Press machine safety protection device preventing hands from being pressed

A safety protection device and protection device technology, applied in the mechanical field, can solve problems such as inability to reliably provide safety protection, susceptibility to external interference, and device reliability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

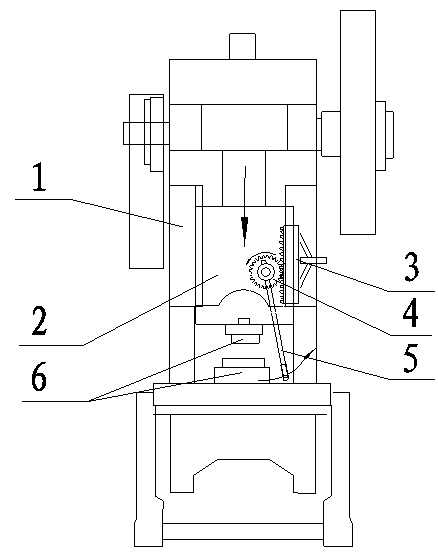

[0009] The specific working conditions proposed by the present invention will be described in detail below in conjunction with Fig. 1. The press slider 2 moves downward along the press guide rail 1, the guide tooth 3 of the protection device is fixed, and the rotating tooth 4 is movable, which can be rotated clockwise or Rotate counterclockwise, when the slider moves down, the rotating gear 4 rotates counterclockwise, when the slider moves down, the rotating gear 4 rotates counterclockwise, driving the anti-pressure hand lever 5 to rotate counterclockwise, at this time, if the operator If the hand does not leave the mold in time, the device will automatically push the operator's hand out to achieve the purpose of active safety protection. When the slider 2 rises along the guide rail 1, the anti-pressure hand device 5 returns to its original position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com