Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Short killing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing process of green tea capable of being brewed by cold water

ActiveCN103999956APromote fragmentationFacilitated releasePre-extraction tea treatmentQuick FreezeMicrowave

The invention discloses a processing process of green tea capable of being brewed by cold water. The processing process comprises the steps of fresh leaf picking, low-temperature quick freezing, microwave thawing water removing, first-step roasting leaf stir-frying, twisting, cooling, piling slight fermentation and drying, wherein in the low-temperature quick freezing step, picked fresh leaves are fast conveyed into a freezer and are fast frozen for 24 to 48 hours at -20 DEG C; in the microwave thawing water removing step, the fast frozen fresh leaves are flatly paved onto a conveying belt of a microwave water removing machine, the thickness is 2 to 4cm, and the microwave water removing machine is started for performing microwave water removing for 5 to 8 minutes until the water content of the fresh leaves is 70 to 75 percent; and in the piling slight fermentation step, the cooled twisted leaves are firstly subjected to piling, the weight in each pile is 30kg, each tea pile is sealed and covered by preservative films after the piling, and the twisted leaves are subjected to slight fermentation for 1 hours in sealed environment. The processing process has the advantages that the tippy quantity of the prepared tea is great, the taste is mellow, the mouth feeling is good, in addition, the cell fragmentation degree is high, and the fragmentation is sufficient, so the green tea is suitable for being brewed by the cold water; and the processing process is simple.

Owner:黄山紫霞茶业有限公司

Chrysanthemum processing method

ActiveCN103652166ADoes not destroy active ingredientsAvoid poor resultsTea substituesDrying timeMoisture

The invention discloses a chrysanthemum processing method which comprises the following operating steps: (1) de-enzyming is performed on chrysanthemum at a temperature of 100-120 DEG C and pressure of 0.35-0.45 Mpa for 50-70 s; (2) the chrysanthemum processed in the step (1) is taken out for dehydration for 4-5 times, the total drying time in the whole dehydration process is 330-430 minutes, and the drying temperature is 50-80 DEG C. According to the invention, since high-temperature rapid de-enzyming method is adopted during the de-enzyming of the chrysanthemum, effective constituents in the chrysanthemum are not damaged, and effects of the chrysanthemum are better; the temperature used in the dehydration process is relatively moderate, and the time is relatively short, so that the dehydration effect is better, the moisture in the chrysanthemum after dehydration is less than 12%, and the guarantee period of the chrysanthemum is prolonged; the chrysanthemum processed through the processing method provided by the invention is high in quality and good in color, is relatively high in reduction degree after being brewed with boiled water; since the de-enzyming time and dehydration time are shortened, the reduction of energy consumption is facilitated, and the cost is reduced.

Owner:常州市孟河双峰中草药科技有限公司

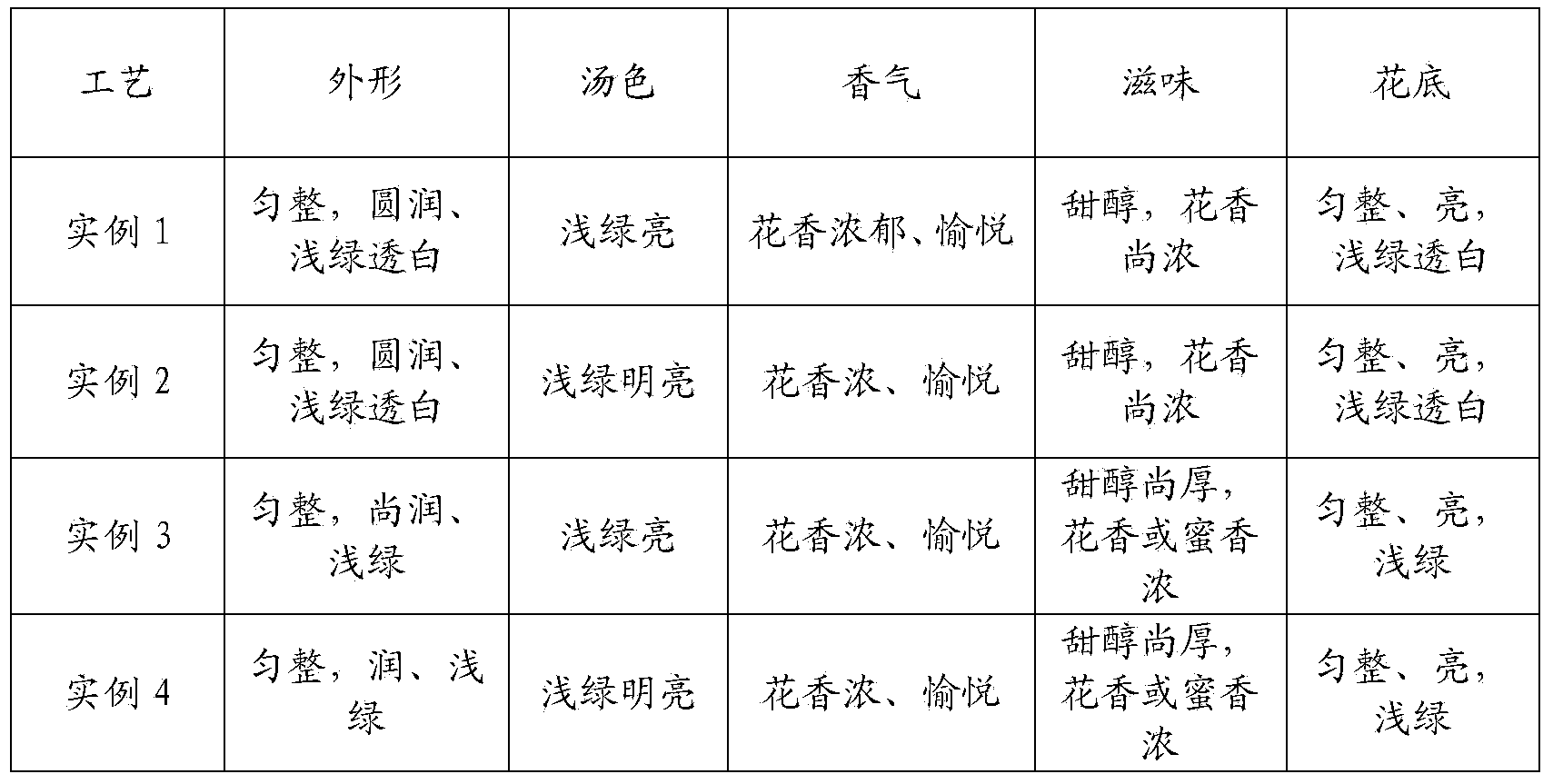

Processing method for tea flowers

The invention relates to a processing method for tea flowers. The processing method comprises the following steps: picking the tea flowers, withering, carrying out fixation, drying and packaging. According to the method, a microwave water removing machine is utilized for rapidly finish fixation in short time; meanwhile, in a fixation process, a lot of water molecules are escaped and evaporated from the tea flowers so as to realize the primary drying aim; the color, the flavor, the shape and the taste of the fresh tea flowers can keep unchanged to the greatest extent and effective substances are kept to the greatest extent; the high-aroma and the high-quality tea flowers are prepared.

Owner:GUANGXI GUILIN TEA RES INST

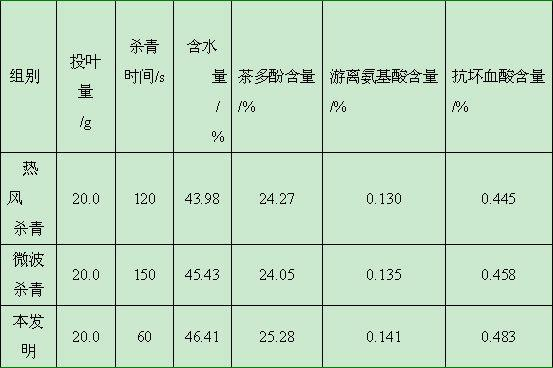

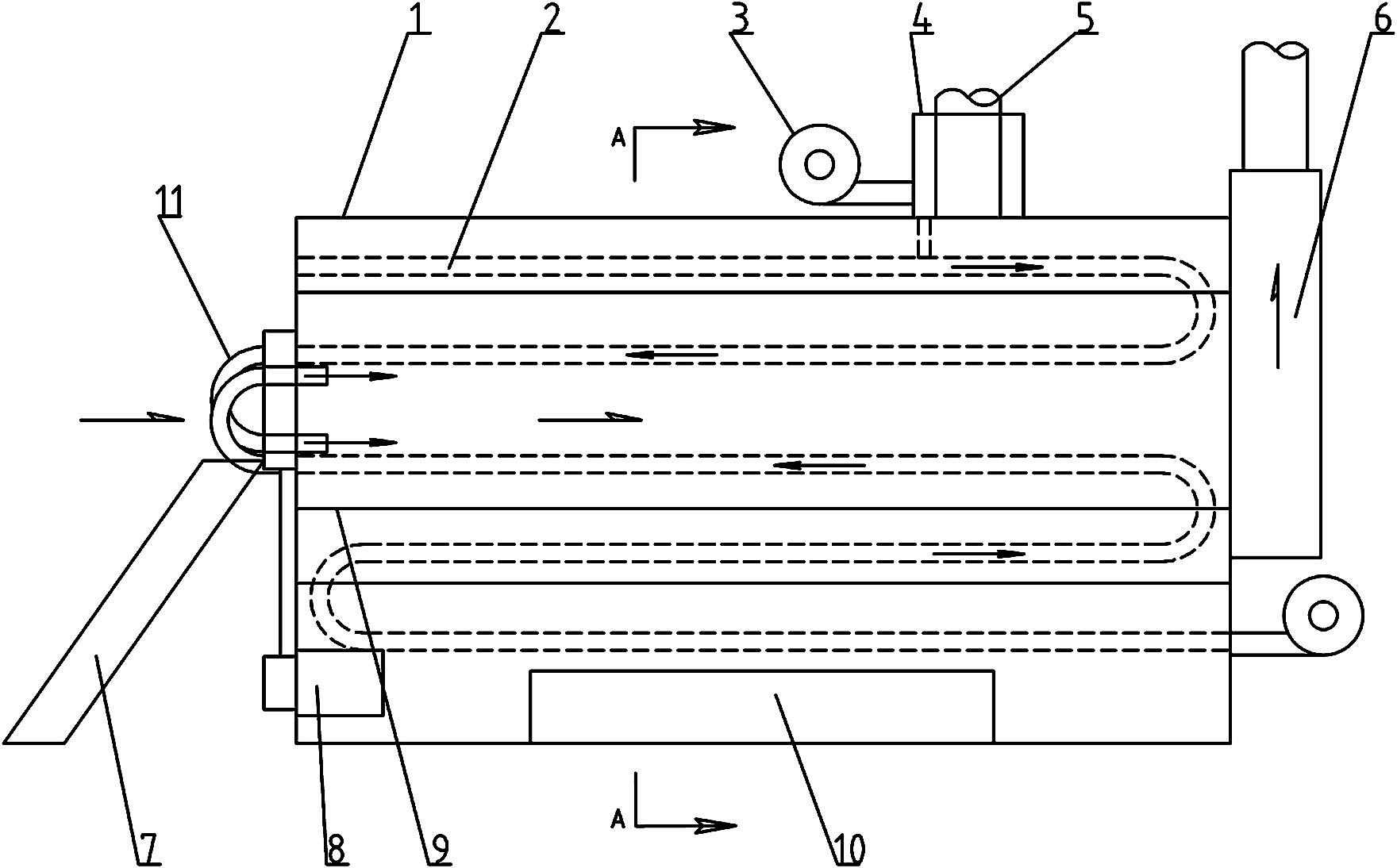

Microwave and hot air combined water removing method for green tea

InactiveCN102524436AIncrease contentSimple methodPre-extraction tea treatmentTransmission beltMicrowave power

The invention discloses a microwave and hot air combined water removing method for green tea and belongs to the technical field of tea water removal. The method comprises the following steps that: (1) fresh tea leaves are placed in a spreading drying groove for spreading drying until the moisture content of the fresh tea leave is 65 percent to 70 percent; (2) a microwave and hot air combined water removing machine is adopted for carrying out water removal on leaves requiring the water removal after the spreading drying, a hot air switch is switched on, the water removing machine is preheated,and the hot air temperature is regulated to 20 to 160 DEG C; and (3) after the temperature of a cavity of the water removing machine reaches the preset temperature, the leaves requiring the water removal are started to be put into the cavity, simultaneously, a microwave switch is switched on, the microwave power is regulated to 0 to 2000W, the leaves requiring the water removal are flatly paved on a transmission belt of the water removing machine, the water removal leaves put into the cavity of the water removing machine are heated for 0.5 to 10 minutes, and the water removing leaves after the water removal are subjected to subsequent processing. The process is simple, the water removing time is short, and the contents of moisture, tea polyphenol, free amino acid and ascorbic acid in the prepared water removing leaves are respectively and obviously improved.

Owner:YANGZHOU UNIV

Pinhead tea processing technology

ActiveCN104012690AShort killing timeLeaf color emerald greenPre-extraction tea treatmentMegasonic cleaningMoisture

The invention discloses a pinhead tea processing technology, which orderly comprises the following steps: cleaning tea, deactivating enzymes of tea, rolling tea and drying the tea. The tea is cleaned through the ultrasonic, a bubble generator is arranged in an ultrasonic cleaner so as to completely clean the pinhead tea, the pinhead tea is processed in a method of firstly steeping and then throwing, the enzyme deactivating time is short, the tea color is green, the fragrance is fresh and cool, the method is better than the method of firstly throwing and then steeping, partial moisture can be removed, the tea strip can become soft, the plasticity is strong, the technology is in favor of the frying to circle of the subsequent technology, the delicate and broken leftover tea can be circled when the moisture is evaporated by frying in a small pot, and the technology is the key for processing the pinhead fresh tea into circles; the pinhead tea is round and tight in appearance, granulated, green and moistening in color, plump in tea bone, similar to pearl, high in fragrance and thick in taste, durable and anti-foam.

Owner:ZHEJIANG PROVINCE XINCHANG COUNTY CHENGTAN TEA FACTORY

Vacuum microwave enzyme deactivating method

InactiveCN103211044AShort killing timeLow boiling pointPre-extraction tea treatmentVitamin CWater vapor

The invention discloses a vacuum microwave enzyme deactivating method, wherein the deactivation of enzyme is carried out on spread tea in a microwave heating manner under the condition of vacuum. Under the condition of vacuum, the microwave power is controlled for carrying out enzyme deactivating, the boiling point of water is reduced, and the evaporation rate of water vapor is increased, so that the enzyme deactivating time of tea is further shortened; and the enzyme deactivating temperature is reduced, so that the method is beneficial to reservation of nutrition substances such as amino acids, vitamin C, chlorophyll, aromatic matters and the like, and the quality of the tea subjected to enzyme deactivating is improved. According to the vacuum microwave enzyme deactivating method, the problems of inconsistent uniformity of enzyme deactivation, red peduncles and red leaves, burned edge, fire point, damage on the nutrition substances, more draining amount and reduction of the tea quality in the existing processes of tea withering, tea drying and tea steaming, high boiling point of water and slow evaporation rate of water in the tea is slow during the process of microwave enzyme deactivation under normal pressure, and serious damage on amino acids, vitamin C, chlorophyll and aromatic matters in the tea because of high water-removing temperature, and the like can be solved. The vacuum microwave water-removing method is simple and easy, and the water-removing tea quality is good.

Owner:何林 +1

Hybrid hot-air enzyme deactivation machine

InactiveCN102308893ATake advantage ofColor greenPre-extraction tea treatmentHeating timeProcess engineering

The invention relates to a hybrid hot-air enzyme deactivation machine, comprising an insulation housing, a heating device inside the insulation housing, a cavity which is disposed between the insulation housing and a roller and is communicated with the heating device, several warm-air pipes arranged inside the cavity, with the outlets of the warm-air pipes located in the roller. By adding a heating device inside and with the cooperation of the warm-air pipes, the hybrid hot-air enzyme deactivation machine provided in the invention makes full use of fuel heat. Compared with the prior art, products are increased from 400kg to 1000kg with the same fuel. Meanwhile, because of fully utilized heat, processing efficiency is improved, i.e. the enzyme deactivation time is shortened. The efficiency is enhanced from the original 400kg / h to 1000kg / h. Besides, as the heating time is shortened, the color of tea is maintained dark green, and the product quality is improved.

Owner:WUFENG TIANCHI TEA MACHINERY +1

Compounded edible fungus meat product and processing method thereof

The invention discloses a compounded edible fungus meat product and a processing method thereof. The method comprises the following steps: by taking fresh edible fungi and mauremys mutica as raw materials, firstly carrying out rinsing, color-protecting, slicing, precooking, salting, desalting and the like on the edible fungi so as to prepare a semi-product; carrying out rinsing, fishy smell removing, precooking, bone soup flavoring, cooling, slitting and the like on the mauremys mutica so as to prepare a semi-product; proportionally combining the semi-product of the edible fungi with the semi-product of the mauremys mutica, adding spices, seasonings and auxiliary materials and evenly mixing so as to obtain the compounded edible fungus meat product. The compounded edible fungus meat product has the advantages of being green and natural, reasonable in nutritional matching, excellent in flavor, good in taste, convenient to eat, long in shelf life and the like.

Owner:CHENGDU UNIV +1

Shatian pomelo fruitcake and making method thereof

ActiveCN104957452AFast sterilizationLess irritatingFood hydrolysisFood ingredient as flavour affecting agentAgarMalic acid

The invention discloses a Shatian pomelo fruitcake and a making method thereof. The Shatian pomelo fruitcake comprises the following components in parts by weight: 35-50 parts of Shatian pomelo, 20-40 parts of starch sirup, 1-3 parts of agar, 15-25 parts of honey, 0.8-1.5 parts of citric acid, 0.1-0.5 part of malic acid, 0.1-0.4 part of sodium citrate and 50-120 parts of magnetized drinking water. According to the fruitcake prepared by the making method disclosed by the invention, the mouth feel of the fruitcake combines the mouth feel of jellies and the mouth feel of soft sweets, the appearance is smooth and transparent, the Shatian pomelo fruitcake is high in elasticity, is fine and smooth in mouth feel and is convenient to eat.

Owner:广西容县锦香食品有限公司

Fixation method for folium mori tea

ActiveCN103999961AKeep the fragranceKeep the colorPre-extraction tea treatmentFixation timeFixation method

The invention discloses a fixation method for folium mori tea. The fixation method is characterized by comprising the following steps: putting picked and selected folium mori into boiling water; boiling while agitating to remove dirt on the folium mori and the grass smell; then fishing out the boiled folium mori and putting the folium mori into cold water for fixing the color; and dehydrating the folium mori with the fixed color, kneading, drying and improving the aroma to obtain the folium mori tea. The time spent on boiling and agitating the folium mori is 90-180 seconds. The step of fixing the color in the cold water is carried out at a water temperature of 10-20 DEG C. The fixation method is short in fixation time and the temperature is not very high so as to be good for keeping useful substances in the folium mori; meanwhile, the faint scent and the color of the folium mori are also kept so that the aims are completely reached.

Owner:南充尚好桑茶有限公司 +1

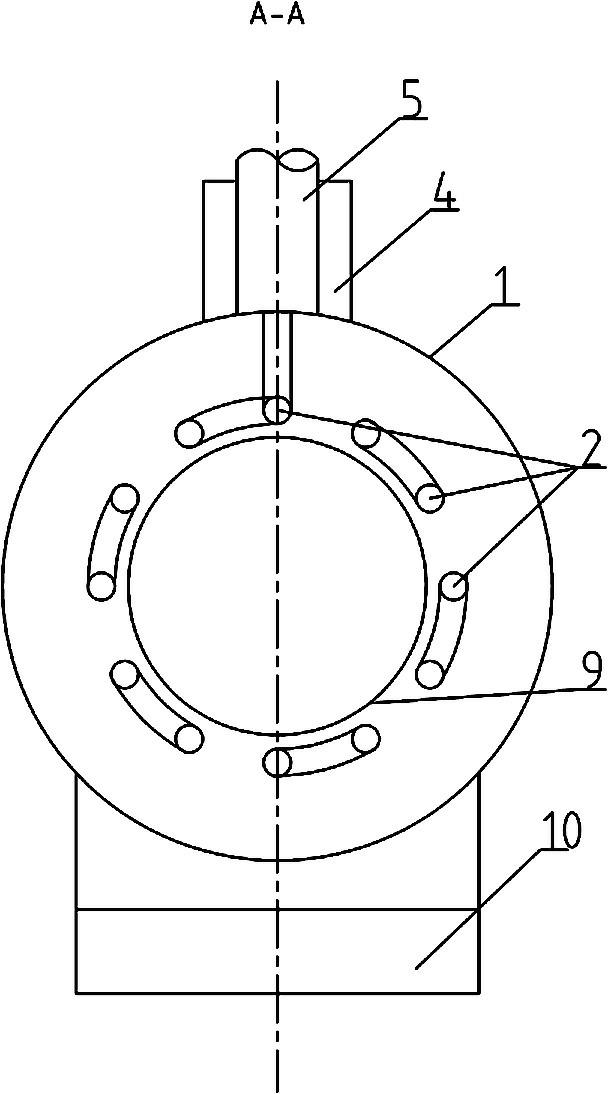

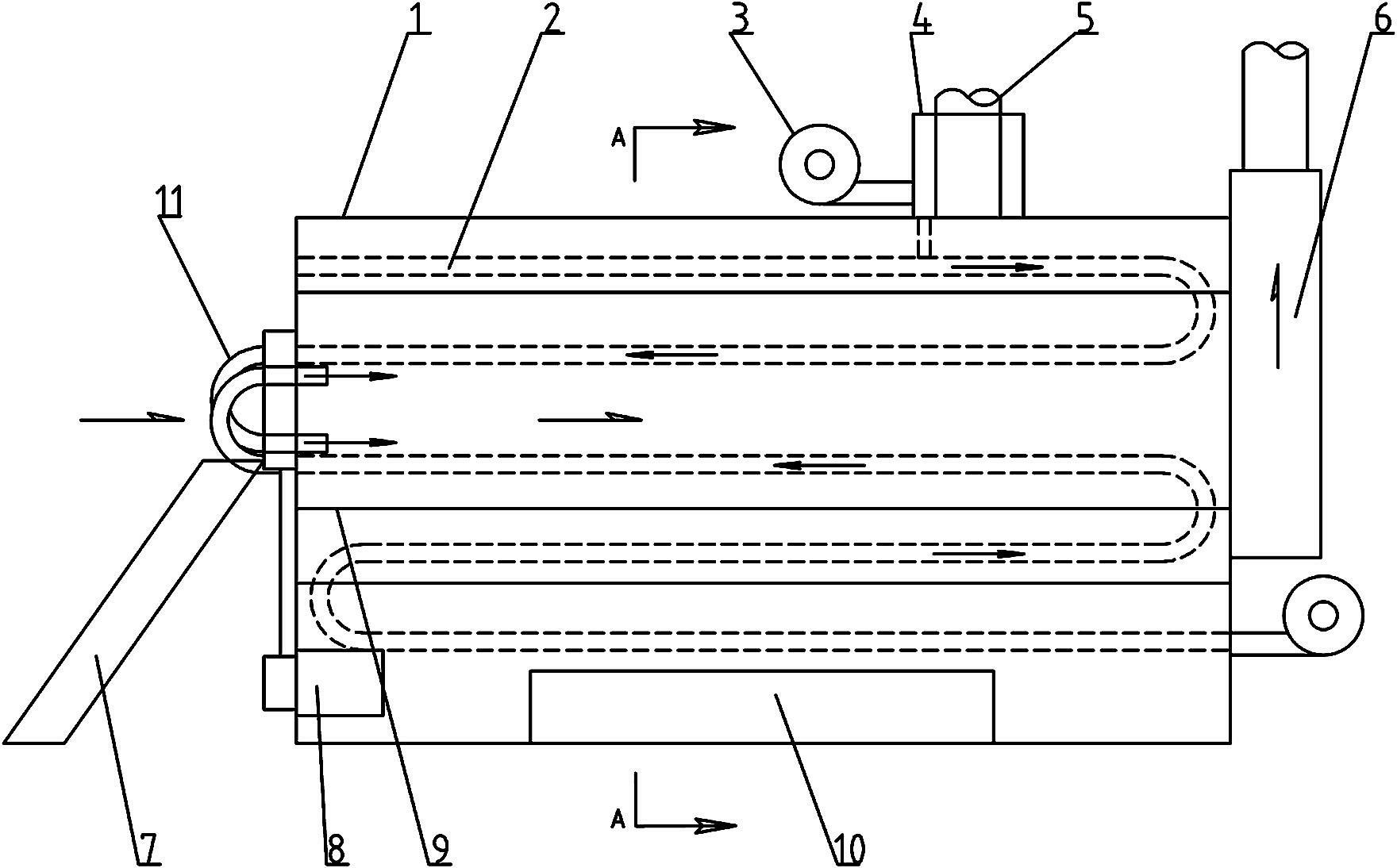

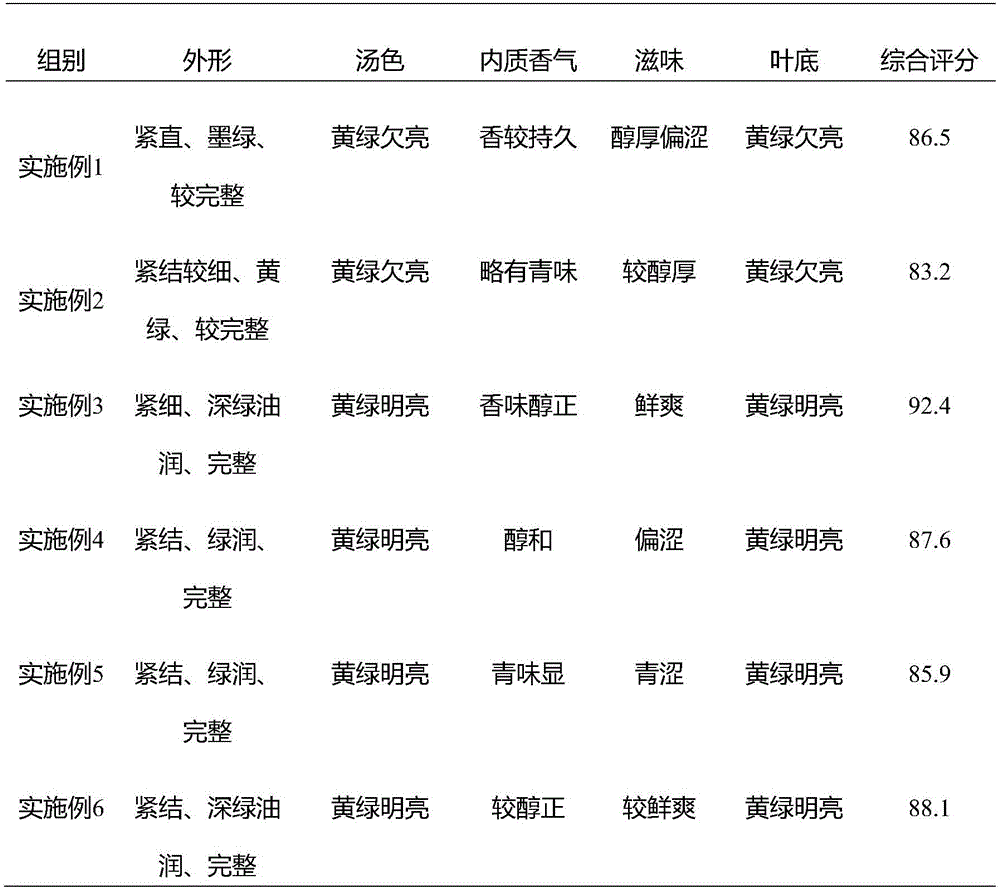

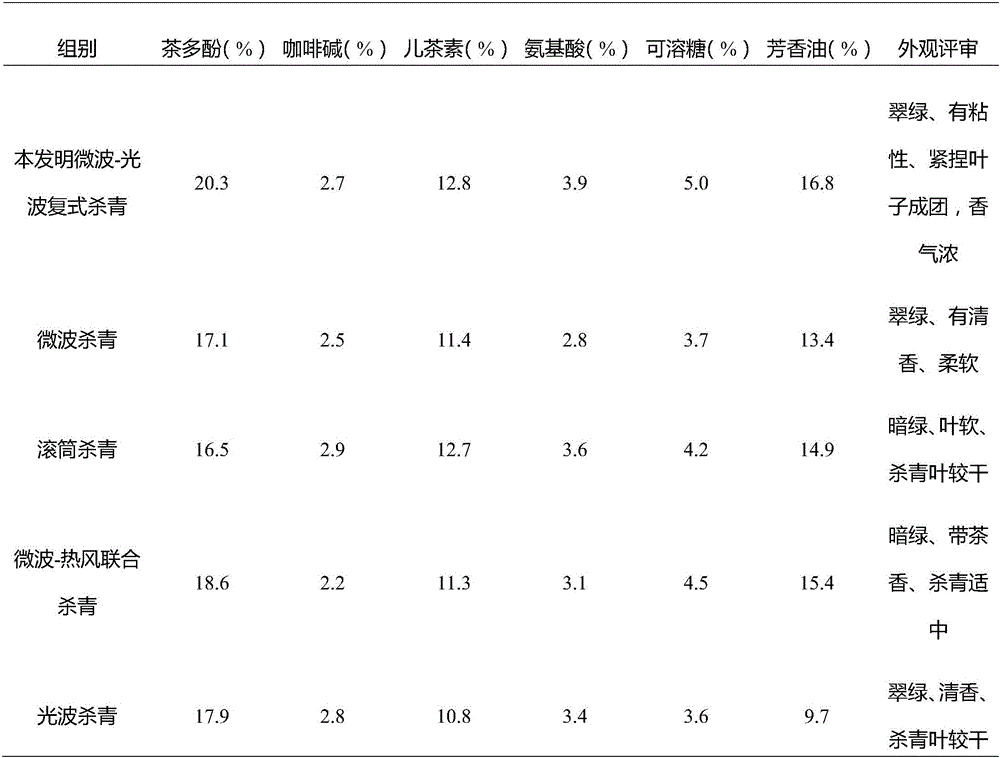

Microwave and light wave compound de-enzyme process

The invention relates to the technical field of tea processing and in particular relates to a microwave and light wave compound de-enzyme process. The microwave and light wave compound de-enzyme process comprises five processing procedures of tedding of fresh leaves, de-enzyming, twisting, secondary de-enzyming and secondary twisting; a prepared tea product has the advantages of high quality, high nutrition, fragrant flavor and delicious taste; in addition, a de-enzyme process has the advantages of high working efficiency, low energy consumption and easiness in operation.

Owner:贵州安顺春来茶业有限公司

Method for processing high-grade and high-quality chrysanthemum beverage

The invention provides a method for processing a high-grade and high-quality chrysanthemum beverage. The method comprises the following steps of: killing green of high-quality feverfew or buds (chrysanthemum buds), which serve as raw materials, by a wire mesh belt steam heat green killing machine with steam and hot air, and then heating, dewatering and drying the processed high-quality feverfew or buds in a closed container with vacuumizing, refrigerating and heating functions under a certain vacuum degree and a certain refrigeration condition until the moisture content of the dried feverfew or buds is less than or equal to 10 percent. The chrysanthemum beverage product keeps more effective substances such as flavones and has the advantages that the color and the form are natural, fresh and live, the fragrance is mellow and rich, the flavor is purely sweet and the quality is high.

Owner:GUANGXI GUILIN TEA RES INST

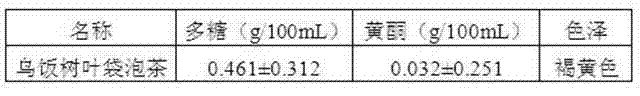

Method for preparing tea bag by oriental blueberry leaf

A method for preparing tea bag by oriental blueberry leaves comprises the following steps of: (A) crushing, that is, performing mechanical crushing of oriental blueberry leaves twice; (B) soaking, that is, mixing the crushed oriental blueberry leaves with water, and soaking; (C) suction filtration, that is, performing suction filtration to realize slag-liquid separation so as to obtain soaked oriental blueberry leaves; (D) enzyme deactivation, that is, performing enzyme deactivation of the soaked oriental blueberry leaves by steam; (E) drying and sterilization, that is, drying and sterilizing the oriental blueberry leaves after enzyme deactivation by hot air circulation; (F) bagging, that is, bagging the dried and sterilized oriental blueberry leaves. The oriental blueberry leaf tea bag prepared by the invention has natural fragrance of oriental blueberry leaves, and high health care value, and thus the invention enlarges the application scope of oriental blueberry leaves, and improves the economical value of oriental blueberry leaves.

Owner:无锡市金和泰农业生物技术有限公司

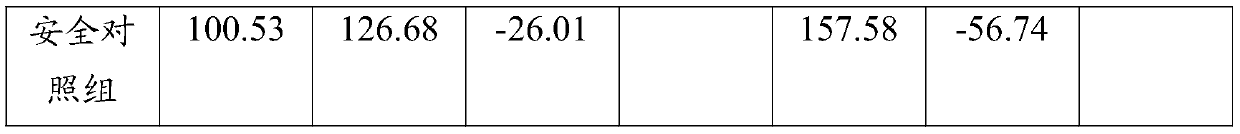

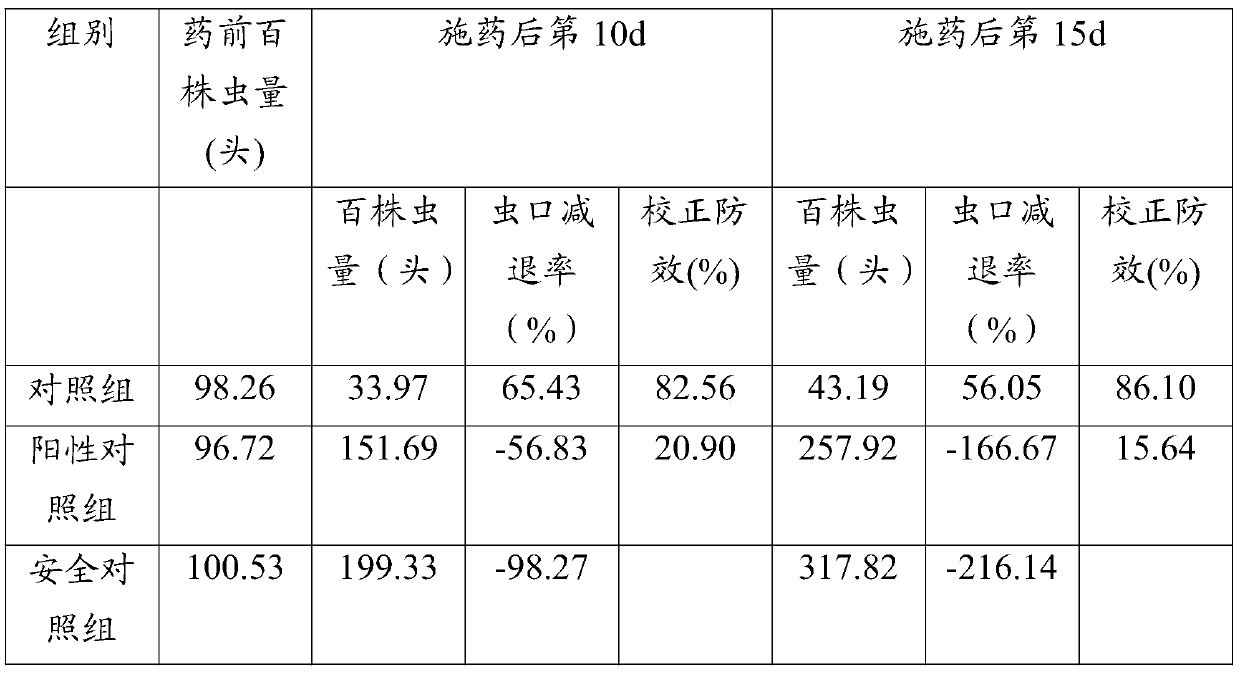

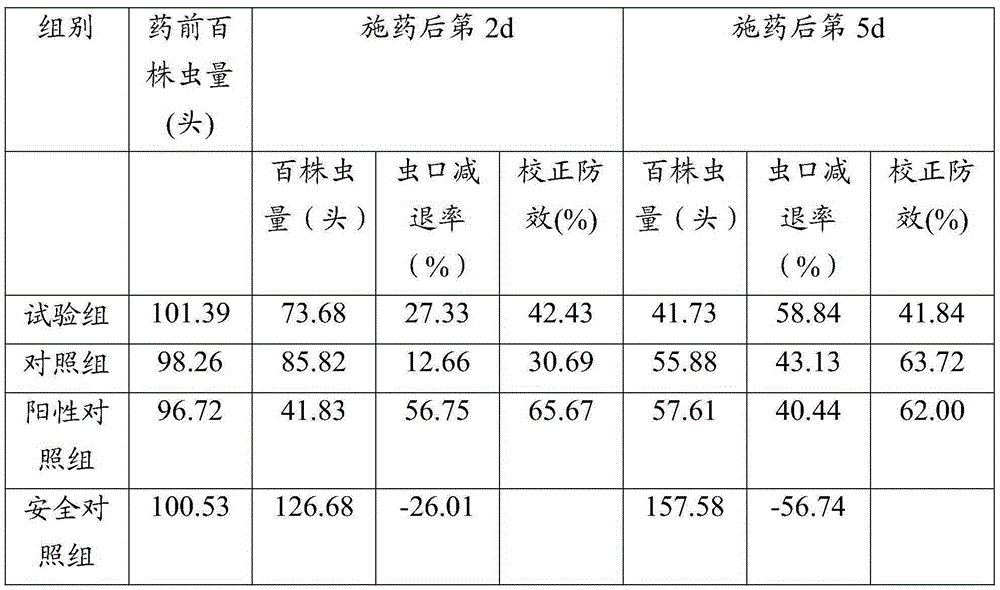

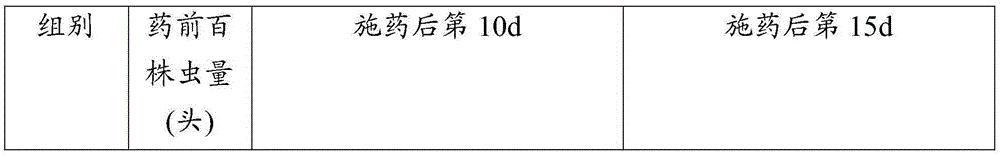

Plant extracted pesticide preventing and controlling Chinese cabbage caterpillar

The invention provides a novel plant extracted pesticide, of which raw materials comprise plant extracted active components, surfactant, synergist, solvent and water. The pesticide has the advantages of small toxicity, small residue, short killing time for Chinese cabbage caterpillar, good effect, and long lasting duration.

Owner:QINGDAO HUAREN TECH INCUBATOR

Manual making technique of green tea

InactiveCN105076519AGuaranteed not to grow greenEven curlPre-extraction tea treatmentGreeningGreen tea

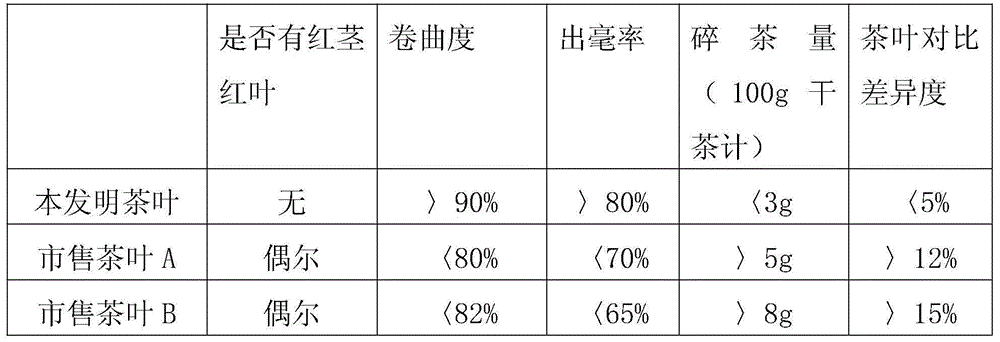

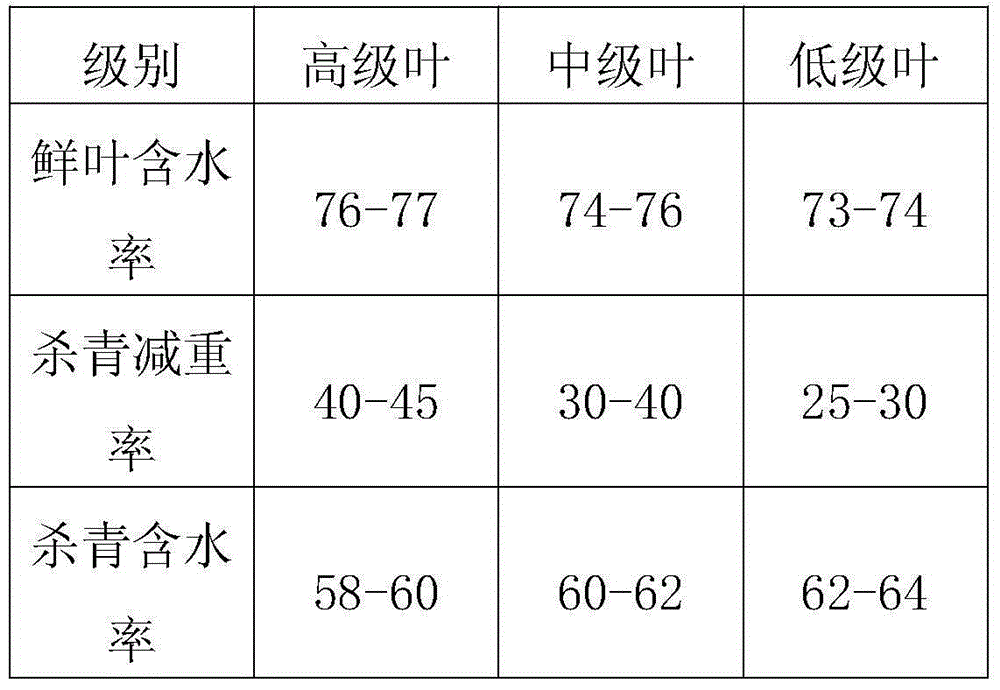

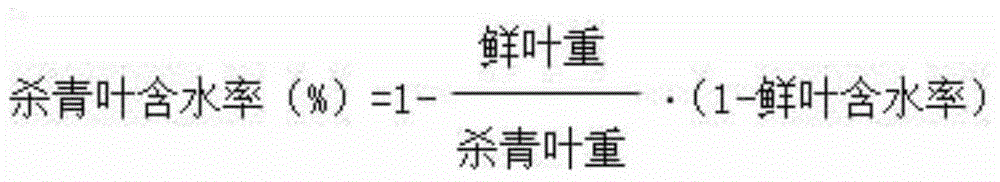

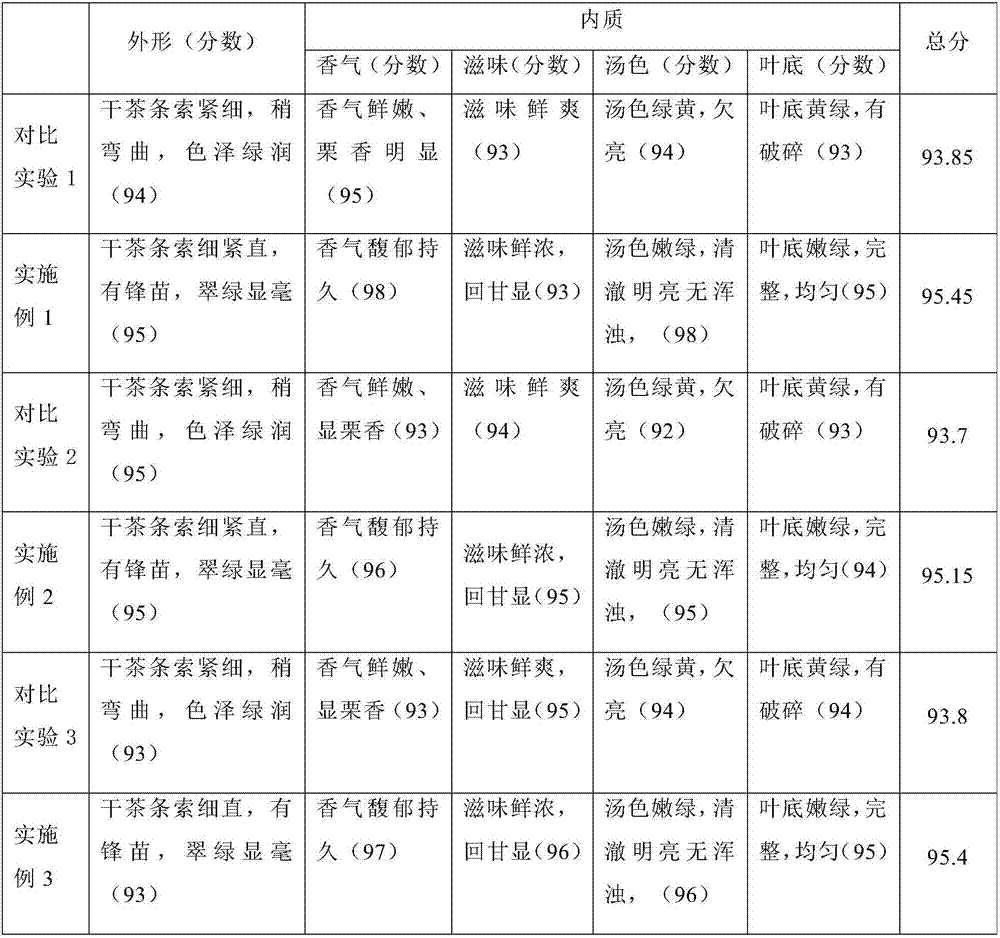

The invention discloses a manual making technique of green tea. The technique includes the steps of A, fixation; B, rolling; C, shaping; D, tipping; E, aroma-improving; and F, drying. The fixation process of the technique ensures tea leaves are free of greening, co-curing, edge burnt, stem and leaf redness, grass smell, water stuffiness odor, curing stuffiness odor and coke odor, at the premise of ensuring 90% to 100% of fixation rate; the rolling process ensures more than 90% of tea leaves are evenly curled; the tipping process ensures tipping rate of the tea leaves is above 80%; In the whole tea processing process, each 500g of fresh tea leaves can be made into 125g of dried tea, and the final dried tea has only 3g to 4g of broken tea. The tea made by the technique has high quality, has no great difference, has uniform color and lasting aroma, is uniform in degree of curling, has uniform, fluffy and cotton-like white hair, is free of stinking, burst and peculiar odor and has few broken tea.

Owner:黔南州梅渊商贸有限公司

Processing method of green tea

InactiveCN107372931AIncrease internal and external temperatureImprove consistencyPre-extraction tea treatmentHorticultureDissolutionGreen tea

The invention discloses a processing method of green tea, which belongs to the technical field of tea processing. The processing method comprises the following steps: picking, withering, fixing, spreading and air-drying, kneading, removing tealeaf tips, pile-fermenting, pressing, floating, drying and improving the fragrance; the fragrance improvement is to treat a tea block which is dried and cooled to the normal temperature with steam of 100 to 120 DEG C for 6 to 12 min, then to place the tea block into a fragrance improving machine, wherein the temperature in the fragrance improving machine is adjusted to 30 to 50 DEG C, after the tea block is treated for 8 to 15 min, the temperature is increased to 60 to 80 DEG C, after the tea block is treated for 6 to 10 min, the temperature is increased to 90 to 110 DEG C, and then the tea block is treated until the water content is 3.0 to 5.5 percent, thus obtaining the green tea. According to the processing method, when the fragrance is improved, the tea block is firstly preheated with steam, so that substances contained in the tealeaves can be changed, a maturity accelerating effect can be achieved, the fragrance of the tealeaves can be significantly improved, the dissolution of tealeaf substances can be increased, and the content of water extract can be increased.

Owner:贵州苗贵客贸易发展有限公司

Process for processing tea flowers

The invention relates to a process for processing tea flowers. The process comprises a step (1) of picking tea flowers: manually picking bloomy tea flowers; a step (2) of cleaning the tea flowers: performing deactivation of enzymes of withered tea flowers; a step (3) of warming and withering the tea flowers: evenly flatly spreading out tea tree flowers having undergone cell wall breaking in a withering device to perform withering, controlling the withering temperature at 30-32 DEG C, and withering for 1.5-3 h until the flower color turns dark, the flower type withers and petals turn soft; a step (4) of performing deactivation of enzymes: performing deactivation of enzymes in a microwave de-enzyme machine; a step (5) of cooling the flowers: placing the well withered tea flowers in a spreading cooling device to spread out and cool the tea flower at normal temperature; a step (6) of performing enzymosis: spraying glucoamylase solvent on the cooled tea flowers; and a step (7) of drying the tea flowers: placing the tea flowers having undergone enzymosis in a dryer to dry the tea flowers. The tea microwave de-enzyme machine is adopted to perform deactivation of enzymes of the tea flowers, the water content of the tea flowers having undergone deactivation of enzymes is lower than when steam de-enzyme is performed, the flowers are complete and good in appearance, the time for deactivation of enzymes is short, and the tea flower fragrance loss is reduced.

Owner:吴潇娅

Poisonless mouse killing agent

InactiveCN1586207AShort killing timeSatisfy the tasteBiocideAnimal repellantsToxicologyGastrointestinal tract

The poison-less mouse killing agent without toxic component consists of No. 525 cement 2-4 weight portions, corn 2-4 weight portions, flour 1-4 weight portions and sesame 1-3 weight portions, and is produced through crushing the material, mixing and sealed packing. The present invention has the advantages of no toxicity, high safety and short mouse killing time. Of the material, the cement chocks the digestive tract of mouse and the other components attract mouse to eat.

Owner:涂民建

High-aroma Maojian and processing technology thereof

InactiveCN107348027AEfficient volatilizationEffective penetrationPre-extraction tea treatmentCooking & bakingSweetness

The invention provides high-aroma Maojian and a processing technology thereof. The processing technology comprises the following steps of performing spreading for cooling, performing rocking of green tea leaves, performing fixation, performing screening, performing moisture regain, performing rolling, performing baking, performing trimming, performing strip tidying and preparing finished products. The high-aroma Maojian is obtained through the processing technology. The high-aroma Maojian is fine and round in dried tea strips, slightly tippy, high in aroma, rich in flower aroma, clear, fresh, green and bright rather than turbid in tea soup color, mellow, fresh and refreshing in taste, obvious in sweetness after taste, and uniform and consistent in leaf bases, and the sense organ enjoyment of people when the people drink the high-aroma Maojian is greatly improved.

Owner:信阳市农业科学院

Method suitable for preservation preparation of south Xinjiang hippophae rhamnoides leaf tea nutritional ingredients

The invention discloses a method suitable for preservation preparation of south Xinjiang hippophae rhamnoides leaf tea nutritional ingredients. According to the method, picking period of hippophae rhamnoides leaf is determined to be September every year; microwave technology is adopted for fresh leaf enzyme deactivation, and microwave sterilization and drying setting are adopted; microwave enzyme deactivation effect is the best when leaf adding amount is controlled to be 40g, enzyme deactivation time is controlled to be 90s, and microwave powder is controlled to be 60%; POD relative enzymatic activity is controlled to be 1.690% or less, tea polyphenol content is controlled to be 16.981% or less, flavones dissolving-out amount is controlled to be 2.340mg / g; hippophae rhamnoides leaf tea is obtained via rolling, drying, and water content controlling. Research is carried out based on south Xinjiang dry inland climate so as to determine appropariate picking period of hippophae rhamnoides leaf and appropriate technology used for preserving the hippophae rhamnoides leaf tea nutritional ingredients. The effective method used for preserving south Xinjiang hippophae rhamnoides leaf tea nutritional ingredients is obtained; and application value is high.

Owner:UQTURFAN COUNTY YANSHAN FRUIT IND CO LTD

Preparation method of fragrant green tea in Guizhou mountain area

InactiveCN108925690AMellow tasteImprove bitter tastePre-extraction tea treatmentTea flavoringFlavorPenetration force

The present invention provides a preparation method of a fragrant green tea in Guizhou mountain area. The method comprises the steps of tea leaf picking, a steaming technology, refrigerating, a rolling technology, shaping, and drying. The steaming step is carried out under a low-pressure environment, and the steaming temperature is controlled at 70-80 DEG C. In the steaming step, the steam has strong penetration force, has short enzyme deactivation time, can rapidly inhibit the activity of oxidase, and can improve the content of various biochemical qualities of the green tea; and at the same time, the green fragrance of the celery is combined with the tea flavor, so that the tea has a more mellow taste, the bitter and astringent taste of the tea leaves is improved, and the tea has a slightfragrant taste, meets the requirements of consumers on tea taste diversification, and has important economic significance.

Owner:贵州省松桃武陵源苗王茶业有限公司

Composite pesticide used for preventing and killing Chinese cabbage Pieris rapae L.

InactiveCN105360187AShort killing timeGood effectBiocideAnimal repellantsAdditive ingredientActive component

The invention provides a novel composite pesticide, and more specifically relates to a composite pesticide used for preventing and killing Chinese cabbage Pieris rapae L. The composite pesticide comprises an active component, a surfactant, a synergist, a solvent, and water. The composite pesticide possesses advantages in preventing and killing Chinese cabbage Pieris rapae L. via adding of chemical pesticide ingredients and plant extracts; toxicity is low; residual amount is low; killing time of Chinese cabbage Pieris rapae L. is short; effect is excellent; and killing effect lasts for a long period of time.

Owner:QINGDAO HUAREN TECH INCUBATOR

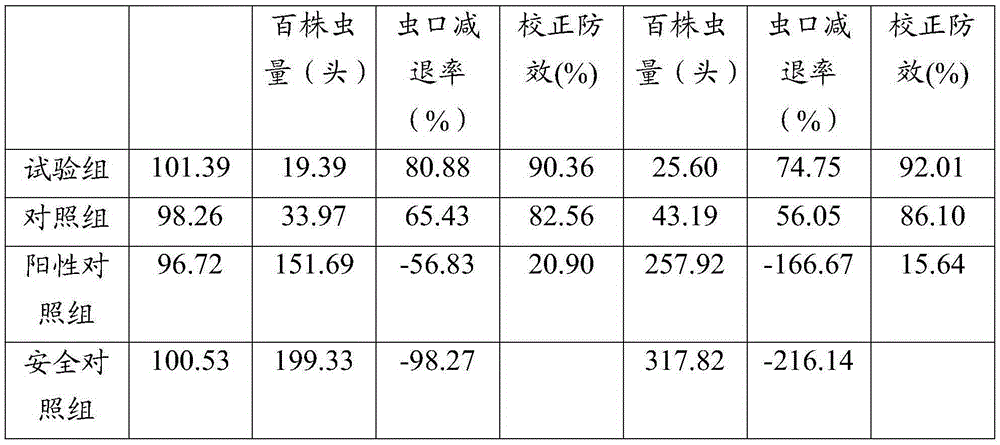

Preparation method of high-quality black tea extract

InactiveCN109043008ARemove green and astringent tasteEffective destructionTea extractionDistilled waterBLACK TEA EXTRACT

The invention relates to the technical field of black tea processing and in particular relates to a preparation method of high-quality black tea extract. The preparation method comprises the followingsteps: S1, taking lotus leaves and carrying out high-temperature steam sterilization; carrying out fixation until the water content is 10 to 15 percent; S2, taking the lotus leaves subjected to the fixation and black tea into a rolling machine and rolling again; S3, putting the rolled lotus leaves and blank tea into a fermentation device; spraying fermentation bacterium liquid and fermenting for10 to 12h; S4, adding distilled water into a fermented product in step S3; raising the temperature and decocting for 1.2 to 1.5h; after decoction is finished, decompressing and concentrating until thevolume is 1 / 3 of a previous volume; then adding xylitol and glucose and uniformly mixing to obtain tea extract; S5, drying and sterilizing. The tea extract prepared by the technology has good stability and excellent mouthfeel and has the health-care effects of lowering blood pressure, lowering blood lipid, inhibiting bacteria and the like.

Owner:贵州芊指岭生态茶业有限公司

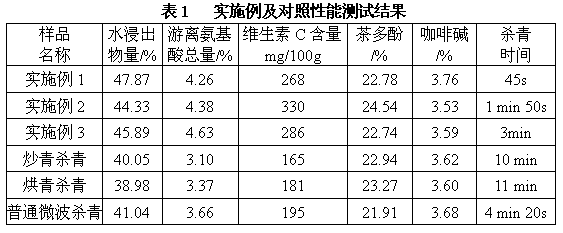

Processing method of common green tea and green tea prepared by processing method

InactiveCN104222342AIncrease the exposed areaInhibitory activityPre-extraction tea treatmentGreen teasTea leaf

The invention provides a processing method and a processing device of common green tea and green tea prepared by the processing method. The processing method comprises the following steps: shearing picked fresh tea leaves into sections with the length of 2-3cm; spreading for 4-6 hours until the water content is less than or equal to 85%; and carrying out fixation and subsequent operation. By adopting the method, the content of tea powder of the tea leaves can be reduced so that the aroma of the finished-product tea leaves is rich, the length of tea leaves is uniform, the sizes are consistent and a phenomenon that burnt tea leaves are obtained is reduced or avoided.

Owner:HUBEI XIUSHUITIANXIANG TEA IND CO LTD

Lotus leaf delicate fragrance type fumigated and enzyme deactivated tea leaves and preparation method thereof

InactiveCN106359709ALow boiling pointPrevent overflowPre-extraction tea treatmentClimate change adaptationAlcoholBoiling point

The present invention discloses lotus leaf delicate fragrance type fumigated and enzyme deactivated tea leaves and a preparation method thereof. The tea leaves are prepared from the following raw materials in parts by weight: edible alcohol, tea fresh leaves, mulberries, sodium citrate, Chinese wolfberry fruits, lotus leaves, fructus hippophae, mint leaves, oat bran, green plum fleshes, grapefruit skins, lotus flowers, lotus root starch, lavender and a right amount of water. The lotus leaves, mint and other freshly delicate materials are subjected to a quick steaming and boiling until the materials are boiled out, color and taste of the leaves are removed, then the boiled materials are smashed into paste, the paste is covered with the lotus root starch, when the lotus root starch is stick with water, a layer of thin membrane covers the surface of the paste materials to prevent the fragrance overflowing and at the same time preventing oxidation, and then the edible alcohol is used to extract the substances with the delicate fragrances. The presence of the alcohol reduces boiling point of water, but pressurization can improve the boiling point, improve the steam temperature, and shorten the enzyme deactivating time. Too long steam fumigation time is easy to cause tea leaf crispness and affects the soaking effect. The steam temperature and the unique permeability property are sufficient to complete the enzyme deactivating.

Owner:张文墨

Device and method for preventing and treating insect damage through carbon dioxide

The invention relates to a device for preventing and treating insect damage through carbon dioxide. The device comprises a sealing tent, and storage materials are contained in the sealing tent; the periphery of the sealing tent is wrapped with a heat preservation and insulation layer; a gas inlet pipe and a gas outlet pipe are arranged on the two sides of the middle of the sealing tent respectively, one end of the gas inlet pipe and one end of the gas outlet pipe are located in the sealing tent, and electromagnetic valves are arranged at the other ends, located outside the sealing tent, of the gas inlet pipe and the gas outlet pipe; a heater is connected with a carbon dioxide gas source, and is connected with the gas inlet pipe, the gas outlet pipe and the sealing tent to form a sealing loop; a carbon dioxide sensor and a temperature sensor are installed in a membrane cover and is connected with a PLC arranged outside the membrane cover and used for controlling the electromagnetic valves; the PLC is connected with the heater. The invention further discloses a method for preventing and treating the insect damage through the carbon dioxide. The method for preventing and treating the insect damage through the carbon dioxide is simple in structure, convenient to use and good in insect killing effect. The method is short in insect killing time; insect killing is thorough; the method is safe, environmentally friendly and free of residues.

Owner:湖南华望熏蒸消毒有限公司

Preparation method for pomegranate bud green tea

A preparation method for pomegranate bud green tea includes: (1), collecting fresh leaves; (2), deactivating enzymes of the leaves by enzyme deactivation pans, and adopting a stir-frying mode combining braising, shaking and scattering to fry the leaves for 8-9 minutes at a rotating speed of 18-20 rounds / minute when the pans are heated to redden the bottoms of the pans slightly and the temperatures of the pans reach 200-240 DEG C, wherein 5-6 kilos of the leaves are put into each pan; or deactivating the enzymes of the leaves in the two enzyme deactivation pans continuously by enzyme deactivation machines, specifically, when the first pan is heated to be reddened slightly and the temperature of the pan reaches 260-280 DEG C, feeding 6-8 kilos of the fresh leaves, covering the pan for braising, removing a pan cover for scatter-frying for 3-4 minutes after steam rises from a seam of the pan cover, opening a pan valve to allow the tea leaves to enter the second pan automatically, controlling the temperature of the second pan at 100-120 DEG C, and taking out the tea after frying the leaves in the second pan for 3-5 minutes; (3), controlling the room temperature of a rolling room at 20-24 DEG C and the humidity of the rolling room at 85-90%; (4), drying the leaves.

Owner:SHANDONG POMO PUNICA JUICE

A clean production process of natural organic green tea

ActiveCN103988921BImprove inner qualityAchieve refinementPre-extraction tea treatmentBiotechnologyNutrition

The invention relates to a natural organic green tea clean-production technology. The natural organic green tea clean-production technology utilizes green tea leaves as making raw materials and the used green tea leaves grow in an organic tea garden and are picked in the spring and summer. The natural organic green tea clean-production technology comprises fresh green tea selection, fresh tea grading tedding, de-enzyming, spreading cooling, winnowing, rolling, deblocking sieving, primary baking, tea strip tidying and shaping, re-baking, autoclaving fragrance-improvement, inspection classification and packaging. The natural organic green tea obtained by the technology has the characteristics of light and elegant tea soup color, sweet tea taste, fresh and lasting fragrance, abundant nutrition and good health care effects, can continuously adjust human body functions, adjust blood pressure, reduce blood fat, prevent cardiovascular diseases, protect heart and cerebral vessels, eliminate fatigue and improve immunity by being drunk by drinkers and is a good health beverage suitable for people of all ages.

Owner:柞水福青山茶文化有限公司

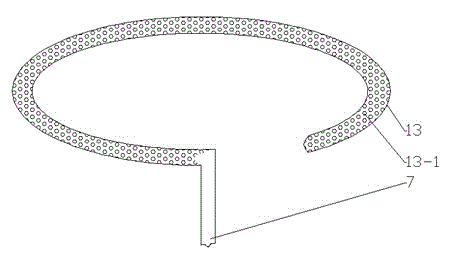

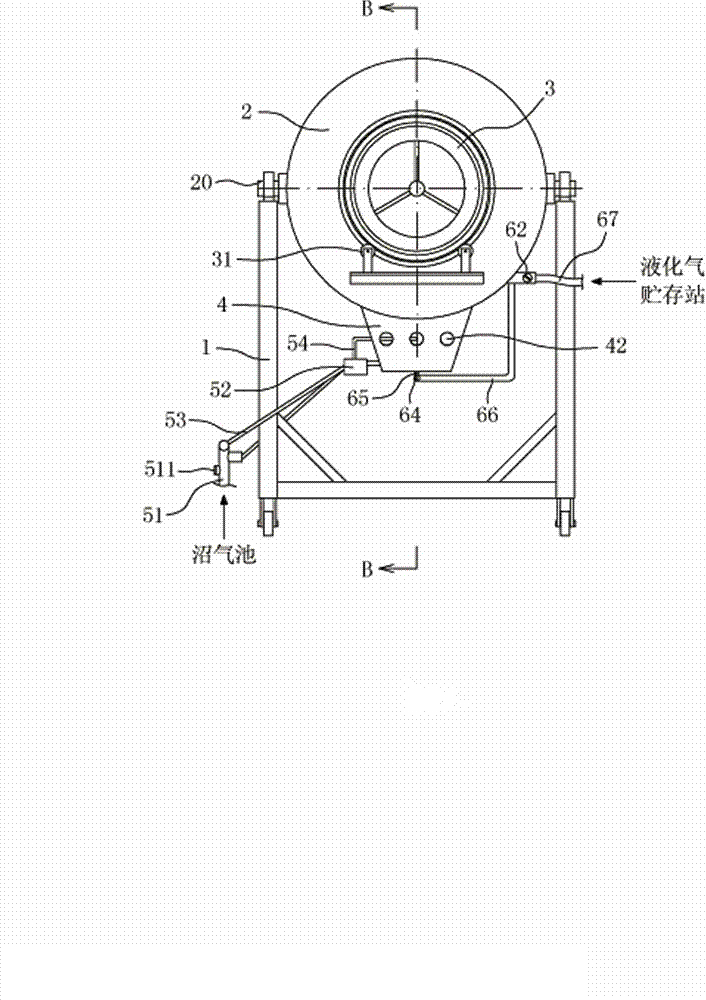

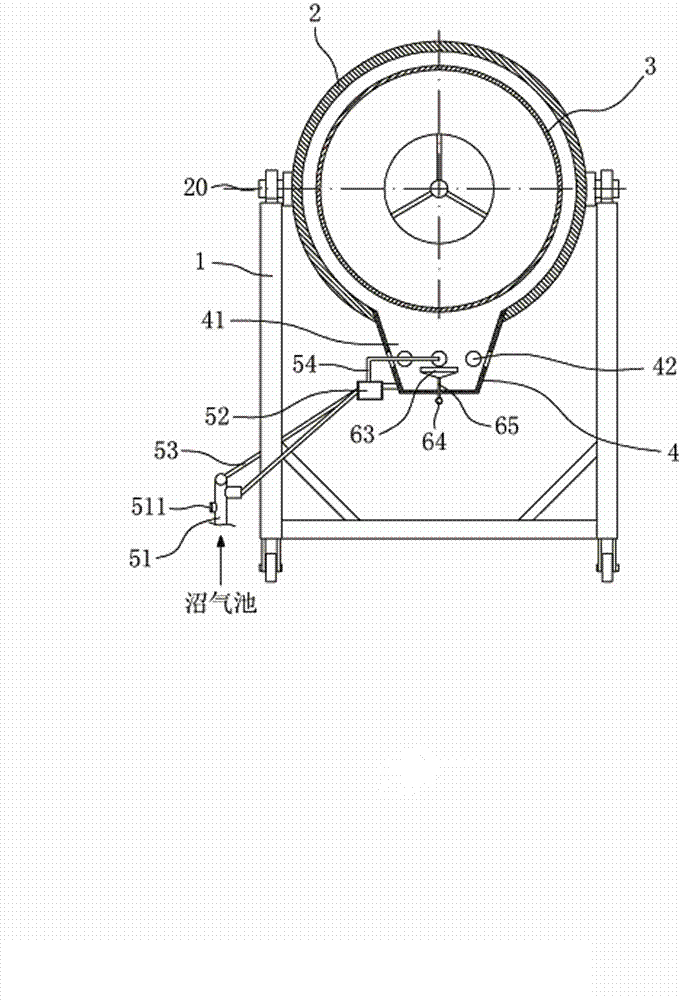

Biogas tea fixing machine

ActiveCN101933544BSmooth air supplySafe and reliable ignitionPre-extraction tea treatmentCombustionMethane

The invention discloses a biogas tea fixing machine, which comprises a frame, a horizontal tea fixing roller arranged on the frame, a driving device driving the tea fixing roller to roll, and a heating device used for heating the tea fixing roller. The biogas tea fixing machine is characterized in that: the heating device comprises a stove and a biogas combustion device arranged under the tea fixing roller; the biogas combustion device comprises a biogas delivery pipeline which is connected with a biogas digester and provided with a valve, and a plurality of high temperature-resistant biogas ejectors connected with the output end of the delivery pipeline; the biogas ejectors pass through the side wall of the stove to extend into the hearth of the stove; and biogas nozzles of all the biogas ejectors are arranged at equal intervals along the length direction of the hearth. The fixing machine is provided with heat by the combustion of the biogas, and the combustion cost is lower, so the manufacturing cost of tea is reduced; the main component of the biogas is methane, and generates water and carbon dioxide after combustion, so the environment is protected; besides, the combustion value of the biogas is high, so the biogas provides enough heat for the fixing machine; therefore, the produced tea has higher quality.

Owner:福建安溪历山茶仙茶业有限公司

Edible fungus processing method

InactiveCN108420053AReduce stirringReduce flipClimate change adaptationFruits/vegetable preservation using acidsFlavorBiotechnology

The invention discloses an edible fungus processing method. The method comprises the steps as follows: fresh edible fungi and a large artery of pig or ox are used as raw materials, the edible fungi ismade into a semi-finished product through procedures of rinsing, color protecting, slicing, precooking, salting, desalination and the like, the large artery of pig or ox is made into a semi-finishedproduct through procedures of rinsing, deodorization, precooking, taste enhancement with bone soup, cooling, cutting and the like, the semi-finished product of edible fungi and the semi-finished product of large artery of pig or ox are matched in proportion, flavoring and seasoning materials and auxiliary materials are mixed uniformly, and an edible fungus product is prepared. The product has theadvantages of being green, natural, reasonable in nutrient matching, good in flavor and taste, convenient to eat, long in expiration date and the like.

Owner:宝鸡胜利现代农业开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com