A metal waste recycling and processing device based on extrusion principle

A technology for recycling and processing metals, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of bacterial growth, human injury, splashing, etc., and achieve the effect of preventing the breeding of bacteria, saving space, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

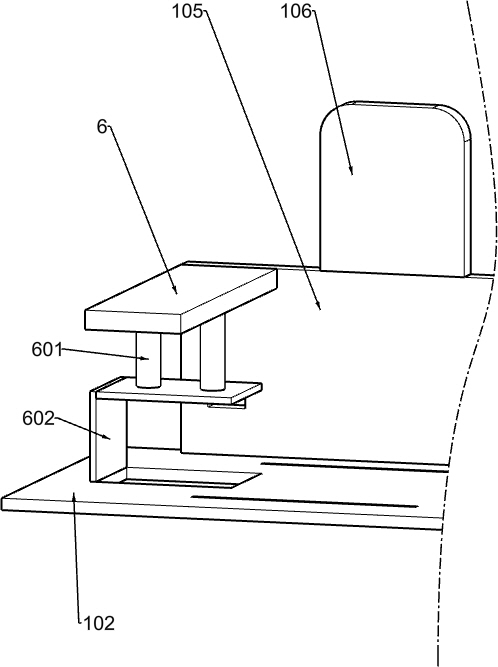

[0033] like Figure 1-8As shown, a metal waste recycling and processing device based on the extrusion principle includes a first support plate 1, a first support rod 101, a second support plate 102, a third support plate 103, a fixed round block 104, a first fixed The plate 105, the second fixing plate 106, the pushing mechanism and the pressing mechanism, there are two first support plates 1, two first support rods 101 are fixedly installed on the right side of the two first support plates 1, and the second The support plate 102 is fixedly installed on the upper ends of the two first support plates 1, the third support plate 103 is fixedly installed on the upper right ends of the two first support rods 101, the third support plate 103 is in contact with the second support plate 102, and the fixed circle The block 104 is fixedly installed at the upper middle position of the third support plate 103, the two first fixing plates 105 are respectively fixedly installed on the upper...

Embodiment 2

[0036] like Figure 2-3 As shown, the pushing mechanism includes a cylinder 2, a fixed round rod 201, a first fixed square rod 202, a first sliding rod 203, a first spring 204, a fixed block 205, a second sliding rod 206, a second spring 207, a sliding The frame 208, the second fixed square rod 209 and the push plate 210, the cylinder 2 is fixedly installed on the fixed round block 104, the cylinder 2 penetrates the left and right sides of the fixed round block 104, and the fixed round rod 201 is fixedly installed on the left end of the telescopic rod of the cylinder 2 , the first fixed square rod 202 is fixedly installed on the left end of the fixed round rod 201, the first sliding rod 203 is fixedly installed on the left end of the first fixed square rod 202, the first spring 204 is sleeved on the first sliding rod 203, the fixed block 205 It is fixedly installed on the lower side of the first fixed square rod 202 , the second sliding rod 206 is slidably connected to the lef...

Embodiment 3

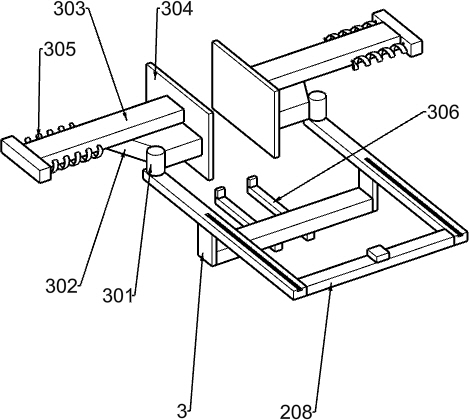

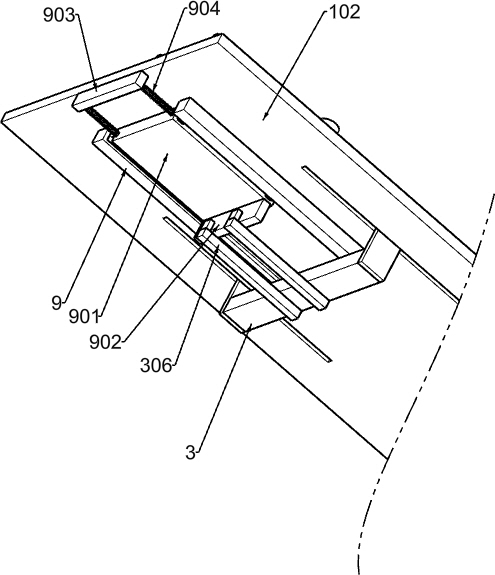

[0039] like Figure 4-5 As shown, the pressing mechanism includes a U-shaped frame 3, a first fixed column 301, a top plate 302, a top rod 303, a pressure plate 304, a third spring 305, a third sliding rod 306, a fourth fixed plate 6, and a second fixed column. 601 and the L-shaped plate 602, the U-shaped frame 3 is fixedly installed at the lower middle position of the sliding frame 208, the U-shaped frame 3 is in sliding contact with the grooves opened on the second support plate 102, and the two first fixing columns 301 are respectively fixed and installed in On the front and rear sides of the upper part of the carriage 208, the two top rods 303 are respectively slidably mounted on the outer sides of the two first fixing plates 105, the two pressing plates 304 are fixedly mounted on the inner ends of the two top rods 303, and the two top plates 302 are respectively It is fixedly installed on the outside of the two pressing plates 304, the two first fixing posts 301 are in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com