Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Speed up cooling and forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

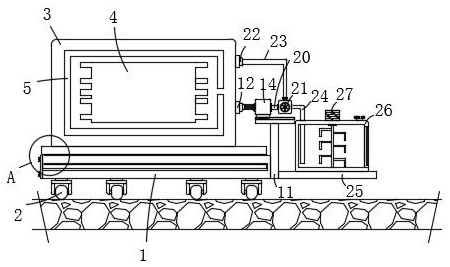

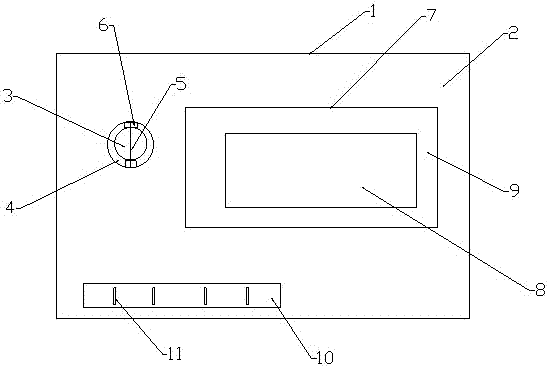

Intelligent high-speed laser cutting machine control system

InactiveCN108436307AAvoid accumulationEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesIntelligent lightingMachine control

The invention discloses an intelligent high-speed laser cutting machine control system which comprises a machine body, a control display screen and a wind opening. A machine tool is arranged above themachine body. Supporting rods are installed on the two sides of the machine tool. A cross beam is fixed onto the supporting rods. A supporting arm is arranged above the cross beam. A laser cutting head is installed at the lower end of the supporting arm. The control display screen is arranged on the right of the machine body. An installing support is fixed below the control display screen. Sliding blocks are installed at the lower ends of the supporting rods. Sliding rails are arranged on the left sides of the sliding blocks. Limiting plates are installed at the lower ends of the sliding blocks. A fixing base is fixed to the bottom of the machine body. Pipelines are installed on the left side and the right side below the machine tool. A water tank is arranged in the machine tool. A movingshaft is installed above the right of the machine tool. The intelligent high-speed laser cutting machine control system is provided with a fan, dust generated by cutting can be sucked into a dust collecting groove, and the influence on the body of a user from the dust is avoided.

Owner:盐城市雷鸣电器制造有限公司

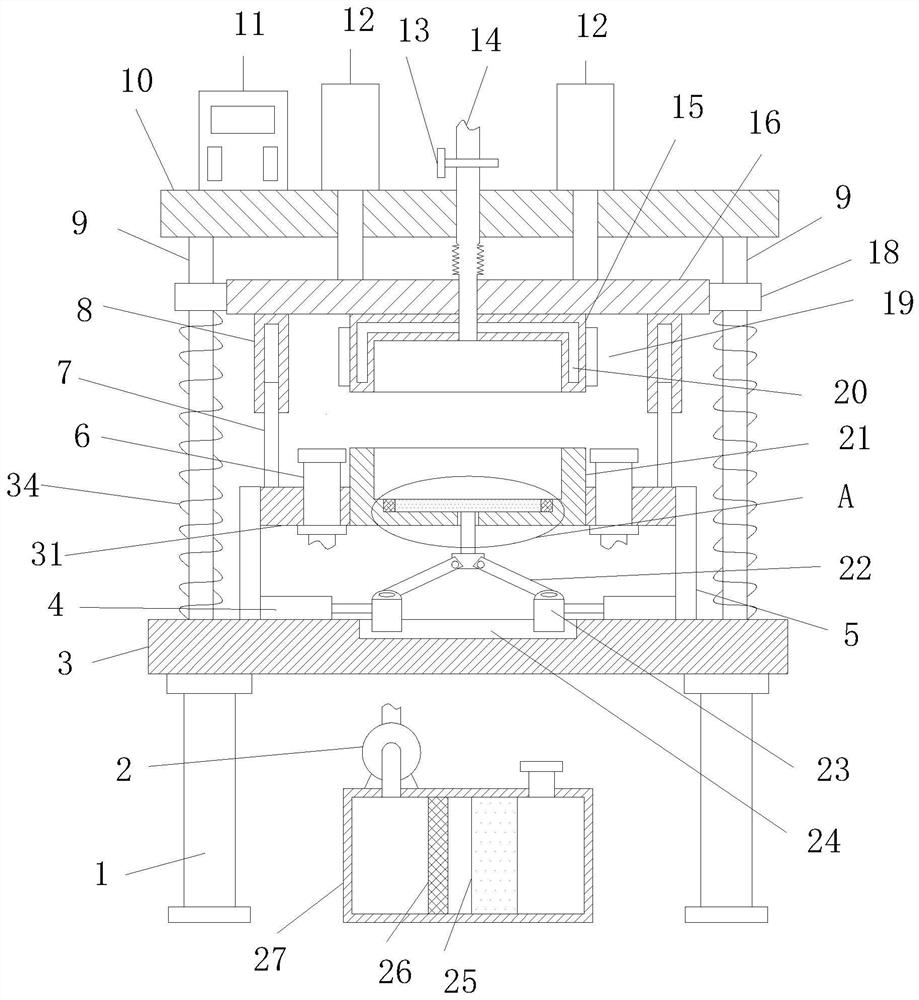

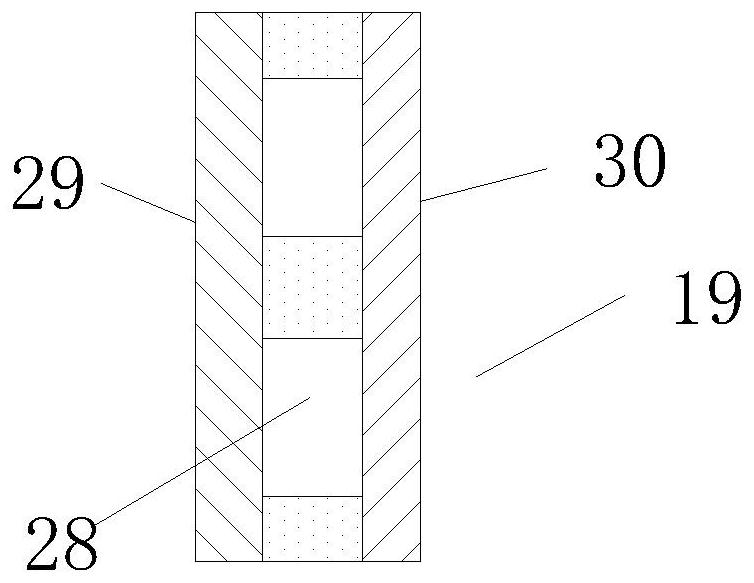

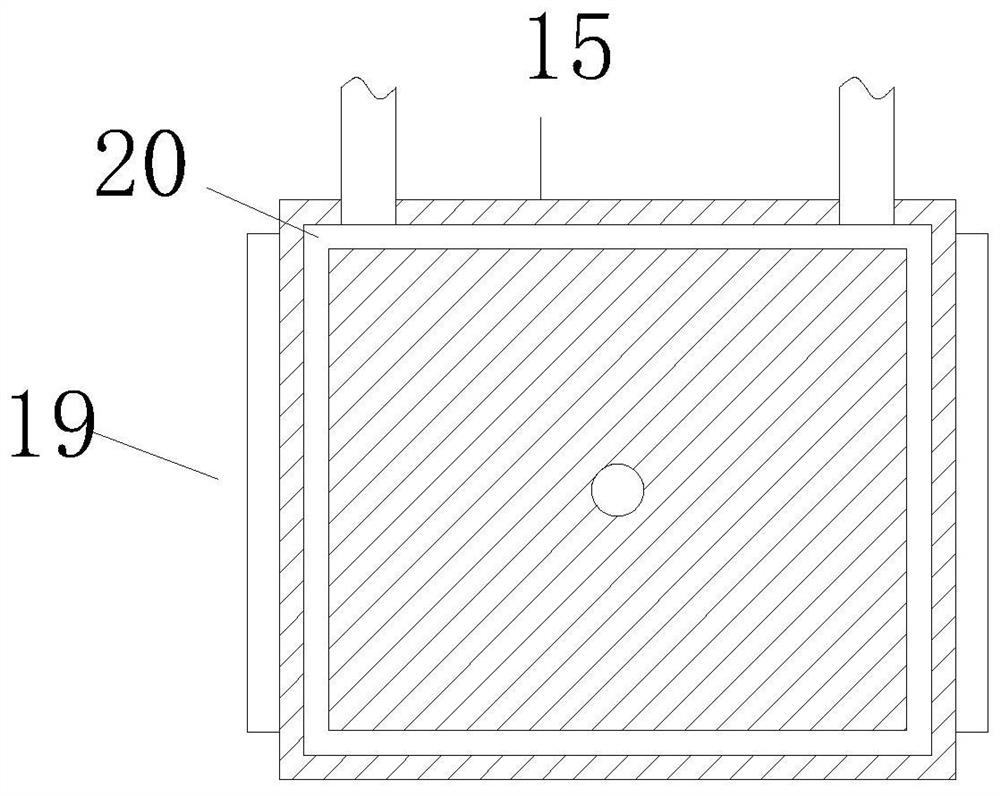

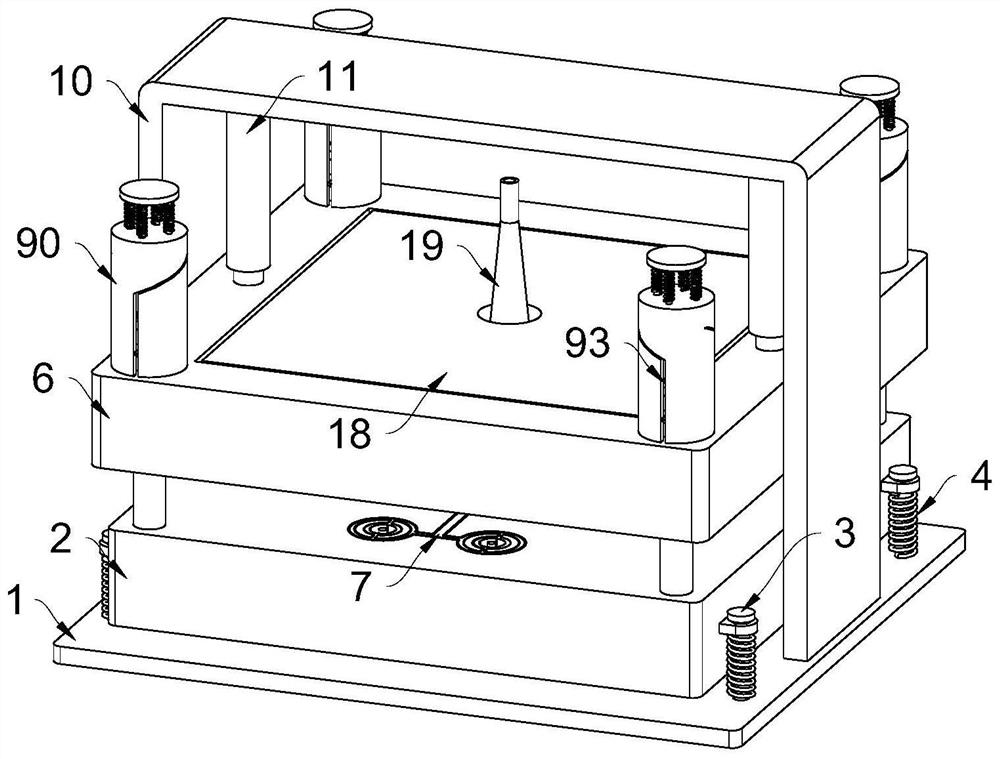

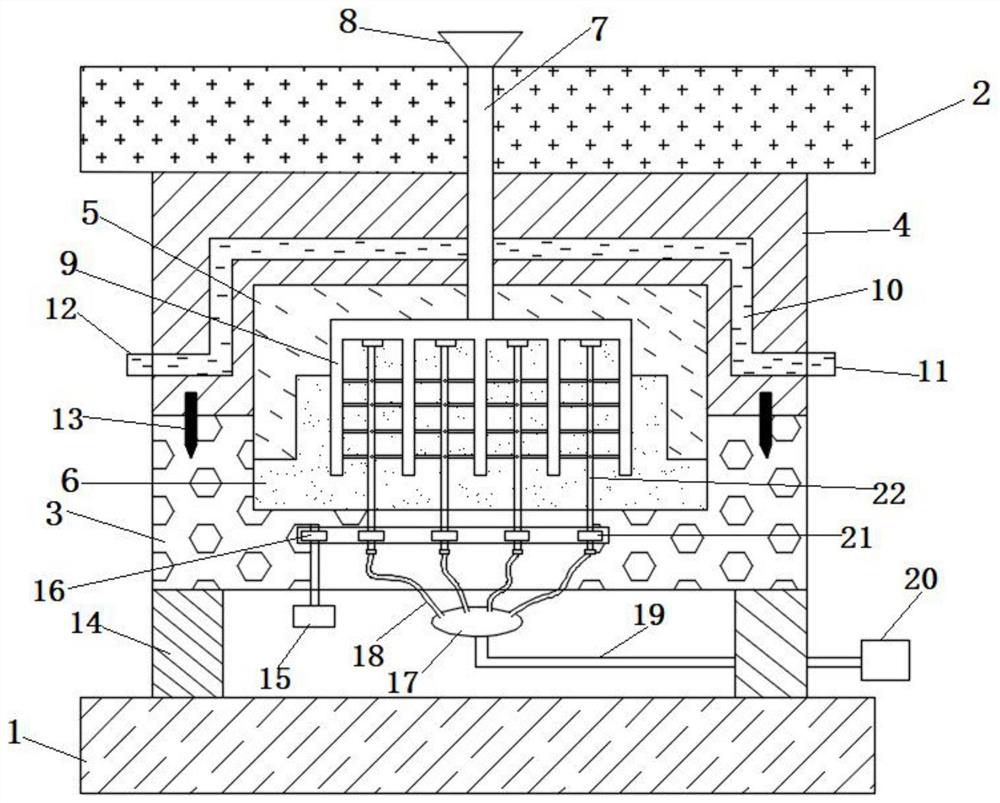

Injection mold for producing resin rubber frame of display screen

The invention discloses an injection mold for producing a resin rubber frame of a display screen. The injection mold comprises a workbench; supporting columns are connected with the corners of the periphery of the bottom end face of the workbench; supporting rods are connected with the corners of the periphery of the upper end face of the workbench; a mounting plate is connected with the top ends of the supporting rods; first air cylinders are mounted at the left side and the right side of the upper end face of the mounting plate correspondingly; the output ends of the first air cylinders are connected with a lifting plate; an upper mold plate is mounted in the middle of the bottom end face of the lifting plate; and a lower mold plate is arranged below the upper mold plate. When the resin rubber frame needs to be taken out, a second cylinder is started, and the second cylinder works to drive sliding blocs at the left and right sides to slides along sliding grooves; and as one end of a connecting rod is hinged to a fixing block below a circular pushing plate, and the other end of the connecting rod is hinged to the upper end faces of the sliding blocks, when the sliding blocks at the left side and the right side relatively move leftwards and rightwards, the circular pushing plate is driven by the connecting rod to move upwards, so that the finished resin rubber frame is pushed out of the lower mold plate, and workers can take materials conveniently.

Owner:HEFEI TOP TECH SCI & TECHNOOGY CO LTD

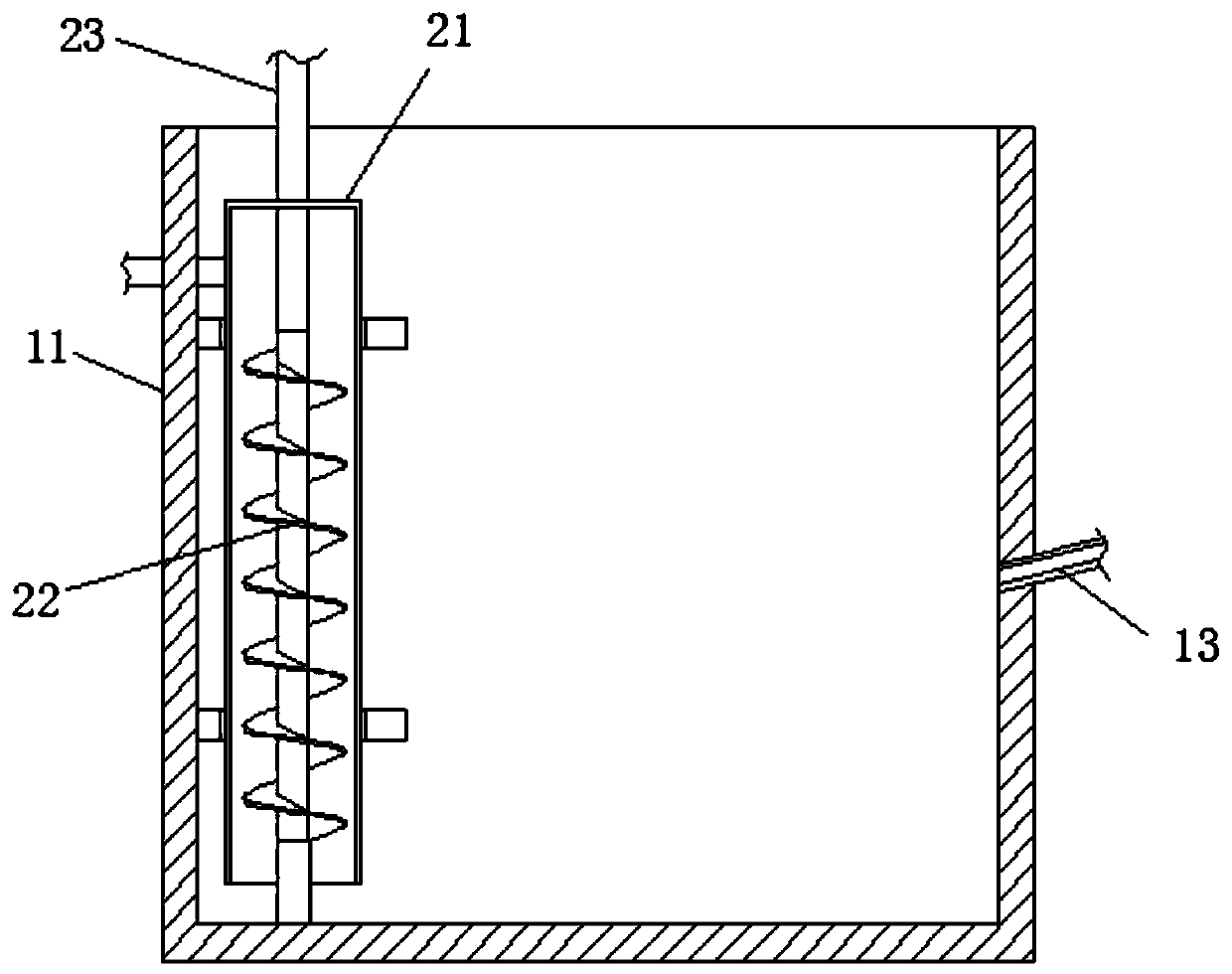

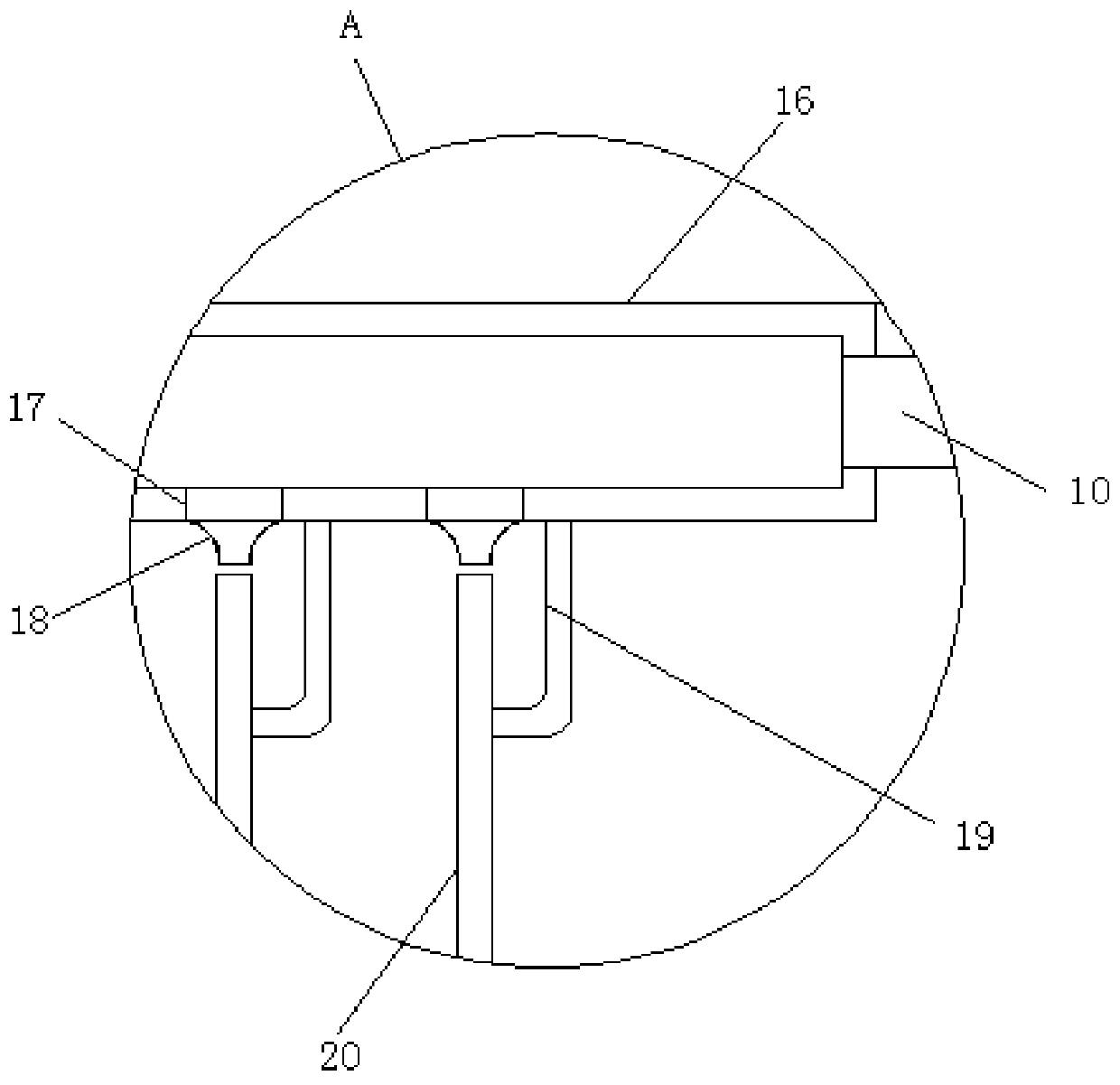

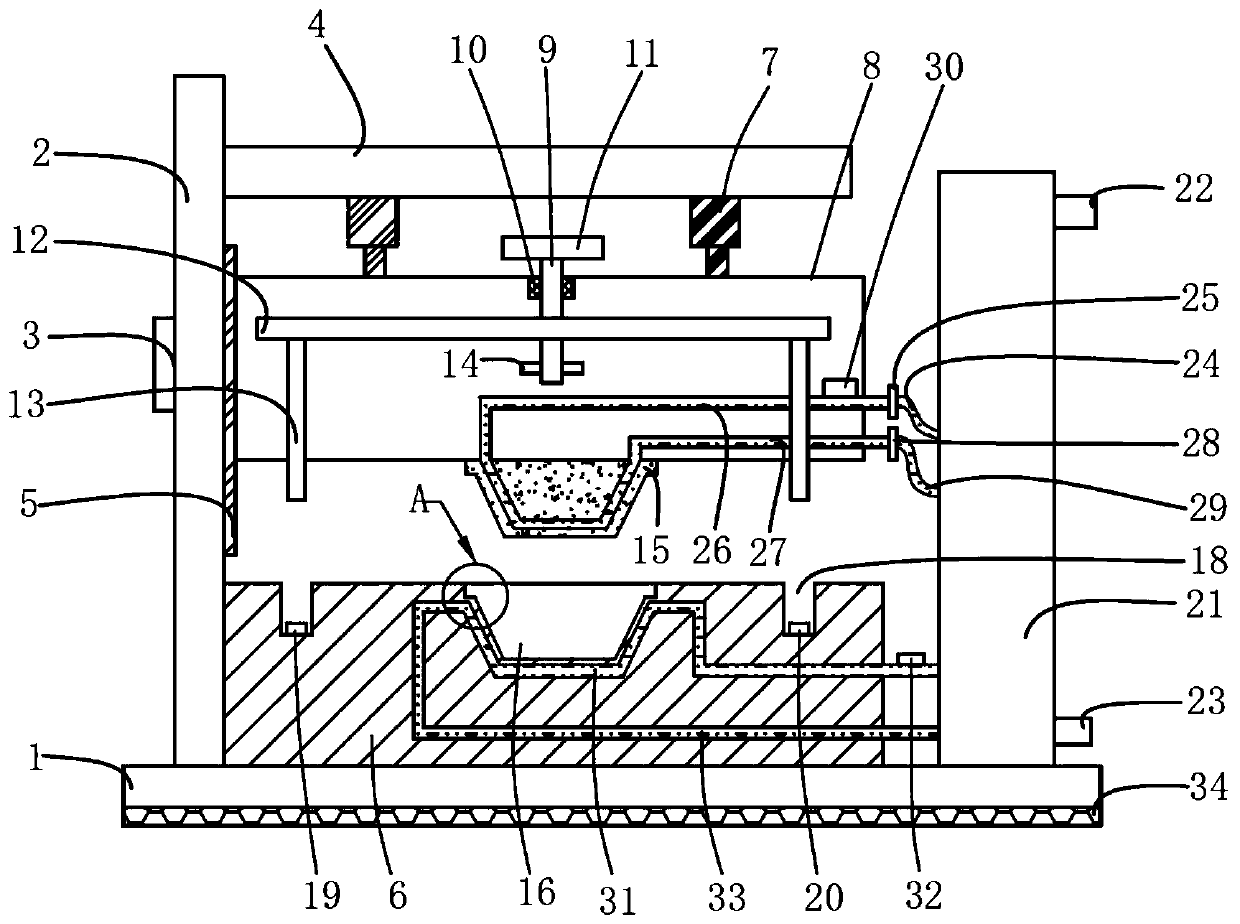

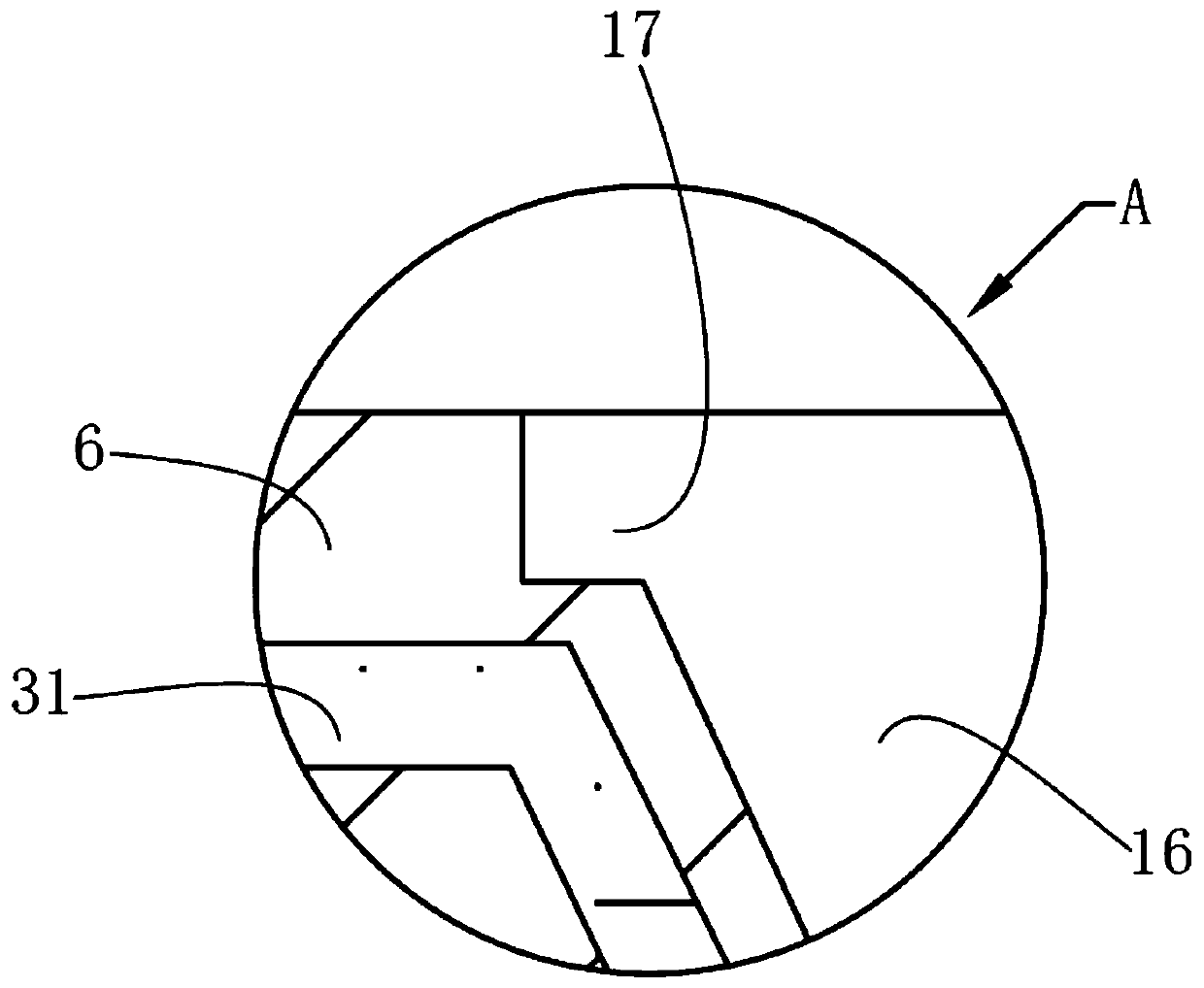

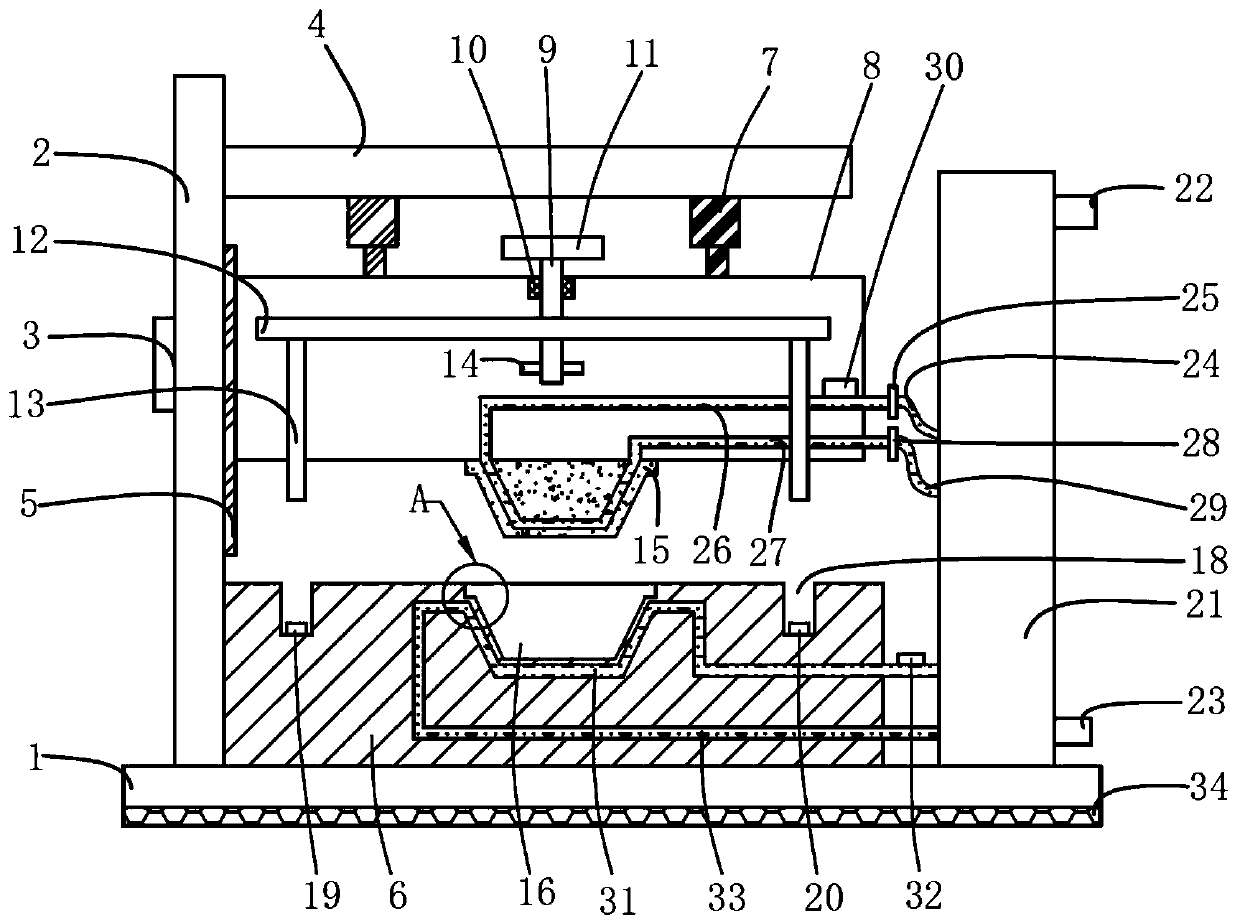

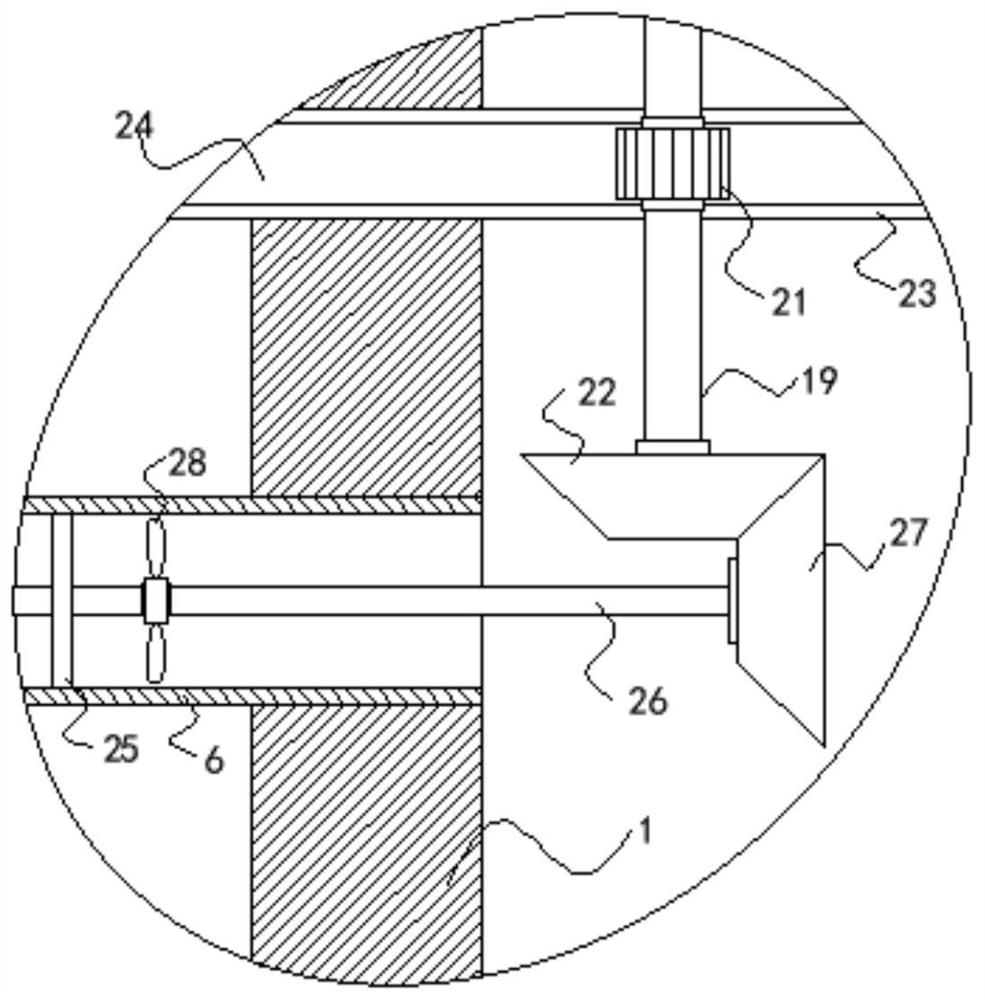

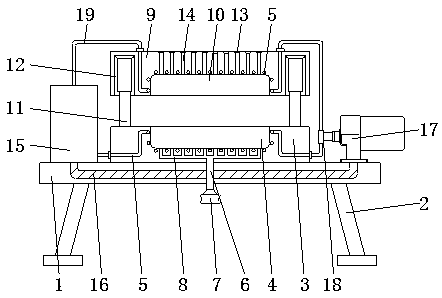

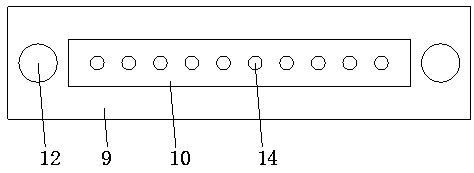

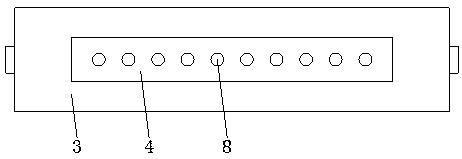

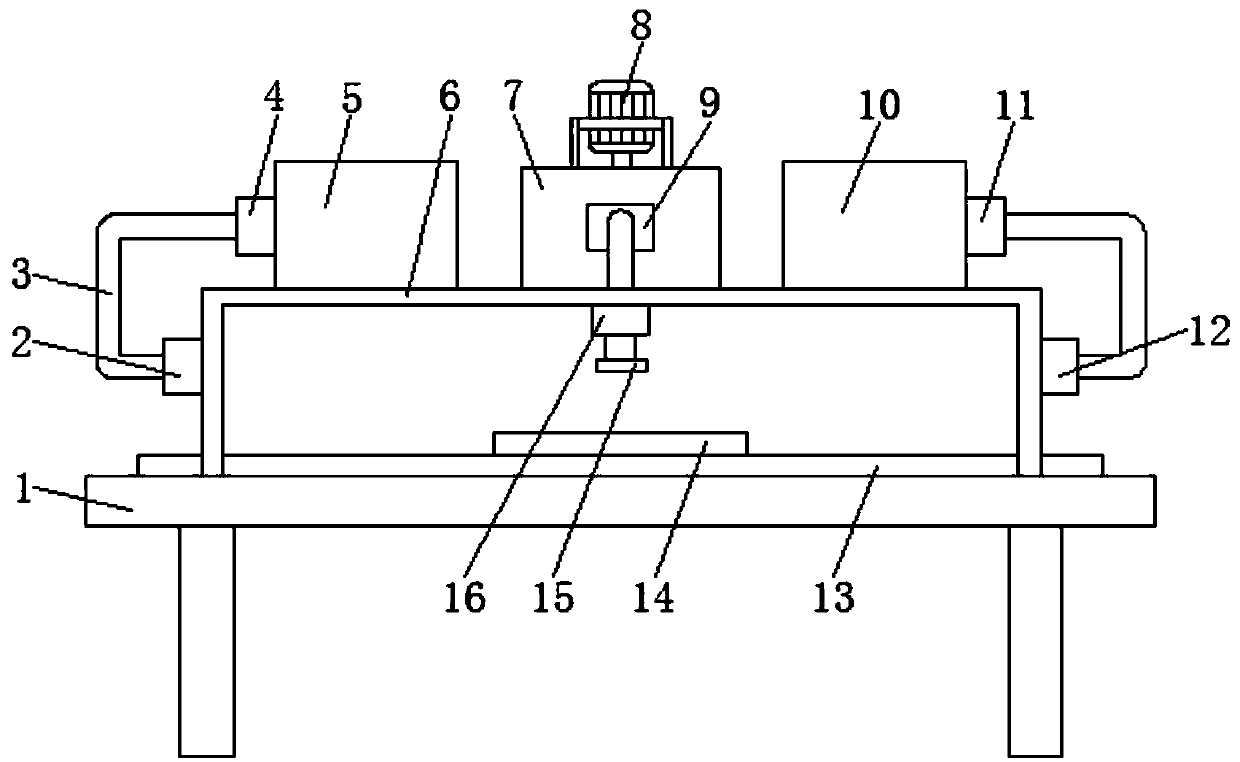

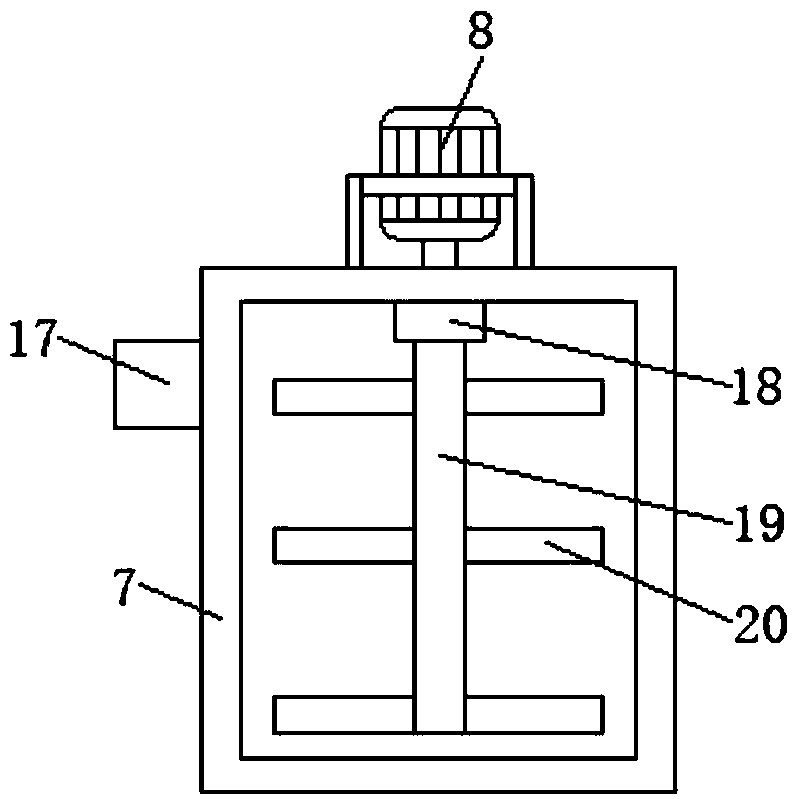

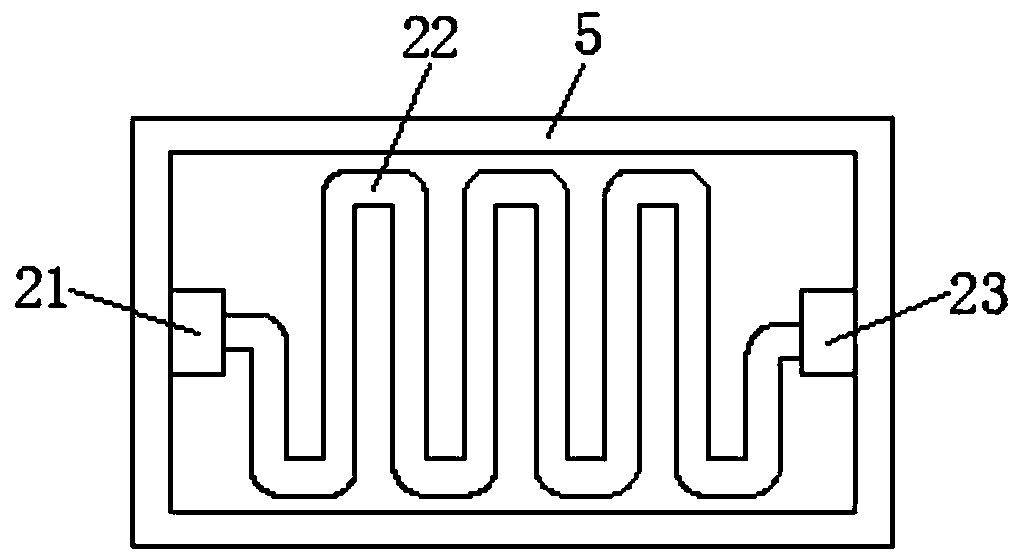

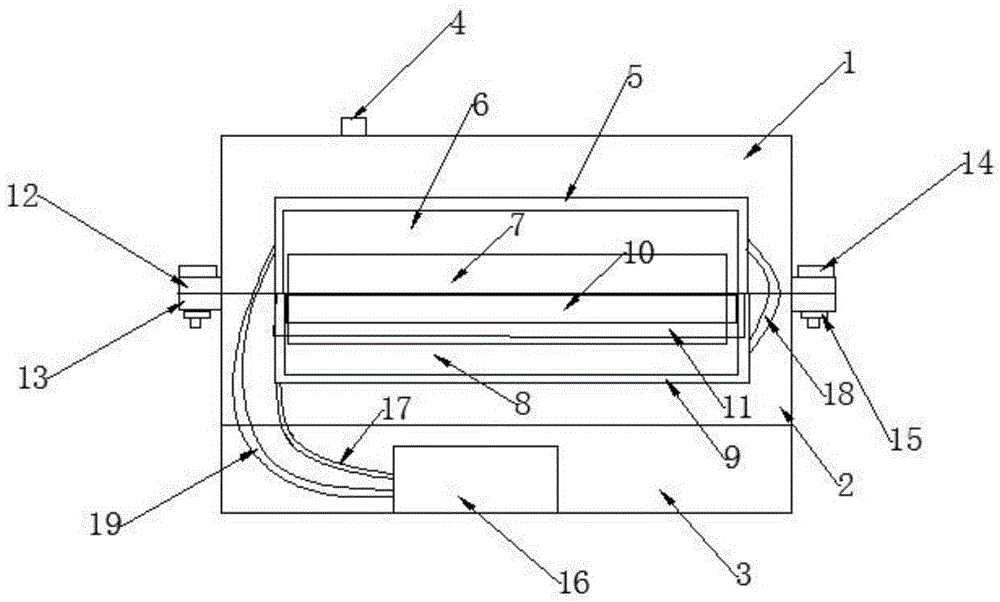

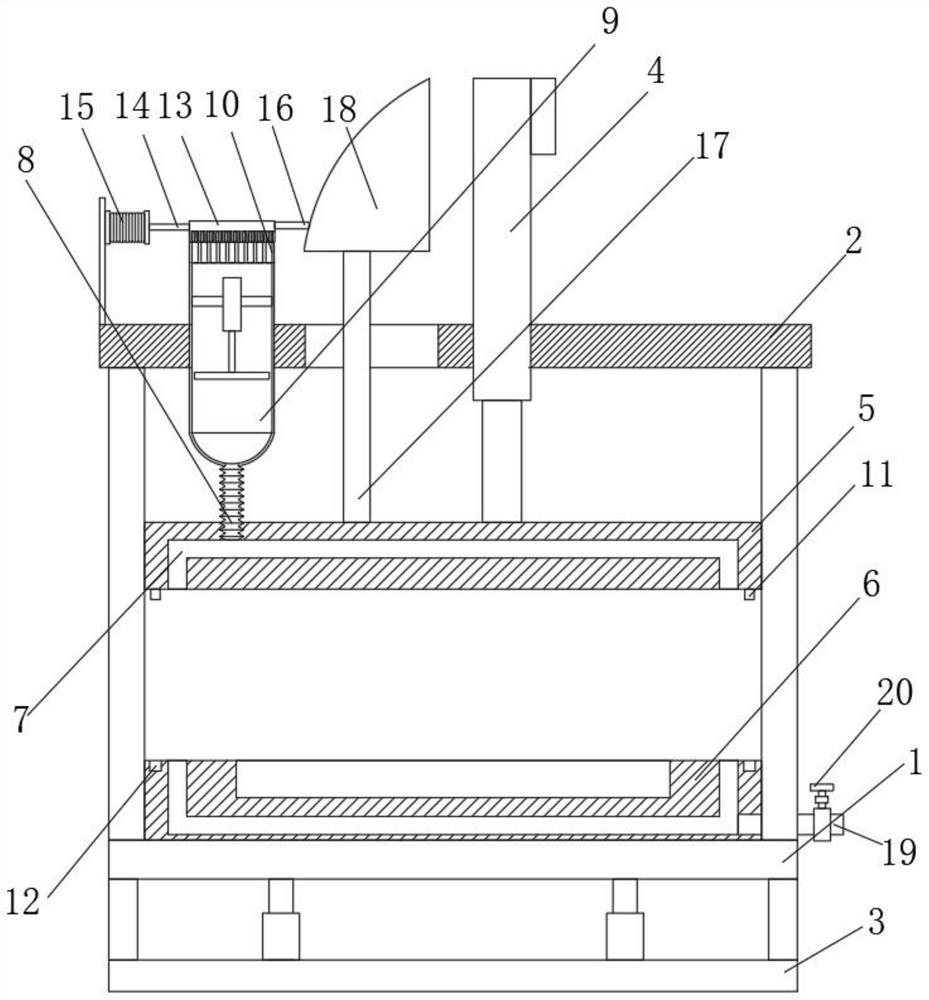

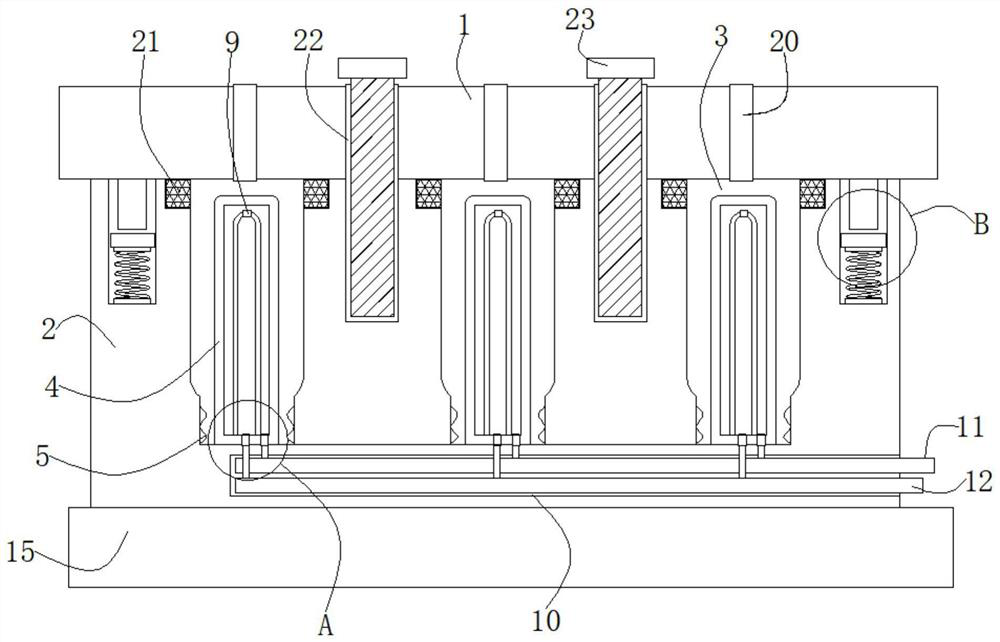

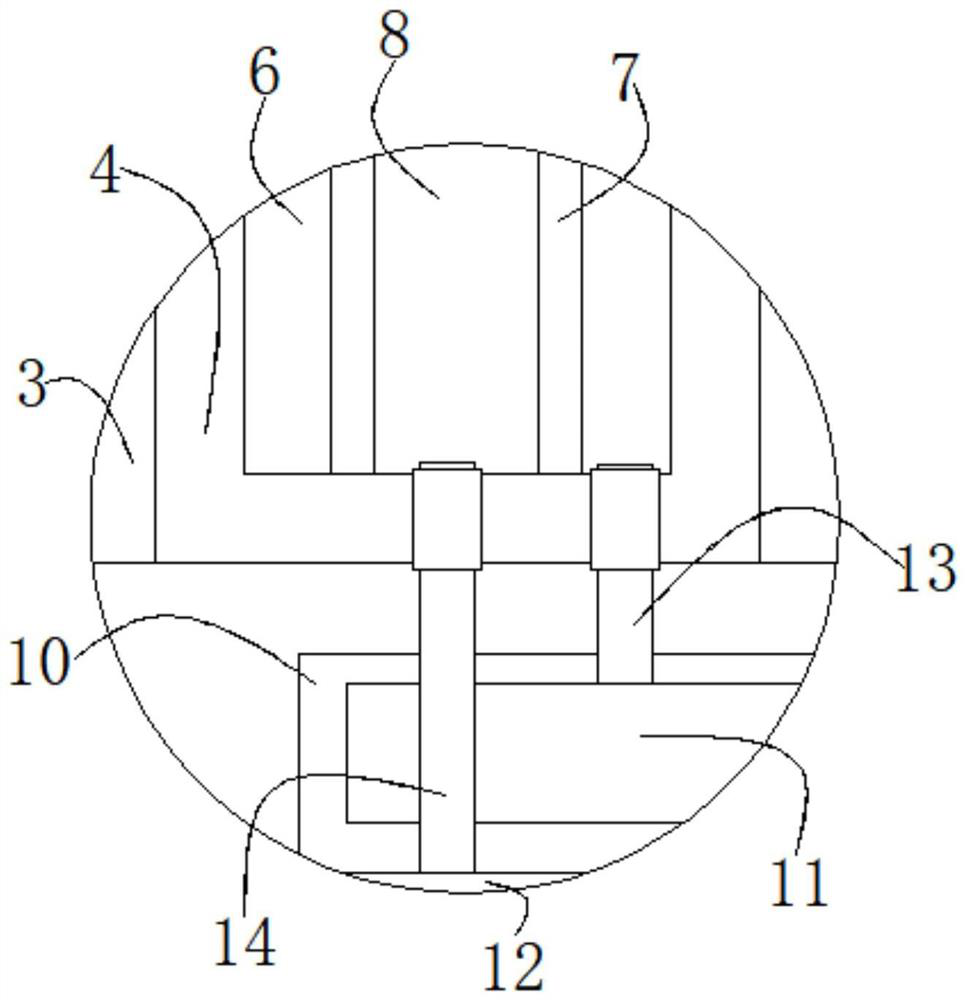

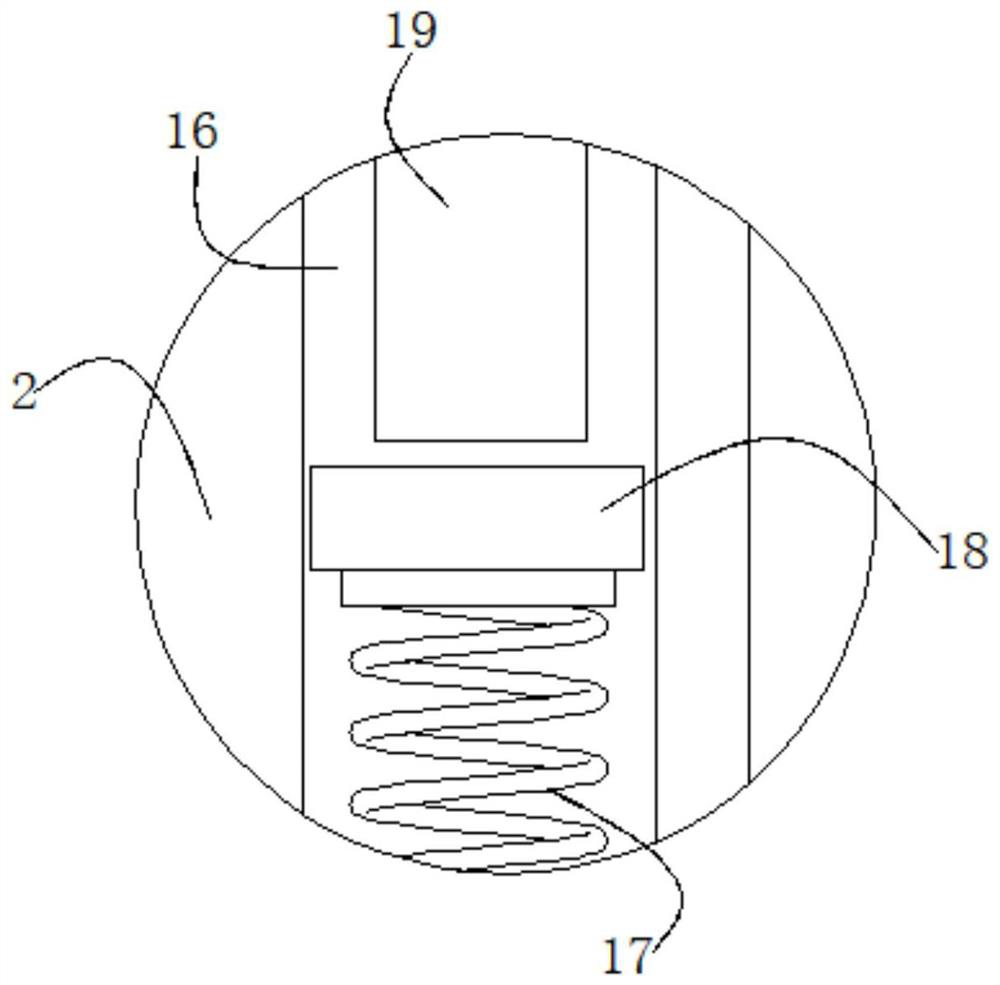

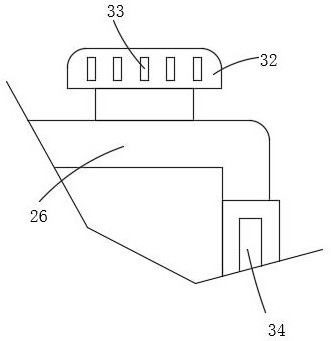

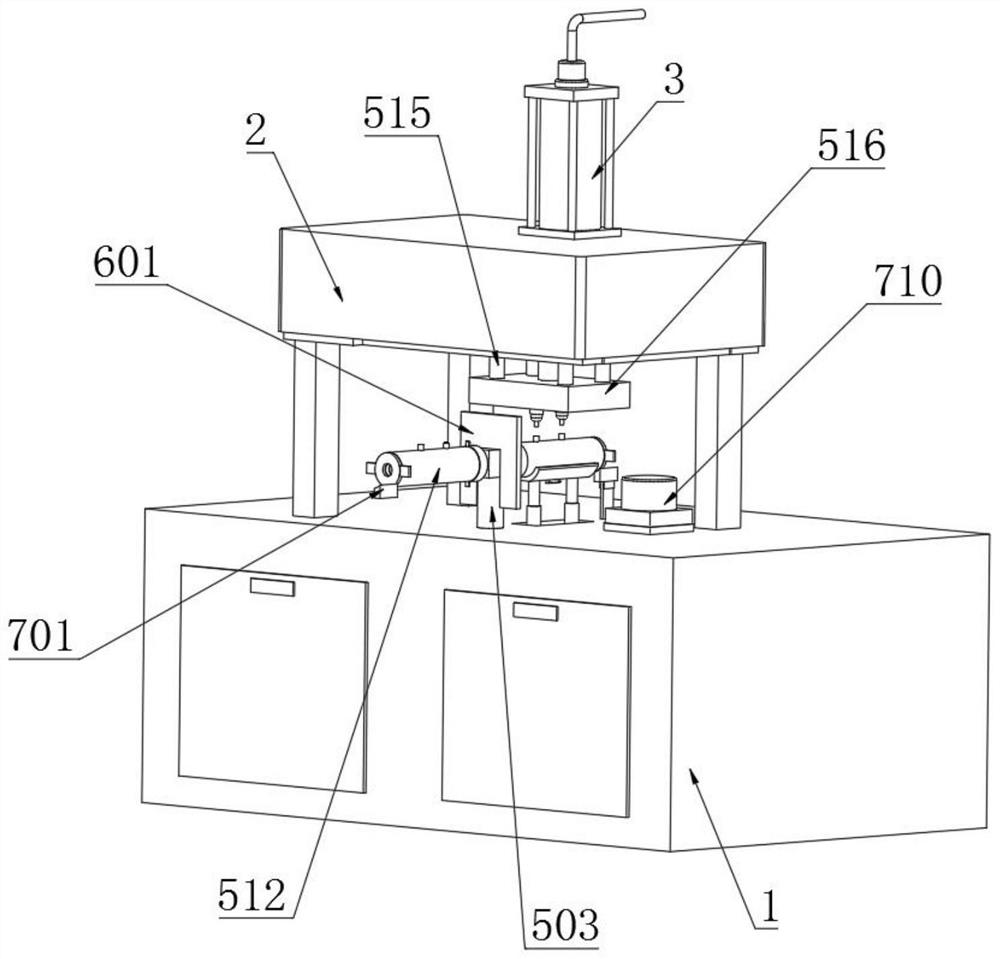

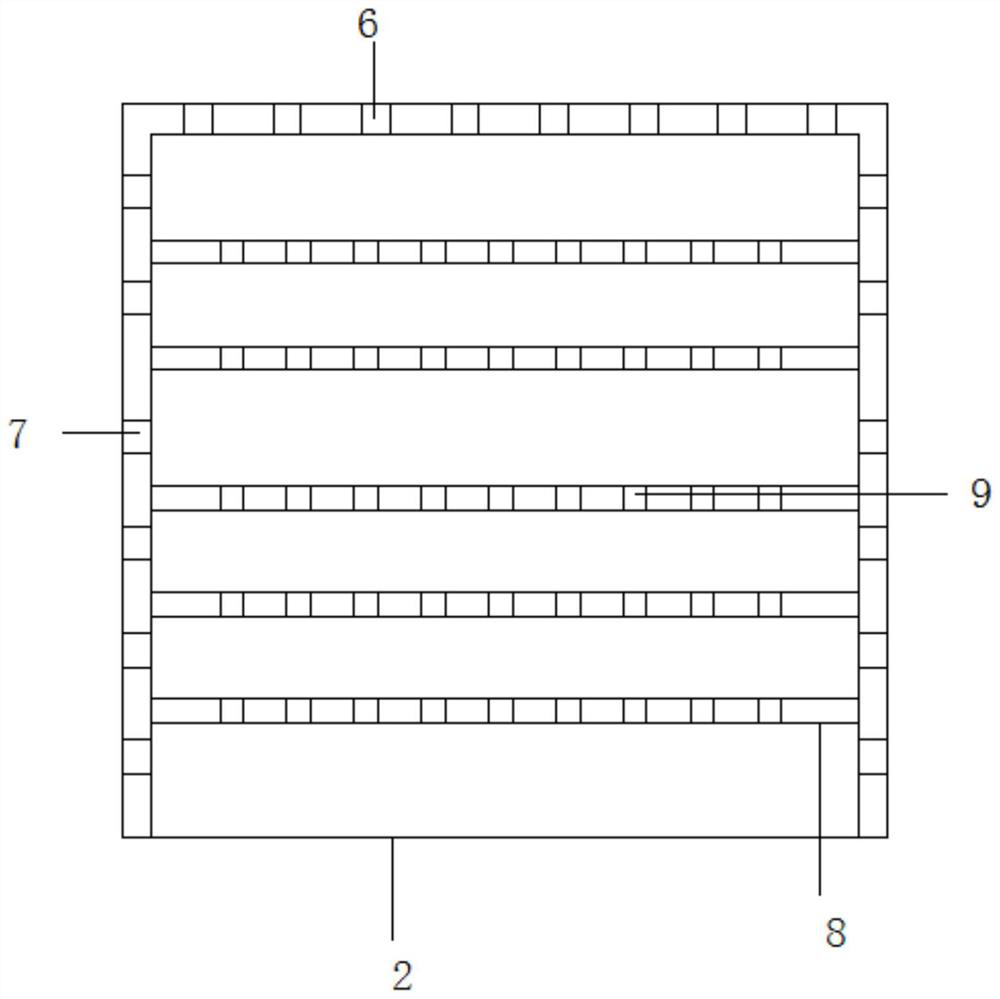

Die for mechanical accessory production

InactiveCN110370551AGuaranteed Binding AccuracySpeed up cooling and formingManufacturing technologyEngineering

The invention discloses a die for mechanical accessory production, and belongs to the technical field of die manufacturing. The die comprises a lower die and an upper die, the upper die is located above the lower die, the lower die is provided with an annular cavity and a circular cavity, the annular cavity communicates with the circular cavity, the annular cavity is arranged at the top of the circular cavity, the two sides of the top of the annular cavity are provided with a water inlet pipe and a water outlet pipe correspondingly, a cold water tank and a collecting plate are arranged below the lower die, a connecting pipe is arranged between the cold water tank and the collecting plate, the bottom of the lower die is provided with a shunt pipe, the end, far away from the lower die, of the water outlet pipe is connected with the shunt pipe, the bottom of the shunt pipe is provided with a plurality of flow holes, the bottom of the flow holes is provided with the water outlet pipe, anda drainage rod is arranged under the water outlet pipe. Forming of the die is realized, the cooling function is arranged on the die, product forming is accelerated, the production efficiency is improved, the cooling cost is low, the energy-saving effect is realized, the design is reasonable, and popularization is easy.

Owner:晋江展辉模具有限公司

Ejection device of injection mold

The invention discloses an ejection device of an injection mold. The ejection device of the injection mold comprises a workbench, wherein supporting legs are fixedly connected to the four opposite angles of the workbench, the tops of the four supporting legs are fixedly connected with the same top plate, a driving motor is fixedly connected to the bottom of the workbench, the output end of the driving motor is fixedly connected with a driving shaft, and the driving shaft penetrates through the workbench and is fixedly connected with a bottom plate. Through cooperative use of the driving motor, the driving shaft, a floor, supporting rods, a bottom mold, a mounting opening, a rotating plate, an air cylinder, a telescopic rod, a fixing plate, an ejector pin, an ejector opening and a connecting plate, injection molding materials can be evenly fed, and then materials can be evenly stored in the bottom mold; and meanwhile through cooperative use of the air cylinder, the telescopic rod, the connecting plate and the fixing plate, rapid and automatic ejection of the injection mold is achieved, the problem that in a traditional device, demolding of an injection mold is achieved in a manual ejection mode is solved, and labor is saved.

Owner:高春鹏

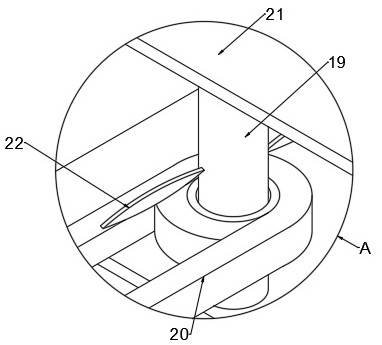

Submarine cable filling strip production equipment and production method

PendingCN113257483APlay a supporting roleAdjustable positionCable/conductor manufactureMarine engineeringElectric cables

The invention discloses submarine cable filling strip production equipment and a production method, and particularly relates to the technical field of submarine cable filling strip production. The submarine cable filling strip production equipment comprises a base; a shaping groove is formed in one side of the base, foot pads are arranged between the base and the shaping groove, and a rubber mixing mill is fixedly connected to the top of the base; discharging pipes are arranged at the two ends of the rubber mixing mill, a connecting pipe is arranged on one side of each discharging pipe, a protection ring is arranged on the outer side of each connecting pipe, and a shaping cover is arranged at the tail end of each connecting pipe; and a guide rail is arranged between the shaping groove and the shaping cover, a supporting frame is arranged on the top of the guide rail, and a clamping frame is arranged on one side of the supporting frame. Rubber mixing and shaping are conducted on rubber raw materials through the rubber mixing mill and the shaping cover, rubber strips are rapidly shaped in cooperation with devices such as a supporting and pressing block and a spray head in the shaping groove, production of the submarine cable filling strips is completed, production is convenient, the production efficiency is high, and meanwhile material waste caused by processing is avoided.

Owner:吴江市欧达塑业有限公司

Aluminum profile extrusion die sleeve

PendingCN110000235AImprove machining accuracyReduce displacementExtrusion diesEngineeringCirculating pump

The invention discloses an aluminum profile extrusion die sleeve. The aluminum profile extrusion die sleeve comprises a bottom plate, wherein an upper die block is fixedly arranged at the output end of a telescopic air cylinder, a lead screw is movably arranged on the side, close to a cross beam, of the upper die block in a penetrating mode, a nut seat is movably arranged on the lead screw in a penetrating mode, triggering rods are symmetrically and fixedly arranged on the side, close to the bottom plate, of the nut seat, a forming die pressing block is fixedly arranged on the side, close to the bottom plate, of the upper die block, a model groove and clamping angles are correspondingly formed in the side, close to the forming die pressing block, of a lower die block, air cylinder stoppingbuttons and circulating pump starting assemblies are correspondingly arranged in grooves, a cooling water tank is provided with a lower die water inlet pipe in a communicating mode, and a lower circulating pump is arranged on the lower die water inlet pipe. According to the aluminum profile extrusion die sleeve, when the thickness requirements of formed aluminum materials are different, the modelposition can be finely adjusted, circulating pumps can be automatically started after the aluminum materials are extruded, an aluminum profile is cooled through condensed water, so that cooling forming is accelerated, and the production efficiency is effectively improved.

Owner:安徽安铝科技发展有限公司

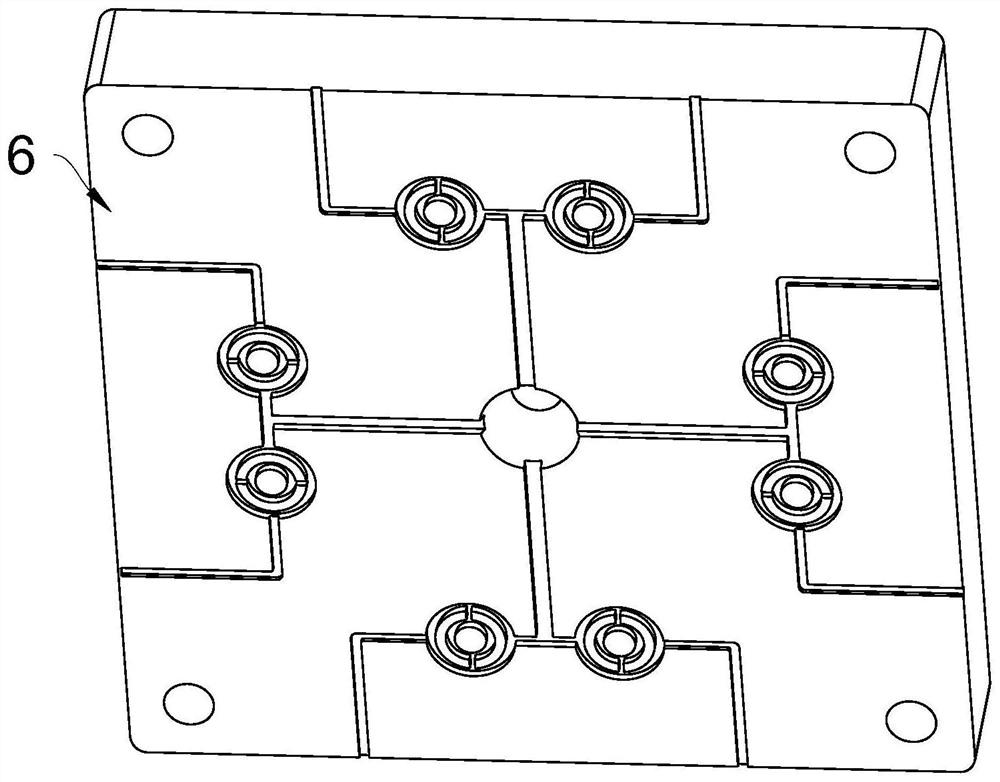

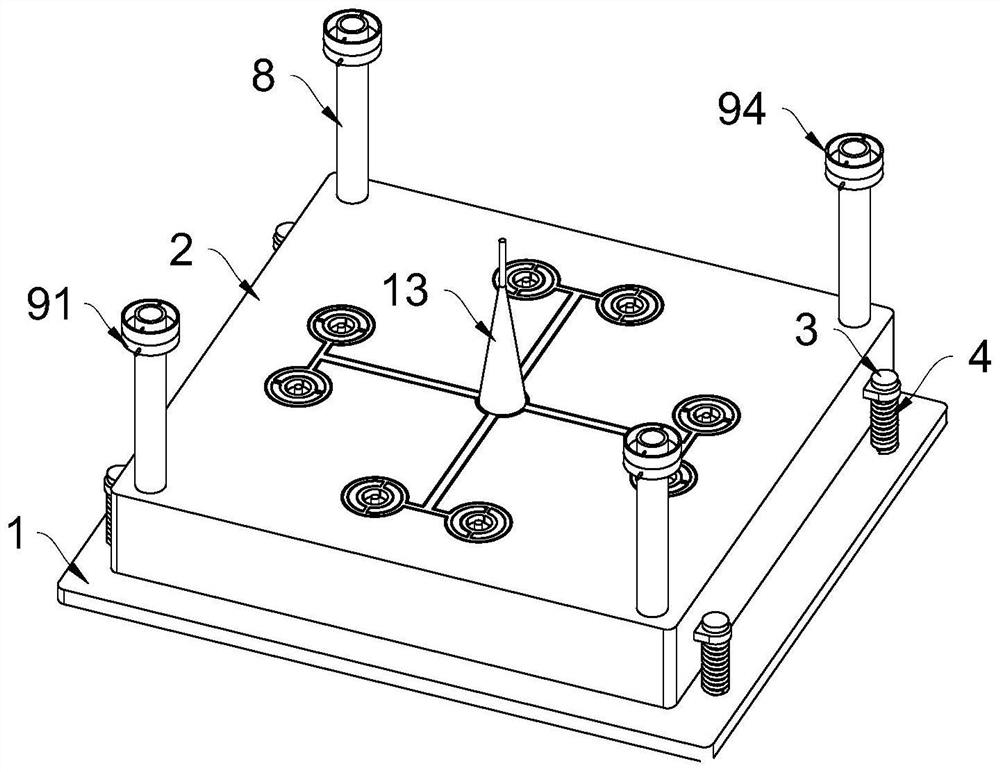

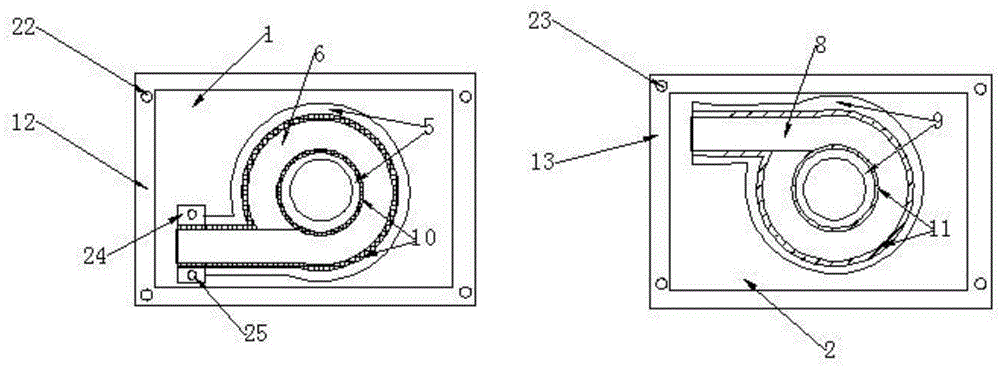

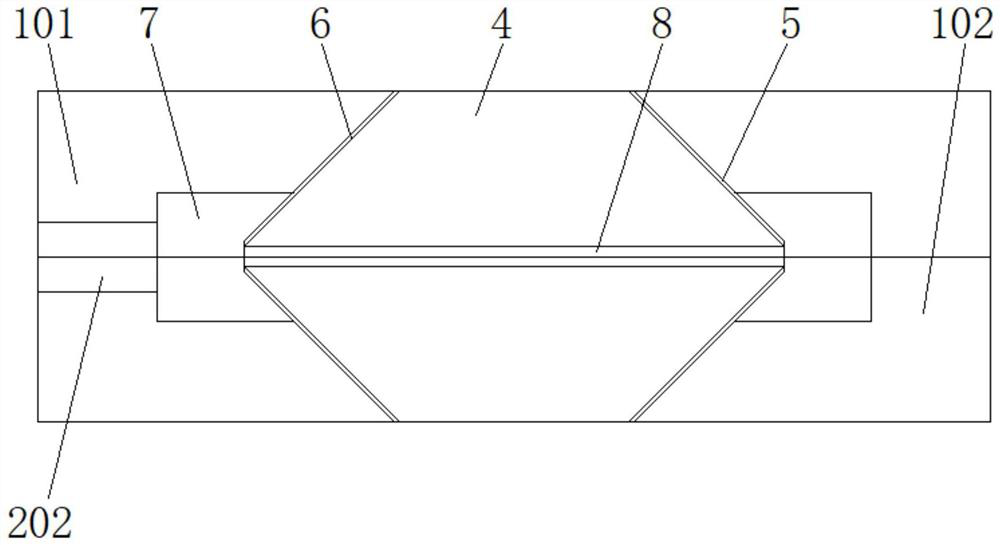

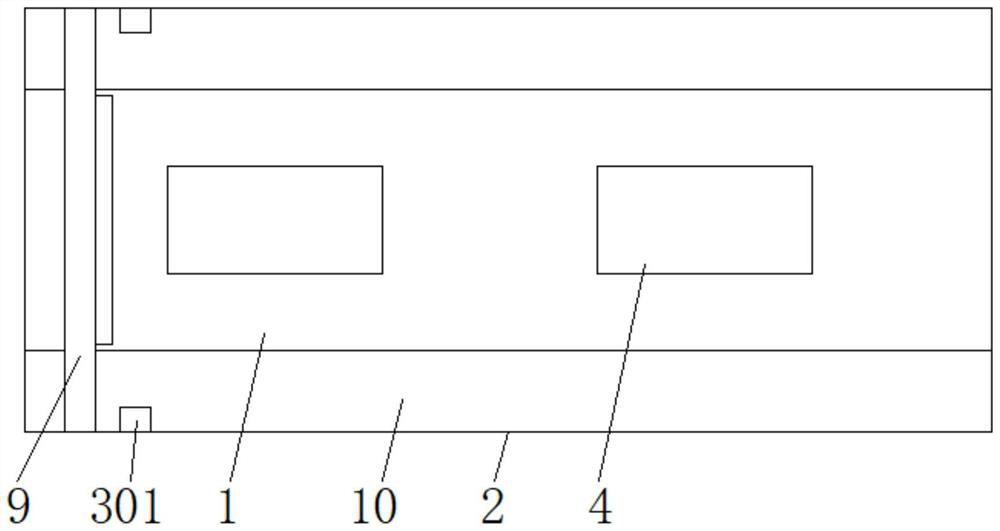

Cross double-channel lens barrel mold structure and forming method thereof

ActiveCN114734582AImprove consistencyImprove injection molding efficiencyGlass productionAdhesive glueStructural engineering

The invention belongs to the technical field of lens cone molds, and particularly relates to a cross-shaped double-flow-channel lens cone mold structure which comprises a base, a lower mold plate is arranged at the top of the base, two fixing plates are fixedly connected to the two sides of the lower mold plate correspondingly, sliding rods are inserted into the fixing plates in a sliding and penetrating mode, and the sliding rods are fixedly connected with the base. The part, located at the bottom of the fixing plate, of the sliding rod is sleeved with a first spring, and a containing groove is formed in the bottom of the lower die plate. In the injection molding process, after injection molding glue enters the glue inlet pipe, due to the fact that the distances from the main injection molding pipe to the branch pipes are the same, the time and pressure of the injection molding glue entering all the first annular pipes are the same, and therefore the consistency of products can be conveniently improved; and then the injection molding glue entering the first annular pipe simultaneously enters the second annular pipe through the two symmetrical connecting pipes located on the outer side of the second annular pipe, so that compared with a traditional injection mold arranged in a straight line, the injection molding efficiency is improved.

Owner:HUBEI HUAXIN PHOTOELECTRIC CO LTD

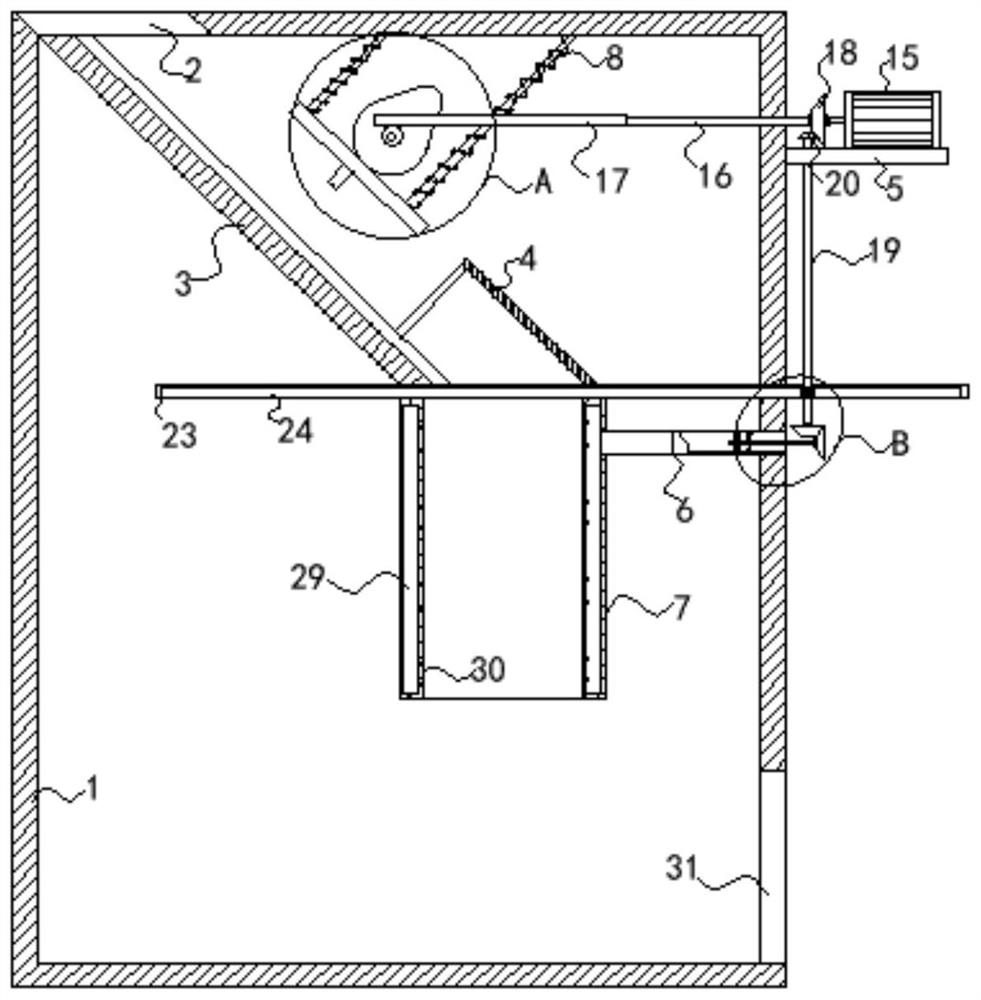

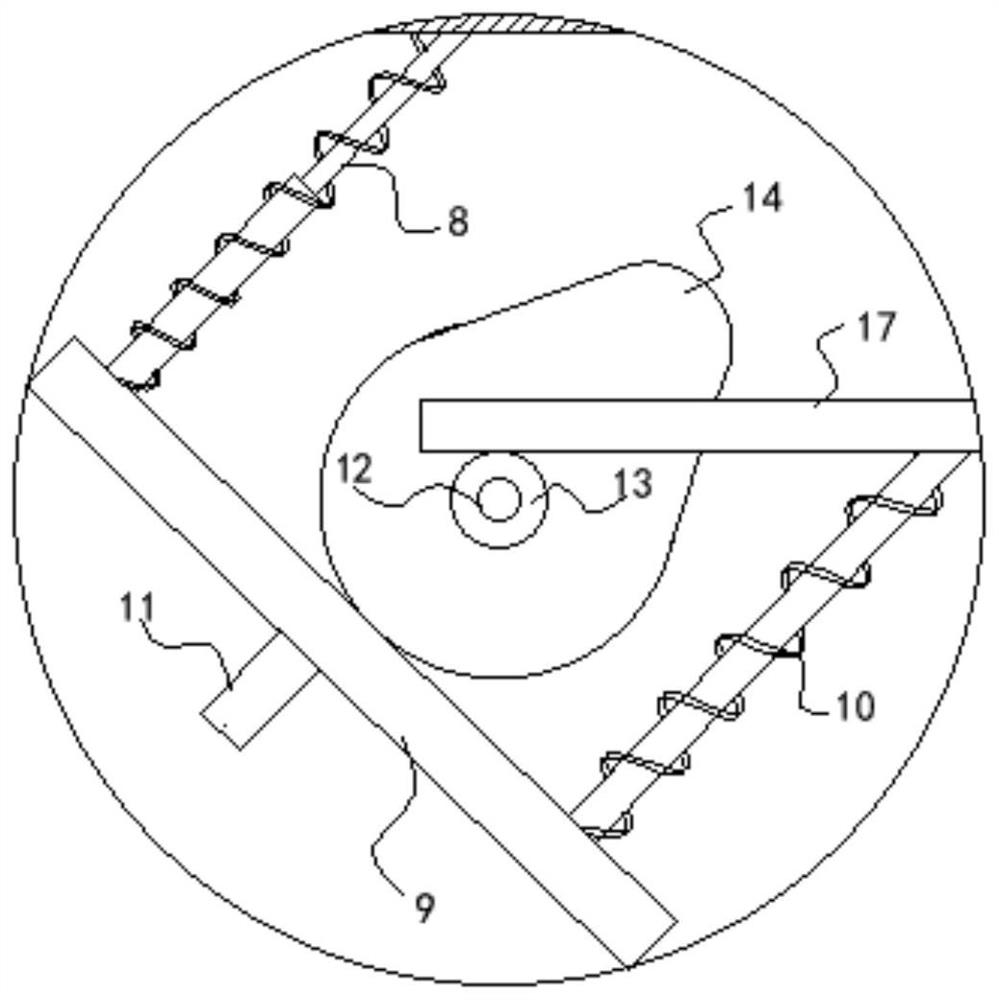

Sealing device for packaging of lithocarpus litseifolius sweet tea

InactiveCN111846451AImprove convenienceImprove efficiencyWrapper twisting/gatheringEngineeringSliding contact

The invention discloses a sealing device for packaging of lithocarpus litseifolius sweet tea. The sealing device comprises a box body, wherein a feeding opening is formed in the top surface of the boxbody; a material guiding plate which is obliquely arranged is mounted in the box body, and is located under the feeding opening; a protective cover is fixedly connected to the material guiding plate;a sealing mechanism with an elastic function is fixedly connected to the top surface of the box body; a cam mechanism for driving the sealing mechanism is rotatably arranged in the box body; a horizontal plate is fixedly connected to a side wall of the box body; a driving mechanism is arranged on the horizontal plate, rotatably penetrates through the side wall of the box body, and is in transmission connection with the cam mechanism; a transmission mechanism is rotatably arranged on the horizontal plate; a supporting mechanism is arranged on the side wall of the box body in a sliding and penetrating manner; and the upper end of the supporting mechanism is in sliding contact with the material guiding plate and the lower end of the protective cover. Through the sealing device disclosed by the invention, tea bags are convenient to seal, and the sealing efficiency is improved favorably; and in addition, the sealed tea bags can also be effectively cooled, so that quick cooling and shapingof sealing are facilitated.

Owner:重庆华丛农业科技有限公司

Radiator metal die facilitating heat dissipation

The invention discloses a radiator metal die facilitating heat dissipation. The radiator metal die includes a bottom plate, a lower die, cooling pipes, injection molding branch pipes, an upper die, acoolant storage tank and a delivery pump, wherein a bracket is mounted at the lower part of the bottom plate; the lower die is mounted at the upper part of the bottom plate; a lower injection moldinggroove is arranged on the lower die; a cooling pipe is mounted inside the lower die; the injection molding branch pipes are mounted between the cooling pipes, and mutually communicate with an injection molding pipe; the lower end of the injection molding pipe penetrates through the bottom plate so as to be fixedly connected with a pipeline connector; the upper die is mounted at the upper part of the lower die; an upper injection molding groove is formed in the upper die; the cooling pipe is mounted inside the upper die; and the coolant storage tank is mounted on the bottom plate on the left side of the lower die. The invention aims to provide the radiator metal die facilitating heat dissipation, the heat dissipation speed of the mold is high, the efficiency is high, the forming speed of aproduct is quickened, and the production speed and efficiency are greatly improved.

Owner:张志凤

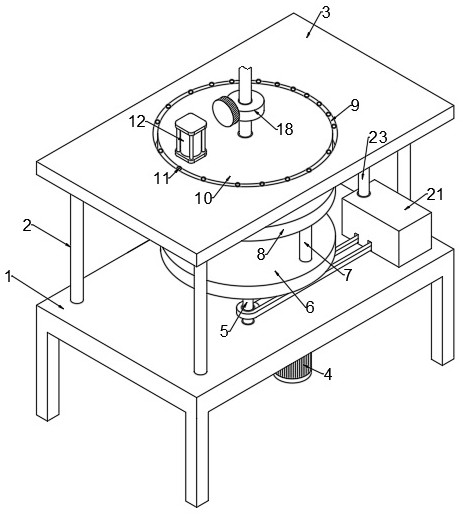

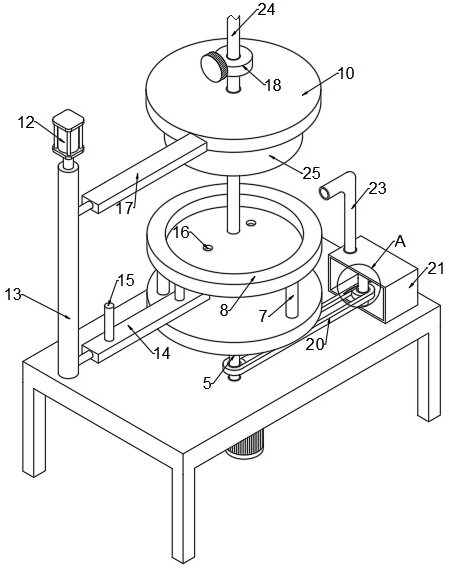

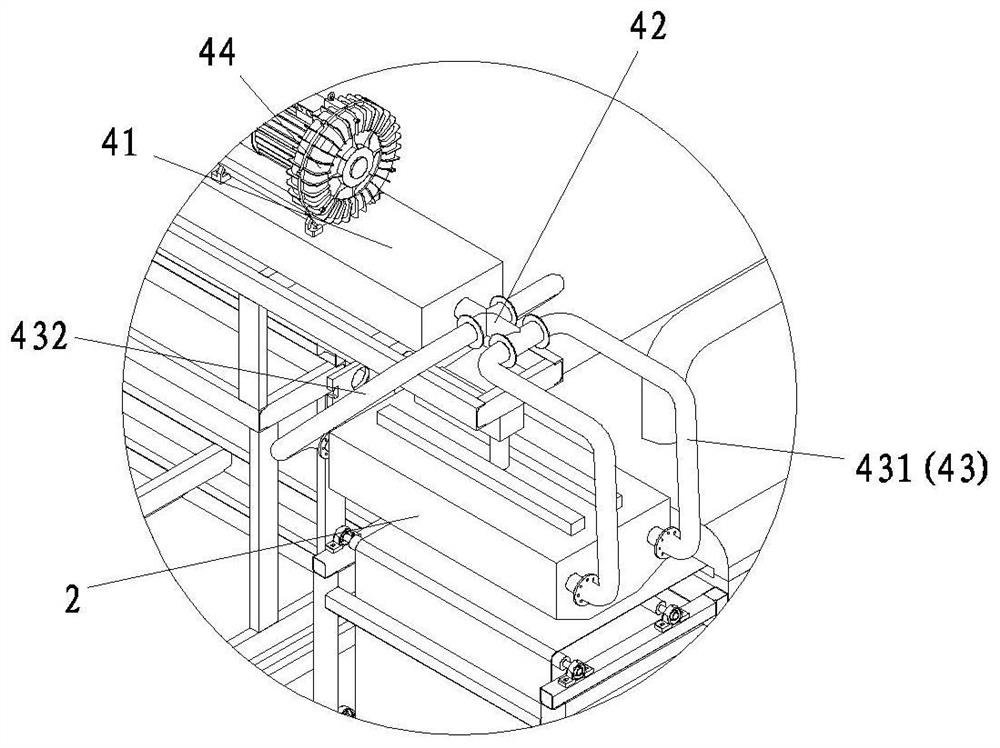

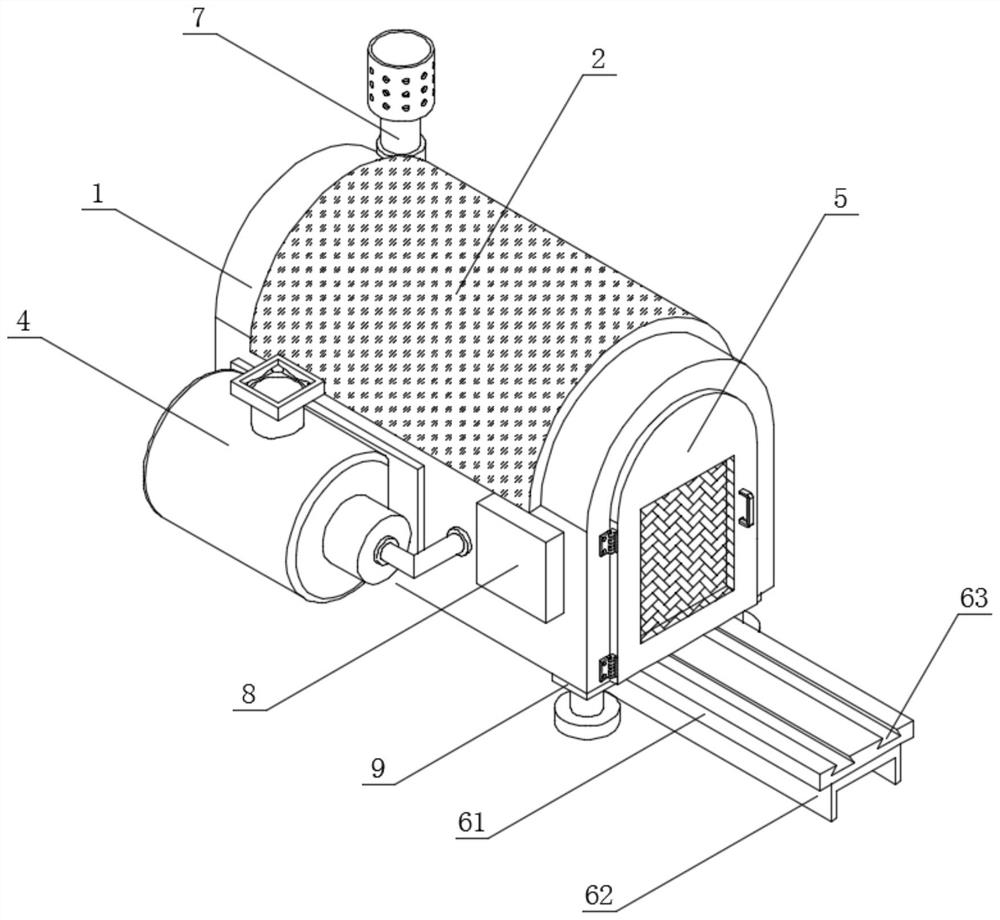

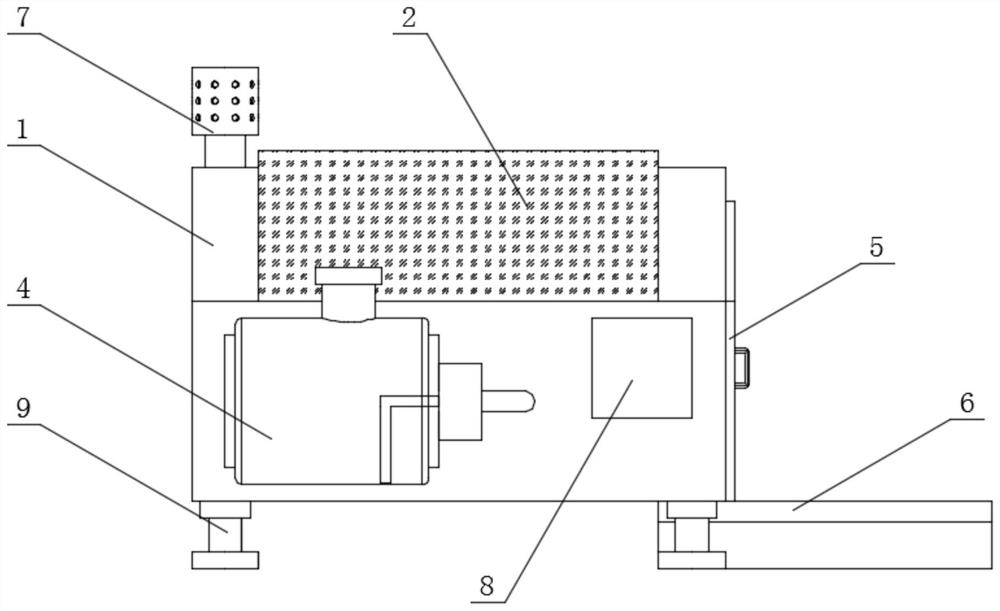

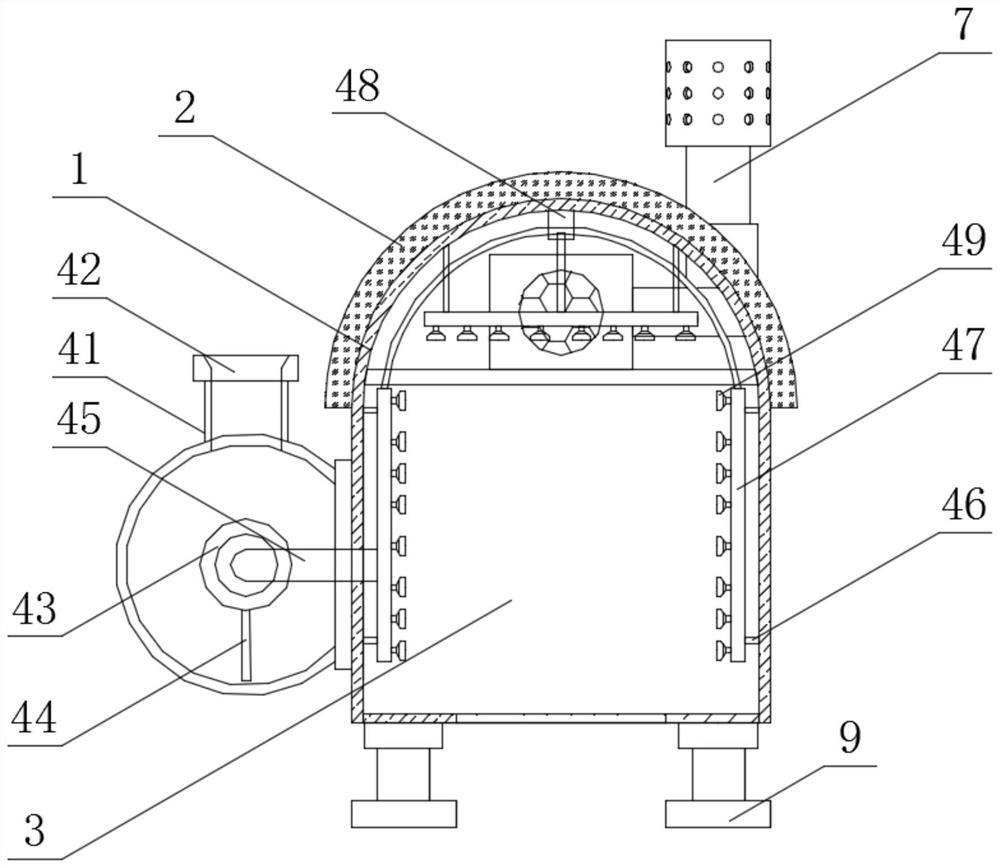

A paint spraying device for wheel hub processing

The invention discloses a paint spraying device for hub machining. The paint spraying device comprises a support frame, a shell is fixedly installed on the top of the support frame, a sliding rail is arranged in the shell, the two ends of the sliding rail both extend to the outer side of the shell, and a containing plate is fixedly installed on the top of the sliding rail; a storing box is fixedly installed on the top of the shell, a feeding pipe is fixedly installed on a left side plate of the storing box, a motor is fixedly installed on the top of the storing box, a rotation shaft of the motor penetrates through a top plate of the storing box and extends into the storing box, and a stirring shaft is connected to the end, located in the storing box, of the rotation shaft of the motor in a transmission mode through a coupler. According to the paint spraying device for hub machining, by arranging a cooling box on the top of the shell, cooling air can be generated in the working process, a hub obtained after paint spraying is cooled, therefore, paint spraying molding can be sped up, the natural cooling time can be shortened, and the working efficiency can be improved.

Owner:沙迪克南通机电科技有限公司

Mold for manufacturing turbocharger

InactiveCN105598393AImprove efficiencyLow costFoundry mouldsFoundry coresBody coolingMaterials science

The invention provides a mold for manufacturing a turbocharger. The mold comprises an upper mold body, a lower mold body, a base, a feed port, an upper mold body cooling interlayer, an upper mold body cavity, a mold core, a lower mold body cavity, a lower mold body cooling interlayer, an inserting plate, an inserting plate groove, an upper mold body fixing edge, a lower mold body fixing edge, fixing screws, nuts and a cooling thermostat; the lower mold body is arranged on the base, the mold core is arranged on the lower mold body, the upper mold body is arranged on the mold core, the feed port is formed in the upper end of the upper mold body, the upper mold body fixing edge is fixedly arranged on the outer edge of the upper mold body, the upper mold body cavity is formed in the upper mold body, the inserting plate is arranged on the outer edge of the upper mold body cavity, the upper mold body cooling interlayer is arranged on the outer edge of the inserting plate, the lower mold body fixing edge is fixedly arranged on the outer edge of the lower mold body, the lower mold body cavity is formed in the lower mold body, the inserting plate groove is formed in the outer edge of the lower mold body cavity, the lower mold body cooling interlayer is arranged on the outer edge of the inserting plate groove, and the cooling thermostat is arranged below the base. The mold has the advantages of being high in efficiency, low in cost and good in product quality.

Owner:TIANJIN RUIPU TIANSHENG AUTO PARTS MFG

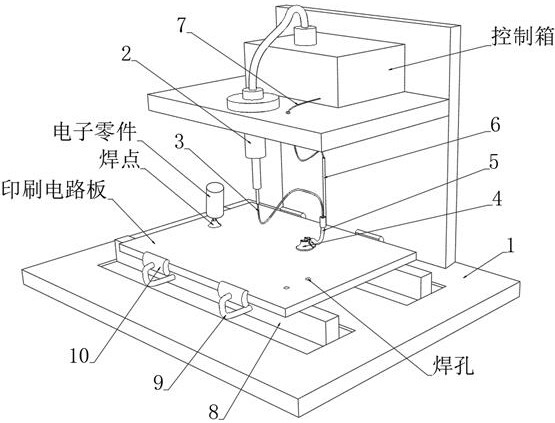

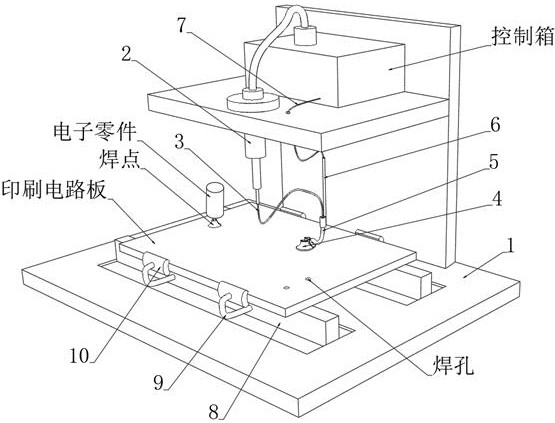

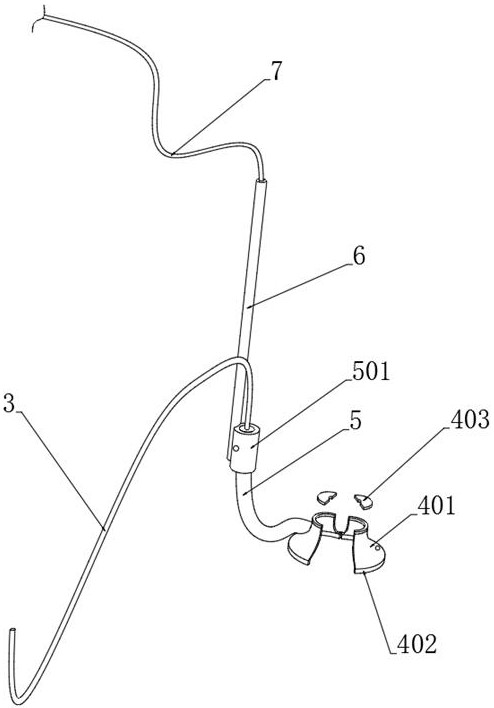

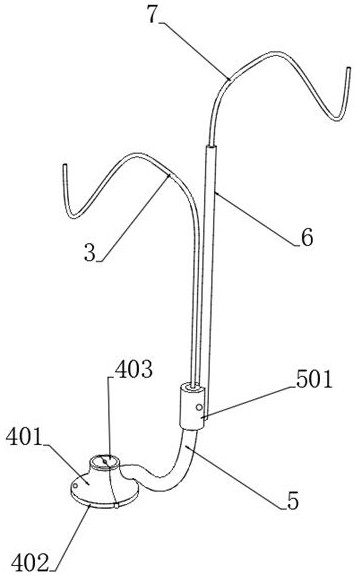

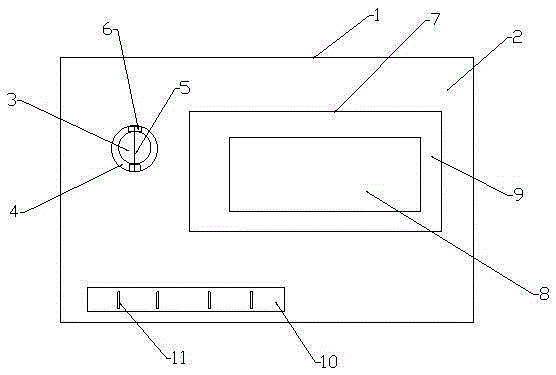

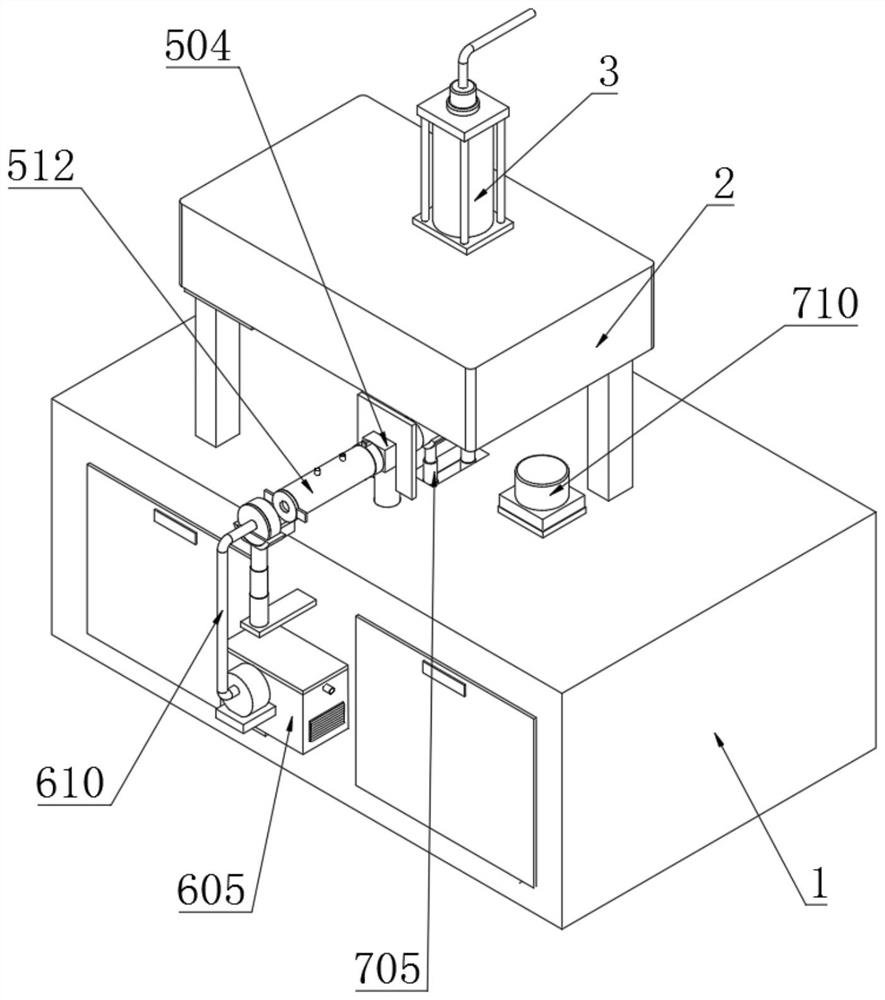

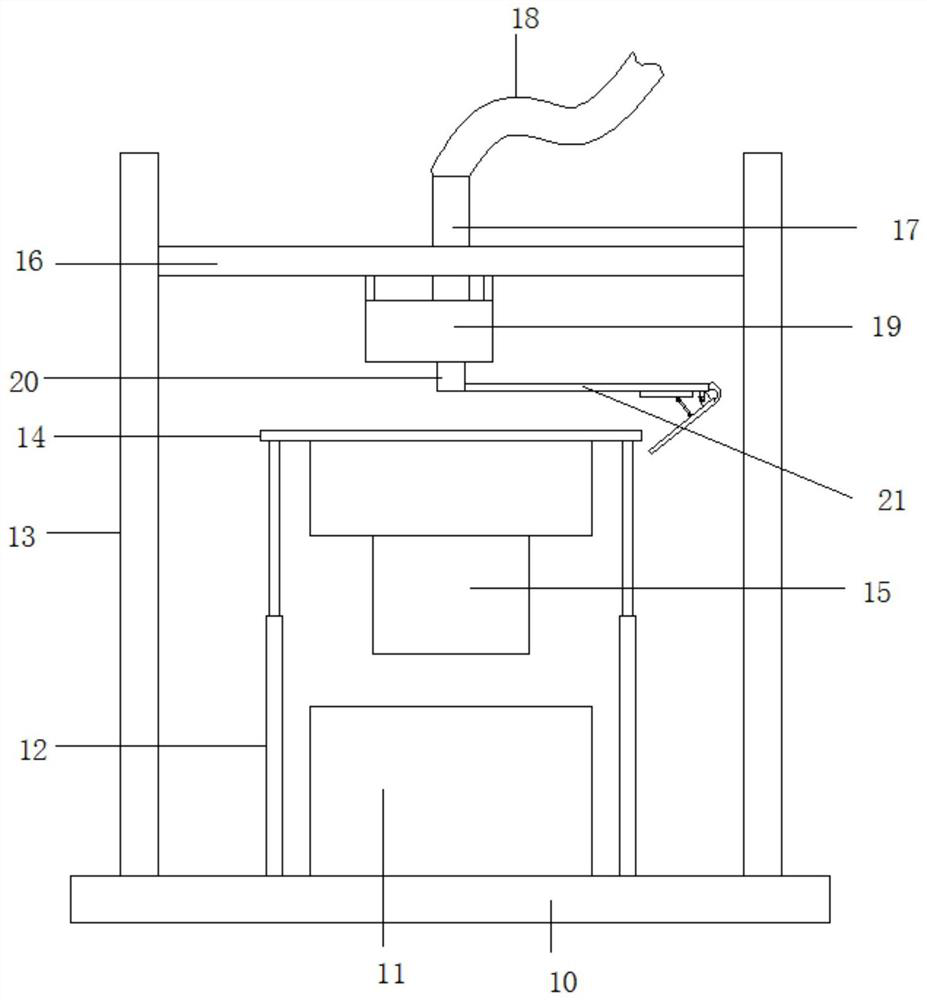

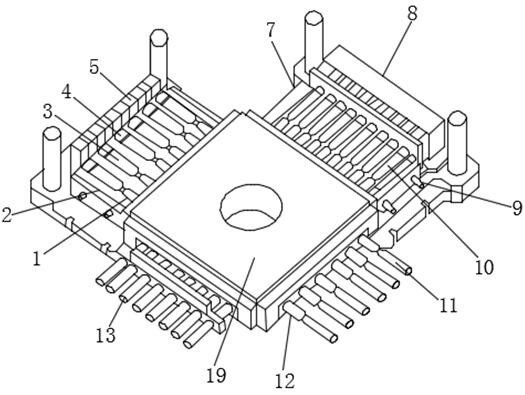

Welding equipment of printed circuit board for electrical element manufacturing

ActiveCN113369628APromote meltingSpeed up cooling and formingPrinted circuit assemblingMetallurgical bondingSolder pasteManufacturing engineering

The invention discloses welding equipment of a printed circuit board for electrical element manufacturing, and belongs to the technical field of welding and manufacturing of electronic parts and printed circuit boards. According to the welding equipment of the printed circuit board for the electrical element manufacturing, a mold disc is arranged at the other end of a spray pipe, the mold disc is composed of a pair of horn-shaped mold petals connected in a rotating mode, and before welding, the mold disc is placed at a welding hole punched in advance and is in complete butt joint with the welding hole; a feeding gun is matched with the spray pipe to inject a proper amount of solder paste into a bonding pad cavity of the mold disc, then a semiconductor chilling plate is matched with a heat conduction pipe to heat the mold disc, the solder paste is promoted to be fused to form a welding spot, then the semiconductor chilling plate is used for refrigerating the mold disc so as to promote cooling forming of the welding spot, fusion and cooling operation can be achieved in the welding process, operation is simple, the mold disc is used as a welding template, fixed-point forming of the solder paste is promoted, the phenomena of pseudo soldering and outward protrusion caused by excessive solder are not prone to being caused, formed welding spots are independent, bridging of the welding spots is not prone to being caused, and welding quality is improved.

Owner:HAIMEN PURPLE PRINTING MACHINERY

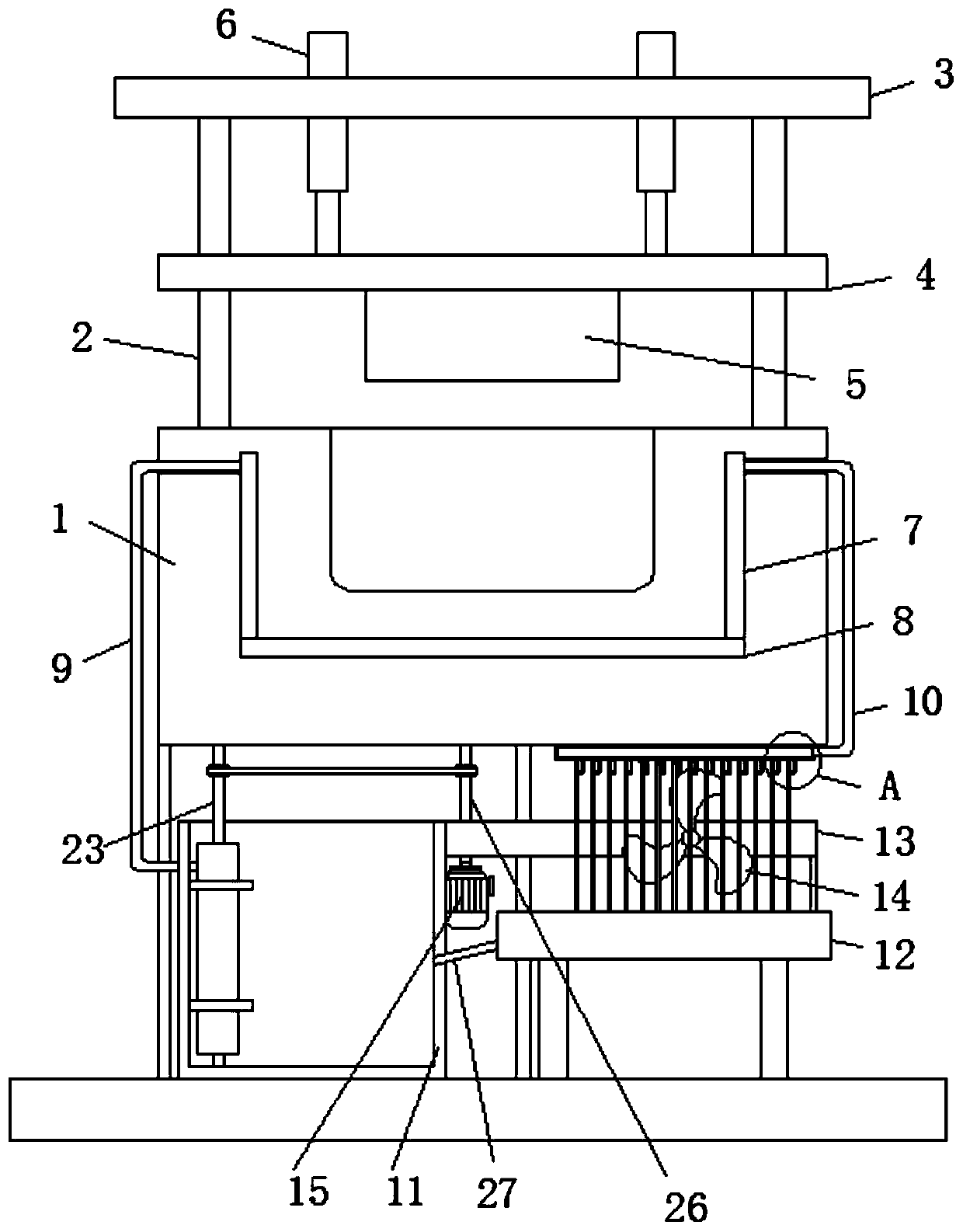

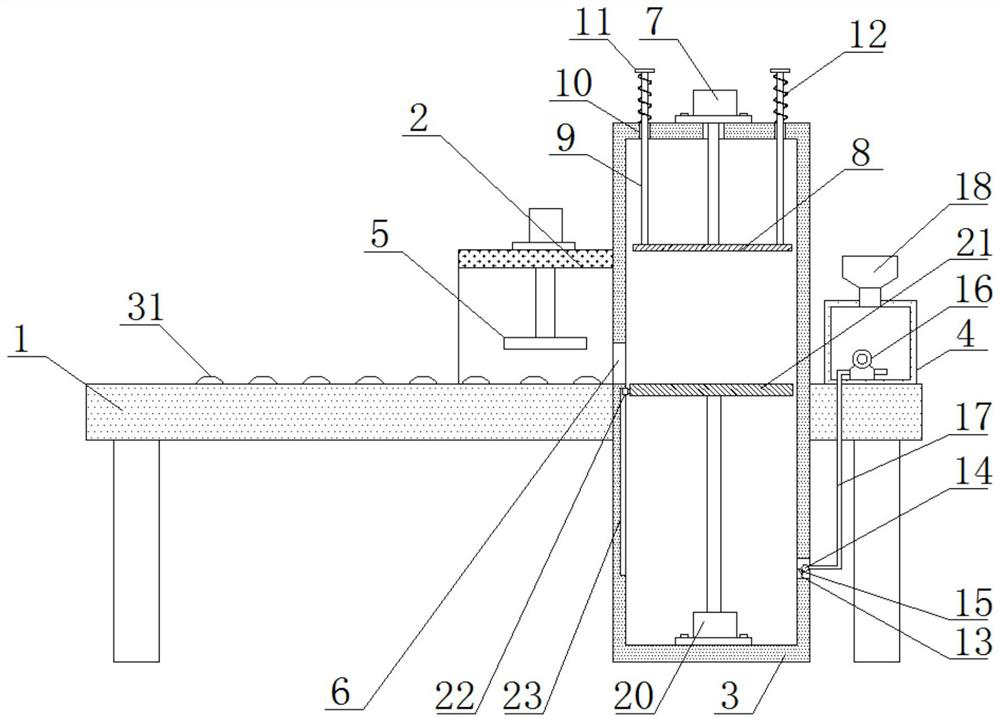

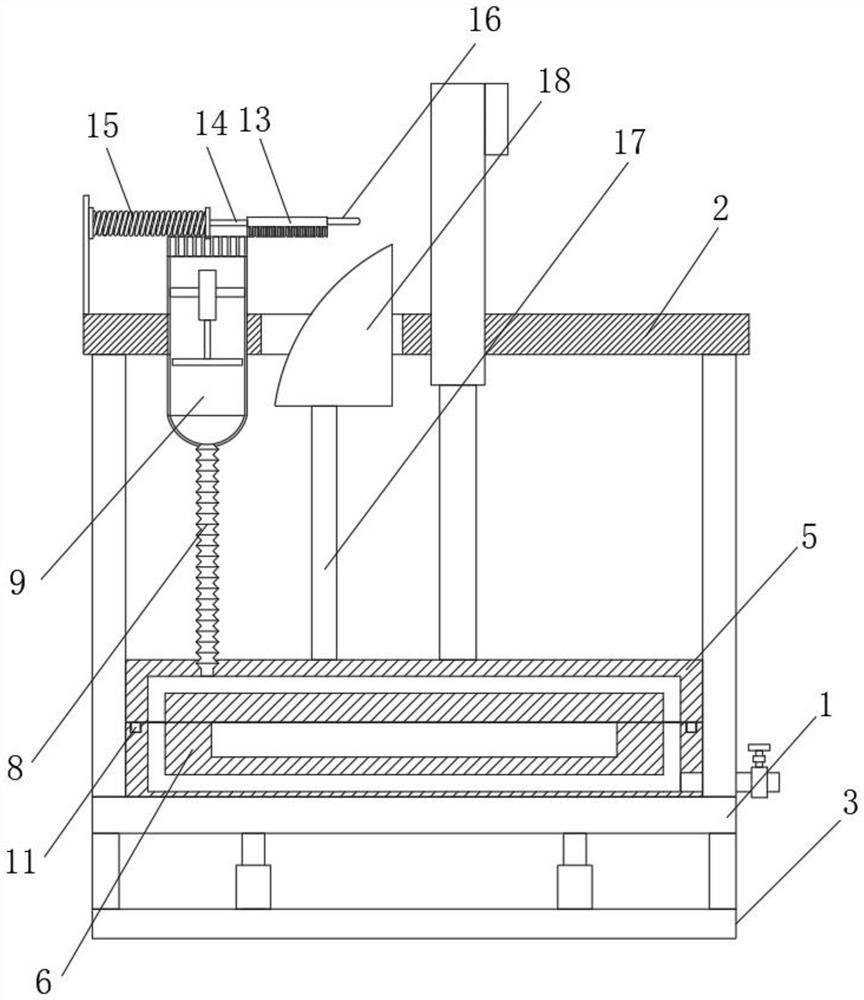

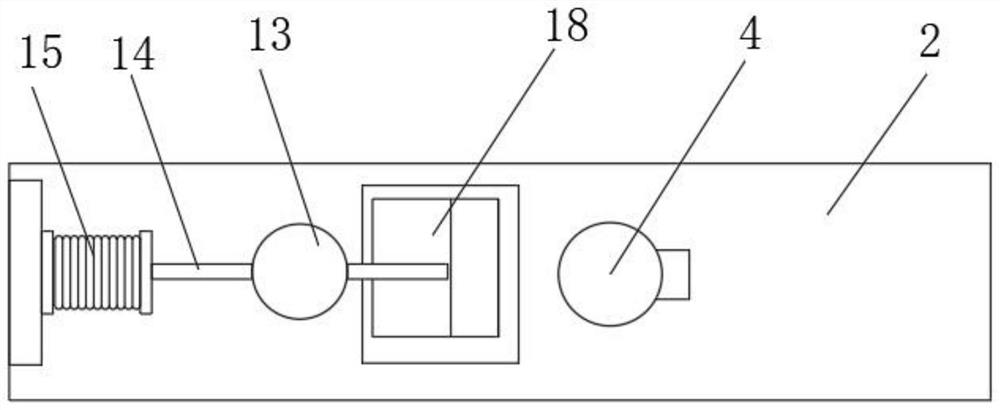

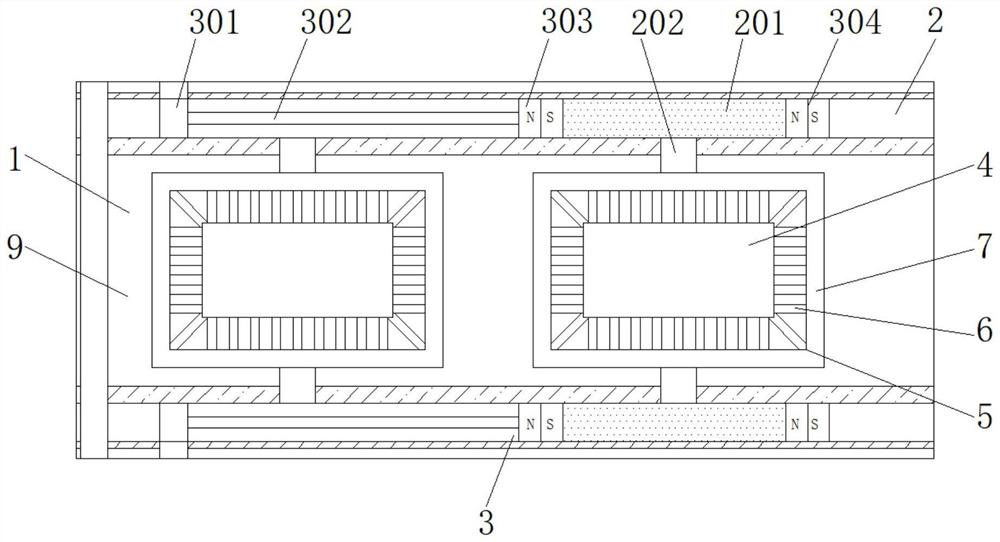

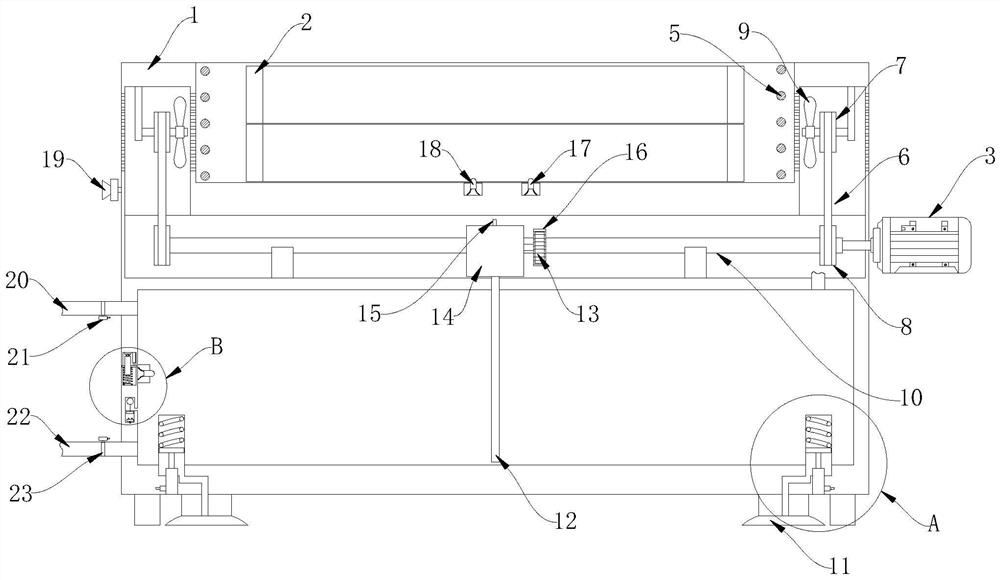

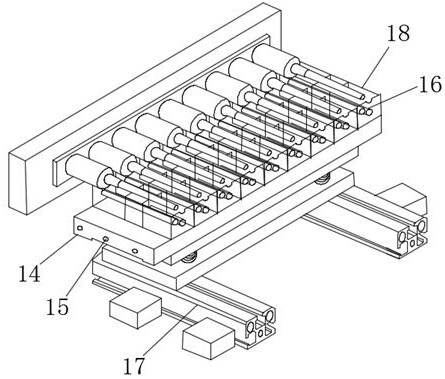

Flattening equipment for steel plate machining

PendingCN112808793ASpeed up cooling and formingImprove work efficiencyShaping toolsStructural engineeringElectromagnetic heating

The invention relates to the technical field of steel plate machining, and discloses flattening equipment for steel plate machining. The flattening equipment for steel plate machining comprises an operation table, a fixing frame and a water tank are fixedly mounted on the upper surface of the operation table, a shell penetrates through and is fixedly mounted on the upper surface of the operation table, the water tank is arranged on the right side of the shell, and the right side of the fixing frame is fixedly connected with the upper end of the left side of the shell. A PLC controller controls an electromagnetic heater to work to heat a steel plate, the heated steel plate is conveyed to a supporting plate in the shell through a first through groove, a first air cylinder is controlled to work, a pressing plate can be pushed to move downwards to flatten the steel plate on the supporting plate, a second air cylinder is controlled to work, the supporting plate can be driven to move downwards, a water pump is controlled to work, water is sprayed to the surface of the steel plate through a nozzle communicating with a through pipe, cooling forming of the steel plate can be accelerated, an electric-hydraulic pusher is controlled to work, the steel plate can be pushed to move to a conveying table, and the working efficiency is high.

Owner:徐州中厚机械科技有限公司

Soldering equipment for printed circuit boards for the manufacture of electrical components

ActiveCN113369628BPromote meltingSpeed up cooling and formingPrinted circuit assemblingMetallurgical bondingSolder pasteSemiconductor

Owner:HAIMEN PURPLE PRINTING MACHINERY

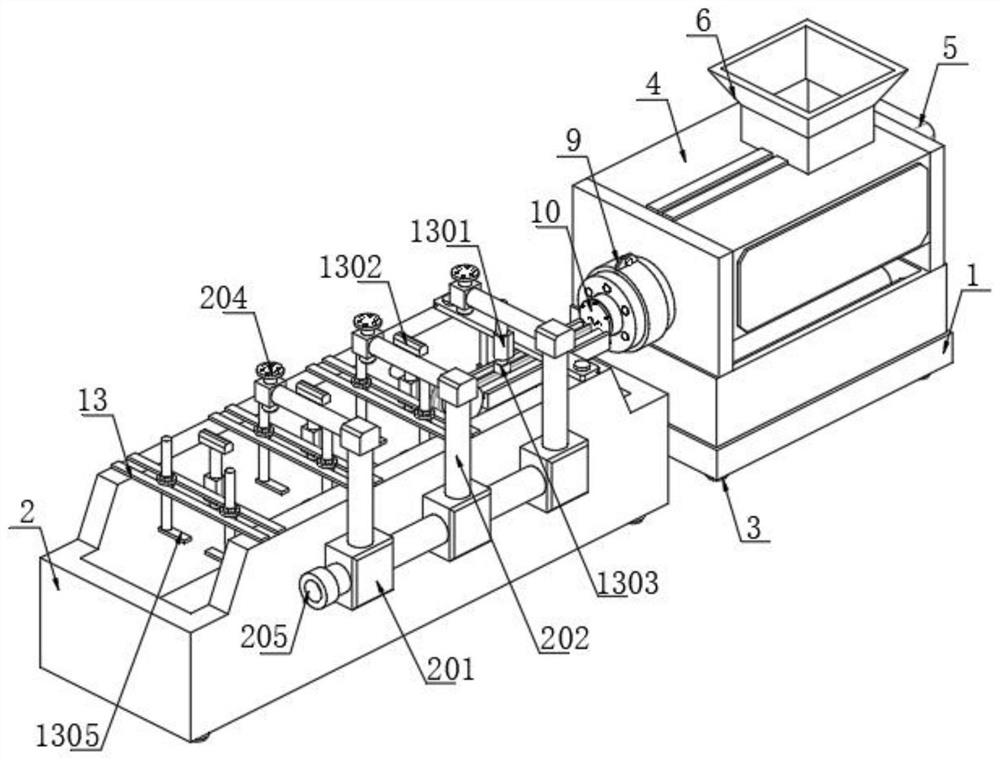

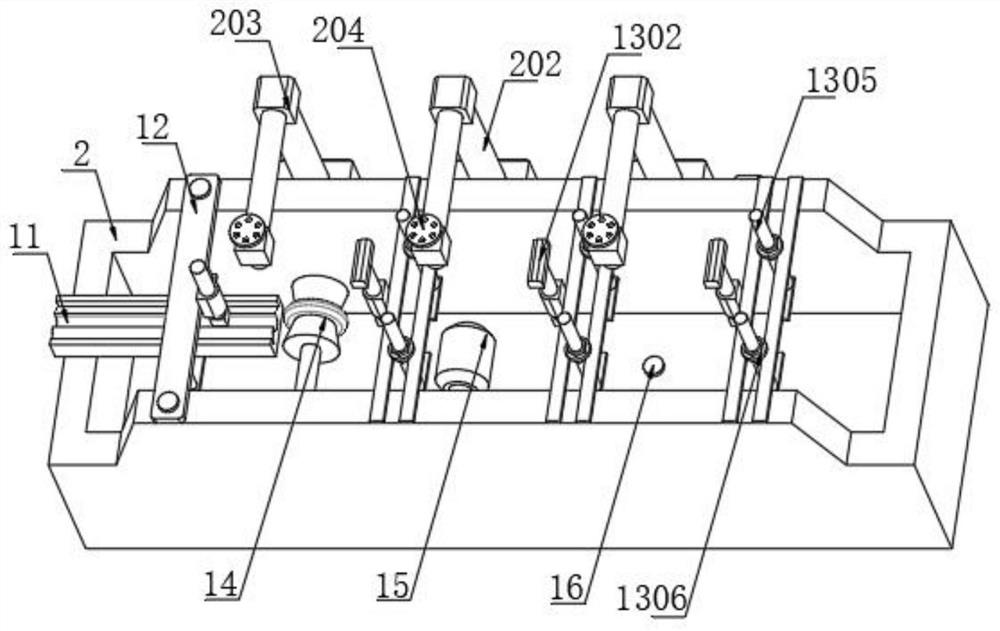

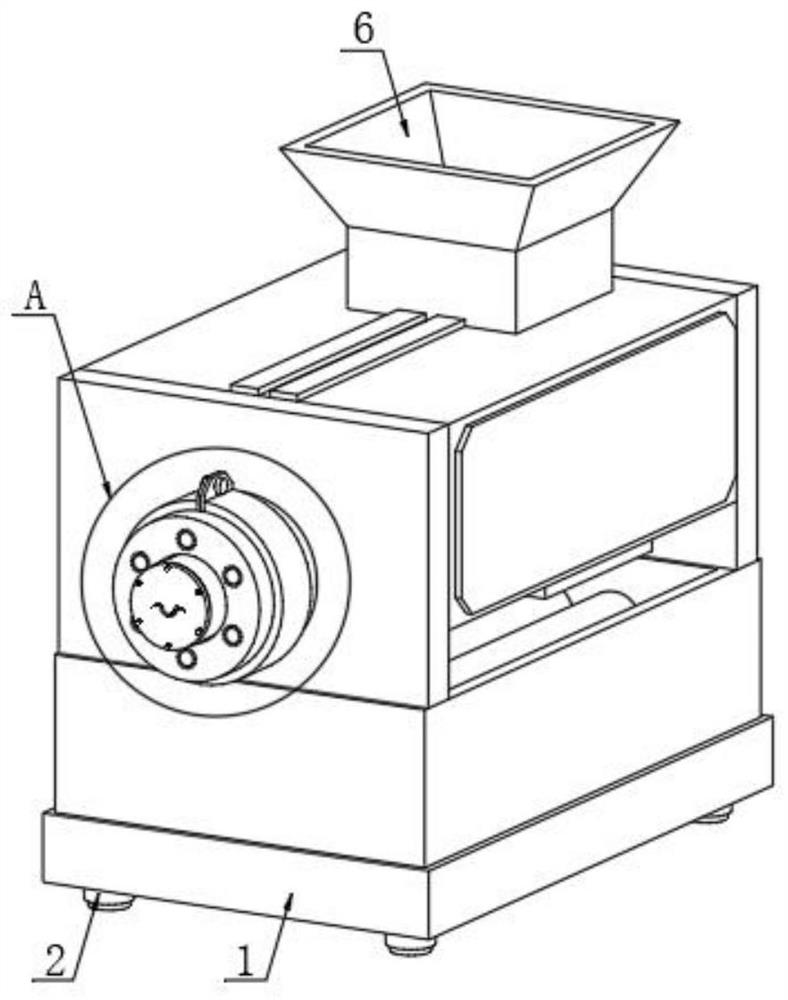

Injection molding jig for notebook computer outer shell

Owner:SUZHOU YUANSHUO PRECISION MOLD

Environment-protecting efficient heat dissipation injection mold

InactiveCN112092320ATo achieve a closed effectAvoid accumulationFouling preventionDispersed particle filtrationCold airThermodynamics

The invention relates to the technical field of injection molds, and particularly discloses an environment-protecting efficient heat dissipation injection mold. The environment-protecting efficient heat dissipation injection mold comprises a base, wherein a support is fixedly connected to the left side and the right side of the top face of the base, and an ejection mechanism is fixedly connected to the bottom face of the base; a hydraulic rod is fixedly connected to the top face of the support, an upper mold base is fixedly connected to the bottom end of the hydraulic rod, and a lower mold base is fixedly connected to the top face of the base; and a mold cavity is formed in the top face of the lower mold base, and cavities are formed inside the upper mold base and the lower mold base. According to the environment-protecting efficient heat dissipation injection mold, an air cooler is arranged on the support, and meanwhile, an air inlet pipe is arranged in a matched mode so that the cavities in the upper mold base and the lower mold base can be inflated through the air cooler, the interiors of the cavities are filled with cold air, then the mold cavity is located in a low-temperatureenvironment, the effect of cooling raw materials inside the mold cavity is achieved, and cooling molding of the raw materials is accelerated.

Owner:中山市泽一照明科技有限公司

Steel plate type solder paste printing mold for SMT (Surface Mount Technology)

InactiveCN114449783AAvoid stickingPrevent short circuitsPrinted circuit assemblingSolder pasteSurface-mount technology

The invention relates to the technical field of SMT elements, and discloses a steel plate type solder paste printing mold for SMT patching, which comprises a printing plate body, a tin liquid groove is formed in the outer wall of the printing plate body, a printing scraper blade is slidably connected to the surface of the printing plate body, the printing plate body comprises an upper plate body and a lower half body, and the upper half body and the lower half body are arranged in the printing plate body. And the upper plate body and the lower half body have the same structure and are symmetrically arranged. According to the printing plate, the edge liquid groove is formed in the periphery of the tin liquid groove of the printing plate body, a solidified scaling powder layer is formed on the outer wall of the tin liquid groove in cooperation with the liquid ring cavity, the liquid separating opening and the liquid transferring thin groove, the scaling powder layer is used for separating tin liquid paste from the outer wall of the tin liquid groove, and therefore the tin liquid paste is prevented from being attached to the outer wall of the tin liquid groove; and by utilizing the characteristic that the soldering flux can absorb heat to evaporate, a gap can be formed between the tin liquid paste and the outer wall of the tin liquid tank after the soldering flux absorbs the heat of the tin liquid paste to evaporate, so that the problem that the printing plate body is adhered to the tin liquid paste during demolding is avoided.

Owner:梁芷欣

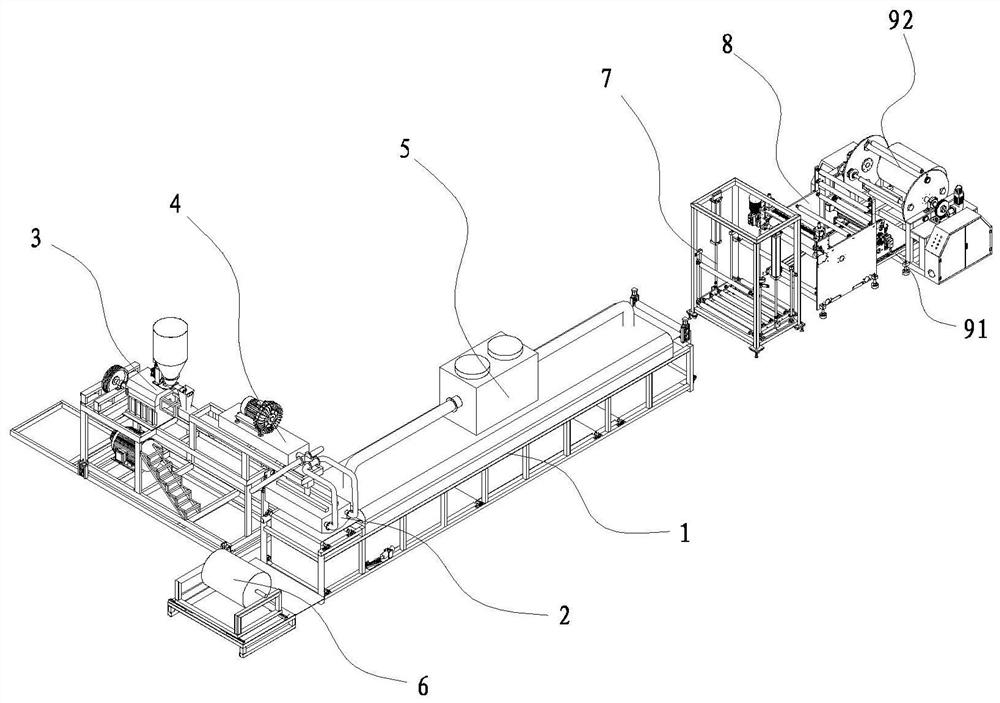

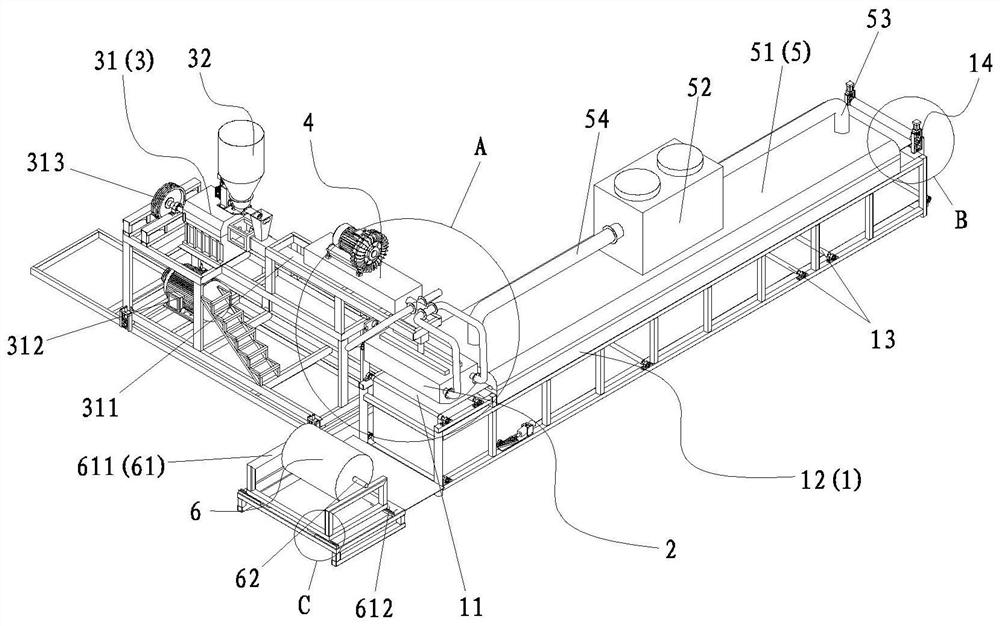

Adhesive applying fabric, setting fabric, processing equipment and processing method

InactiveCN112853621AImprove breathabilityImprove comfortFilm/foil adhesivesFilament/thread formingHot air ovenHot blast

The invention discloses an adhesive applying fabric. The adhesive applying fabric comprises a base fabric layer and an adhesive layer, wherein the adhesive layer comprises staggered adhesive threads and air holes formed among the adhesive threads, and has relatively good air permeability. The invention further discloses a setting fabric. The setting fabric comprises the adhesive applying fabric. The breathable performance of shoe and clothes products is improved, and the shoe and clothes products are more comfortable to wear. The invention further discloses processing equipment. The processing equipment comprises a conveying mechanism, a melt-blowing mechanism and a winding mechanism, wherein the melt-blowing mechanism comprises a melt-blowing mold, an extrusion device and a hot blast stove; the melt-blowing mold is provided with a melt-blowing nozzle; the extrusion device conveys materials into the melt-blowing mold; and the hot blast stove conveys hot air to the melt-blowing mold. The processing equipment can improve the fluidity of the materials, so that the materials can be conveniently sprayed out by the melt-blowing mold, and the melt-blowing efficiency and the melt-blowing quality are improved. The invention further provides a processing method. The processing method comprises the following steps of conveying the base fabric layer; melting the materials; extruding the materials; heating the materials; melt-blowing the materials to the base fabric layer; performing cooling; and performing drawing, cutting and winding. The air permeability and the production efficiency of the setting fabric are improved.

Owner:泉州安力鞋服有限公司

Mold for producing plastic medicine bottle

PendingCN114683485AImprove thermal conductivitySpeed up cooling and formingEngineeringDrainage tubes

The mold for producing the plastic medicine bottle comprises an upper mold body and a lower mold body, a mold cavity is formed in the lower mold body, threads are arranged at the bottom of the side face of the inner wall of the mold cavity, a middle column is fixedly connected to the middle of the bottom of the inner wall of the mold cavity, a cooling cavity is formed in the middle column, and a partition plate is fixedly connected to the middle of the cooling cavity; a water drainage cavity is formed in the partition plate, a water drainage hole is formed in the top of the water drainage cavity and communicates with the cooling cavity, the bottom of the cooling cavity communicates with a water inlet pipe, the bottom of the water drainage cavity communicates with a water drainage pipe, a mounting groove is formed in the lower mold, and a water injection pipe and a backflow pipe are arranged in the mounting groove; the invention relates to the technical field of plastic bottle production. According to the mold for producing the plastic medicine bottle, the problems that an existing mold for producing the plastic bottle does not have good cooling measures, the time needed by cooling forming is long, and the working efficiency is low are solved.

Owner:安徽华康药品包装有限公司

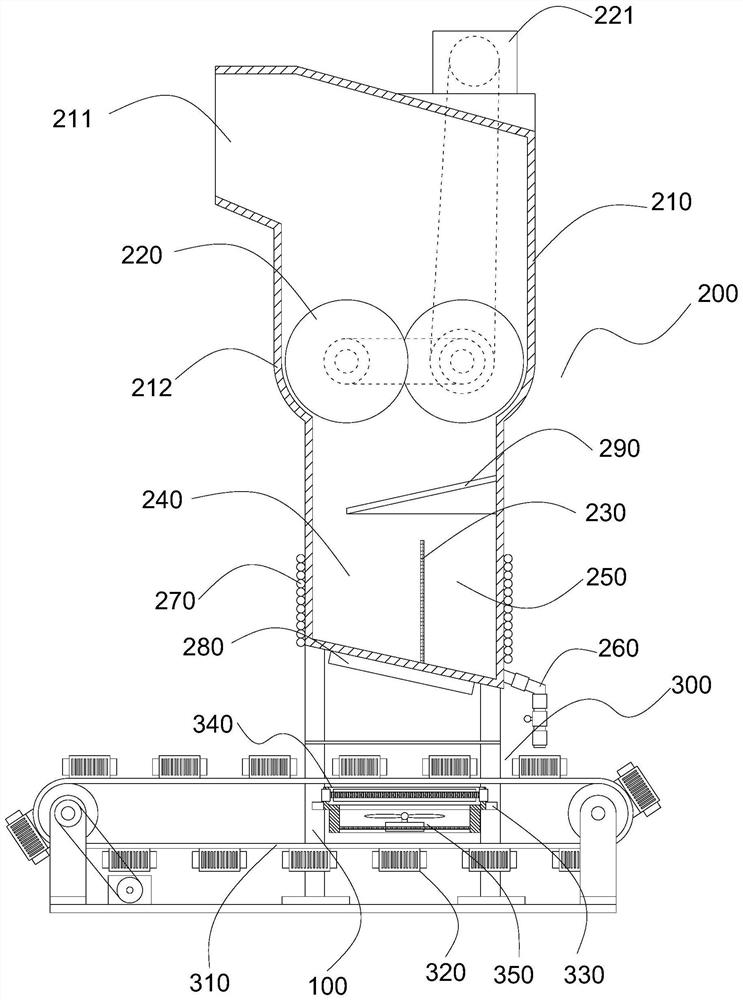

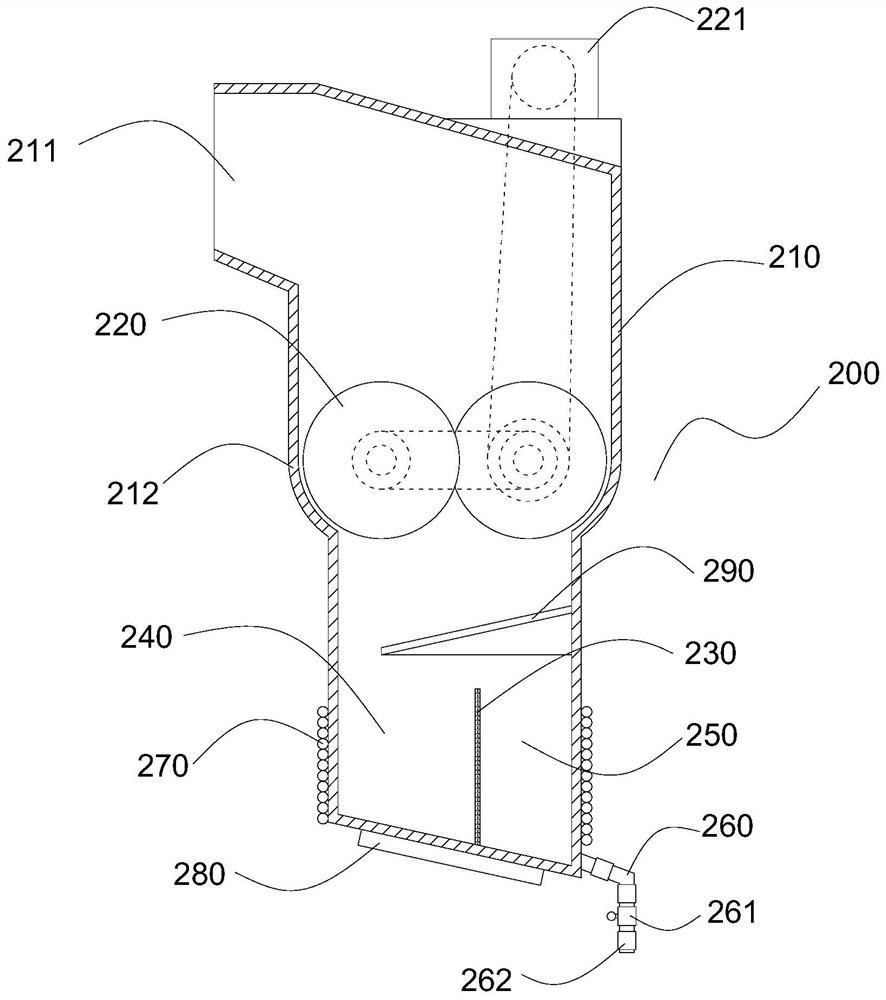

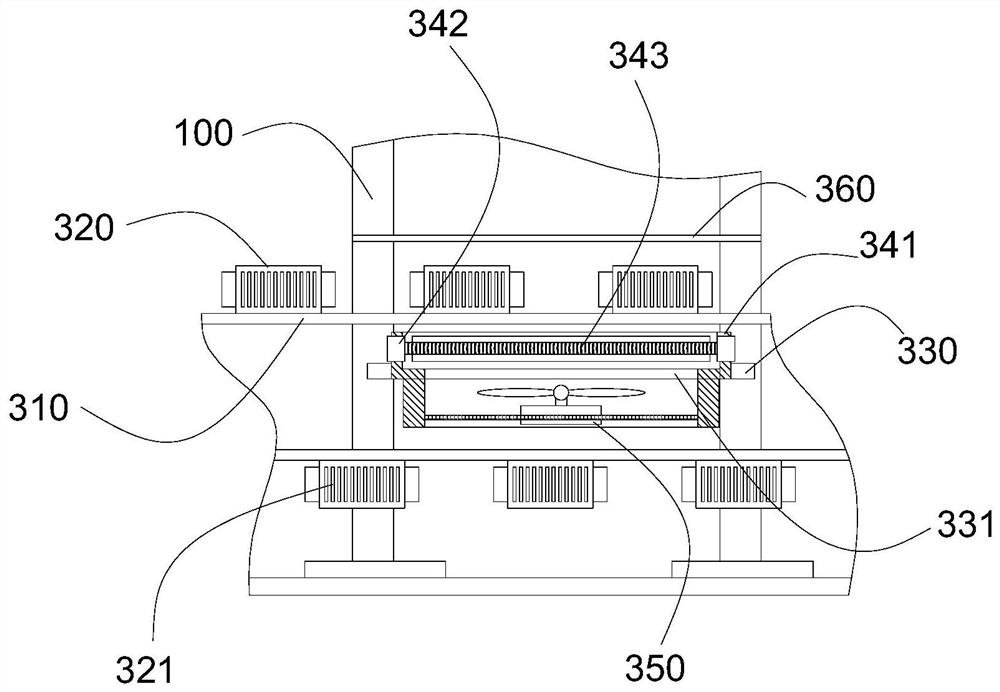

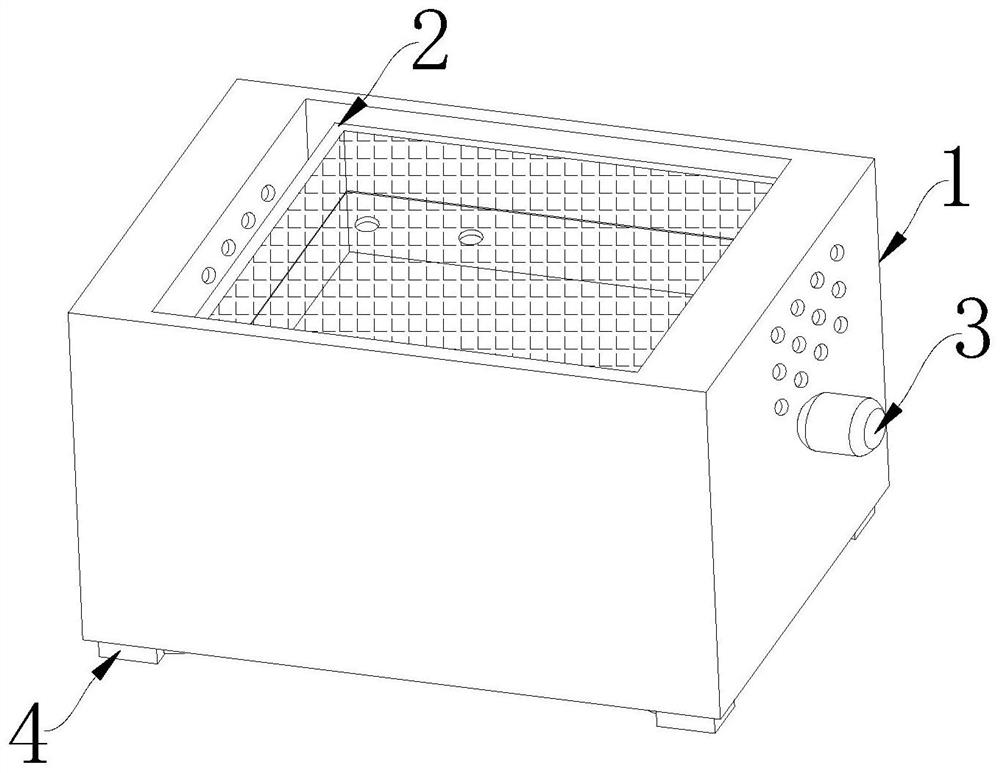

Reclaimed copper leftover recovery equipment

ActiveCN112575201ANovel structureEffective coolingProcess efficiency improvementMolten metal conveying equipmentsMoulding deviceElectric heating

The invention provides reclaimed copper leftover recovery equipment. The reclaimed copper leftover recovery equipment comprises a crushing and hot melting device and a cooling molding device; the crushing and hot melting device comprises a barrel body, and a crushing roller is erected in the middle of the barrel body; the bottom of the barrel body is obliquely arranged, and the bottom of the barrel body is divided into a material fixing area and a molten slurry area through a filter plate; the molten slurry area is located on the lower oblique side of the barrel body, and a discharging pipe isarranged on the lower oblique side of the barrel body in a communicating mode; a solenoid valve is arranged on the discharging pipe; an electric heating coil is wound on the outer wall of the bottomof the barrel body; an electric heating plate is mounted at the bottom of the barrel body; a material guide plate is arranged above the filter plate, and one end of the material guide plate is downwards inclined towards one side of the material fixing area; the cooling molding device comprises a conveyor belt, and the conveyor belt is of a mesh belt structure; a plurality of forming dies are installed on the conveyor belt, and an air refrigeration structure is installed between the upper belt face and the lower belt face of the conveyor belt; and a cooling fan is installed below the air refrigeration structure. A series of working procedures of crushing, hot-melting, pouring and cooling the copper leftover materials can be conducted, the recovery efficiency is effectively improved, and theproduction and machining are facilitated.

Owner:清远楚江高精铜带有限公司

Wiring terminal injection mold with rapid cooling function

InactiveCN112172060ATimely evacuationSpeed up cooling and formingDomestic articlesPlastic materialsEngineering

The invention discloses a wiring terminal injection mold with a rapid cooling function. The wiring terminal injection mold comprises a movable base, wherein a plurality of universal wheels are arranged at the bottom end of the movable base; a detachable injection mold body is arranged at the top end of the movable base, and an injection molding empty groove is formed inside the detachable injection mold body; and an injection molding opening communicating with the injection molding empty groove is formed in one side wall of the detachable injection mold body, and a cooling liquid flowing cavity is formed in the side wall of the detachable injection mold body. According to the wiring terminal injection mold with the rapid cooling function, water can be used as a heat conduction medium, a water source is introduced into the cooling liquid flowing cavity by means of a liquid suction pump and a liquid circulation connecting structure, and the water source is promoted to dissipate heat emitted from the injection molding empty groove in time, so that cooling forming of plastic raw materials is accelerated, and the cooling efficiency is improved; and dismounting and mounting are convenient, the structural design is reasonable, the mechanical degree is high, the operation is very easy to get started, and the wiring terminal injection mold is worth popularizing and using in the later period.

Owner:朱翠叶

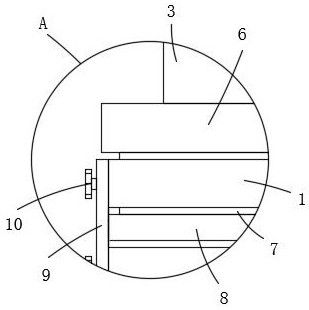

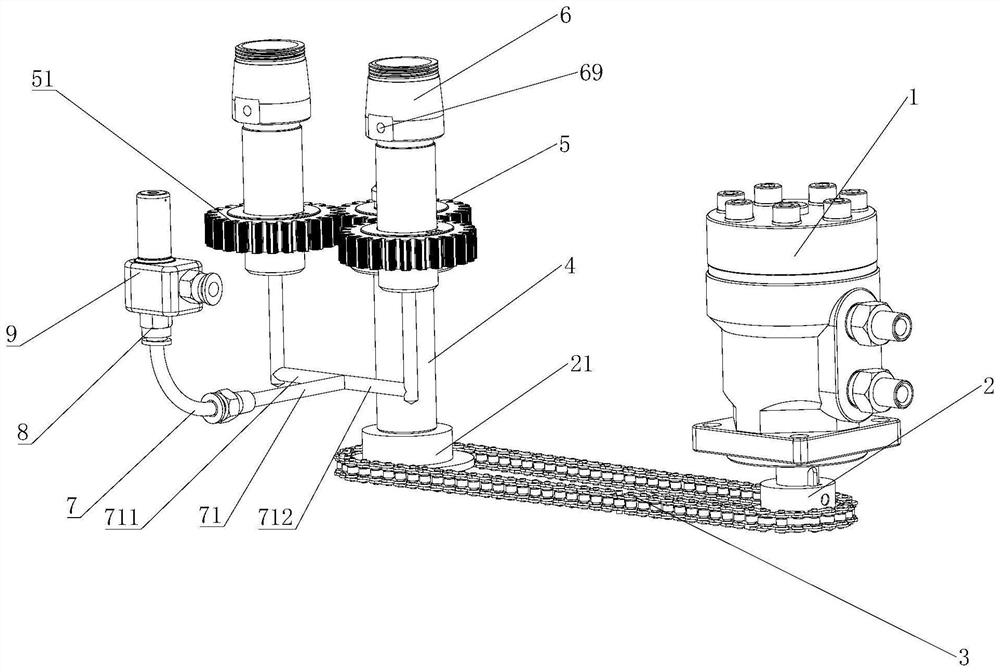

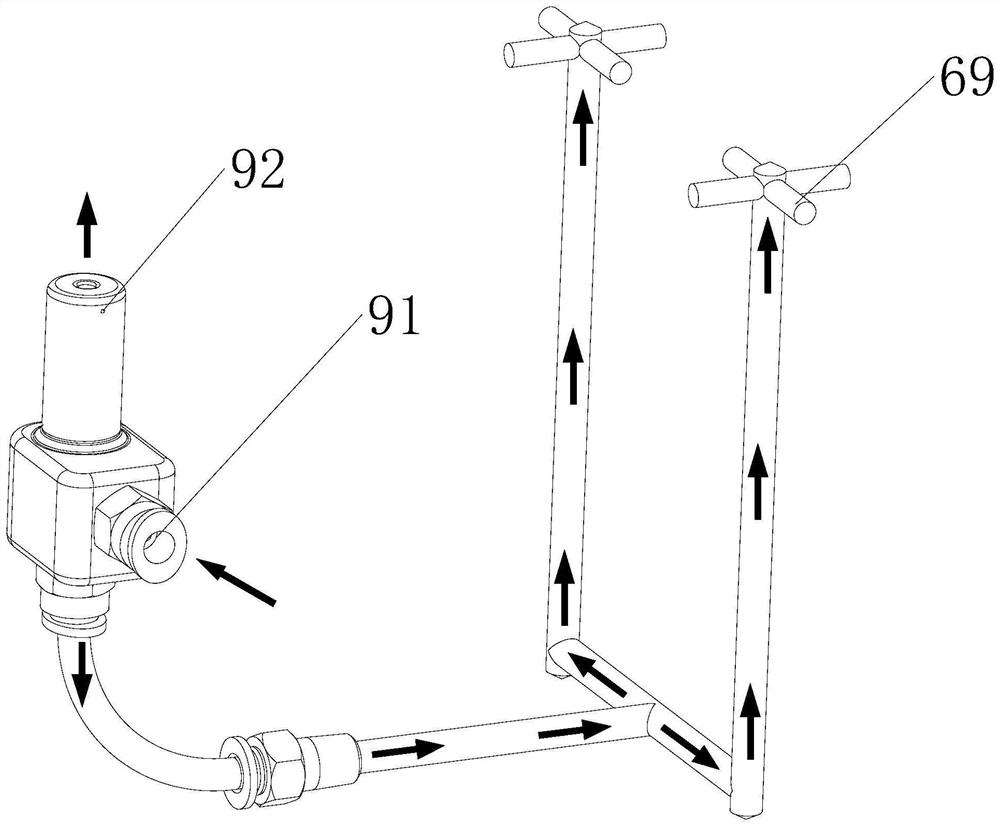

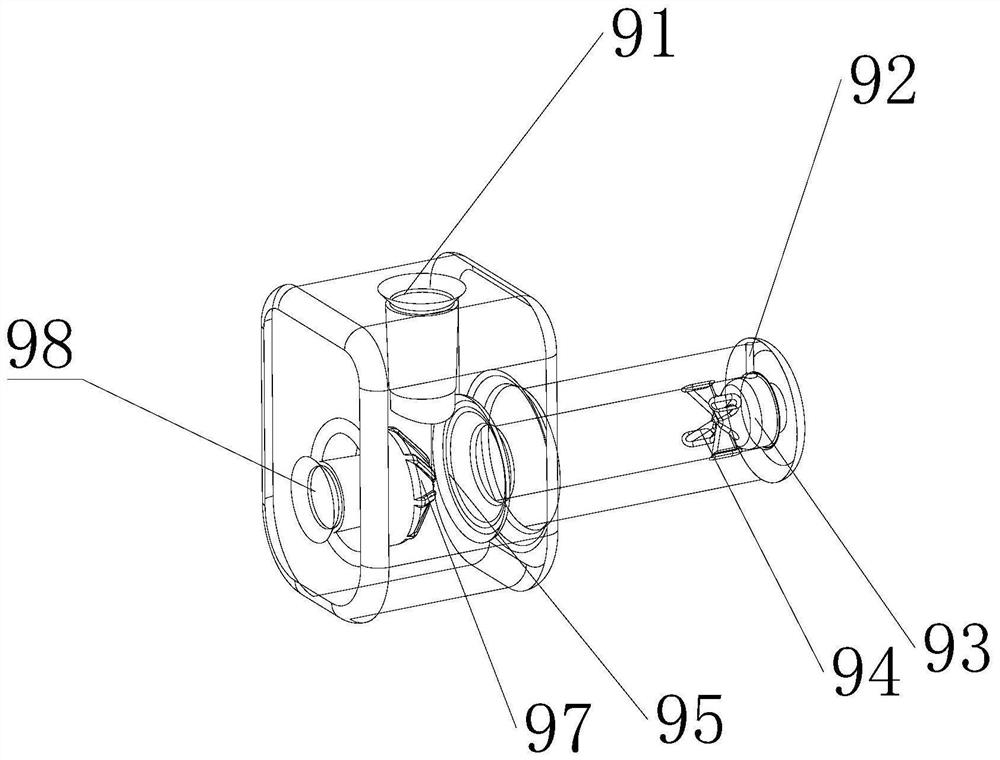

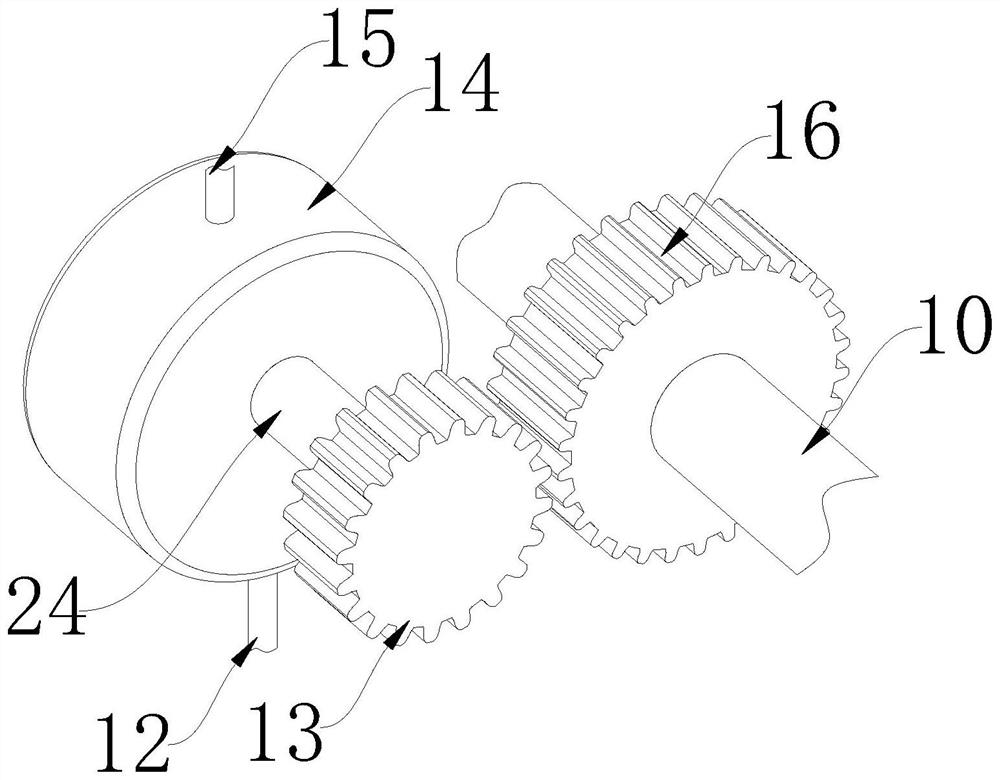

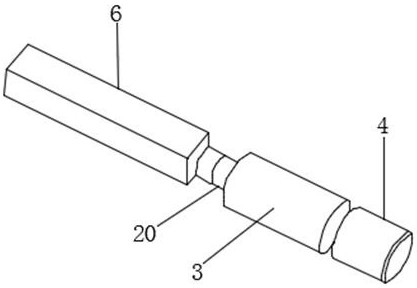

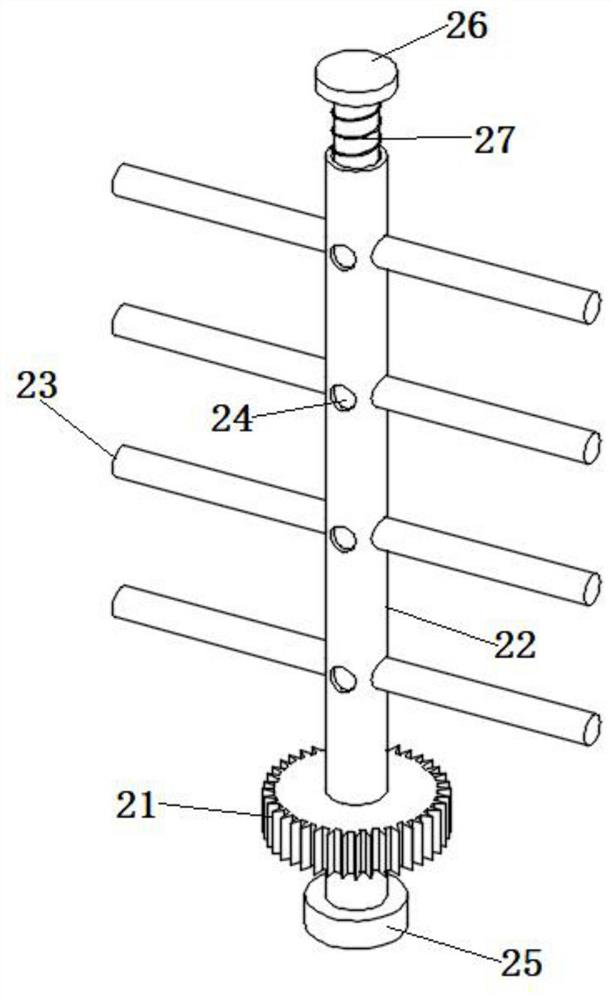

Internal thread mold

PendingCN114654688ASpeed up cooling and formingImprove product qualityScrew-threads articlesGear wheelEngineering

The invention discloses an internal thread mold which comprises a driving structure, the driving structure is connected with a gear assembly, the gear assembly is provided with a rotary mold core, the rotary mold core is connected with a cooling separation device, the cooling separation device is provided with an air inlet, and air enters the cooling separation device from the air inlet to be cooled, so that the cooled air cools the rotary mold core. According to the internal thread mold provided by the invention, by designing the cooling and separating device, external normal-temperature air is cooled through the cooling and separating device and flows into the rotary mold core to cool the rotary mold core, so that a product can be cooled and molded more quickly, and the production quality of the product is improved.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +1

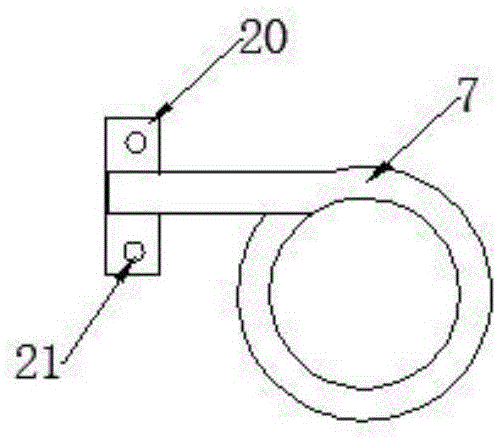

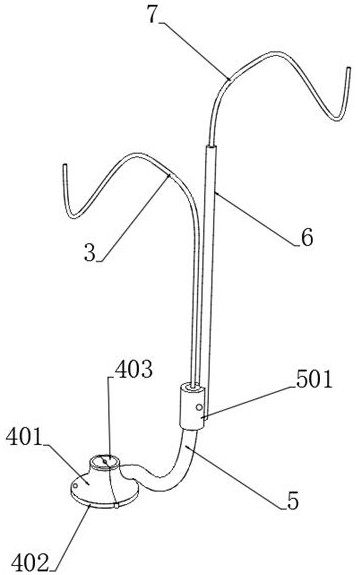

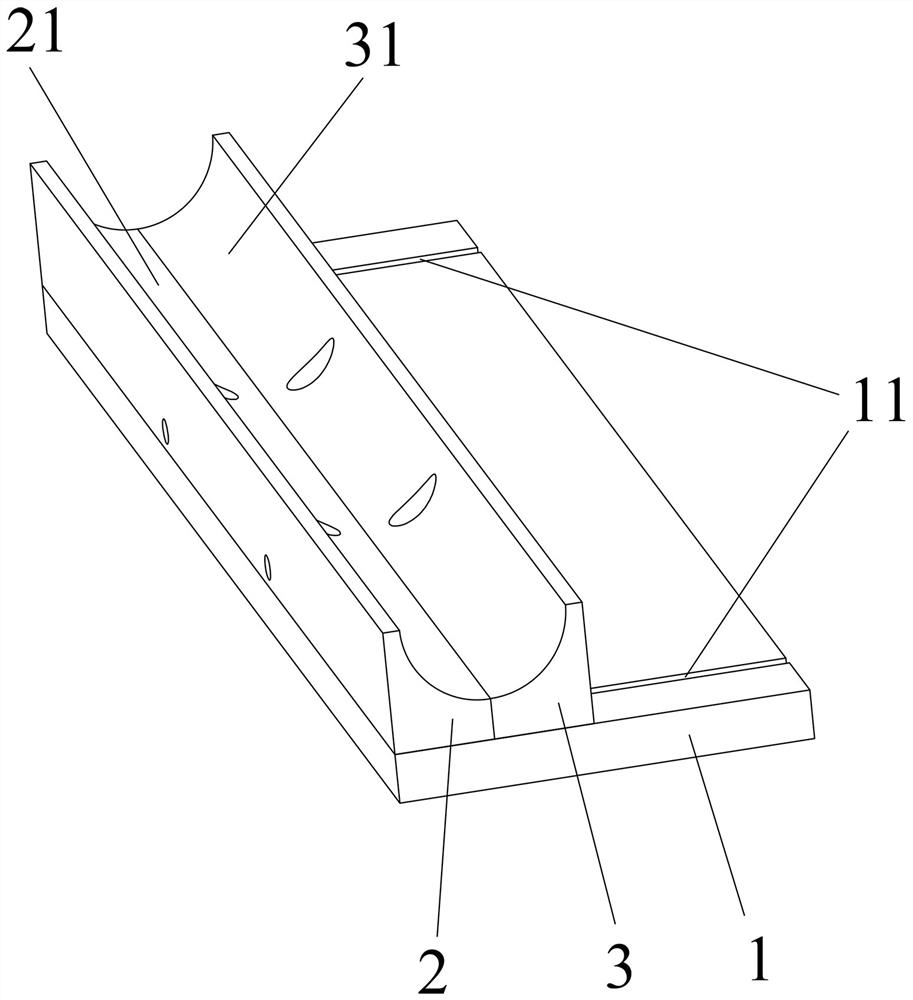

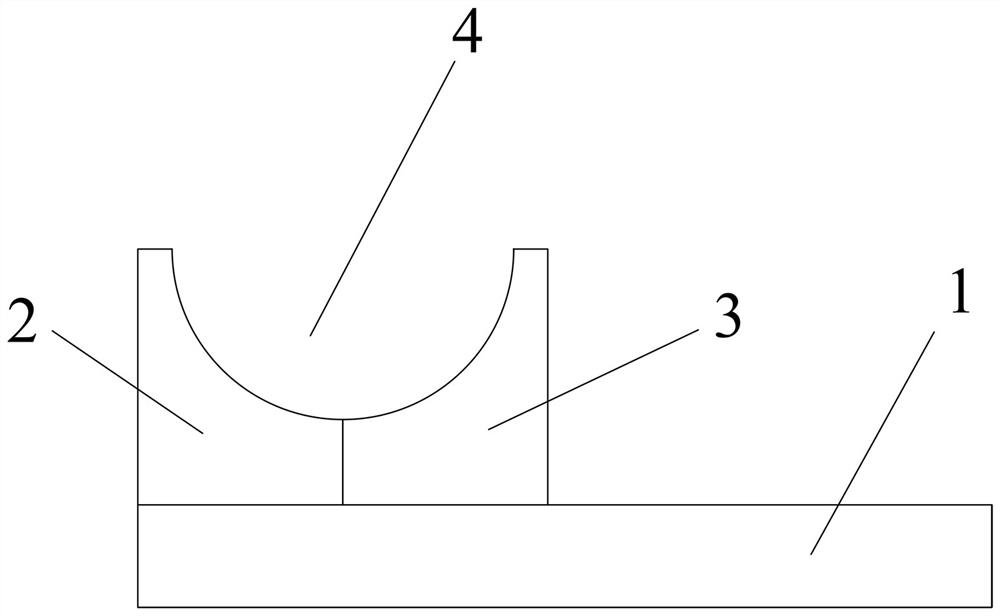

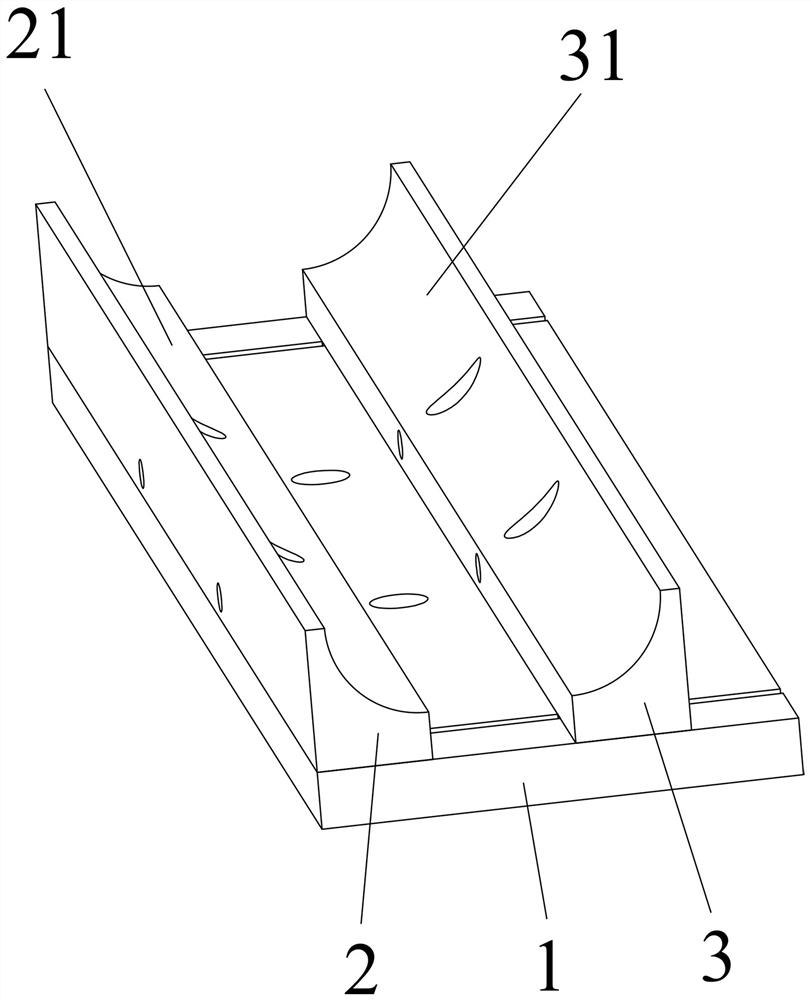

Pipe limiting devices and pipe lifting equipment

The invention relates to the technical field of pipe conveying, in particular to pipe limiting devices and pipe lifting equipment. The pipe limiting devices comprise base installation plates, front bearing seats and rear bearing seats, wherein the front bearing seats and the rear bearing seats are arranged front and back, and are installed on the base installation plates, the front bearing seats are provided with front bearing faces used for bearing pipes, the rear bearing seats are provided with rear bearing faces used for bearing the pipes, and containing grooves used for limiting the pipes are formed between the front bearing faces and the rear bearing faces. According to the pipe limiting devices and the pipe lifting equipment, the containing grooves have good limiting effects on the pipes so that a conveying belt can be preferably in a vertical state, and the space occupied by the equipment in the surrounding area is reduced; moreover, the possibility that the pipes slide down from the containing grooves due to external accidental factors can be avoided, and the anti-interference performance of the pipe limiting devices on the pipe limiting effects is improved; and meanwhile, the distance between the adjacent pipe limiting devices can be controlled within a large range so that the various pipes of different specifications can all fall into the containing grooves, and the compatibility of the pipe lifting equipment to the pipes of different specifications is improved.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

A kind of notebook shell injection molding fixture

Owner:SUZHOU YUANSHUO PRECISION MOLD

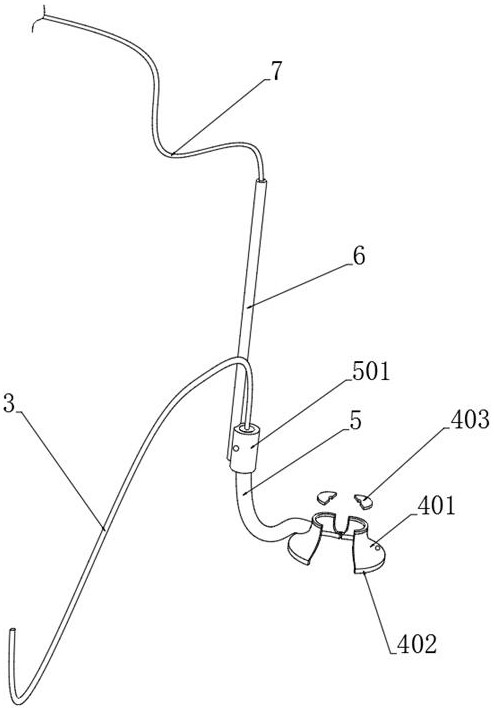

Portable injection mold for manufacturing intravascular stent

A mold base is fixedly installed at the top end of a workbench, a liquid injection pipe is fixedly installed in the middle of the top end of the mold base, a connecting pipeline is fixedly connected to the top end of the liquid injection pipe, and a convenient injection molding mechanism is fixedly installed in the middle of the top end of the workbench. The hydraulic telescopic rod can drive the lifting mold plate and the injection molding head to move up and down, the injection molding head is directly inserted into an injection molding pipe, injection molding raw materials are downwards injected into the attaching position of the outer sealing sleeve and the injection molding sleeve, and the outer sealing sleeve is tightly attached to the outer surface of the injection molding sleeve, so that the injection molding raw materials only flow along an injection molding rail groove; the intravascular stent is subjected to injection molding in the injection molding track groove, the molding mode is simple and convenient, injection molding raw materials cannot permeate, it is guaranteed that burrs cannot occur, the two injection molding heads and the injection molding pipe are subjected to injection molding at the same time, the raw materials can uniformly flow downwards, it is guaranteed that the intravascular stent subjected to injection molding is more uniform in structure, and the situation that due to insufficient raw materials, a part of the intravascular stent is sunken is avoided.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

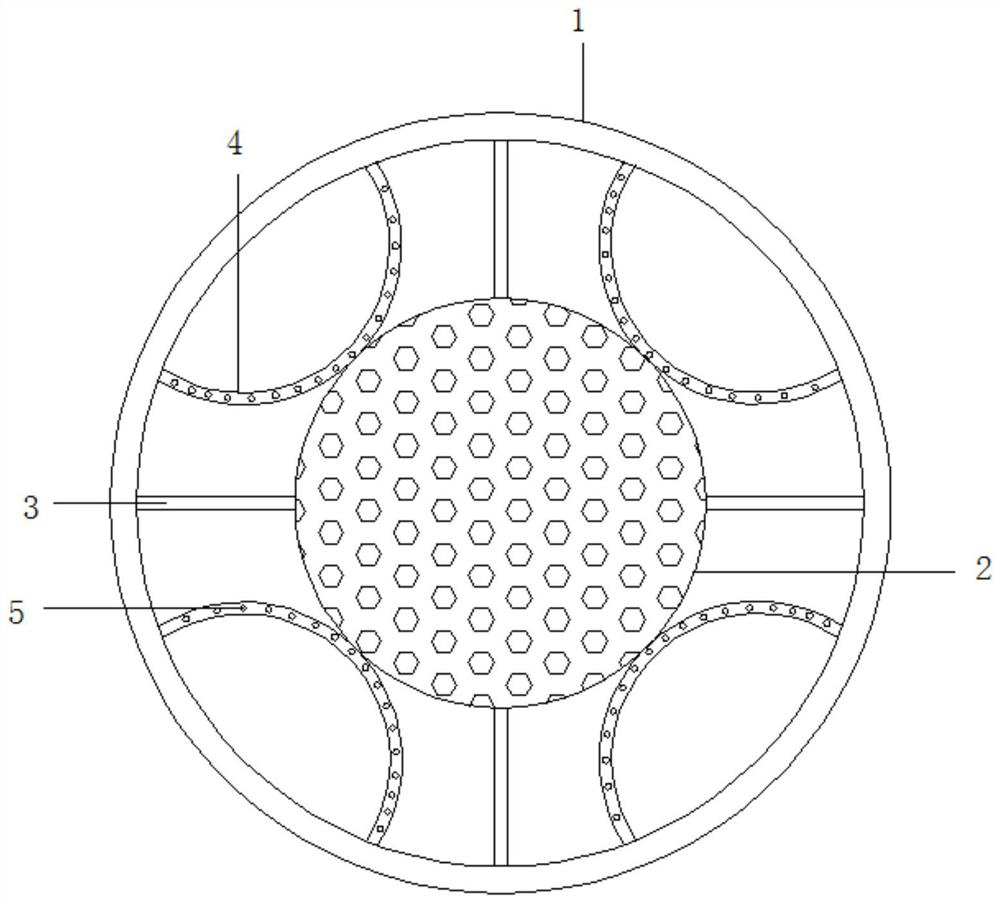

Metal garland packing and production equipment thereof

PendingCN114225888AImprove throughputFirmly connectedChemical/physical/physico-chemical processesStructural engineeringMechanical engineering

The invention discloses a metal garland packing and production equipment thereof, and belongs to the technical field of garland packings.The metal garland packing comprises a ring body, a cylinder is arranged in the ring body, a connecting rod is fixed between the cylinder and the inner side of the ring body, and four arc-shaped reinforcing rods which are annularly and evenly arranged are fixed to the curved surface of the cylinder; the two ends of the arc-shaped reinforcing rods are fixedly connected with the ring body, a plurality of first through holes which are evenly distributed are formed in the top of the cylinder, a plurality of second through holes which are evenly distributed are formed in the curved surface of the cylinder, a plurality of partition plates are fixed in the cylinder, and a plurality of third through holes which are evenly distributed are formed in the partition plates; the flux of the filler is greatly increased, the gas-liquid contact area is increased during use, all-directional water spraying on the upper mold and the lower mold is achieved, cooling forming is accelerated, and the production efficiency is improved.

Owner:萍乡市圣峰填料有限公司

Casting mold for metal prefabricated part

PendingCN114346167AGuaranteed cooling efficiencySpeed up cooling and formingFoundry mouldsFoundry coresElectromagnetic valveCold air

The invention relates to the technical field of prefabricated part machining, in particular to a casting mold for a metal prefabricated part. A groove is formed in the top wall of a device shell, a sand mold is movably installed in the groove, a pouring opening and an exhaust hole are formed in the sand mold, and four supporting columns are evenly and fixedly connected to the bottom end of the device shell; a water tank is arranged at the bottom end of the device shell, a water inlet pipe and a water outlet pipe are fixedly connected to one side wall of the device shell, the water inlet pipe and the water outlet pipe both communicate with the water tank, and a first electromagnetic valve is arranged on the water inlet pipe. Cooling is conducted through the condensation pipe, the pump core in the shell can guide cold water in the water tank into the condensation pipe and enable the cold water to flow in the condensation pipe, the cooling efficiency can be guaranteed, cooling forming of the metal prefabricated part can be accelerated, the production efficiency can be improved, circulation of cold air in the grooves can be accelerated in the rotating process of the fan blades, and the cooling effect is improved. And the cooling efficiency can be further improved.

Owner:刘佳伟

A precision injection-blow mold for the production of cosmetic packaging bottles and its production method

ActiveCN109968632BExtended service lifePromote sheddingDomestic articlesInjection molding machineBottle

The invention discloses a precision injection blow mold for the production of cosmetic packaging bottles and a production method thereof. It includes an injection mold seat, a plurality of fixing bolts are arranged on the injection mold seat, the injection mold seat is arranged on the right side wall of the central transfer mold, and a plurality of blank grooves are opened on the upper end surface of the injection mold seat , each of the preform grooves is provided with an injection tube, and the opening end of each of the injection tubes is fixedly installed on the injection cavity. In the present invention, the stretching rod adopts beryllium copper, which has good heat dissipation performance, accelerates the heat dissipation of the packaged preform, and promotes the cooling and forming of the packaged preform, and the outer surface is electroplated with chromium, which increases the service life of the stretching rod on the one hand, and on the other hand The smooth surface makes it easier for the stretch rod to fall off, thereby facilitating the manufacture of the stretch rod.

Owner:苏州晴朗工业科技有限公司

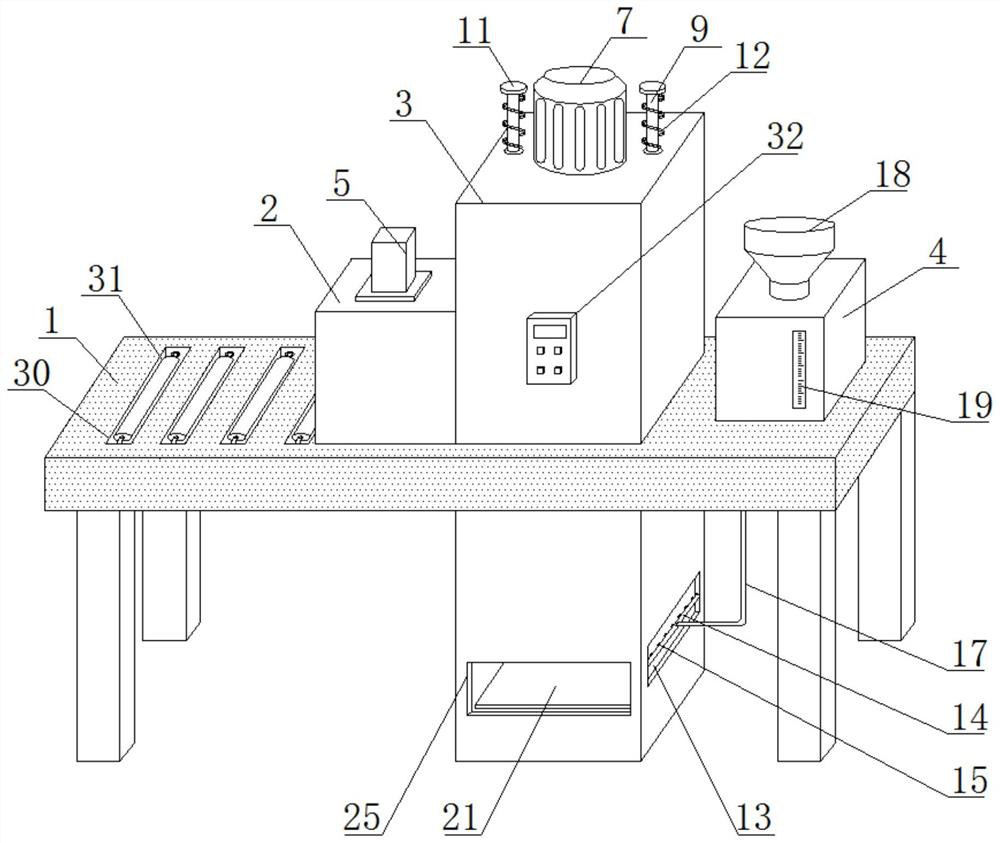

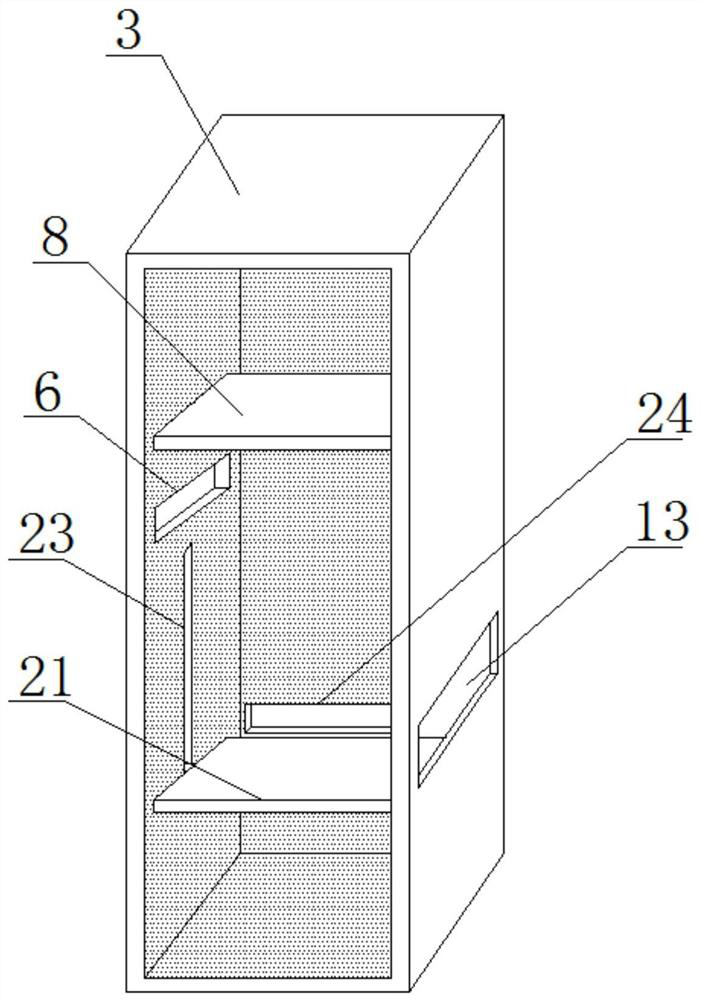

Forming machinery equipment used for processing of water tank and working method of forming machinery equipment used for processing of water tank

InactiveCN112720959AEasy to adjustStable supportDispersed particle filtrationDomestic articlesMolding machineCooling effect

The invention discloses forming machinery equipment used for processing of a water tank and a working method of the forming machinery equipment used for processing of the water tank. The forming machinery equipment comprises a shell, a heat-conducting board, a forming chamber, a spraying assembly, a bin door, a delivery assembly, a cooling assembly and load-bearing bases, wherein the heat-conducting board is installed on the top end surface of the shell in an attached mode, the forming chamber is formed in the shell, the cooling assembly is arranged at the top of the inner side of the forming chamber, the delivery assembly is arranged at the bottom of the inner side of the forming chamber, the spraying assembly is installed at one side of an end surface of the shell, the spraying assembly is connected with the interior of the forming chamber, and the bin door is fixedly installed at the front end of the shell through hinges. During work of the forming machinery equipment used for processing of the water tank, the processed water tank can be subjected to cooling treatment, and by adopting two cooling modes of air cooling and water cooling, a cooling effect is good so that the water tank can be quickly formed; and meanwhile, in a cooling process, the water tank can be cleaned, and dust and impurities on surfaces of the water tank can be effectively removed, so that the forming quality of the water tank is improved.

Owner:马鞍山安慧智电子科技有限公司

An air-cap rapid demoulding device for injection mold production

ActiveCN113021797BImprove demoulding efficiencySpeed up cooling and formingElectric machineAir pump

The invention discloses a quick release device for an air cap used in the production of injection molds, and relates to the technical field of injection molds. The invention comprises a fixed mold fixed plate, a movable mold fixed plate, a fixed mold base, a movable mold base, an upper mold core, a lower mold core and an air cap device. The present invention aims at the problems of difficult demoulding between the existing deep-cavity products and the injection mold, and a high rate of defective products. The air cap device composed of the air pipe, the third air pipe and the air pump, after injection molding, the air pump starts to deliver gas to the first air pipe, and the first motor drives the first air pipe to rotate, so that the first rotating rod is in the first sliding position. Sliding in the groove, the gas blows from the first air delivery hole to the side wall of the deep cavity product; thus loosening the side contact surface between the deep cavity product and the lower mold core; the first ejector plate rotates accordingly, making the deep cavity product The top contact surface with the lower mold core is loose, which improves the demoulding efficiency of deep cavity products.

Owner:浙江天能精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com