Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193 results about "Rotated tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description: Crooked or rotated teeth are one of the most common cosmetic concerns. Having crooked teeth can result in compromised contact with adjacent teeth and cause food to be trapped between the teeth, which may lead to gingival damage. It can also be a cause of tooth decay and other related disorders.

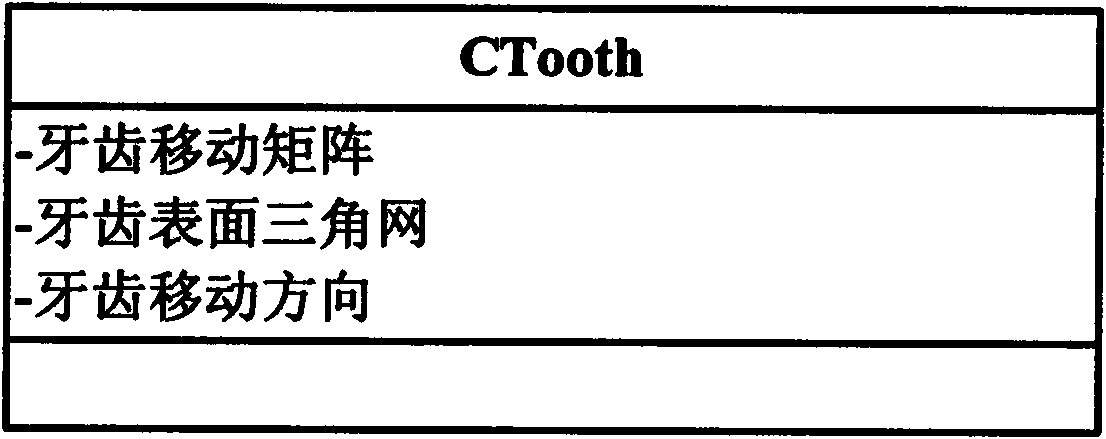

Tooth mover for computer-assisting tooth orthodontics

The invention relates to a tooth mover for computer-assisting tooth orthodontics, which can most quickly and conveniently move and rotate teeth with strong moving precision and sense of direction. The invention comprises the following steps: 1) initializing a program; 2) initializing a tooth move; 3) reading in a tooth 3D model; 4) choosing a tooth needing to move, displaying by the tooth mover, and presenting the chosen tooth at the crossing point of the moving arrowhead on each direction of the tooth mover; 5) waiting the operation of a user; 6) changing the viewing angle of a tooth displaying window, while the tooth mover follows the changed the viewing angle; clicking the arrowhead on a translation direction or a rotation direction in the tooth mover by mouse, moving the chosen tooth in the tooth displaying window along the assigned direction, or rotating along the assigned rotary shaft and the assigned rotary direction; clicking the icon for changing the rotary shaft in the tooth mover, changing the color of the icon representing the rotary shaft into the color of corresponding rotary shaft, and assigning a new rotary shaft.

Owner:XIAN HENGHUI TECH

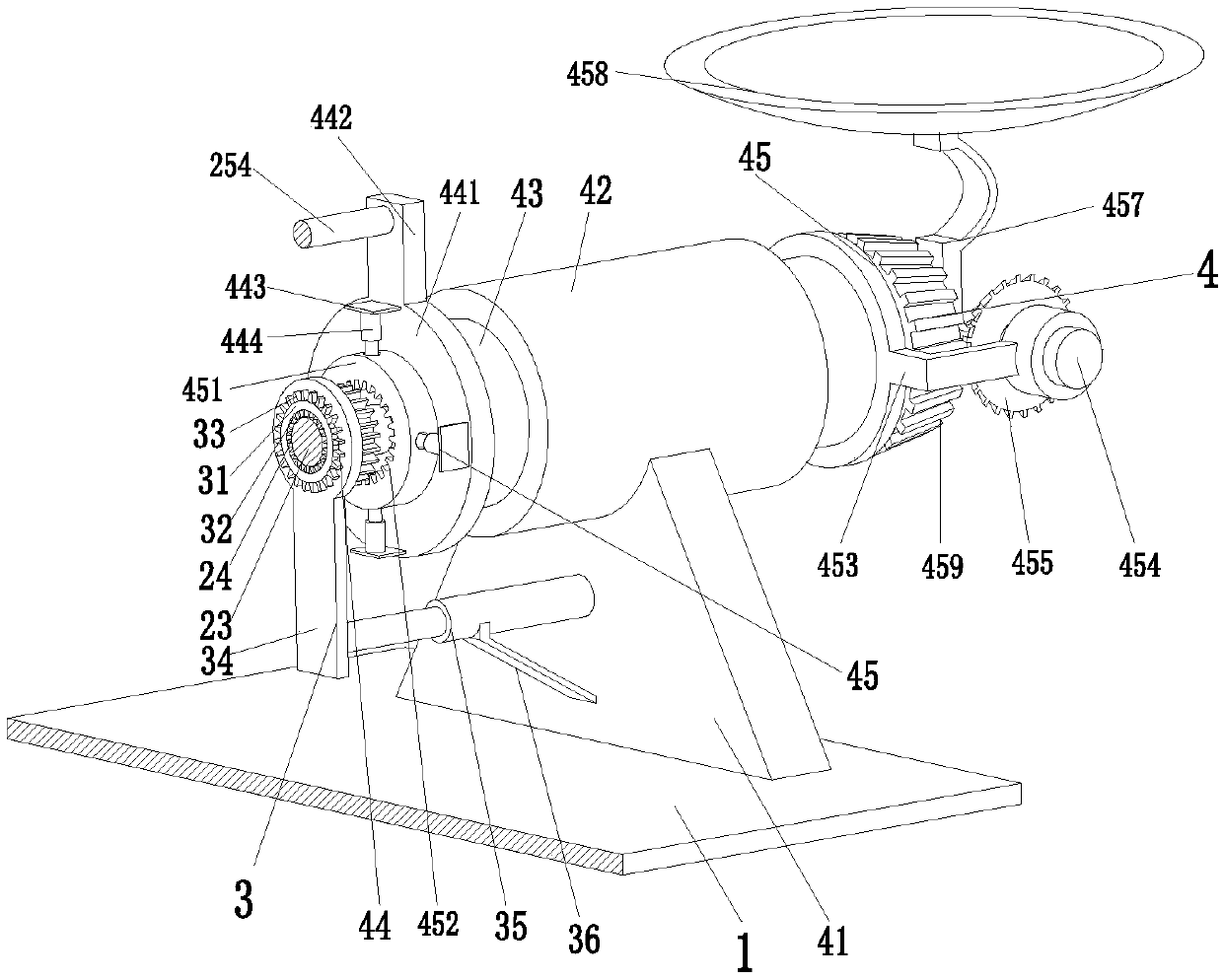

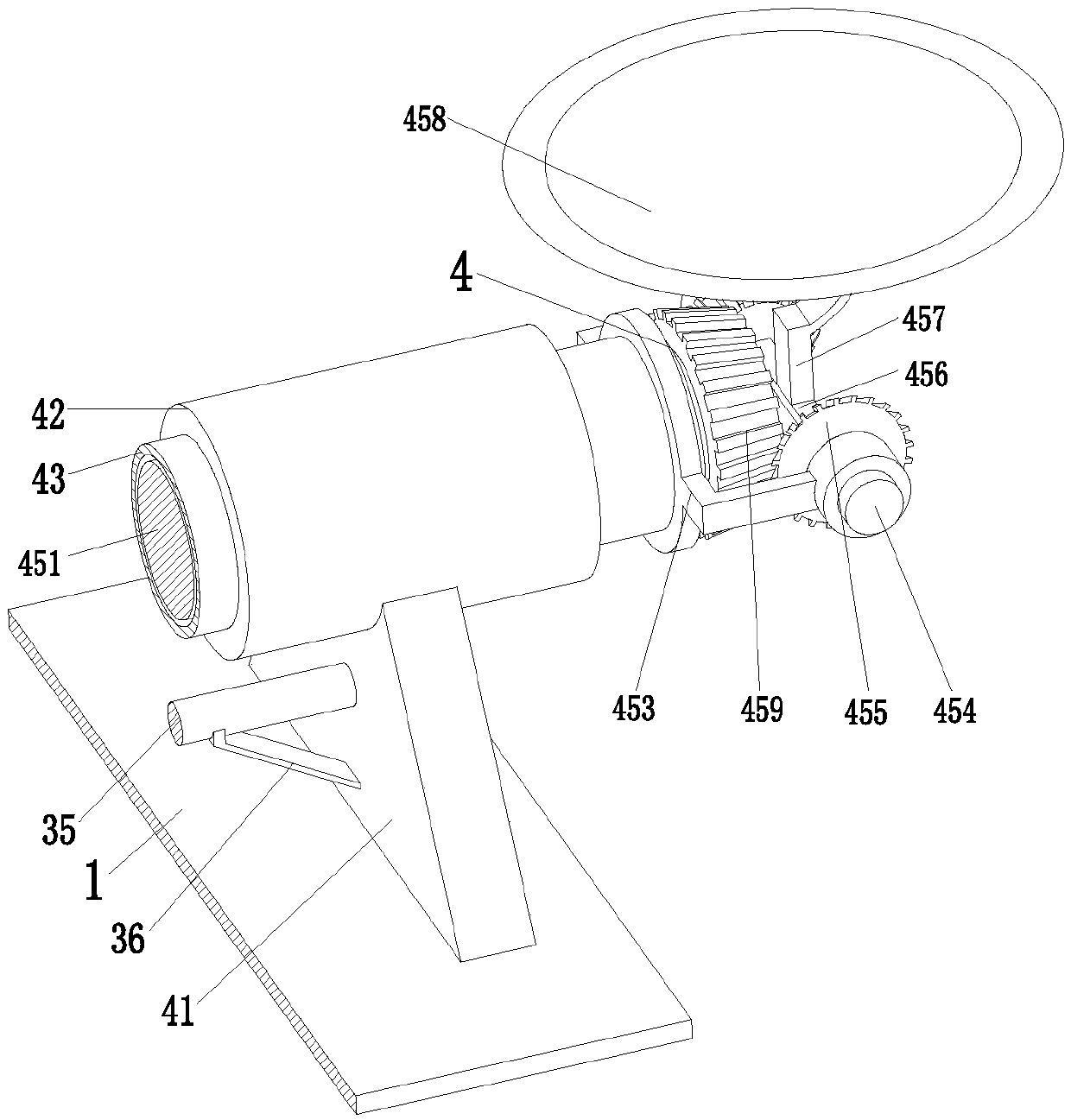

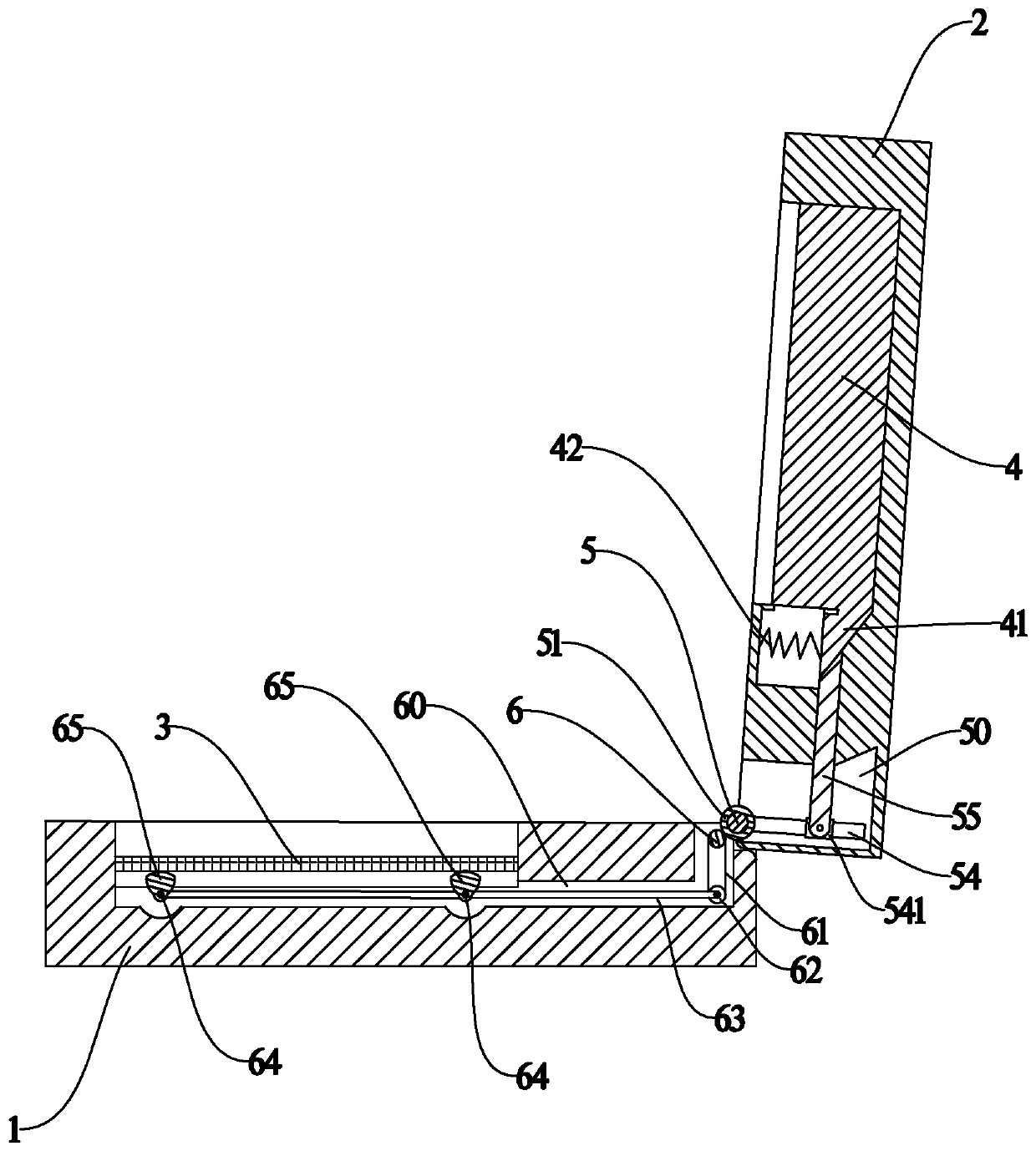

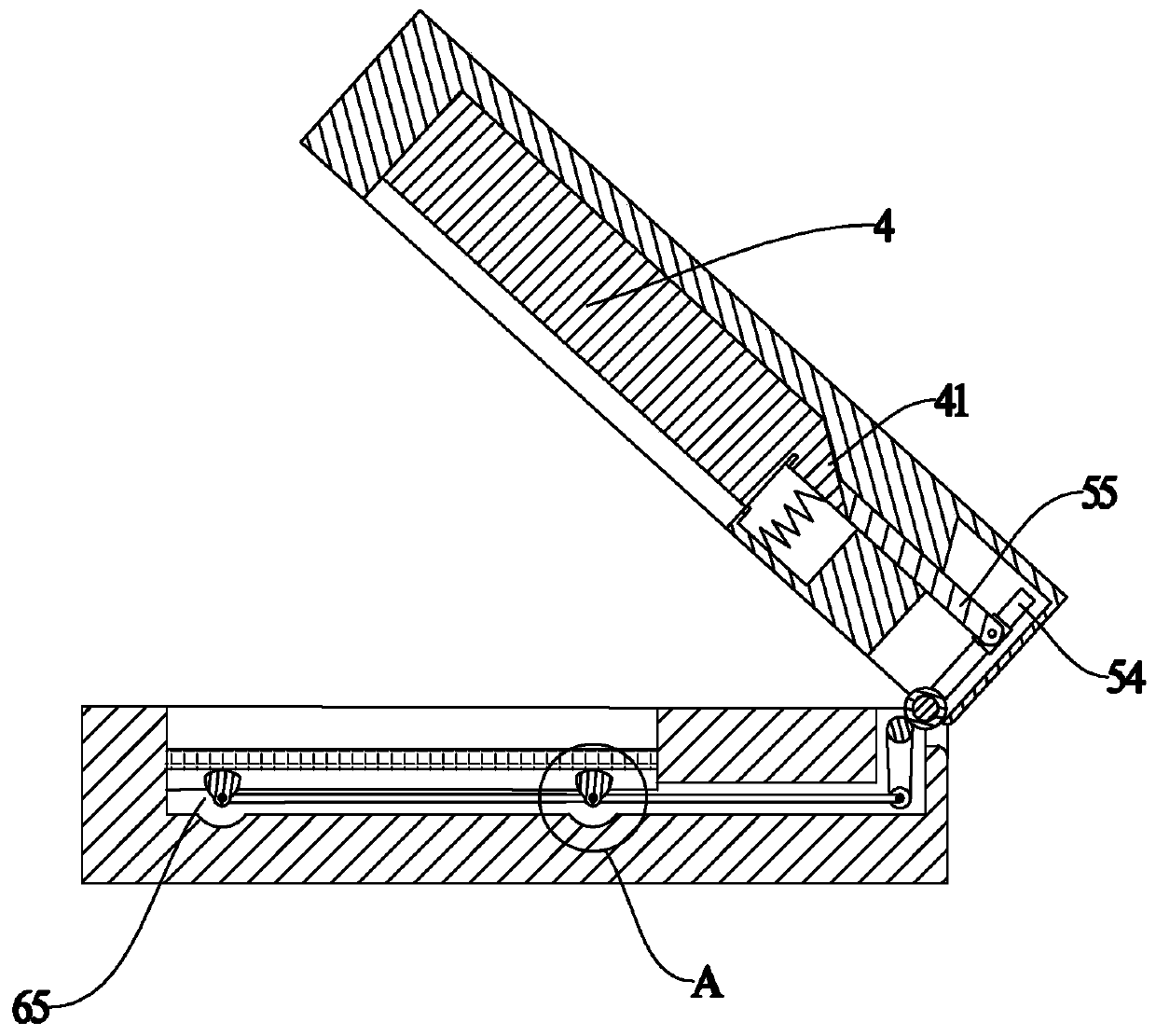

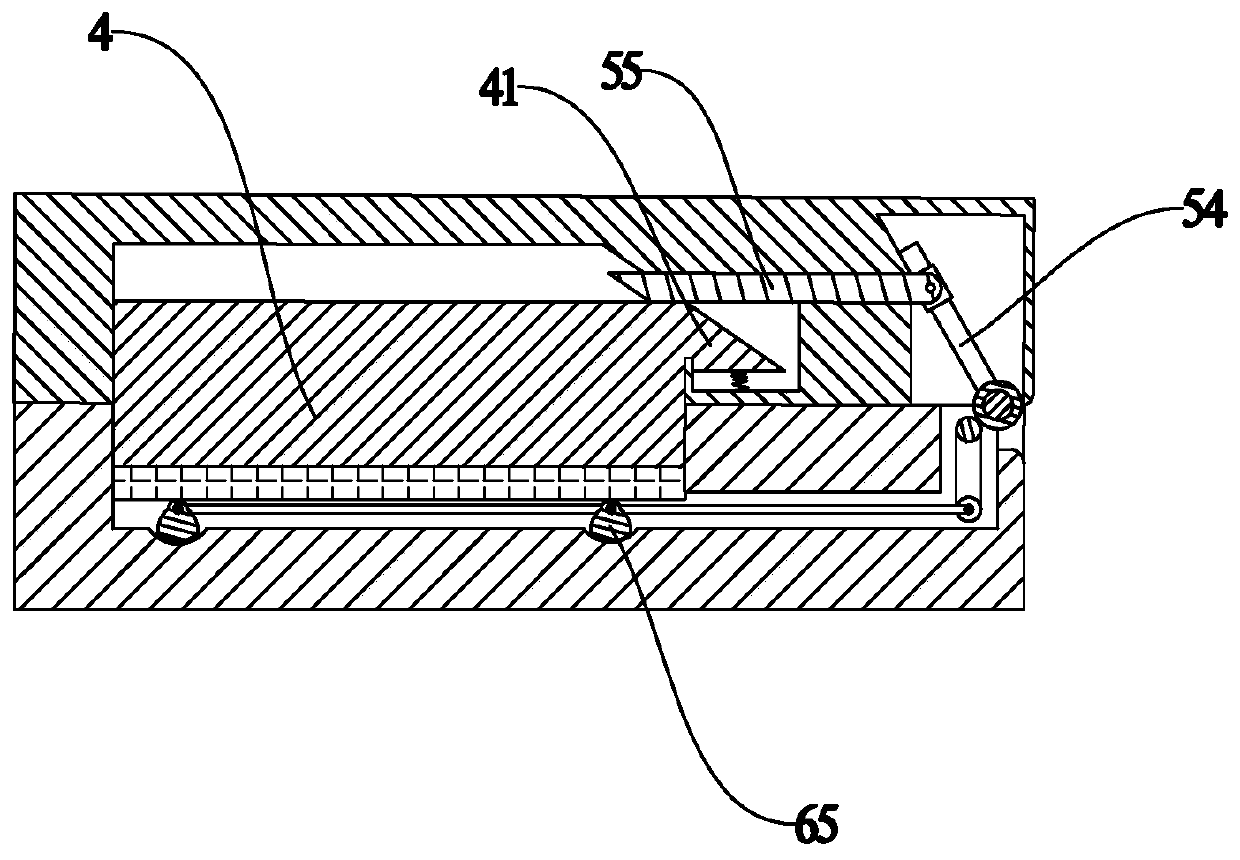

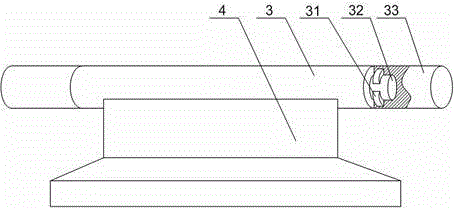

Adjustment seat for satellite signal receiver

PendingCN109524784ASolve stressSolve the adjustmentAntenna supports/mountingsCouplingWorking pressure

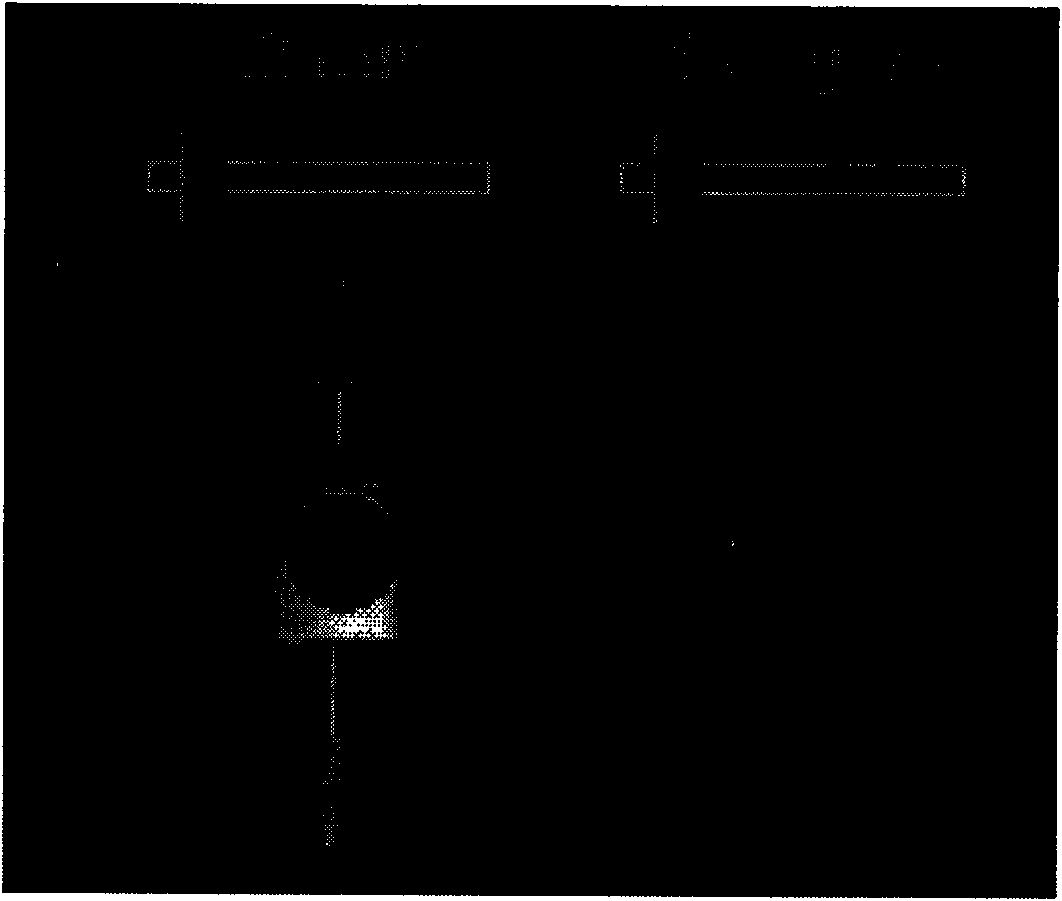

The invention relates to an adjustment seat for a satellite signal receiver. The adjustment seat comprises a bottom plate, a rotation mechanism, a conversion mechanism and an adjustment mechanism, wherein the rotation mechanism, the conversion mechanism and the adjustment mechanism are successively mounted on the upper end surface of the bottom plate from left to right; the rotation mechanism comprises a motor table mounted on the left side of the upper end surface of the bottom plate; a rotating motor is mounted on the upper end surface of the motor table through a motor frame; the output shaft of the rotating motor is connected to the left end of a rotating shaft through a shaft coupling; the right end of the rotating shaft is mounted on the right end of the adjustment mechanism througha bearing; and rotating teeth are mounted in the middle of the side wall of the rotating shaft. The adjustment seat can solve the problems that the receiver has a small rotation amplitude, and when ttwo motors are adjusted, the lower motor has high working pressure and the receiver has complicated adjustment steps easy to confuse, can achieve the multi-angle rotation and simple and convenient adjustment steps of the receiver, and can achieve a large rotation angle, a large amplitude, low motor working pressure and simple receiver adjustment steps.

Owner:XIAN HUAYUN TIANCHENG COMM TECH

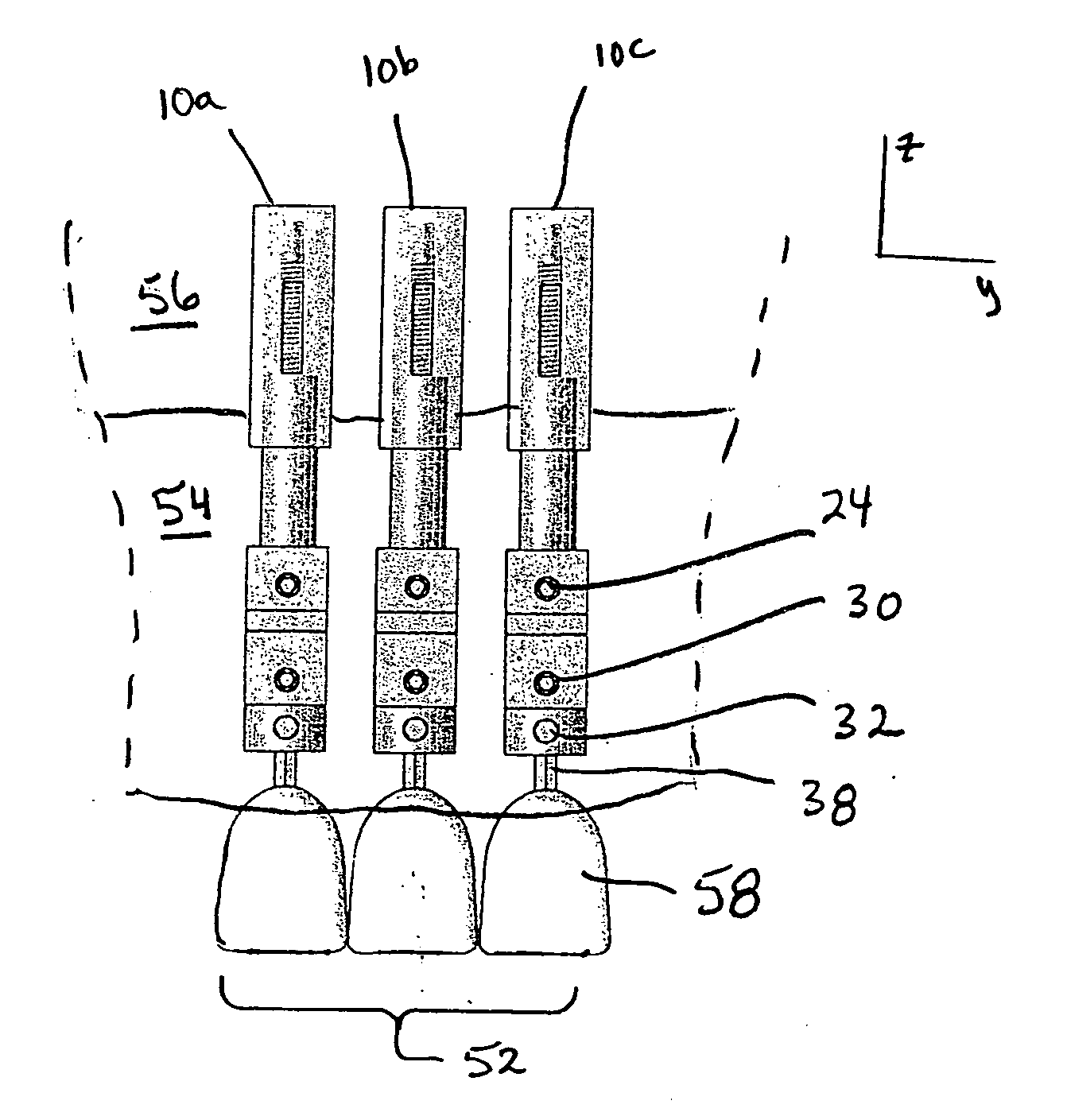

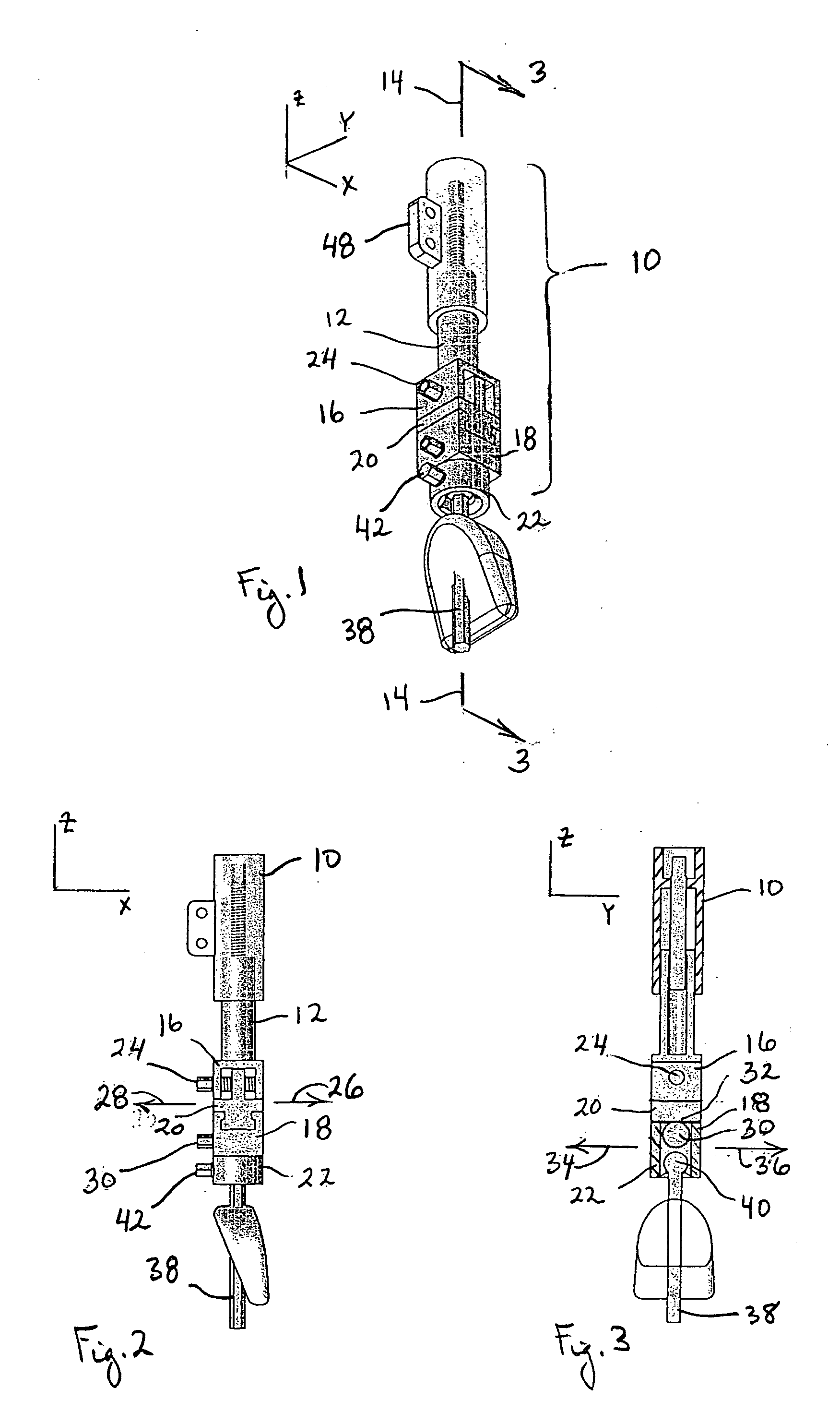

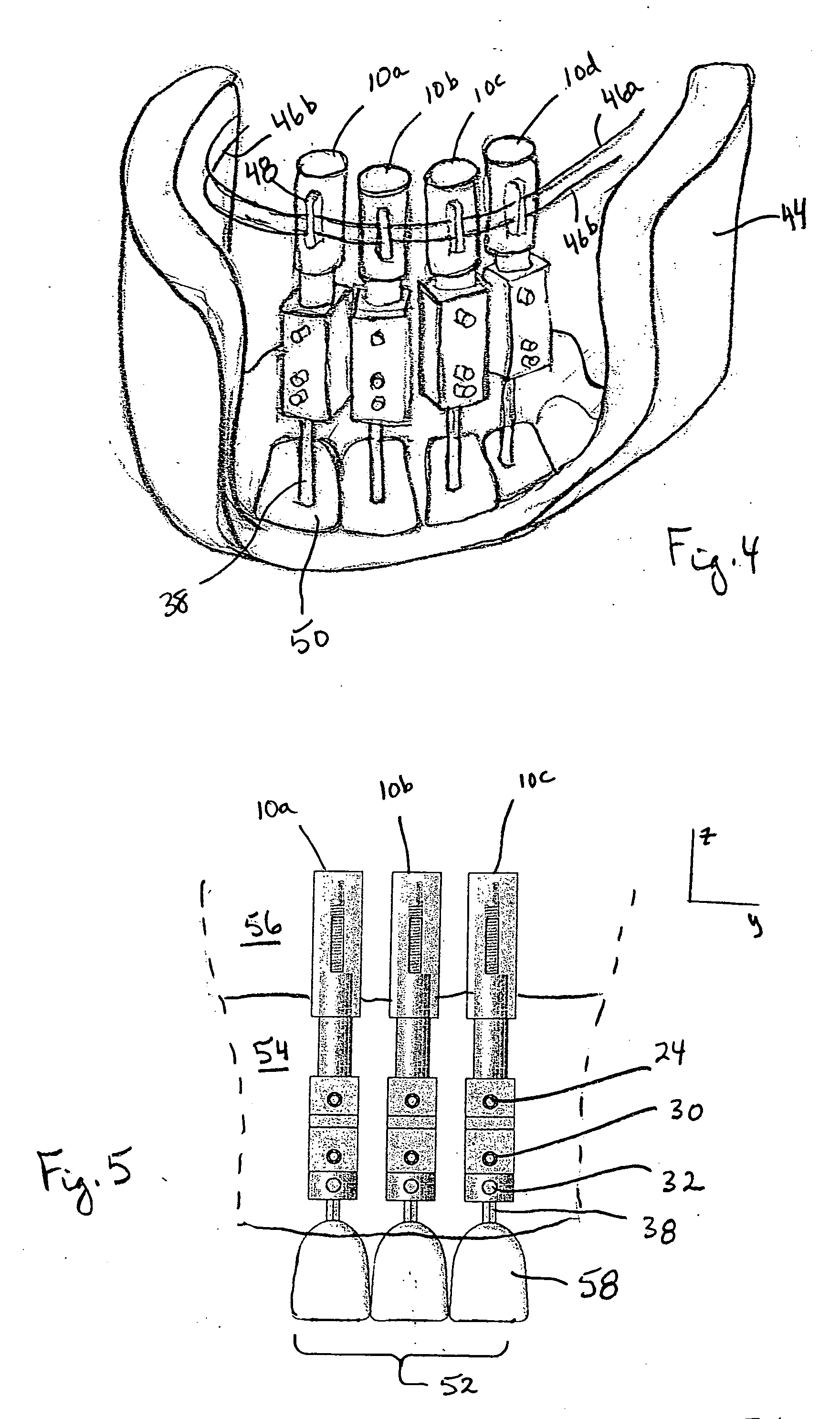

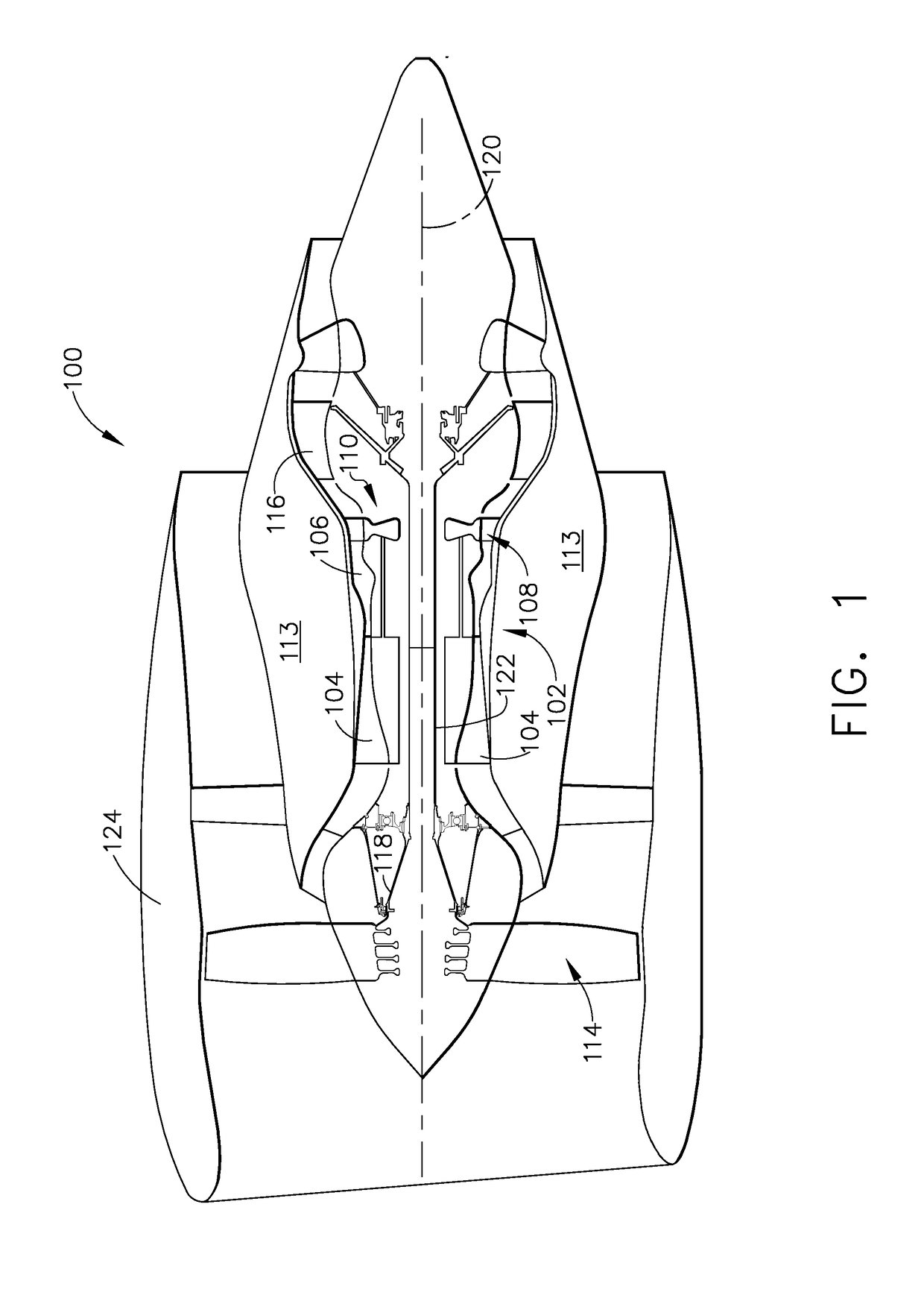

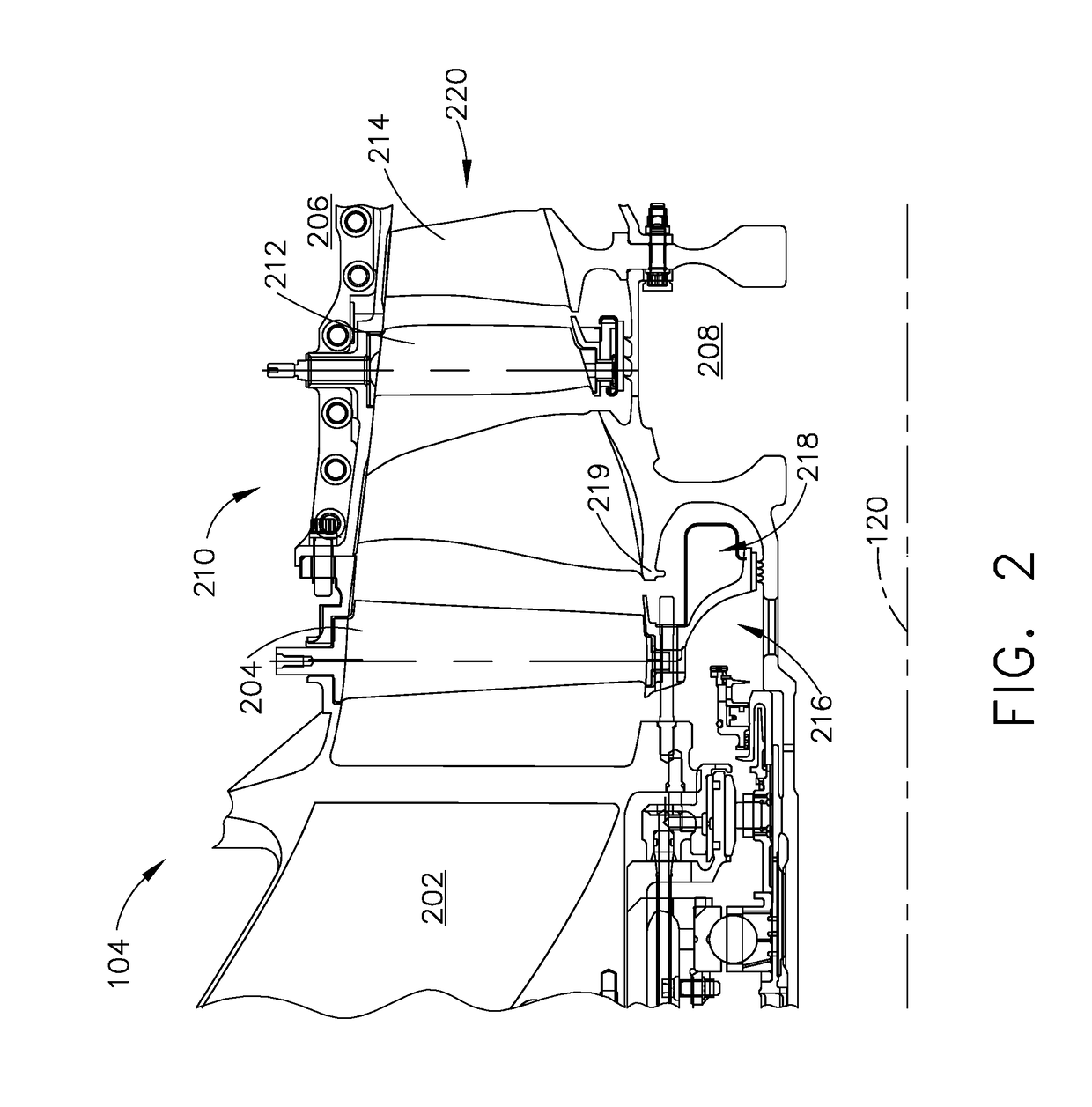

Method and apparatus for repositioning teeth

A system for straightening teeth includes a casting of teeth that is made of a rigid material, and a gum casting made of a flexible material that is joined to the teeth casting. A respective articulating tool for each tooth is provided with a post that is embedded into the tooth. Tooth moving components, accessible through the gum casting, are mounted on each post to selectively provide for left-right, fore-aft, and rotational tooth movements. In its operation, the system involves selectively orienting individual teeth in the teeth casting, to prepare a series of sequentially useable appliances that will straighten teeth in accordance with a pre-planned procedure.

Owner:JOE DENTIST

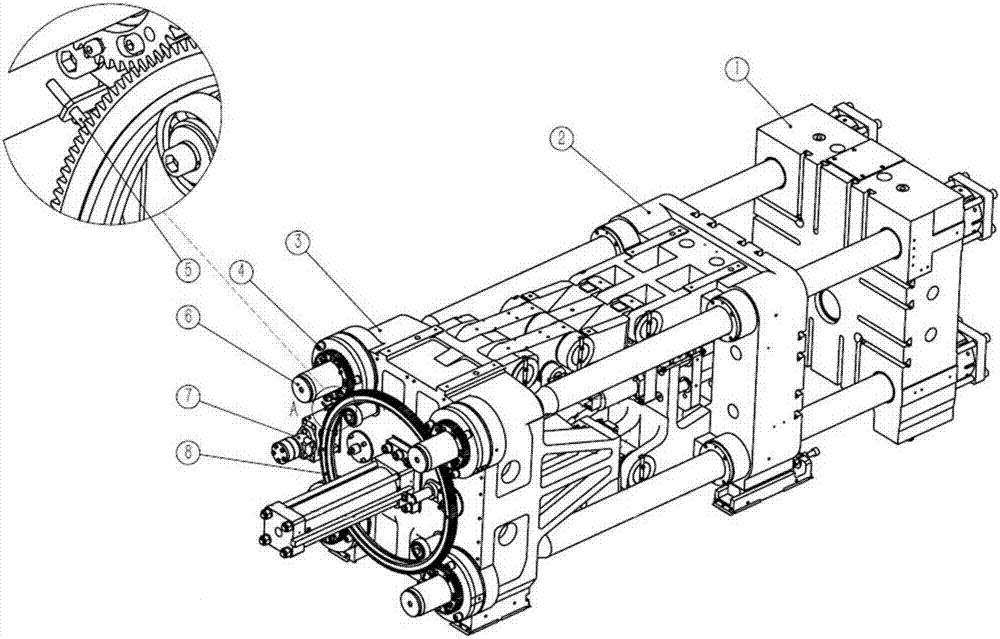

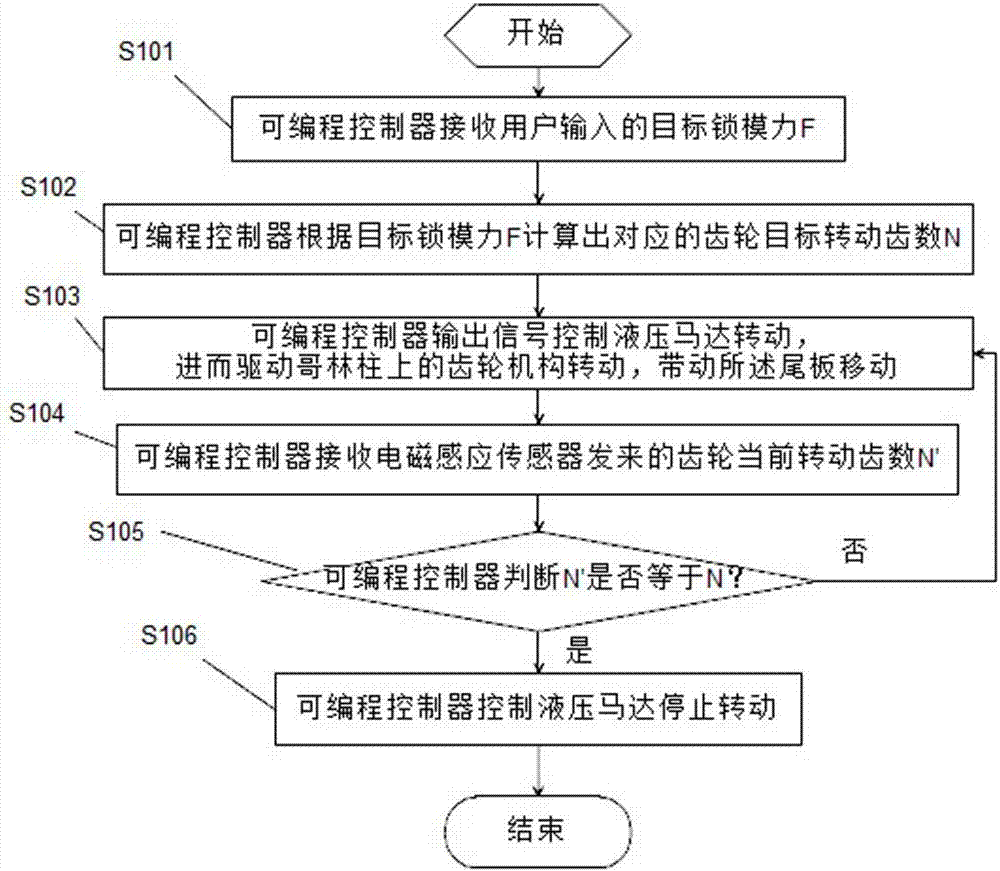

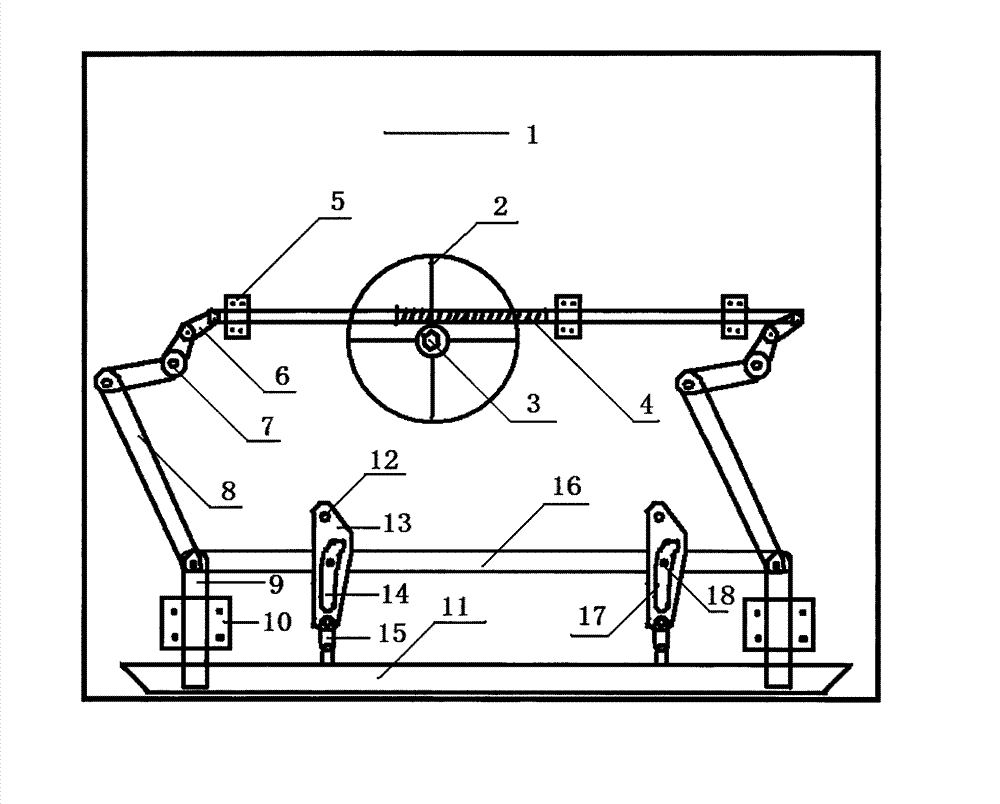

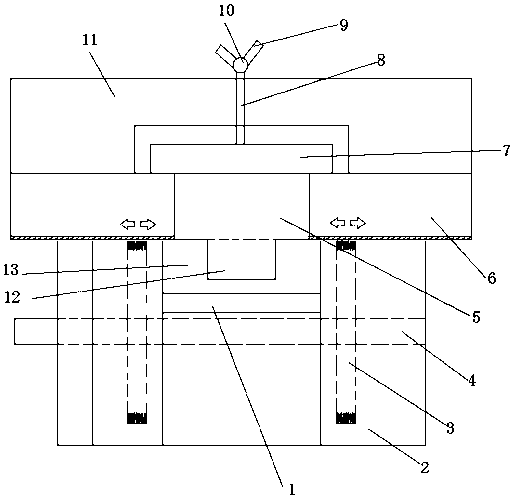

System and method for adjusting mould clamping force

The invention discloses a method for adjusting the mould clamping force. The method comprises the following steps that A, a programmable logic controller (PLC) receives the target mould clamping force F input by a user; B, according to the target mould clamping force F, the PLC calculates the target rotating tooth number N of a corresponding gear; C, the PLC outputs a signal to control a hydraulic motor to rotate and then drives a gear mechanism on a tie bar to rotate, and a movable mould plate is driven to move; D, the PLC receives the current rotating tooth number N', sent by an electromagnetic induction sensor, of the gear; and E, when N'=N, the PLC controls the hydraulic motor to stop rotating, the process is finished, and otherwise, the step C is returned. Through a system, the mould clamping force of a machine hinging type mould closing mechanism can be automatically adjusted, the cost is effectively reduced, meanwhile, the system adopts all-digital signals, the interference or data distorting phenomenon does not occur, and the mould adjusting efficiency is greatly improved.

Owner:宁波保税区海天智胜金属成型设备有限公司

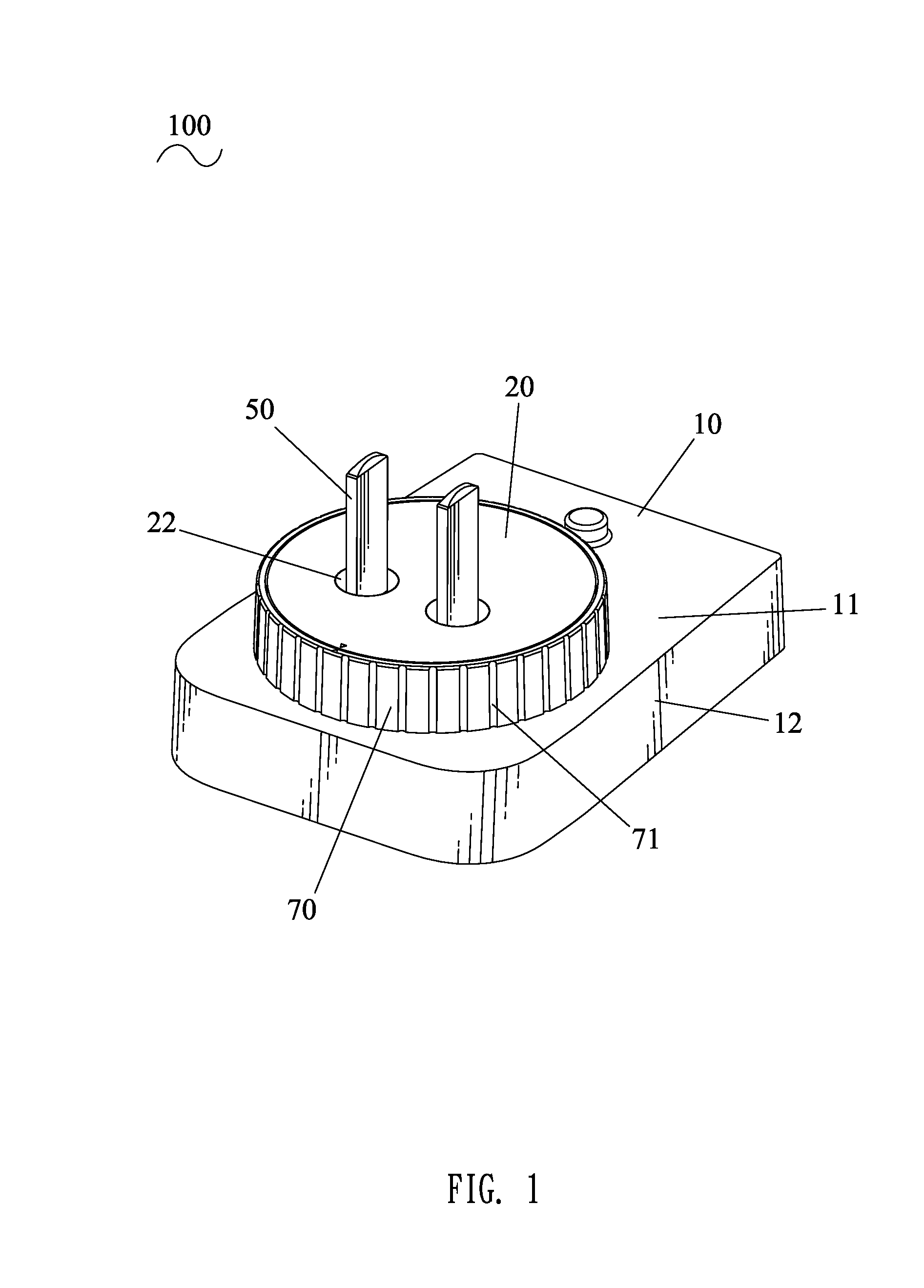

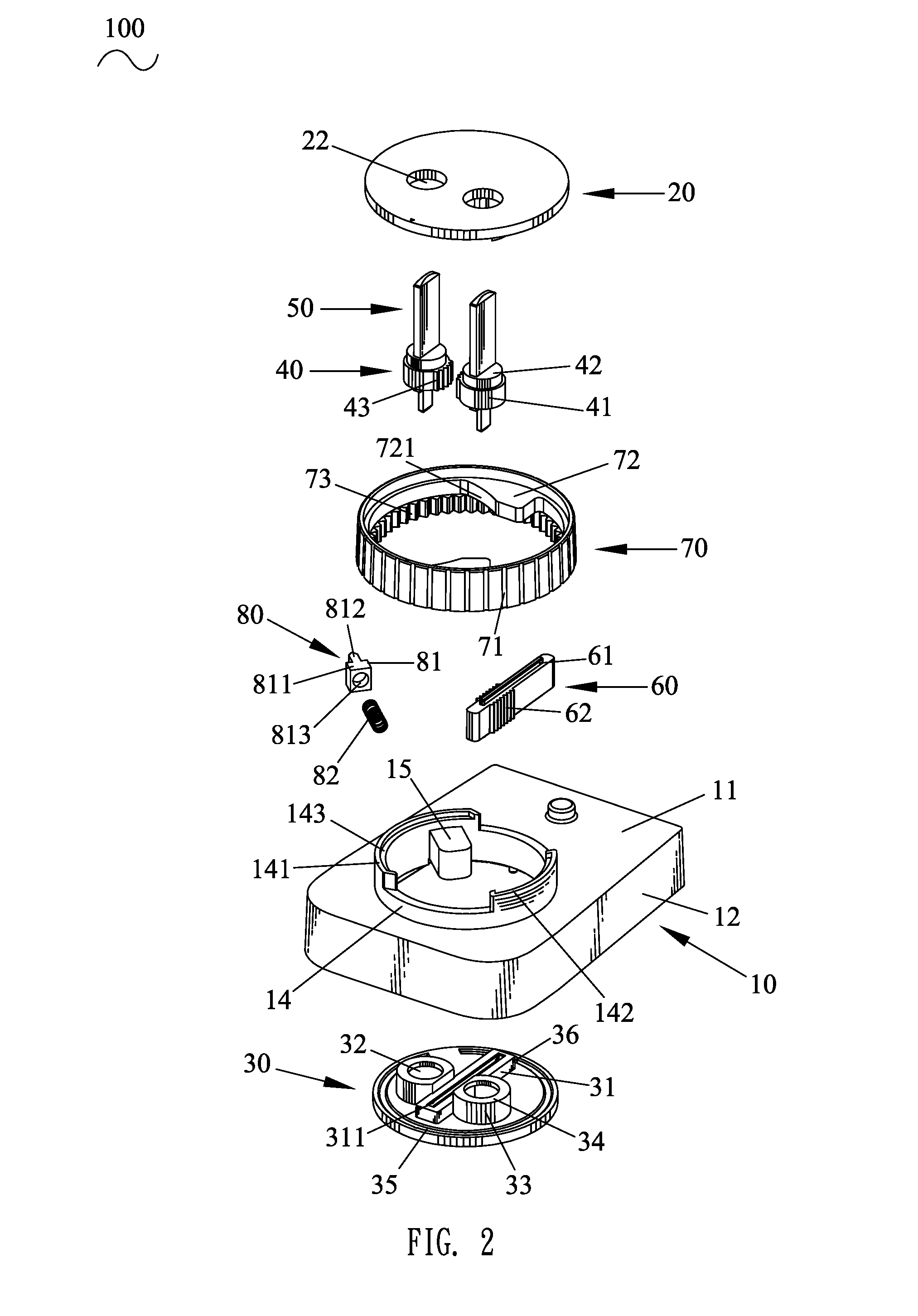

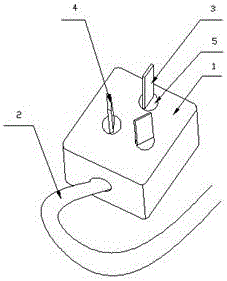

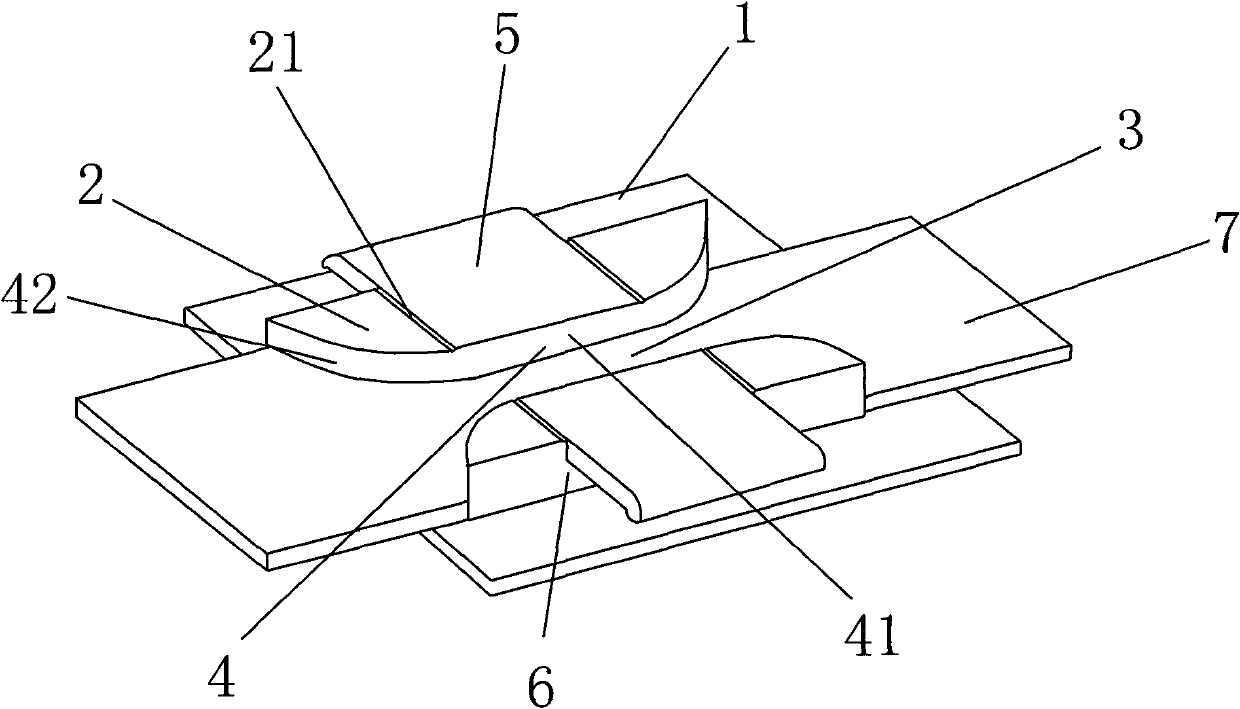

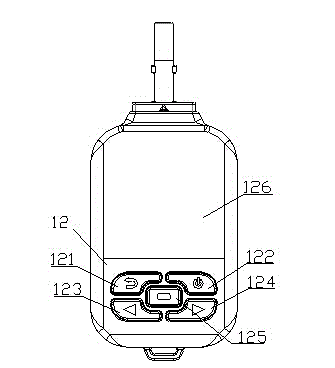

Power plug

ActiveUS8876541B1Easy to convertTwo pole connectionsTwo-part coupling devicesMechanical engineeringRotated tooth

A power plug includes an insulating housing in which a receiving barrel is crossed, top and bottom covers covering top and bottom ends of the receiving barrel, a sliding strip slidably located between the top and bottom covers with serrated sliding teeth protruding on two opposite sides thereof, two rotating axles located at two sides of the sliding strip with rotating teeth protruding on two relative insides thereof and meshed with the sliding teeth, two plug pins vertically integrated in the rotating axles and a rotating ring sheathing outside the receiving barrel with two pushing blocks protruding at an inside wall thereof. The pushing blocks project into the receiving barrel and are against two ends of the sliding strip to push the sliding strip to slide by rotating the rotating ring so as to drive the rotating axles together with the plug pins to rotate relatively.

Owner:WELL SHIN TECH

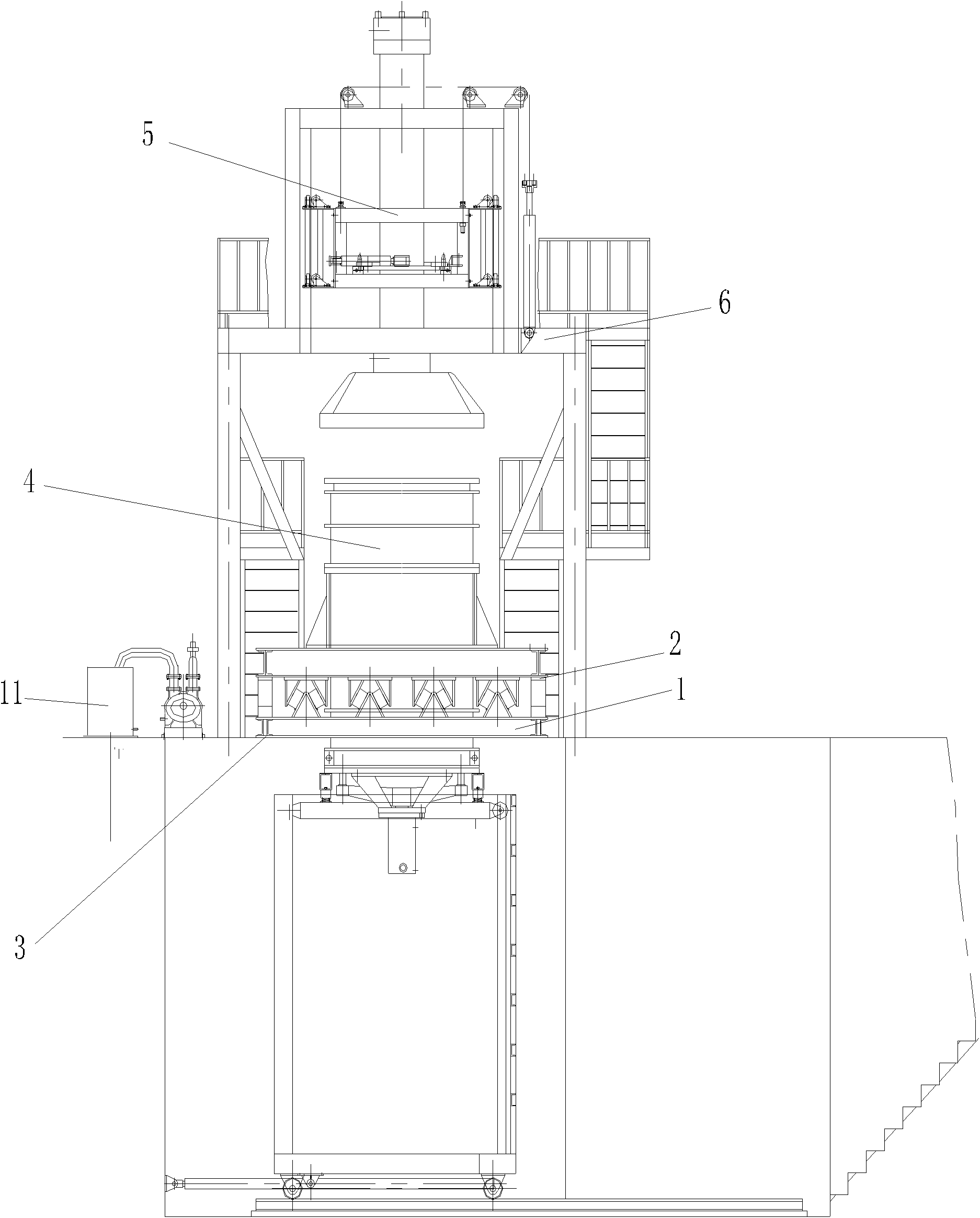

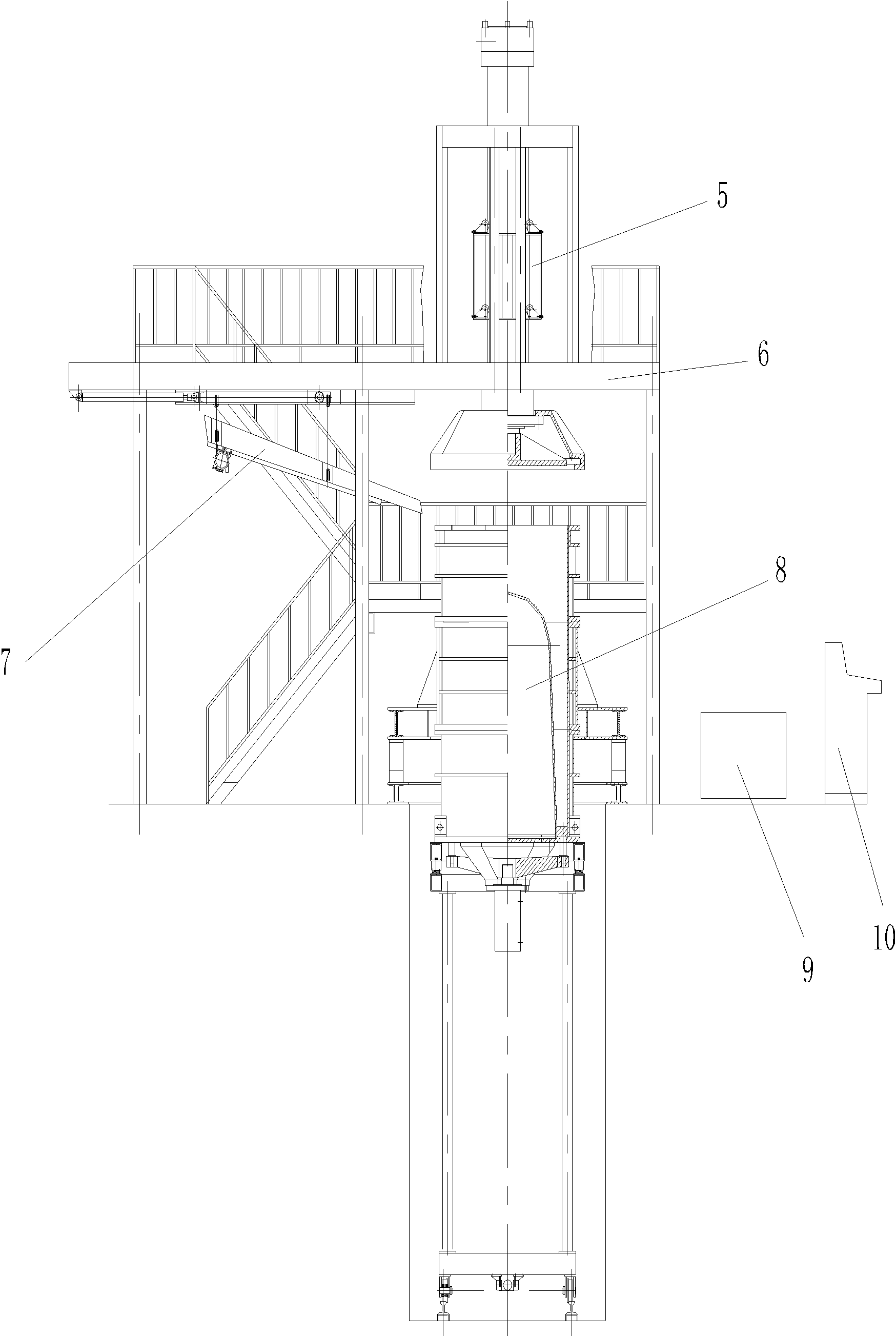

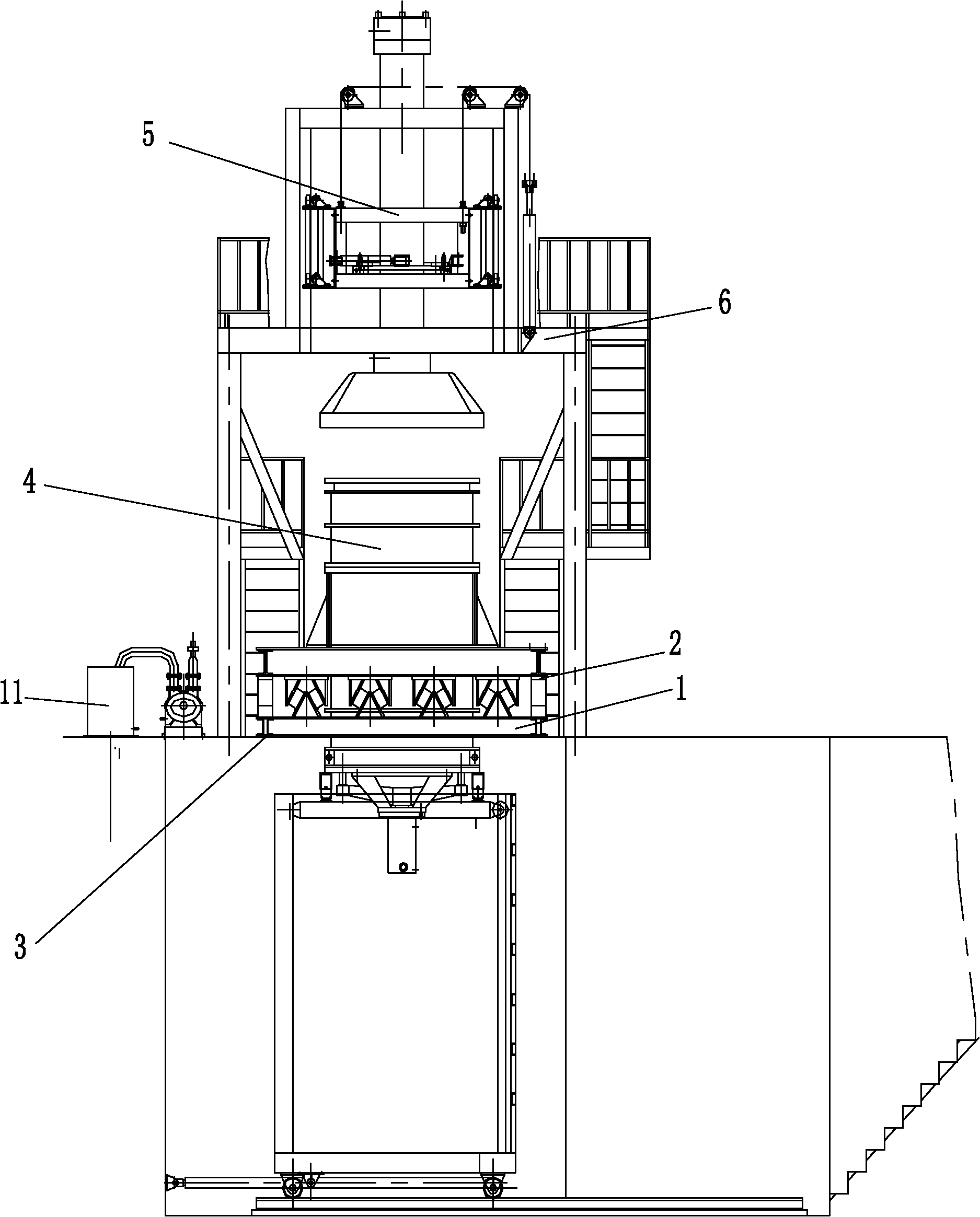

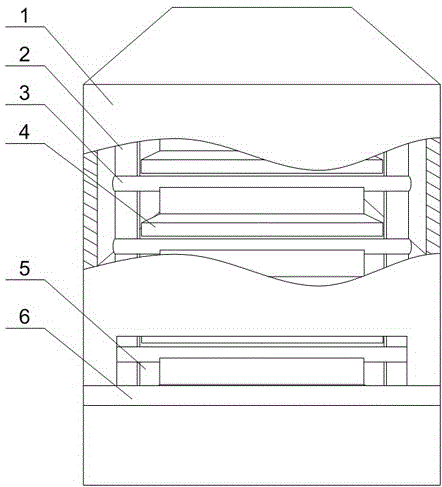

Crucible forming machine

InactiveCN102248581AImprove performanceEliminate inner fissureCeramic shaping apparatusAutomatic controlCrucible

The invention discloses a crucible forming machine, which relates to a pressure machine which uses a pressure head. The crucible forming machine is provided with a hydraulic system, an electrical control system, a vacuum system, a vibration platform, a vibration source, an engine seat, an external mold, an upper pressure head, a frame, a charging mechanism and an internal mold, wherein the vibration platform is arranged on a rubber spring of the engine seat; the vibration source is connected with the vibration platform through a universal shaft; the middle part of the external mold is connected with the vibration platform; the upper pressure head is connected with the external mold through a rotating tooth; the charging mechanism is arranged above the internal mold and the external mold; the internal mold is connected with the external mold through a lock; and the vibration platform is arranged at the middle position between the internal mold and the external mold. The crucible forming machine can be manually or automatically controlled, a crucible is formed at a time and has high integral performance, the density of a crucible product can reach 1.73g / cm<3>, the density difference of all parts is less than 0.03g / cm<3>, and product yield can reach over 95 percent; and a large-sized crucible with the diameter of 1,400mm*2,100mm can be manufactured. The crucible forming machine eliminates the internal cracks of the product, has more uniform mechanical vibration force and makes the density difference between the upper part and the lower part of the product less than 0.02g / cm<3>.

Owner:福建兴朝阳硅材料股份有限公司

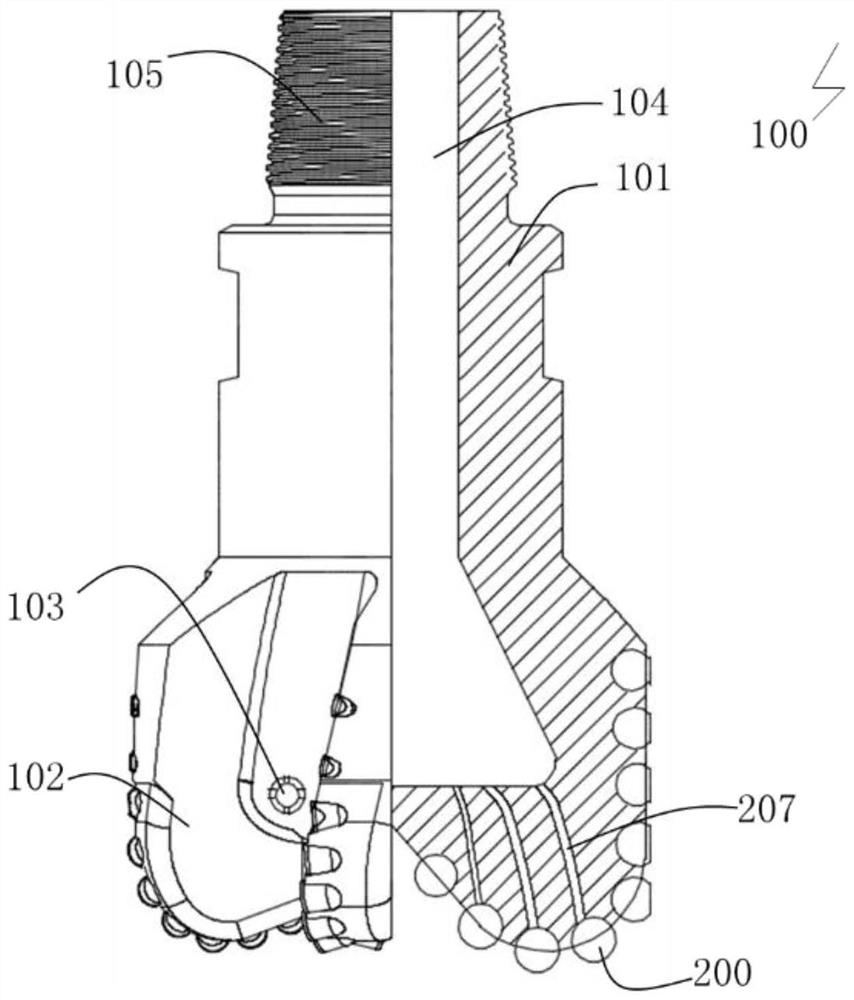

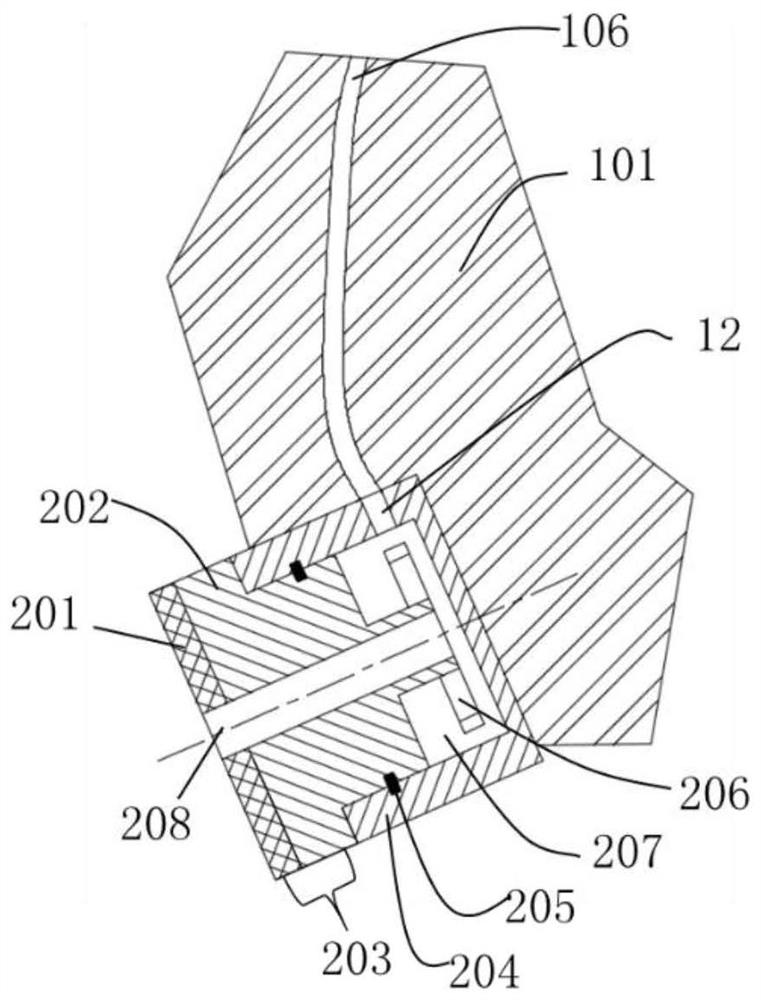

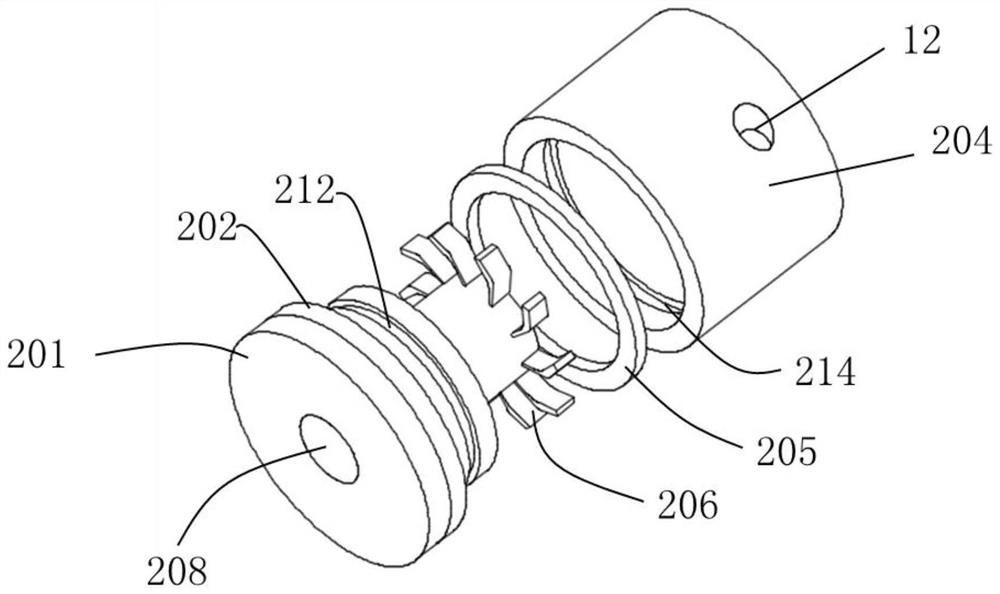

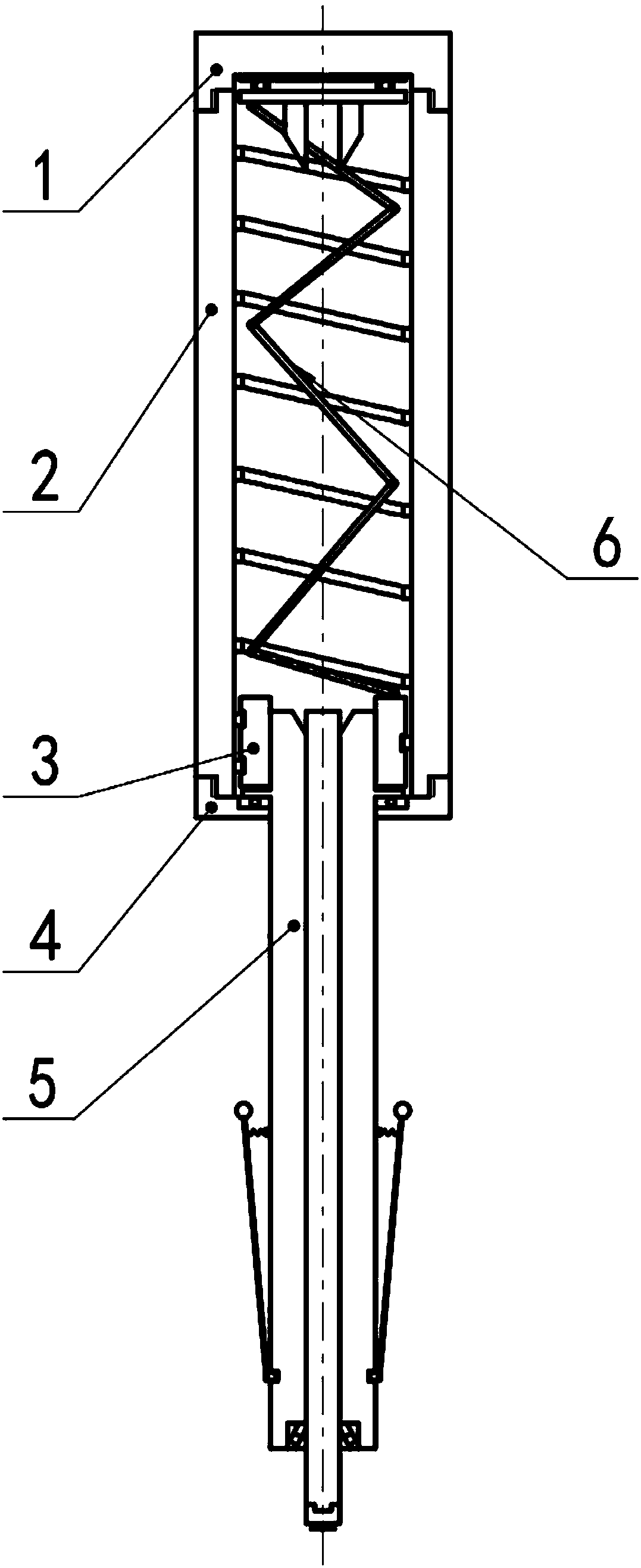

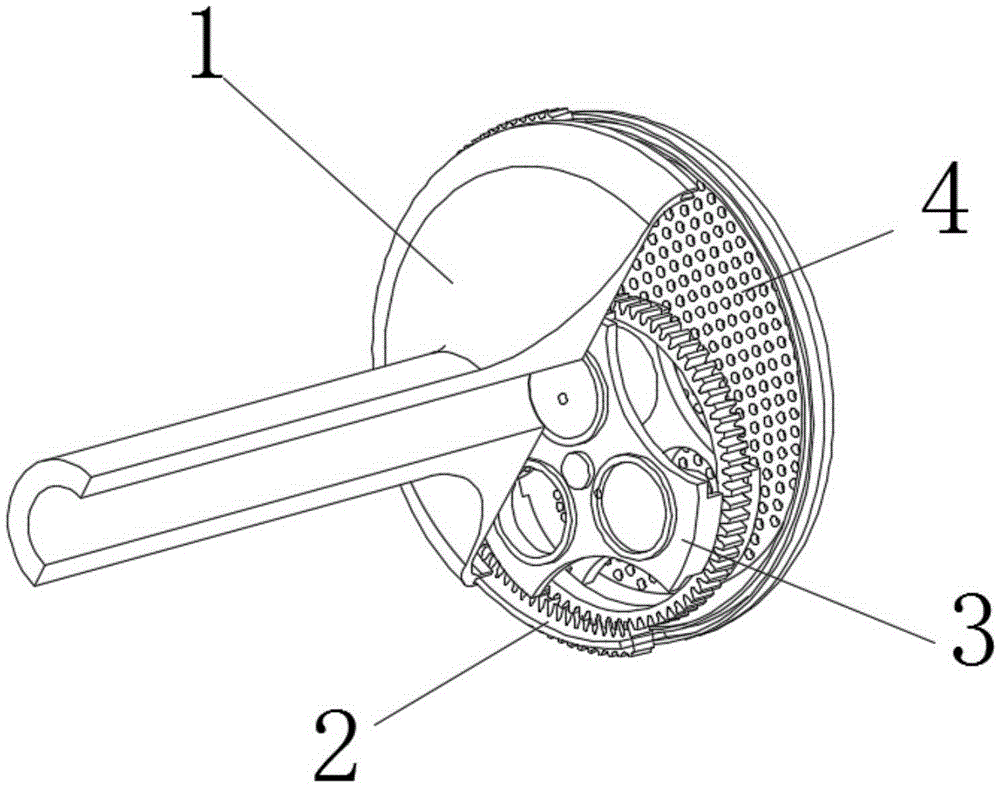

Polycrystalline diamond compact (PDC) bit with rotatable cutting tooth

PendingCN111852342AExtend your lifeAchieve coolingDrill bitsConstructionsPolycrystalline diamondEngineering

A polycrystalline diamond compact (PDC) bit with a rotatable cutting tooth comprises a bit body, the bit body is provided with a tool wing, a nozzle and a main fluid channel, and the cutting tooth isinstalled on the tool wing. The PDC bit is characterized in that a first fluid channel connected with the main fluid channel is arranged in the bit body; the cutting tooth is formed by a central rotating tooth, a bush, a limiting device and a hydraulic drive rotator; the bush is provided with a hole connected with the first fluid channel, and a second fluid channel is formed between the bush and the central rotating tooth; a flow channel space is arranged in the central rotating tooth to form a third fluid channel; the main channel, the first fluid channel, the second fluid channel and the third fluid channel communicate in sequence; and the central rotating tooth is provided with a limiting groove, the bush is provided with a limiting hole or a limiting groove, and the central rotating tooth is connected with the bush through the limiting device. The utilization rate of a cutting tooth diamond layer can be improved through the cutting tool of the structure, meanwhile cooling and cleaning of the cutting tooth can be realized, and the service life of the cutting tool is effectively prolonged.

Owner:刘伟

Sandwich machine

The invention discloses a sandwich machine. The sandwich machine comprises a base, a flip cover, a tray located in the base and a rotating shaft used for hinging the base and the flip cover. A flip cover cavity and a blade set are arranged in the flip cover; a blade set handle is arranged on the side, close to the flip cover cavity, of the blade set. A spring is arranged on the blade set handle; one end of the spring is fixed to the side away from the inclined face of the blade set handle and the other end of the spring is fixed to the flip cover; a driving mechanism for driving the blade sethandle is arranged in the flip cover cavity, rotating teeth are arranged on the rotating shaft, and the driving mechanism cooperates with the rotating teeth. A base cavity is formed in the flip cover,a cam for controlling the height of the tray is arranged below the tray, the cam is connected with a rotating mechanism located in the base cavity, and the rotating mechanism cooperates with the rotating teeth. When bread is directly put into the sandwich machine, the sandwich machine can automatically slice the bread by closing the flip cover.

Owner:慈溪市艾肯电器有限公司

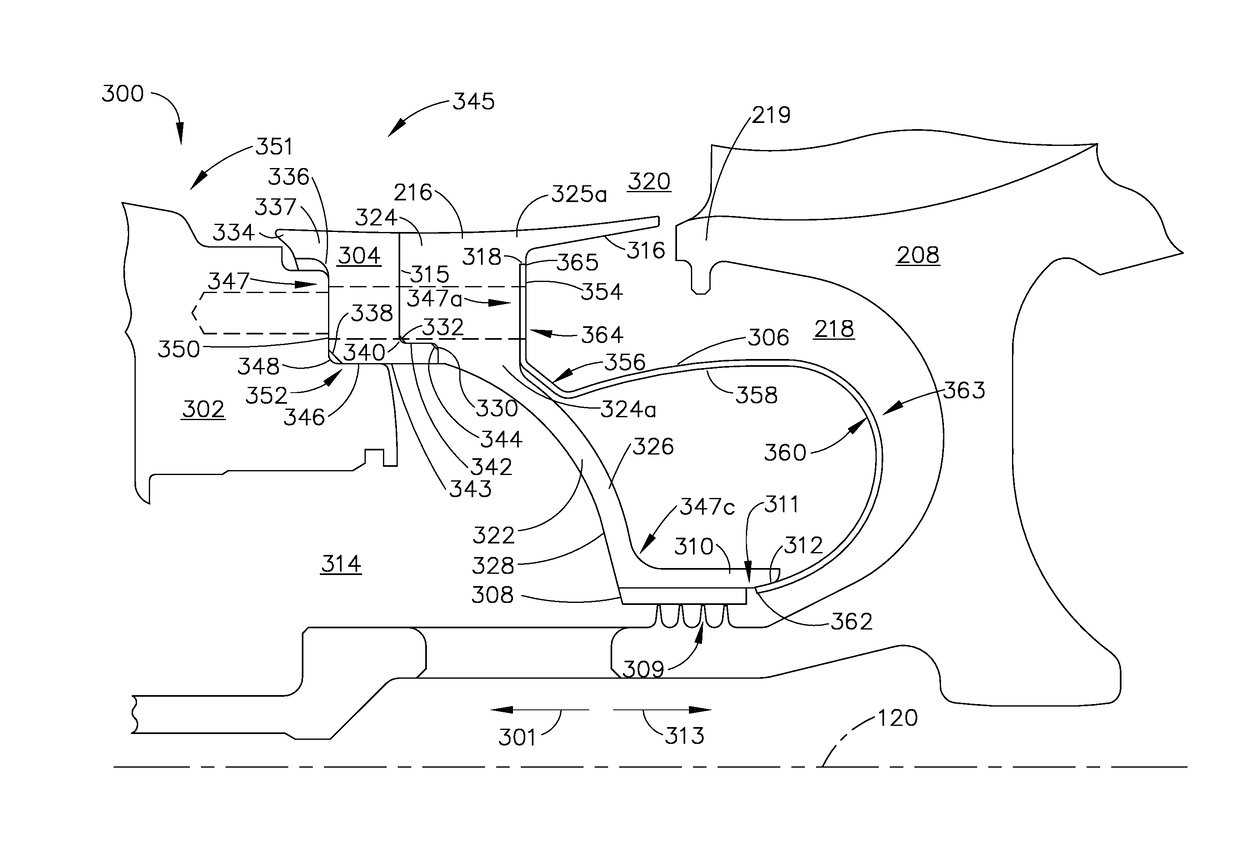

System for an inlet guide vane shroud and baffle assembly

A system for an inlet guide vane shroud and baffle assembly includes a shroud. The shroud includes a first end configured to couple to an annular support member of the gas turbine engine, and a second end. The shroud also includes a distal end including an axially aft extending lip, and a seal assembly configured to form a seal with an annular set of rotating teeth on a rotor of the gas turbine engine. The shroud further includes an arcuate shroud body extending between the distal end and the second end. The shroud and baffle assembly also includes a baffle coupled to an aft side of the shroud. The baffle includes a radially outward end coupled to the aft side, a radially inward end coupled to the axially aft extending lip, and an arcuate baffle body extending there between. Both the shroud and the baffle extend circumferentially about a central axis.

Owner:GENERAL ELECTRIC CO

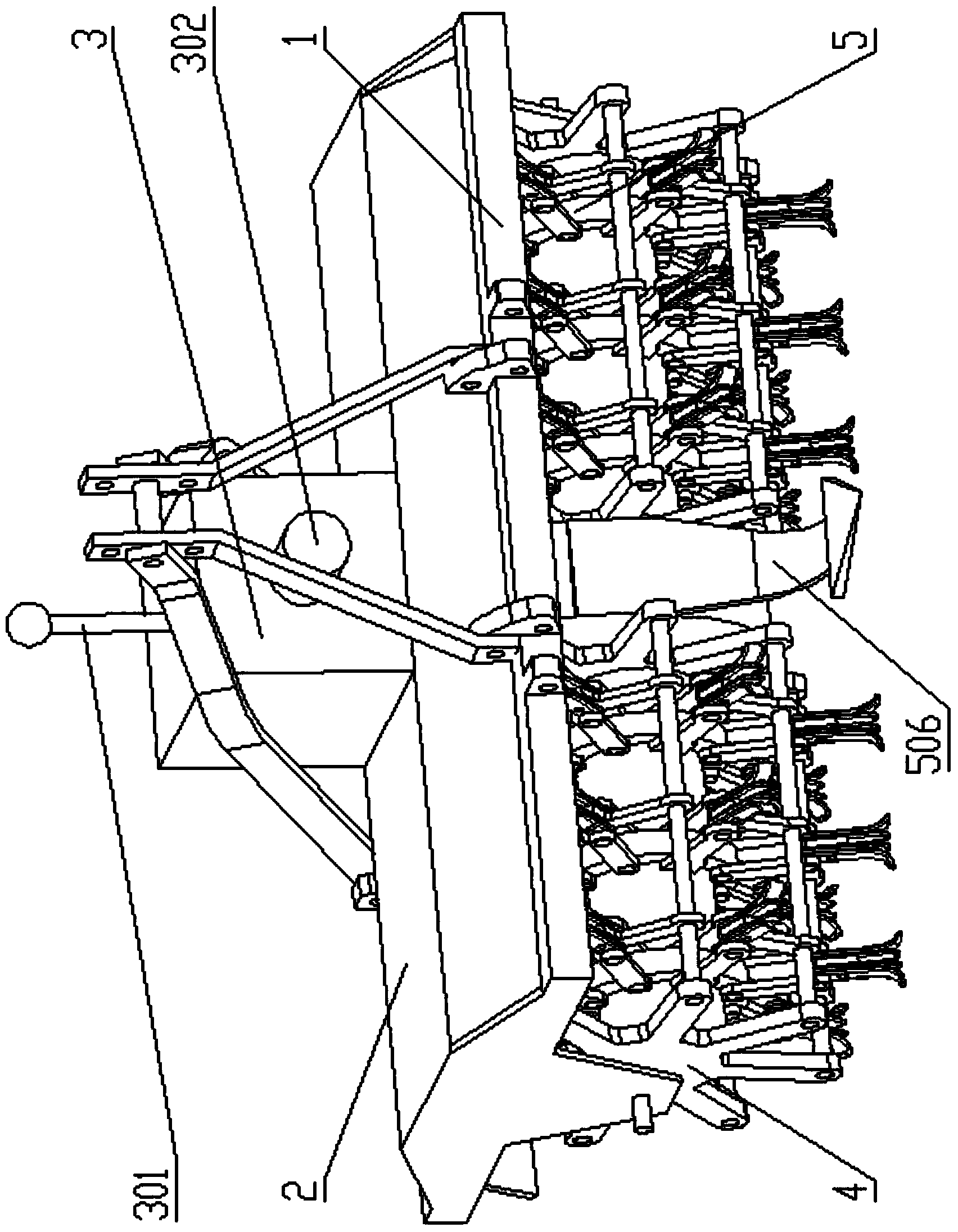

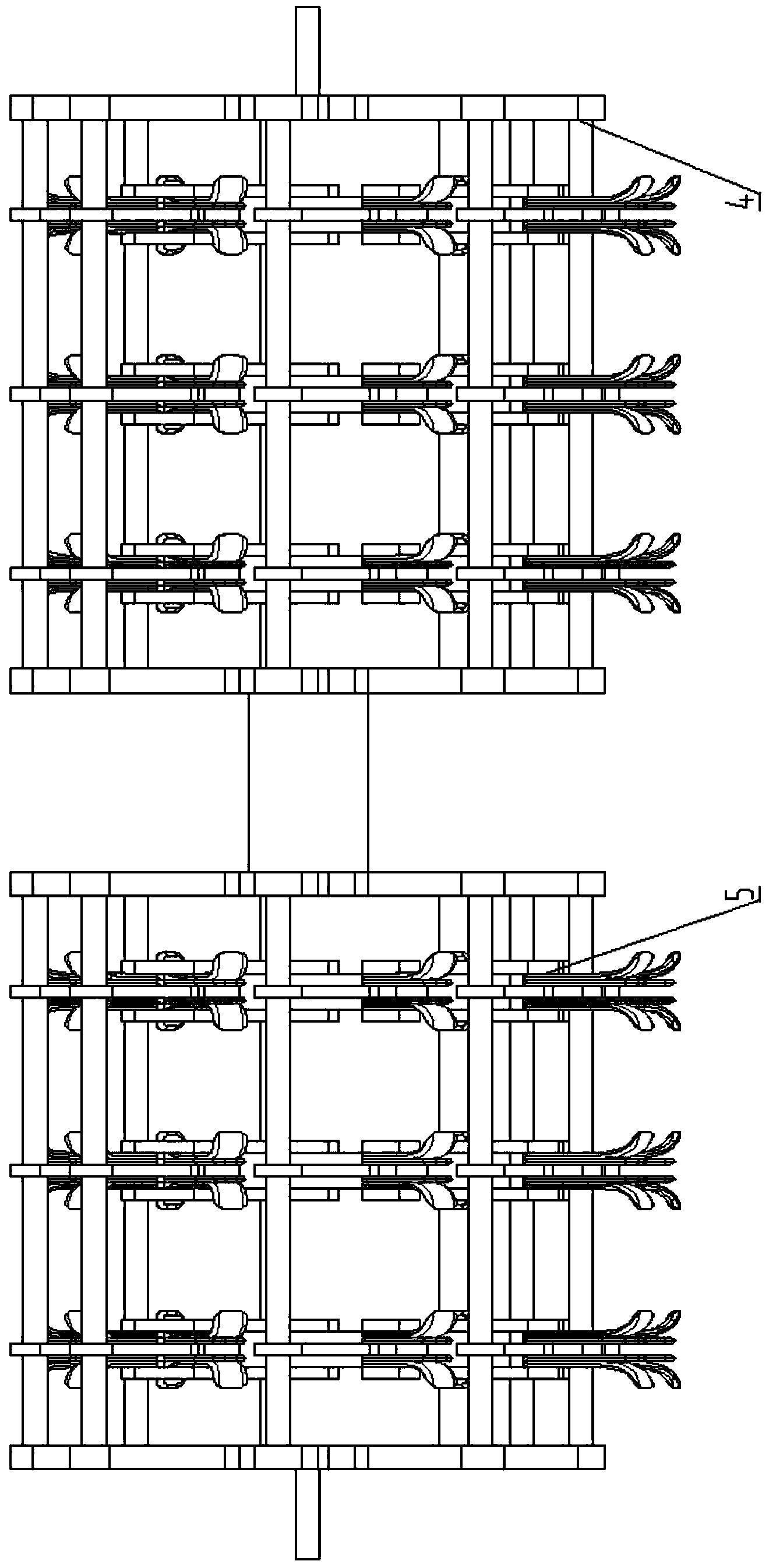

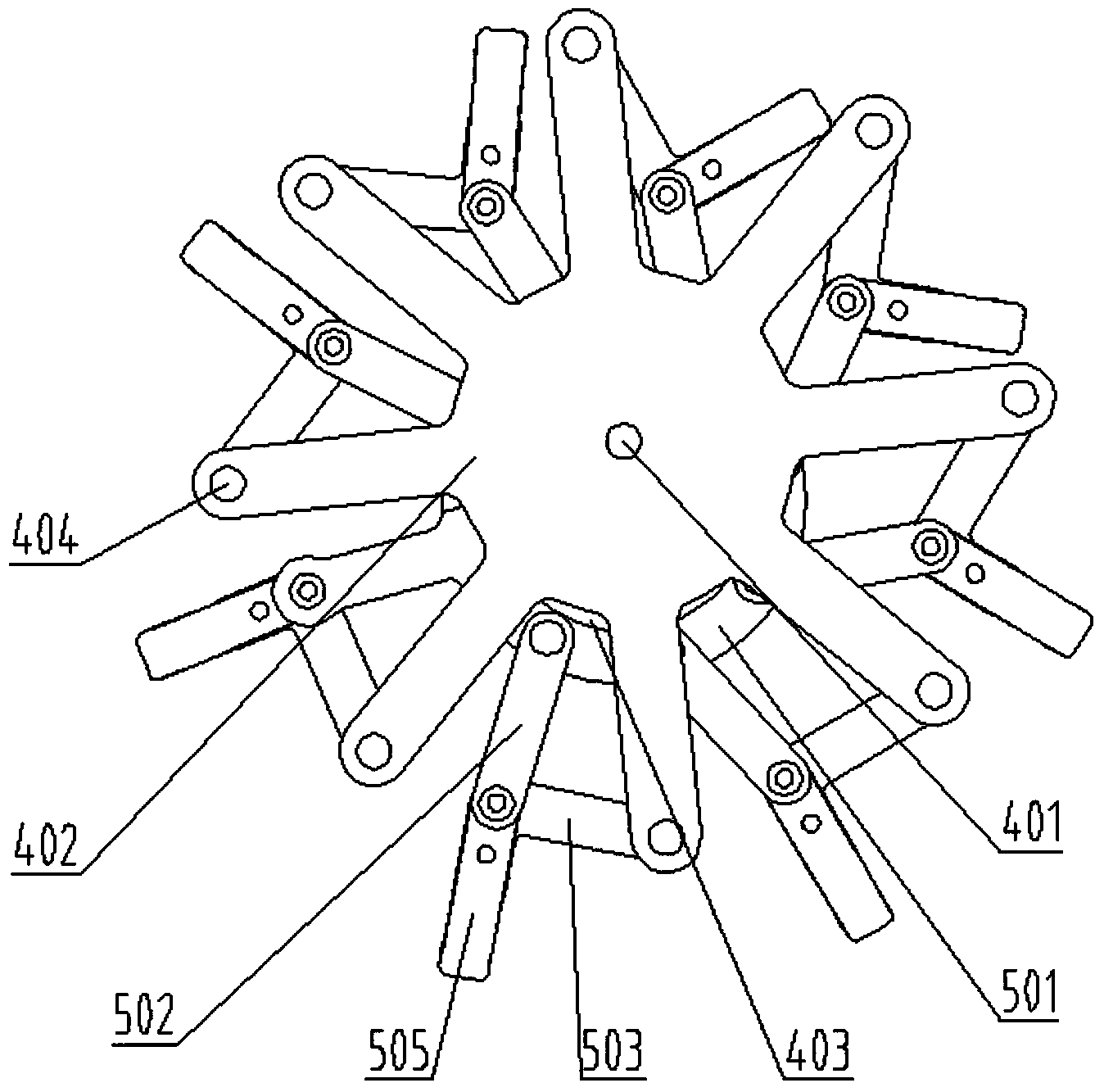

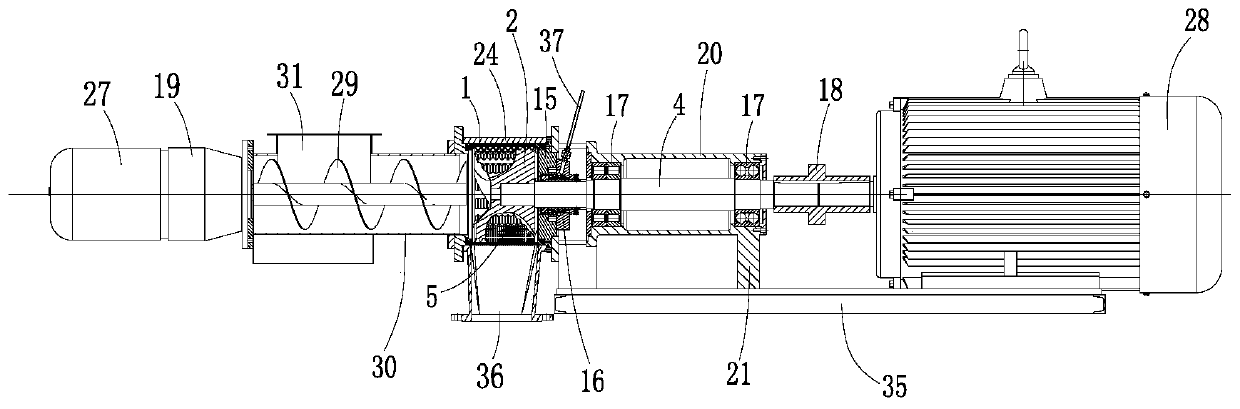

Straw breaking and rotary tillage integrated machine

ActiveCN104255092AAchieve smashRealize functionTilling equipmentsCuttersDrive shaftAgricultural engineering

The invention discloses a straw breaking and rotary tillage integrated machine which comprises a machine frame, a machine casing and a gearbox and further comprises a transmission mechanism and a rotating tooth mechanism. The transmission mechanism is composed of fixed shafts, rotating wheels, eccentric bodies, rotating wheel connection rods and transmission shafts. The rotating tooth mechanism is composed of driven rings, first connection rods, second connection rods, first blades and second blades. The machine has the advantages of reducing rolling of the cropland, reducing energy consumption of a tractor, saving time and materials, improving working efficiency, reducing cost and the like, and enables machine tools to be small and light. The machine is multipurpose, is favorable for popularization and development of agriculture machinery and is applicable to cropland straw breaking and rotary tillage land one-step forming.

Owner:万华禾香生态科技股份有限公司

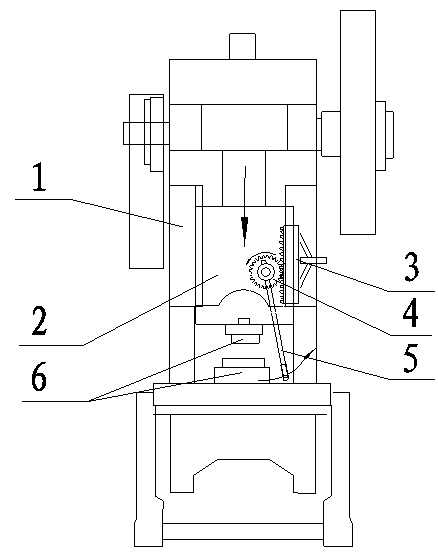

Press machine safety protection device preventing hands from being pressed

InactiveCN103660353ATo achieve the purpose of active safety protectionImprove the protective effectEngineering safety devicesPressesEngineeringMechanical engineering

The invention relates to a press machine safety protection device preventing hands from being pressed. A press machine sliding block is connected with a press machine guide rail, and protection device guide straight teeth are connected with protection device rotating teeth and are fixed on the press machine sliding block of the protection device rotating teeth. The protection device is added on a common press machine, so that the protection device rotating teeth rotate anticlockwise to drive a hand-press-preventing rod to rotate anticlockwise to push away the hands of an operator, the automatic safety protection purpose is achieved, and safety protection level is effectively improved.

Owner:重庆针尖内燃机部件制造有限公司

Cloth pressing mechanism

The invention discloses a cloth pressing mechanism, and belongs to the field of textile processing machinery and equipment. The cloth pressing mechanism comprises a fixation bracket, a lifting and pressing rod, a rotating swinging plate, a material-bearing plate, a lifting bracket, a material-pressing cam, a translation driving plate and a translation air cylinder; the lifting and pressing rod is vertically arranged at one side of a lifting guide plate in a sliding mode, and one side of the rotating swinging plate is provided with a rotating tooth-shaped surface matched with a lifting gear strip; material-bearing guide rods are vertically and symmetrically arranged at the two sides below the material-bearing plate respectively and vertically arranged on the lifting bracket in a sliding mode; the translation driving plate is horizontally arranged on the lower side of the fixation bracket in a sliding mode, and a cloth-pressing connecting rod is arranged between the rotating swinging plate and one end of the upper side of the translation driving plate; a material-pressing tooth-shaped surface matched with a translation gear strip is arranged at the lower side of the material-pressing cam. The cloth pressing mechanism is reasonable in structural design, the upper and lower sides of cloth can be pressed and fixed quickly, efficiently, stably, synchronously and tightly, the efficiency and quality of cloth processing are improved, and the demands of production and usage are met.

Owner:浙江正辉针织科技股份有限公司

Sealed ground beam

InactiveCN103114795ANot to be wornReduced tightnessConstruction fastening devicesSealing arrangementsJet aeroplaneEngineering

The invention provides a sealed ground beam. The sealed ground beam is composed of a protective door, a manual gear rotating table, a rotating table fixed shaft, a cross rod with rotating teeth, horizontal fixed riveting grooves, transverse movable linking bars, reversing connecting bars, vertical movable linking bars, vertical fixed riveting grooves, latching bolts, a linkage cross rod with positioning bolts, an amplitude reduction chute with radian, a movable linking piece and a sealed ground beam body. According to the sealed ground beam, influences of the sealed ground beam body to a channel can be avoided, meanwhile, the ground beam body can be protected from being worn, sealing effects can be improved, and the protective door with the sealed ground beam body can be used for occasions where requirements on protection levels are high, such as headquarters, funk holes and airplane shelters in wars.

Owner:苏州市江诚人防设备有限公司

Linear moving energy storage screwdriver

The invention discloses a linear moving energy storage screwdriver. The screwdriver comprises a knife handle, an inner sliding block and a knife body; a hollow cavity is formed inside the knife handle, a protruding spiral line is arranged on the inner wall of the knife handle, a spiral line groove is formed in the outer side surface of the inner sliding block, and a center hole matched with the knife body in diameter is formed in the center of the inner sliding block; one side end surface of the inner sliding block is provided with one-way rotating teeth, the inner sliding block is rotationally connected to the knife handle through a spiral line groove, and the inner sliding block sleeves the upper part of the knife body, and is connected to the teeth on the position, close to the upper surface, of the flange of the outer wall of the knife body through one-way rotating teeth; and when the knife handle is pressed, the linear movement of the knife handle is converted into the rotating movement of the knife body through the inner sliding block. According to the screwdriver, linear motion of the knife handle is converted into the rotation of the knife body through the spiral rotating mechanism arranged in the knife handle, so that operation of pressing the screwing screw is realized, and operation is convenient; and an energy storage mechanism is arranged on the knife body so thatthe energy storage can be carried out firstly, and then the stored energy is converted into rotation to realize fastening of the screw.

Owner:铜陵市科达生产力促进中心有限公司

Worm wheel with rotating teeth

InactiveCN101629624ASimple structureEasy to manufacturePortable liftingGearing elementsEngineeringFriction force

The invention discloses a worm wheel with rotating teeth, comprising a wheel body and worm teeth arranged on the outer edge of the wheel body. The worm teeth are matched with a worm. The worm wheel is characterized in that each worm tooth consists of a shaft arranged on a tooth path and a bearing or a shaft sleeve. The shaft is fixed to the wheel body and arranged uniformly on the tooth path, and the outside diameter of the bearing or the shaft sleeve jacketed on the shaft is as wide as the tooth path. The worm wheel has the shaft arranged on the outer edge of the worm wheel body only, is provided with the bearing or the shaft sleeve to form the tooth and also has the advantages of simple structure, low processing and manufacturing cost, small drive friction force and little power loss. Since the drive friction force of the worm wheel is small in the working process, the wheel body and a wheel tooth (including the shaft, the bearing or the shaft sleeve arranged on the shaft) can be made of general steel material, thereby reducing the manufacturing cost of the worm wheel.

Owner:李正心

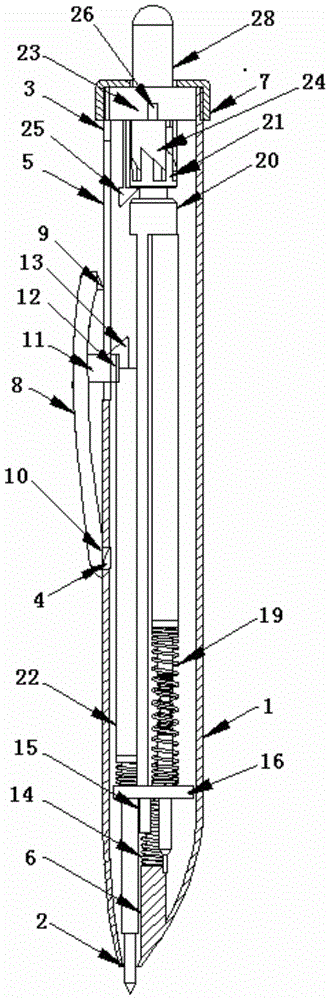

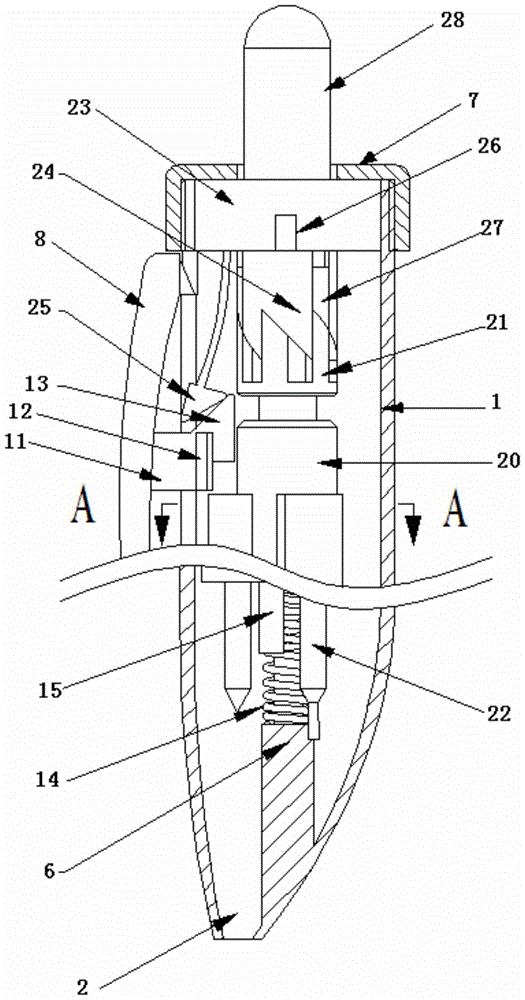

Multifunctional pen provided with rotary refill library and eccentric pen hole

ActiveCN105667125AMeet different writing requirementsLarge diameterWriting implement attachmentsWriting unitsRotated toothEngineering

The invention discloses a multifunctional pen provided with a rotary refill library and an eccentric pen hole. The multifunctional pen comprises a hollow pen holder and a pen cap, wherein the pen cap is arranged at the upper end of the pen holder and provided with a round hole. A refill push rod is arranged on the side wall of the pen holder. The eccentric pen hole is formed in the bottom of the pen holder. A stepped boss is arranged on the inner side of the bottom of the pen holder. A reset spring, the rotary refill library, a fixed pawl and a pressing rod are arranged in the pen holder in sequence from bottom to top, the resets spring is arranged at the upper end of the stepped boss, and the pressing rod is provided with sliding teeth. The rotary refill library comprises refills and a refill rack. The refill rack is integrally composed of a refill rack ejector rod, a refill rack fixing rod and a refill rack circular truncated cone, wherein the refill rack ejector rod, the refill rack fixing rod and the refill rack circular truncated cone are sequentially connected from top to bottom. Rotating teeth of an integrated structure are arranged on the refill rack ejector rod in the circumferential direction. Arc-shaped grooves used for fixing the refills are formed in the side wall of the refill rack fixing rod. According to the multifunctional pen provided with the rotary refill library and the eccentric pen hole, different writing requirements can be met; and in addition, the space of the pen holder is fully utilized, the diameters of the refills are increased, and the refill replacement time is prolonged.

Owner:TIANJIN UNIV

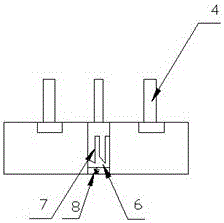

Novel attaching plug

InactiveCN106450889ASimple structureHigh implementabilityCoupling contact membersEngineeringRotating disc

The invention discloses a novel attaching plug which comprises a base and a power plug wire connected with the base, wherein pins are arranged on the base; the pins include a front pin and two rear pins; rotating discs are arranged at the bottom ends of the two rear pins; the rotating discs are of circular shape and are embedded into the base; an automatic switch is arranged at the bottom of the front pin; the automatic switch comprises a rotating tooth part; unequal helical teeth are arranged at the top of the rotating tooth part; the helical teeth are blocked in clamping slots; a small spring is arranged at the bottom of the rotating tooth part; a switch is arranged on the base. The novel attaching plug has a simple structure; the adopted materials are economical and low-cost; the rotating discs are arranged at the bottom of the rear pins, so that the rear pins can be rotated; when the attaching plug is served as a secondary plug, the rotating discs are rotated to the fixed points, and then the front pin is pressed and the front pin can be contracted into the base by the automatic switch, so that the attaching plug can be inserted into a jack of a used socket; when the front pin is pressed again, the front pin is popped out of the base and then the rotating discs are rotated, so that the attaching plug can be used as a secondary grounding plug.

Owner:安徽梦派智能科技有限公司

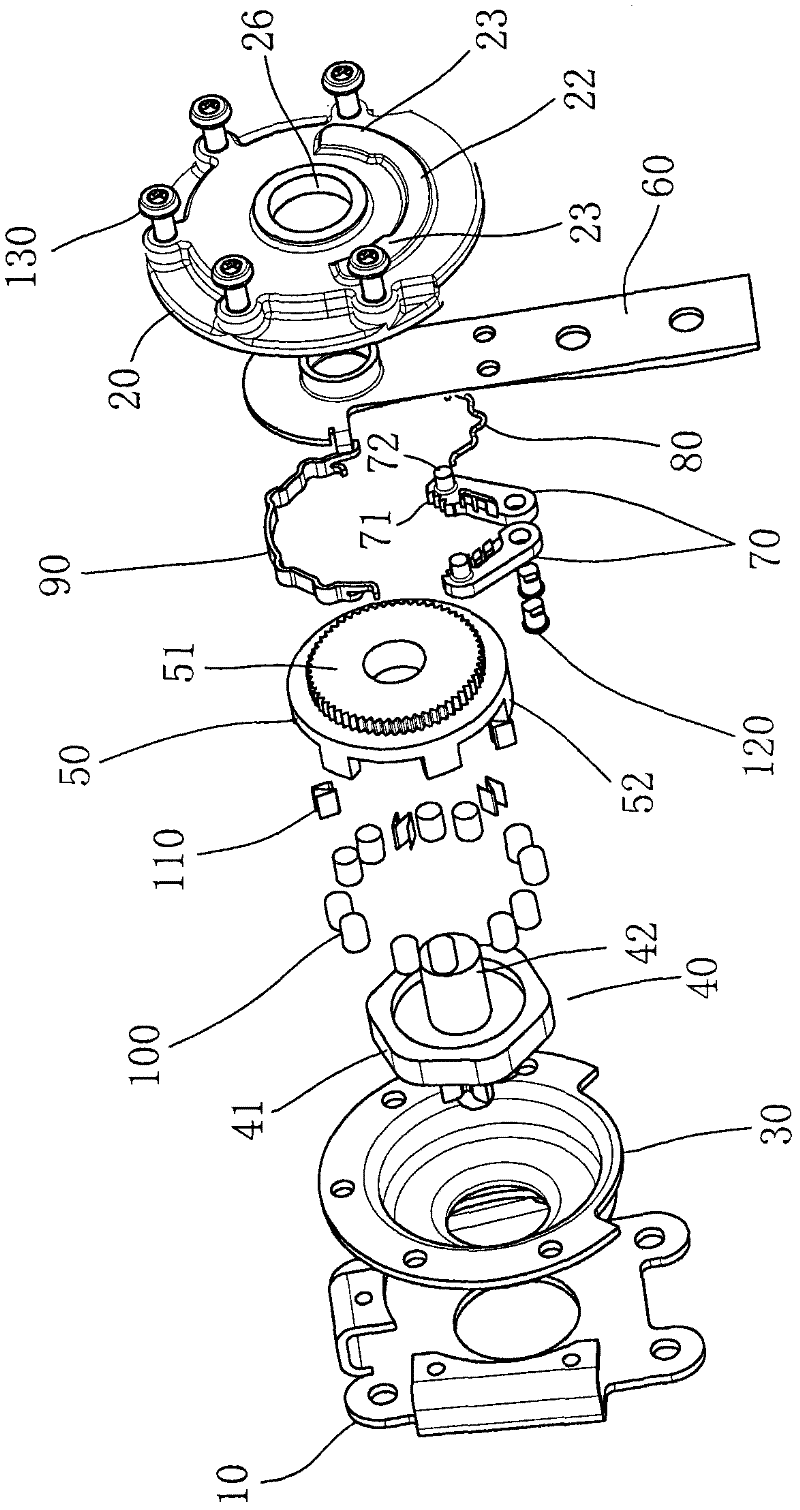

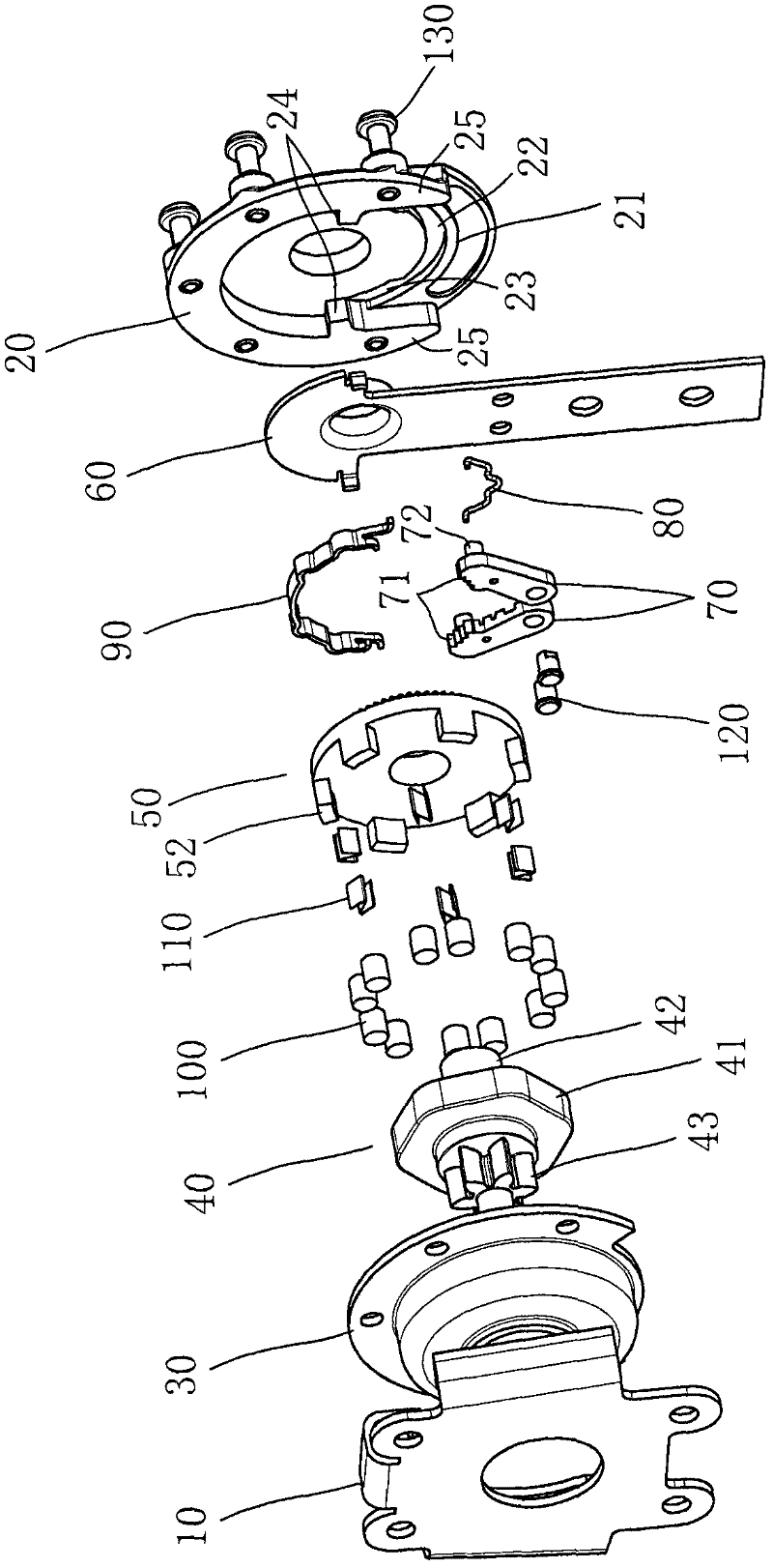

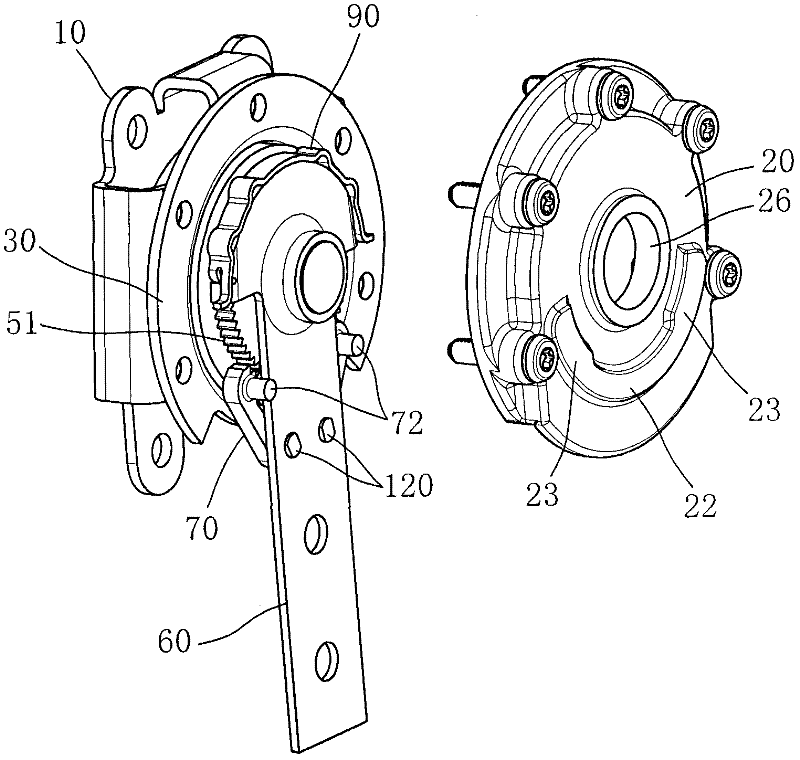

Automobile seat heightening pump

The invention relates to the technical field of accessories of automobile seats, in particular to an automobile seat heightening pump. A shell is fixed on a fixing rack and is fastened with a cover via screws, the fixing rack and the shell are respectively provided with corresponding through holes, a toothed shaft is sleeved in the shell, a cylinder is arranged on the upper end surface of the toothed shaft, and rotating teeth are arranged on the lower end surface of the toothed shaft and respectively penetrate through the through holes of the fixing rack and the shell; a toothed disc is sleeved outside the toothed shaft, a disc with a toothed edge is formed on the upper end surface of the toothed disc, a through hole is arranged in the middle of the toothed disc, the cylinder of the toothed shaft penetrates through the through hole of the toothed disc, a handle is sleeved on the cylinder and drives a pawl, a tooth portion is arranged at the front end of the pawl, the rear end of the pawl is riveted on the handle, and the tooth portion of the pawl is meshed with the disc, with the toothed edge, formed on the upper end surface of the toothed disc; and the pawl can drive the toothed disc to rotate by means of rotating the handle, so that the height of a seat is adjusted. Compared with a foreign product, the automobile seat heightening pump is more optimal and simpler in structure, but the service effect of the automobile seat heightening pump is identical to that of the foreign product.

Owner:东莞市凌锐汽车零部件有限公司 +1

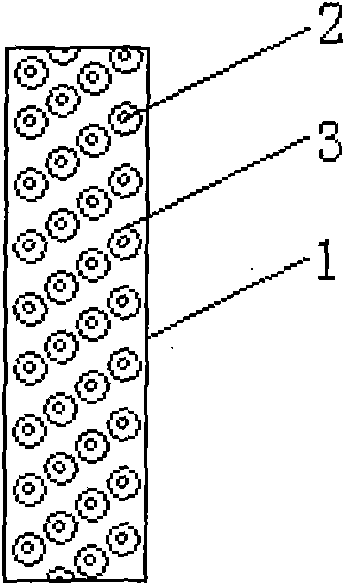

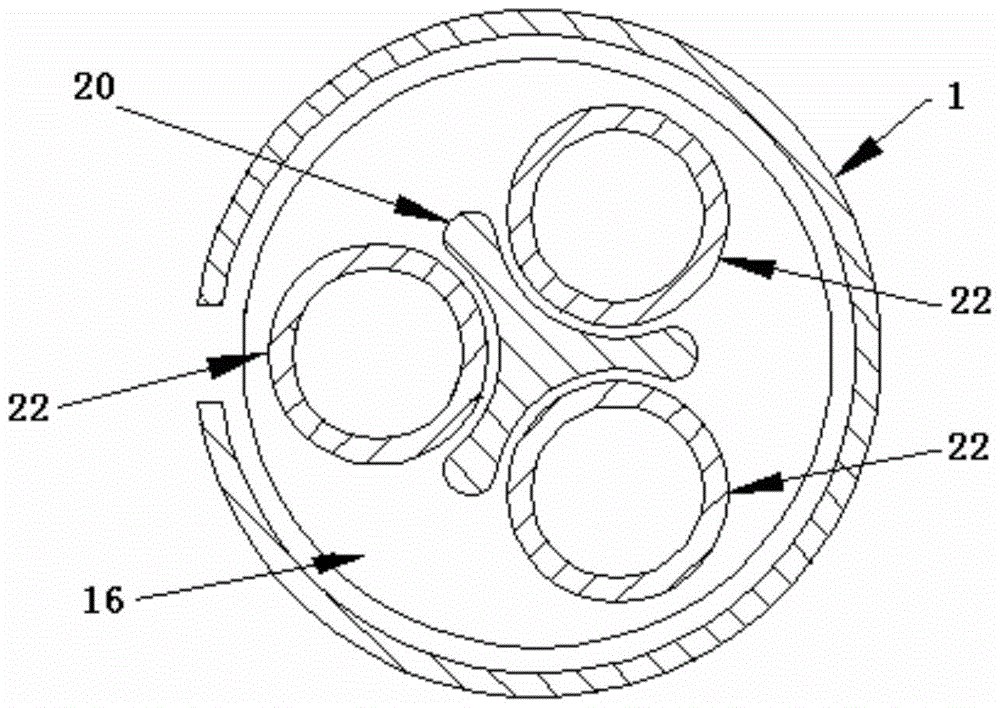

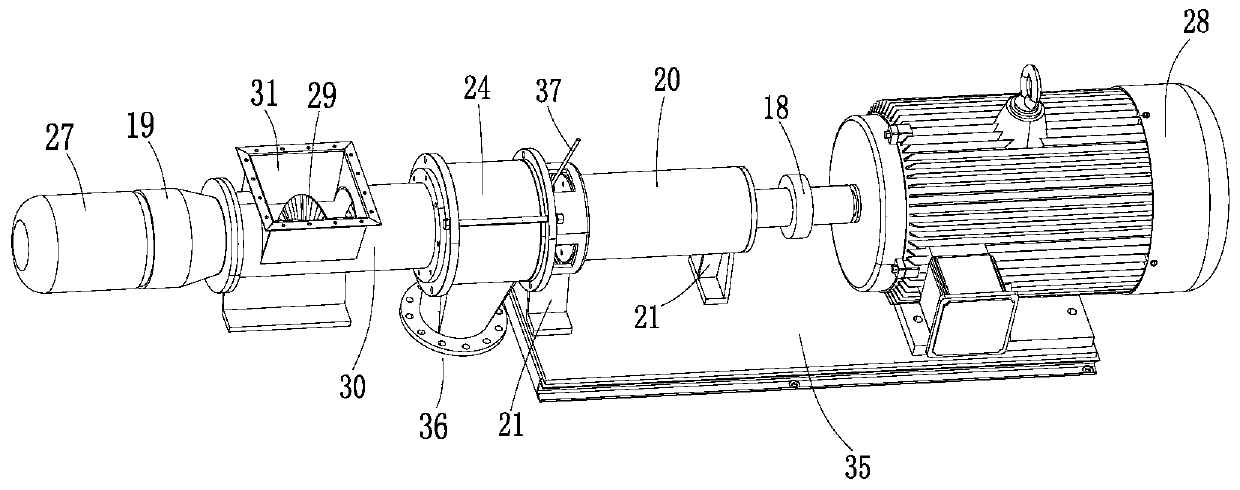

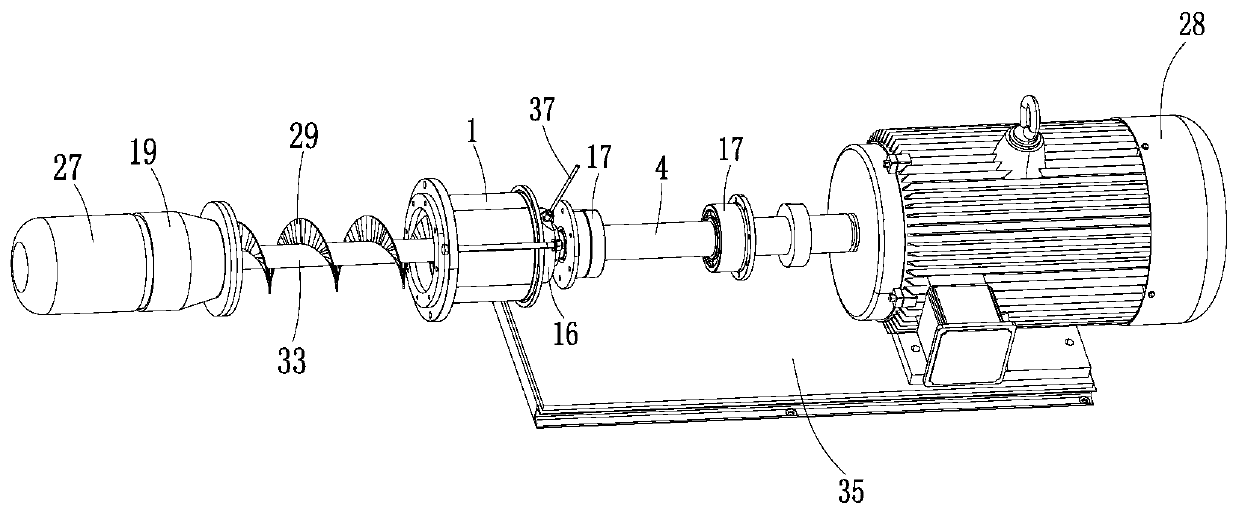

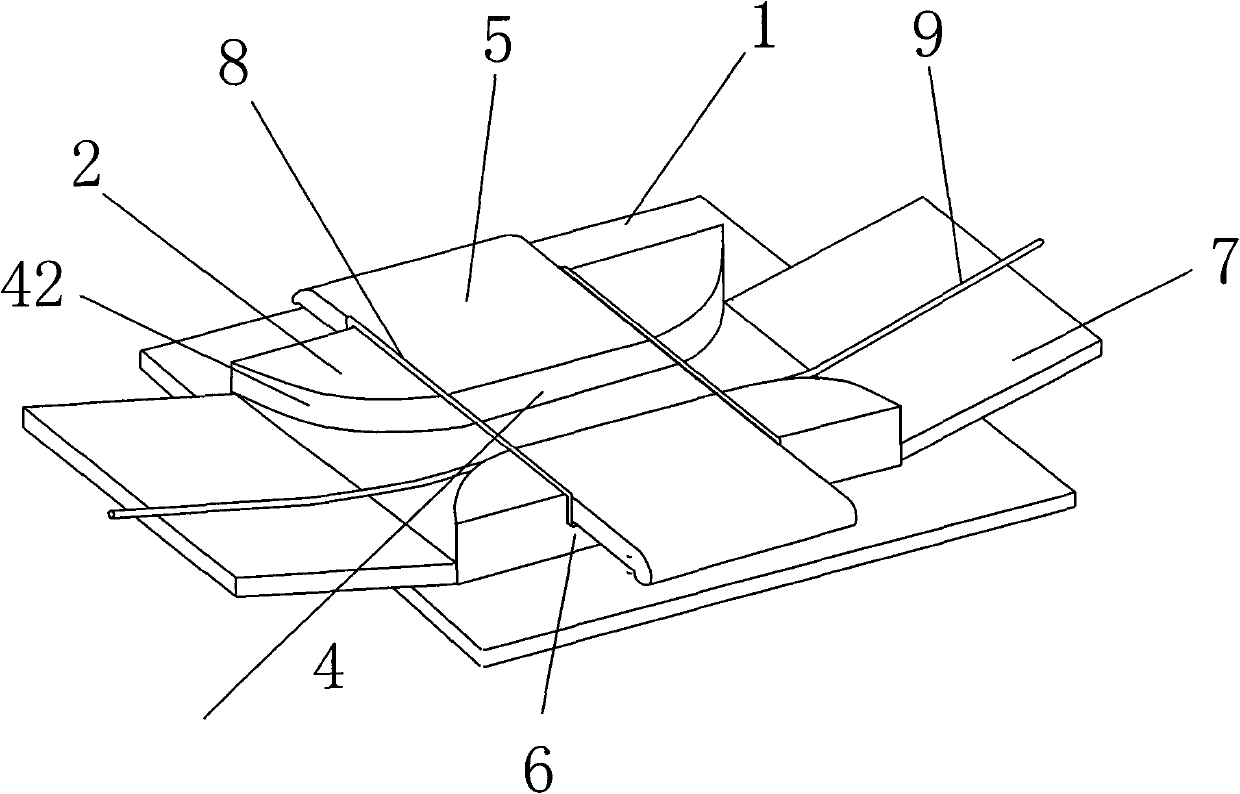

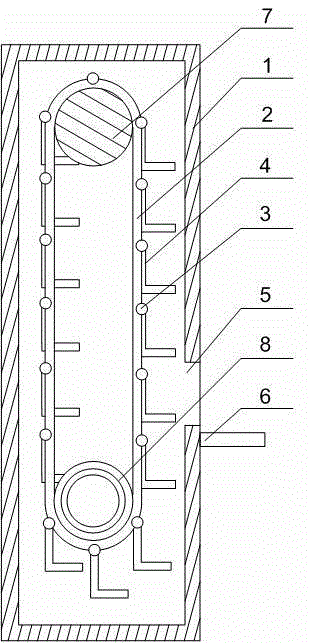

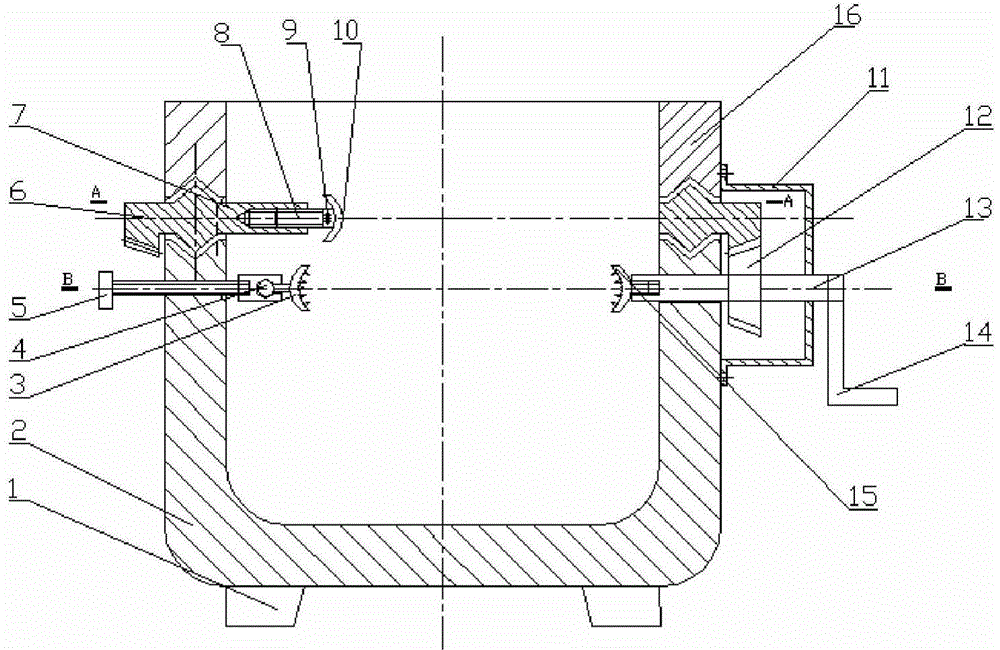

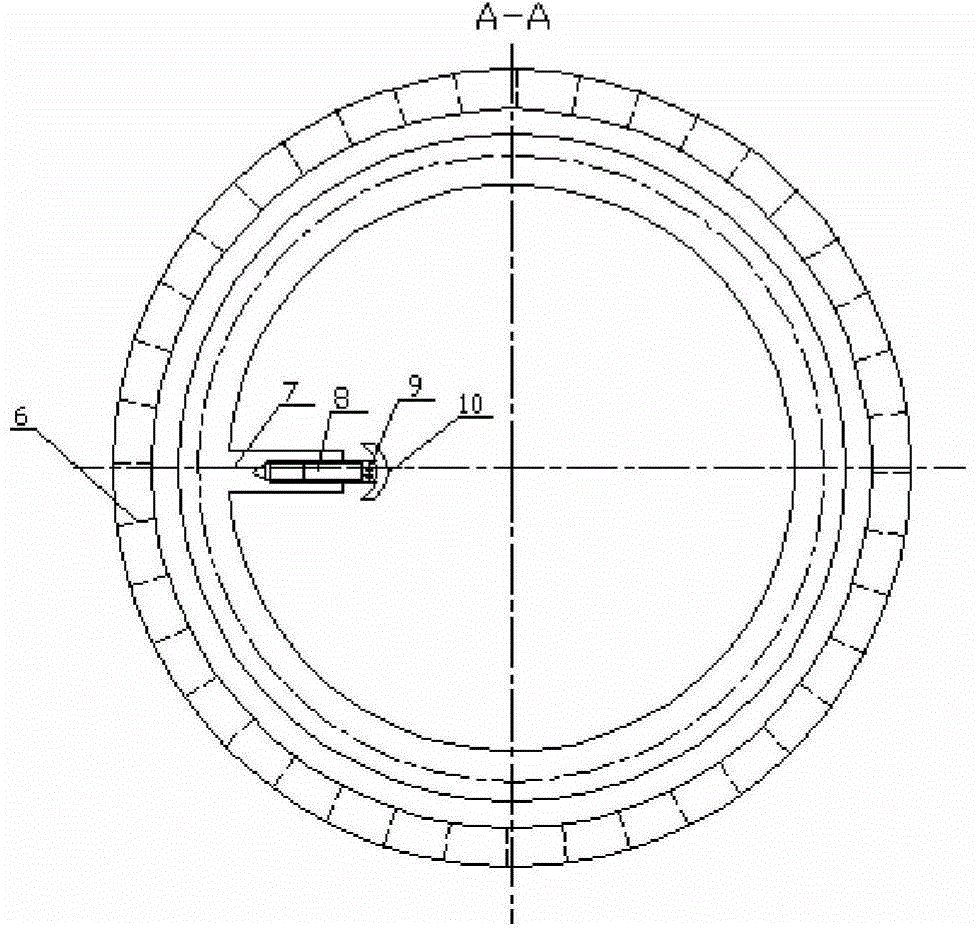

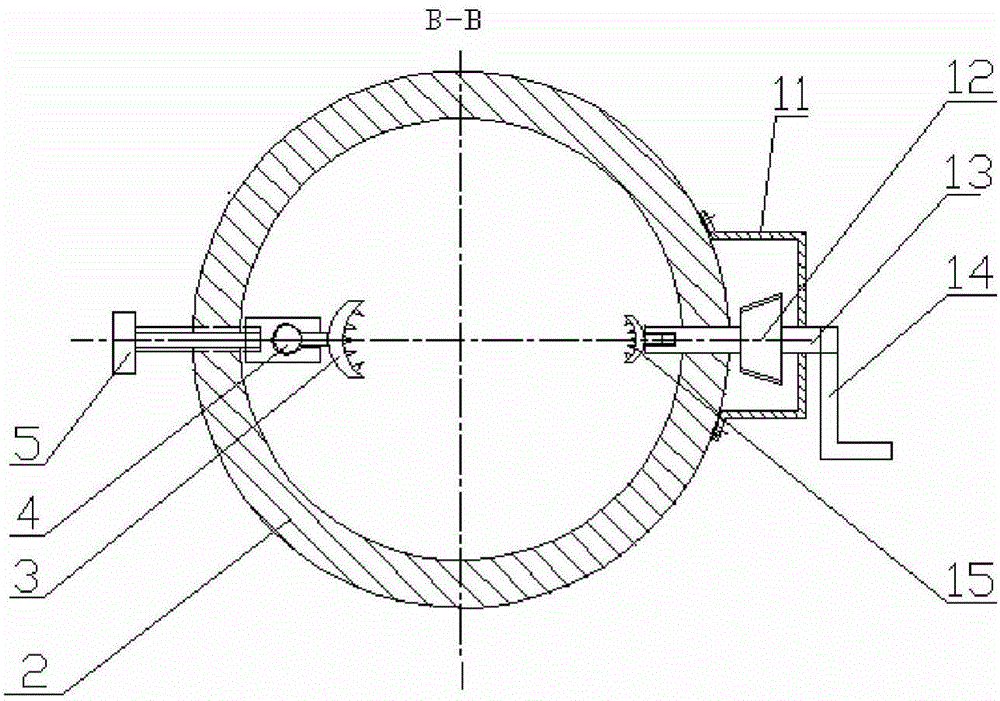

Coal pulp pulverizer

The invention provides a coal pulp pulverizer. The coal pulp pulverizer comprises a feeding port (31), a feeding part, a pulverizing part and a discharging port (36) which are connected in sequence; the pulverizing part comprises a cylinder (1) and a rotor (2); the cylinder (1) is provided with a screen mesh (5) area; the inner wall of the cylinder (1) is provided with a plurality of convex fixedteeth (7) which are arranged in a plurality of rows along the inner wall of the cylinder (1); each row comprises a plurality of the convex fixed teeth (7) which are arranged in the vertical direction;a gap section (8) is arranged between two adjacent rows of the convex fixed teeth (7) to serve as the space for a material to fall down; a plurality of convex rotating teeth (9) are arranged on the periphery of the rotor (2); at least two rows of the convex rotating teeth (9) are arranged along the periphery of the rotor (2); each row comprises a plurality of the convex rotating teeth (9) which are arranged in the vertical direction; a gap groove (23) is formed between two adjacent rows of the convex rotating teeth (9) to serve as the space for the material to fall down; space required for atarget particle size of the material is reserved between the convex rotating teeth (9) and the convex fixed teeth (7) which are engaged with each other; the pulverized material particles are uniform;and the pulverizing efficiency is high.

Owner:宁波领智机械科技有限公司

Teeth orthodontic bracket

InactiveCN101785708AReduced scoring resistanceReduce ligation resistanceBracketsArch wiresOrthodontic wire

The invention discloses a teeth orthodontic bracket, comprising a base plate and a bracket body, wherein the base plate is connected with the bracket body; a groove is arranged in the middle of the bracket body; ligation wings are arranged at the outer side of the groove wall of the groove; the groove comprises a straight groove wall and a circular arc groove wall; the circular arc groove wall is trumpet-shaped; one end or two ends of the groove are provided with twisted wings; and the twisted wings are connected with the bracket body. The teeth orthodontic bracket is also provided with a spring clamp which is matched with the ligation wings. The teeth orthodontic bracket has simple structure and reasonable design, the designed spring clamp is clamped on the groove wall and has no ligation resistance with an orthodontic wire, the two ends of the straight groove are designed to circular arc groove walls so as to reduce the frictional resistance between the bracket and the orthodontic wire, the teeth can move under smaller force, the bracket is beneficial to the quick alignment of the teeth, and the orthodontic treatment process is shortened; the twisted wings are matched with the single-wing bracket, and the elasticity of the orthodontic wire can be relatively increased, thereby leading the rotated teeth correction to be easier and leading the orthodontic effect to be better; and the orthodontic wire is fixed by the spring clamp, thereby being convenient in operation and shortening the operation time of the doctor.

Owner:周建国

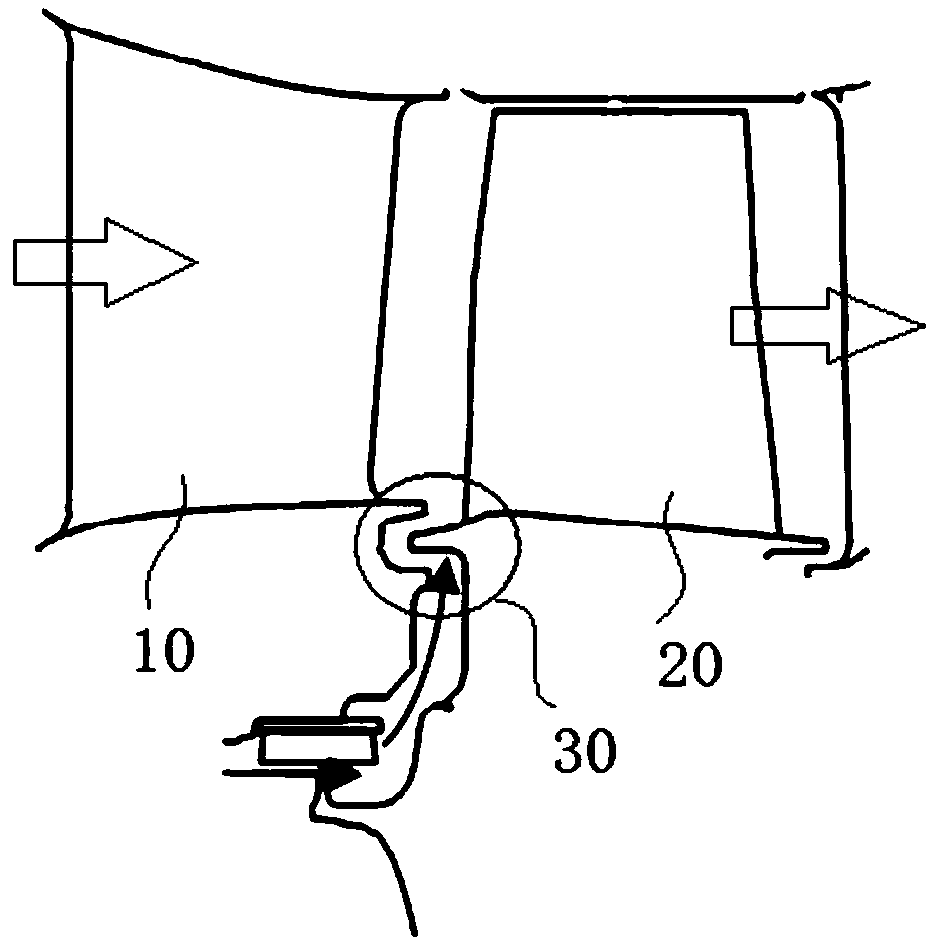

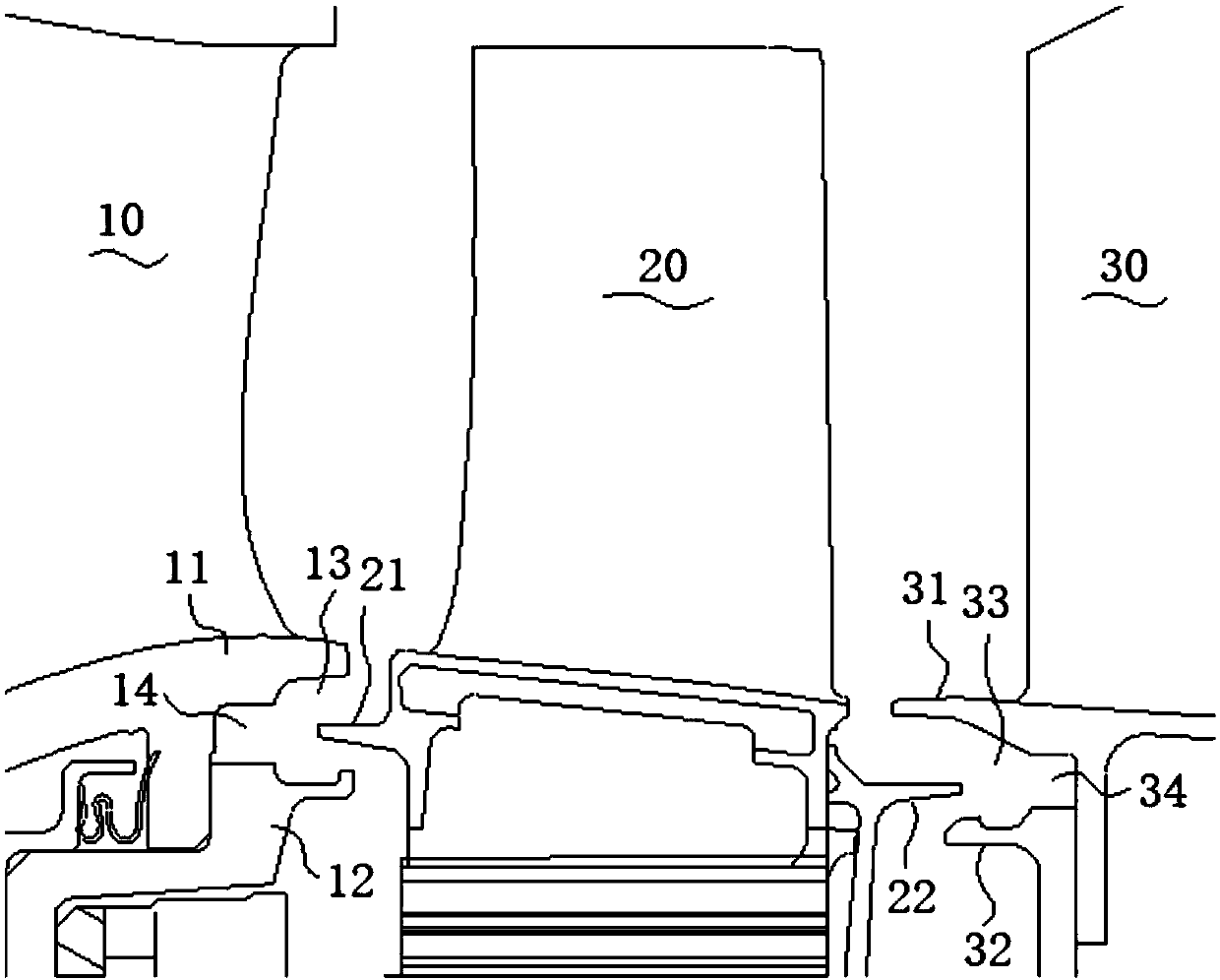

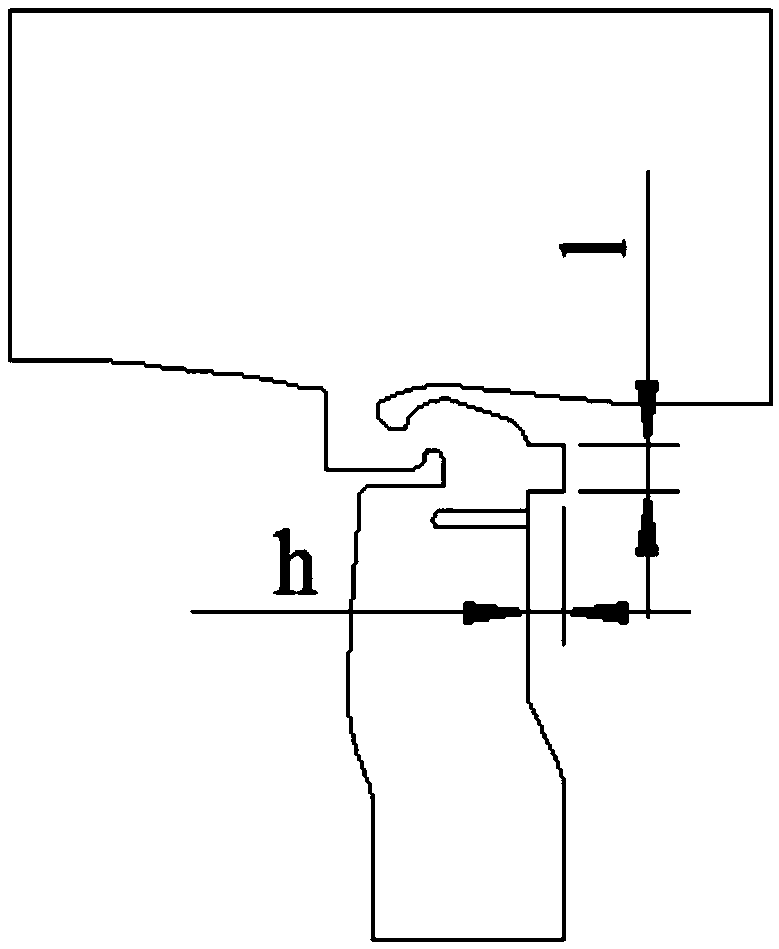

Meshing seal structure and aircraft engine with same

ActiveCN109630210AReduce leakageReduce air permeabilityBlade accessoriesLeakage preventionAviationEngineering

The invention discloses a meshing seal structure. The meshing seal structure comprises a rotor blade and stator blades, wherein rotating teeth protruding towards the root parts of the stator blades are arranged on the root part of the rotor blade; and first-stage grooves matched with the rotating teeth are formed in the root parts of the stator blades, second-stage grooves are further formed in the first-stage grooves, and the rotating teeth, the first-stage grooves and the second-stage grooves form a meshing seal unit. According to the meshing seal structure, the motion direction of jet flowafter throttling is changed, the breathability effect is reduced, the change of the throttling position and throttling area of a tooth tip are directly influenced by the size of the meshing seal structure, the influence on labyrinth seal performance is great, the plate edge labyrinth leakage amount is reduced due to the meshing seal structure with the grooves, and a better seal effect is achieved;groove structural parameters are designed to follow the relationship of I=+ / -1.23h by the computational analysis and experimental verification, and the obtained seal effect is better.

Owner:AECC SHENYANG ENGINE RES INST

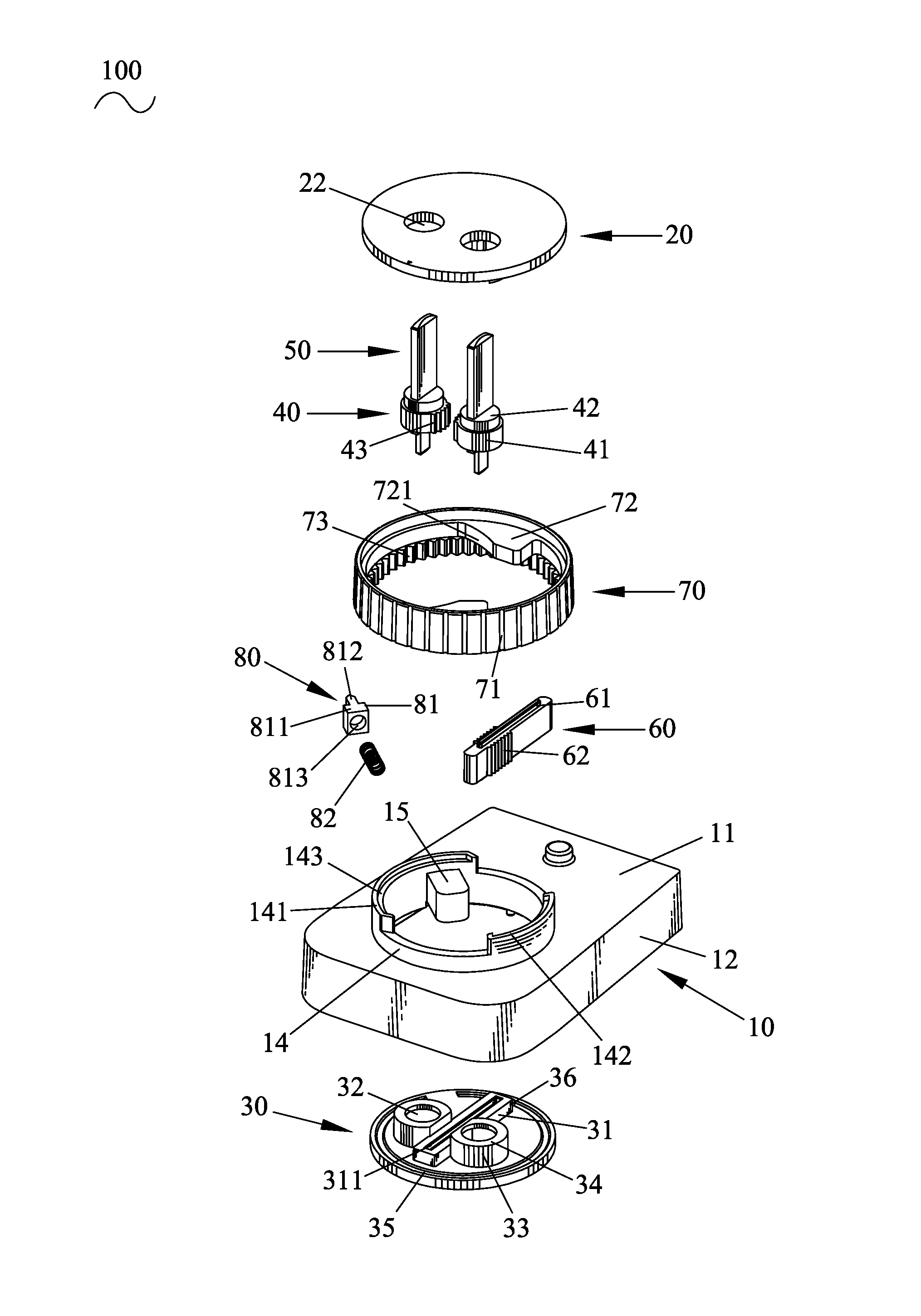

Safe and intelligent lock

ActiveCN104481275AImprove security levelBatteries circuit arrangementsElectromagnetic wave systemSecurity levelRotated tooth

The invention discloses a safe and intelligent lock. The safe and intelligent lock comprises a lock cylinder, a key and a key hanging plate, wherein the key is matched with the lock cylinder; the key can be stored on the key hanging plate and can be charged by the key hanging plate; a first magnetic column and a second magnetic column are arranged in the key; a third magnetic column and a fourth magnetic column which are respectively matched with the first magnetic column and the second magnetic column are arranged in the lock cylinder; two mechanical rotating teeth are respectively arranged at opposite ends of the outer side of a key rod; and two mechanical positioning teeth which correspond to the two mechanical rotating teeth are arranged in the lock cylinder. The safe and intelligent lock has a two-stage locking effect; and the security level is improved.

Owner:江苏今越控股集团有限公司

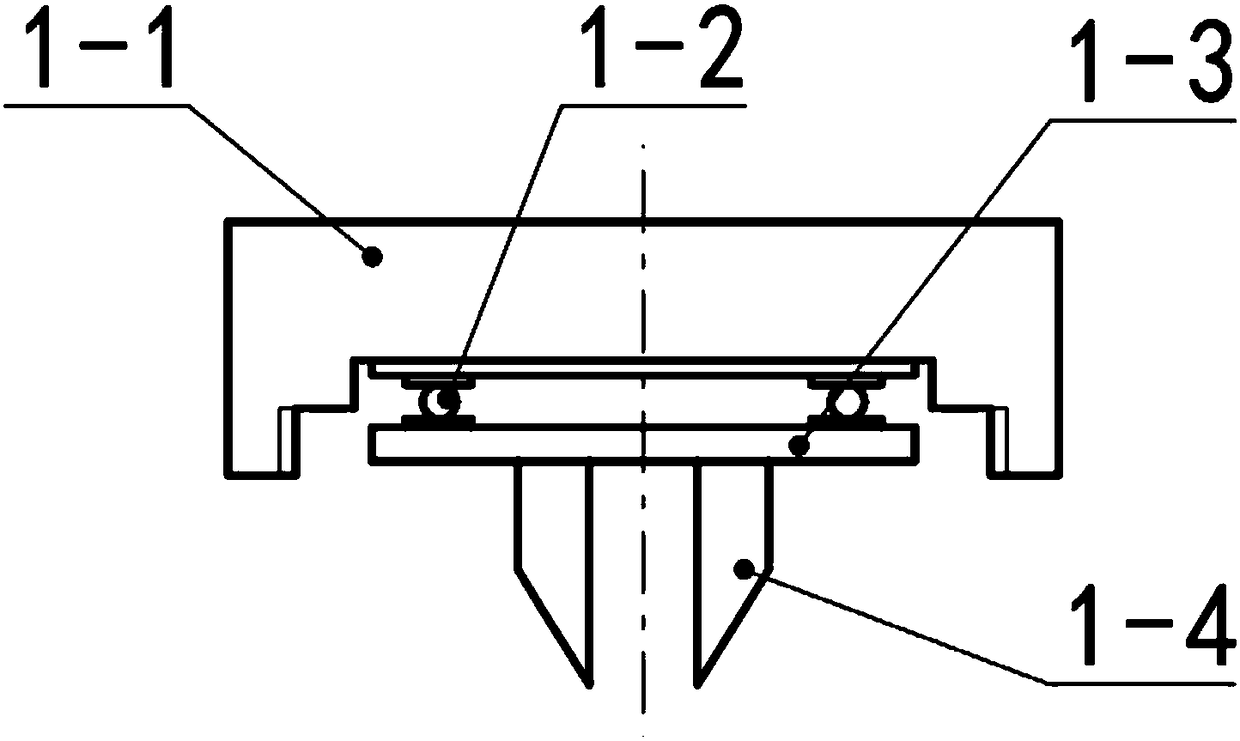

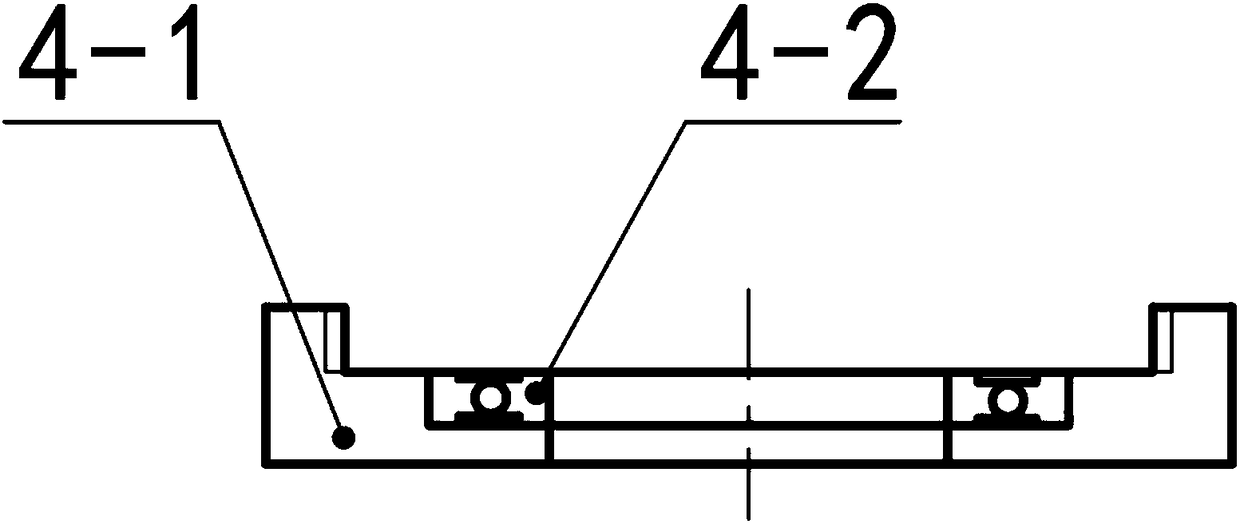

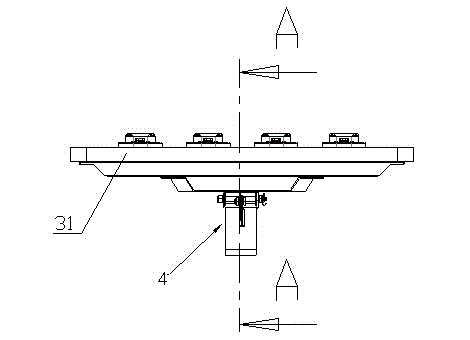

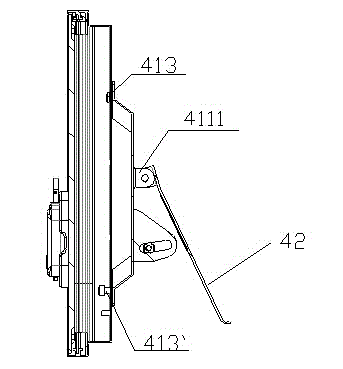

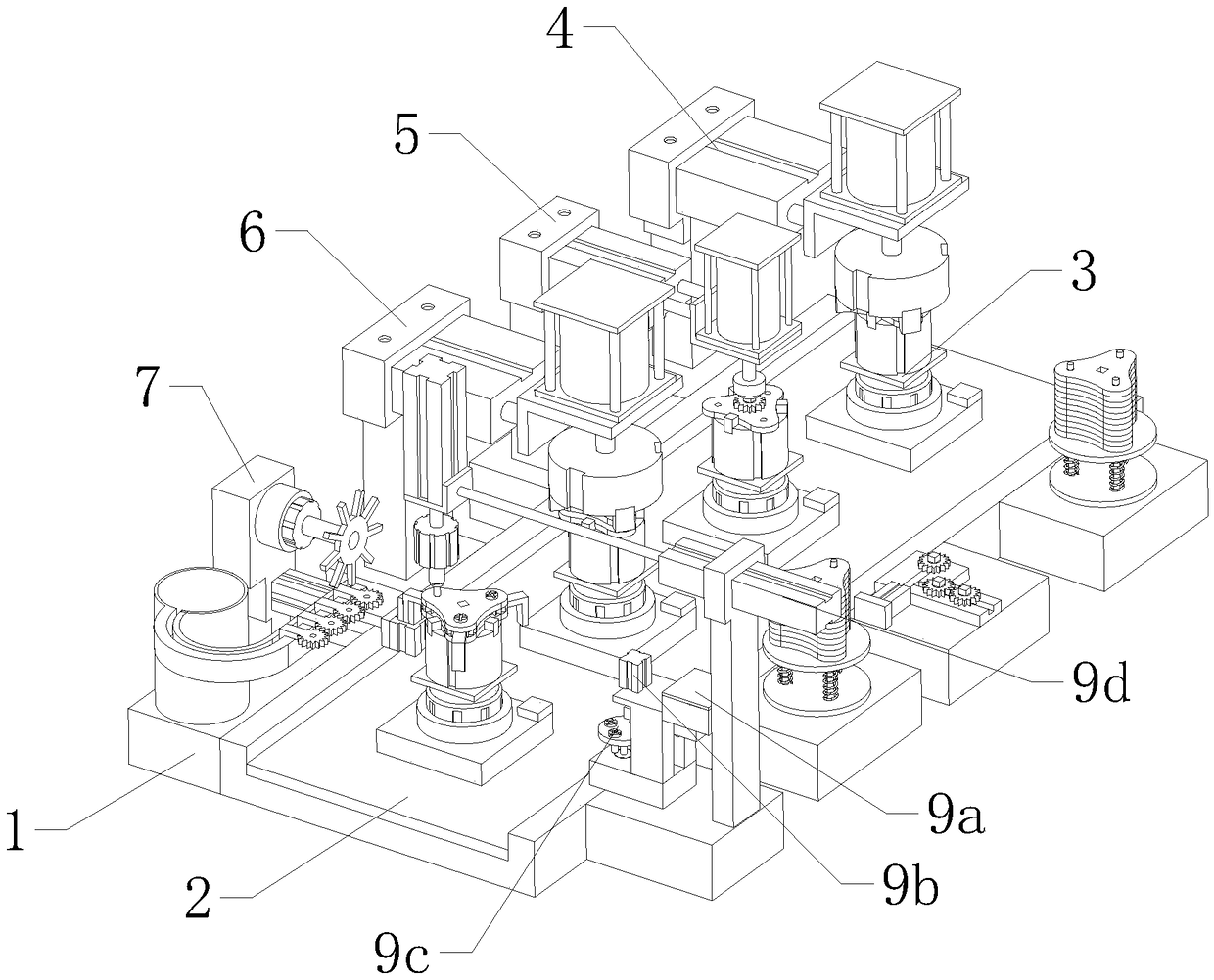

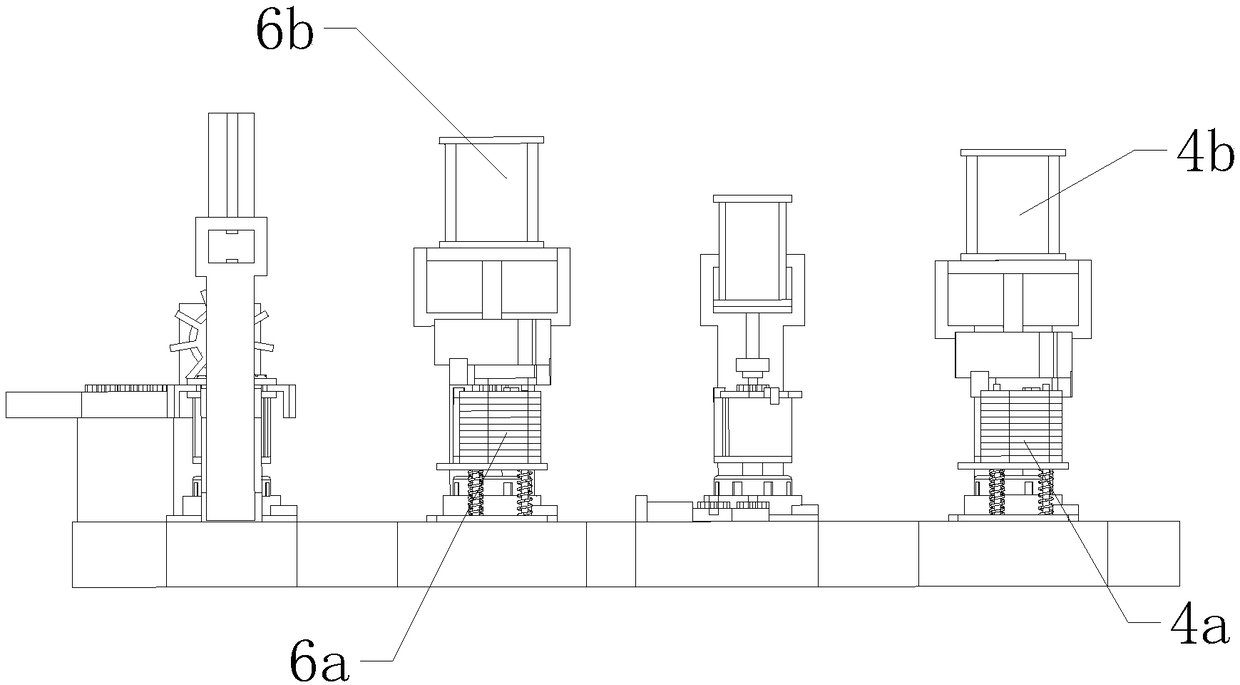

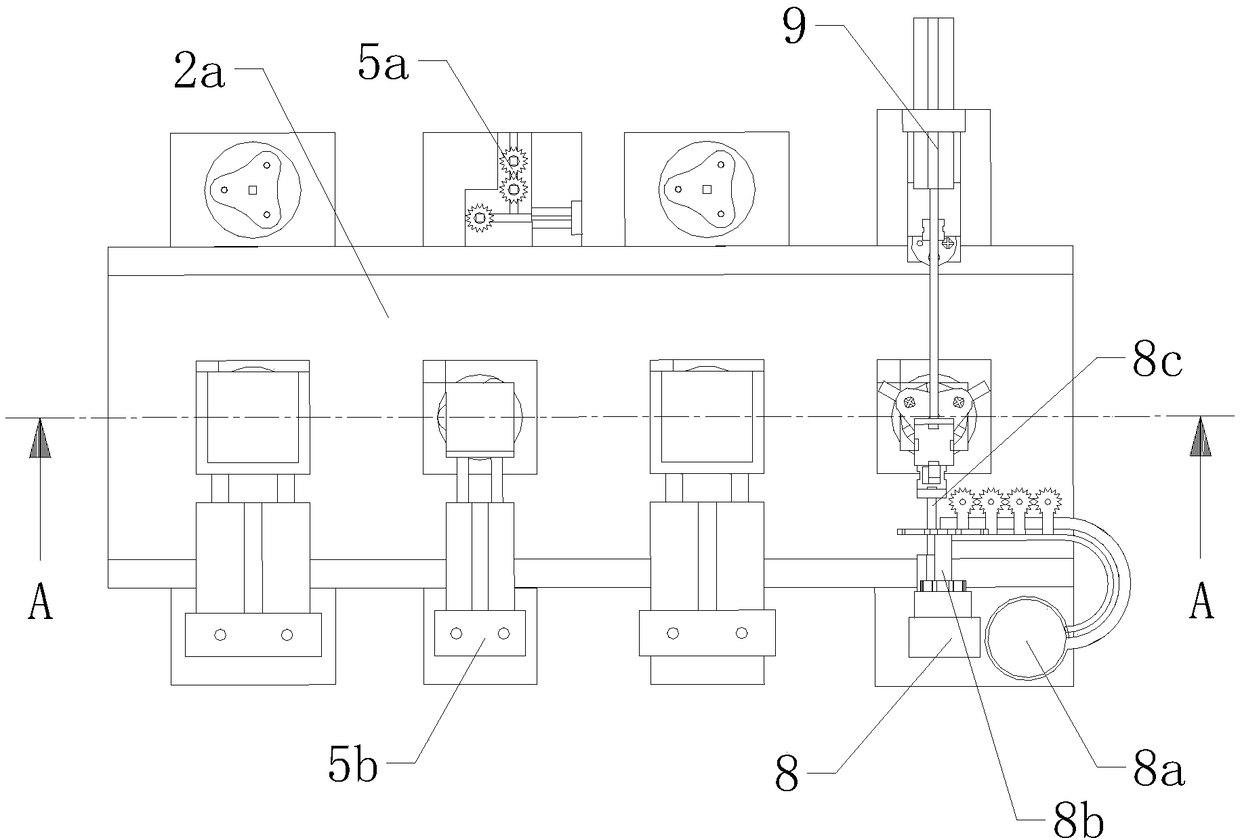

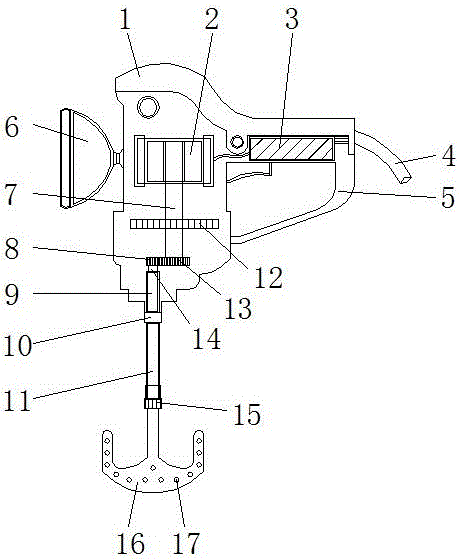

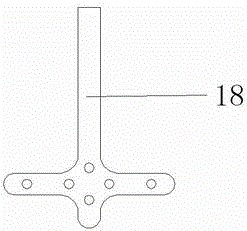

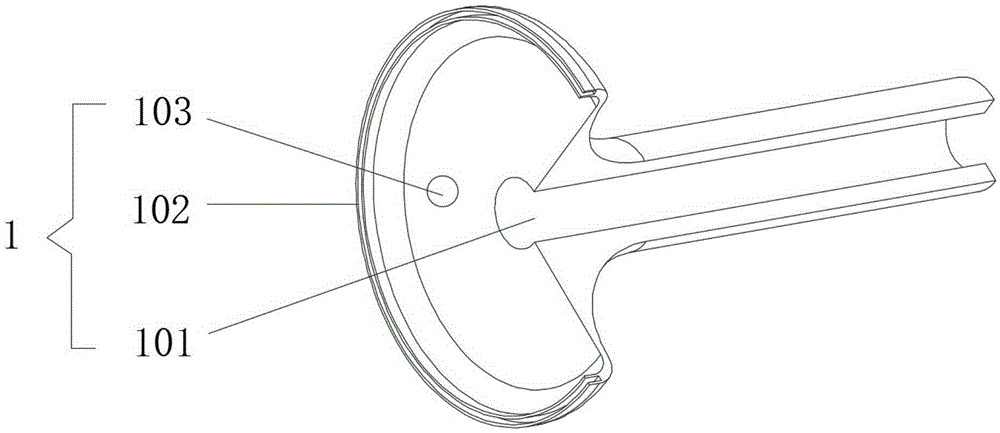

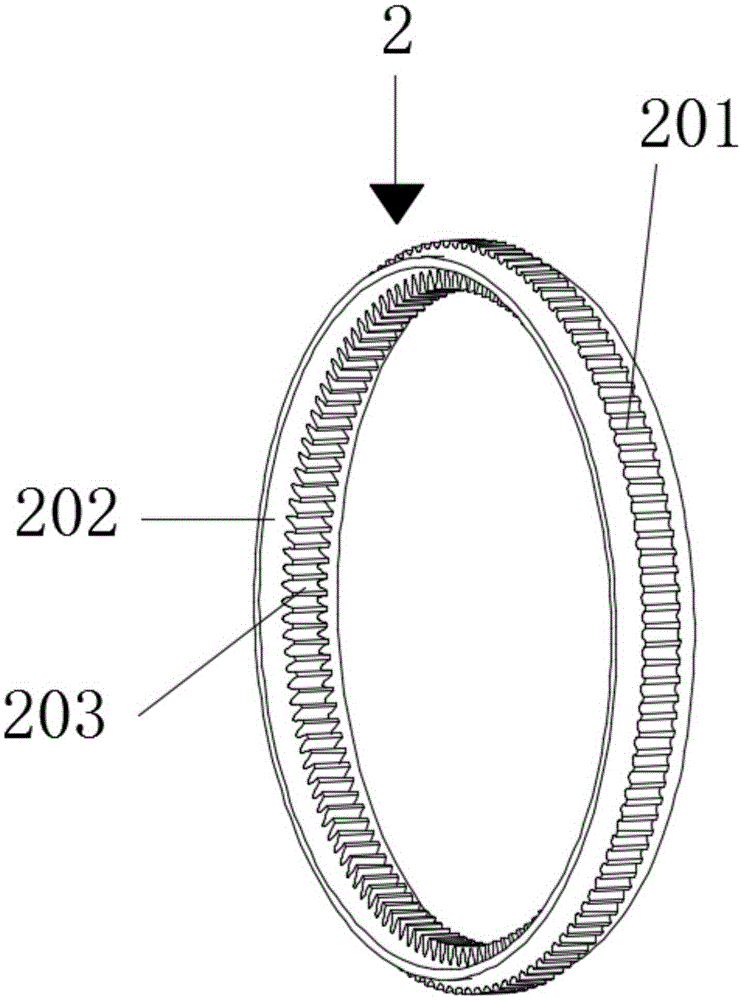

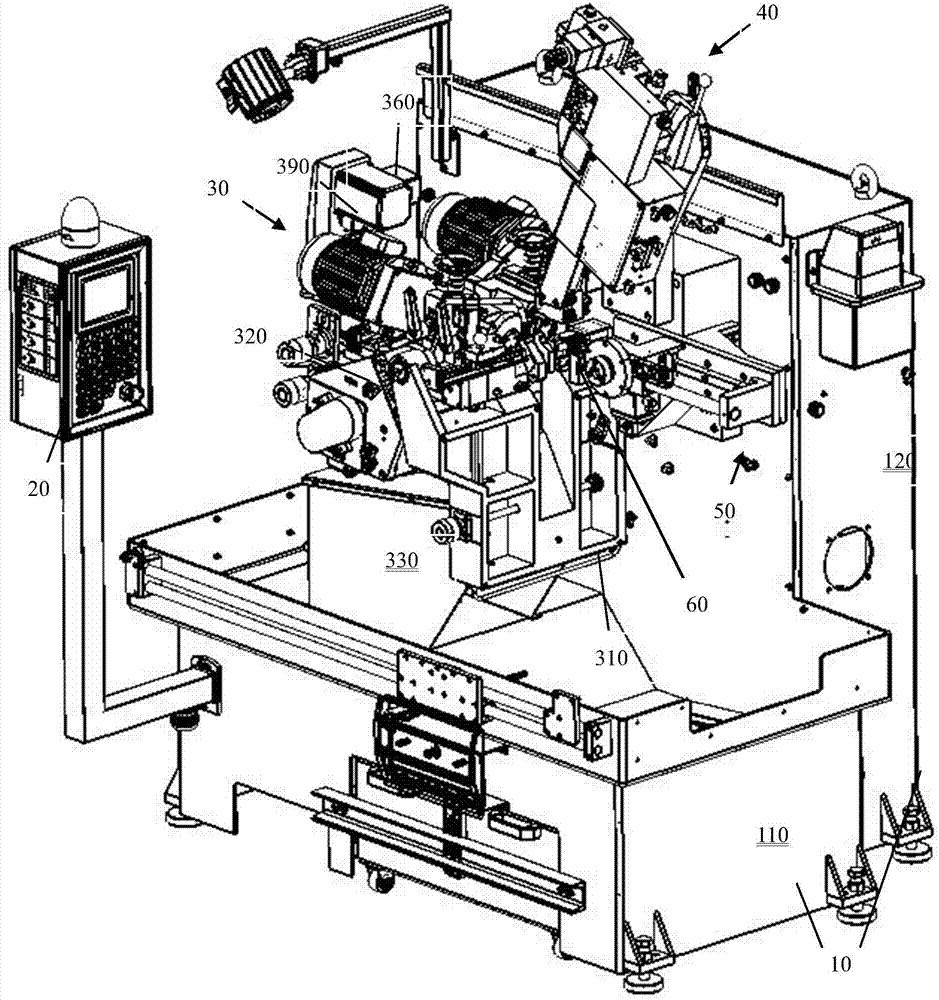

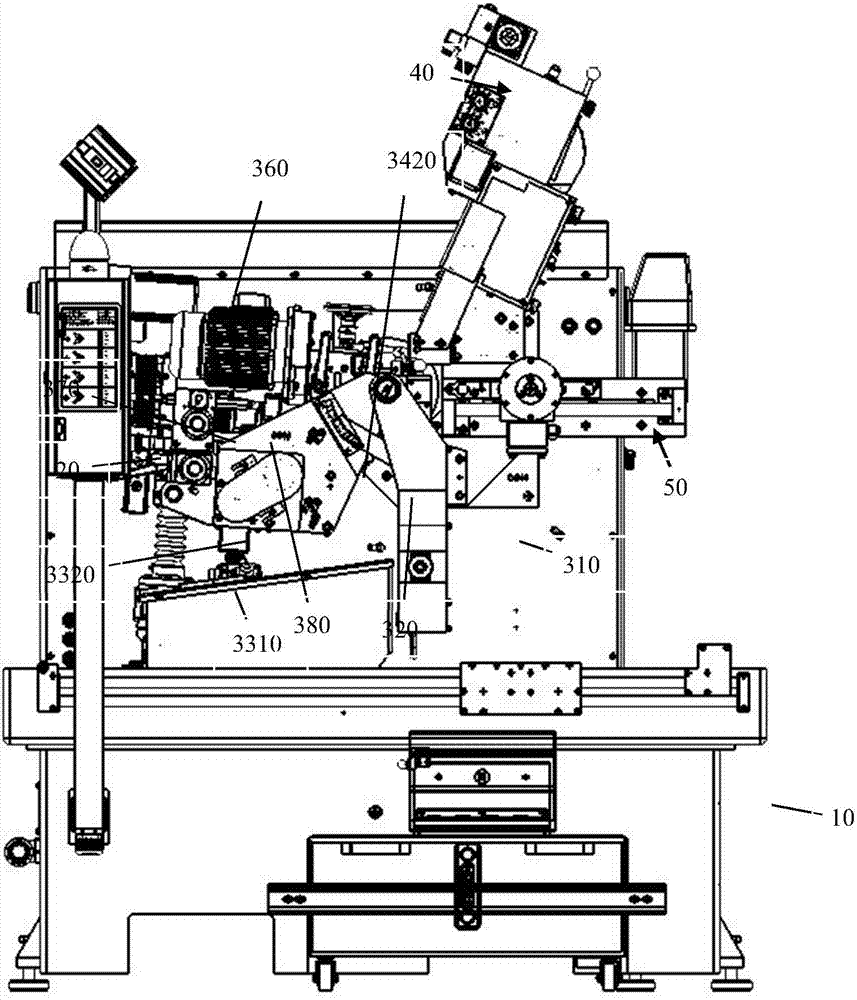

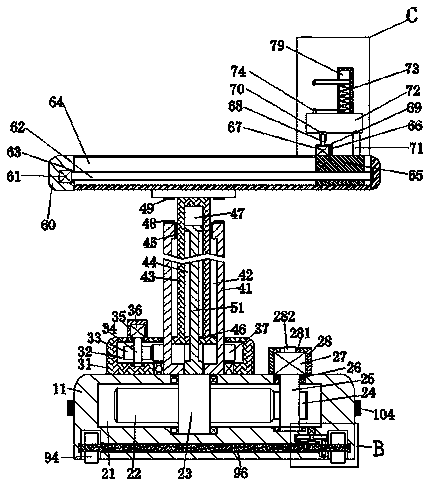

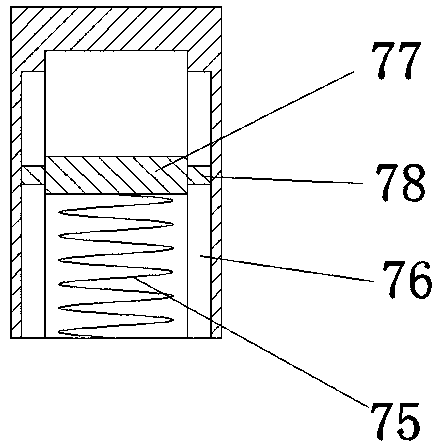

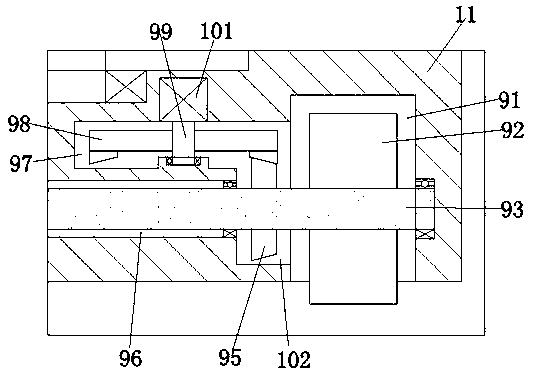

Spanner frame assembly device of vehicle machine oil filter element spanner automatic assembly machine

ActiveCN108655727AImprove assembly efficiencyAssembly machinesMetal working apparatusEngineeringAssembly machine

The invention relates to the field of spanner automatic assembly, in particular to a spanner frame assembly device of a vehicle machine oil filter element spanner automatic assembly machine. The device comprises a worktable, a conveying device, a positioning device, a chassis assembly device, a rotating tooth assembly device, a top cover assembly device and a spanner frame assembly device; the spanner frame assembly device comprises a spanner frame assembly module and a screw tightening module; the spanner frame assembly module comprises a spanner frame loading part, a spanner frame poking part and a spanner frame clamping part; and the screw tightening module comprises a screw conveying part, a screw loading part, a rotating part and a screw tightening part. Spanner frames are arranged onthe spanner frame loading part, and are fed in the spanner frame clamping part under poking by the spanner frame poking part; screws are arranged on the screw conveying part, and are screwed; after the screws are taken, the screws are rotated on a chassis and a top cover; and then, the next spanner frames are installed, so that full-automatic assembly is realized, and the assembly efficiency is high.

Owner:蓝全进

Circulating locker

InactiveCN105015994ARealize automatic controlRealize semi-closed storageCabinetsStorage devicesRotated toothSprocket

The invention discloses a circulating locker. The circulating locker comprises a locker body, two motors and two sets of driving chain wheels and driven chain wheels, wherein a rotating shaft consists of a main body at a middle section, and fixed sections at two ends; a hopper is fixed on the main body; a movable cavity with an elliptic cross section is arranged in the fixed section; the two ends of the main body outwards extend to form shrinkage sections; two limiting blocks with thicknesses gradually increased in the peripheral directions of the shrinkage sections are symmetrically arranged on the outer walls of the shrinkage sections along the axes; inner annular teeth are arranged at the middle parts of the driving chain wheels; and multiple rotating teeth engaged with the inner annular teeth are fixed on the outer wall of a rotating drum. When the maximum ends of the limiting blocks slide through the tail end of the half long shaft of the cross section of the movable cavity, the maximum ends of the limiting blocks are contacted with the wall of the movable cavity to stop continuous rotation of the limiting blocks, the rotating shaft and the hopper so as to prevent the collision with the adjacent or approached hopper caused by continuously increased shaking amplitude of the hopper.

Owner:SICHUAN JINFENG CONSTR

Handheld stirrer

InactiveCN106732112AImprove stirring efficiencyTransportation and packagingMixersDrive shaftAgricultural engineering

The invention discloses a handheld stirrer which comprises an outer shell body, a stirring shaft, an anchor stirring blade and a paddle stirring blade, wherein the outer shell body mainly comprises a motor, a speed regulator, a connection bearing, a driven tooth plate and a driving tooth plate inside; the lower end of the speed regulator is connected with the outer shell body and is provided with a grip; the motor and the speed regulator are connected through an electric signal; the motor is connected with the driving tooth plate through the action of the connection bearing; the driven tooth plate is clamped with the driving tooth plate; the driven tooth plate is connected with a driving shaft through the action of a shaft disc connection block; the stirring shaft is connected with the driving shaft through the action of a connection end; and a stirring blade fixing end is arranged at the front end of the stirring shaft. The handheld stirrer is designed by combining an existing stirrer structure and acts on the connection bearing and the rotating tooth plate through drive of the motor, so that the externally connected stirring blade rotates at 360 degrees and the stirring efficiency is improved.

Owner:WUXI AOYUTE NEW TECH DEV

Adjustable spraying head

InactiveCN106824573AIncrease the spray patternChange the spray patternSpray nozzlesMechanical engineeringWater spray

The invention discloses an adjustable nozzle, which comprises a shell with a handle and an end cover connected with the shell with uniformly distributed holes, and the edges of the shell and the end cover are respectively provided with an annular groove and an annular groove Two and two annular grooves are installed with a gear ring, the gear ring includes inner teeth, outer teeth and ring edges, and a rotating core is installed on the installation shaft, and the rotating core includes a first connecting plate and a second connecting plate plate, the first connecting plate and the second connecting plate are fixed by three connecting sides and there is a shaft hole in the center of the two connecting plates, the first connecting plate and the second connecting plate are integrally formed with a first pair of interface, the second interface and the third interface, the connecting side is integrally formed with rotating teeth, and the device adds a variety of spraying modes to the nozzle through the matching structure of the ring teeth and the rotating core, which can be used in the face of different The water spray form of the nozzle can be quickly changed by adjusting the different docking states of the docking holes when using the needs.

Owner:CHONGQING HEXAGON NETWORK TECH CO LTD

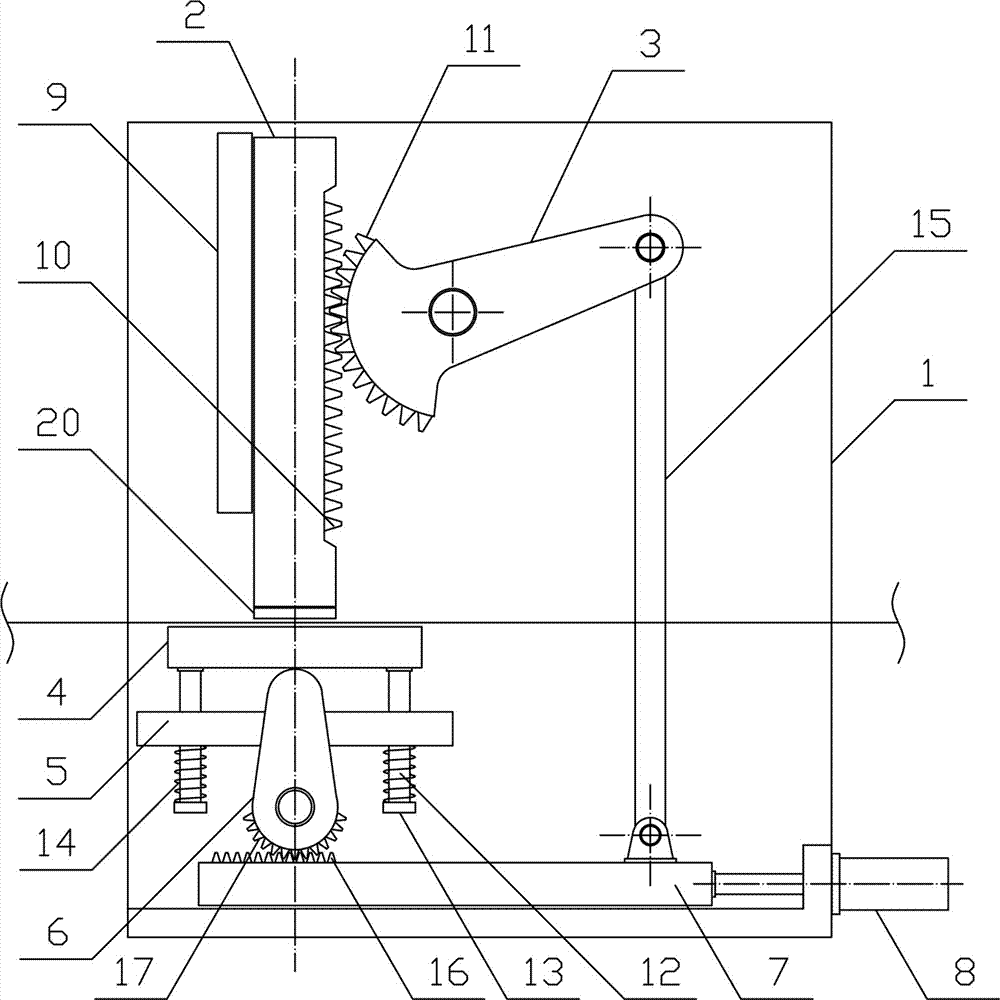

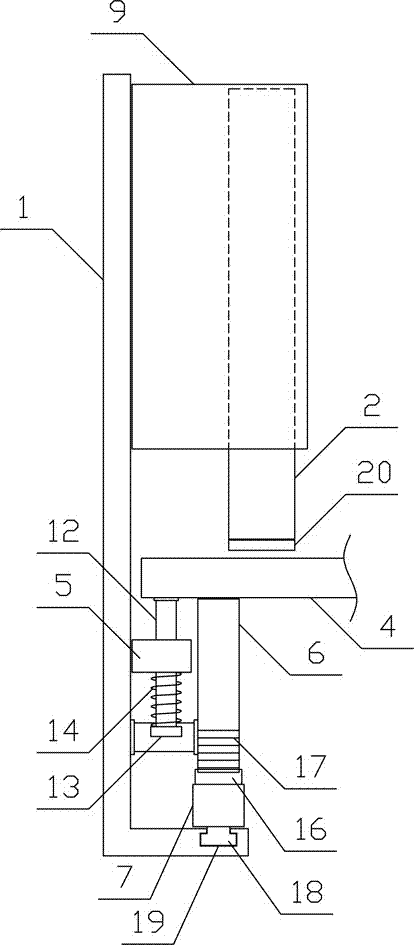

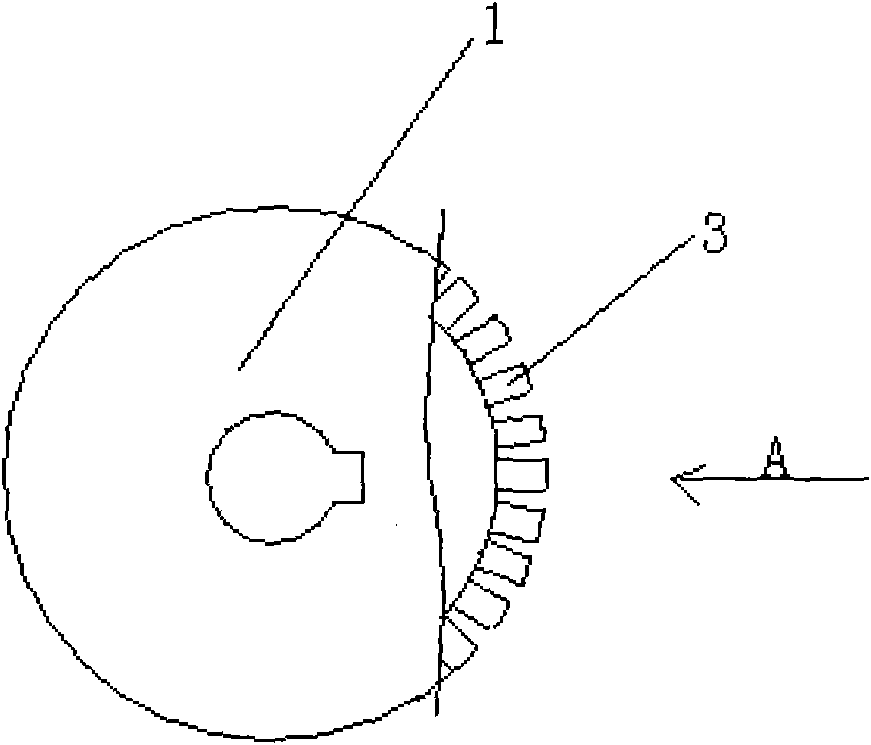

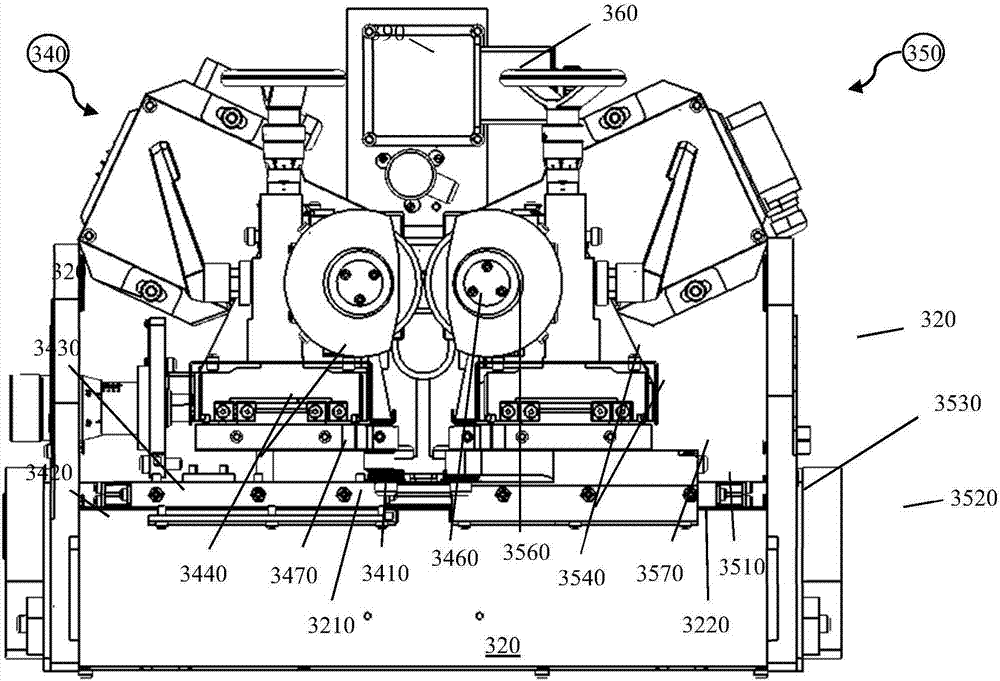

Full-automatic two-side-surface saw blade grinding machine

ActiveCN107081478AGuaranteed cutting stabilityExtended service lifeSawing tools dressing arrangementsEngineeringElectric control

The invention belongs to the technical field of grinding of saw blades, and particularly discloses a full-automatic two-side-surface saw blade grinding machine. The full-automatic two-side-surface saw blade grinding machine comprises a machine tool seat and an electric control system, wherein a grinding device, a tooth dialing mechanism, a saw blade fixing mechanism and a saw blade clamping mechanism are arranged on the machine tool seat; the machine tool seat is used for mounting and bearing other assemblies or components; the saw blade fixing mechanism is used for fixing saw blades which need to be processed; the saw blade clamping mechanism is used for clamping the saw blade which need to be processed; the grinding device is used for completing the grinding of two side surfaces of each of the saw teeth; the tooth dialing mechanism is used for realizing the rotating tooth replacement of the saw blade; and the electric control system is used for providing a system control function. According to the full-automatic two-side-surface saw blade grinding machine provided by the invention, through the organic cooperation between the grinding device, the tooth dialing mechanism, the saw blade fixing mechanism, the saw blade clamping mechanism and the electric control system, the processing of two side surfaces of the saw blade can be completed at a time; and the full-automatic two-side-surface saw blade grinding machine is high in adaptability, good in accuracy and stability, high in automation degree, low in labor intensity and high in production efficiency.

Owner:东莞市领邦机械科技有限公司

Box type hand-cranking fruit peeler

The invention discloses a box type hand-cranking fruit peeler. A cylindrical box body consists of an upper box body and a lower box body; a guide slot is formed in each of the opposite end surfaces of the upper box body and the lower box body; a conical knife rest rotating tooth ring matched with the guide slots between the upper box body and the lower box body is arranged in the guide slots; a concentric hole is formed in each of corresponding box walls on the center of the lower box body; a positioning bolt is arranged in one hole provided with screw threads; a movable ball head and a rotary positioning claw are sequentially connected with the end of the positioning bolt; a crank shaft is arranged in the other hole; one end of the crank shaft is connected with the positioning claw; a conical gear and a crank sequentially sleeve the other end of the crank shaft; the conical gear is meshed with the conical knife rest rotating tooth ring; a convex cylindrical tooth ring with a threaded central hole and a knife rest connecting body are arranged on the inner circle of the conical knife rest rotating tooth ring; a knife head connecting bolt is arranged in the threaded central hole; the end of the knife head connecting bolt is connected with a knife head through a knife head connecting screw. The box type hand-cranking fruit peeler has the characteristics of convenient operation, high safety, simple structure, easy carrying, low failure rate, good economy, high efficiency and the like.

Owner:ZHENJIANG WATERCRAFT COLLEGE OF PLA

Photographing device

InactiveCN108758191ASimple structureEasy to operateTelevision system detailsColor television detailsComputer scienceRotated tooth

Owner:邓聪迪

Plastic coating mold

The invention discloses a plastic coating mold. The plastic coating mold comprises a base provided with an caulking groove, wherein a pair of sliding blocks are arranged at the top of the base and areseparately arranged at the two sides of the caulking groove; a movable mold covers the top of the sliding blocks, and the movable mold, the sliding blocks and the embedded groove form a mold cavity;the sliding blocks are correspondingly driven by a screw rod in the base through rotating teeth; and an injection hole is connected to the mold cavity through the movable mold. An insert is fixed by the caulking groove, the size of the mold cavity is adjusted by the sliding blocks, and an outer space of a first firmware, namely, the size of an outer plastic coating is cooperatively adjusted by thesliding blocks and a moving block. Condensation is accelerated through a condenser tube. Various inserts are matched through the replaceable moving block and an embedded block. The injection hole isconnected with a plurality of plastic injection liquids to form a multi-layer and multi-material injection molded part through a directional valve. At the same time, demoulding and taking out parts are facilitated through opening and closing of the sliding blocks and the movable mold. The plastic coating mold is simple in structure, convenient to use, rich in functions and diversified in finishedproducts of injection molded parts, and has strong practicability and wide applicability.

Owner:JIANGSU BOYINGTE ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com