Vacuum microwave enzyme deactivating method

A technology of vacuum microwave and greening, applied in the direction of tea processing before extraction, can solve problems such as inconsistency in penetration, and achieve the effects of improving quality and quality, speeding up evaporation, and reducing boiling point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

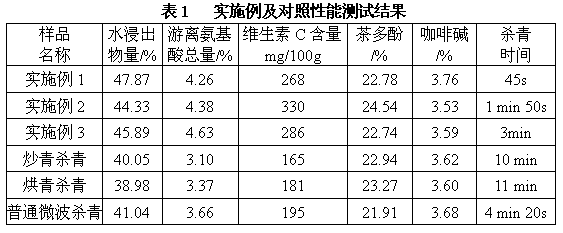

[0007] Embodiment 1 of the present invention: a vacuum microwave de-enzyme method, the green tea after spreading is carried out microwave de-enzyme under the condition of vacuum degree of -0.09 MPa, the microwave power is 30 W / g, and the de-enzyme time is 45s.

Embodiment 2

[0008] Embodiment 2 of the present invention: a vacuum microwave de-enzyme method, the green tea after spreading is carried out microwave de-enzyme under the condition of vacuum degree of -0.05 MPa, the microwave power is 20 W / g, and the de-enzyme time is 1 min 50 s.

Embodiment 3

[0009] Embodiment 3 of the present invention: a vacuum microwave deenzyming method, the green tea after spreading is carried out microwave deenzyming under the condition of vacuum degree is-0.01 MPa, and microwave power is 10W / g, and deenzyming time is 3min.

[0010] With the green tea leaves spread out identical to those in the examples, the existing methods of frying greens, baking greens, and ordinary microwave fixing methods are used for processing, wherein, the time required for frying greens and finishing tea leaves is 10 min, and the finishing is uneven and scorched edges appear; It takes 11 minutes to bake green tea leaves, and the green leaves are uneven, and red stalks and red leaves appear; the time required for ordinary microwave curing is 4 minutes 20 seconds, and the quality of green leaves is good and the color is emerald green.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com