Welding equipment of printed circuit board for electrical element manufacturing

A technology for printed circuit boards and electrical components, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components, and can solve the problems of cumbersome operation, unsatisfactory welding effect, and virtual soldering package solder joint surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

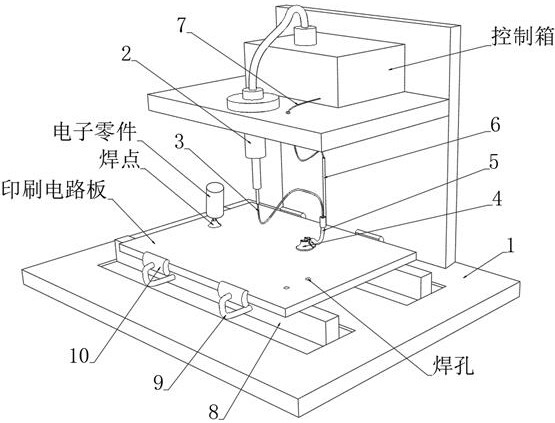

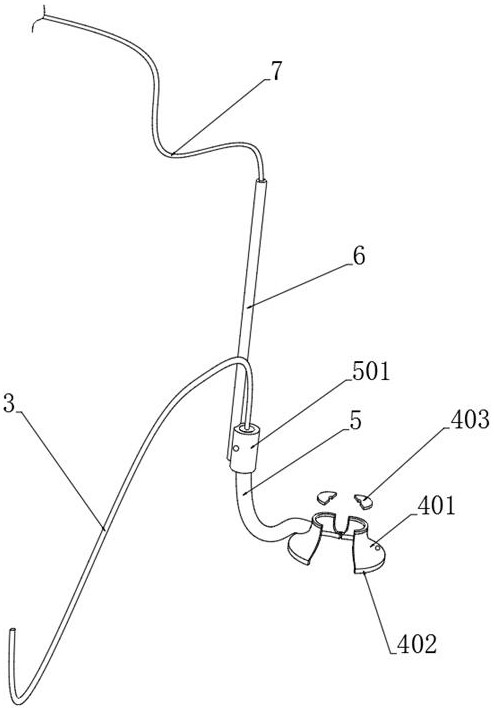

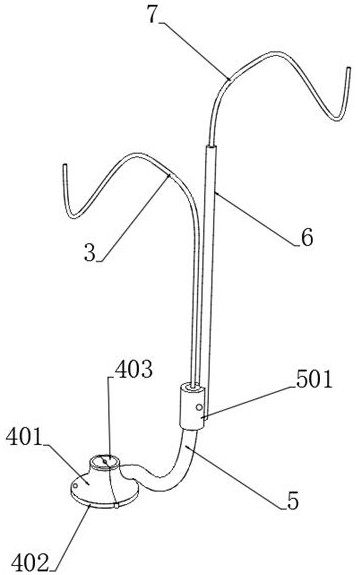

[0045] see Figure 1-3 , a welding equipment for printed circuit boards used in the manufacture of electrical components, comprising a control console 1 and a control box installed on the top of the console 1, and a feeding gun 2 connected to the control box is also installed on the top of the console 1, for The discharge end of the material gun 2 is connected to the mold plate 4 through the nozzle 3, the mold plate 4 is composed of a pair of horn-shaped mold petals 401 that are connected by rotation, and a pair of heat-insulating flexible pads 402 are provided with a connecting block at the joint of rotation. A pair of connecting blocks are rotationally connected by a connecting shaft, and the inner wall of a pair of trumpet-shaped mold parts 401 far away from the connecting shaft is covered with a magnetic layer arranged by mutual magnetic attraction, which is easy to disassemble and install the mold plate 4 .

[0046] see Figure 3-6 , the bottom end of the trumpet-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com