Worm wheel with rotating teeth

A technology of rotating gears and worm gears, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve problems such as difficult processing and complex transmission device structure, and achieve low processing and manufacturing costs. Precious metals, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

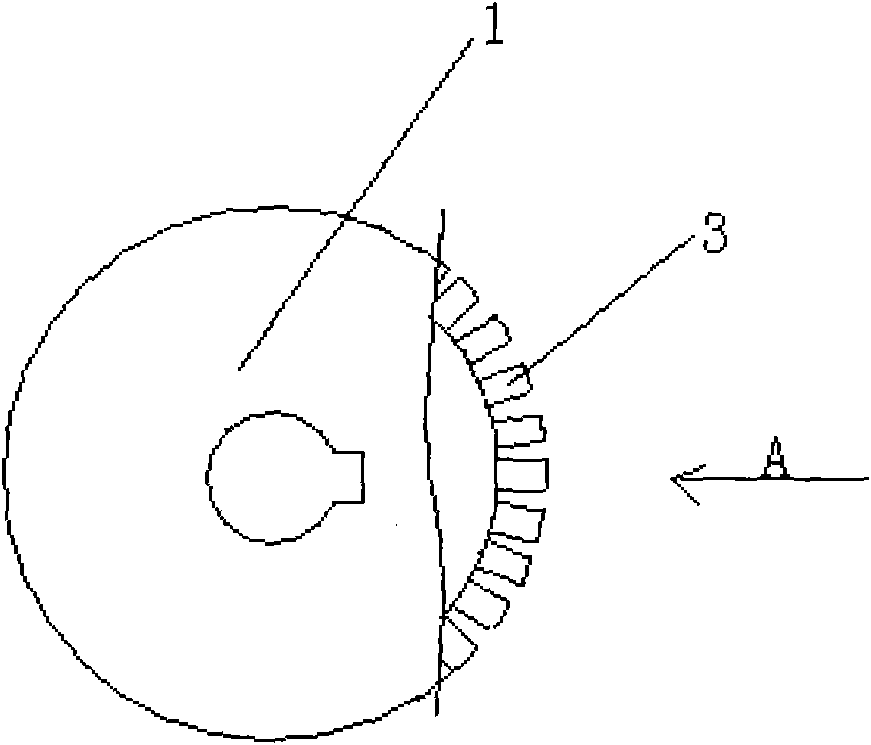

[0015] Such as figure 1 As shown, a worm wheel with rotating teeth includes a wheel body and worm teeth arranged on the outer edge of the wheel, and the worm teeth are matched with the worm.

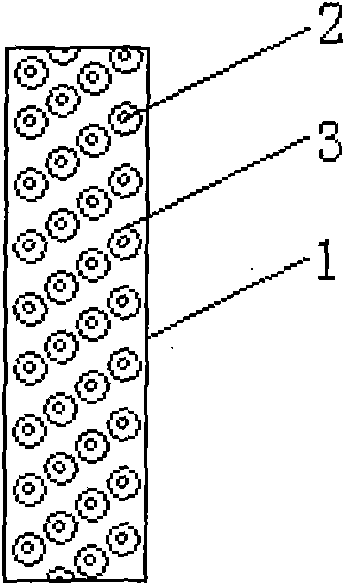

[0016] Such as figure 1 , 2 As shown, the worm gear is composed of a shaft 2 and a bearing 3 arranged on the tooth track. The shaft 2 is fixedly connected to the wheel body 1 and arranged in equal parts on the tooth track, and the outer diameter of the bearing 3 assembled on the shaft 2 is equal to the tooth track width.

[0017] In this embodiment, the worm wheel body 1, the shaft 2 arranged on the outer edge of the wheel body 1, and the outer casing of the bearing 3 assembled on the shaft 2 are made of steel material (high-quality carbon steel structure can be used).

Embodiment 2

[0019] A worm wheel with rotating teeth includes a wheel body and worm teeth arranged on the outer edge of the wheel, and the worm teeth are matched with the worm. The worm gear is composed of a bearing 3 and a shaft 2 arranged on the tooth track, and a blind hole (not shown in the figure) is arranged on the wheel body 1, and the bearing 3 is plugged into the blind hole and fixedly connected (the outer end of the bearing 3 is connected to the outer end of the wheel body) edge on one face), the shaft 2 assembled on the bearing 3 extends out of the diameter of the bearing 3 part and the equal width of the tooth track.

[0020] All the other implementations are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com