Die for mechanical accessory production

A technology for mechanical parts and molds, applied in the field of mold manufacturing, can solve the problems of low production efficiency, high cooling cost, long time, etc., and achieve the effects of low cooling cost, increased productivity, and accelerated product molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples.

[0026] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

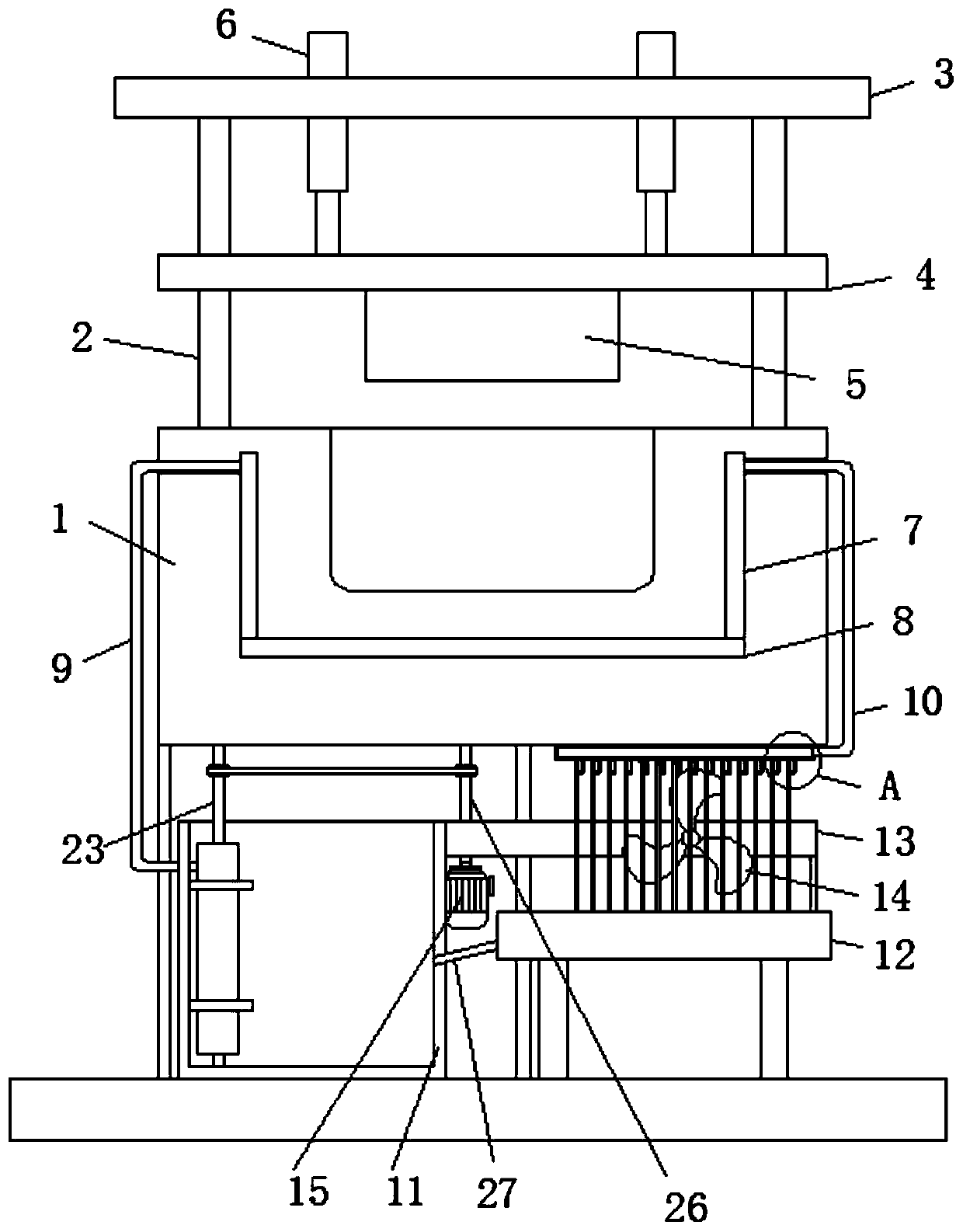

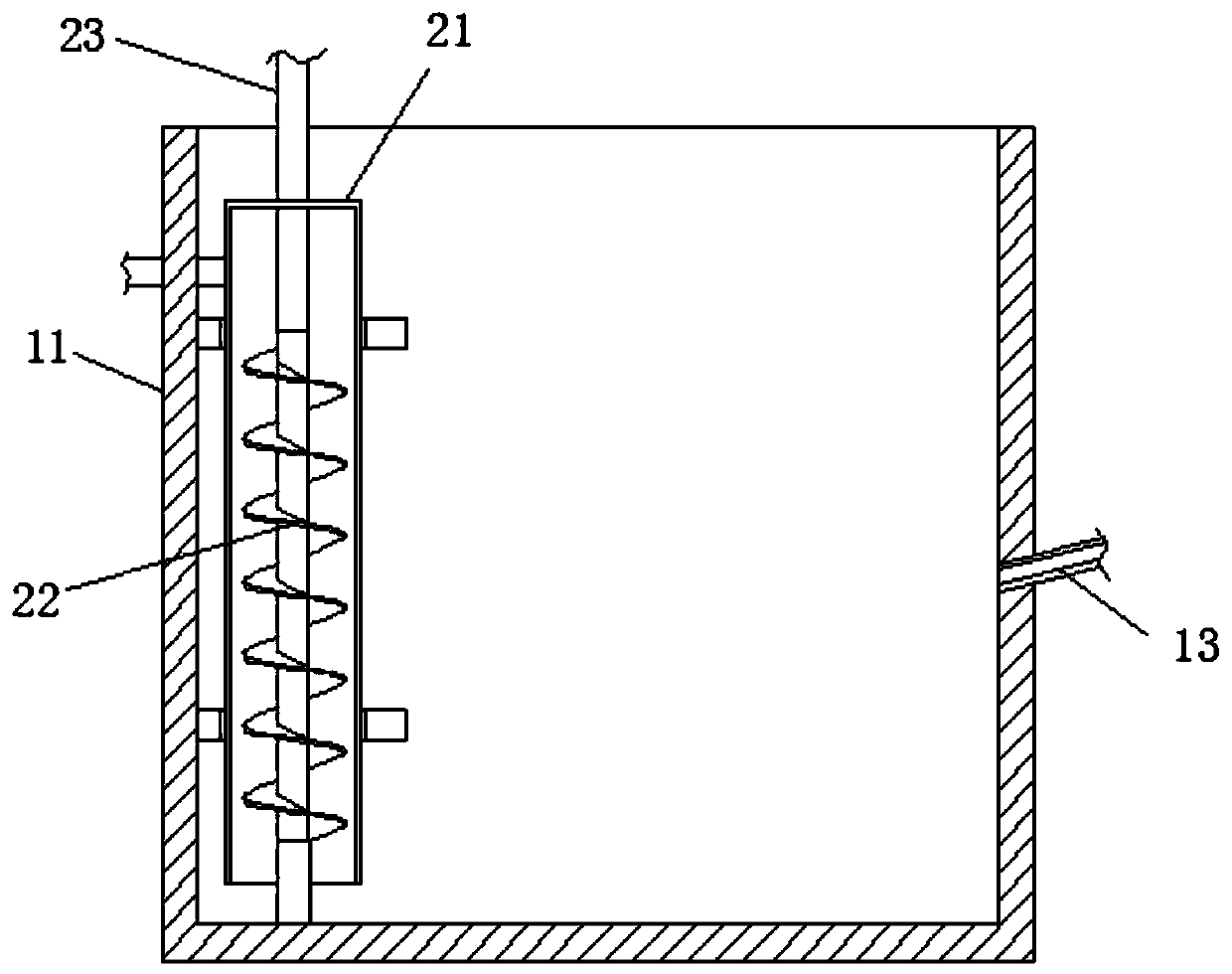

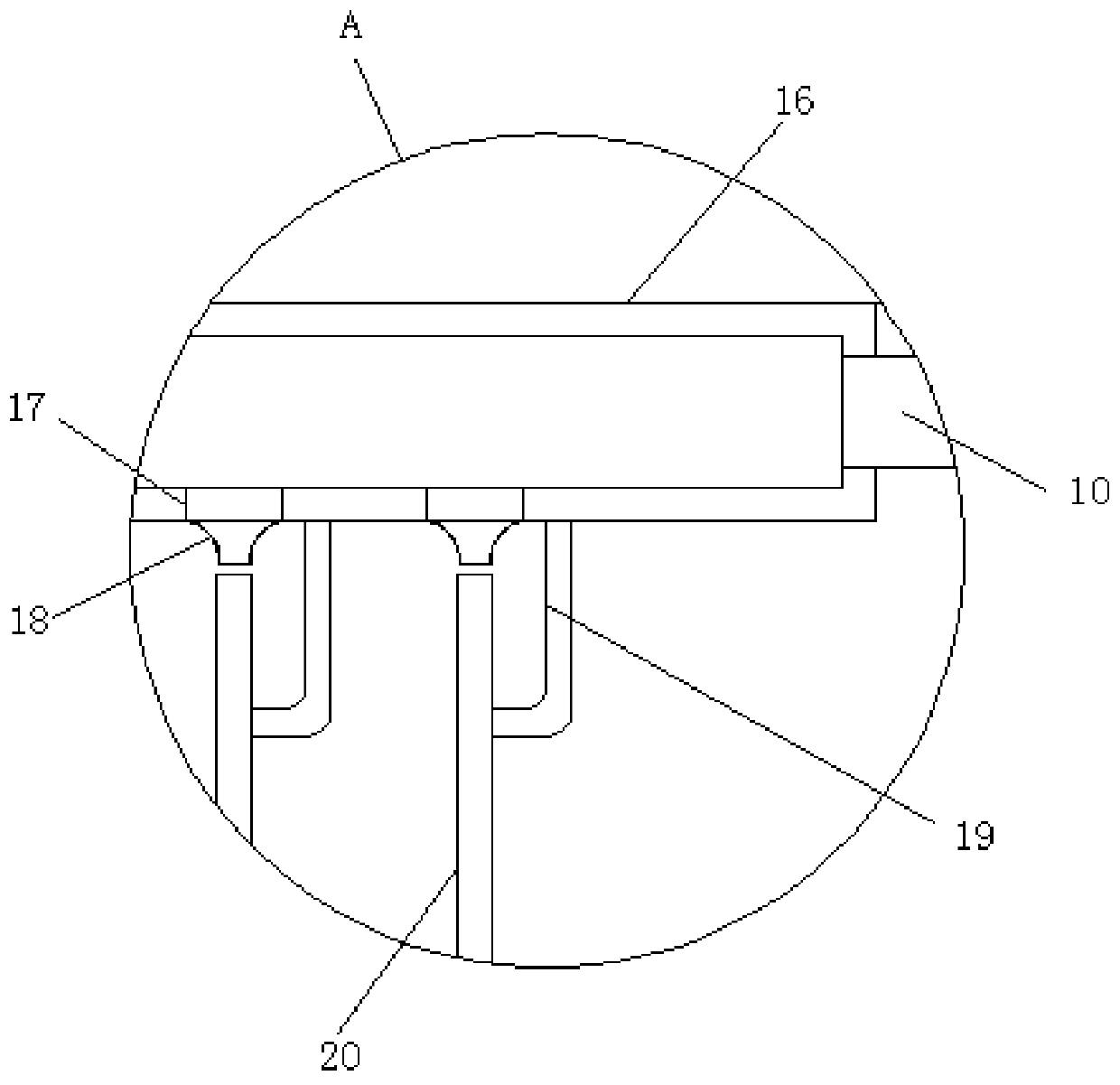

[0027] see Figure 1-6 , the present invention provides a mold for the production of mechanical parts, comprising a lower mold 1 and an upper mold 5, the upper mold 5 is located above the lower mold 1, the lower mold 1 is provided with an annular cavity 7 and a circular cavity 8, the annular cavity 7 and the The circular cavity 8 is connected, and the annular cavity 7 is set on the top of the circular cavity 8. The two sides of the top of the circular cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com