Spanner frame assembly device of vehicle machine oil filter element spanner automatic assembly machine

A technology of assembling device and wrench holder, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of slow assembly efficiency, inability to adjust the size of hinged wrench, loose wrench head and belt, etc., to achieve high assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

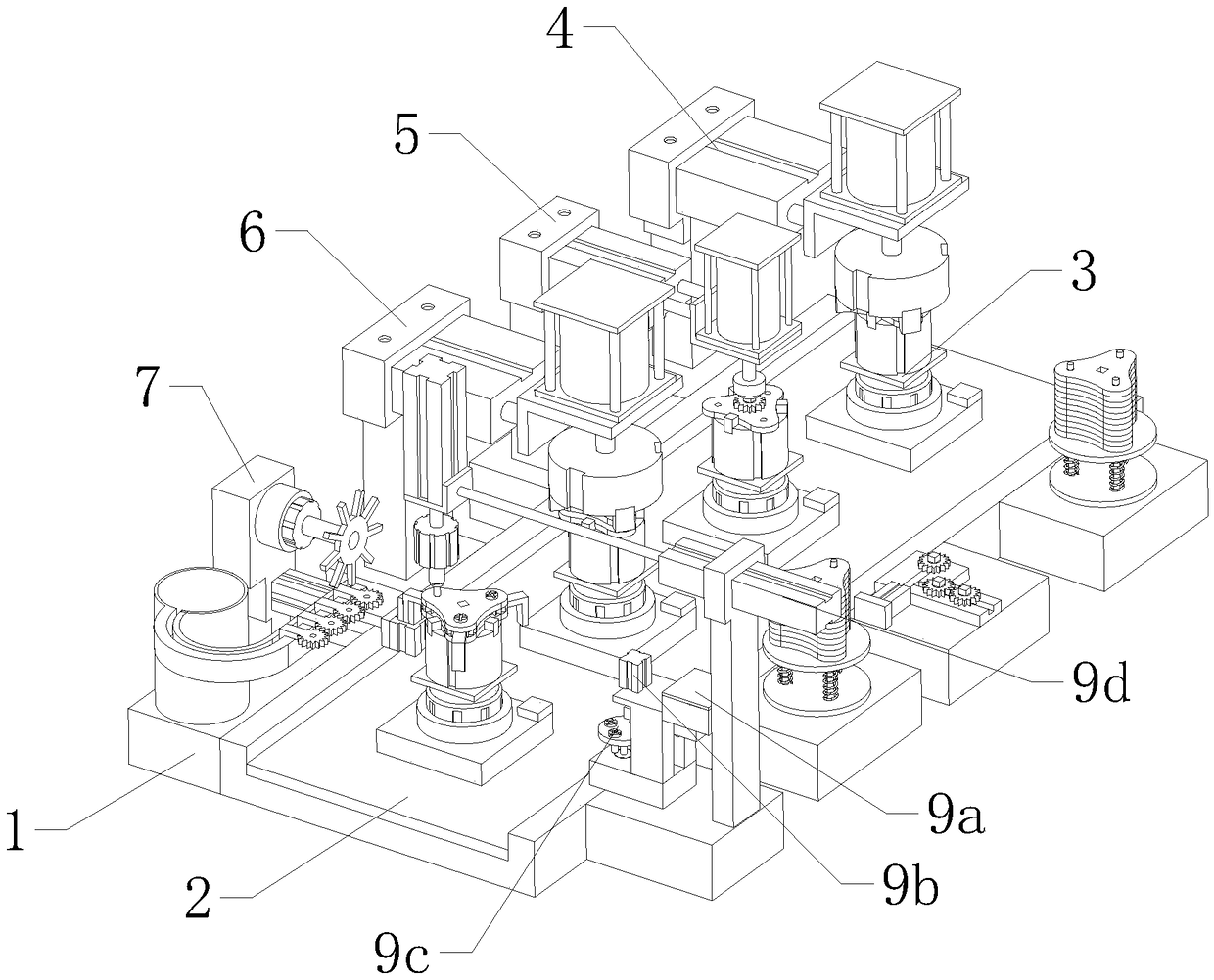

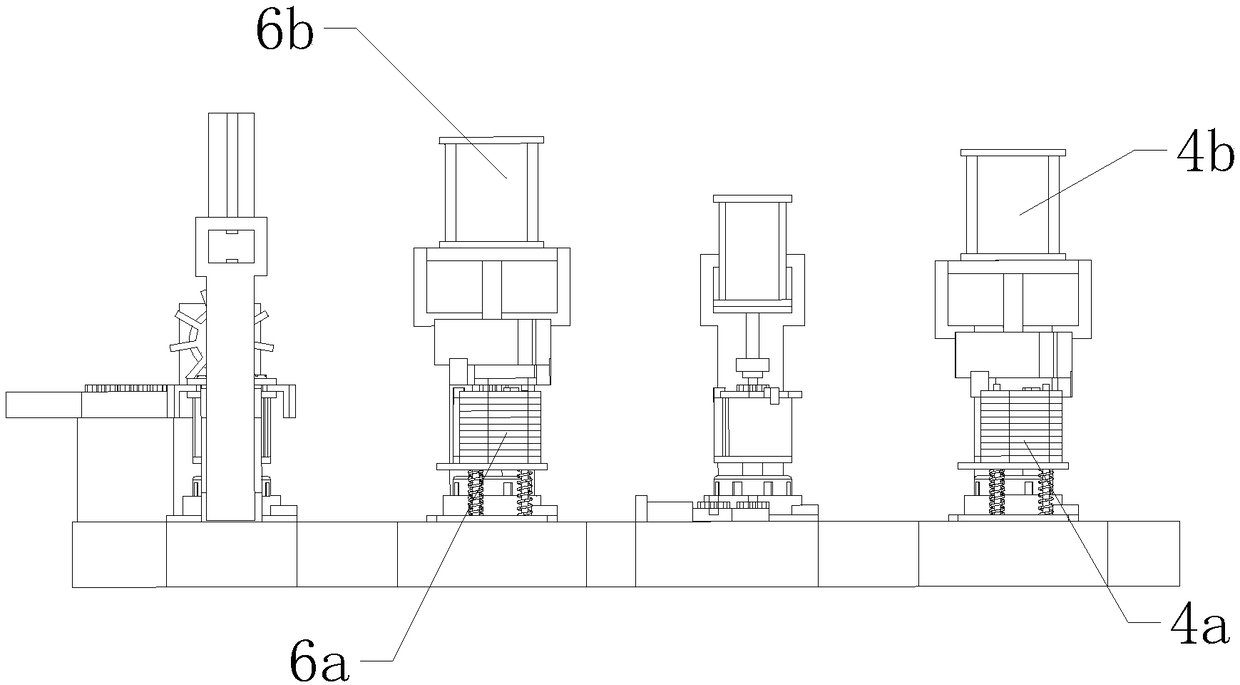

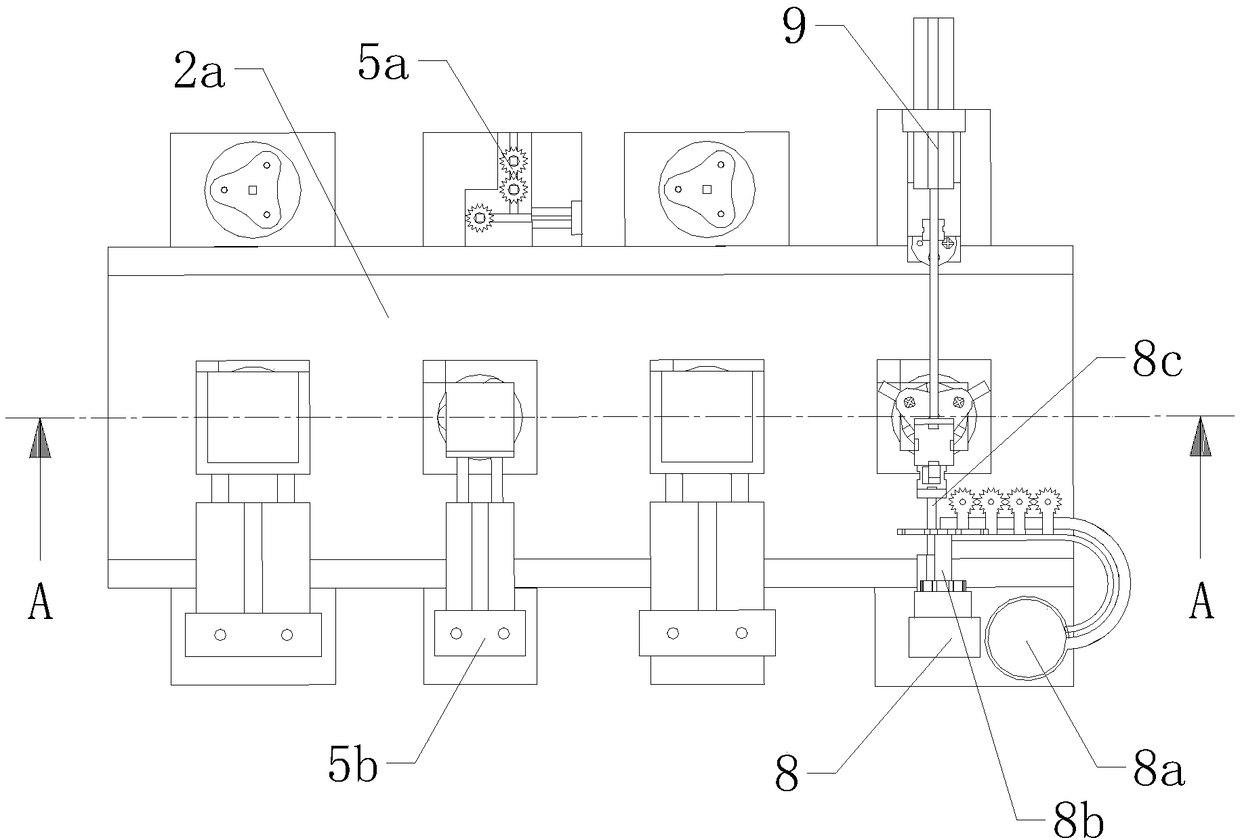

[0033] refer to Figure 1 to Figure 13 A kind of auto oil filter wrench automatic assembly machine shown, comprises workbench 1, the conveying device 2 that is arranged on the top of workbench 1, the positioning device 3 that is arranged on the top of conveying device 2 and is fixedly connected with conveying device 2, is arranged on the workbench The chassis assembly device 4 on the top of the table 1, the rotary tooth assembly device 5 arranged on the side of the chassis assembly device 4, the top cover assembly device 6 arranged on the side of the rotary tooth assembly device 5, and the top cover assembly device 6 arranged on the side Wrench assembly device 7, the transmission device 2 includes a transmission assembly 2a, the transmission assembly 2a is arranged on the top of the workbench 1 and is slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com