Reclaimed copper leftover recovery equipment

A technology for recycling equipment and regenerating copper, which is applied in casting equipment, metal processing equipment, equipment that sends molten metal into molds, etc., and can solve problems affecting the speed and efficiency of melting and affecting processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

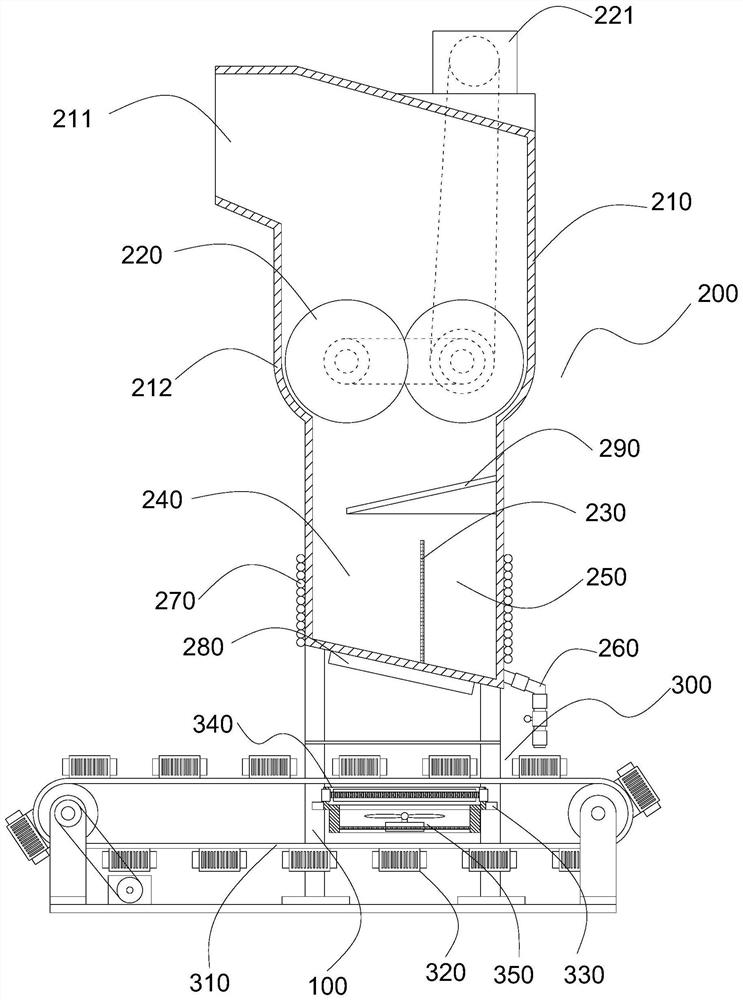

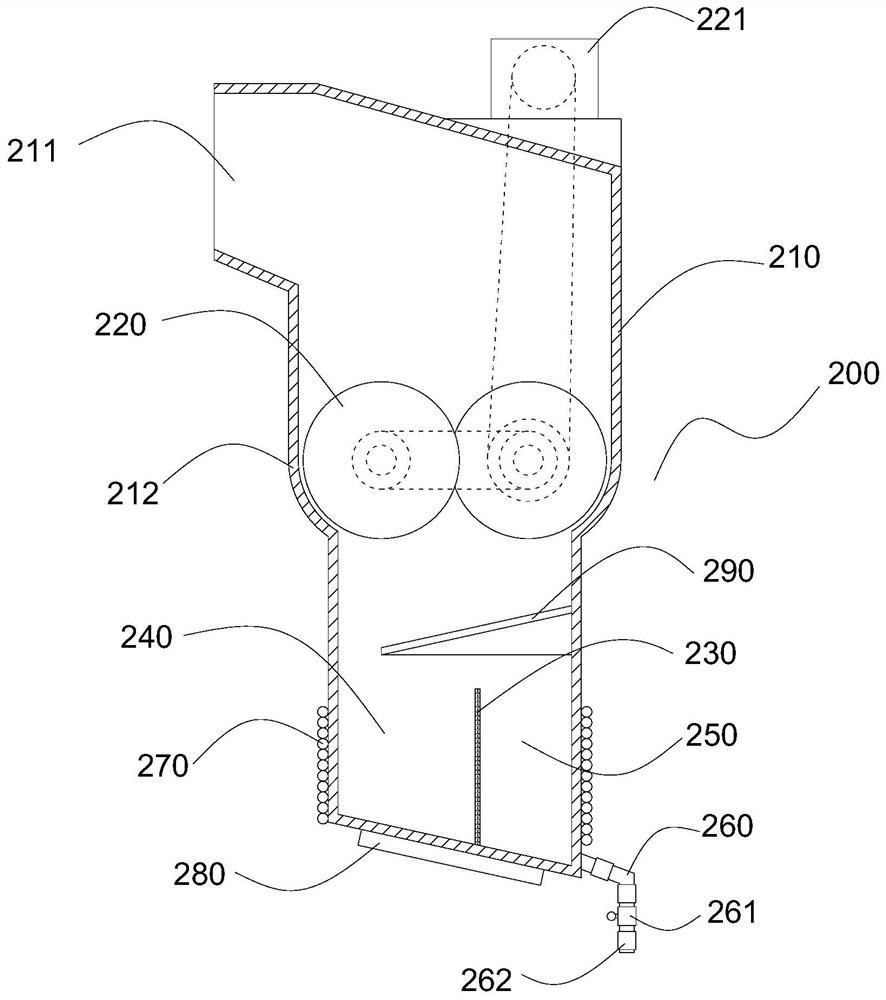

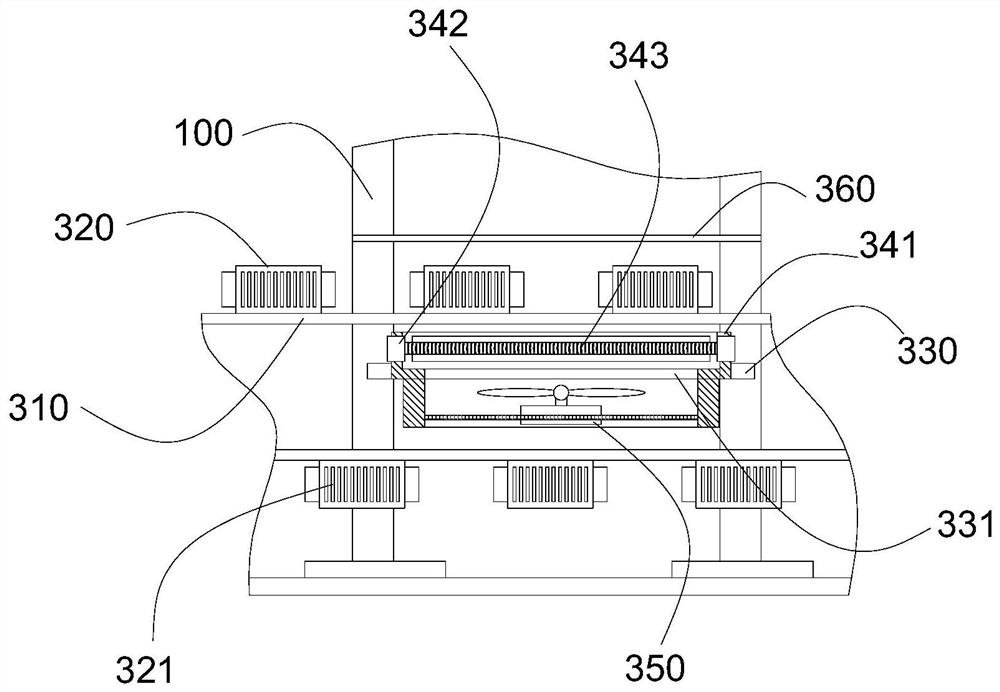

[0020] Such as Figure 1 to Figure 3 As shown, in the specific embodiment of the present invention, a recycled copper scrap recovery equipment is disclosed, including a frame 100, a crushing and melting device 200 fixed on the frame 100, and the crushing and melting device 200 A cooling forming device 300 is provided below; the crushing and hot-melting device 200 includes a barrel body 210, the top of the barrel body 210 is provided with a feeding port 211, and the middle part of the barrel body 210 is provided with two opposite crushing rollers 220 , the two crushing rollers 220 are all driven by the first motor 221; the bottom of the barrel body 210 is inclined, and the bottom inner wall of the barrel body 210 is fixed with a filter plate 230, and the filter plate 230 divides the barrel body The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com