Portable injection mold for manufacturing intravascular stent

An injection mold and vascular stent technology, applied in the field of portable injection molds, can solve problems such as affecting the normal use of the stent, burrs on the sides of the stent, and small size of the vascular stent, and achieves simple molding method, safe and convenient use, and reduction of injection molding completion. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

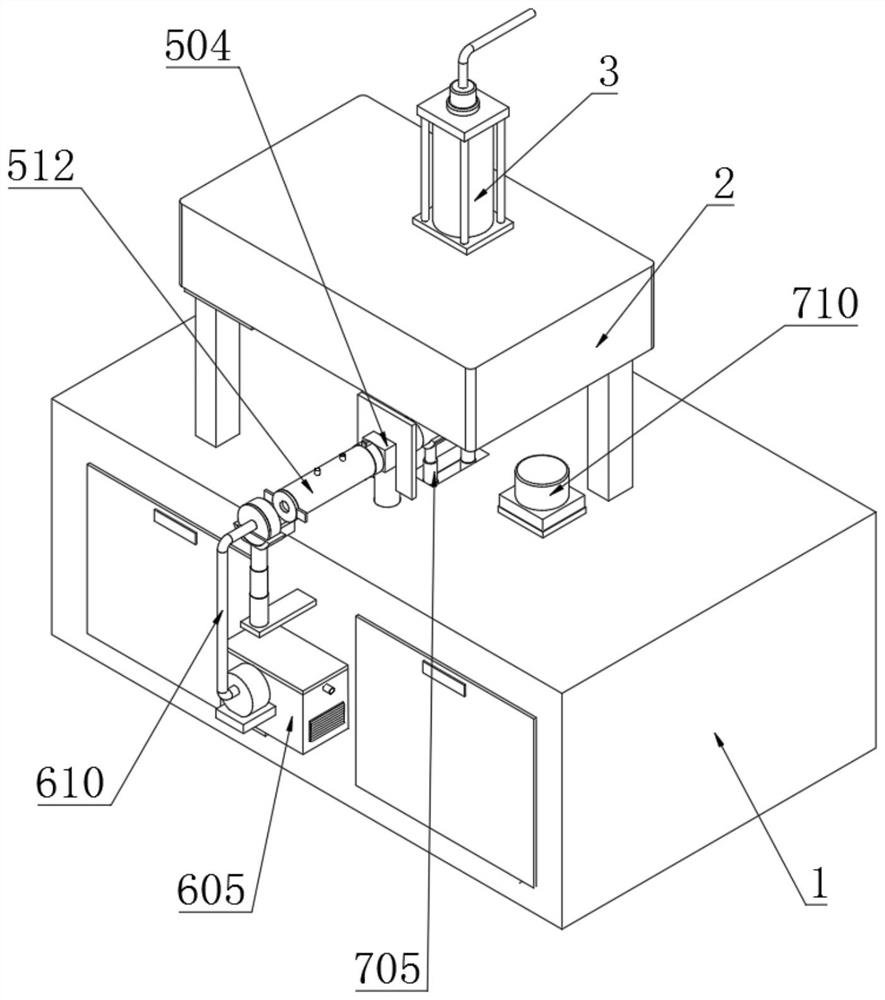

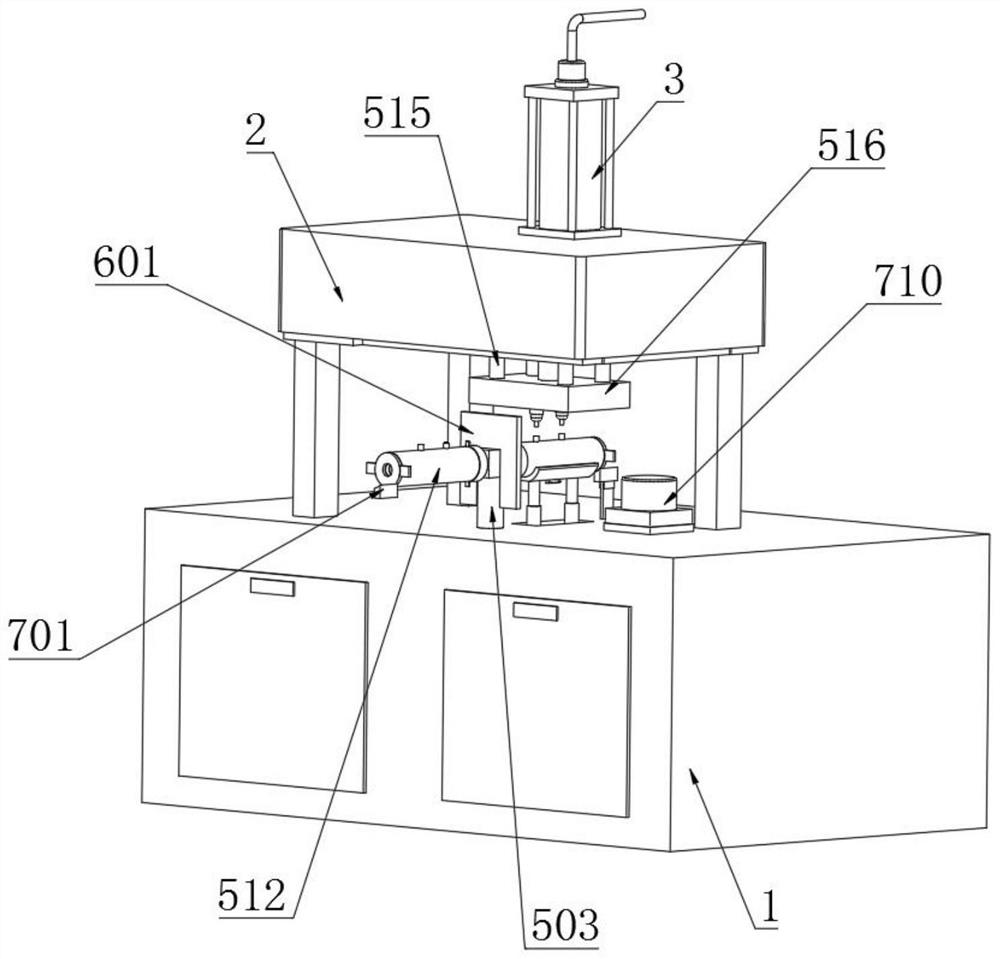

[0044] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a portable injection mold for making vascular stents, including a workbench 1, a mold base 2 is fixedly installed on the top of the workbench 1, and a liquid injection mold is fixedly installed in the middle of the top of the mold base 2 The pipe 3 and the top of the liquid injection pipe 3 are fixedly connected with a connecting pipe 4, and one end of the connecting pipe 4 is connected with an external raw material melting furnace;

[0045] The middle part of the top of the workbench 1 is fixed with a convenient injection molding mechanism 5, which is equipped with double stations, and the injection molded workpieces are removed at the same time as the injection molding, and the injection molding is carried out alternately, which improves the work efficiency;

[0046] The convenient injection molding mechanism 5 includes a card slot 501, a rotating block 502, a rotating rod 503,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com