Coal pulp pulverizer

A pulverizer and coal slurry technology, applied in grain processing and other directions, can solve the problems of different material sizes, low pulverization efficiency, and large equipment footprint, and achieve the effects of uniform material particles, high pulverization efficiency, and reasonable internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

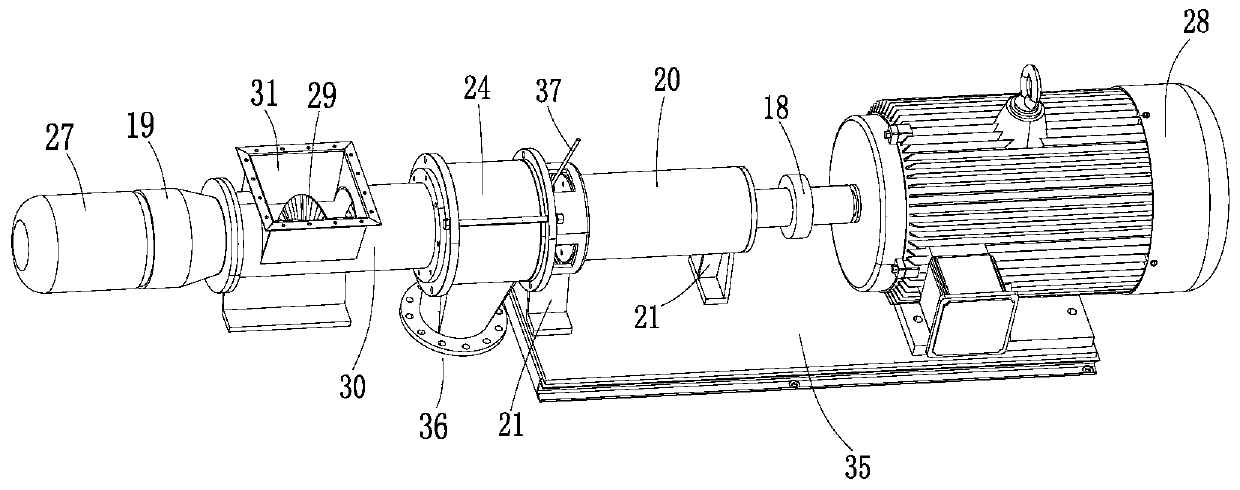

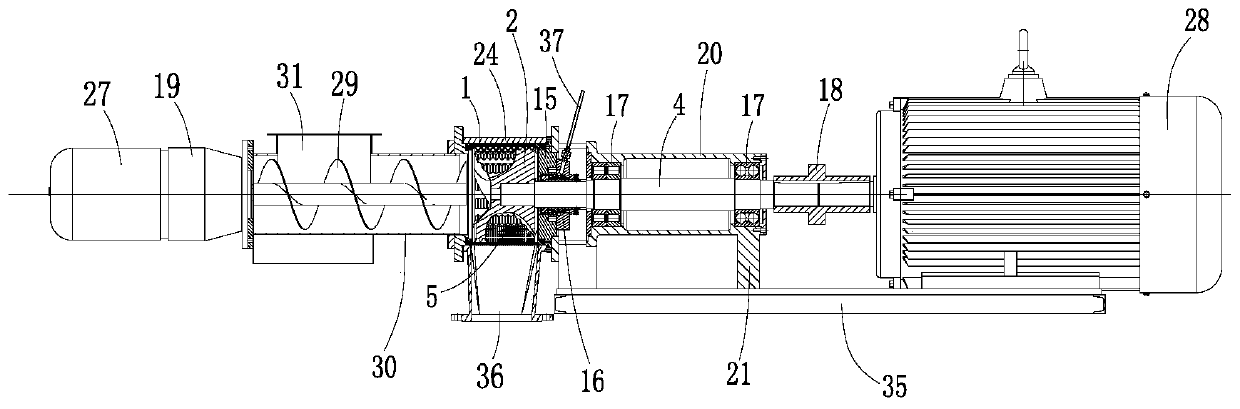

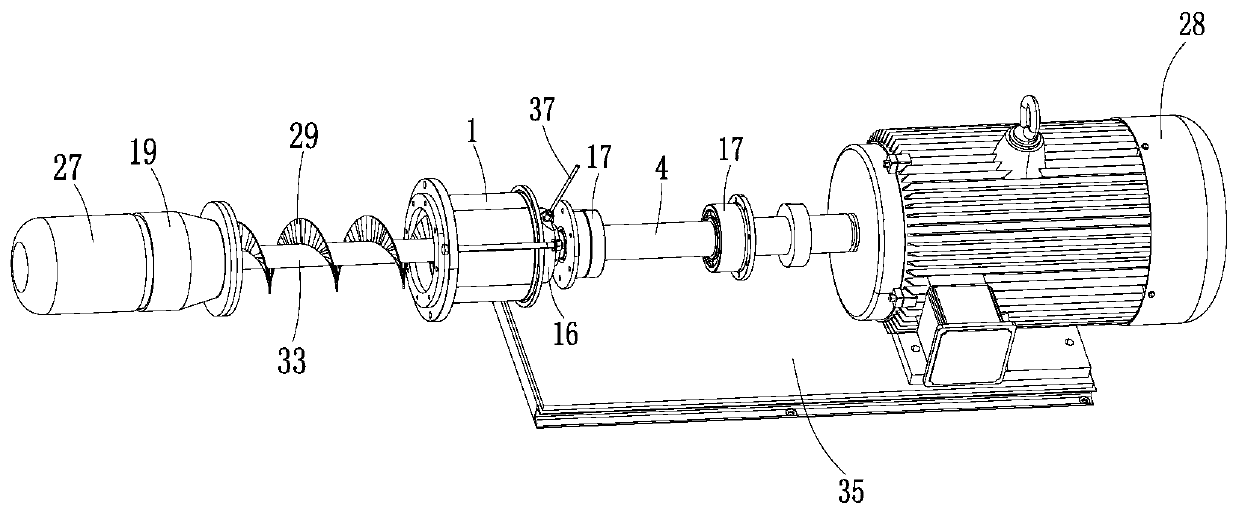

[0034] Following Figure 1 to Figure 16 The illustrated horizontal coal slurry grinder is taken as an example to illustrate the specific implementation of the present invention.

[0035] Such as figure 1 , figure 2 , image 3 As shown, a horizontal coal slurry pulverizer includes a feed port 31, a feed part, a crushing part, and a discharge port 36 that are connected in sequence. The feed part includes a screw conveyor 29 driven by a first motor 27 and a screw conveyor set in it. Outside the first outer sleeve 30, the first outer sleeve 30 is provided with an upward feeding port 31; the pulverizing part includes a cylinder 1 and a rotor 2 in the cylinder 1 driven by a second motor 28, and the cylinder 1 A chassis 15 is provided at the end where the bottom surface of the rotor 2 is located, and a shaft sealing device 16 is provided outside the chassis 15.

[0036] Such as figure 2 , Figure 5 , Figure 7 As shown, the area on the lower side of the cylinder wall of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com