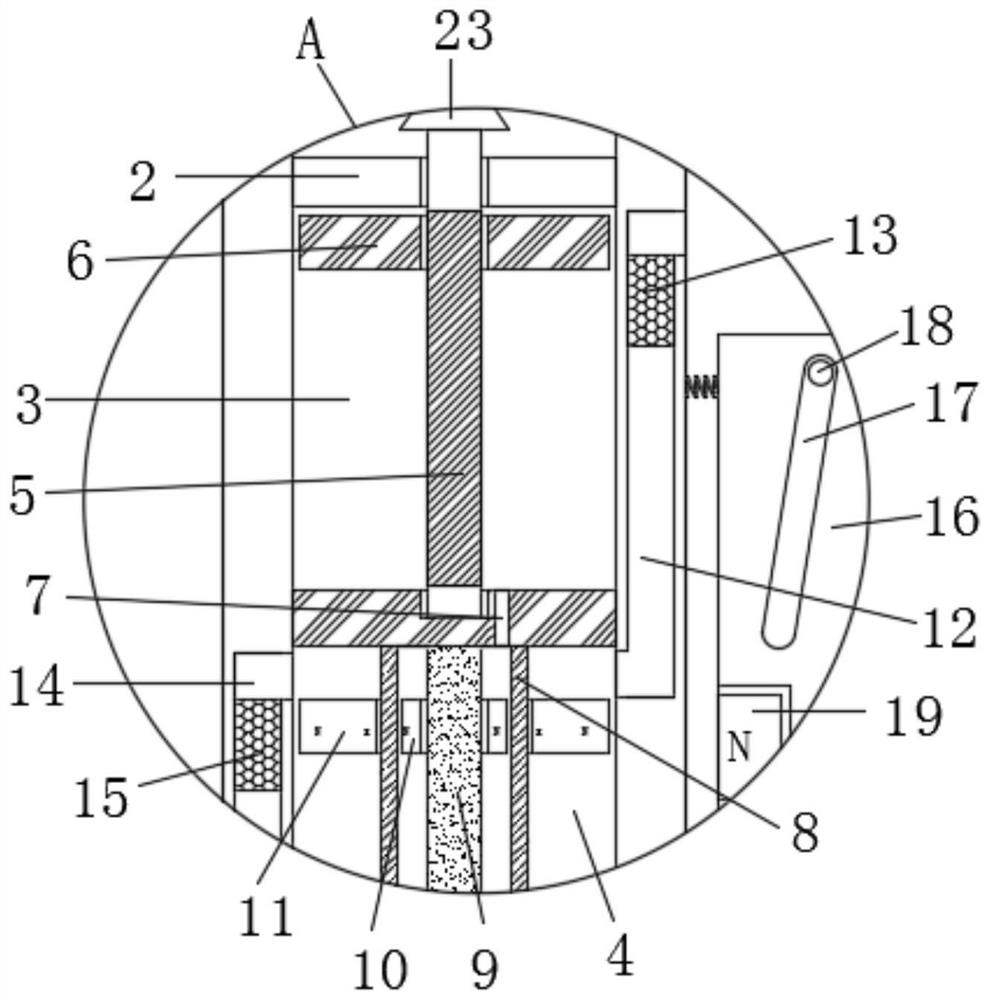

Kitchen garbage solid-liquid separation device based on rotary extrusion

ActiveCN112743896ASqueeze thoroughlyAvoid easy cloggingDrying gas arrangementsWaste collection and transferProcess engineeringSeparation process

The invention relates to a garbage treatment device, in particular to a kitchen garbage solid-liquid separation device based on rotary extrusion. The technical purpose of the invention is to provide the kitchen garbage solid-liquid separation device based on rotary extrusion, which can realize quantitative feeding and reciprocating rotation in an extrusion process. According to the technical implementation scheme of the invention, the kitchen garbage solid-liquid separation device based on rotary extrusion comprises a base, two support plates, a support pipe and the like; the support plates and the support pipe are arrange on the base, the two support plates are symmetrically arranged along the periphery of the base, and one end of the support pipe is fixedly connected with the center position of the base. The solid-liquid kitchen garbage can rotate and extrude garbage simultaneously during separation of solid-liquid kitchen garbage through cooperation of an extrusion assembly and a cylinder, so that filter holes are not easy to be blocked in the separation process, and extrusion of the kitchen garbage can be more thorough.

Owner:安必思环保科技(淄博)有限公司

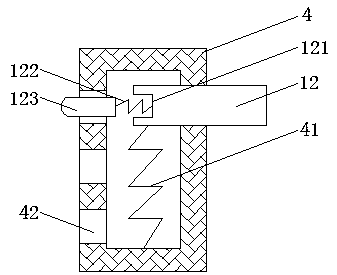

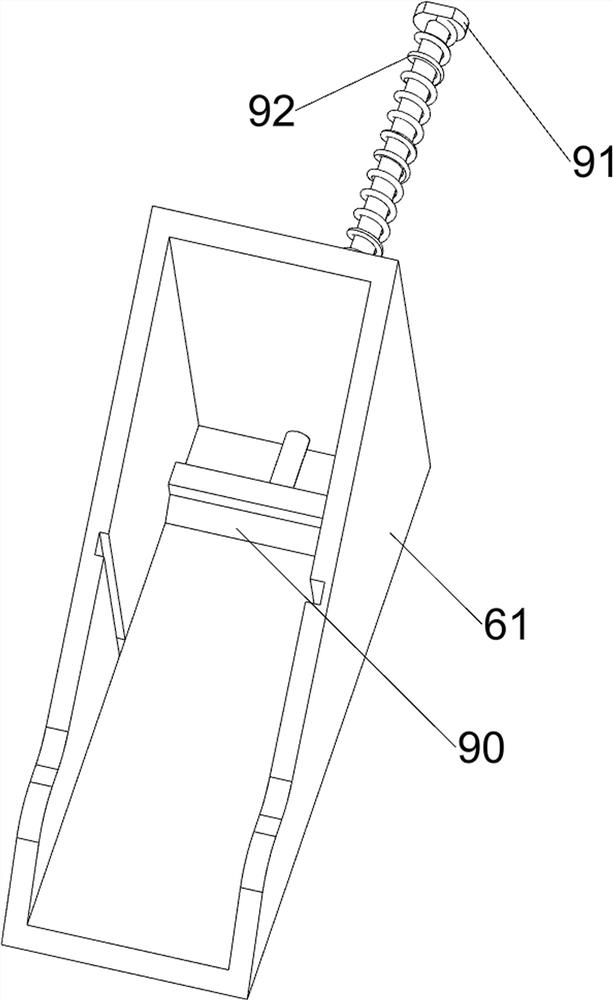

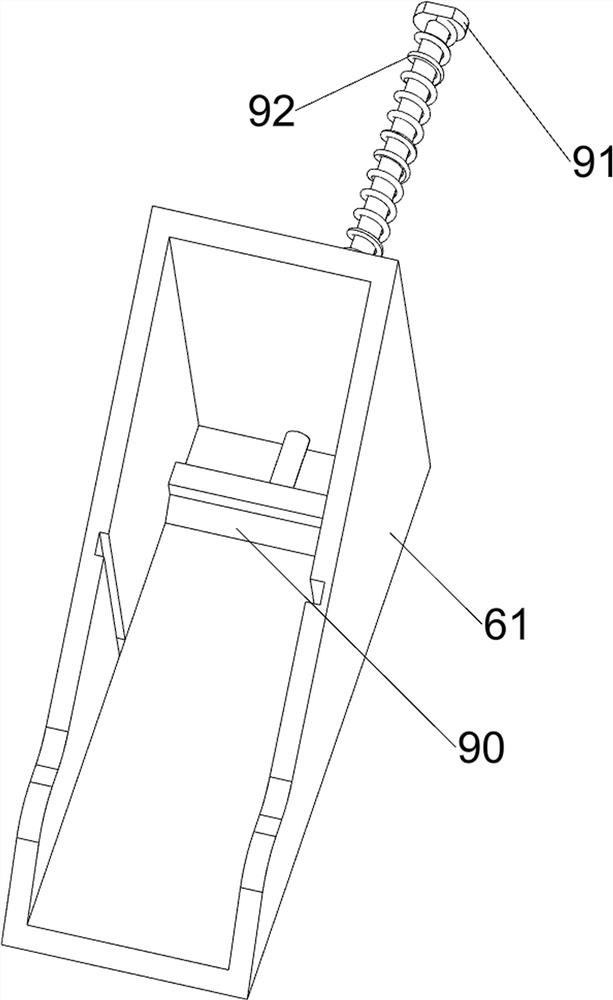

Intelligent toothpaste squeezing device

ActiveCN109987300ASqueeze thoroughlySqueeze accuratelyUnpacking by expelling contentsScrew positionToothpaste

The invention discloses an intelligent toothpaste squeezing device. The device comprises a front panel and a rear panel, wherein a feeding through groove is formed in the center of the front panel; apressing groove is formed in the center of the rear panel, and a tail fixing device is arranged above the pressing groove; the tail fixing device comprises a T-shaped pressing block; a placing base and an extrusion device are arranged between the front panel and the rear panel; the extrusion device comprises two moving screws positioned between the front panel and the rear panel; moving blocks arescrewed on the moving screws; adjusting blocks are arranged above the moving blocks; a rotating roller is hinged between the two moving blocks and another rotating roller is hinged between the two adjusting blocks; and a front limiting mechanism is arranged on the front side wall of the front panel. The device has advantages that automatic toothpaste squeezing can be achieved by only one-hand operation, toothpaste can be thoroughly squeezed to reduce waste, and toothpaste can be accurately squeezed onto the brush by arranging two infrared sensors simultaneously sensing toothbrush head.

Owner:SHANDONG CHENXIN NEW ENERGY

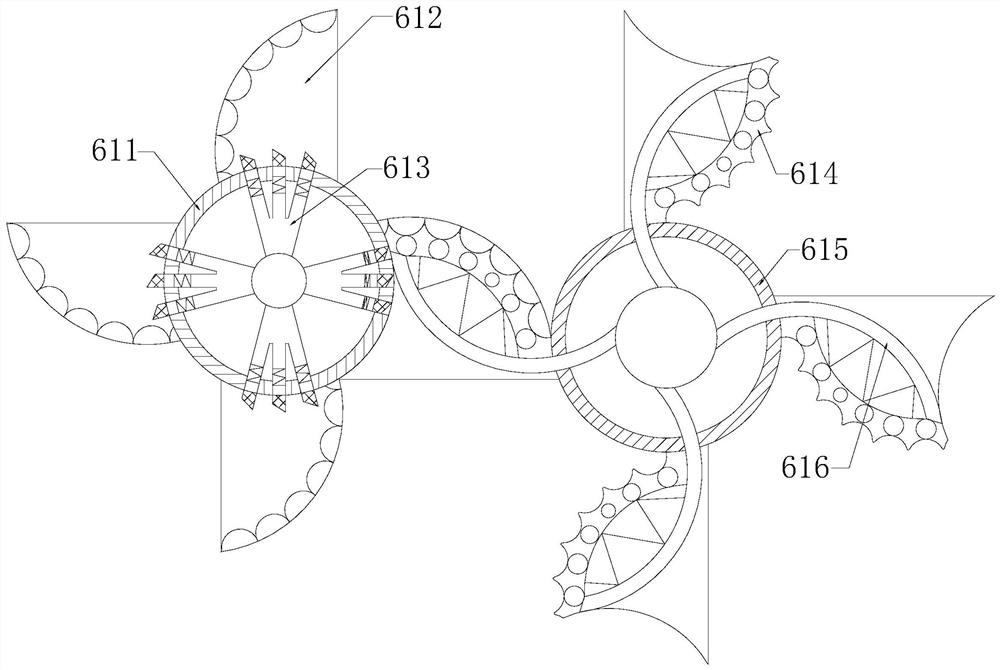

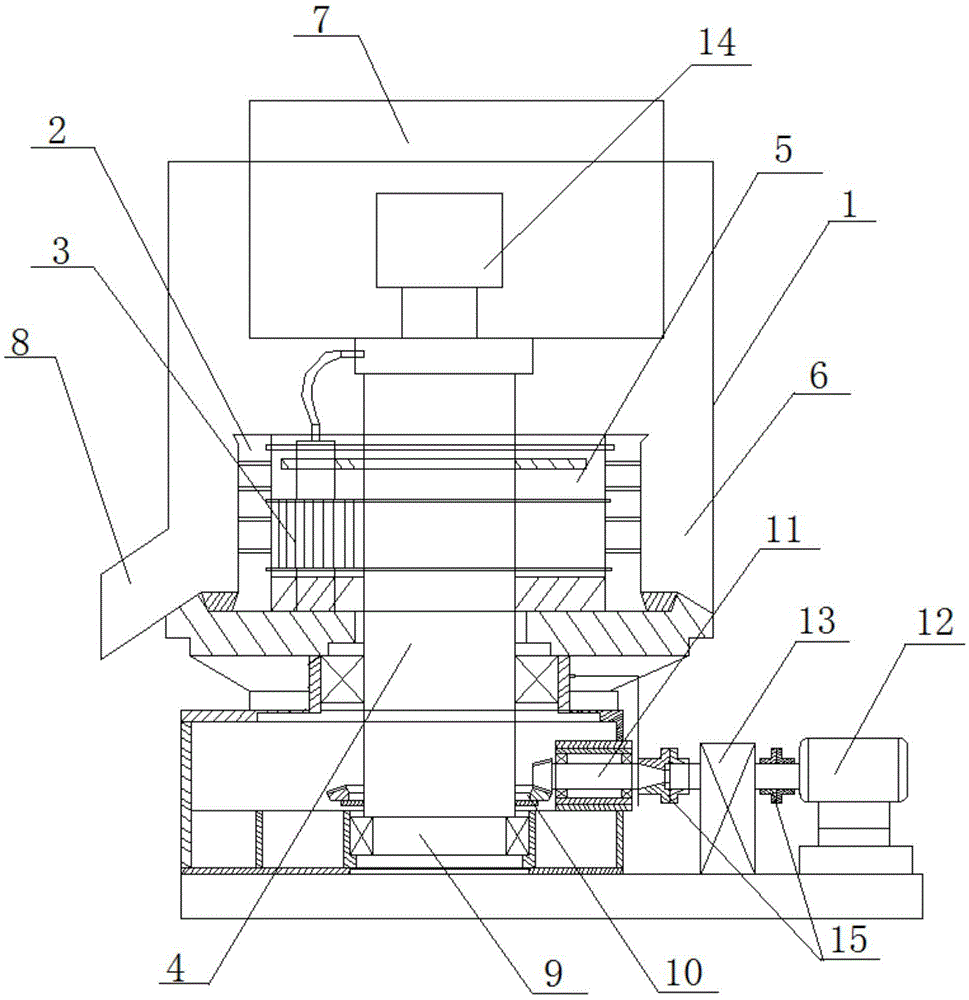

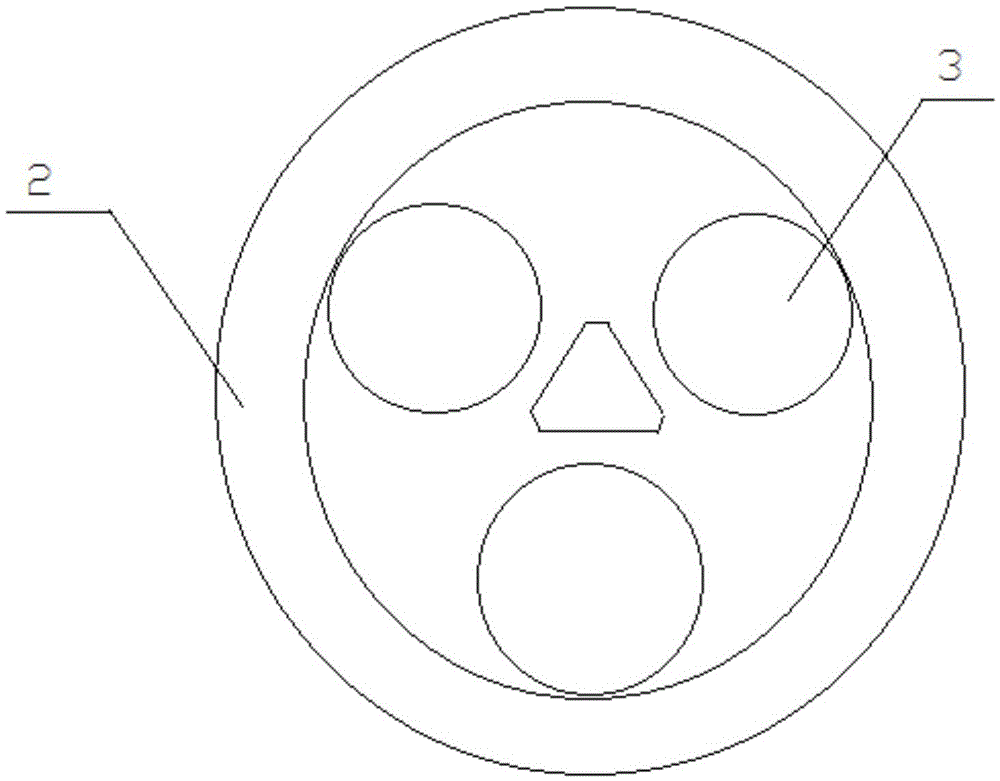

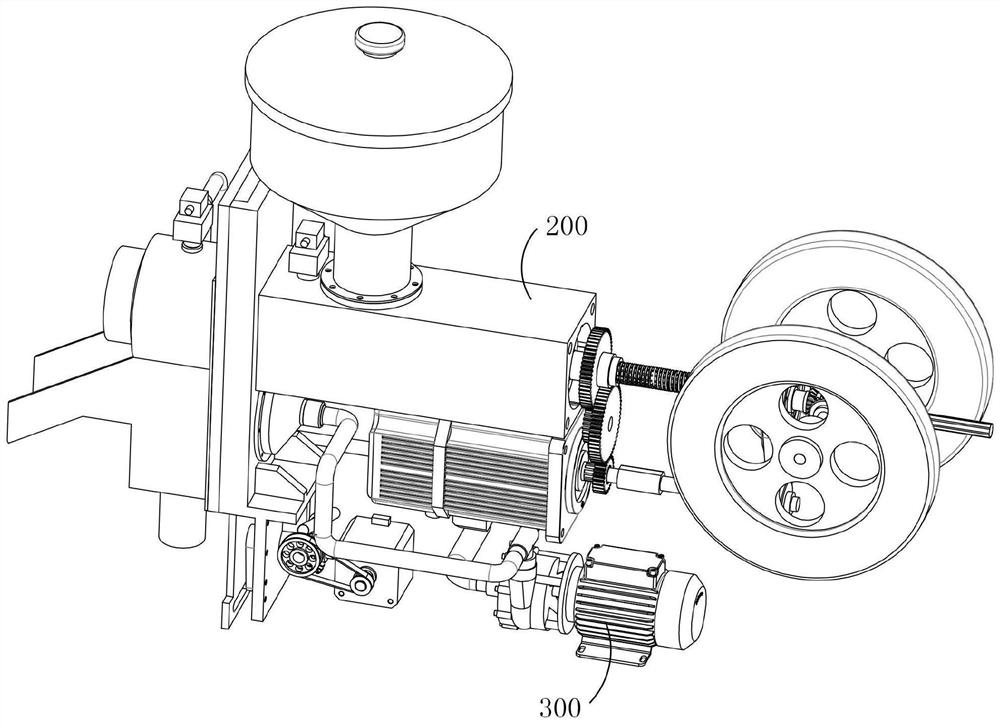

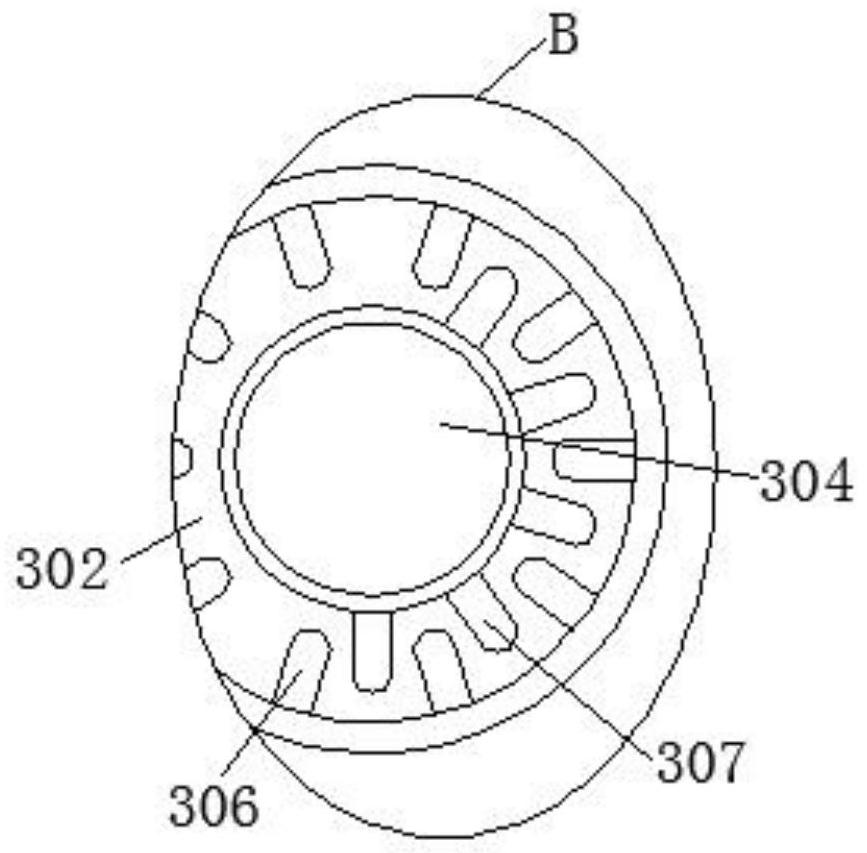

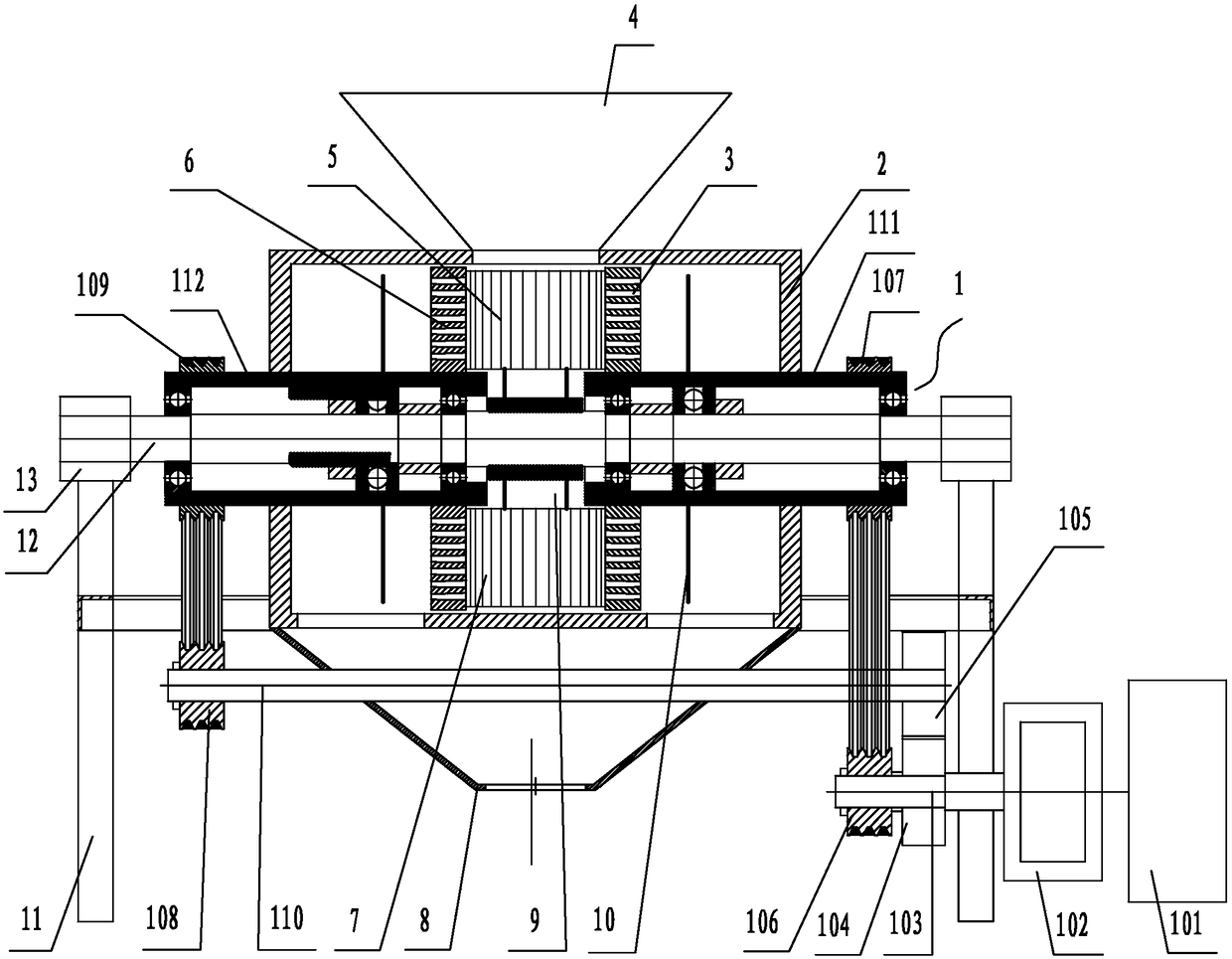

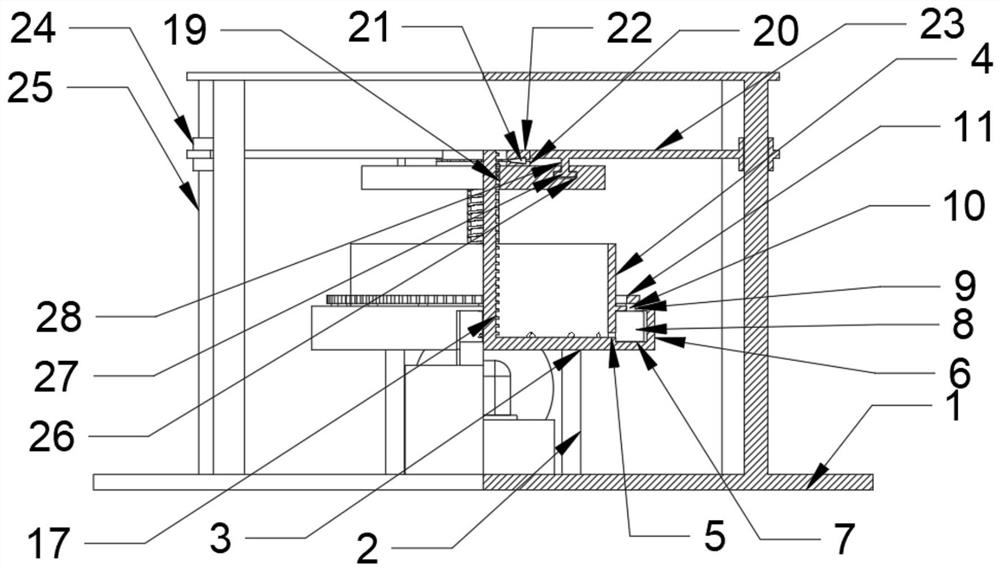

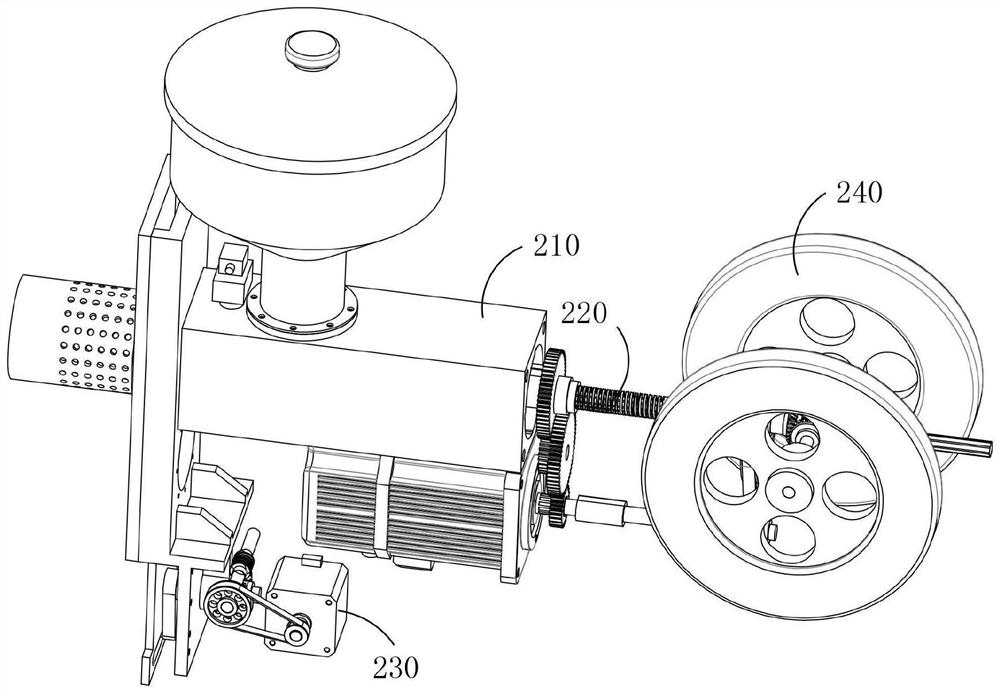

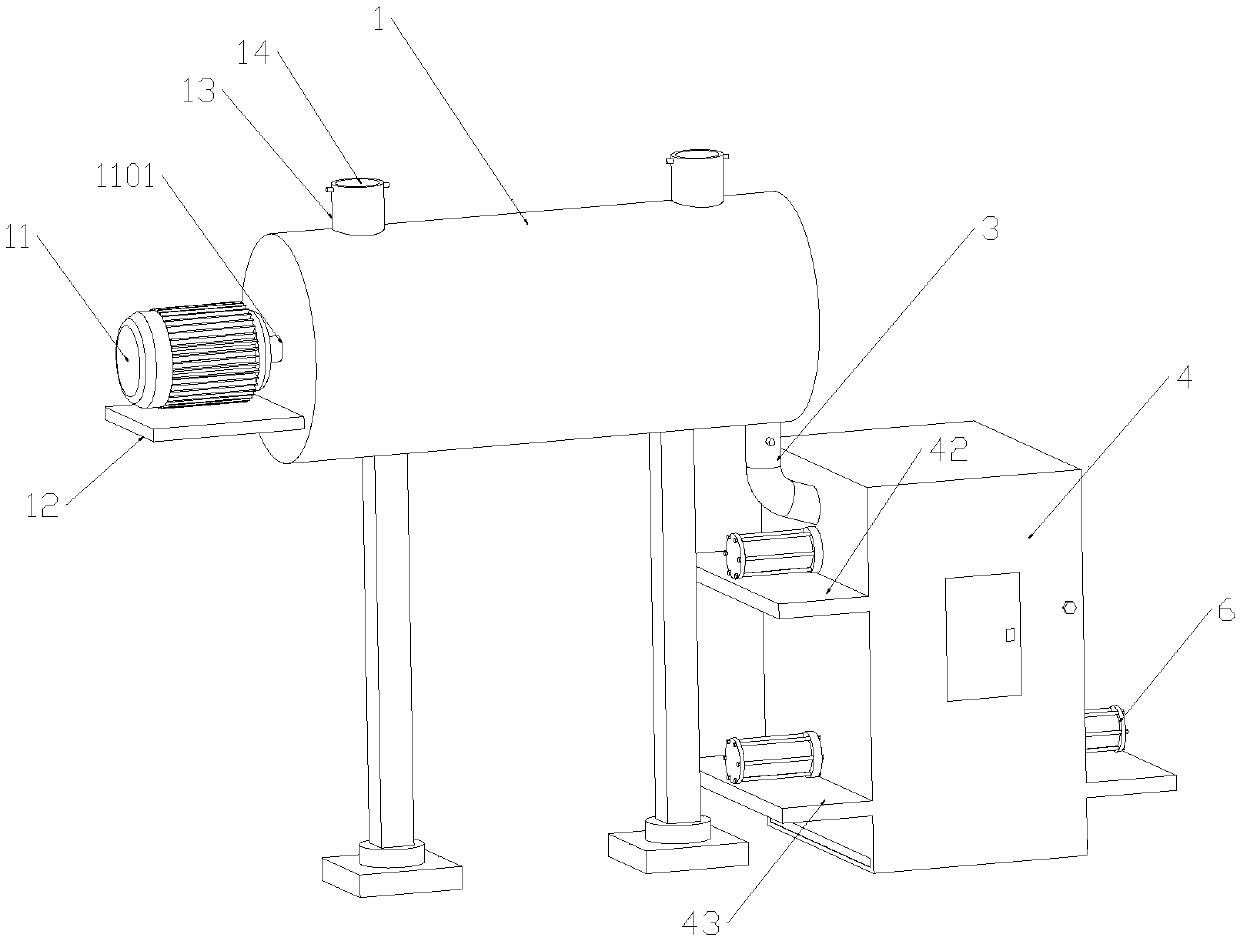

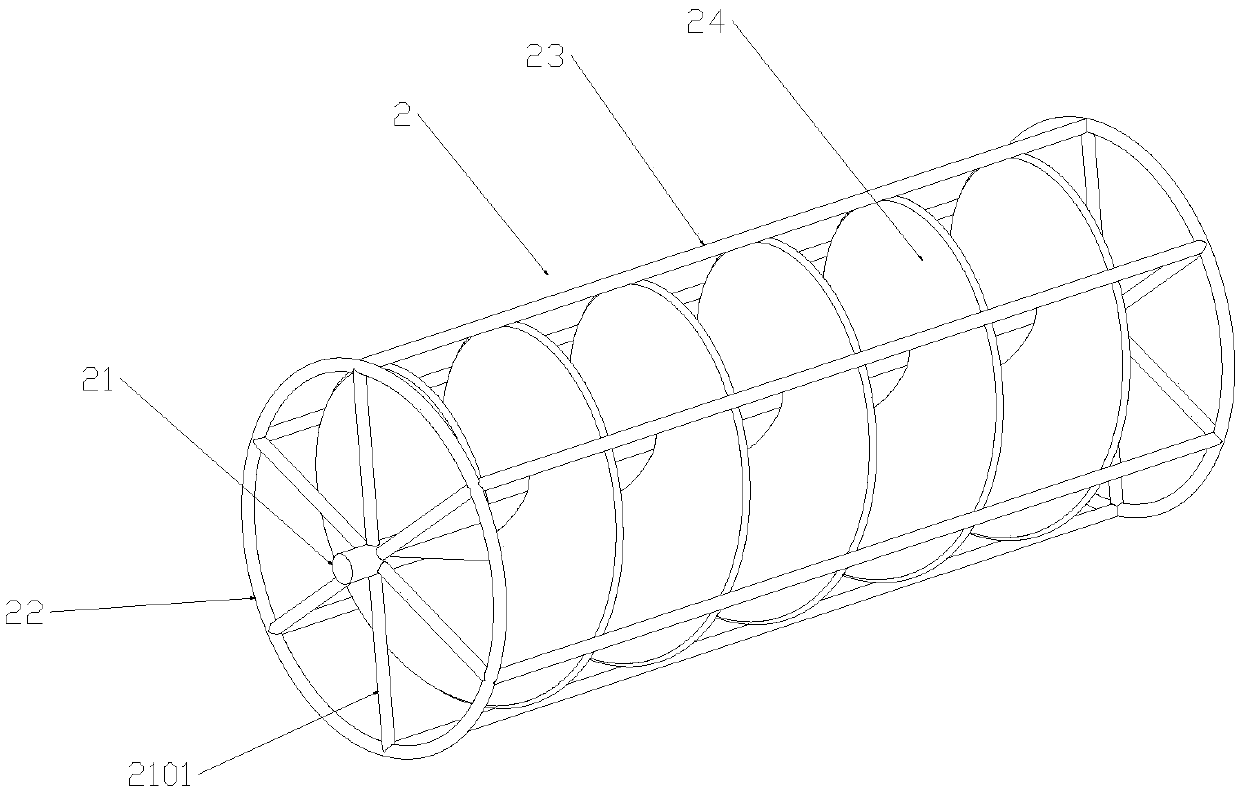

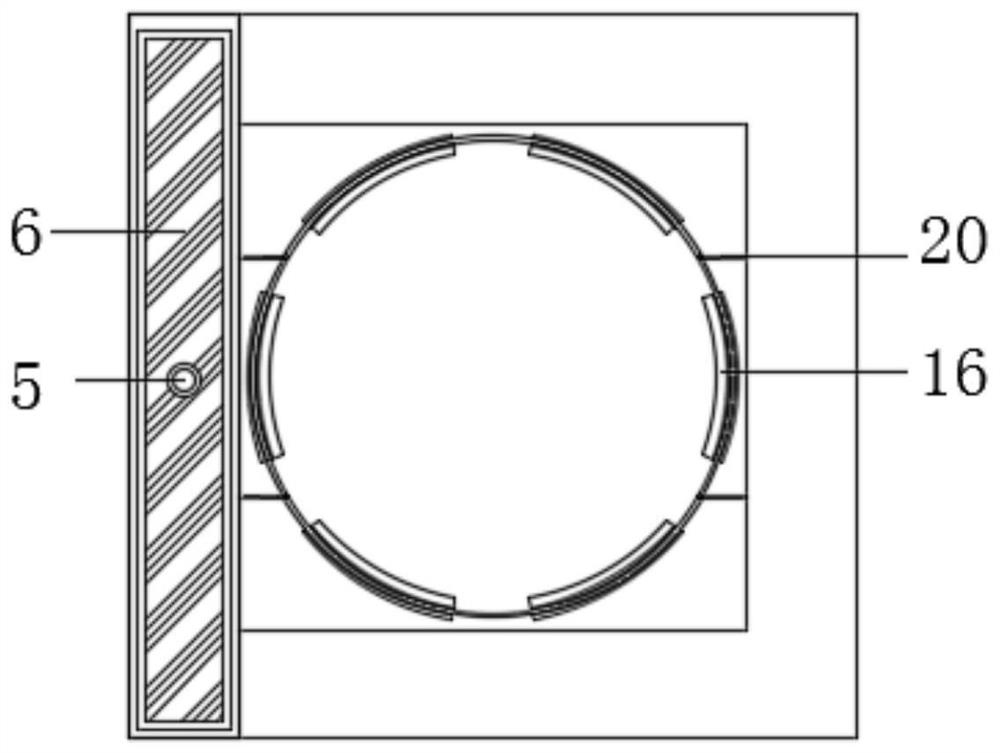

Novel three-press-roll speed-variable granulation machine

InactiveCN105597625ASqueeze thoroughlyReduce wearBiofuelsSolid fuelsMechanical engineeringRaw material

The invention discloses a novel three-press-roll speed-variable granulation machine which comprises a granulation device and a driving device for supplying power to the granulation device, wherein the granulation device comprises a shell and an annular mould arranged in the shell; three press rolls are arranged in the annular mould; the press rolls are driven to rotate through a rotating shaft by the driving device; the axial direction of the annular mould is vertically arranged; and the axial direction of the press rolls, the axial direction of the annular mould and the axial direction of the rotating shaft are parallel to each other. According to the novel three-press-roll speed-variable granulation machine, three press rolls are arranged in the annular mould, the three press rolls are symmetrically arranged, the pressure is offset with each other, the abrasion is reduced, the uniform stress endured by the device is ensured, the device is difficult to be damaged, the materials are thoroughly extruded, no dead angle is leaved and the production efficiency is increased; the driving device is horizontally arranged through a bevel gear; a multi-level gearbox is used, so that the suitable extruding speed can be selected according to the raw materials; the transmission speed is changed while the torsion is increased; and the effect of driving a big device through a small motor is achieved.

Owner:宜兴市凯世达科技有限公司

Compression molding method of household garbage

InactiveCN111873525ASmall smellEasy to transportSolid waste disposalPressesCompression moldingReciprocating motion

The invention discloses a compression molding method for household garbage. The compression molding method comprises the steps that the household garbage falls into a compression pipeline; a power assembly drives a threaded rod and a compression piston to move close to a first fixing plate, the compression piston extrudes the household garbage to enable the household garbage to be in a circular block shape, and sewage generated in the extrusion process is discharged to the outside through a filter plate and a water outlet hole; in the compression process, a transmission assembly synchronouslydrives a rotating shaft and a linkage pin to rotate, so that a driving hammer does reciprocating motion of getting away and then getting close to a fixed end cover; a sealing plate is switched to a cleaning state, meanwhile, the power assembly operates reversely, the sealing plate is switched to a water filtering state after the compressed gas provided by a compressed gas source enables the household garbage to be output outwards, and the process is repeated in this way; in the process that the sealing plate is in a water filtering state and a compression mechanism compresses the household garbage, an appliance cleaning mechanism cleans the water outlet hole; and in the process that the sealing plate is in a cleaning state and the compression mechanism reversely operates to recover the original shape, the appliance cleaning mechanism cleans the filter plate.

Owner:安徽奉念城机电设计服务有限公司

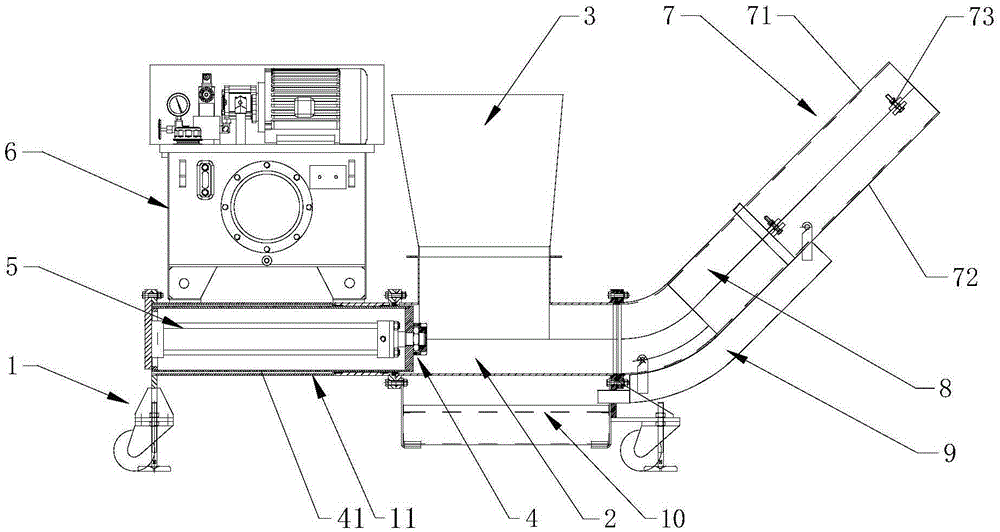

Sludge conveying and dewatering equipment used for sludge treatment

InactiveCN110002713AAchieve exclusion effectReduce moisture contentSludge treatmentSewageMaterial supply

The invention discloses sludge conveying and dewatering equipment used for sludge treatment. The equipment comprises a material conveying cylinder used for conveying sludge, a plurality of supportinglegs used for supporting the material conveying cylinder and a collecting box used for collecting the treated sludge; and the material conveying cylinder is provided with a material inlet hopper and aspiral material supply rod, at least one dewatering box used for dewatering treatment of the sludge and first driving member used for driving rotation of the dewatering box are arranged below the material conveying cylinder, the first driving member is fixedly arranged on the collecting box, and the dewatering box is provided with a dewatering device. According to the equipment provided by the invention, through arrangement of the above structure, the sludge can be uniformly conveyed through the material conveying cylinder, so that volume treatment of the sludge is realized, and blockage caused by a too large volume of the sludge is avoided; and at the same time, the sludge can be treated by the dewatering device, so that the sludge can be dried in a certain shape in batches, forming specifications of the sludge are substantially same, mutual adhesion of the sludge can be avoided, collection arrangement of the sludge is facilitated, and the control utilization rate of the collection container is improved.

Owner:杭州更蓝生物科技有限公司

Waste rubber sorting device

The invention discloses a waste rubber sorting device in the field of waste sorting. A sorting mechanism comprises a sorting machine case, the top of the sorting machine case is provided with a secondfeeding port, and a first feeding port communicates with the second feeding port; a roller and an arc-shaped plate are arranged in the sorting machine case and located under the second feeding port,and a gap is reserved between the roller and the arc-shaped plate; a plurality of sawteeth are arranged on the surface of the roller, a second motor is arranged at one end of the roller, and the roller is rotatably connected with the second motor; the arc-shaped plate is fixedly connected with the sorting machine case, and a plurality of sawteeth are arranged on the face, close to the roller, of the arc-shaped plate; and a first discharging tank is arranged at the bottom of the sorting machine case, a plurality of sorting pipes are vertically arranged in the first discharging tank at intervals, an opening is formed in the bottom of the first discharging tank, and a second discharging tank is arranged under the first discharging tank and located under the opening. By adopting the waste rubber sorting device, the labor intensity of workers can be reduced, and the working efficiency can be greatly improved.

Owner:丁道勇

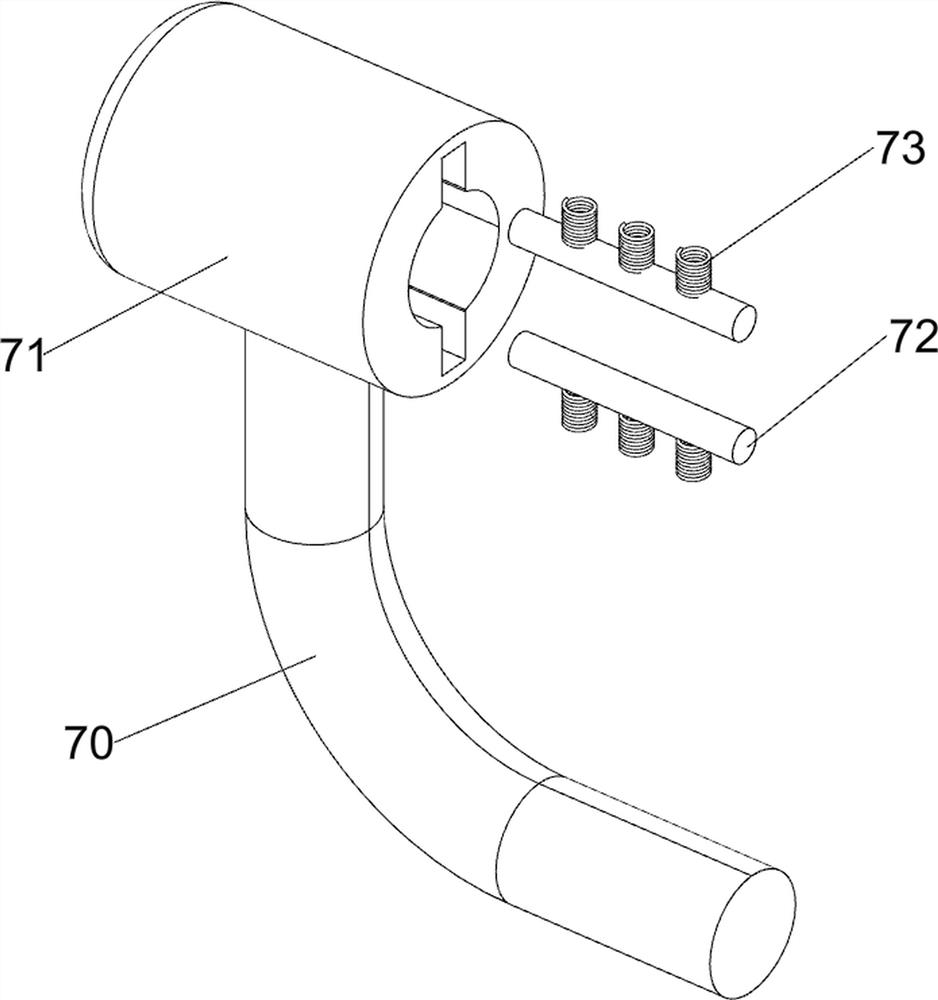

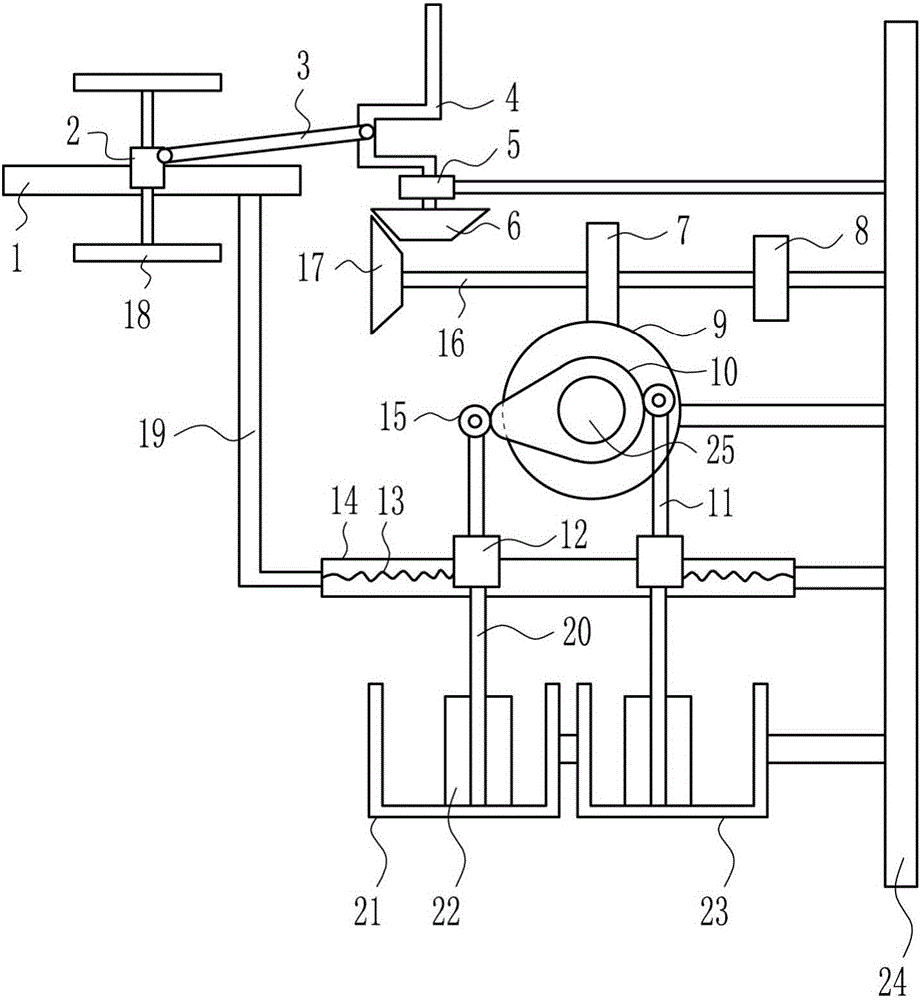

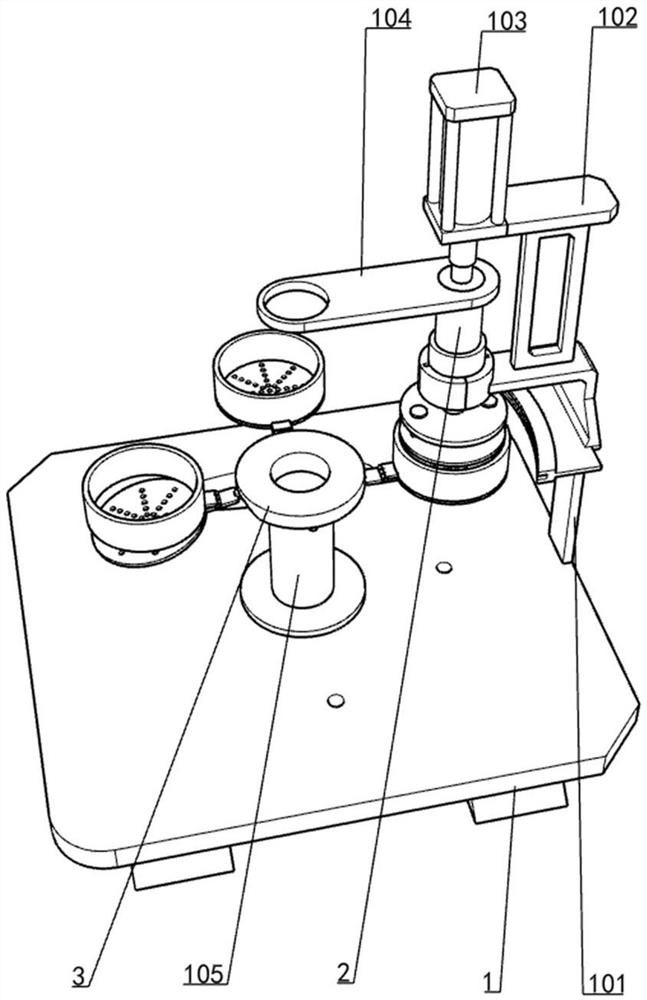

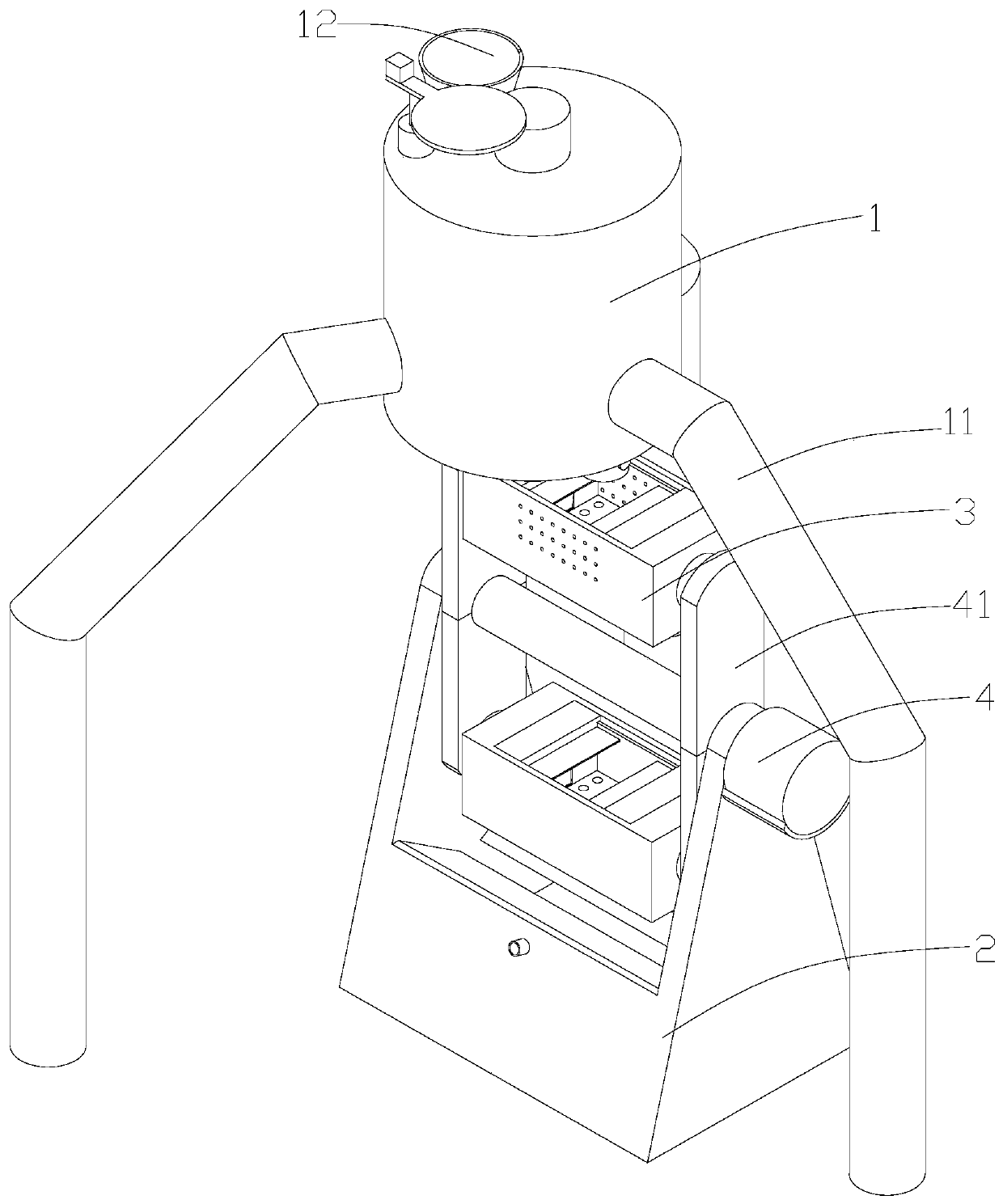

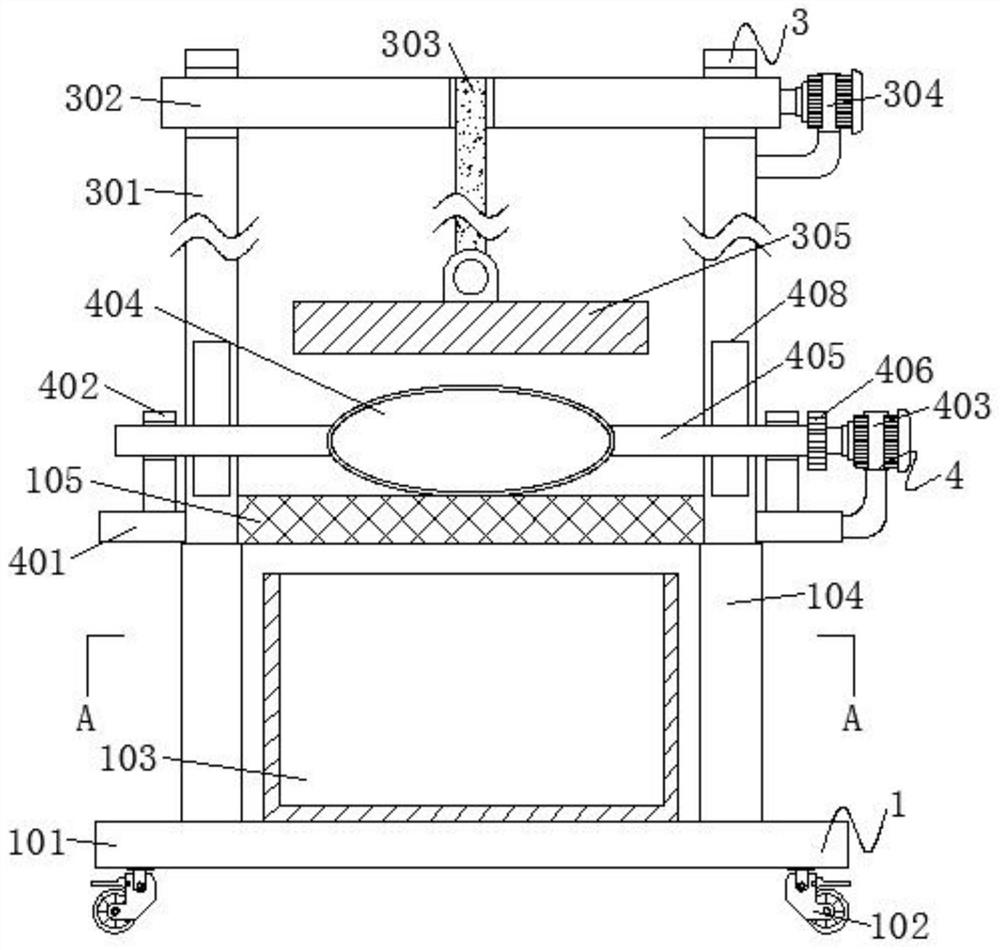

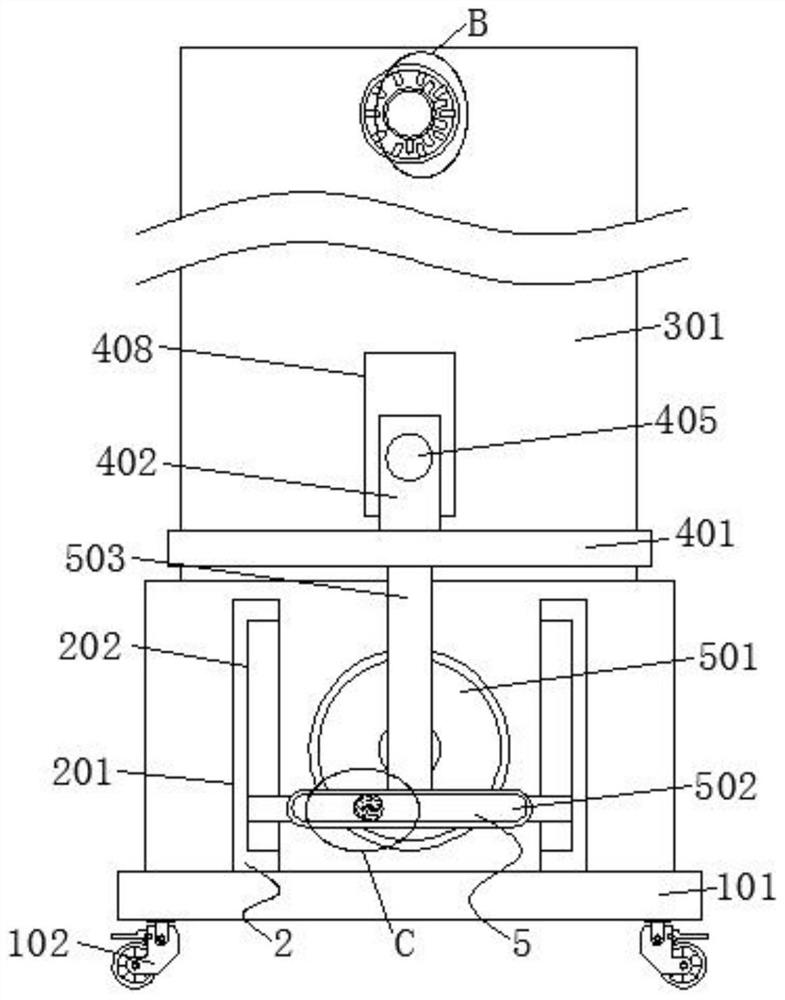

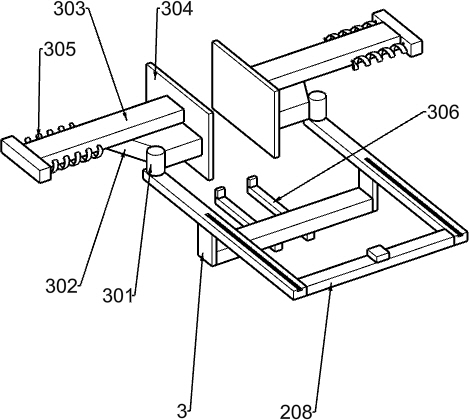

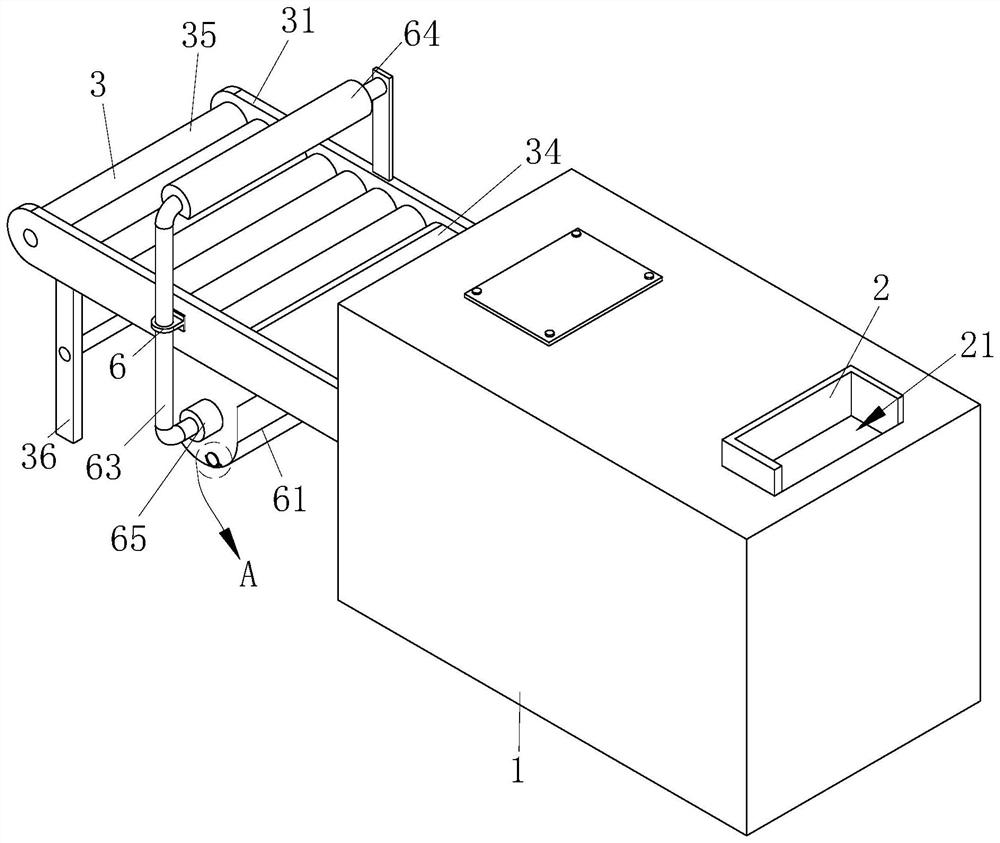

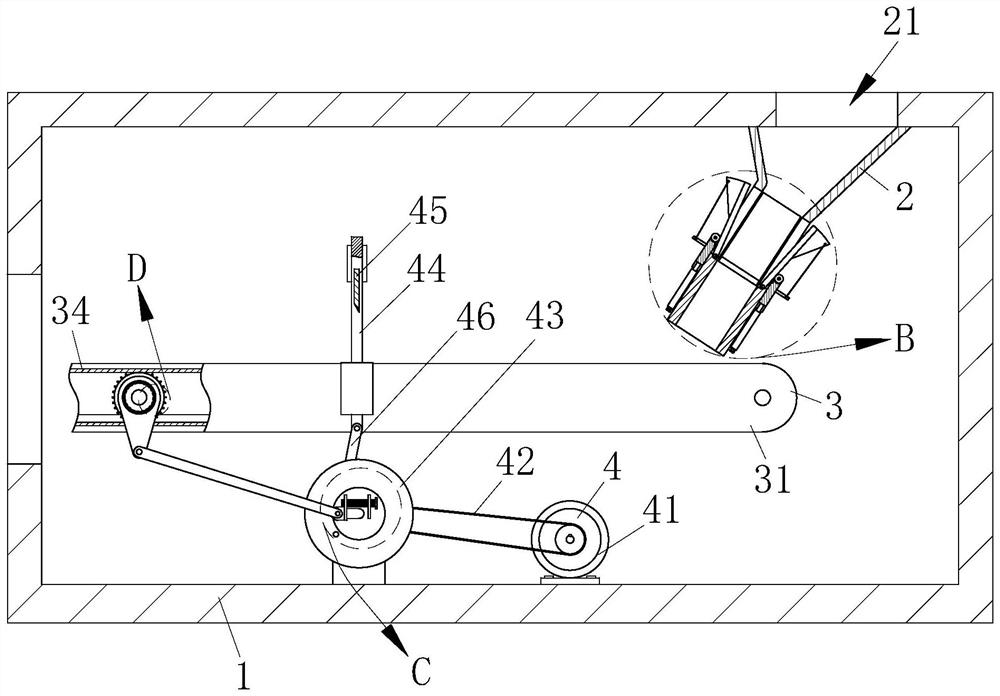

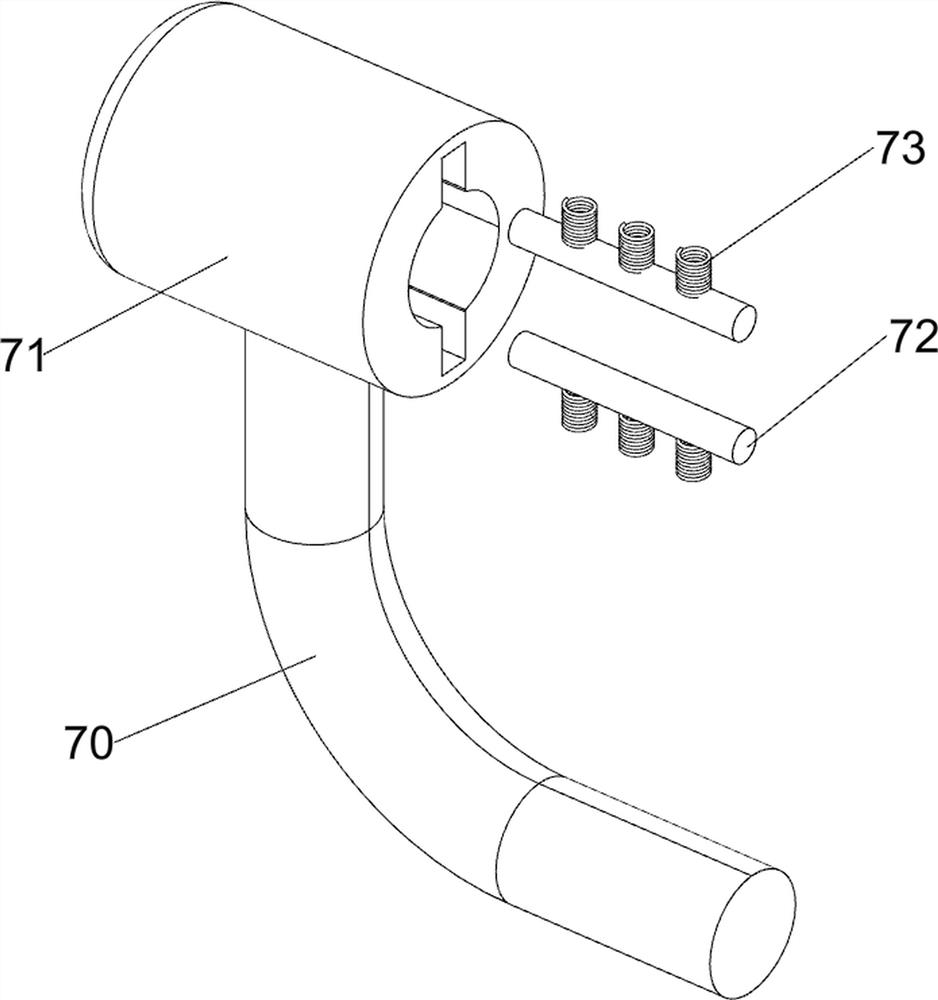

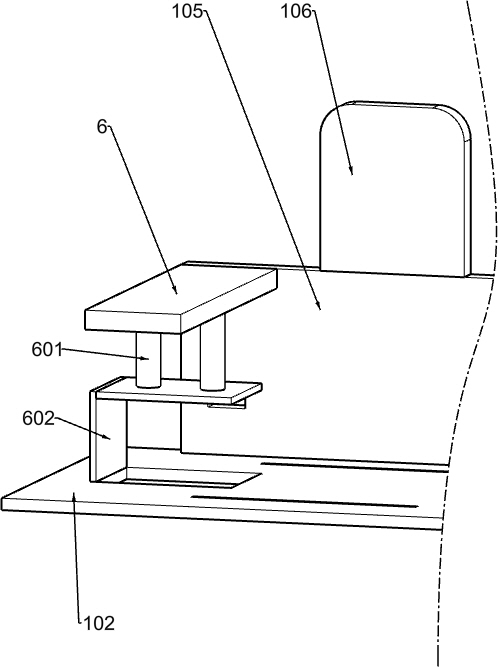

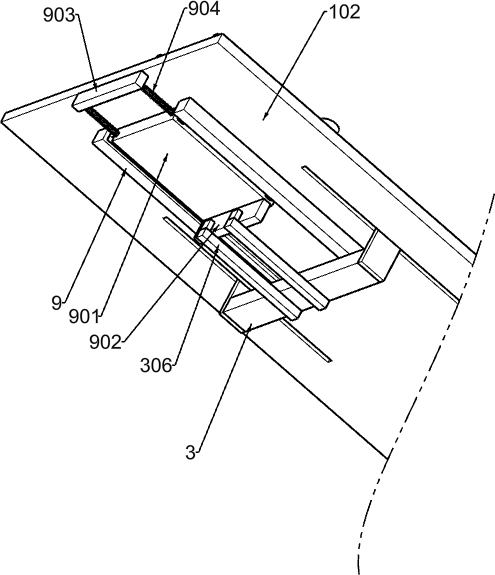

Automatic equipment for yellow rice wine processing process

PendingCN112776397ASqueeze thoroughlyImprove crushing efficiencyPressesBiotechnologyElectric machinery

The invention discloses automatic equipment for a yellow rice wine processing process, and relates to the technical field of yellow rice wine processing. The automatic equipment comprises a bottom device, a limiting device, a squeezing device, a turnover device and a moving device, wherein the limiting device, the squeezing device and the moving device are all arranged at the top of the bottom device and are all fixedly connected to the bottom device, the squeezing device is arranged over the turnover device, the turnover device is arranged at the top of the moving device and fixedly connected to the moving device, and the squeezing device comprises a vertical plate, a round rod, a steel cable, a top motor, a squeezing iron plate, first teeth and second teeth. According to the automatic equipment disclosed by the invention, the turnover device and the moving device are arranged, when a mixture in a containing sleeve is squeezed, the mixture in the containing sleeve can be turned over through the combined action of the turnover device and the moving device, the mixture can be squeezed more comprehensively and thoroughly when the mixture is squeezed, and the squeezing efficiency of the mixture is improved.

Owner:贵州省旱粮研究所

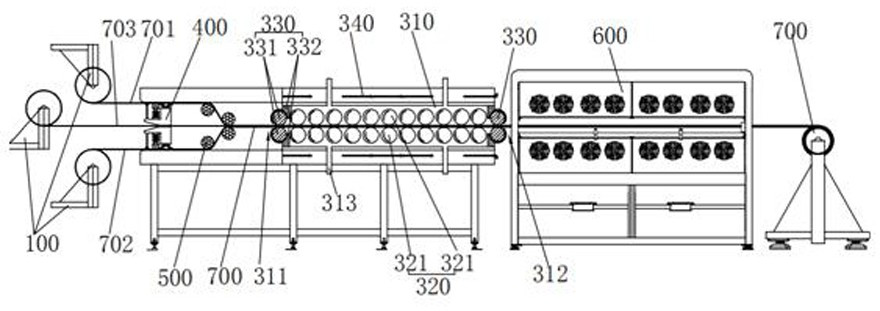

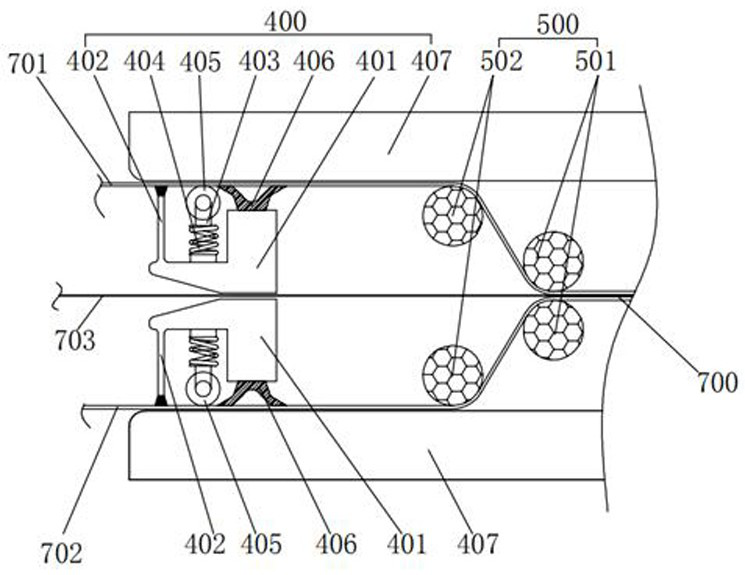

Encapsulation method of flexible solar cell module coil

ActiveCN110091572BIncrease transmission speedFully excludeLayered product treatmentLaminationEngineeringSolar battery

The present invention aims at the problem of low heating efficiency when packaging flexible solar cell components in the prior art, and provides a packaging method for flexible solar cell component coils. A group of hot pressing rollers located on the same conveying plane extrude and heat until the component is solidified, and vacuumize while extruding and heating the component, the vacuum degree is -0.8×10 5 Pa to -0.6×10 5 Pa, the vacuuming time is 30-40 minutes. The method of the present invention is used for component packaging, and the heating efficiency is high during the heating process. Simultaneously vacuuming during heating can make the air bubbles more thoroughly removed and the packaging effect better.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

A sorting device for waste rubber

ActiveCN109291320BReduce labor intensityImprove work efficiencyPlastic recyclingWaste rubberElectric machinery

Owner:丁道勇

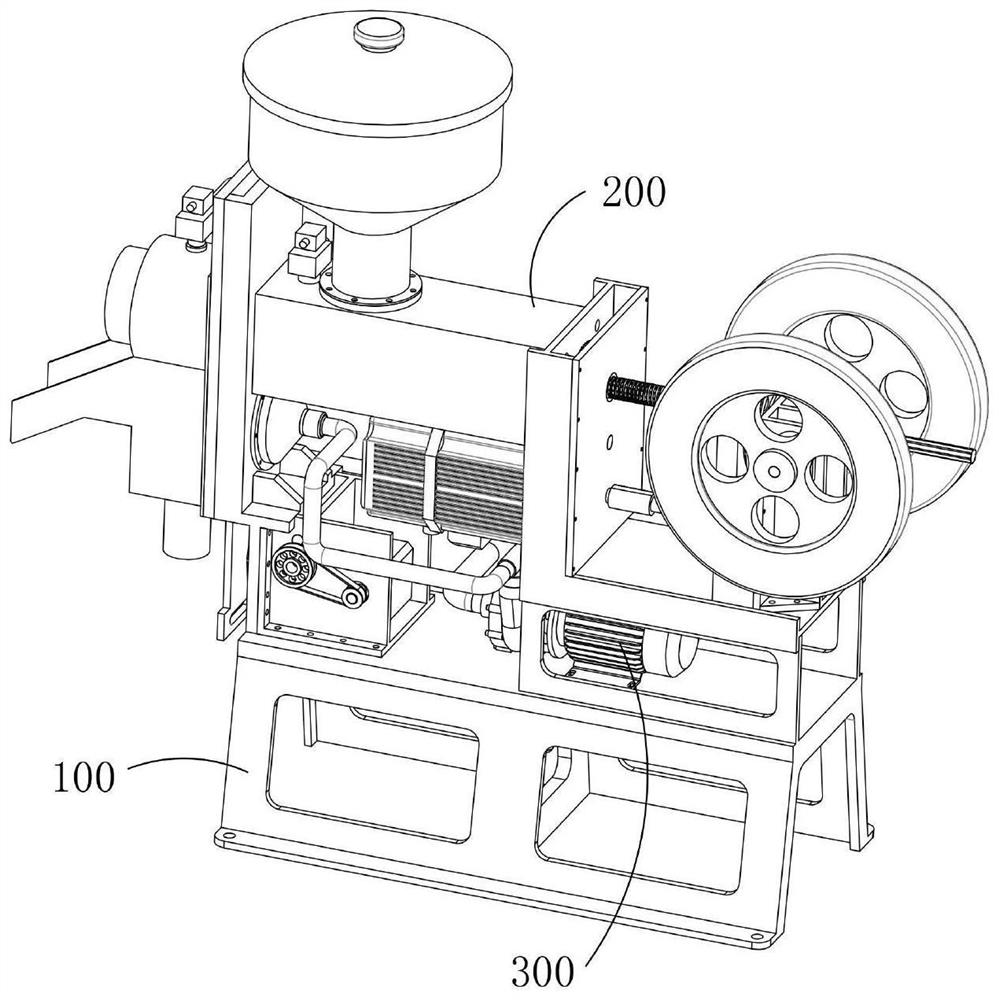

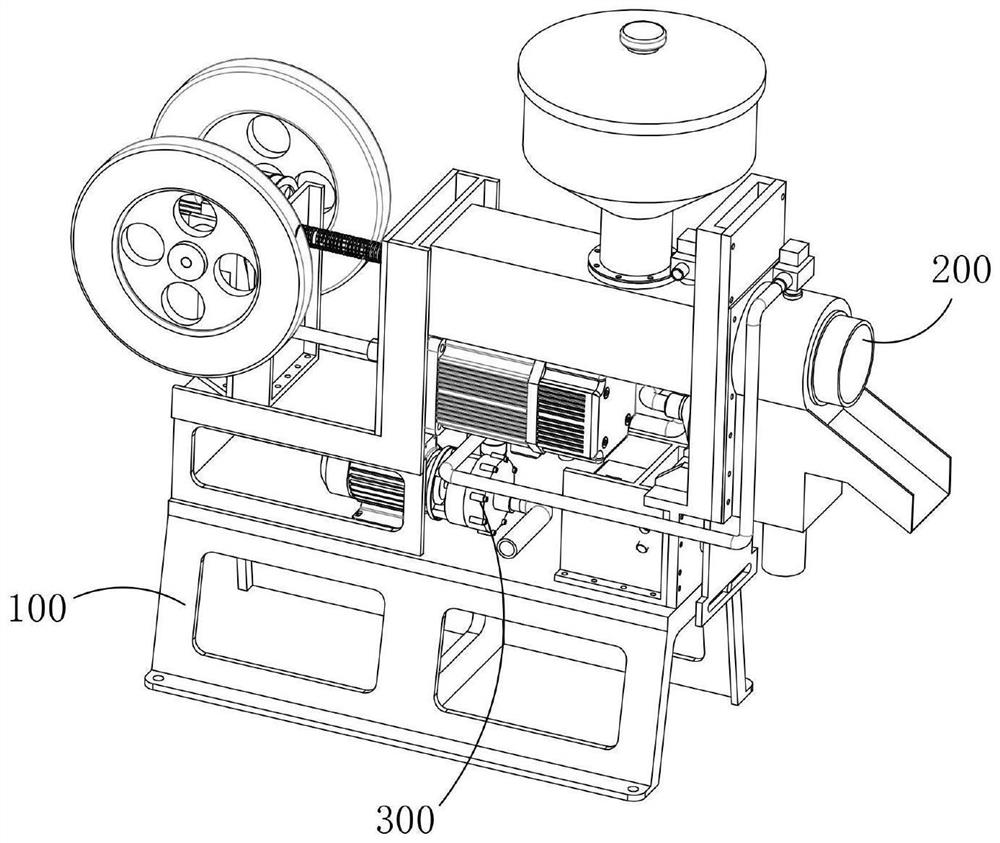

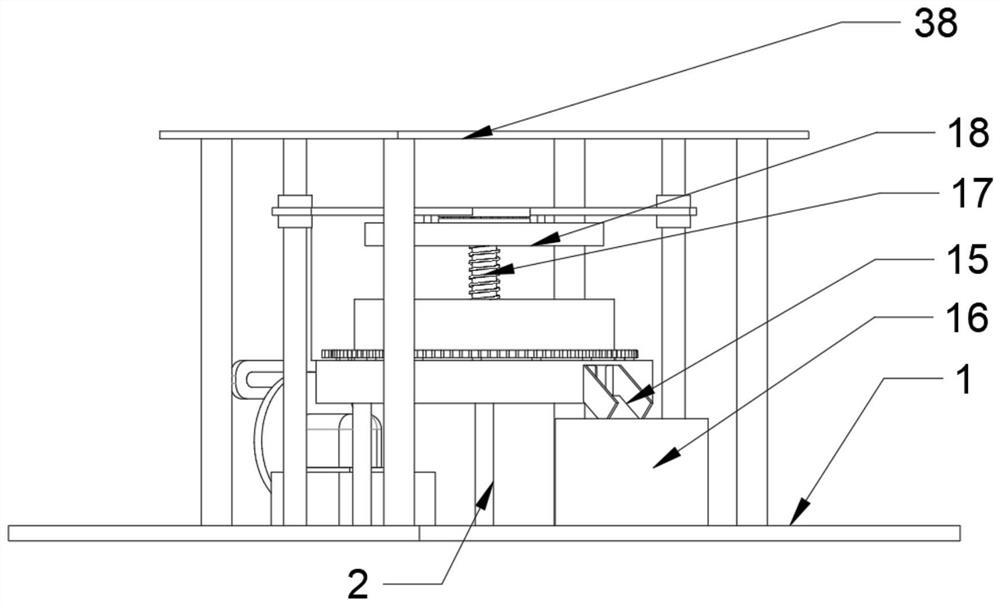

Equipment for compression molding of household garbage

InactiveCN111907108ASmall smellEasy to transportRefuse receptaclesRefuse transferringCompression moldingProcess engineering

The invention provides equipment for compression molding of household gabage. The equipment comprises a mounting frame body and a garbage compression device mounted on the mounting frame body, the garbage compression device is used for receiving the household garbage and compressing the household garbage into a round block structure, and the garbage compression device comprises a shell set and a compression mechanism; and the shell set is used for receiving the household garbage, and the compression mechanism is used for compressing the household garbage in the shell set, and the household garbage is finally compressed into the circular block structure and outputted outwards. The equipment can receive the household garbage and compress the household garbage into the round block structure,so that on the one hand, sewage in the household garbage is extruded and discharged, and the smell of the household garbage is reduced; and on the other hand, the household garbage manufactured into the round block structure is convenient to transport. In the whole compression process, the household garbage can be dumped into a funnel only through manual work or an existing mechanical means, so that subsequent compression treatment is automatic, the labor intensity is greatly reduced, and the compression efficiency is improved.

Owner:安徽奉念城机电设计服务有限公司

A kind of electrode material mixing device for lithium ion battery production

ActiveCN108704562BImprove extrusion efficiencySqueeze thoroughlyTransportation and packagingRotary stirring mixersEngineeringLithium-ion battery

Owner:江西省中子能源有限公司

A metal waste recycling and processing device based on extrusion principle

The invention discloses a metal garbage recycling and processing device based on the extrusion principle. The technical problem to be solved is to provide a splash-proof metal waste recycling and processing device based on the extrusion principle that separates cans and water. The technical embodiment of the present invention is: a metal waste recycling and processing device based on the extrusion principle, comprising a first support plate, a first support rod, a second support plate, a third support plate and a fixed round block, etc.; There are two support plates, the two first support rods are respectively fixedly installed on one side of the two first support plates, and the second support plates are fixedly installed at one end of the two first support plates. In the device, a fixed L-shaped plate, two movable pressing plates and a push plate are used to form a closed space to smash the metal waste, which effectively avoids the splashing of fragments caused by squeezing the metal waste.

Owner:上海森恒环保科技有限公司

Rapid cooling and discharging device for rotary kiln roasting furnace burden

PendingCN113883906AEasy to stack and storeEasy to pass byCharge manipulationHandling discharged materialWater useRatchet

The invention relates to the field of furnace burden cooling devices, in particular to a rapid cooling and discharging device for rotary kiln roasting furnace burden. The rapid cooling and discharging device comprises a main body, a modelling mechanism is arranged in the main body, a conveying mechanism is arranged on the main body, the conveying mechanism extends to the outside of the main body, and a cutting mechanism is erected on the conveying mechanism; and the conveying mechanism is provided with a feeding mechanism, the cutting mechanism drives the feeding mechanism, and the conveying mechanism is provided with a cooling mechanism. Through the arrangement of the modelling mechanism, roasting materials can be conveniently shaped, and the roasting materials can be conveniently stacked and stored in the later period; materials are cut conveniently through the arrangement of the cutting mechanism, so that the length size of the single materials is stipulated; the conveying mechanism is driven conveniently through the arrangement of the feeding mechanism to achieve ratchet wheel feeding, enough time is reserved for cutting of the cutting mechanism, and it is guaranteed that a cutting opening is tidy; and through the arrangement of the cooling mechanism, it can be guaranteed that cooling water is recycled while the materials are cooled, and waste of water resources is avoided.

Owner:莱芜钢铁集团泰东实业有限公司

A kind of equipment for making dried chili powder in workshop

ActiveCN112403567BAchieve extrusionFast preparationGrain treatmentsFood scienceProcess engineeringMechanical engineering

The invention relates to a kind of equipment for making dried chili powder, in particular to a kind of equipment for making dried chili powder for workshops. The invention provides a workshop-used dried chili powder production equipment capable of thoroughly crushing dried chili and screening the dried chili. A kind of equipment for making dried chili powder for workshops, comprising: a base plate with a support mechanism; a beating mechanism with a beating mechanism on the base plate. The present invention realizes the support of the device through the support mechanism, and then realizes the extrusion of dried peppers with the cooperation of the beating mechanism, and then realizes the rapid production of minced peppers; through the cooperation of the beating mechanism and the rotation mechanism, the rotation mechanism is realized. The up and down movement of the chassis realizes the automatic flipping of the chassis, so that people do not need to manually flip the chassis.

Owner:乐陵市益民调味食品有限公司

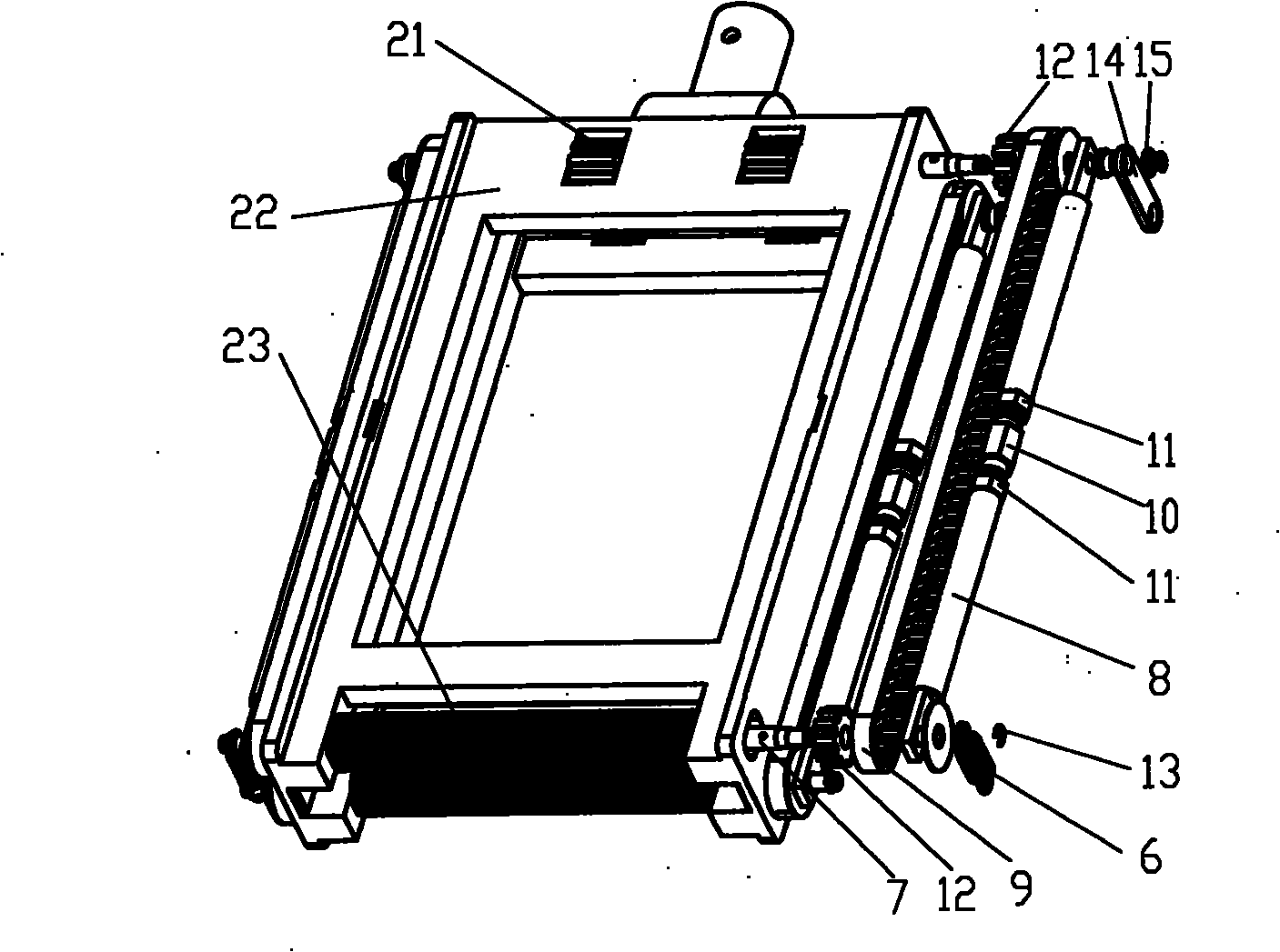

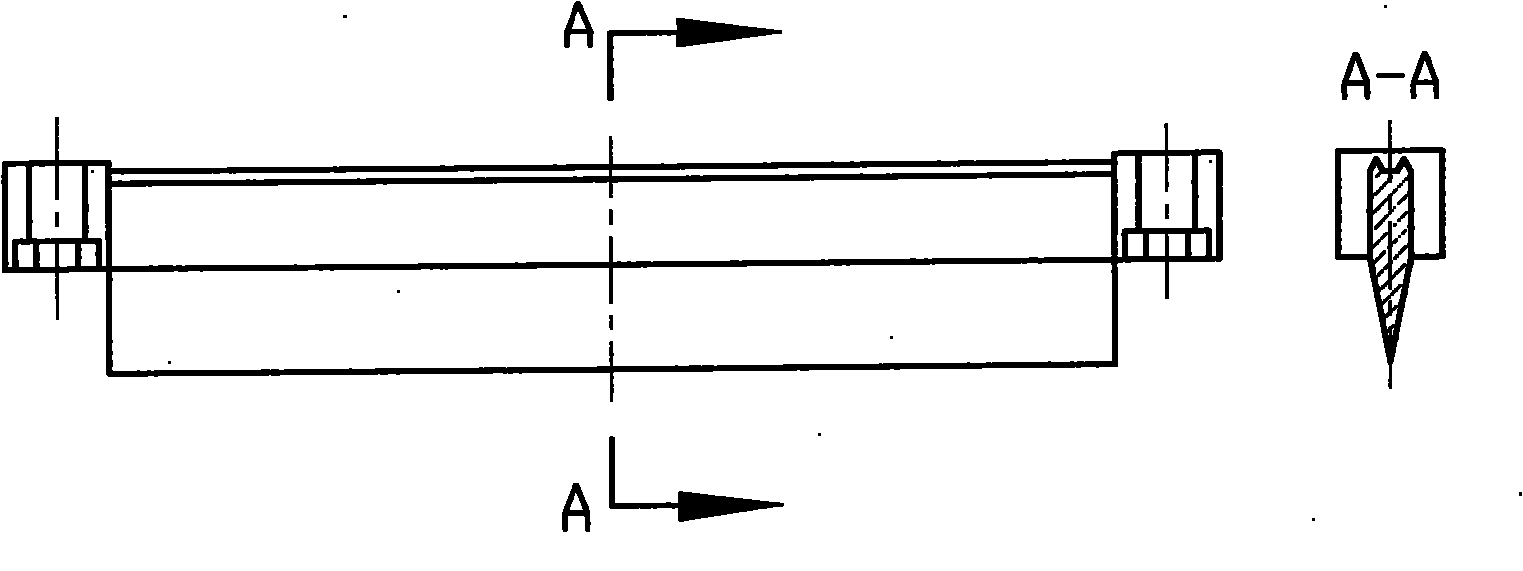

Label papersqueezing machine

InactiveCN105415734AReduce moisture contentReduce volumePress ramPulp and paper industryWater content

The invention discloses a label paper squeezing machine. The label paper squeezing machine comprises a rack, wherein a first squeezing barrel is horizontally mounted on the rack; a discharge port is formed in the downstream end of the first squeezing barrel; a material receiving hopper is mounted at the upper part of the first squeezing barrel; the first squeezing barrel is communicated with the inside of the material receiving hopper; a plurality of liquid outlet holes are formed in the first squeezing barrel; a squeezing part is movably mounted in the first squeezing barrel, is matched with the first squeezing barrel in shape and size and is driven by a linear power device. The squeezing machine pushes the squeezing part by means of the linear power device to squeeze label paper, the size is small, the use cost is low, the label paper is completely squeezed, and the squeezed label paper contains little water and cannot become pasty.

Owner:NANJING LEHUI LIGHT IND EQUIP

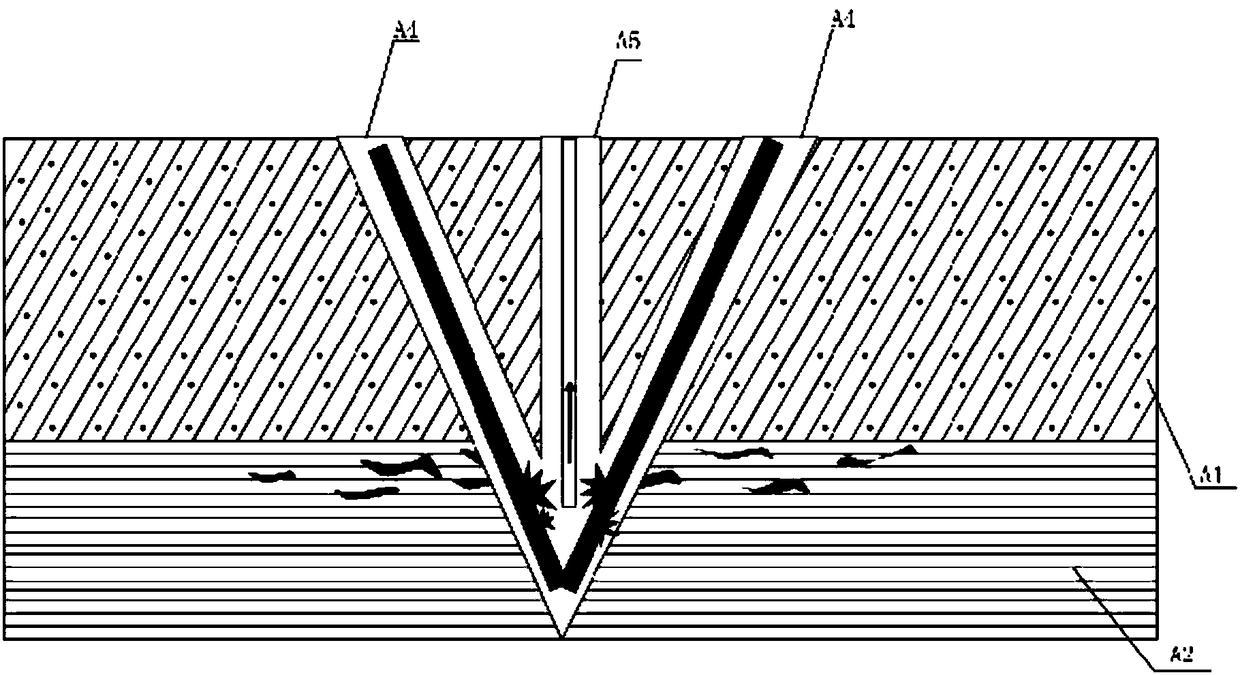

Method for exploiting shale gas using biomass thermal power

Owner:QINZHOU UNIV

Metal garbage recycling device based on extrusion principle

ActiveCN112958188APrevent splashAvoid breedingGrain treatmentsPressesProcess engineeringIndustrial engineering

The invention discloses a metal garbage recycling device based on an extrusion principle. The metal garbage recycling device based on the extrusion principle can prevent splashing and separating zip-top cans from water. According to the technical scheme, the metal garbage recycling device based on the extrusion principle comprises two first supporting plate, two first supporting rod, second supporting plates, a third supporting plate, a fixed round block and the like; and the two first supporting rods are correspondingly and fixedly installed on one sides of the two first supporting plates, and the second supporting plates are fixedly installed at one ends of the two first supporting plates. According to the metal garbage recycling device based on the extrusion principle, a fixed L-shaped plate, two movable pressing plates and a push plate are adopted to form a closed space to crush the metal garbage, and splashing of fragments caused when the metal garbage is extruded is effectively avoided.

Owner:上海森恒环保科技有限公司

Plant juice extractor for cosmetic production

InactiveCN112829360AAchieve rotary extrusionSqueeze thoroughlyPressesAgricultural engineeringStructural engineering

The invention relates to a plant extraction device, and discloses a plant juice extractor for cosmetic production. The plant juice extractor comprises a base, the middle position of the base is fixedly connected to a first support rod, the top end of the first support rod is fixedly connected to an upper fixing plate, the middle position of the upper surface of the upper fixing plate is fixedly connected to a raw material cylinder, a liquid outlet is formed in the bottom end of the inner wall of the raw material barrel, an outer side plate is fixedly connected to the edge of the upper surface of the upper fixing plate, a material guiding groove is formed between the outer side plate and the outer wall of the raw material barrel, a plurality of scraping plates are arranged in the material guiding groove, a first connecting rod is fixedly connected to the top ends of the scraping plates, the top end of the first connecting rod penetrates through a first guide groove formed in the top end of the material guiding groove to be fixedly connected to a fixing ring. a screw rod is fixedly connected to the center position inside the raw material cylinder, and a pressing block is arranged on the screw rod. According to the plant juice extractor, through arrangement of the screw rod, the pressing block is rotated and lifted, so that plant raw materials are rotated and extruded, the plant raw materials are extruded by the device more thoroughly, the extraction rate of juice is increased, and the practicability of the device is improved.

Owner:罗礼明

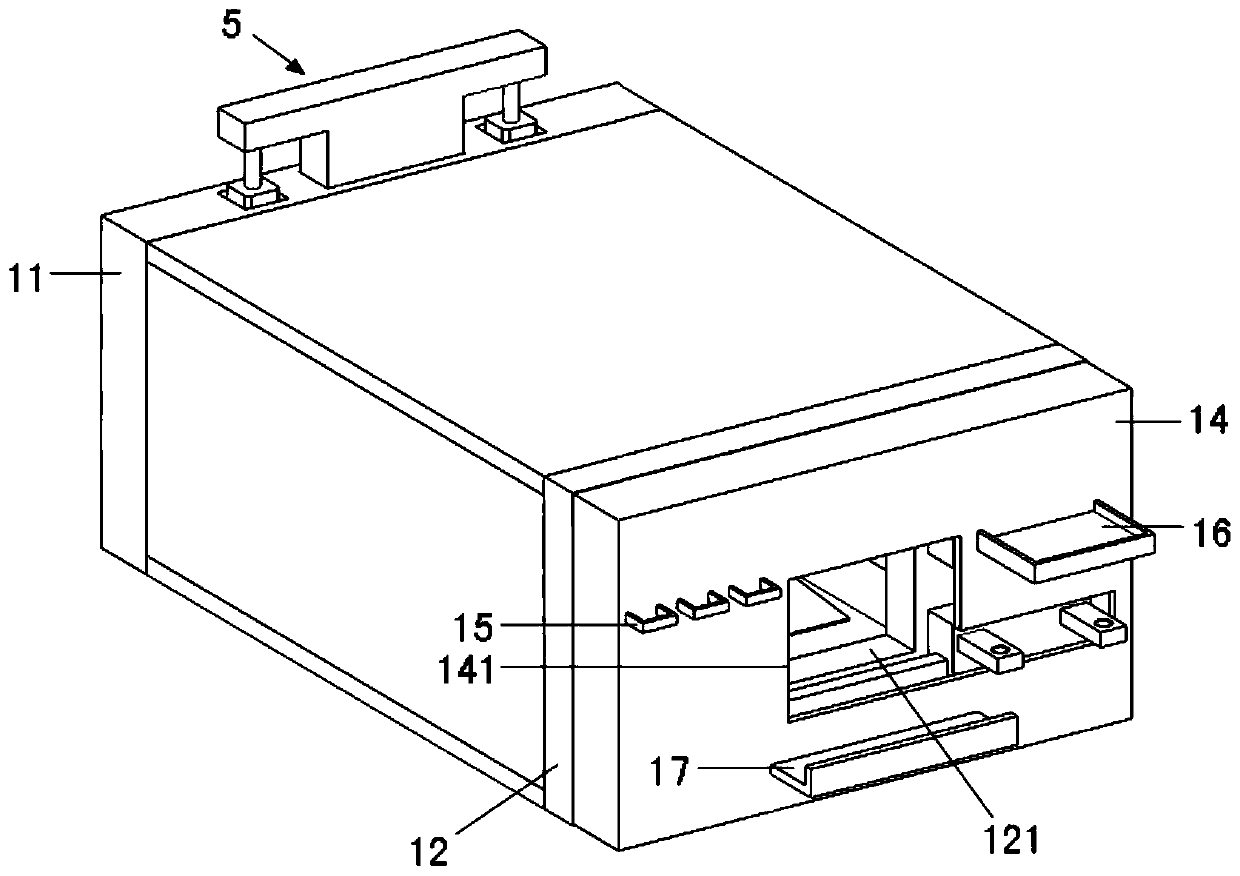

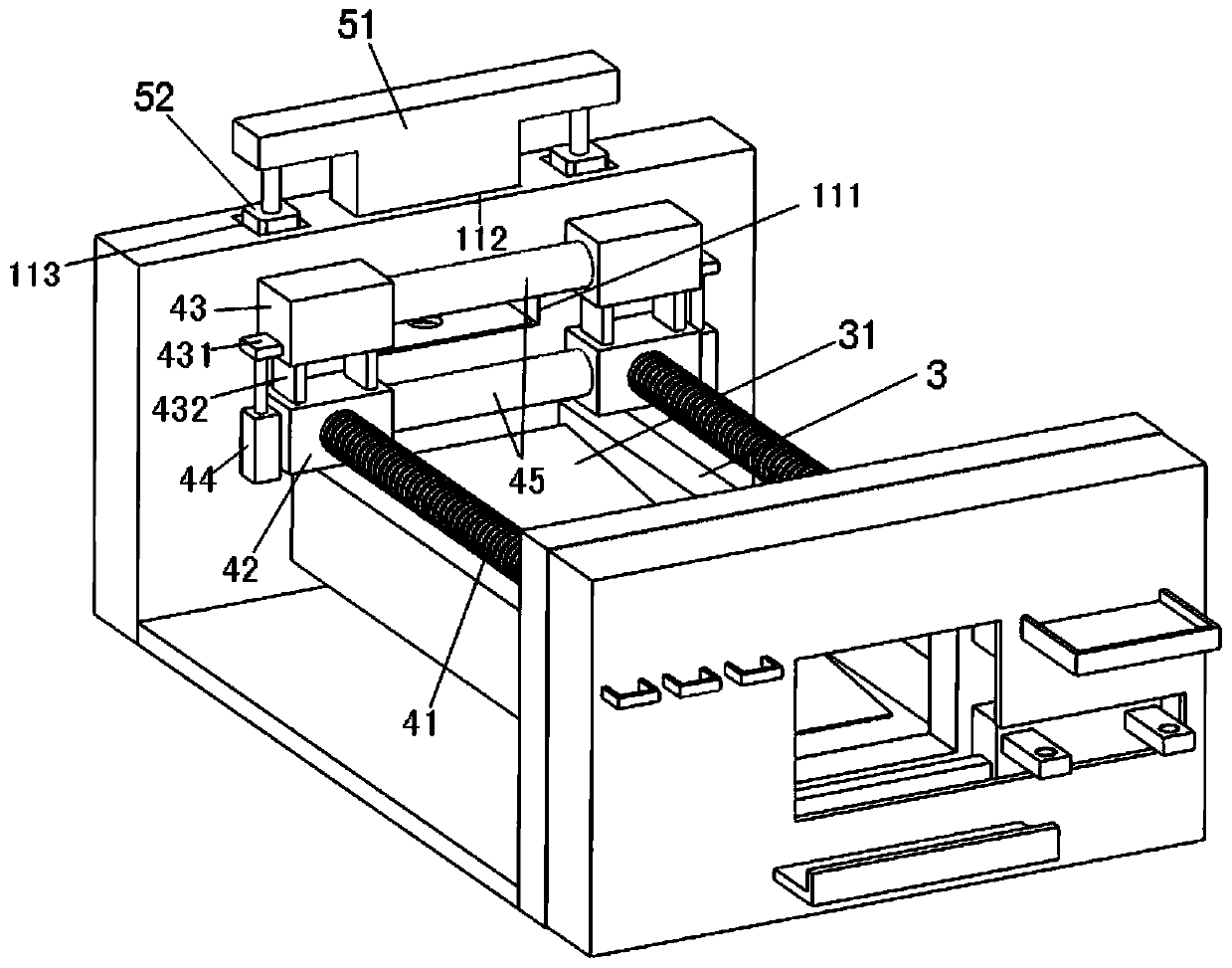

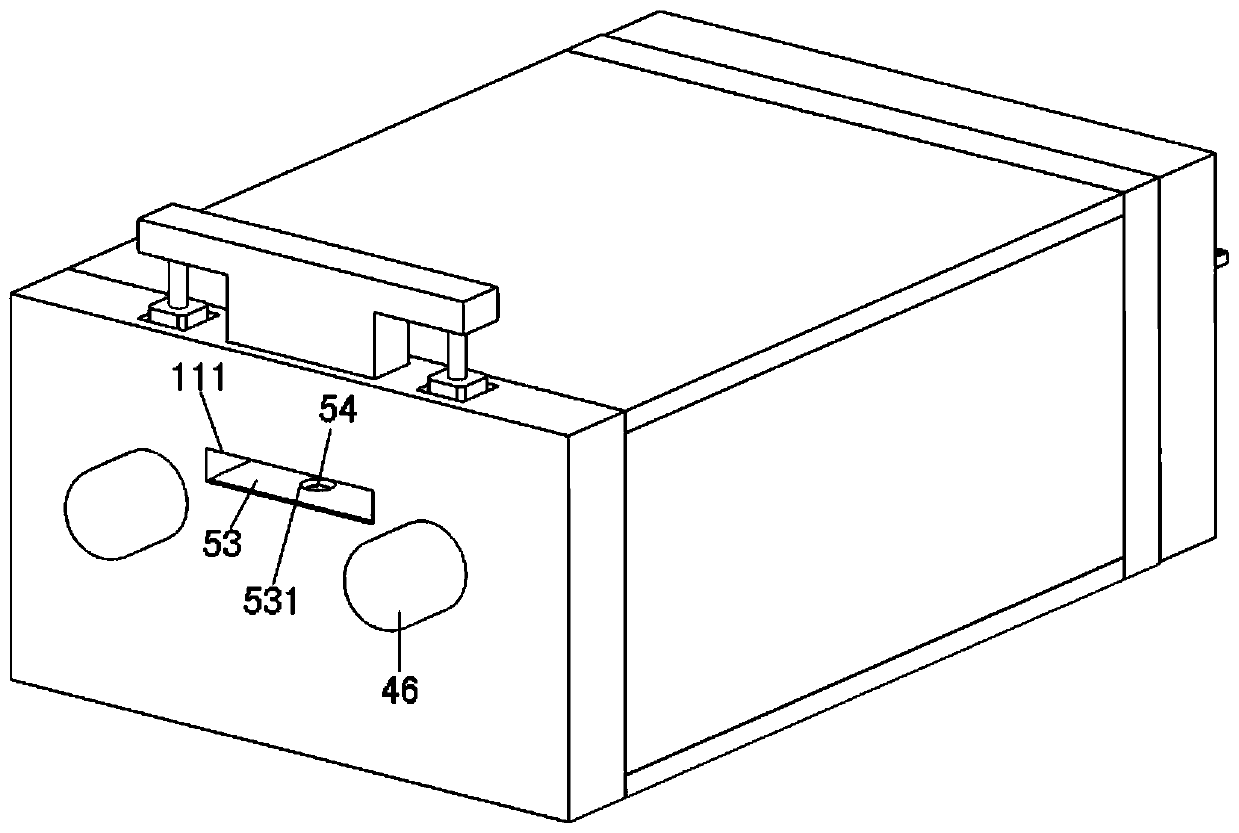

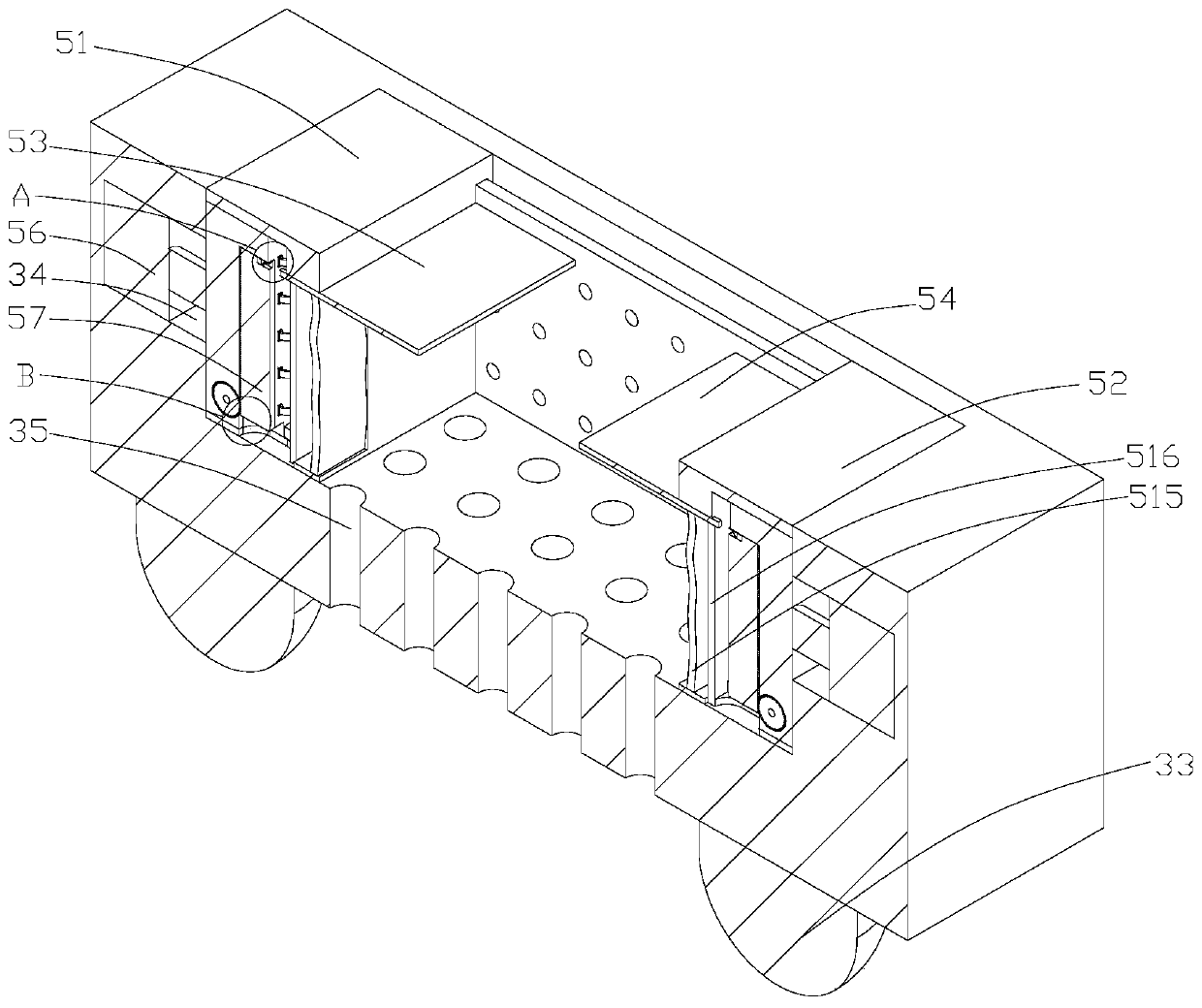

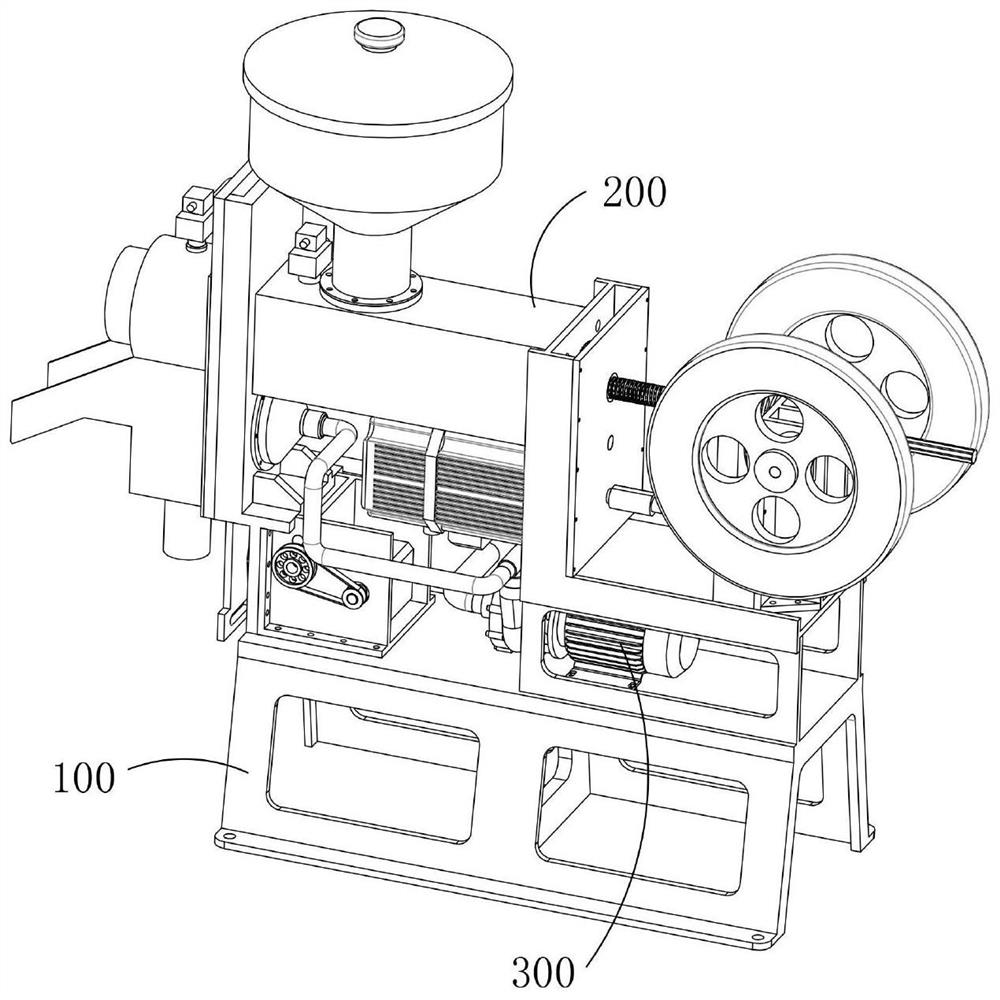

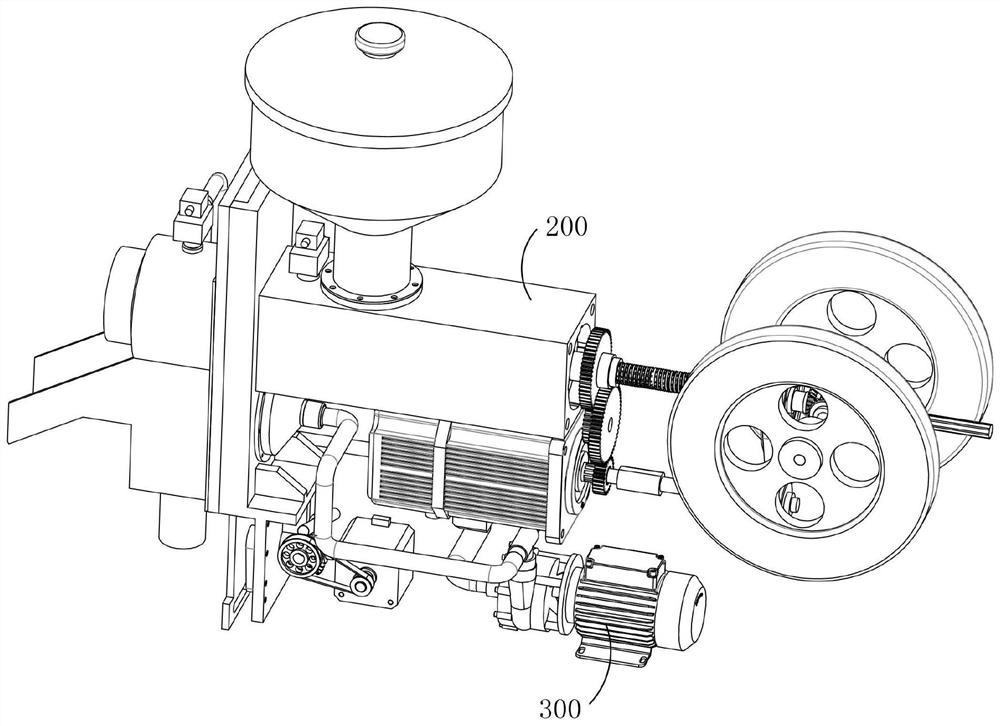

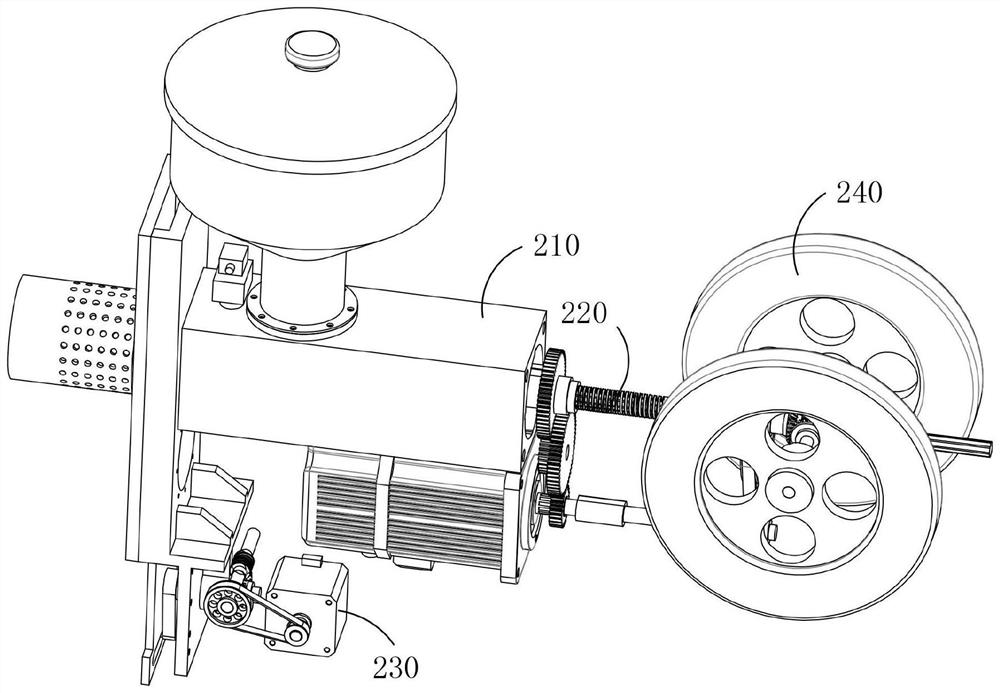

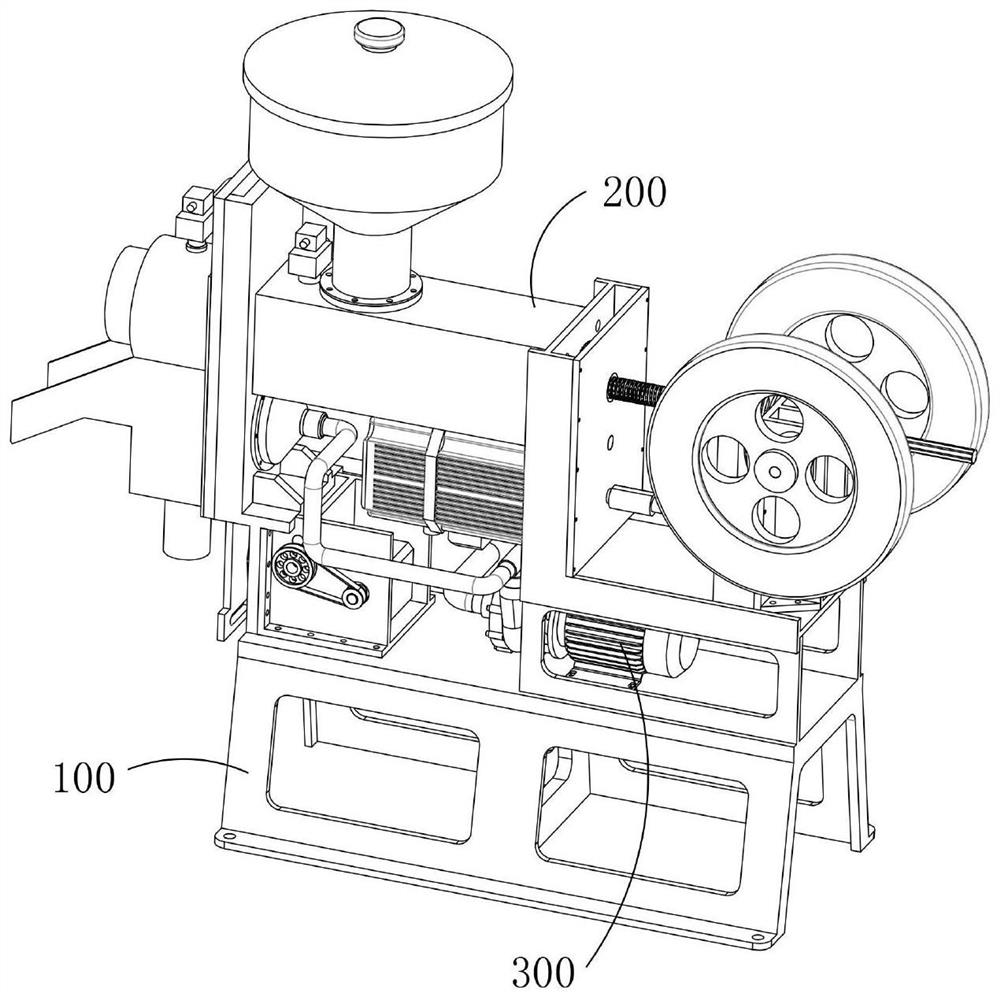

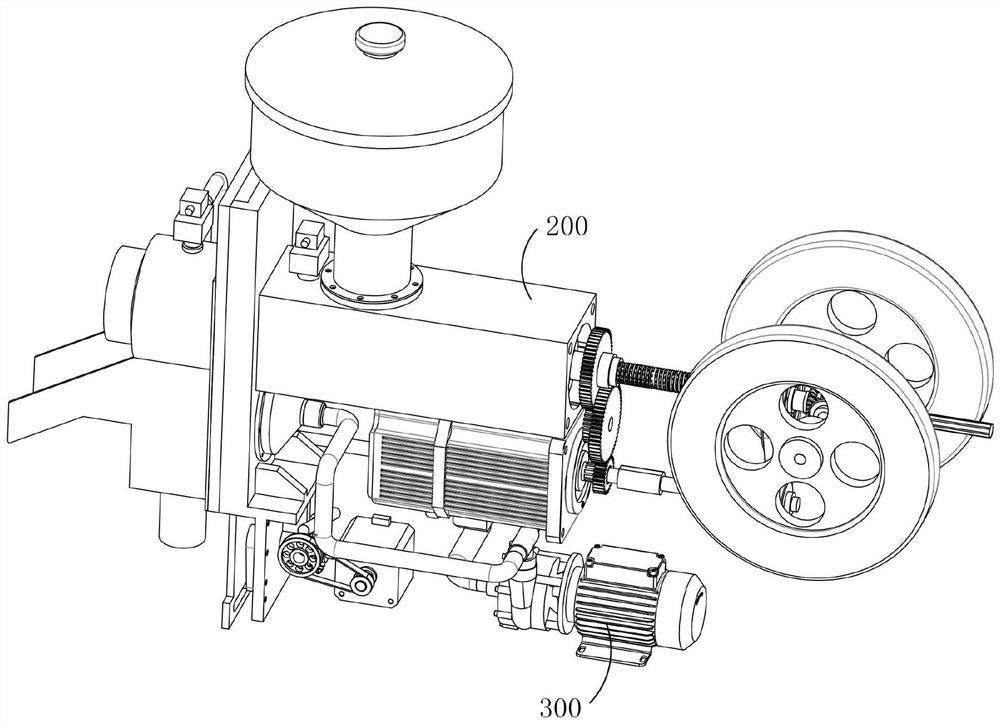

Compression assembly applied to household waste treatment

The invention provides a compression assembly applied to household waste treatment. The compression assembly applied to household waste treatment comprises an installation frame body (100) and a wastecompression device (200) installed on the installation frame body (100), wherein the waste compression device (200) comprises a shell body group (210) and a compression mechanism (220); the shell body group (210) is used for receiving household waste; the compression mechanism (220) comprises a compression member (2210) and a power member (2220); the compression member (2210) is used for carryingout compression treatment on the household waste in a compression pipeline (212) and the household waste is finally compressed to be of a circular-block-shaped structure; the power member (2220) is used for providing power for the running of the compression member (2210); the compression member (2210) further comprises a driving hammer assembly; the power member (2220) further comprises a transfer assembly; the driving hammer assembly is used for carrying out reciprocating driving hammering action on a closed end of a compression piston (2211) in the compression piston (2211); the transfer assembly is used for receiving the power of the power assembly and transferring the power to the driving hammer assembly; and an energy storage mechanism (240) is further connected to the transfer assembly.

Owner:安徽奉念城机电设计服务有限公司

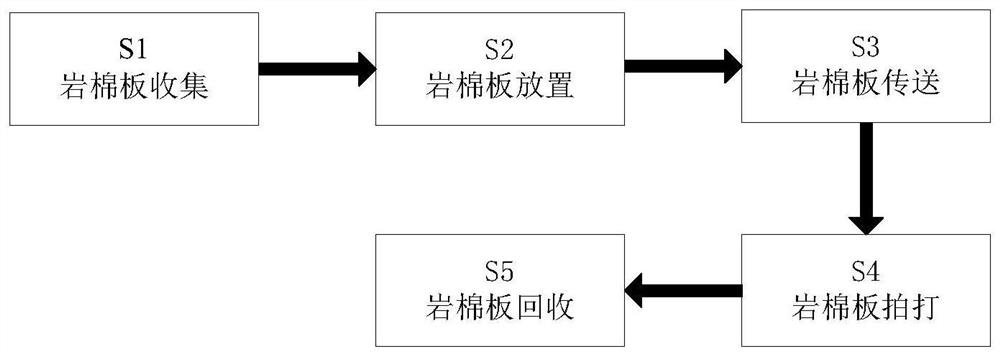

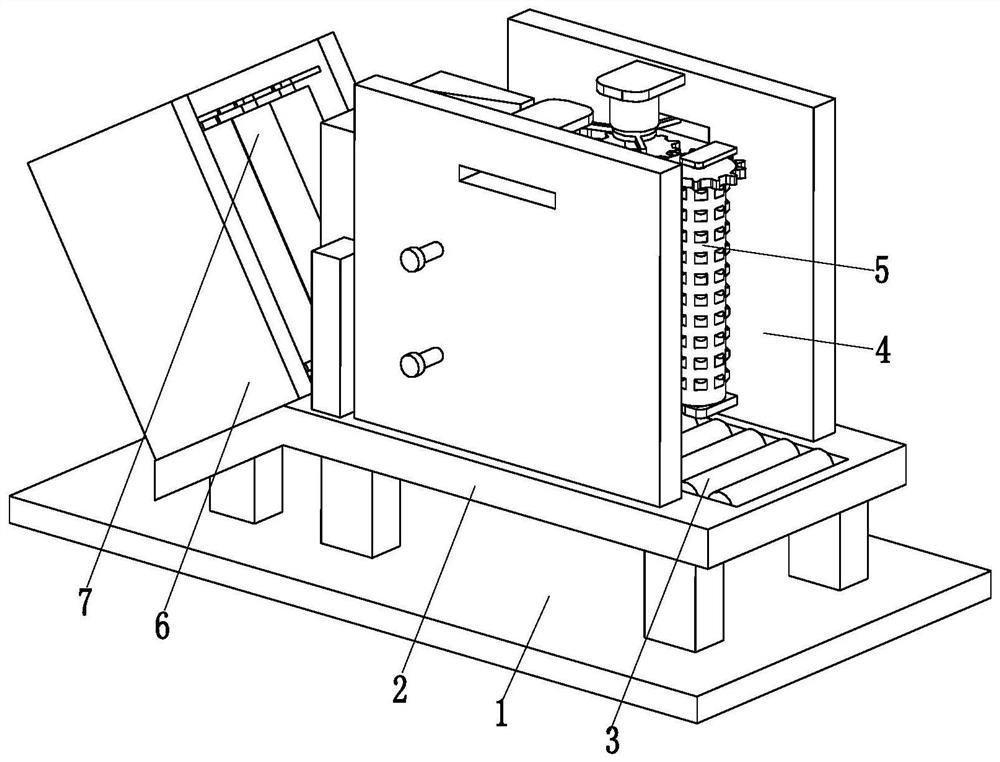

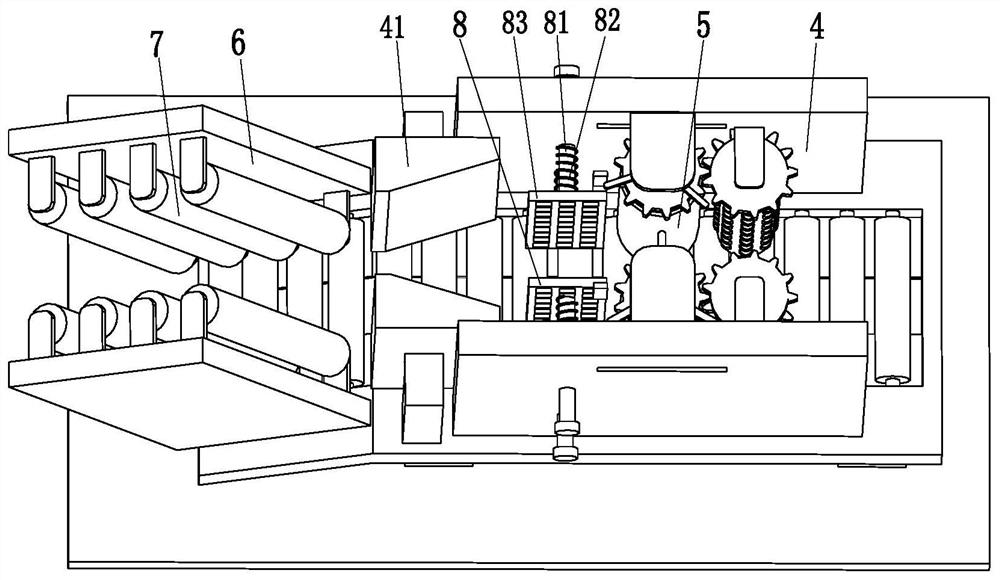

A kind of recycling processing method of building rock wool board

ActiveCN111298879BImprove recycling effectSqueeze thoroughlyGrain treatmentsCleaning processes and apparatusArchitectural engineeringWaste management

Owner:MAANSHAN HONGDA INSULATION MATERIAL

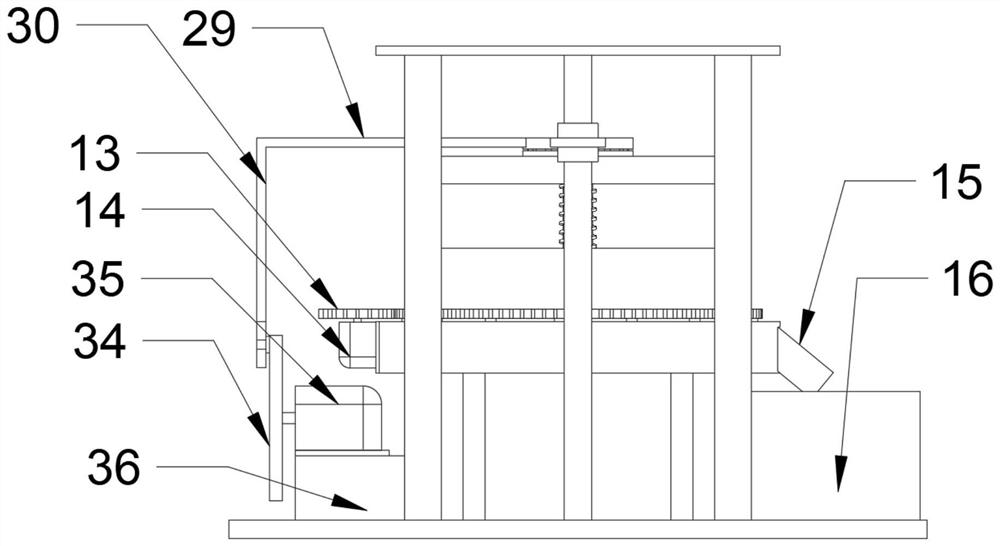

An energy-saving feed processing pellet machine

The present invention discloses an energy-saving type granulation machine for feed processing. The granulation machine mainly includes: a machine shell, a material inlet, a material outlet, a ring mold, a rotary shaft, a driving mechanism, and a pressure self-regulation device. Three compression rollers are arranged in the ring mold of the energy-saving type granulation machine for feed processing, can reduce wear, enable the device to be stressed uniformly, extrude feed raw materials thoroughly without dead angles, and improve production efficiency. Through an umbrella-type gear, the horizontal driving mechanism and a multi-stage gearbox, torsion is improved and an effect of using a small motor to drive the big device is achieved. The pressure self-regulation device automatically adjusts the pressure of each compression roller, reduces the wear of each compression roller under the premise of feed product molding, and can save energy, improve granulation efficiency and extend the use life of the device. The energy-saving type granulation machine for feed processing has application prospects in the feed processing machinery field.

Owner:江苏凯信环保材料有限公司

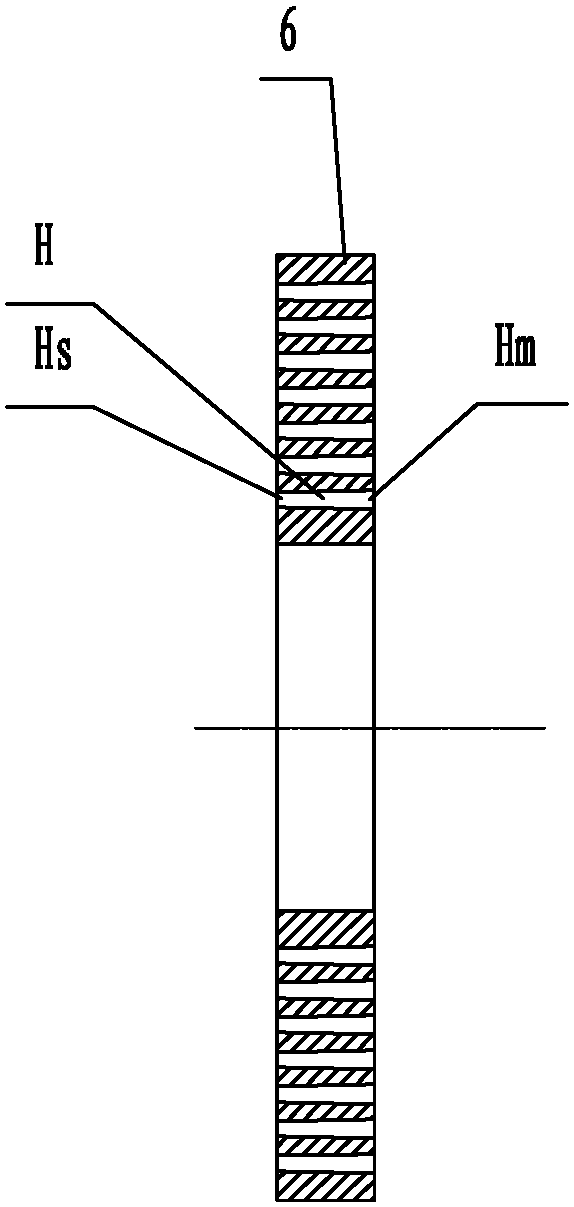

Ceramic membrane production blending and extruding device with anti-blocking function

InactiveCN109569309ASqueeze thoroughlyGuaranteed extrusion efficiencySemi-permeable membranesRotary stirring mixersCeramic membraneExtrusion

The invention discloses a ceramic membrane production blending and extruding device with an anti-blocking function. The ceramic membrane production blending and extruding device with the anti-blockingfunction comprises a mixing box; a mixing mechanism is arranged inside the mixing box and composed of a rotating shaft, a mixing connecting rod and mixing blades; the bottom end of the mixing box iscommunicated with a flow pipe, the inner wall of the flow pipe is fixedly provided with a first rotating pair, a second rotating pair and a support connecting rod, and the bottom end of the flow pipeis communicated with an extruding box; the side wall of the extruding box is provided with a first air cylinder and a second air cylinder. According to the ceramic membrane production blending and extruding device with the anti-blocking function, the mixing mechanism can fully mix ceramic membrane materials before extruding to ensure the mixing quality and the size of particles to be extruded; theinside of the upper end of the flow pipe is provided with the rotating pairs and the support connecting rod, so that when blocking happens, a user can draw outwards the support connecting to increasethe distance between anti-blocking separating plates and further to solve the problem of raw material blocking; a first extruding plate is applied to extruding the raw material, a second extruding plate is arranged in a mirror-like mode relative to the first extruding plate, so that opposite extruding force can ensure thorough extrusion and guarantee the extruding efficiency to a large extent.

Owner:HEFEI XINDA MEMBRANE TECH

Garbage can capable of absorbing odor

InactiveCN114560195AReduce pressureSave spaceWaste collection and transferRefuse receptaclesEngineeringMechanical engineering

The garbage can comprises a can body and a can cover, a mounting cavity is formed in one side wall of the can body, a pair of partition plates are horizontally and fixedly connected in the mounting cavity, the two partition plates sequentially divide the mounting cavity into a rotating cavity, an extrusion cavity and a suction cavity from top to bottom, an extrusion component is arranged in the extrusion cavity, and a suction component is arranged in the suction cavity. A driving part is arranged in the rotating cavity, a suction part is arranged in the suction cavity, and the extrusion part comprises a threaded rod which is vertically and rotatably mounted in the extrusion cavity. The device comprises a rotating rod, an extrusion plate and a mounting shell. Through cooperation of the first magnetic block, the second magnetic block and other components, odor in the can body can be sucked into the extrusion cavity when the can cover is opened, and the odor in the extrusion cavity can be discharged out of the extrusion cavity when the can cover is closed, so that a user does not smell the odor in the can body when discarding garbage.

Owner:卞庆凤

A pressure grinding device for the lead-out line of the high-voltage side of the capacitor for dynamic reactive power compensation

ActiveCN106158432BSqueeze thoroughlyImprove smoothing effectCapacitor manufactureReactive power compensationPower compensationHigh pressure

The invention relates to a pressing and grinding device, in particular to a pressing and grinding device for the lead-out line at the high-voltage side of a capacitor used for electric dynamic reactive power compensation. The technical problem to be solved by the present invention is to provide a grinding device for the lead-out line of the high-voltage side of the capacitor used for electric dynamic reactive power compensation with thorough extrusion, good grinding effect and strong practicability. In order to solve the above-mentioned technical problems, the present invention provides such a grinding device for electric dynamic reactive power compensation capacitor high-voltage side lead wires, which includes a second slide rail, a second slide block, a first connecting rod, a first rotating rod, The first bearing seat, the first bevel gear, the first helical gear, the second bearing seat, the second helical gear, etc.; the first bearing seat is connected with the first rotating rod, and the middle part of the first rotating rod is connected with the first connecting rod The lower end of the first rotary rod is connected with the first bevel gear. The invention achieves the effects of thorough extrusion, good grinding effect and strong practicability, and is suitable for pressing and grinding the lead wires at the high voltage side of the capacitor.

Owner:南通日精电子有限公司

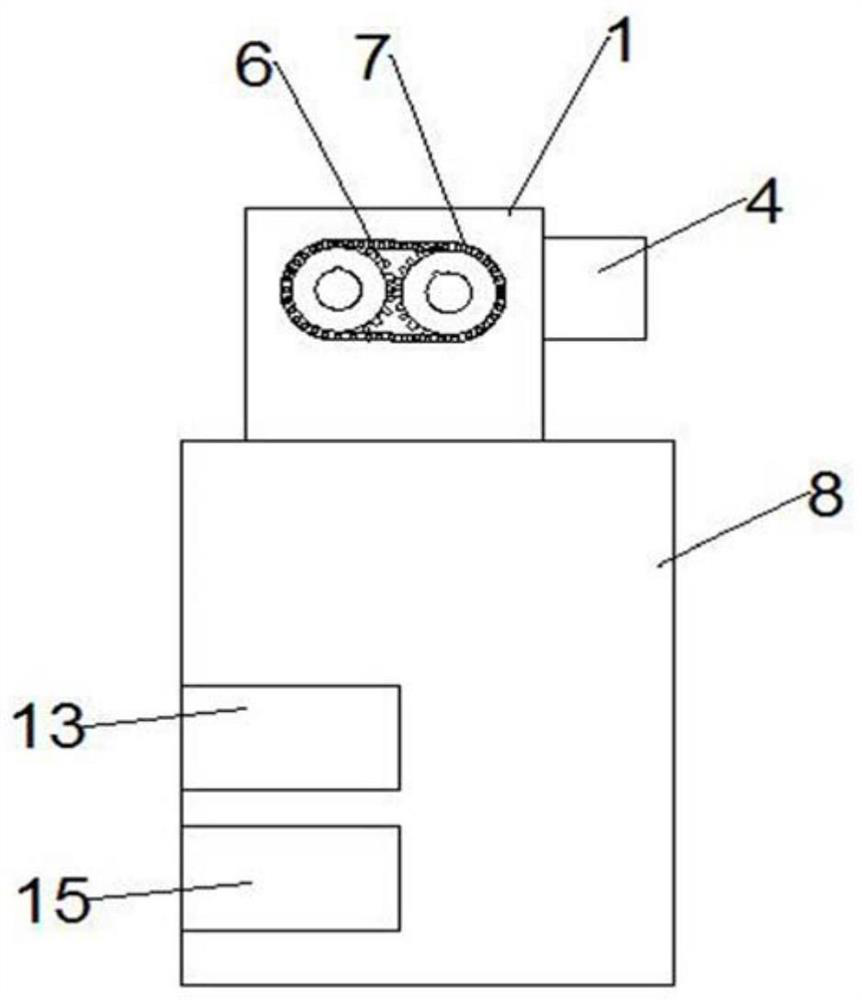

Fast extrusion device

InactiveCN103591771APrevent random splashingPlay the role of positioningDrying solid materials without heatRotary pressEngineeringRotated tooth

The invention relates to a fast extrusion device and relates to the technical field of fertilizer production. The fast extrusion device is characterized by comprising a support. A motor is disposed on one side of the support. A fixing plate is disposed on the support. Two sets of extrusion rolls connected with rotating teeth are disposed on the fixing plate. The rotating teeth are connected to the motor through chains. Each set of extrusion rolls comprises two rolls. A retaining plate is disposed between the two sets of extrusion rolls. The width of the retaining plate is half of the distance between the two sets of extrusion rolls. The fast extrusion device is reasonable in structure, convenient to use and good in use effect.

Owner:ANHUI HUIPU BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com