Crucible forming machine

A molding machine and crucible technology, applied in the field of presses, can solve the problems of waste of raw materials, high cost, low output, etc., and achieve the effects of improving product qualification rate, uniform machine vibration force, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

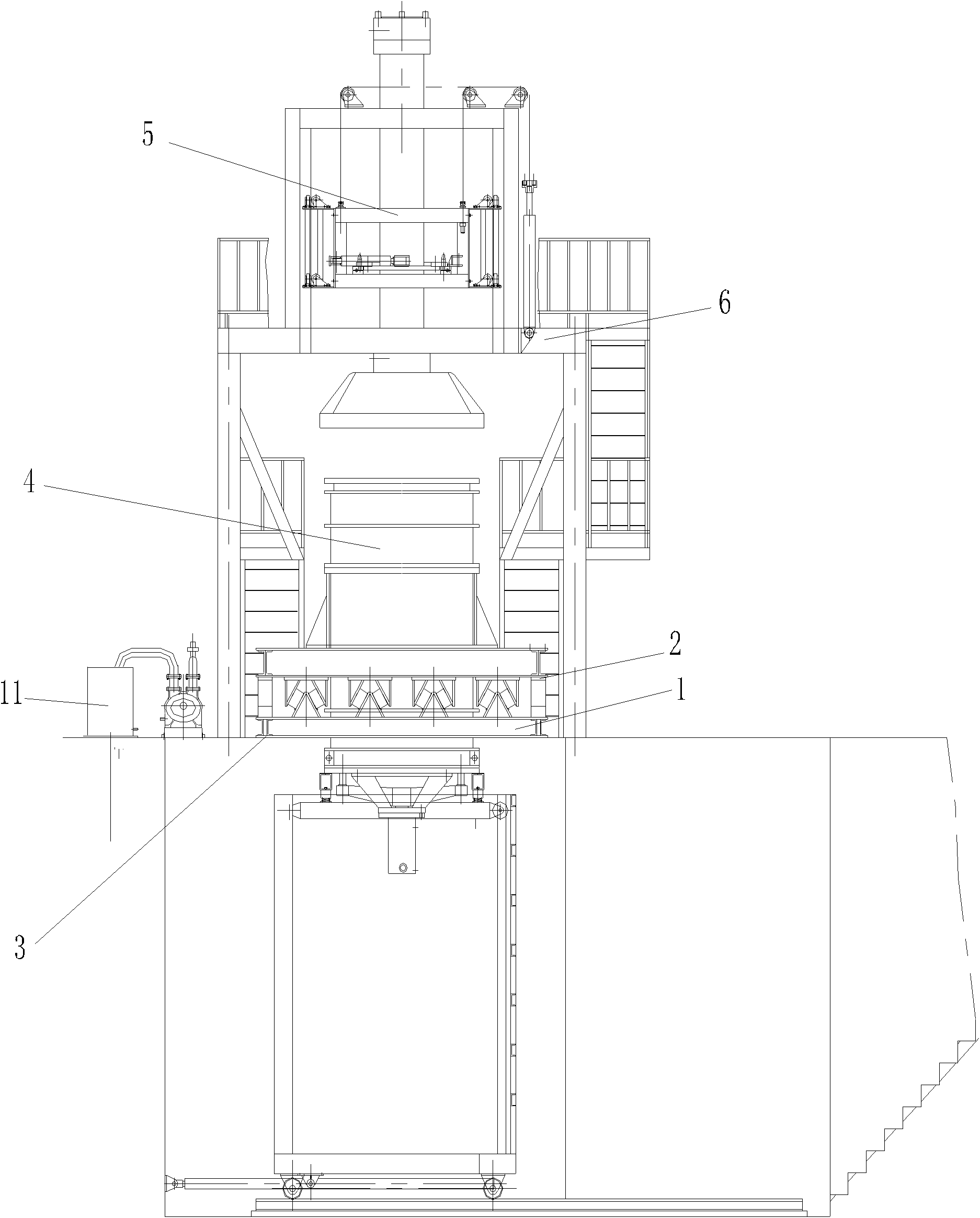

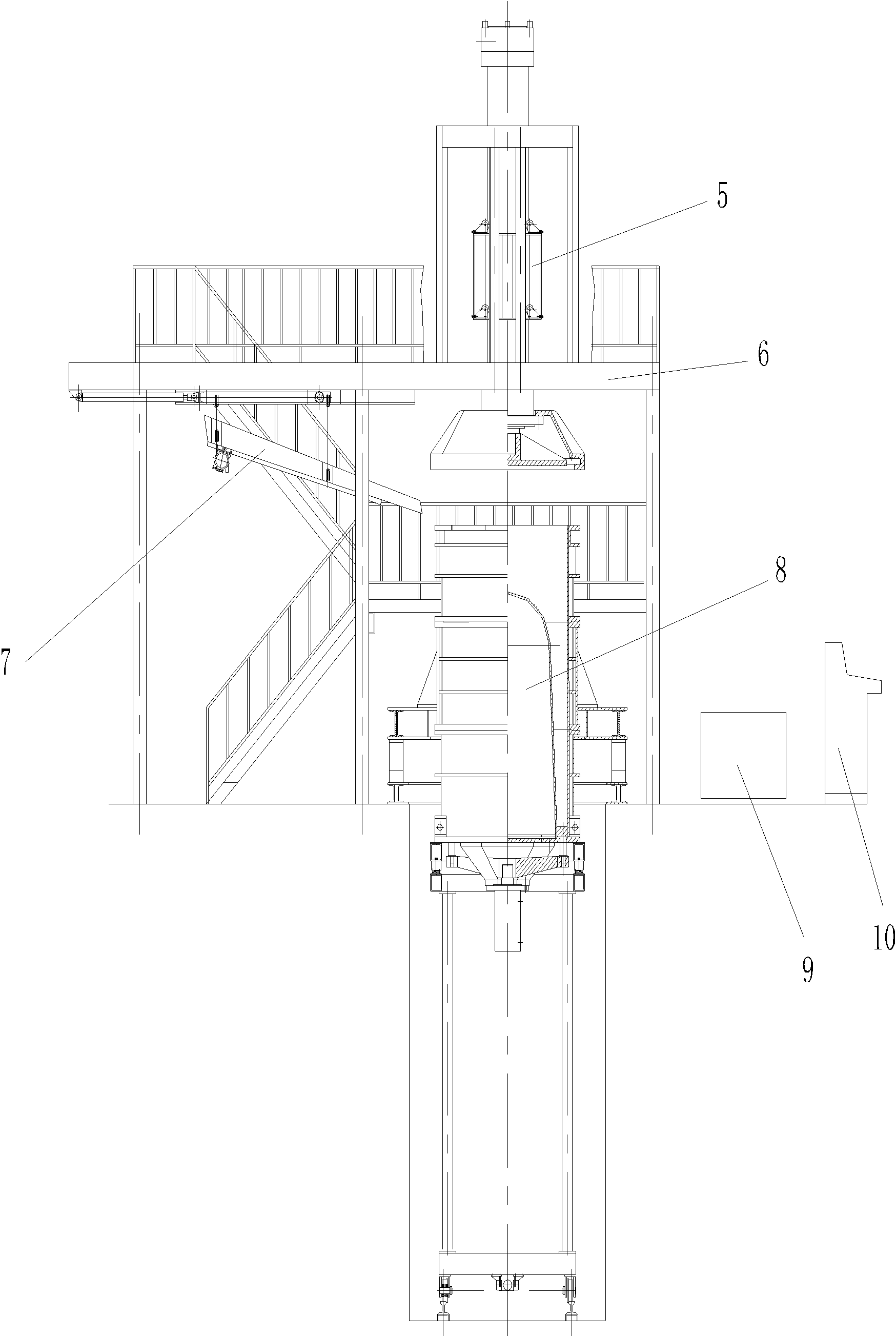

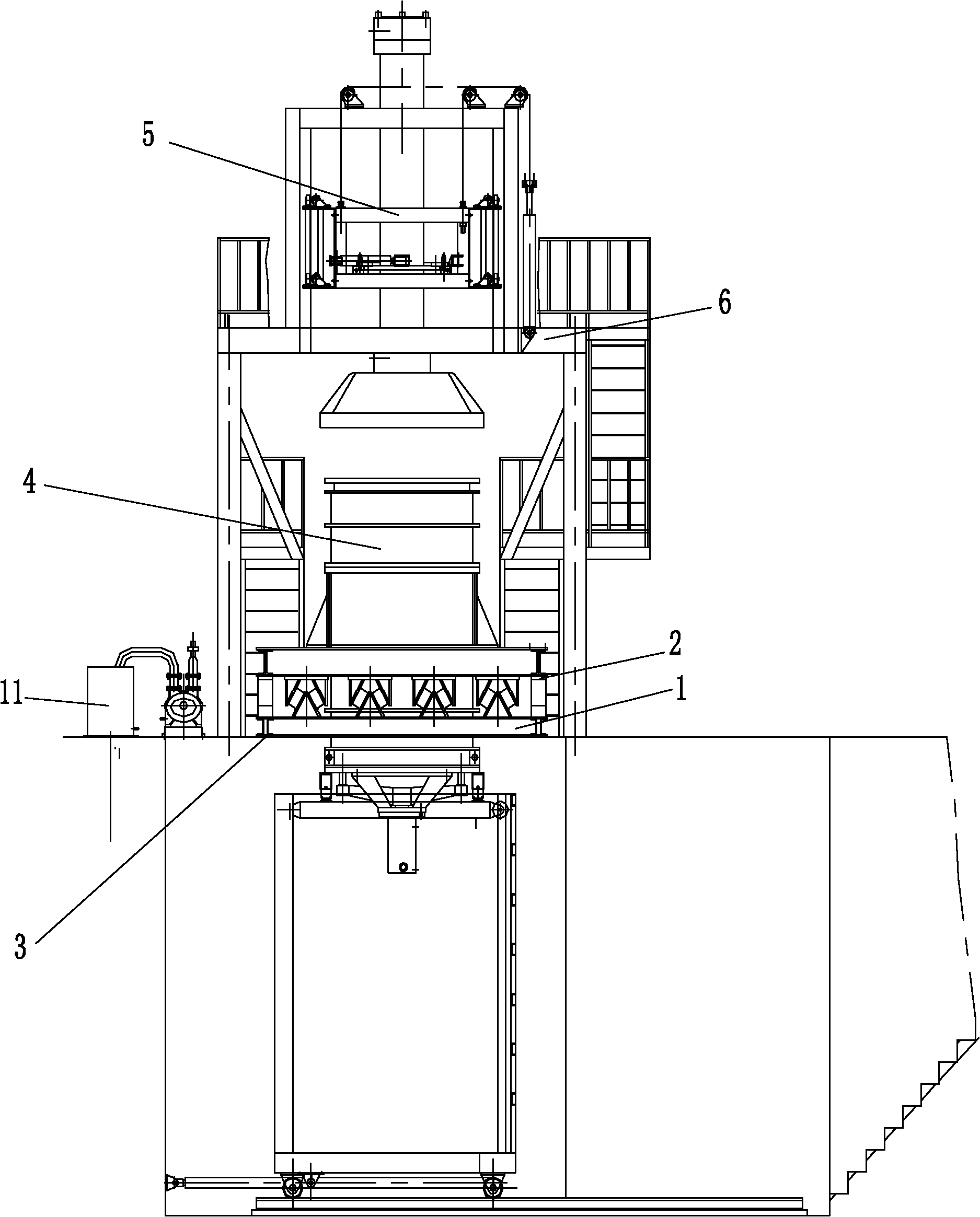

[0021] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings

[0022] see figure 1 and 2 , the embodiment of the present invention is provided with vibration platform 1, vibration source 2, support 3, outer mold 4, upper pressure head 5, frame 6, feeding mechanism 7, inner mold 8, hydraulic system 9, electric control system 10 and vacuum System 11; the vibration platform 1 is set on the rubber spring of the machine base 3, the vibration source 2 is connected with the vibration platform 1 through the cardan shaft, the middle part of the outer mold 4 is connected with the vibration platform 1, and the upper pressing head 5 is connected with the outer mold through the rotating teeth. The mold 4 is connected, the feeding mechanism 7 is arranged above the inner mold 8 and the outer mold 4, the inner mold 8 is connected with the outer mold 4 through a lock, and the vibration platform 1 is placed in the middle of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com