Dry chili powder manufacturing equipment for workshops

A dried chili powder technology, which is applied in the field of dried chili powder production equipment, can solve the problems of inability to crush dried chili peppers and screen chili powder, and achieve the effects of difficult position, fast production, and precise rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

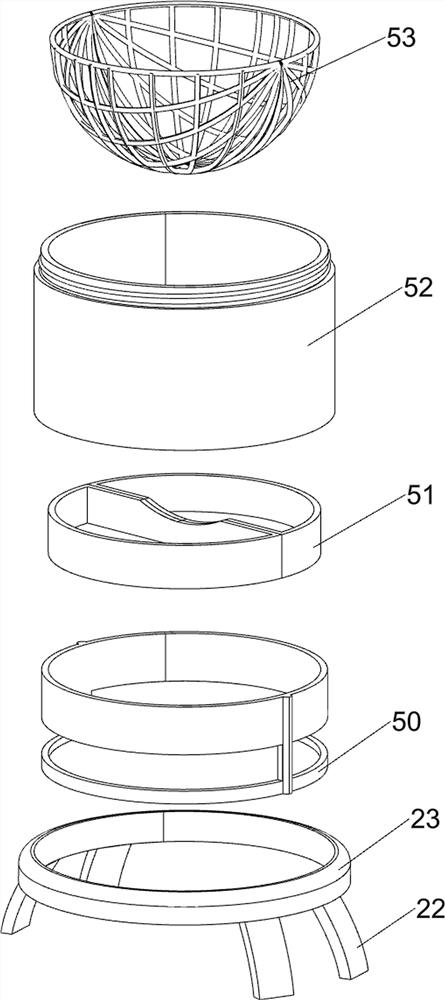

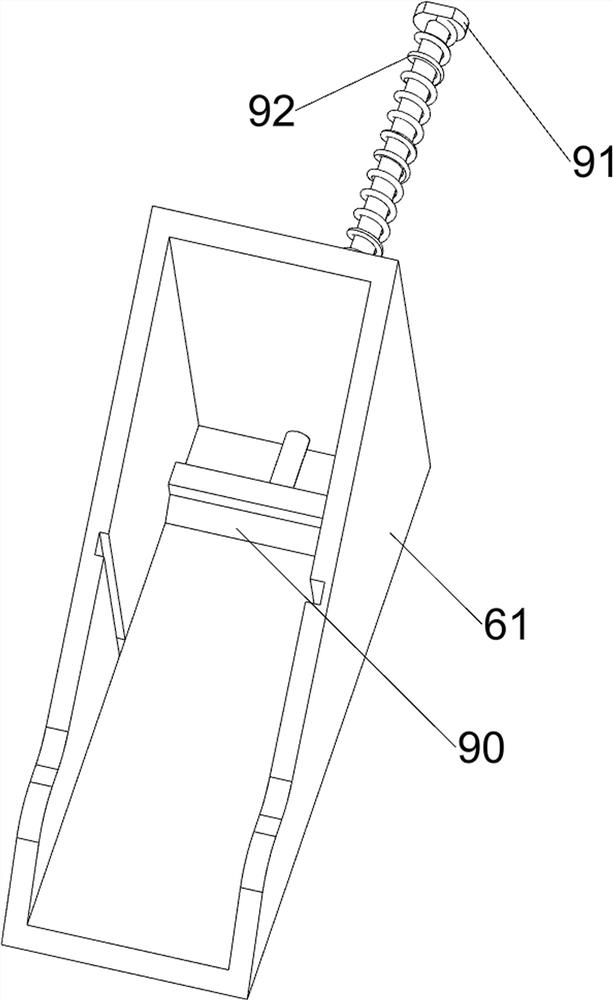

[0033] A kind of equipment for making dried chili powder in workshops, such as figure 1 , figure 2 , image 3 with Figure 4 Shown, comprise base plate 1, supporting mechanism 2 and beating mechanism 3, base plate 1 is provided with supporting mechanism 2, and base plate 1 is provided with beating mechanism 3.

[0034] When people need to use this device, first people put the dried peppers into the beating mechanism 3, then they can start the supporting mechanism 2, and the supporting mechanism 2 drives the beating mechanism 3 to operate, so that the parts of the beating mechanism 3 are continuously moved up and down, thereby the beating The dried chili in the mechanism 3 is squeezed into fine powder, and then after the extrusion is completed, people can take out the chili powder, so that the dried chili can be quickly squeezed into fine powder by repeating this, when people do not need to use this equipment , close the supporting mechanism 2 and get final product.

[003...

Embodiment 2

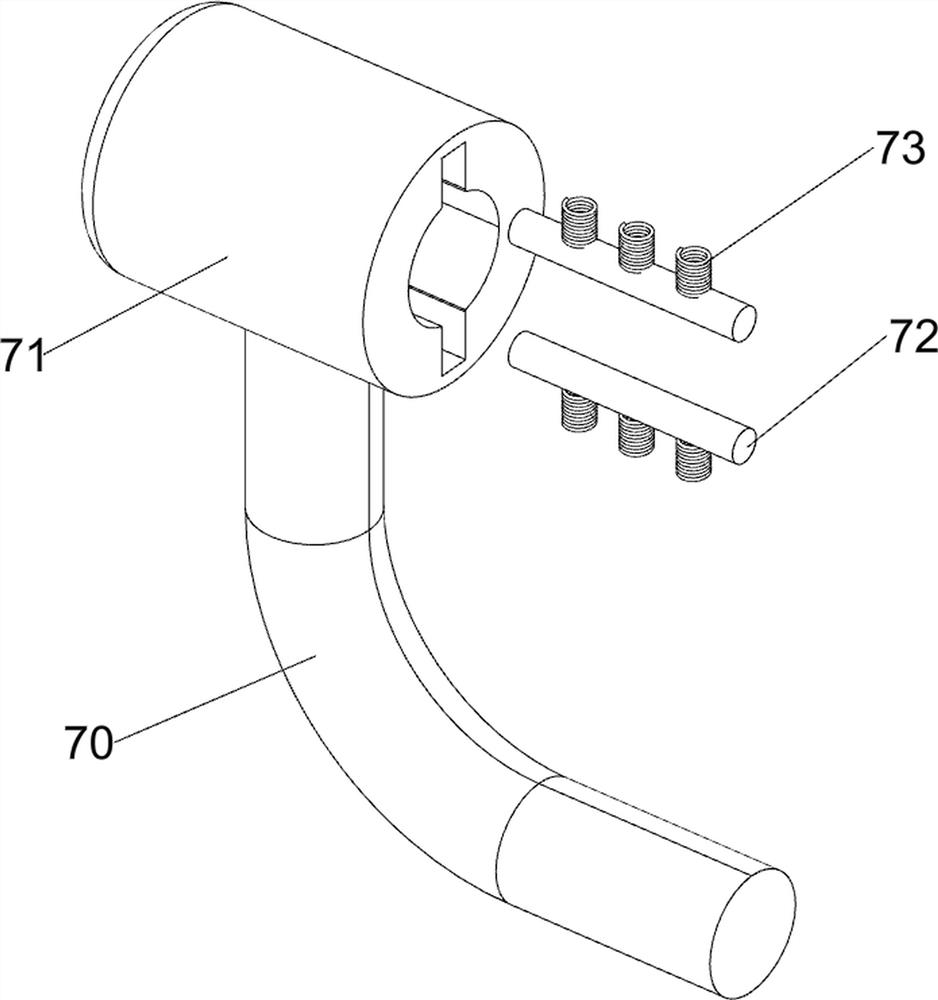

[0040] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, it also includes a rotating mechanism 4, the rotating mechanism 4 includes a first connecting rod 40, a mounting plate 41, a ratchet 42, a first spring 43, a rotating shaft 44 and a ratchet 45, and the upper part of the hammering connecting rod 32 is symmetrically provided with the first connecting rod. Rod 40, the bottom of the first connecting rod 40 is provided with a mounting plate 41, the mounting plate 41 is provided with a ratchet 42 in a sliding manner, the first spring 43 is symmetrically arranged between the ratchet 42 and the mounting plate 41, and the chassis 35 both sides A rotating shaft 44 is provided, and the rotating shaft 44 is rotatably connected with the container 31 , and a ratchet 45 is provided on the rotating shaft 44 , and the ratchet 45 meshes with the ratchet 42 .

[0041] When the beating connecting rod 32 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com