Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Smooth air supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

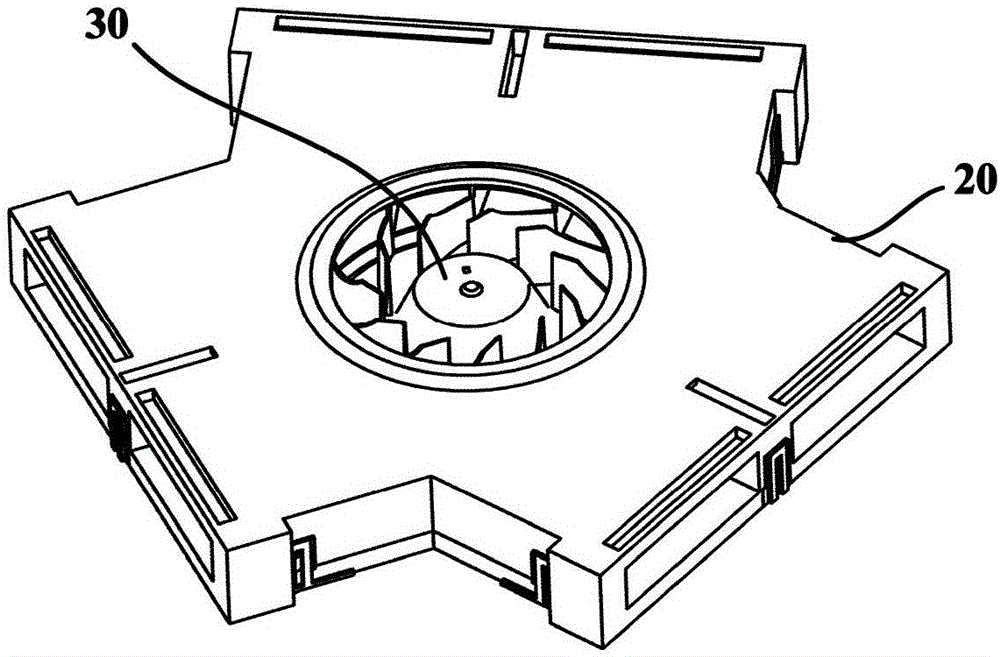

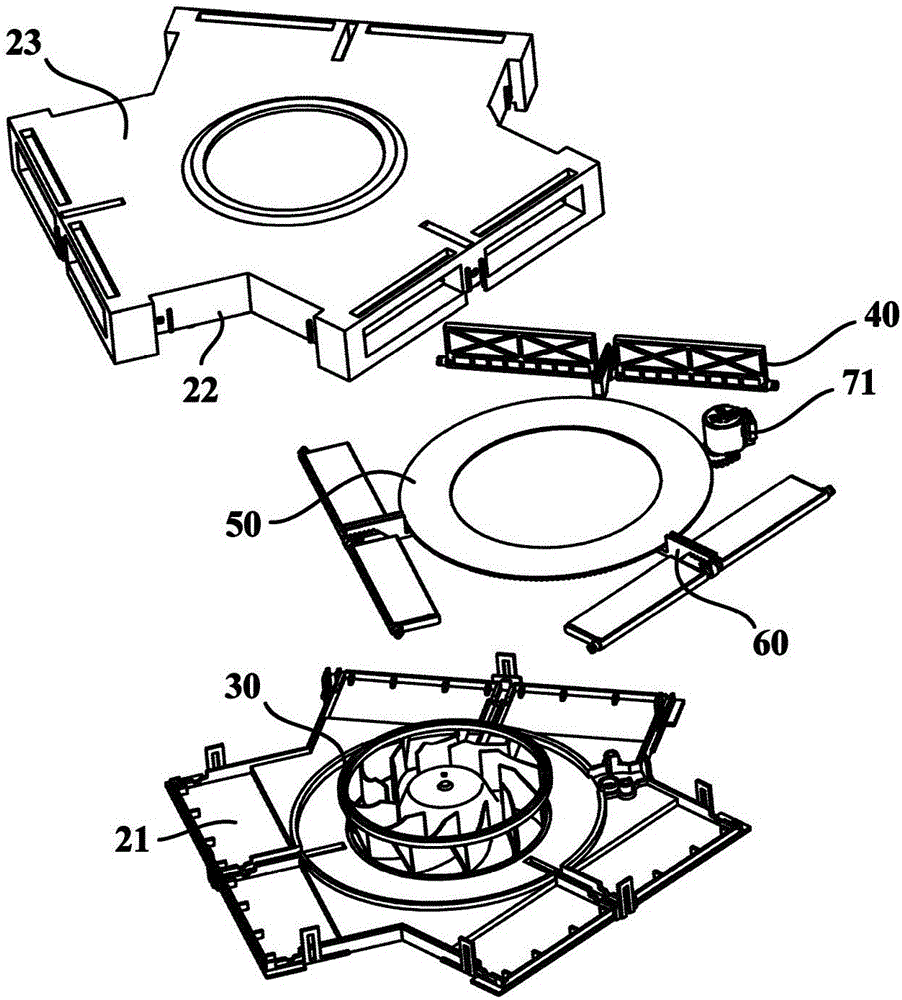

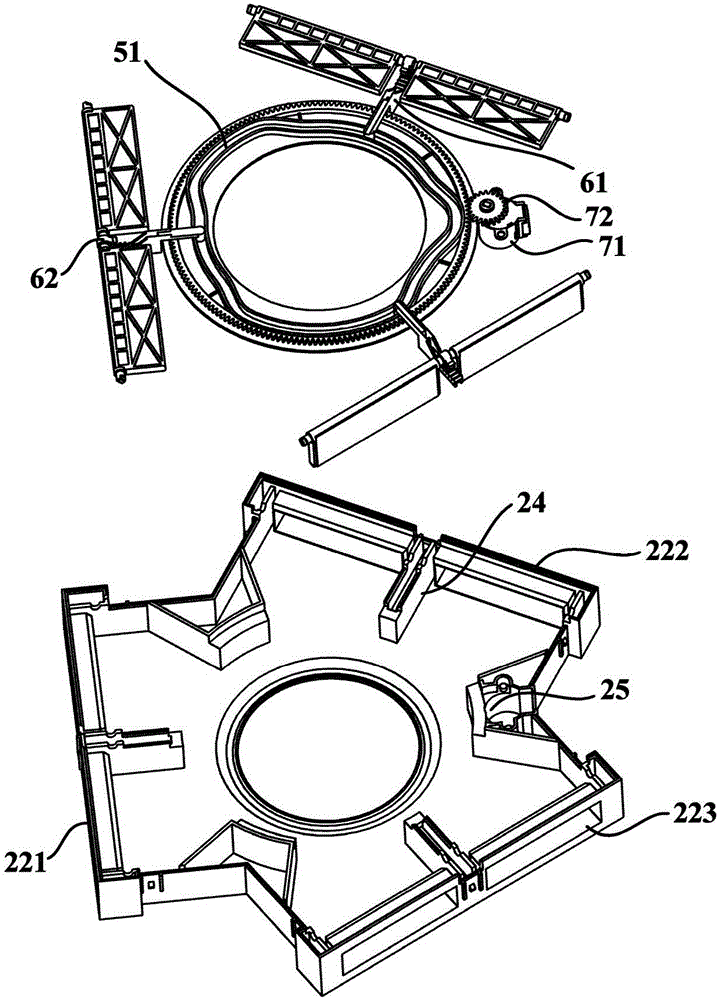

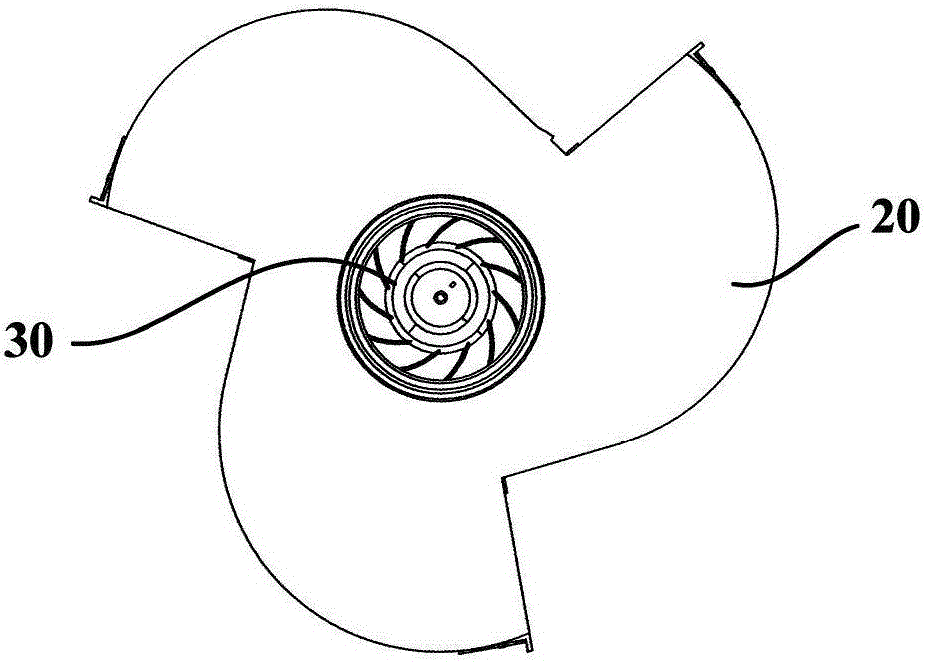

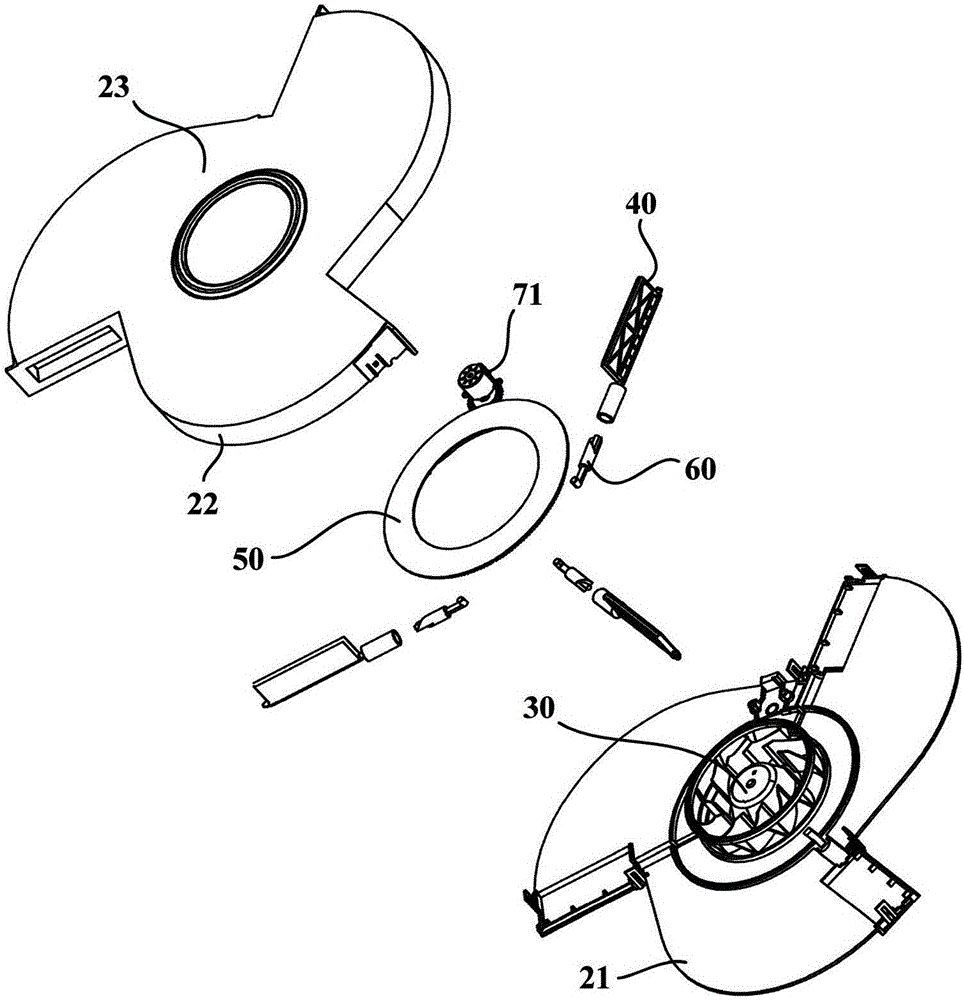

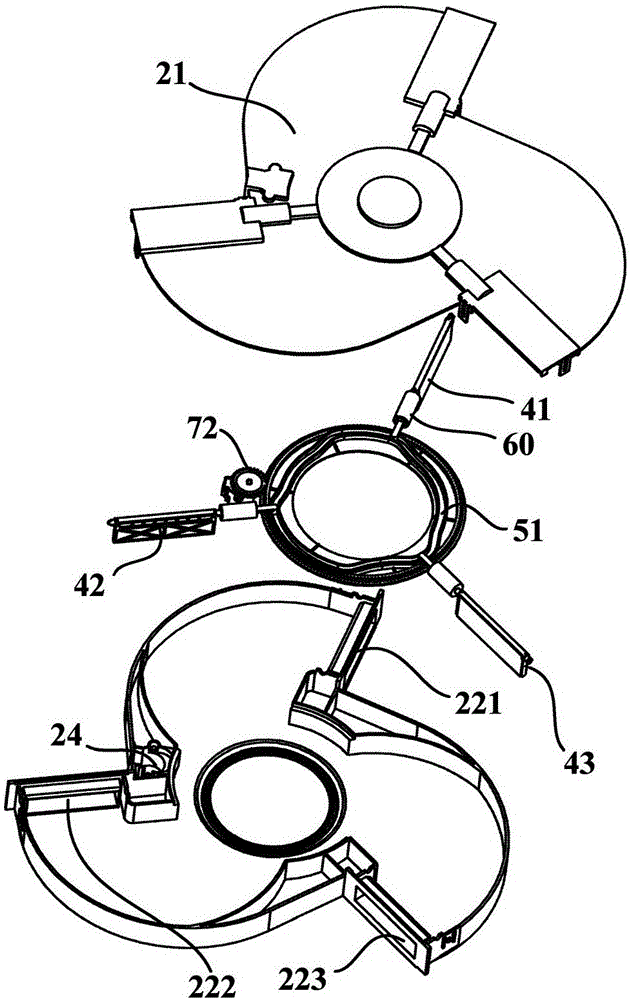

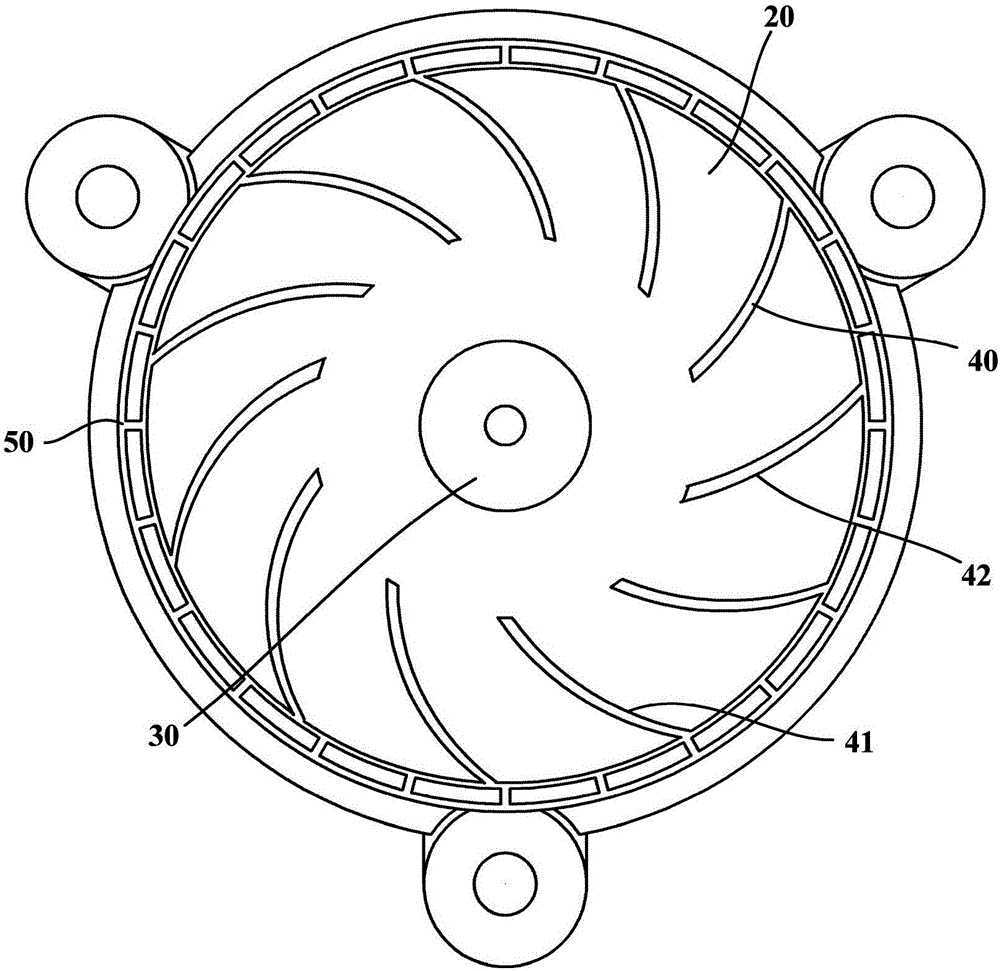

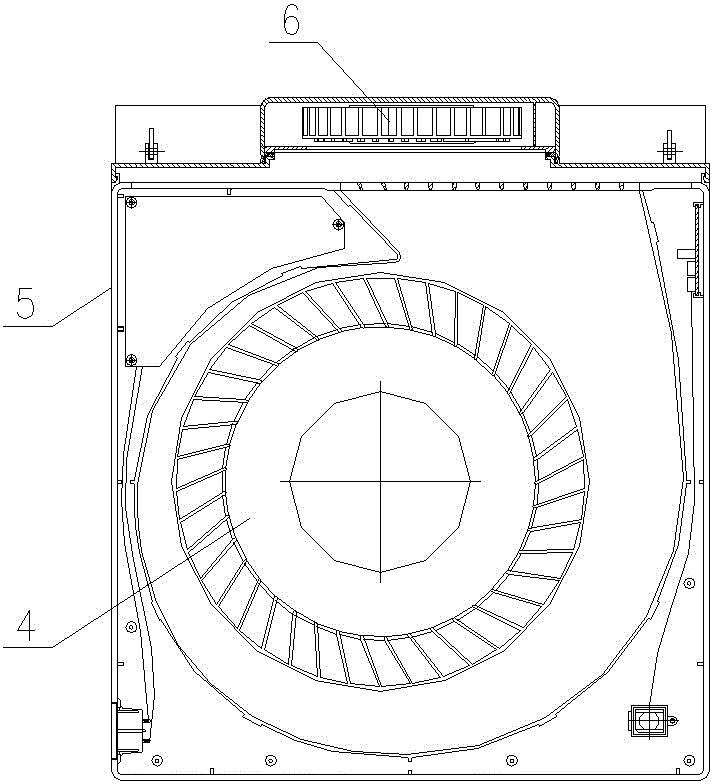

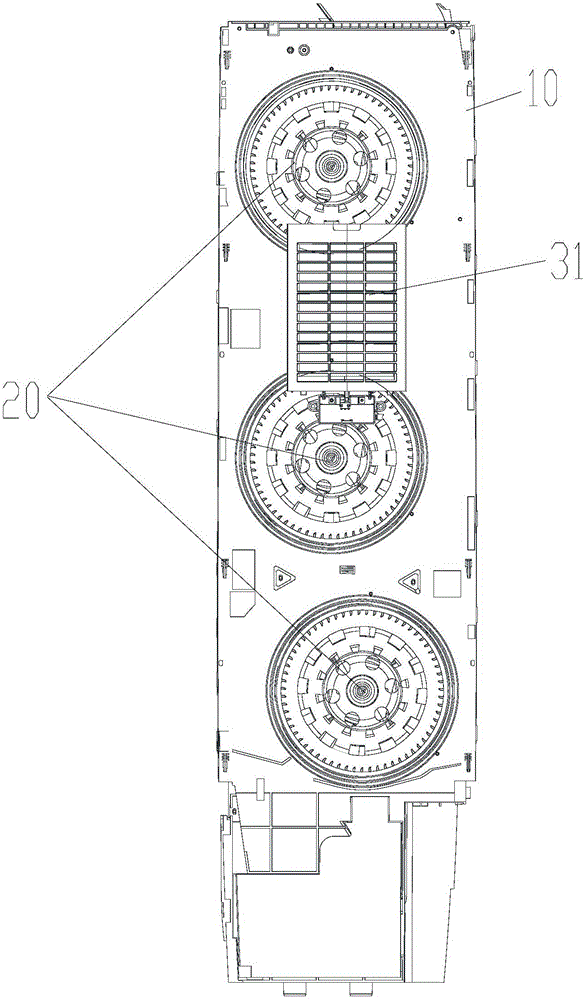

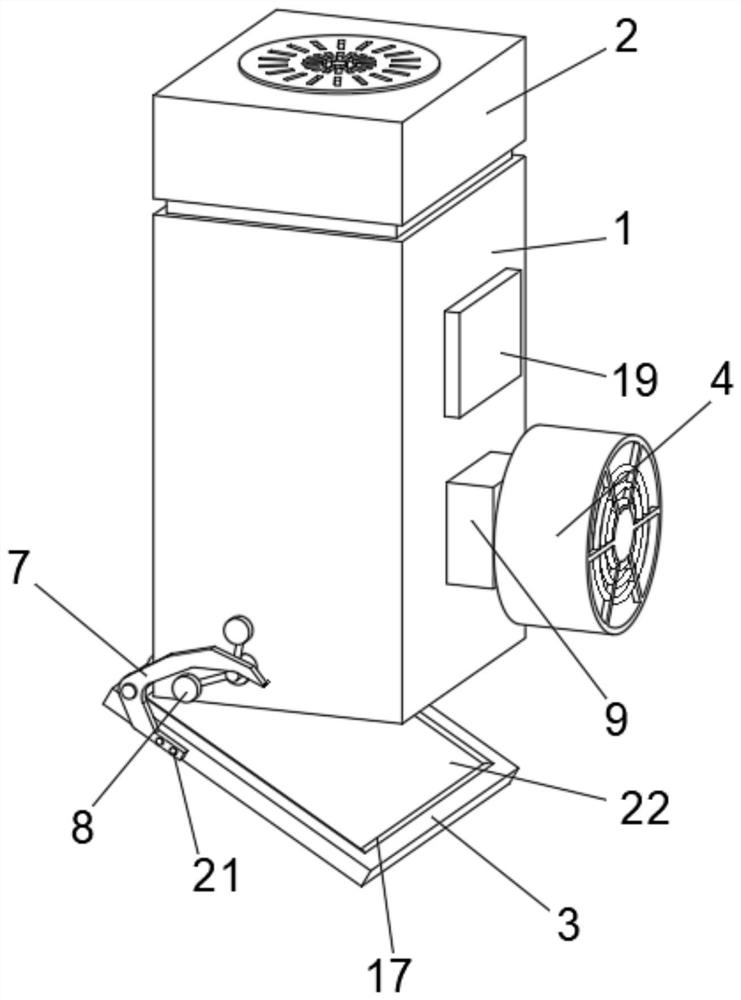

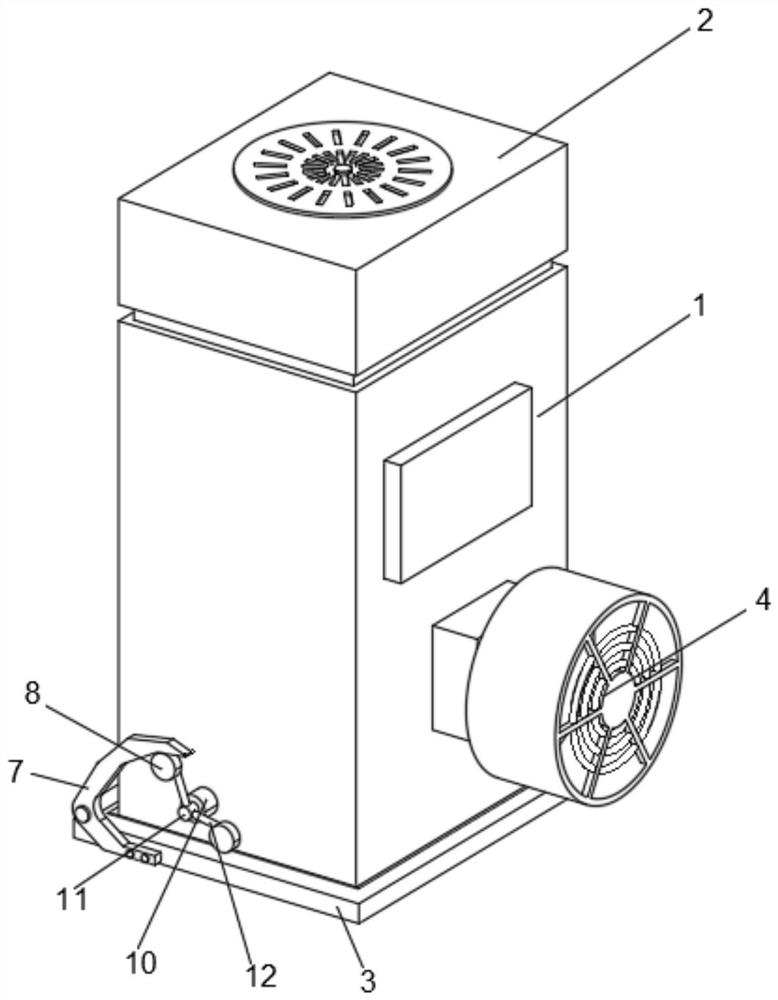

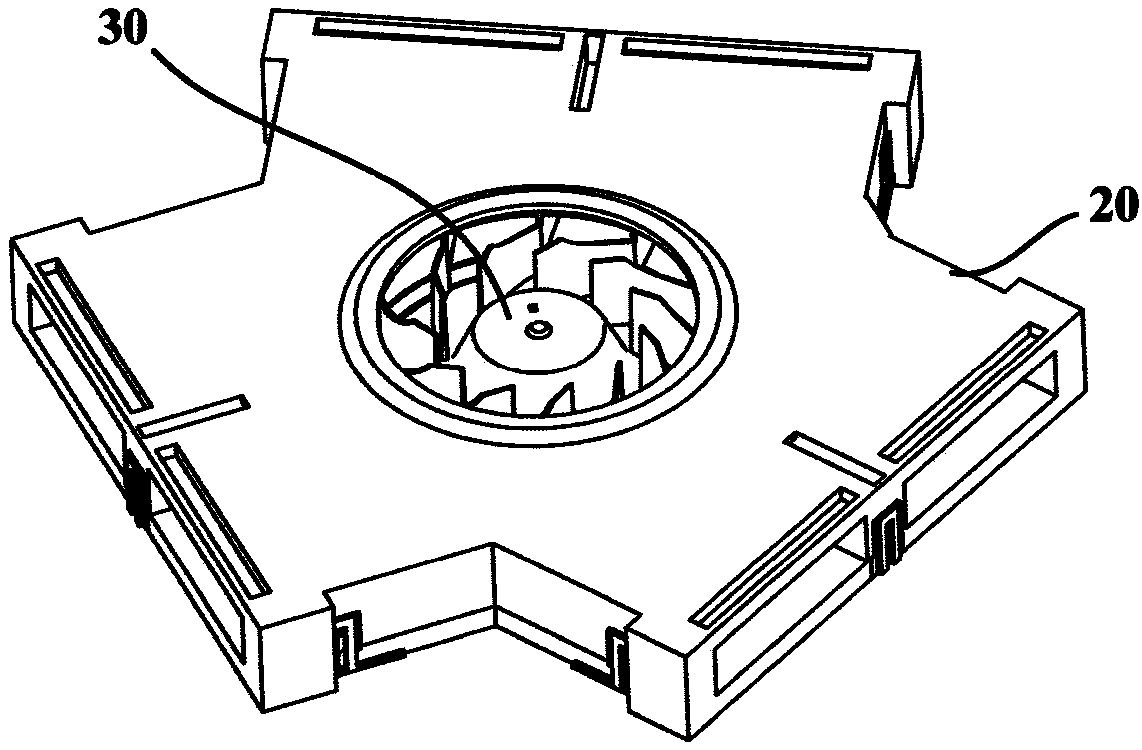

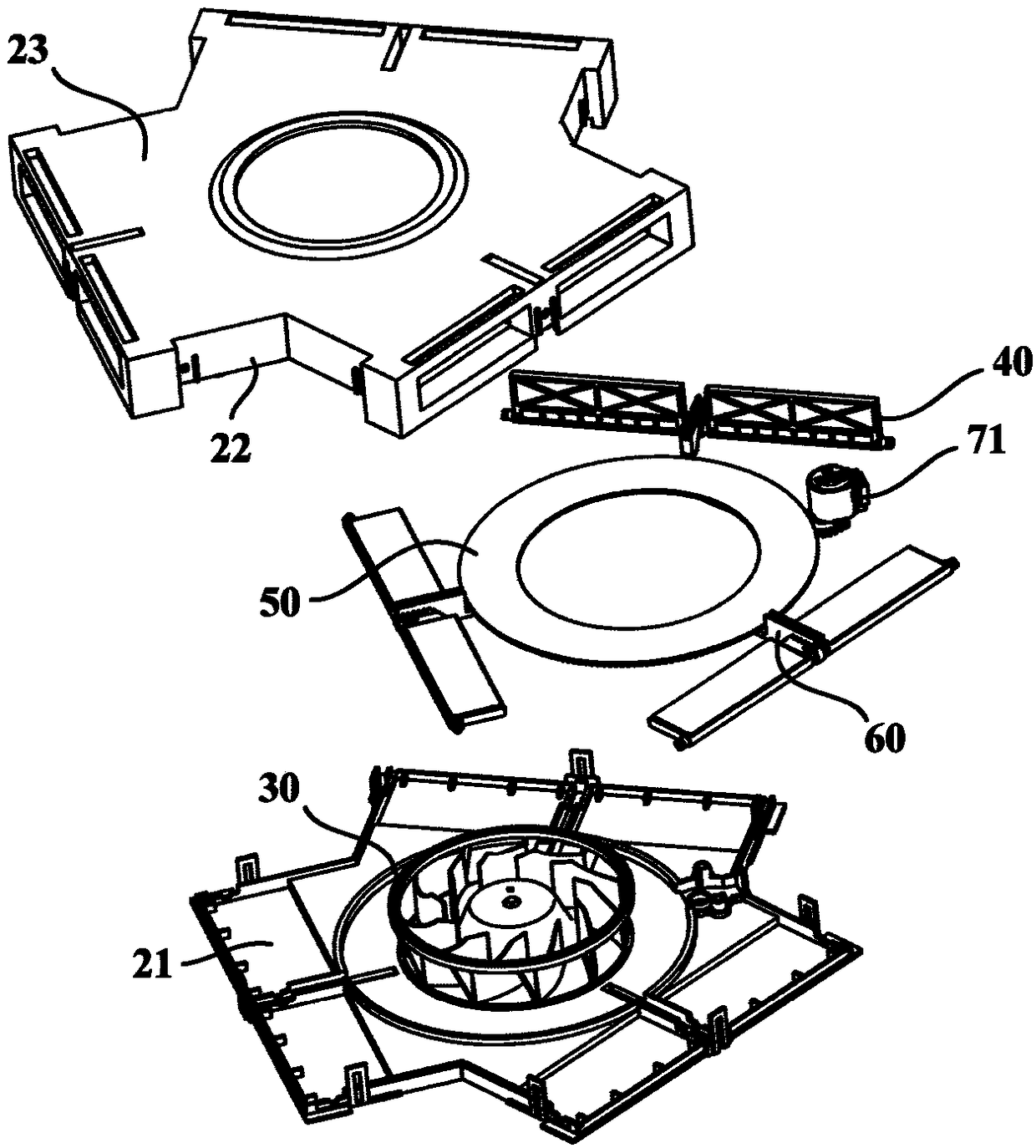

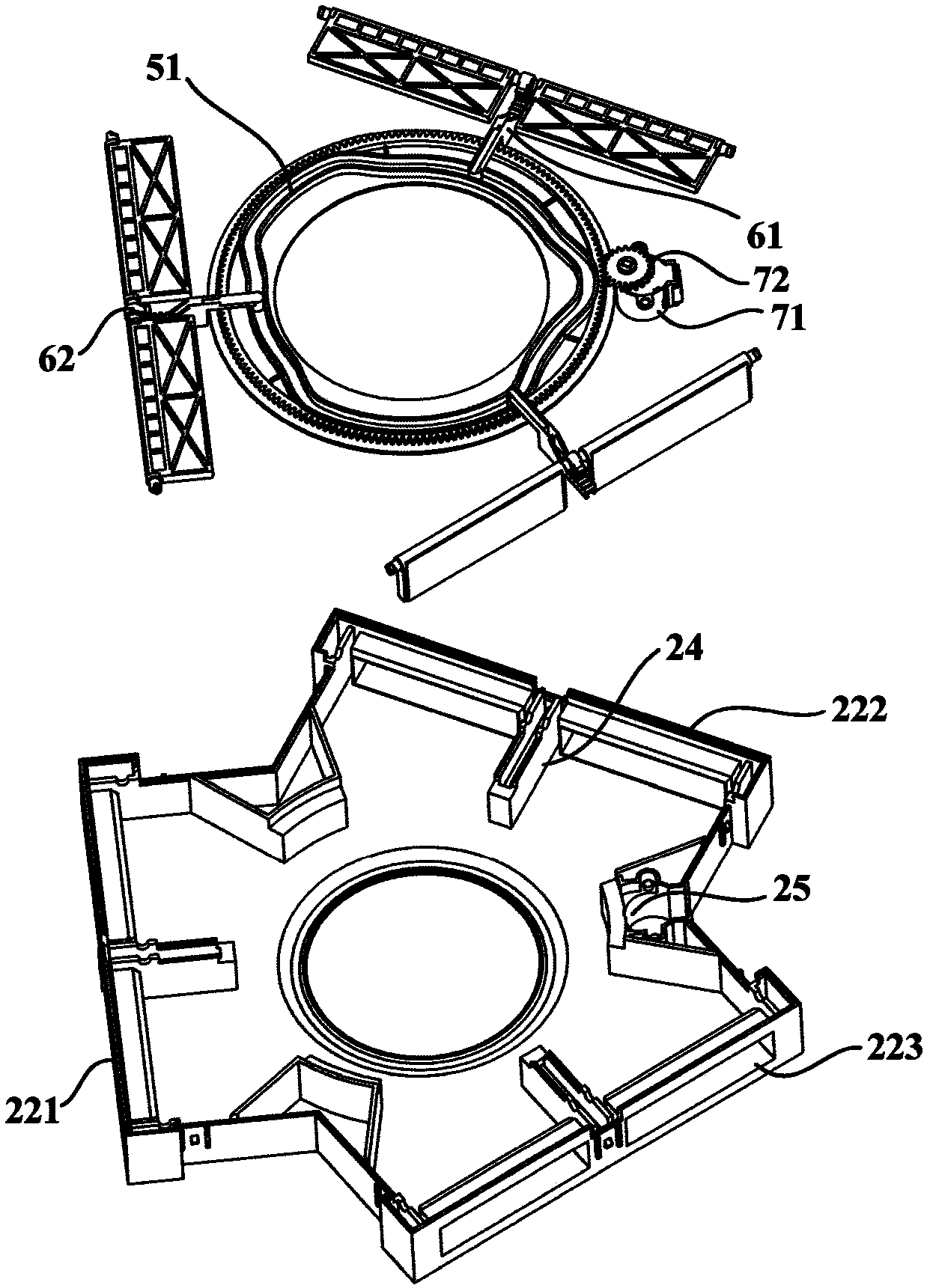

Centrifugal fan

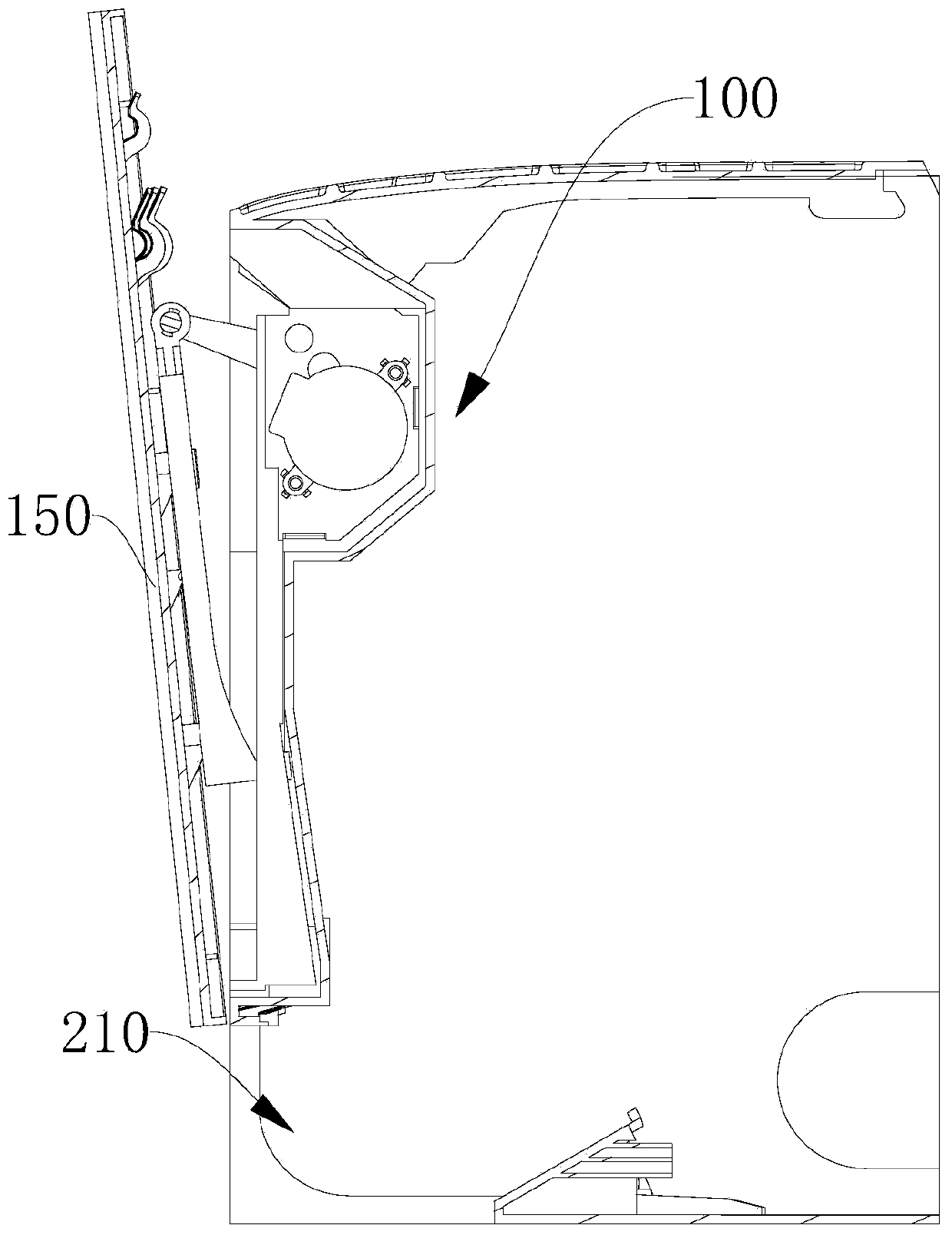

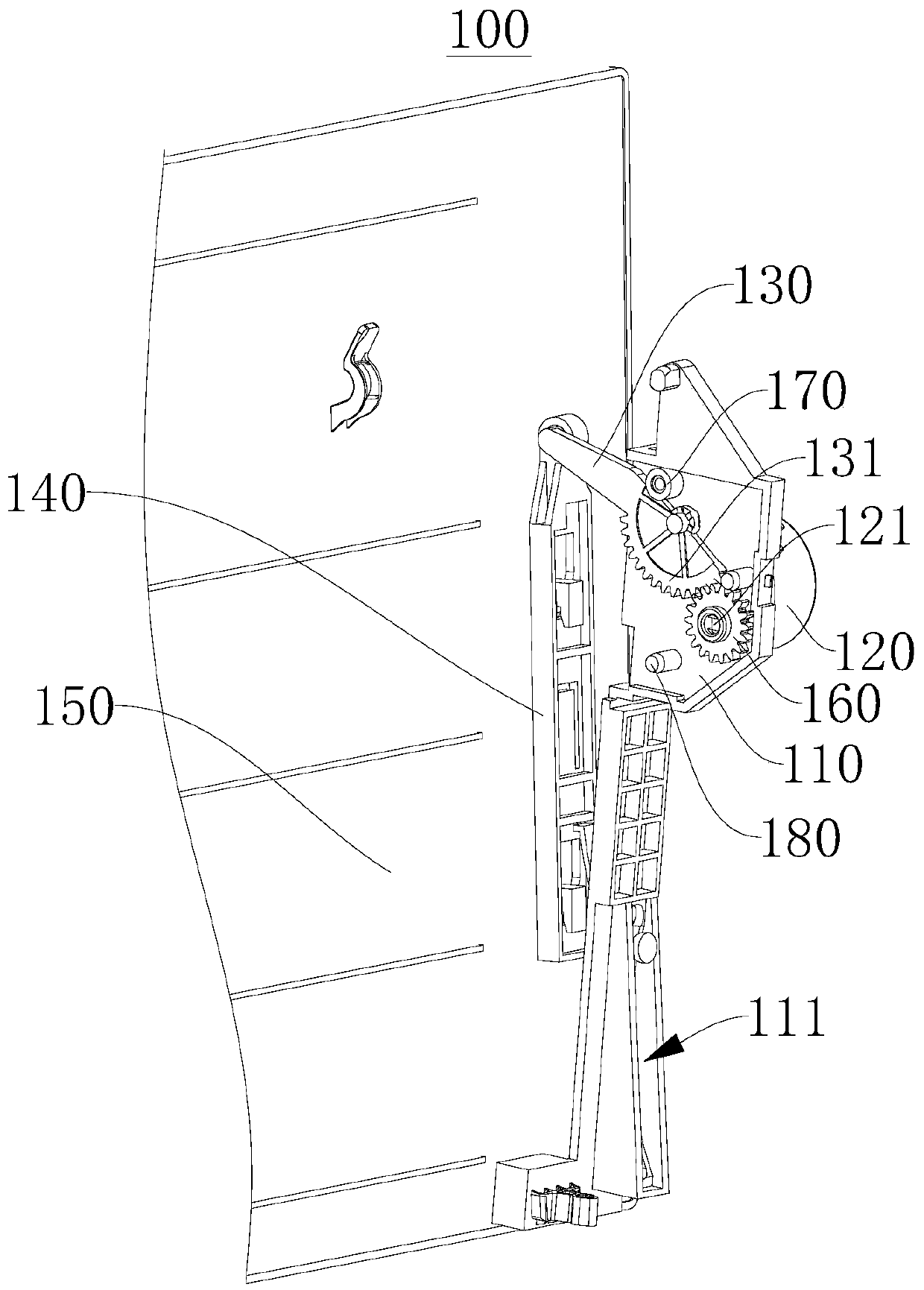

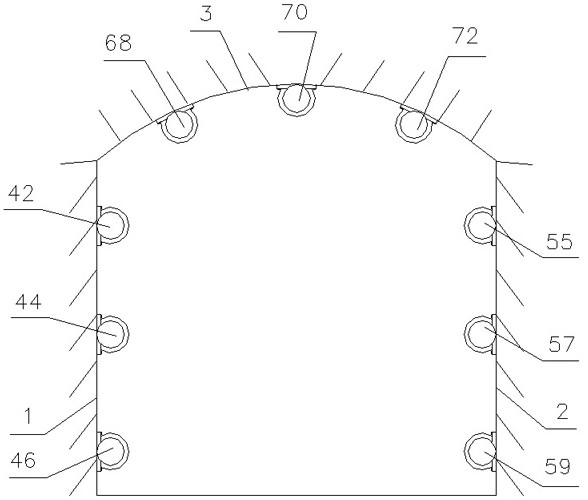

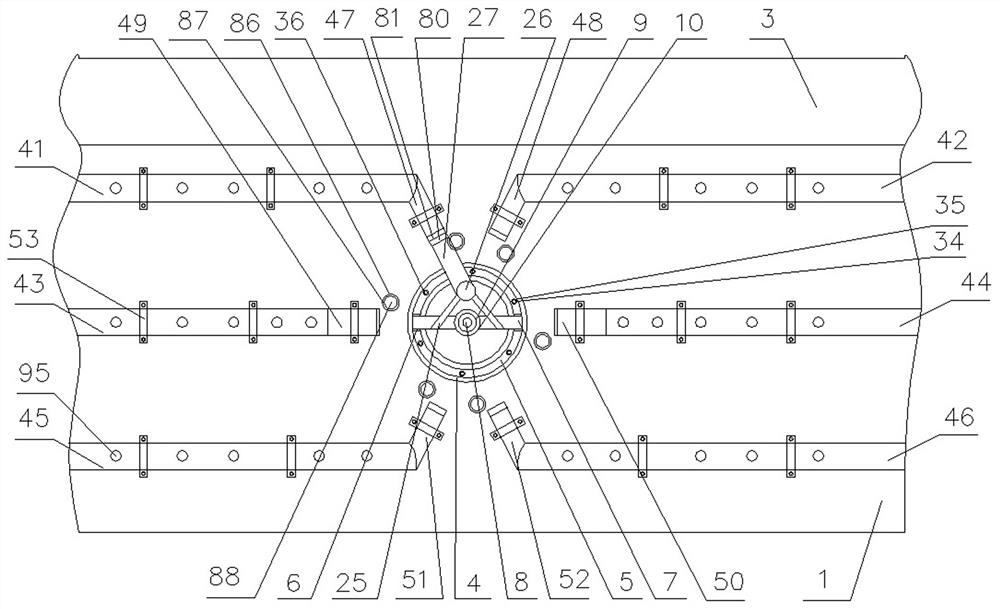

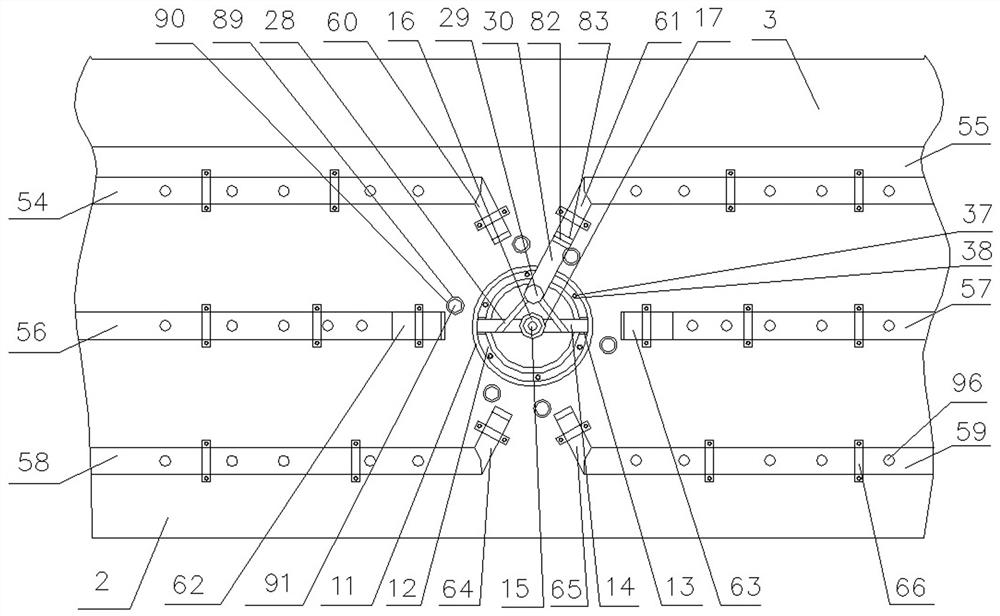

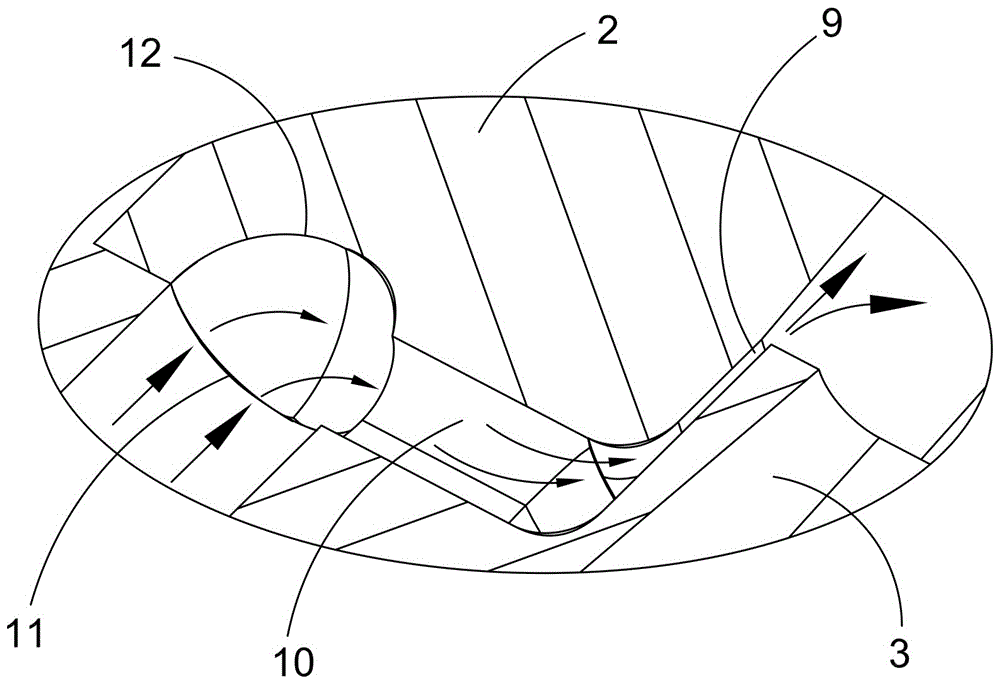

The invention provides a centrifugal fan. The centrifugal fan comprises a shell, a wind wheel, a plurality of groups air door catches, a rotating piece and a transmission mechanism, wherein an air inlet is formed in the cover plate of the shell, and a plurality of groups of air outlets are formed in the peripheral wall part of the shell; the wind wheel is arranged as that air flow is forced to flow in the shell from the air inlet and flow out of the shell through one or more of the plurality of air outlets; each air door catch is arranged at the air outlet movably and arranged that a controlled place is moved to different shading positions so as to completely shade, partially shade or completely expose the air outlet, so that the air outlet area of the air outlet can be adjusted; the rotating piece is rotatably arranged on the shell; and the transmission mechanism is arranged as that the rotation motion of the rotating piece is transmitted to the plurality of air door catches. According to the centrifugal fan, the air door catches can be driven to move through the rotation of the rotating piece, so as to controllably shade the plurality of air outlet and realize the air supply for a plurality of directions, the air outlet directions can be selected, and the air outlet volume of each air outlet can be adjusted to realize reasonable air supply.

Owner:QINGDAO HAIER SPECIAL REFRIGERATION ELECTRIC APPLIANCE CO LTD +1

Centrifugal fan

ActiveCN106523433ARealize reasonable air supplySmooth air supplyPump componentsPumpsExhaust valveEngineering

The invention provides a centrifugal fan. The centrifugal fan comprises a shell, a wind wheel, multiple wind door baffle plates, a rotating piece, and a transmission mechanism, wherein an intake space communicated with an intake port and multiple exhaust wind ways bent to extend are defined in the shell; the wind wheel is configured to accelerate air currents to flow in the shell from the intake port and to flow out of the shell by one or more of the multiple exhaust ports; the multiple wind door baffle plates respectively adjust the exhaust areas of the multiple exhaust ports or the exhaust wind ways; and the transmission mechanism is configured to transfer a rotating motion of the rotating piece to the multiple wind door baffle plates, so that the multiple wind door baffle plates move to respectively corresponding shielding positions. The centrifugal fan can drive the wind door baffle plates to rotate through rotation of the rotating piece to controllably shield the multiple exhaust ports so as to realize synchronous air supply in multiple directions, and can select the exhaust directions and adjust the exhaust quantities of all the exhaust ports to realize reasonable air supply.

Owner:HAIER SMART HOME CO LTD

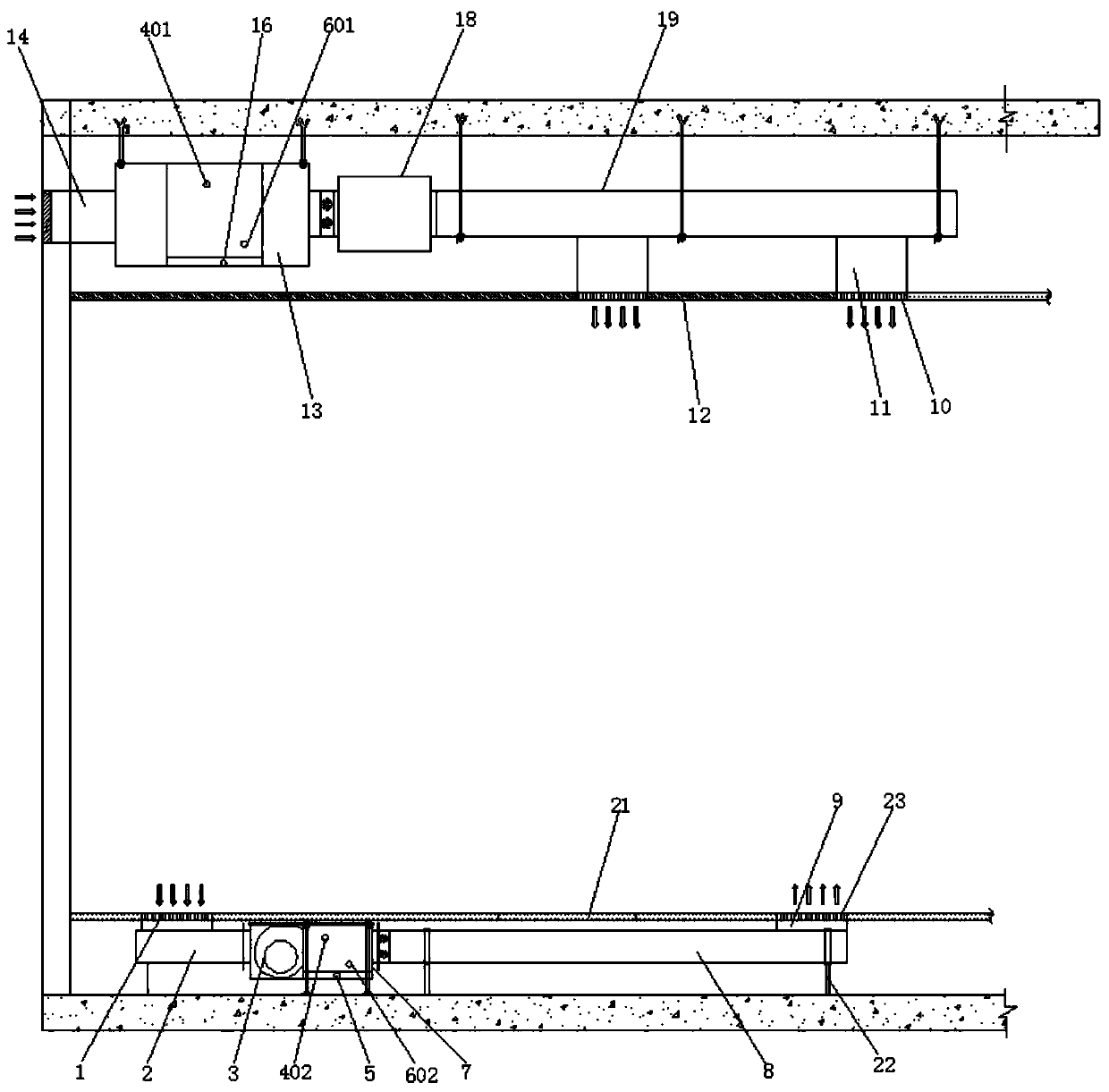

Novel stereoscopic air supply air conditioning system

PendingCN110094866AAchieve healthy and comfortable resultsReduce wind pressureDucting arrangementsLighting and heating apparatusFresh airAir conditioning

The invention discloses a novel stereoscopic air supply air conditioning system which comprises a floor air supply pipe and a ceiling fresh air pipeline. The novel stereoscopic air supply air conditioning system is characterized in that the outer side of the floor air supply pipe is mounted on the ground through an air pipe support; an elevated floor is arranged at the position above the floor airsupply pipe; a floor air outlet pipe is arranged at the top end of the floor air supply pipe; one side of the floor air supply pipe is connected with a fan coiled pipe; one side of the fan coiled pipe is connected with a fan; an air inlet of the fan is connected with a floor air return pipe; and a suspended ceiling is arranged at the position below the ceiling fresh air pipeline. According to thenovel stereoscopic air supply air conditioning system, the floor air return pipe, the floor air supply pipe and the ceiling fresh air pipeline are arranged, and the problems that when the stereoscopic air supply air conditioning system is used, small-density indoor circulating air is hardly sprayed out from the underground space and naturally float up through the stereoscopic air supply air conditioning system, meanwhile, large-density fresh air is hardly supplied from top to bottom, and use comfort of the stereoscopic air supply air conditioning system is influenced are avoided.

Owner:深圳市东畅空调机电系统科技有限公司

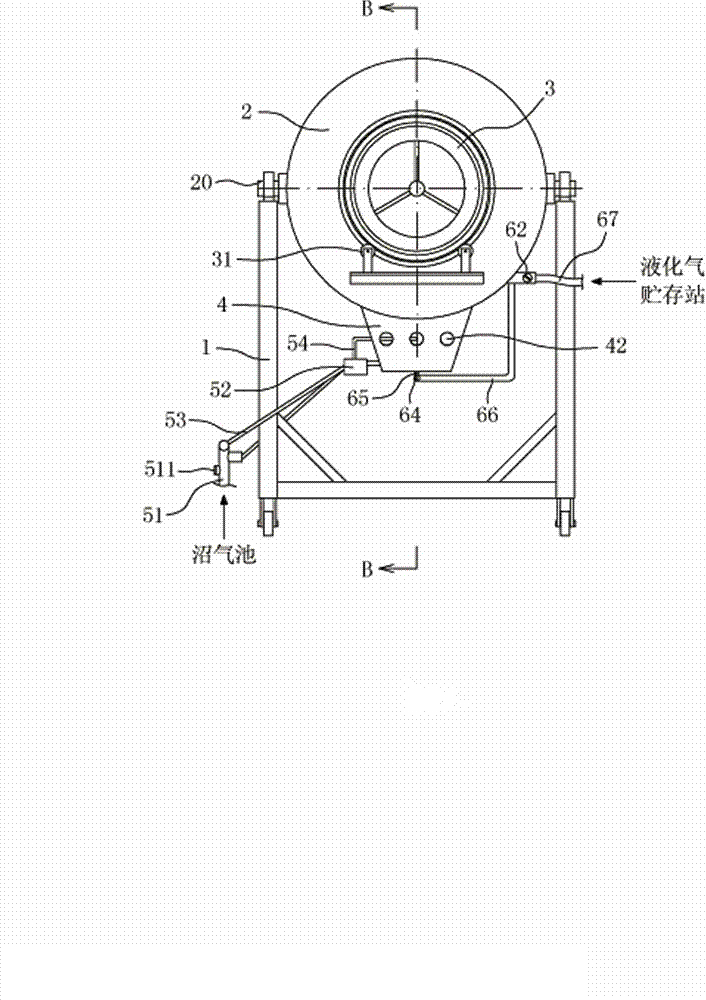

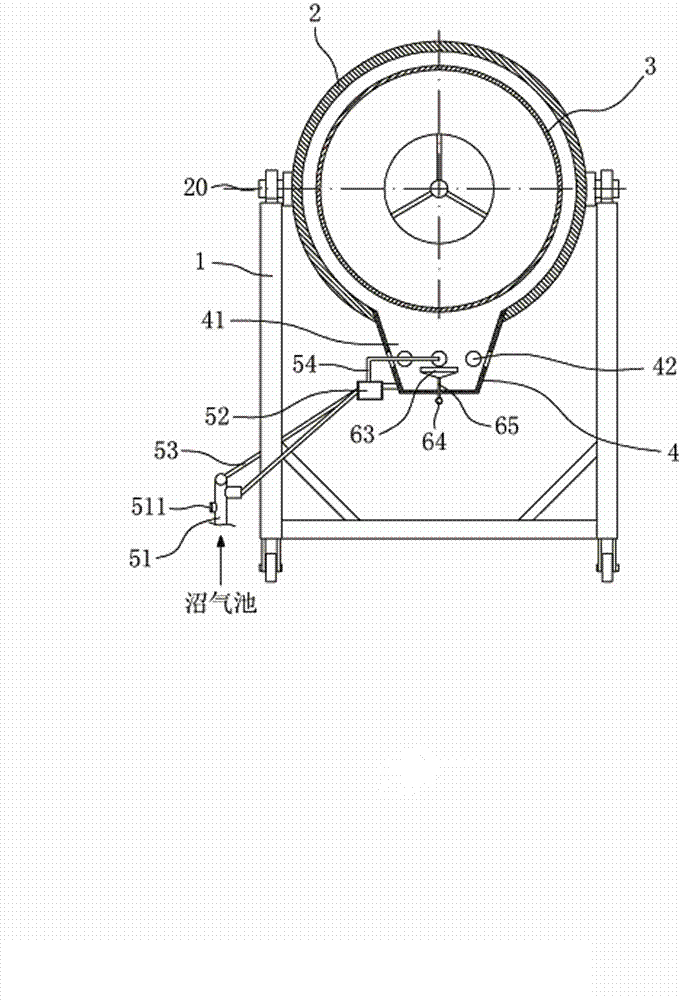

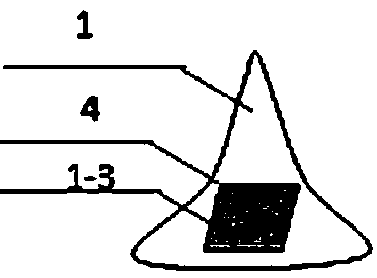

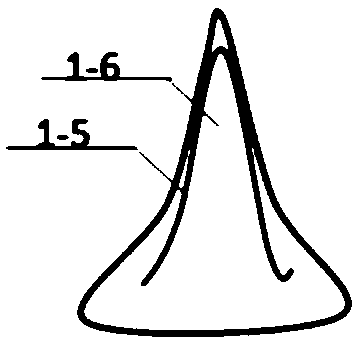

Biogas tea fixing machine

ActiveCN101933544ASmooth air supplySafe and reliable ignitionPre-extraction tea treatmentBiogasTracheid

The invention discloses a biogas tea fixing machine, which comprises a frame, a horizontal tea fixing roller arranged on the frame, a driving device driving the tea fixing roller to roll, and a heating device used for heating the tea fixing roller. The biogas tea fixing machine is characterized in that: the heating device comprises a stove and a biogas combustion device arranged under the tea fixing roller; the biogas combustion device comprises a biogas delivery pipeline which is connected with a biogas digester and provided with a valve, and a plurality of high temperature-resistant biogas ejectors connected with the output end of the delivery pipeline; the biogas ejectors pass through the side wall of the stove to extend into the hearth of the stove; and biogas nozzles of all the biogas ejectors are arranged at equal intervals along the length direction of the hearth. The fixing machine is provided with heat by the combustion of the biogas, and the combustion cost is lower, so the manufacturing cost of tea is reduced; the main component of the biogas is methane, and generates water and carbon dioxide after combustion, so the environment is protected; besides, the combustion value of the biogas is high, so the biogas provides enough heat for the fixing machine; therefore, the produced tea has higher quality.

Owner:福建安溪历山茶仙茶业有限公司

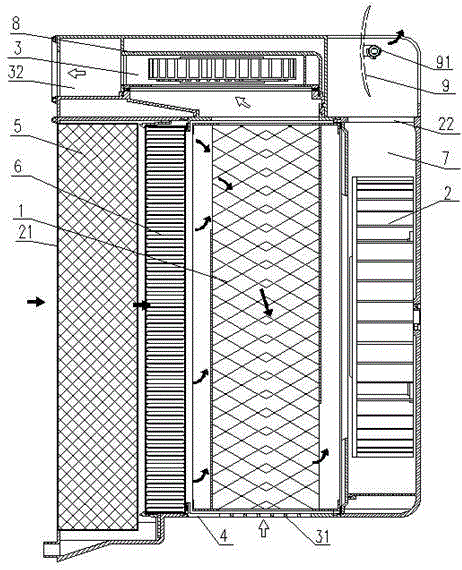

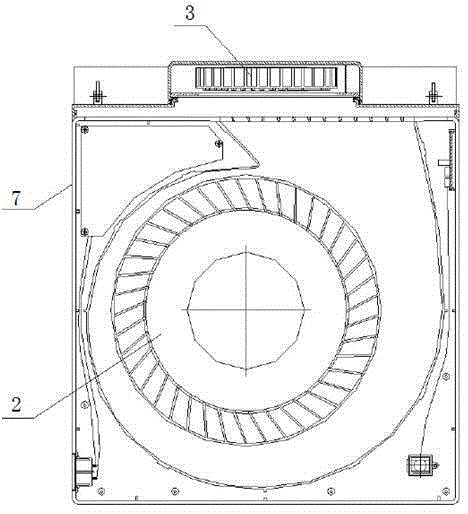

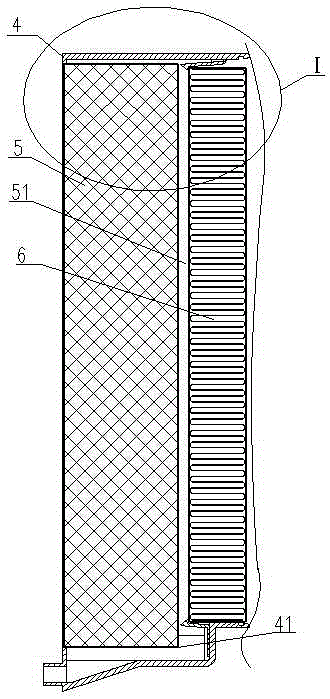

Centrifugal fan and air-cooled refrigerator provided with same

ActiveCN106593946AReduce noiseImprove energy efficiencyPump componentsLighting and heating apparatusEngineeringRefrigerated temperature

The invention relates to a centrifugal fan and an air-cooled refrigerator provided with the same. The centrifugal fan comprises an inner hub and multiple fan blades, wherein an accommodating cavity is defined in the inner hub; the multiple fan blades are arranged on the outer side in the radial direction of the inner hub and uniformly distributed in the circumferential direction of the inner hub; the distance between an axis of the inner hub and the inner radial end edge of each fan blade is 1.43-2.15 times of the radius of the peripheral surface of the inner hub; the distance between the axis of the inner hub and the outer radial end edge of each fan blade is 2.8-3.9 times of the radius of the peripheral surface of the inner hub. According to the centrifugal fan and the air-cooled refrigerator provided with the same, compared with existing centrifugal fans, the centrifugal fan is low in wind resistance and high in air output, realizes smooth air supply and remarkably reduces noise caused by air guiding, rotation and the like due to a special structure, so that energy efficiency of the refrigerator can be remarkably improved, and noise caused by operation of the refrigerator is reduced.

Owner:HAIER SMART HOME CO LTD

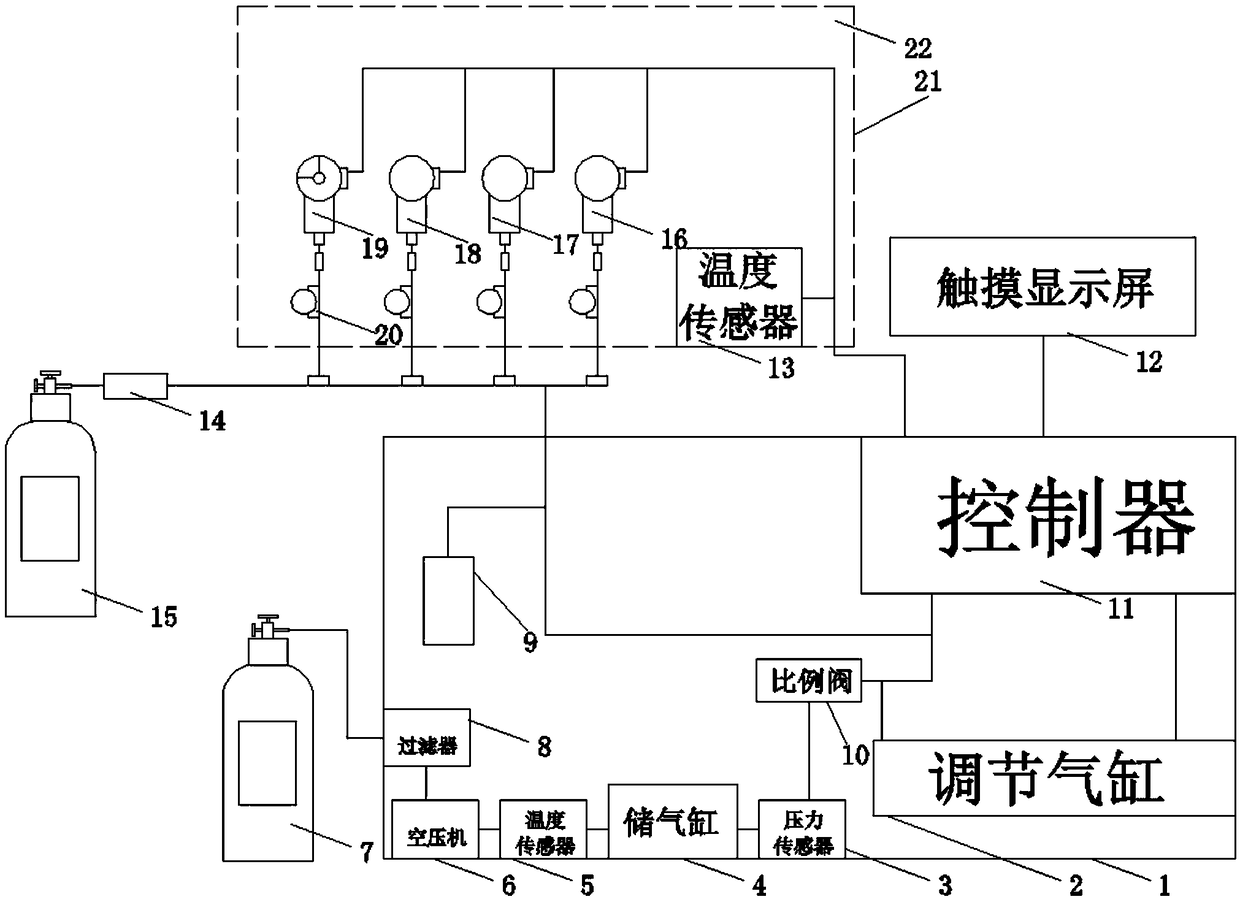

Multifunctional verifying device for sulfur hexafluoride density relay

InactiveCN108761326ARealize verificationReliable inCircuit interrupters testingSulfur hexafluorideTest frame

The invention discloses a multifunctional verifying device for a sulfur hexafluoride density relay. The multifunctional verifying device has more precise verifying functions, and can verify a plurality of relays at a time, recover sulfur hexafluoride gas and calibrate a temperature compensation value of the sulfur hexafluoride density relay. The multifunctional verifying device comprises a verifying component and a high-low temperature test chamber, wherein a separation board is arranged inside a test cavity of the high-low temperature test chamber; a test frame for supporting the density relay and a standard pressure gauge is arranged on the separation board; side plates of the test cavity are all insulation boards; a pipeline opening for allowing a communicating pipe to penetrate throughis formed in the insulation board on one side of the test cavity and is a through hole; the verifying component contains a controller; the controller is connected with a touch display screen, a to-be-verified density relay and the standard pressure gauge; and the verifying component also contains an inflating pipeline.

Owner:国网新疆电力有限公司和田供电公司 +1

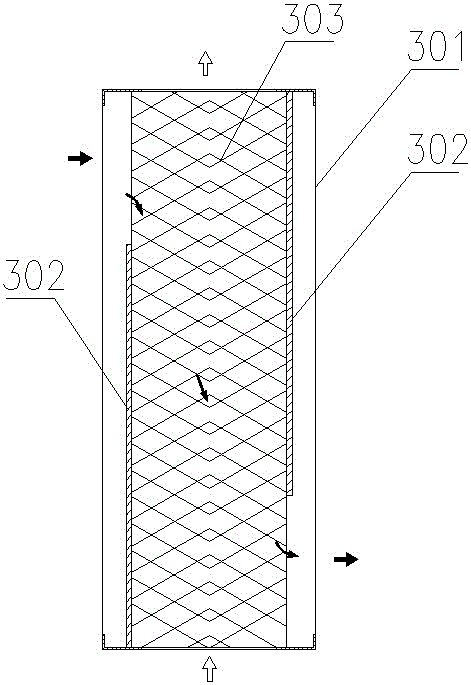

Novel energy-saving fan

InactiveCN105371413ASolve rationalitySolve the insufficient utilization of waste heatMechanical apparatusLighting and heating apparatusEngineeringFilter effect

A novel energy-saving fan comprises a main case; a filter, a heat exchanger and a supply fan are sequentially arranged in the main case along the air flowing path; an exhaust fan is also mounted on the main case; the supply fan is perpendicular to the exhaust fan; and the heat exchanger adopts a counter-current heat exchange structure, so that fresh air supplied by the supply fan is vertically staggered from exhaust air exhausted by the exhaust fan, and then the fresh air and the exhaust air are discharged from a fresh air outlet and an exhaust air outlet. The novel energy-saving fan has the advantages that on one hand, heat exchange dead angles are eliminated, and the waste heat utilization rate is improved, and the energy-saving effect is good; and on the other hand, the wind resistance is small, the air exhaust is smooth, and the filtering effect is good.

Owner:BROAD A Q TECH

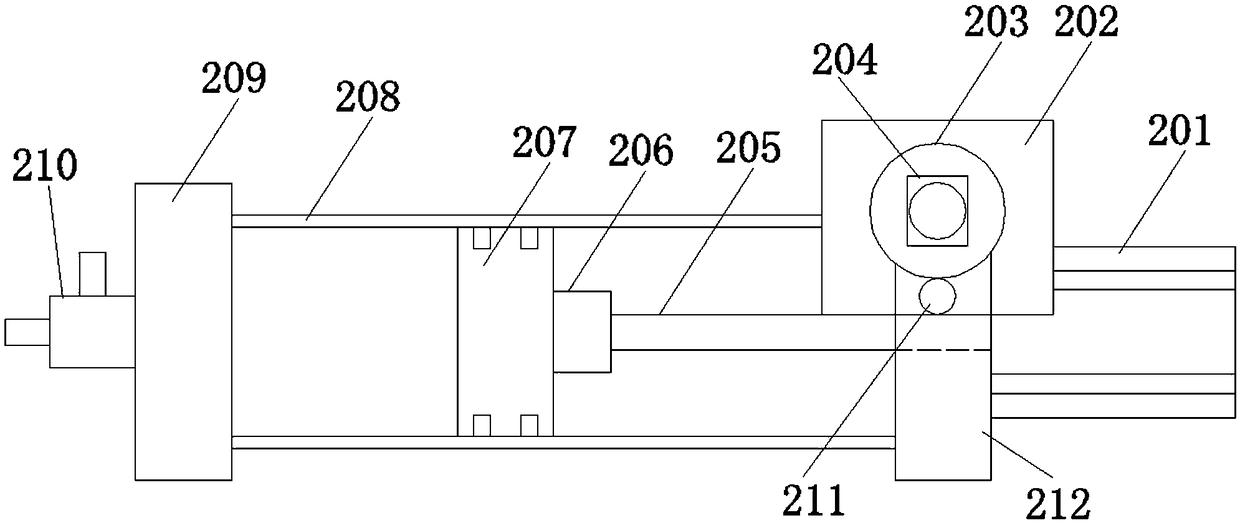

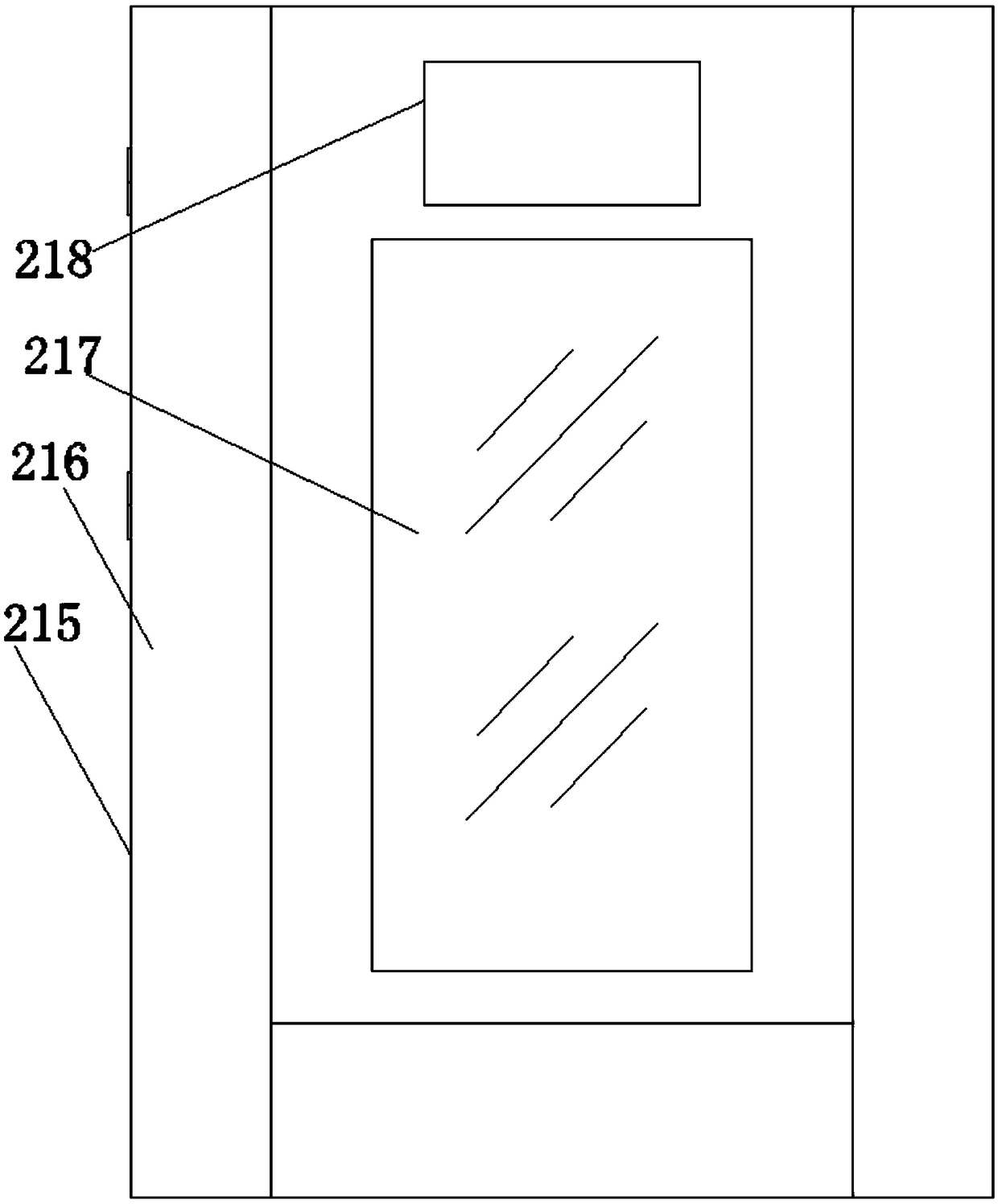

Panel lifting mechanism and air conditioner

PendingCN111351203AAchieve liftingAvoid occlusionLighting and heating apparatusAir conditioning systemsAir volumeElectric machinery

The invention discloses a panel lifting mechanism and an air conditioner, and relates to the technical field of air conditioning. The panel lifting mechanism includes a driving box, a driving motor, arocker, a connecting rod and a panel. The driving motor is fixedly installed on the driving box and is connected with the rocker. The driving box is provided with a sliding groove, the connecting rodis connected to the panel, one end of the connecting rod is hinged to the rocker, and the other end of the connecting rod is slidably arranged in the sliding groove. The driving motor can drive the connecting rod to slide relative to the sliding groove through the rocker to enable the panel to rise or fall. Compared with the prior art, the panel lifting mechanism adopts the driving motor connected with the rocker and the connecting rod capable of sliding relative to the sliding groove, and therefore the rising or falling of the panel are realized, so that an air outlet is fully opened, and thus the panel is prevented from blocking the air outlet, the air outlet is increased, and the smooth air supply is ensured.

Owner:NINGBO AUX ELECTRIC +1

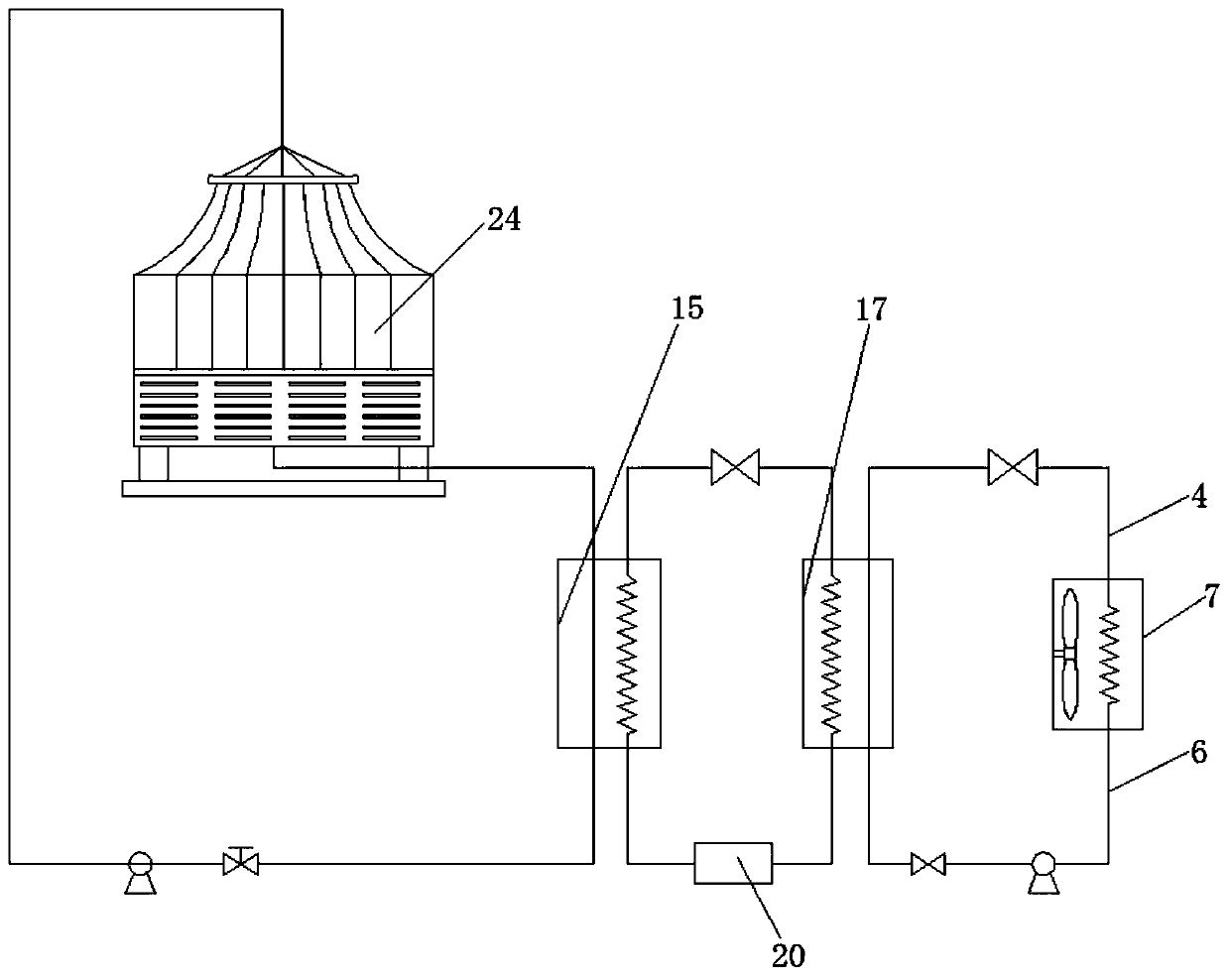

Detection system of sulfur hexafluoride density relay

InactiveCN108872847AAvoid affecting test accuracyIncrease the number of testsMachine part testingCircuit interrupters testingEngineeringTest chamber

The invention discloses a detection system of a sulfur hexafluoride density relay. The detection system having the precise calibration function is capable of calibrating temperature compensation values of multiple groups of density relays once and is capable of recycling sulfur hexafluoride gas. The detection system is composed of a calibration assembly and a high-and-low-temperature test box. Thehigh-and-low-temperature test box consists of a box body, a refrigeration system, a refrigeration system box, a compressor, a control module and an electrical cabinet; the electrical cabinet is arranged at one side of the box body; a control module and a memory are arranged in the electrical cabinet; and a compressor and a refrigeration system are arranged in the refrigeration system box. The boxbody is divided into a test chamber, a return air passage and a refrigeration system box by a lower chamber bottom plate and a test chamber sidewall; a condenser, a heater and a centrifugal fan are arranged in the return air passage; and an air outlet and a return air outlet are formed in the test chamber sidewall. A test frame for supporting density relays and a standard pressure gauge are arranged at a test rack. The calibration assembly includes a controller.

Owner:国网新疆电力有限公司和田供电公司 +1

Heat recovery fresh air machine

InactiveCN105020798ASolve rationalitySolve the insufficient utilization of waste heatEnergy recovery in ventilation and heatingMechanical apparatusFresh airEngineering

The invention relates to a heat recovery fresh air machine. The machine comprises a machine shell, a primary filter, a high-efficiency filter, a plate type heat exchanger, an air supply machine and an exhaust fan. Counter-flow heat exchange enabling fresh air and exhausted air to be vertically staggered is adopted in the fresh air machine. The fresh air is conveyed outwards via a fresh air outlet after sequentially passing through the primary filter, the high-efficiency filter, the plate type heat exchanger and the air supply machine which are arrayed in parallel. The exhausted air is exhausted via an exhausted air outlet after sequentially passing through the plate type heat exchanger and the exhaust fan. The fresh air machine has the advantages that the structure is compact; the waste heat is fully used; the design of an air channel is ingenious; the cost is low; and the installation is convenient.

Owner:张跃

Biogas tea fixing machine

ActiveCN101933544BSmooth air supplySafe and reliable ignitionPre-extraction tea treatmentCombustionMethane

The invention discloses a biogas tea fixing machine, which comprises a frame, a horizontal tea fixing roller arranged on the frame, a driving device driving the tea fixing roller to roll, and a heating device used for heating the tea fixing roller. The biogas tea fixing machine is characterized in that: the heating device comprises a stove and a biogas combustion device arranged under the tea fixing roller; the biogas combustion device comprises a biogas delivery pipeline which is connected with a biogas digester and provided with a valve, and a plurality of high temperature-resistant biogas ejectors connected with the output end of the delivery pipeline; the biogas ejectors pass through the side wall of the stove to extend into the hearth of the stove; and biogas nozzles of all the biogas ejectors are arranged at equal intervals along the length direction of the hearth. The fixing machine is provided with heat by the combustion of the biogas, and the combustion cost is lower, so the manufacturing cost of tea is reduced; the main component of the biogas is methane, and generates water and carbon dioxide after combustion, so the environment is protected; besides, the combustion value of the biogas is high, so the biogas provides enough heat for the fixing machine; therefore, the produced tea has higher quality.

Owner:福建安溪历山茶仙茶业有限公司

Novel energy-saving draught fan

InactiveCN106016563AFull counterflow heat exchangeCompact structureEnergy recovery in ventilation and heatingMechanical apparatusPlate heat exchangerFresh air

The invention discloses a novel energy-saving draught fan which comprises a main case, wherein a filter, a heat exchanger and a pressure fan are sequentially arranged in the main case in the air flow path; an exhaust fan is further mounted on the main case and is perpendicular to the pressure fan; the heat exchanger adopts a reverse-flow type heat exchanging structure, so that fresh air of the pressure fan and exhausted air of the exhaust fan are perpendicular and stagger and then are discharged through a fresh air outlet and an exhaust outlet respectively. On one hand, the novel energy-saving draught fan eliminates the dead angle of heat exchange, increases the utilization ratio of waste heat, and is excellent in energy-saving effect, and on the other hand, the novel energy-saving draught fan is small in wind drag, smooth in exhausting air and excellent in filtering effect.

Owner:张跃

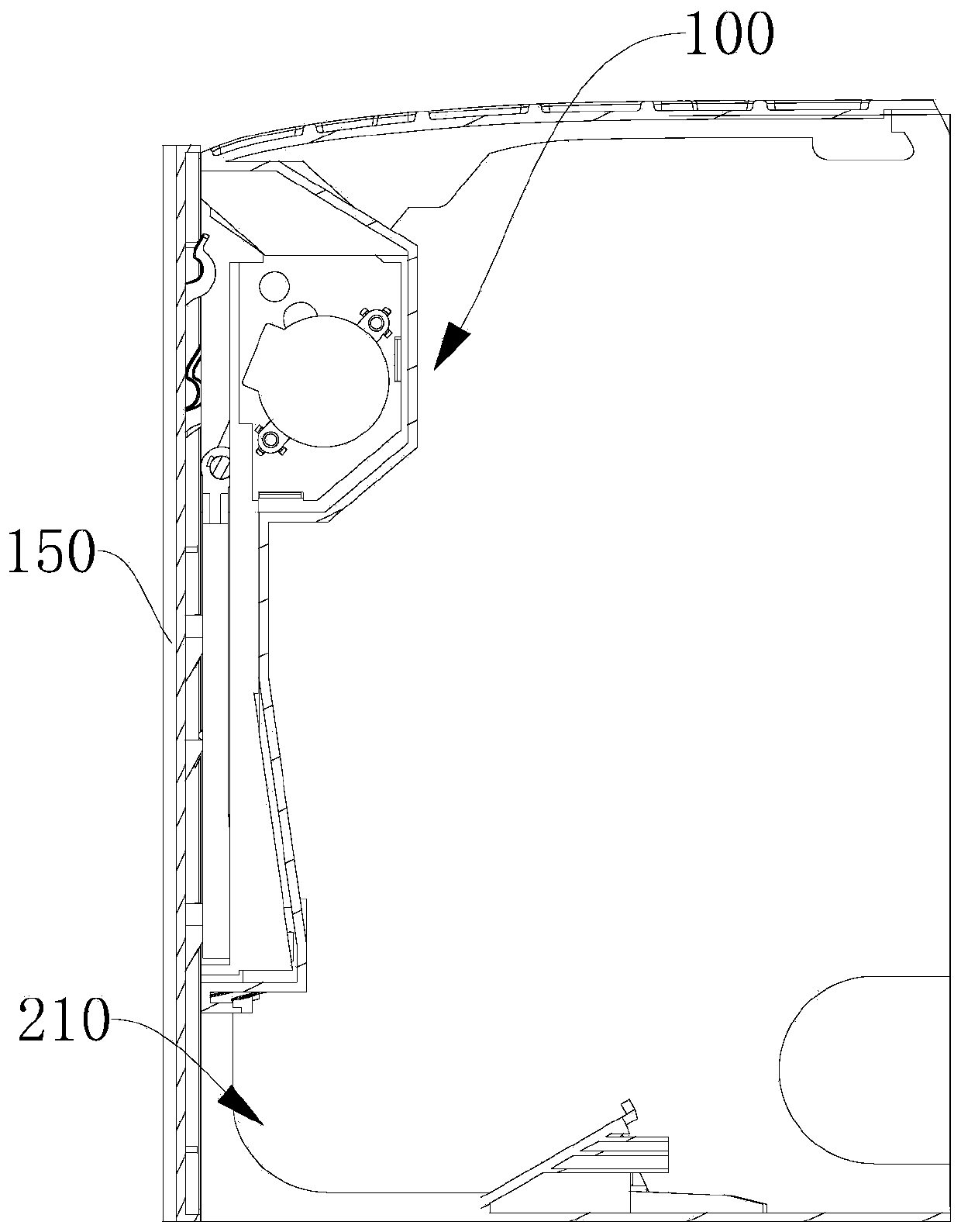

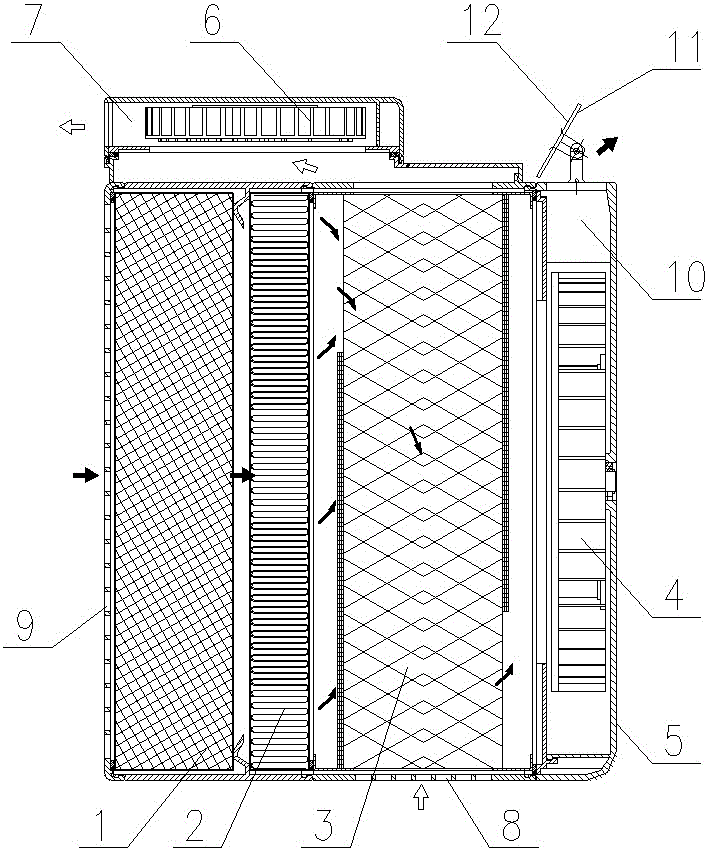

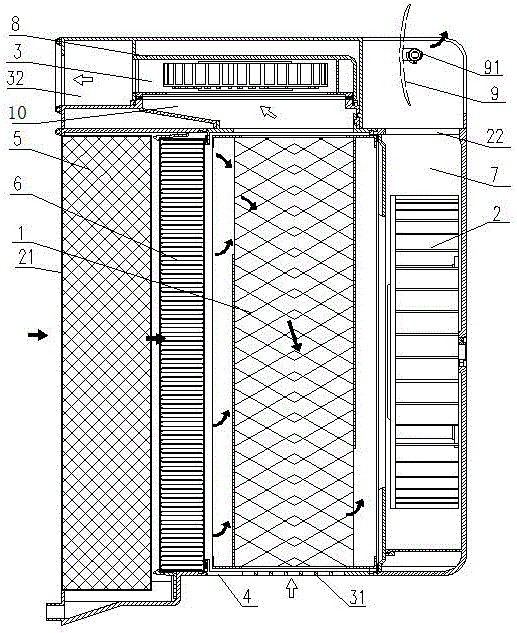

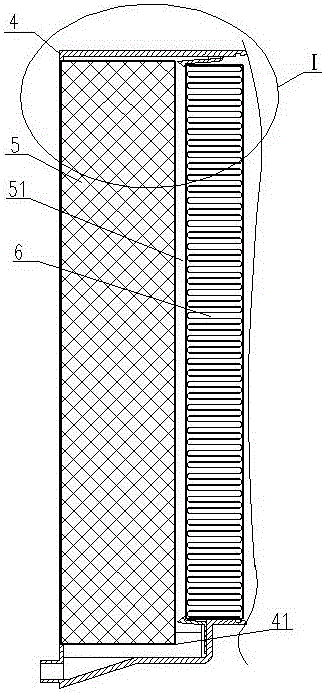

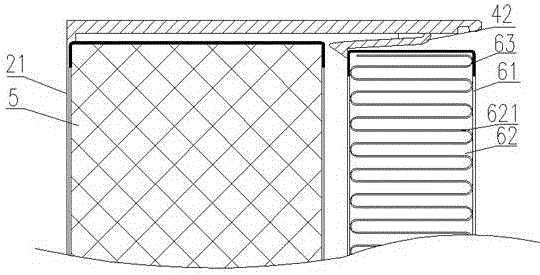

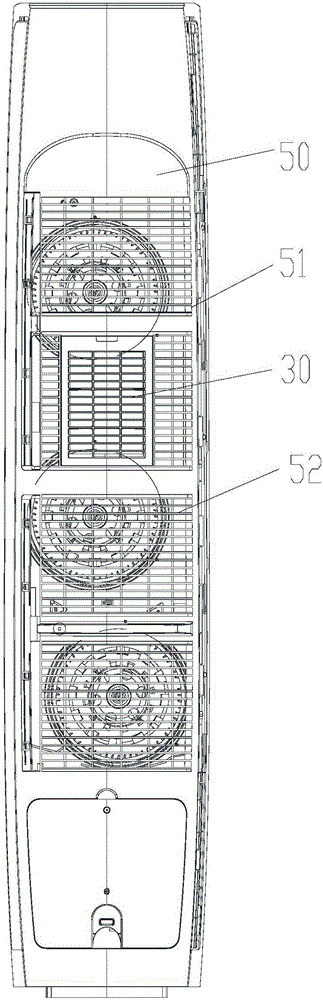

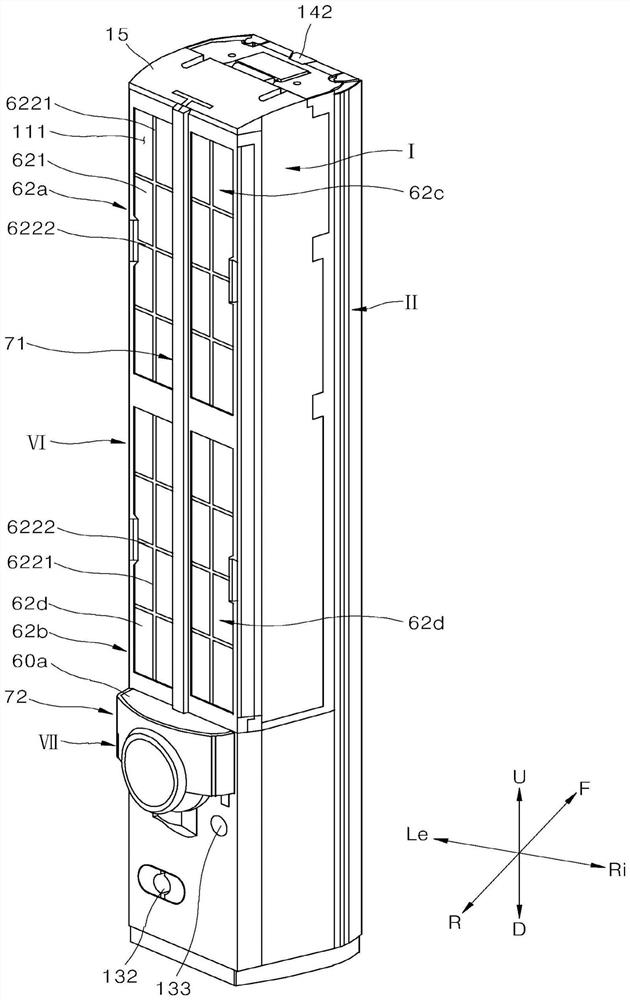

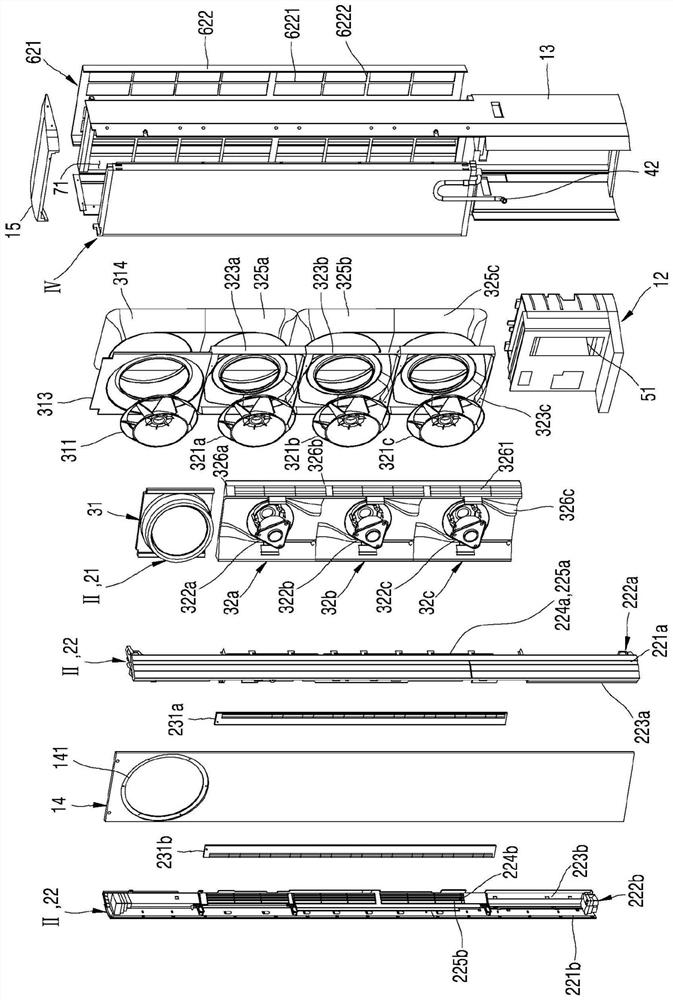

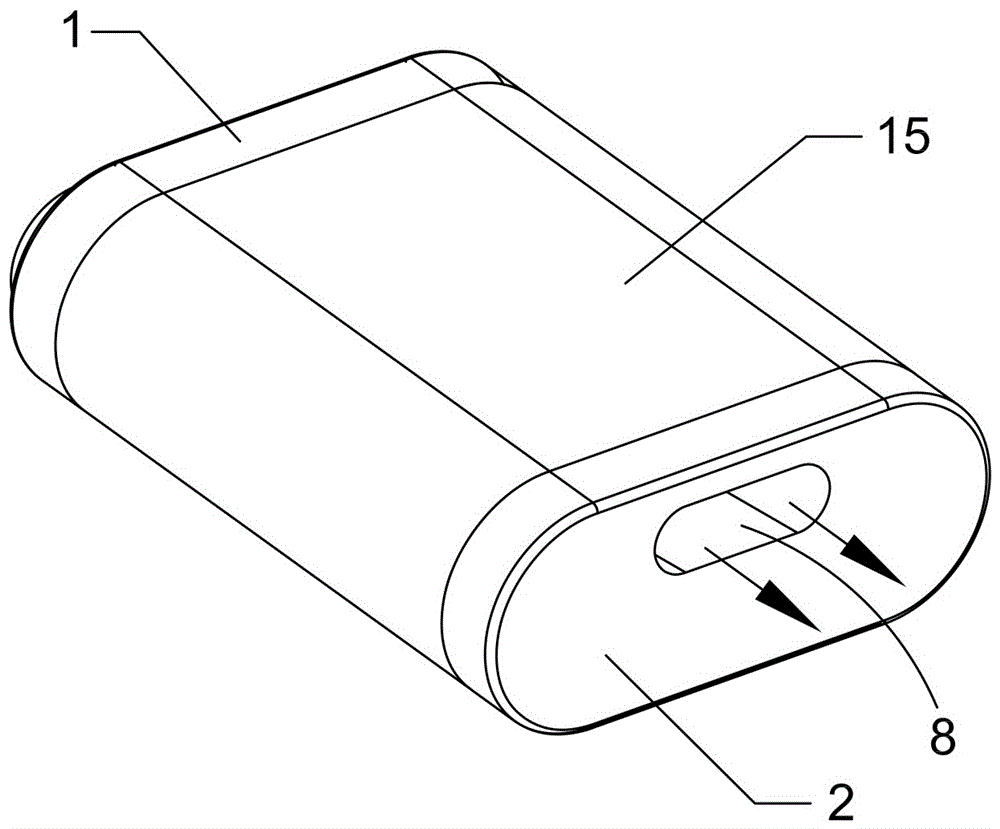

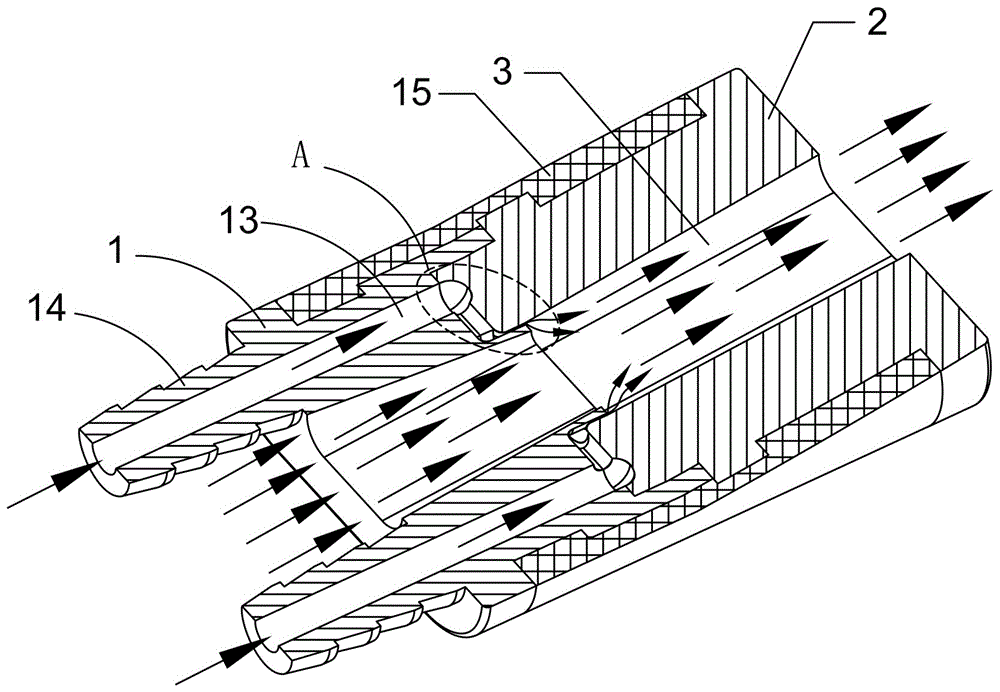

Air supply device and air conditioner with same

ActiveCN105890134ASmooth air supplyAir intake optimizationDucting arrangementsLighting and heating apparatusCentrifugal fanWaste management

The invention provides an air supply device and an air conditioner with the same. The air supply device comprises an air outlet frame, at least two centrifugal fans and an IFD purifying module, wherein an air channel is arranged on the air outlet frame; the at least two centrifugal fans are all arranged in the air channel and are sequentially arranged in the height direction of the air outlet frame; and the IFD purifying module is positioned at the air inlet ends of the centrifugal fans and is arranged between two adjacent centrifugal fans of the at least two centrifugal fans. According to the air supply device and the air conditioner with the same, the air supply device more smoothly supplies air and optimizes inlet air, minimum resistance is ensured in the air supply process of the air supply device, and the air supply quantity of the air supply device is improved.

Owner:GREE ELECTRIC APPLIANCES INC

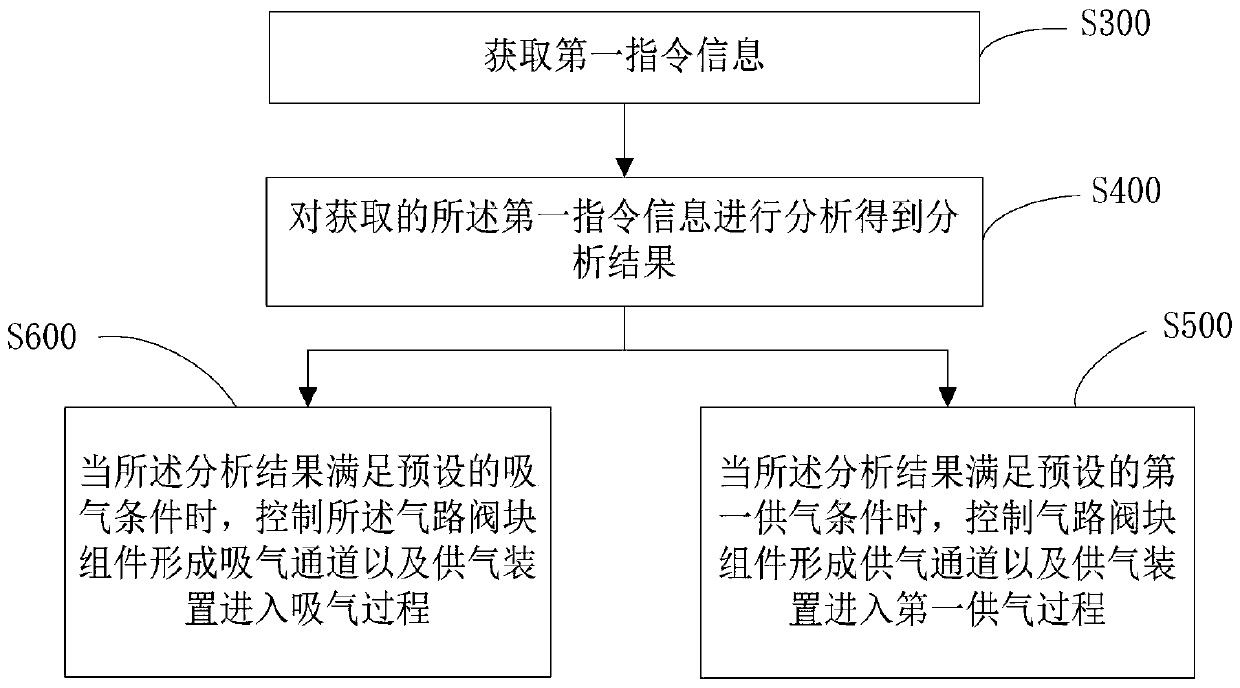

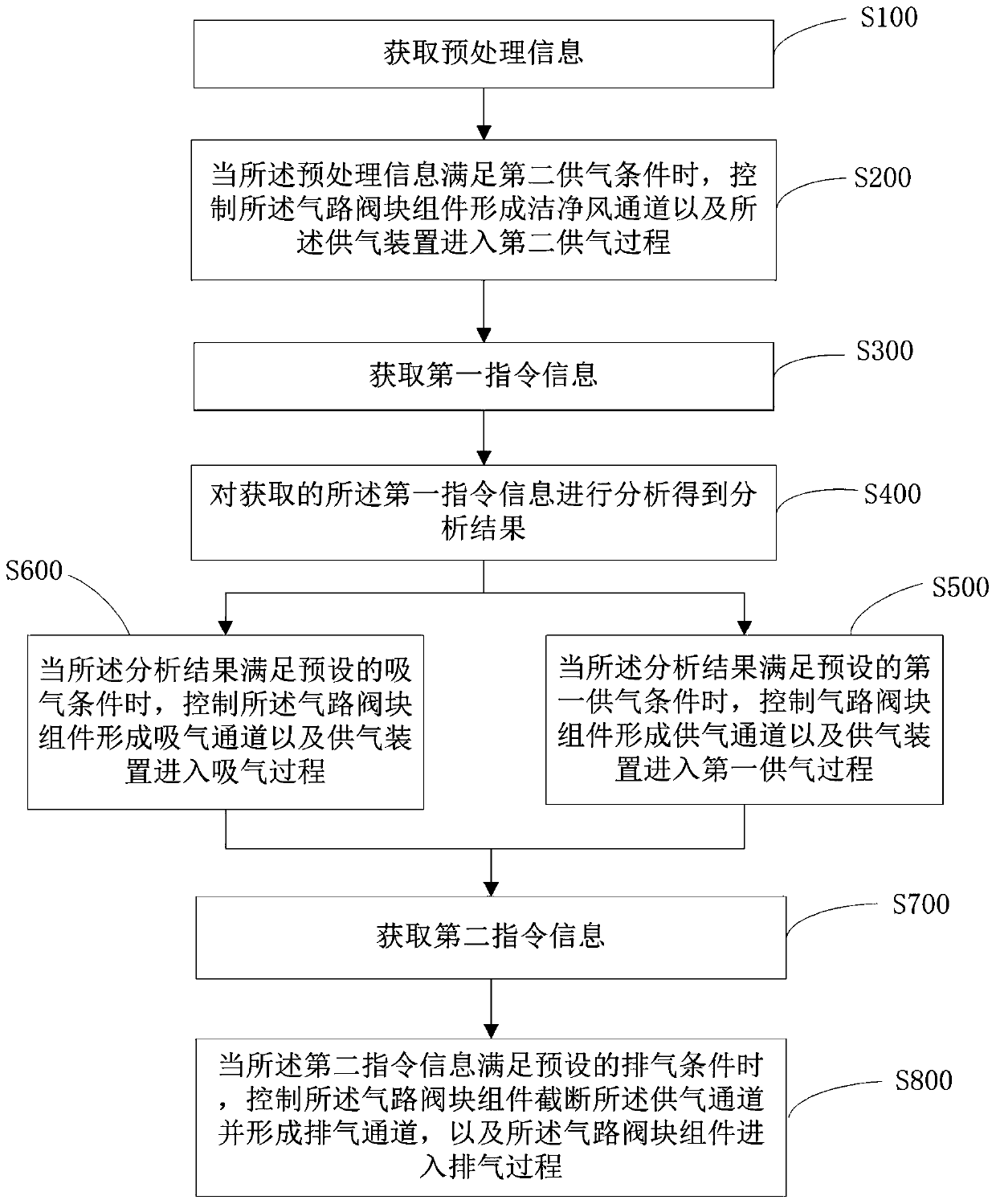

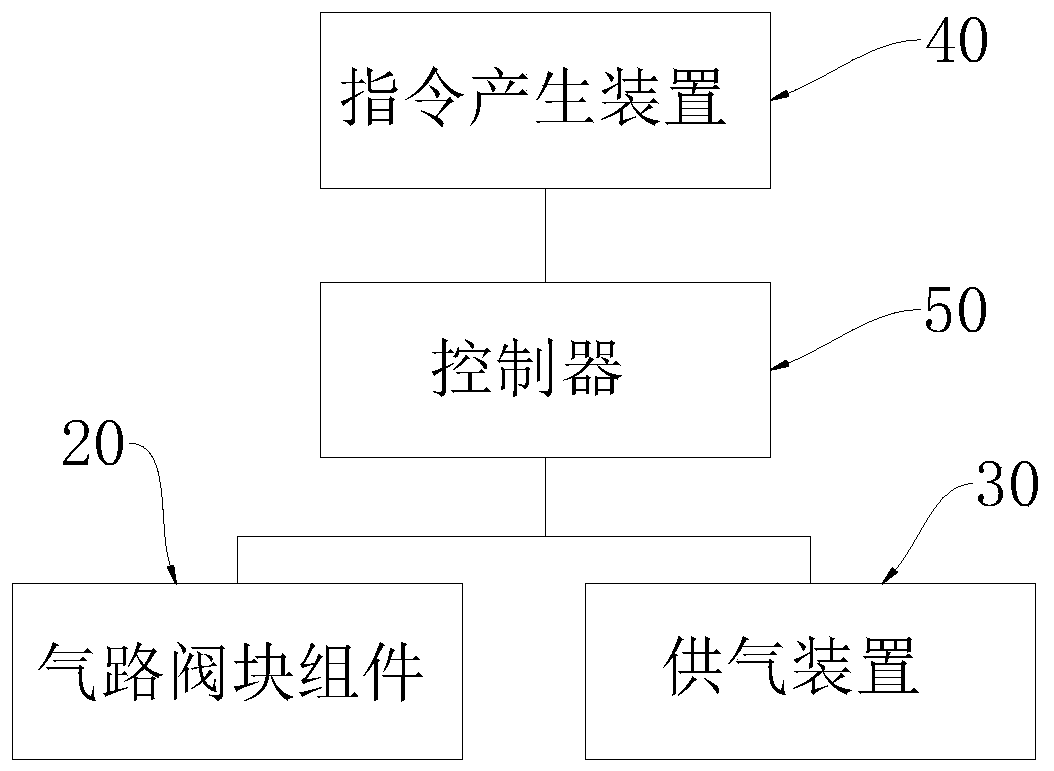

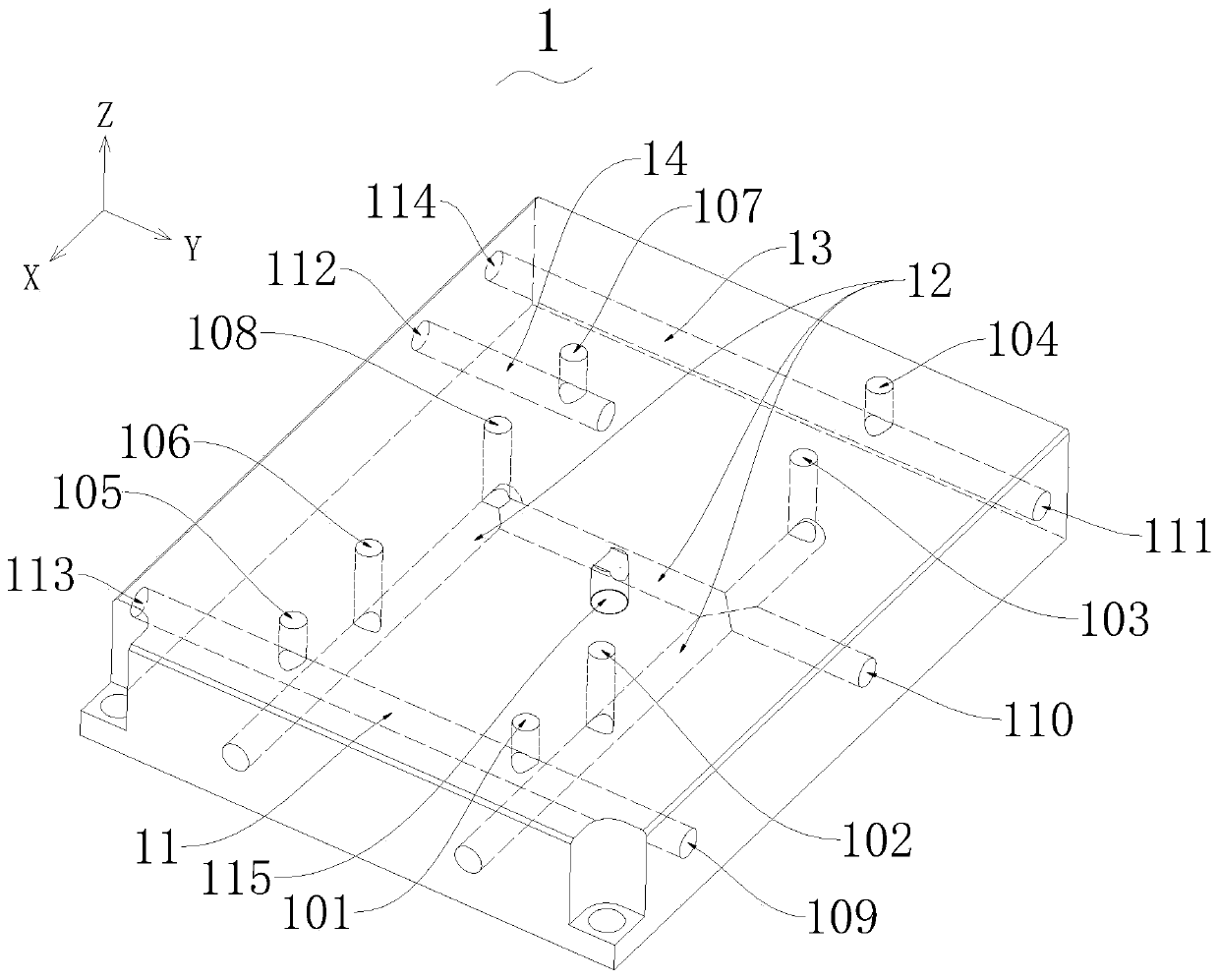

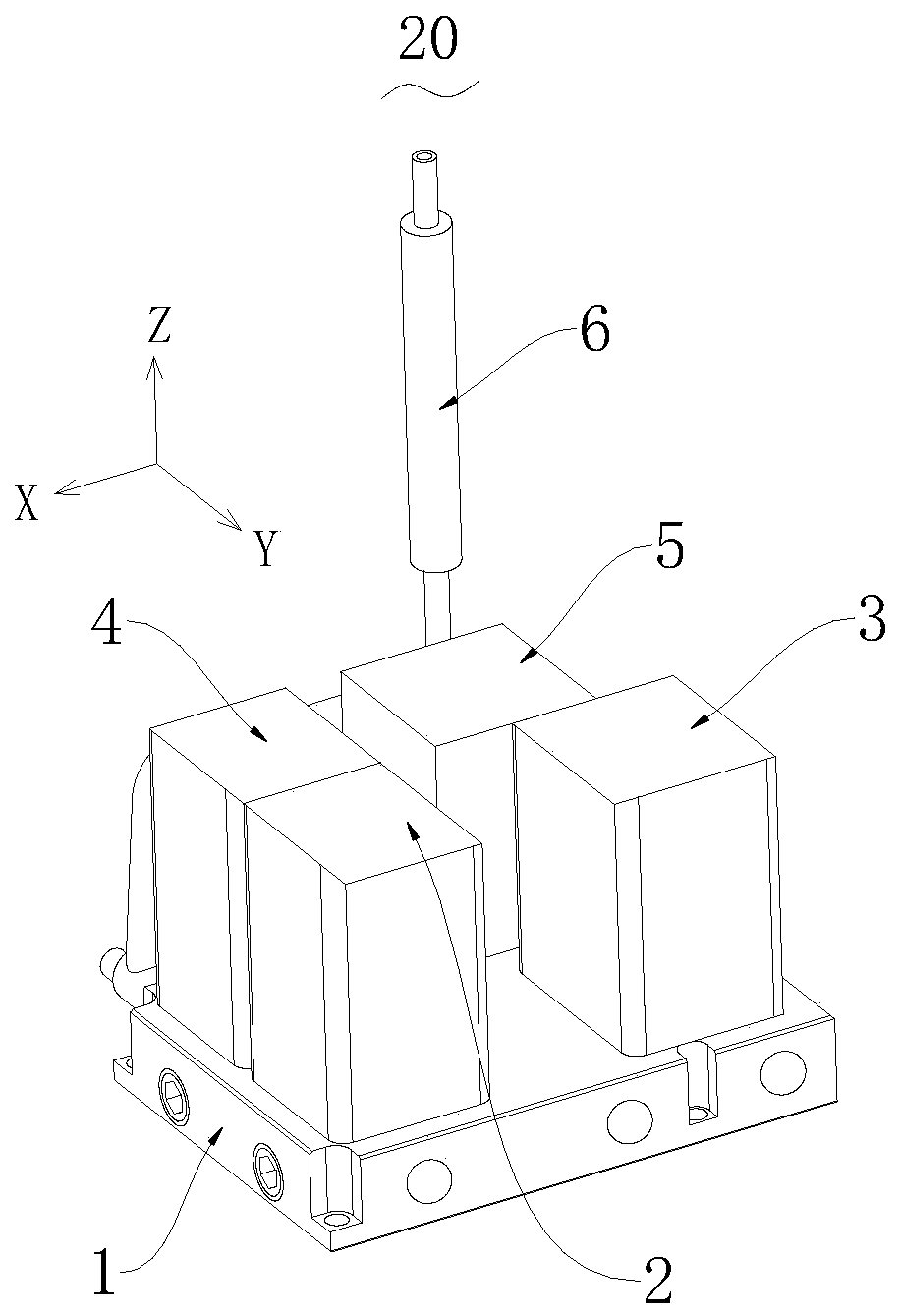

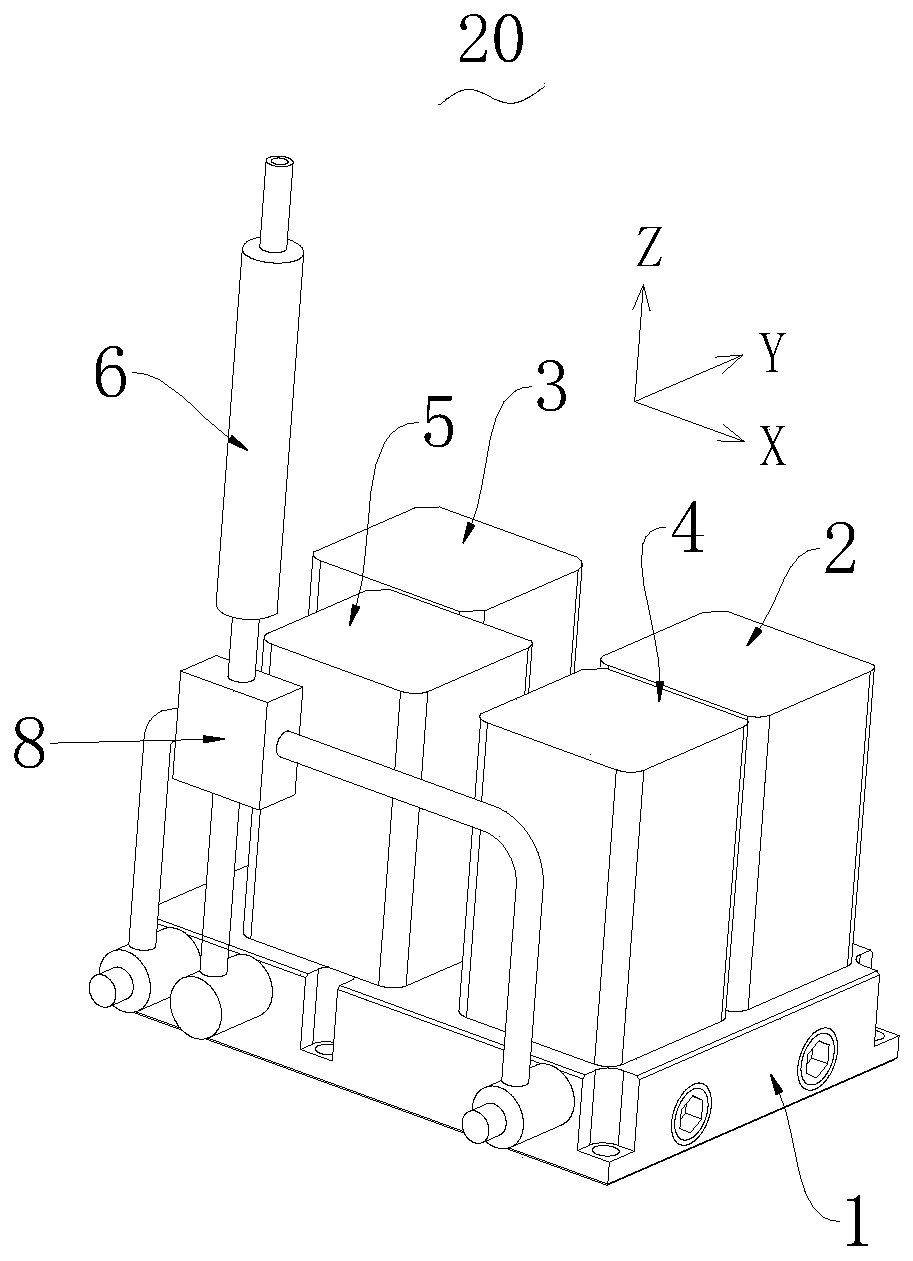

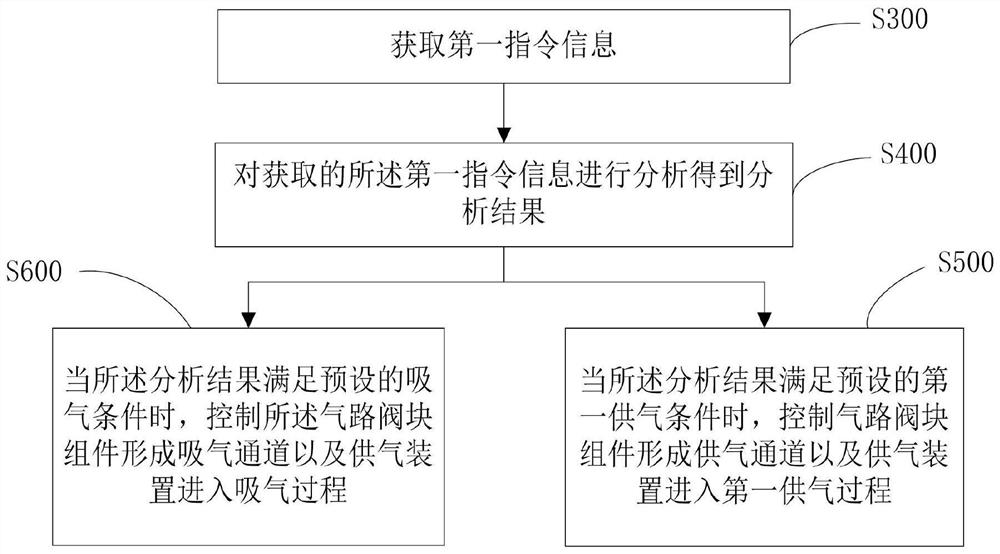

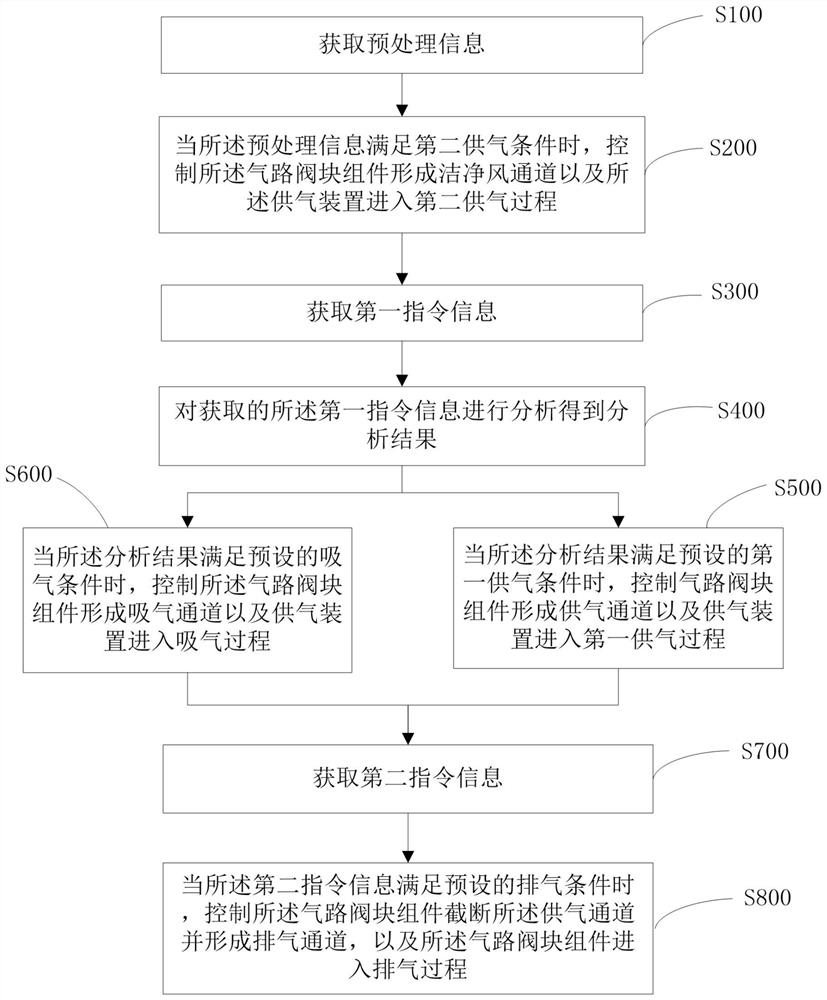

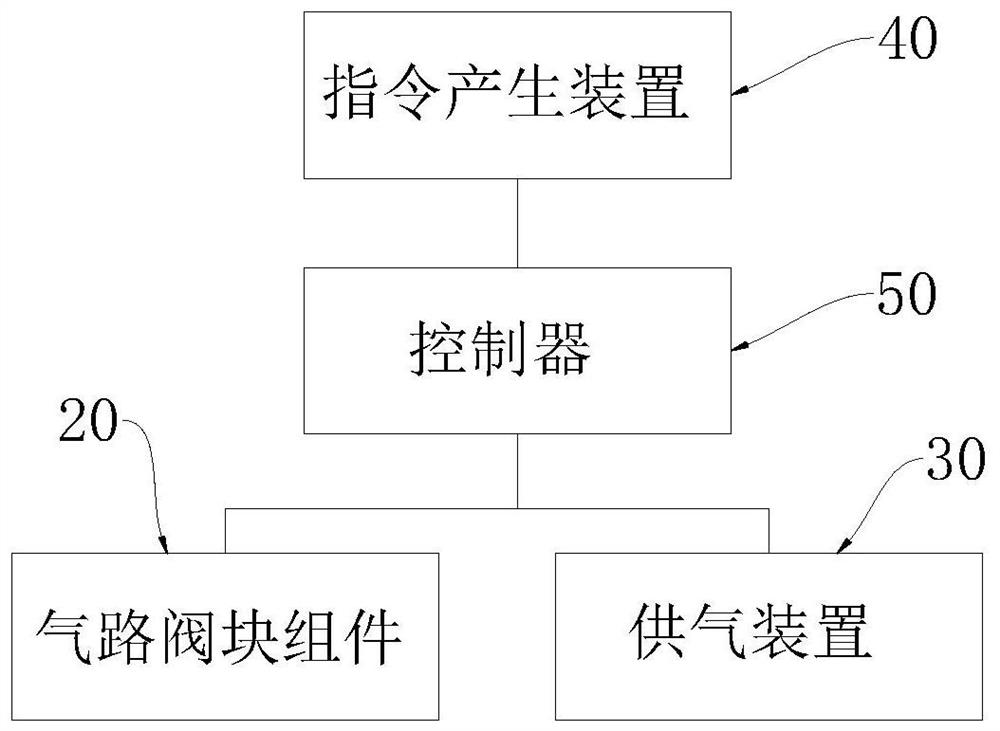

Integrated gas circuit control method and device and storage medium

ActiveCN111237276AImprove work efficiencyAvoid accumulationServomotor componentsPiston pumpsControl engineeringGas supply

The invention provides an integrated gas circuit control method and device and a storage medium. The integrated gas circuit control method comprises the steps that first instruction information is acquired; the acquired first instruction information is analyzed to obtain an analysis result; when the analysis result meets a preset first gas supply condition, a gas circuit valve block assembly is controlled to form a gas supply channel, and a gas supply device enters a first gas supply process; and when the analysis result meets a preset suction condition, the gas circuit valve block assembly iscontrolled to form a suction channel, and the air supply device enters a suction process. According to the integrated gas circuit control method, the gas circuit valve block assembly can be controlled to form the gas supply channel, and the gas circuit valve block assembly can be controlled to form the suction channel according to working requirements, so that the integrated gas circuit control method can adapt to different working conditions, and the working efficiency is improved.

Owner:安婷

Intelligent ventilation device for building construction

InactiveCN113587304AEasy to clean upGuaranteed smooth air supplyMechanical apparatusSpace heating and ventilation safety systemsCheck valveDust control

The invention discloses an intelligent ventilation device for building construction. The intelligent ventilation device comprises a ventilation shell, an induced draft fan and a partition plate, the bottom and the top of the ventilation shell are each of an opening structure, the induced draft fan is installed at the opening of the top of the ventilation shell in a sealed mode, and the partition plate is hinged to the opening of the bottom of the ventilation shell; a filter plate for filtering air is arranged in the ventilation shell; and the intelligent ventilation device further comprises a dust removal assembly arranged on the ventilation shell and used for conducting reverse blowing on the filter plate. The ventilation device is provided with a reverse blowing fan used for carrying out dust removal operation on the filter plate in the ventilation device, air flow of the reverse blowing fan ejects a second check valve open, enters the ventilation shell and blows towards the filter plate, a first check valve is closed, the air flow reversely blows dust on the filter plate to fall off, and the dust is discharged from an air outlet along with the air flow, so that ash removal treatment and maintenance of the filter plate are realized.

Owner:安徽恒晟揽智科技有限公司

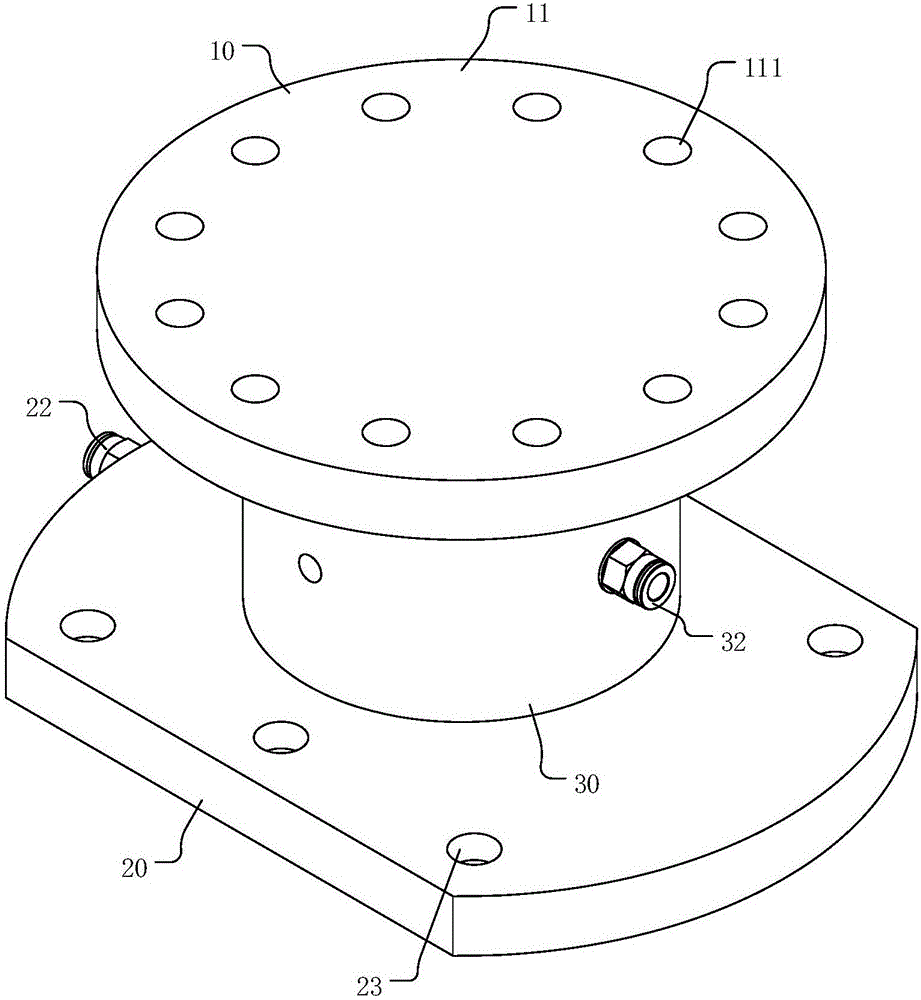

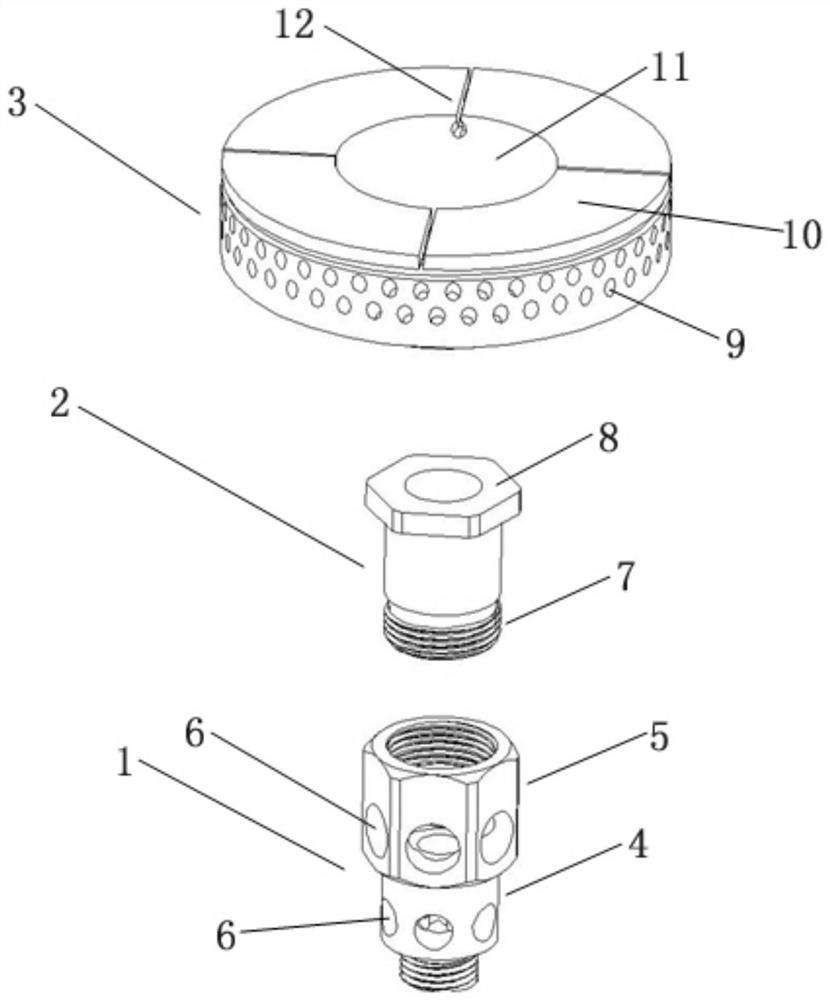

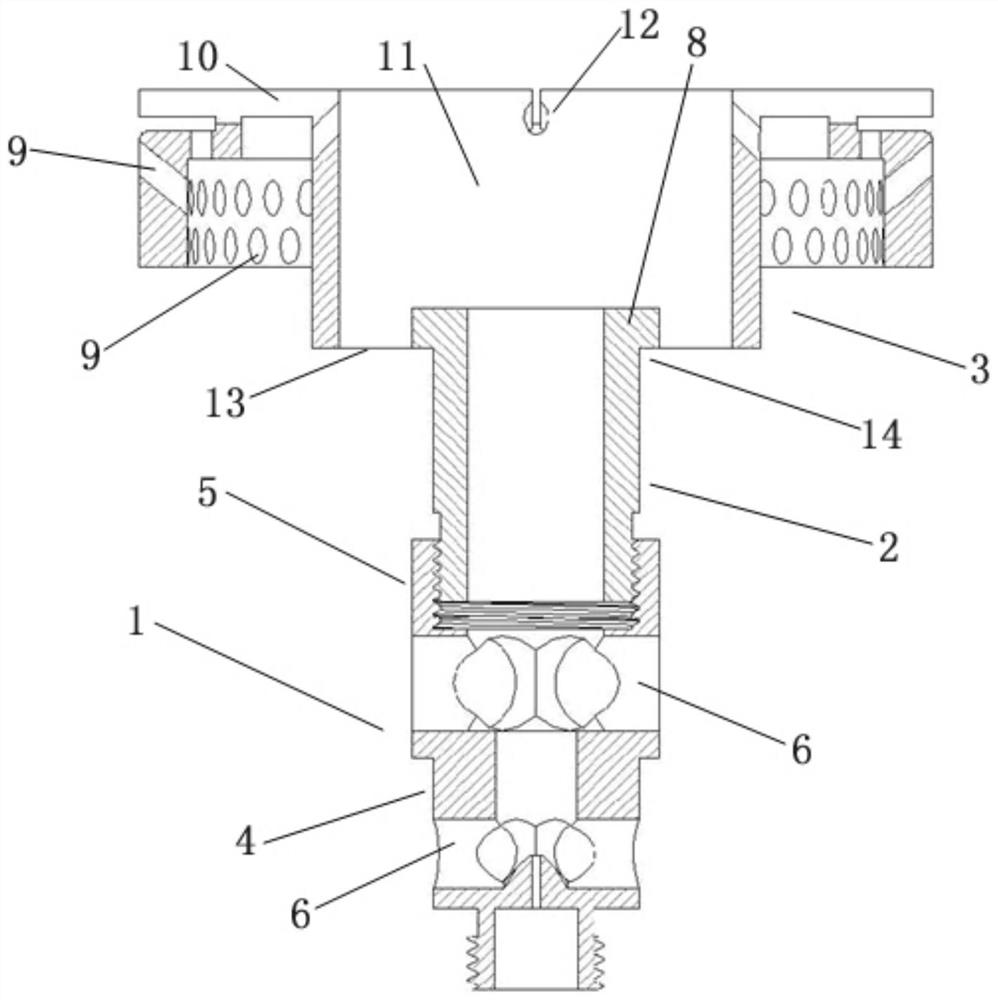

Pneumatic component installing structure

ActiveCN106695763ASmooth air supplyAvoid damageProgramme-controlled manipulatorPipeline systemsRelative motionEngineering

The invention discloses a pneumatic component installing structure, comprising a pneumatic component connecting structure and a gas supply connecting structure, wherein the gas supply connecting structure is internally provided with a first gas supply channel, and the pneumatic component connecting structure is internally provided with a second gas supply channel; the gas supply connecting structure can be rotated relatively to the pneumatic component connecting structure. The pneumatic component installing structure also comprises a connecting channel used for communicating the first gas supply channel with the second gas supply channel and extending in the direction of relative motion of the gas supply connecting structure to the pneumatic component installing structure. In the pneumatic component installing structure provided by the invention, the gas supply connecting structure able to move relatively to the pneumatic component installing structure is arranged to ensure that a gas supply pipeline is not driven to move in operation of the pneumatic component, so that smooth gas supply of the gas supply pipeline to the pneumatic component can be ensured, but also damage to the gas supply pipeline due to movement can be prevented.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Anti-epidemic respirator (mask) and use method thereof

The invention relates to an anti-epidemic respirator (mask) and a use method thereof. People can wear the respirator to be prevented from inhaling germs, particles and other harmful substances in environment air, and specifically respiratory diseases are prevented. The respirator is composed of three major parts: a nose and mouth mark device, a breathable air source device and an air guide tube for connecting the nose and mouth mark device and the breathable air source device. External air can only be guided into the nose and mouth mark device in one direction from the gas guide tube through the breathable air source device; and an air pumping device is arranged in the breathable air source device, and the inhaling of a wearer is facilitated. Various types of sterilizing and disinfecting parts and filtering parts are arranged in the breathable air source device. An electronic temperature adjusting facility is arranged inside and used for maintaining the long-term conveying of fresh air. The respirator is provided with a temperature measuring and body temperature uploading part, and the body temperature features of personnel in an area under administration can be monitored through awireless network. A movable window of the nose and mouth mark device can be opened so that a melt-blow fabric can be replaced, and the nose and mouth mark device can be conveniently disinfected. Therespirator is wide in application range and high in practicability. The anti-epidemic respirator has the advantages of being simple in production process, easy to industrialize and convenient to use.

Owner:郑州太德网络科技有限公司

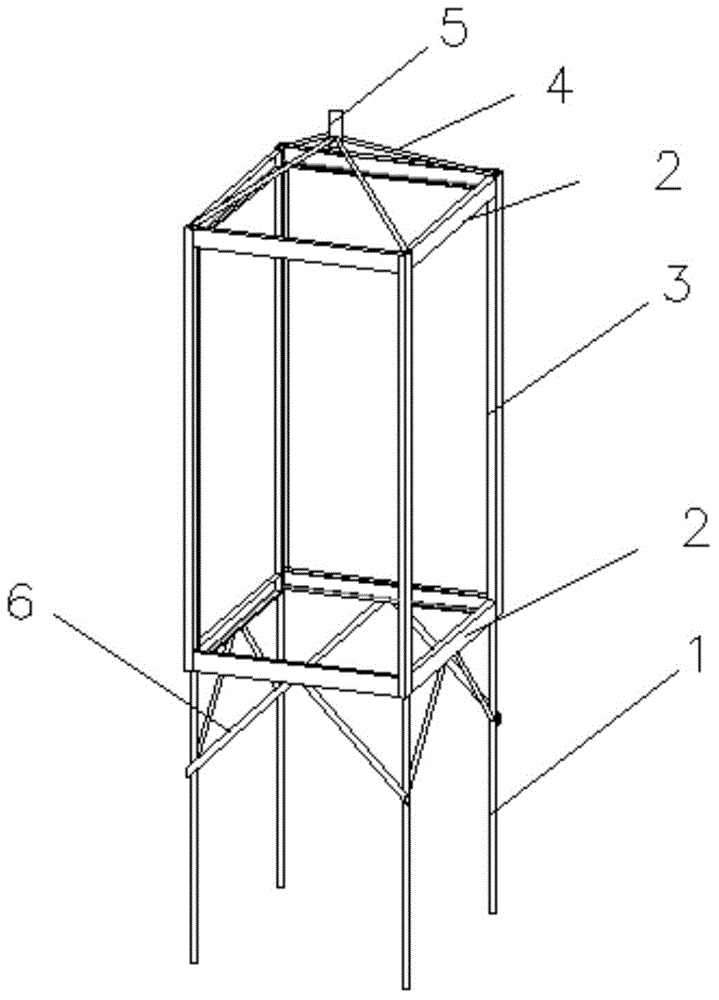

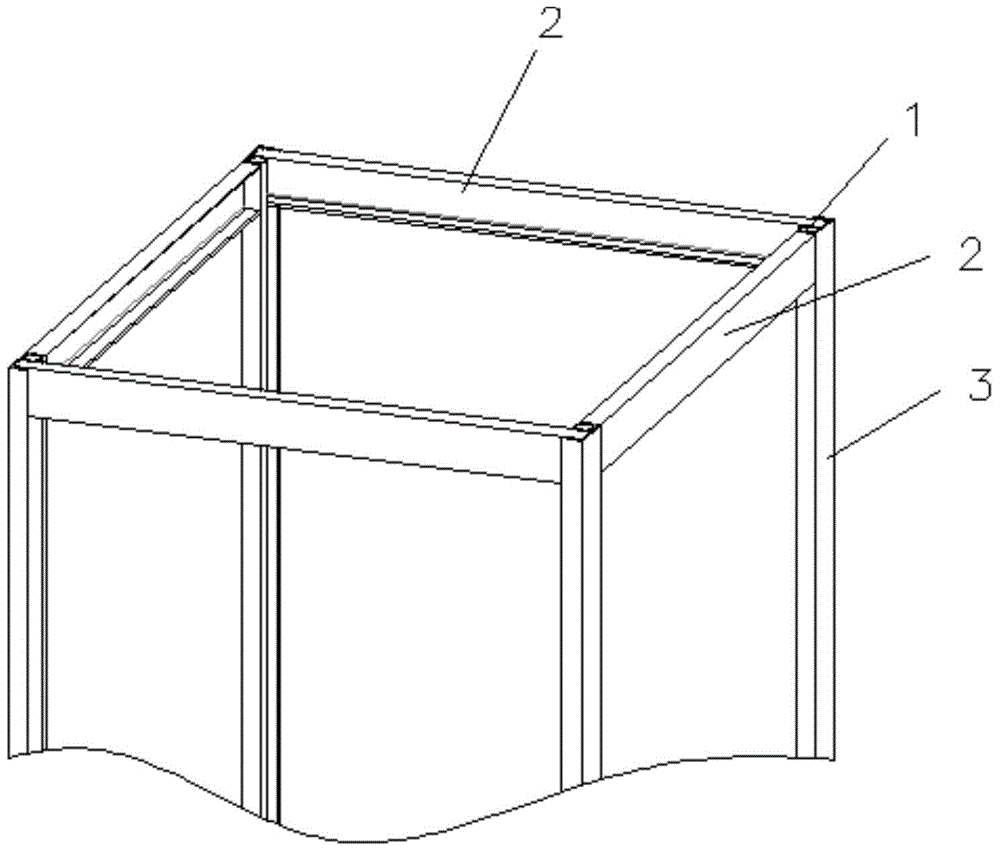

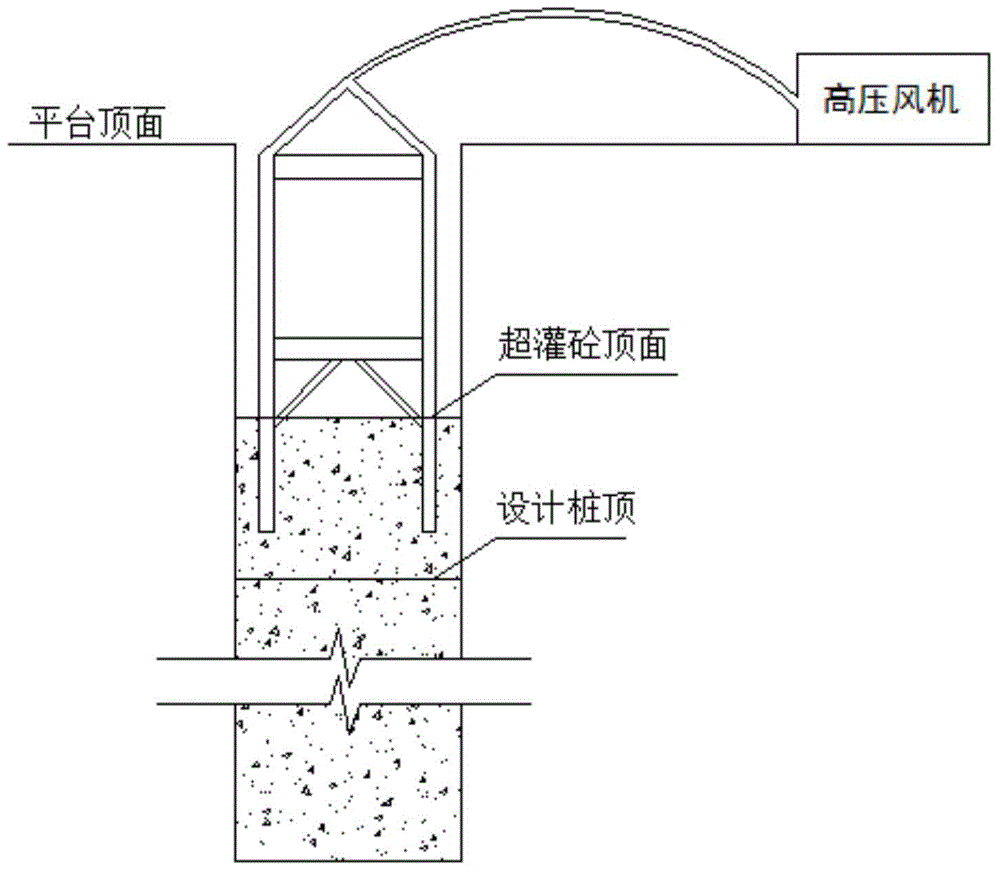

Air supply device and method for cleaning bridge drilled pile head through air supply device

The invention provides an air supply device which comprises a plurality of vertical pipes and a fixing mechanism arranged among the vertical pipes. The fixing mechanism is arranged on the upper portions of the vertical pipes and is of a frame structural mode, and the tops of the vertical pipes are communicated with a high-pressure fan. A method for cleaning a bridge drilled pile head through the air supply device comprises the following steps of (1) placing the air supply device down to a designated elevation position in a steel casing; (2) enabling an air supply pipe and the high-pressure fan to be communicated and starting the high-pressure fan; (3) pumping out concrete which loses efficacy in the steel casing through a slime pump; and (4) carrying out secondary cleaning on concrete in the steel casing manually. The air supply device is simple in structure; the function of supplying air to the concrete in the steel casing is achieved through the vertical pipes, and smooth air supply is guaranteed. According to the method, the high-pressure fan supplies air through the vertical pipes of the air supply device, and therefore setting of cement in the steel casing is prevented, and the cleaning method saves time and labor.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Ventilation device convenient to adjust for tunnel construction and using and adjusting method

PendingCN112177660AMeet the air supply needsDon't waste energyTunnel/mines ventillationElectric machineCoupling

The invention provides a ventilation device convenient to adjust for tunnel construction and a using and adjusting method. The ventilation device comprises a tunnel, wherein the tunnel is provided with a left tunnel wall, a right tunnel wall and a top tunnel wall, the left tunnel wall is provided with a left annular fixing ring, the left annular fixing ring is provided with a left trapezoidal annular groove, the left trapezoidal annular groove is provided with a left sliding block, the left sliding block is connected through a left rotating plate, the left rotating plate is connected with a left rotating shaft, the left rotating shaft is connected with a left coupler, and the left coupler is connected with a left motor; the right tunnel wall is provided with a right annular fixing ring, the right annular fixing ring is provided with a right trapezoidal annular groove, the right trapezoidal annular groove is provided with a right sliding block, the right sliding block is connected through a right rotating plate, the right rotating plate is connected with a right rotating shaft, the right rotating shaft is connected with a right coupler, and the right coupler is connected with a right motor; and the top tunnel wall is provided with a top annular fixing ring, the top annular fixing ring is provided with a top trapezoidal annular groove, the top trapezoidal annular groove is provided with a top sliding block, the top sliding block is connected through a top rotating plate, the top rotating plate is connected with a top rotating shaft, the top rotating shaft is connected with atop coupler, and the top coupler is connected with a top motor. The ventilation device is used for tunnel ventilation.

Owner:黑龙江农垦建工路桥有限公司

Traditional Chinese medicine preparation for treating asthma and preparation method thereof

InactiveCN113117009ARegulate Yin and Yang balanceRegulate immunityDigestive systemAntinoxious agentsBelamcanda chinensisWolfiporia extensa

The invention discloses a traditional Chinese medicine preparation for treating asthma and a preparation method thereof, and the traditional Chinese medicine preparation comprises the following raw materials in parts by weight: 8-12 parts of prepared monkshood, cinnamon, prepared rhizome of rehmannia, cortex moutan, rhizoma alismatis, common yam rhizome, schisandra chinensis, pulp of dogwood fruit, blackberry lily, platycodon grandiflorum and almond, 16-24 parts of poria cocos, 12-18 parts of fructus lycii, 12-18 parts of fructus psoraleae, 12-18 parts of morinda officinalis, 10-14 parts of walnut meat and 3-5 parts of tendril-leaved fritillary bulb powder. And different formulas are formulated for asthma caused by different causes. The preparation method of the traditional Chinese medicine preparation comprises the following steps: crushing the raw materials, mixing and blending, heating, drying and granulating, automatically and quantitatively packaging, and warehousing. The traditional Chinese medicine preparation prepared by the invention is safe and free of toxic and side effects, has the advantages of strong effect, quick response, lasting drug effect and the like, has no dependence, drug resistance and toxic and side effects, and has very important clinical significance for treating asthma.

Owner:睿特环中医药科技发展有限公司 +1

Novel gas nozzle with sufficient combustion

The invention provides a novel gas nozzle capable of achieving sufficient combustion. The novel gas nozzle comprises a gas mixing cavity, a gas mixing extension cavity and a gas flame-out tractor which are sequentially arranged from bottom to top; the gas mixing cavity and the gas mixing extension cavity are screwed together through threads; and after the bottom of the gas mixing extension cavitypenetrates through a circular cavity in the top of the gas flame-out tractor to be placed in, the hexagonal top face of the top of the gas mixing extension cavity is blocked by a circular boss on theouter circumference of a gas inlet through hole in the bottom of the gas flame-out tractor, and therefore the gas mixing extension cavity and the gas flame-out tractor are combined together. Due to the arrangement of a lower gas mixing cavity and an upper gas mixing cavity of the gas mixing cavity, secondary gas mixing can be achieved, and sufficient gas mixing is guaranteed; due to the arrangement of the gas mixing extension cavity, stable fuel gas can be formed, and detonation is avoided. due to the arrangement of the circular cavity of the gas flame-out tractor, fuel gas combusted at the position can directly heat the bottom of a pot, negative pressure traction firepower can be formed at the position, negative pressure suction is formed for the fuel gas in the gas inlet through hole andan inclined spray hole, the gas outlet speed of the fuel gas is increased, and the heat efficiency is improved.

Owner:广东火密码厨具有限公司

Air circuit integration block and air circuit valve block component

ActiveCN111102262ASmall footprintReduce connectionsServomotor componentsFluid-pressure actuator componentsMechanical engineeringElectrical and Electronics engineering

Owner:安婷

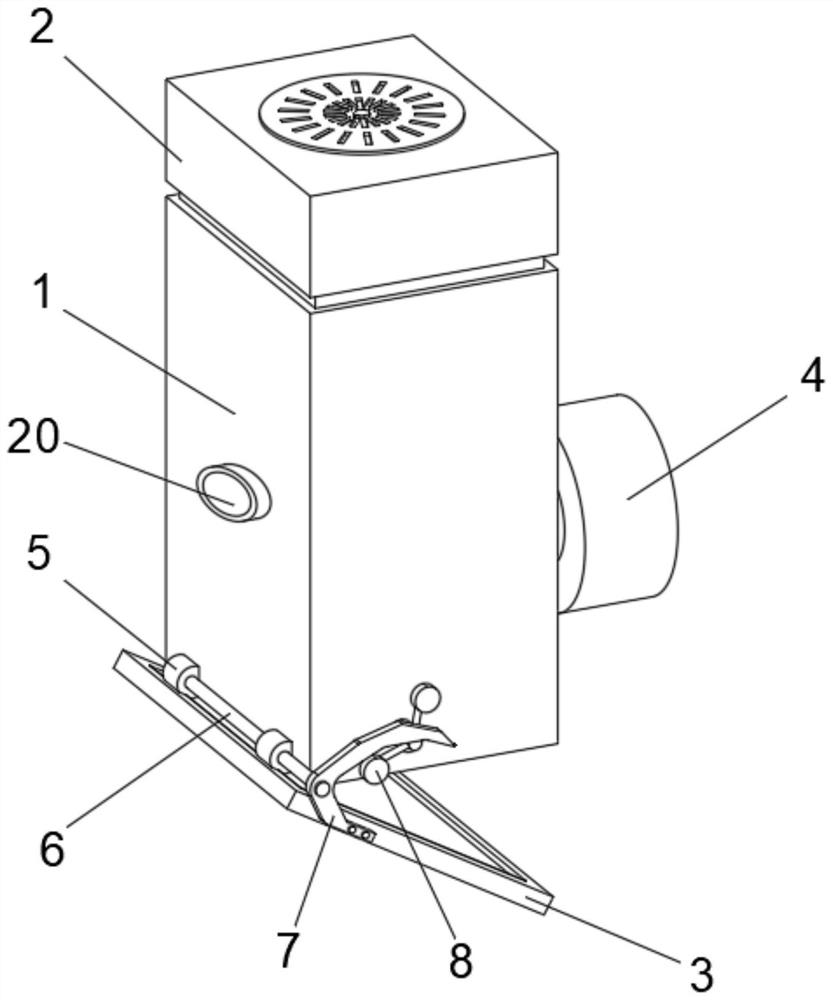

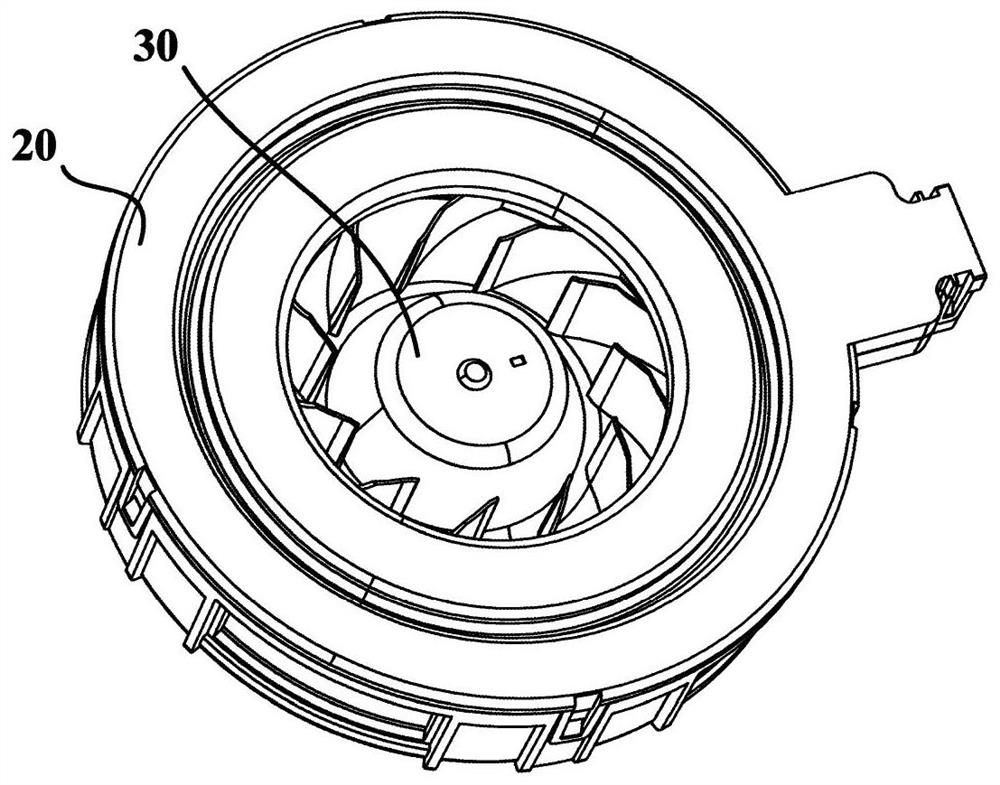

centrifugal fan

ActiveCN106194804BRealize reasonable air supplySmooth air supplyPump componentsMechanical energy handlingAir volumeElectric machinery

The invention provides a centrifugal fan. The centrifugal fan includes: a casing, an air inlet is opened on the cover, and a plurality of air outlets are opened on the surrounding wall; a wind wheel assembly, which has a wind wheel motor and a plurality of fan blades; an air supply control device, which is rotatably arranged in the casing, and has one or more shielding parts; the adjusting motor is arranged on the radially outer side of the surrounding wall; Each shielding part is rotated to different rotation positions to completely cover, partially cover or fully expose each air outlet, thereby adjusting the respective air outlet areas of the multiple air outlets. The centrifugal fan can controllably shield multiple air outlets through the rotation of the air supply control device, so as to realize simultaneous air supply to multiple directions / multiple places, and can select the air outlet direction / air supply place and Adjust the air volume of each air outlet to achieve a reasonable air supply.

Owner:HAIER SMART HOME CO LTD

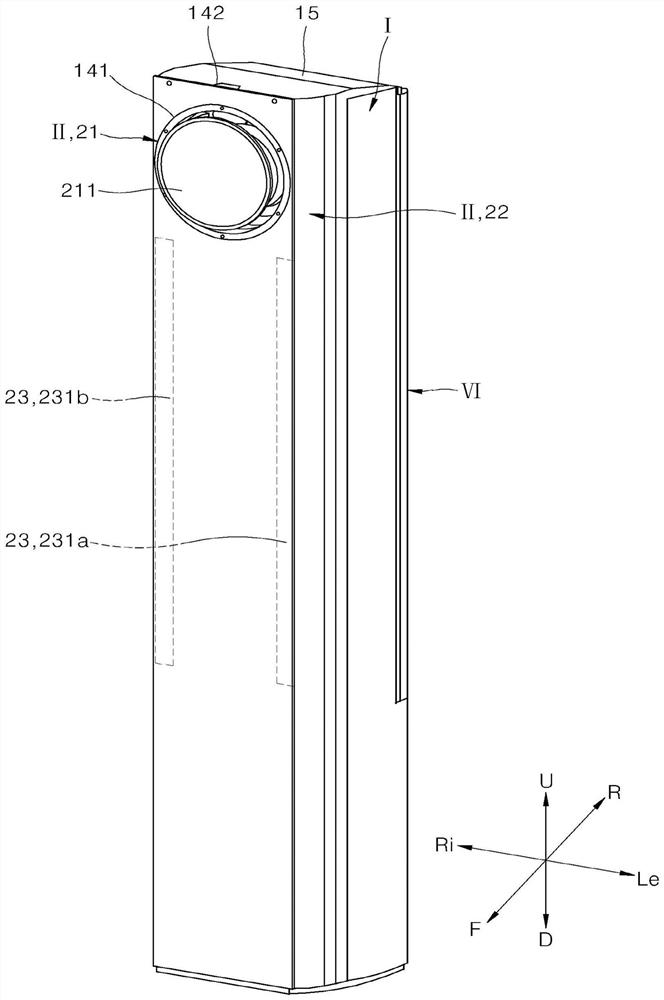

Air conditioner

PendingCN113932287AChange airflow directionSmooth air supplyDucting arrangementsLighting and heating apparatusEngineeringAir conditioning

The invention relates to the technical field of air conditioning devices, and discloses an air conditioner. The air conditioner comprises an air duct outer shell with an air inlet and an air outlet, and further comprises an air duct inner shell, an air supply mechanism and a driving mechanism, wherein the air duct inner shell is arranged inside the air duct outer shell and comprises an air flow inlet and an air flow outlet, the air flow inlet faces the air inlet, and the air flow outlet faces the air outlet; the air supply mechanism is arranged at the air flow inlet; and the driving mechanism is connected with the air duct inner shell and drives the air duct inner shell to rotate around the air supply mechanism so that the air flow outlet can correspond to different positions of the air outlet. According to the air conditioner, the air flow outlet of the air duct inner shell can correspond to different positions of the air outlet, so that the air supply flow of the air conditioner is blown to different directions; the air flow direction is changed through rotation of the air duct inner shell, and the flowing direction of the air flow in the air duct inner shell cannot be suddenly changed, so that smooth air supply can be kept; and compared with a mode that the air outlet direction is changed by adopting a flow guide plate, the mode in the invention has the characteristics that the air outlet wind resistance and the air outlet noise are reduced.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

A Furnace Charge Replacement Method Under A Blast Furnace Accident

ActiveCN105368995BSmooth air supplyImprove liquidityBlast furnace detailsProcess efficiency improvementFurnace temperatureSlag

The invention discloses a furnace charge replacement method under a blast furnace accident. Blast furnace air supply continues to be carried out through an existing air supply system under the condition that blast furnace top pressure is normal pressure. The area of an air opening is reduced (the air opening is blocked, and the diameter of the air opening is reduced). After air supply, a certain amount of coke is added, then light load materials and clean coke are added at intervals for feeding, and the light load materials are obtained through gradual transition according to the furnace temperature, the furnace condition antegrade condition and the slag iron discharge condition. The furnace temperature is sufficient, discharging is carried out stably and smoothly, the air opening is gradually opened to increase the air blast according to the condition of the furnace top pressure, a work air opening is more than 2 / 3 of the whole air opening, replacement of heavy load materials is completed, blast furnace temperature is sufficient, and furnace blocking materials start to be fed. Slag iron is treated in a normal production manner, the labor intensity of workers cannot be increased, the workers do not need to enter a blast furnace, and water lifting is avoided. Meanwhile, when air supply restores, the blast furnace is basically filled with coke, air supply restores relatively smoothly, and the probability of bursting cool slag iron through blasting is extremely low. The influence on the service life of the blast furnace is small. Treatment cost is low, treatment time is short, and the influence on production is small.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

An integrated gas circuit control method, device and storage medium

ActiveCN111237276BImprove work efficiencyAvoid accumulationServomotor componentsPiston pumpsControl engineeringProcess engineering

Owner:安婷

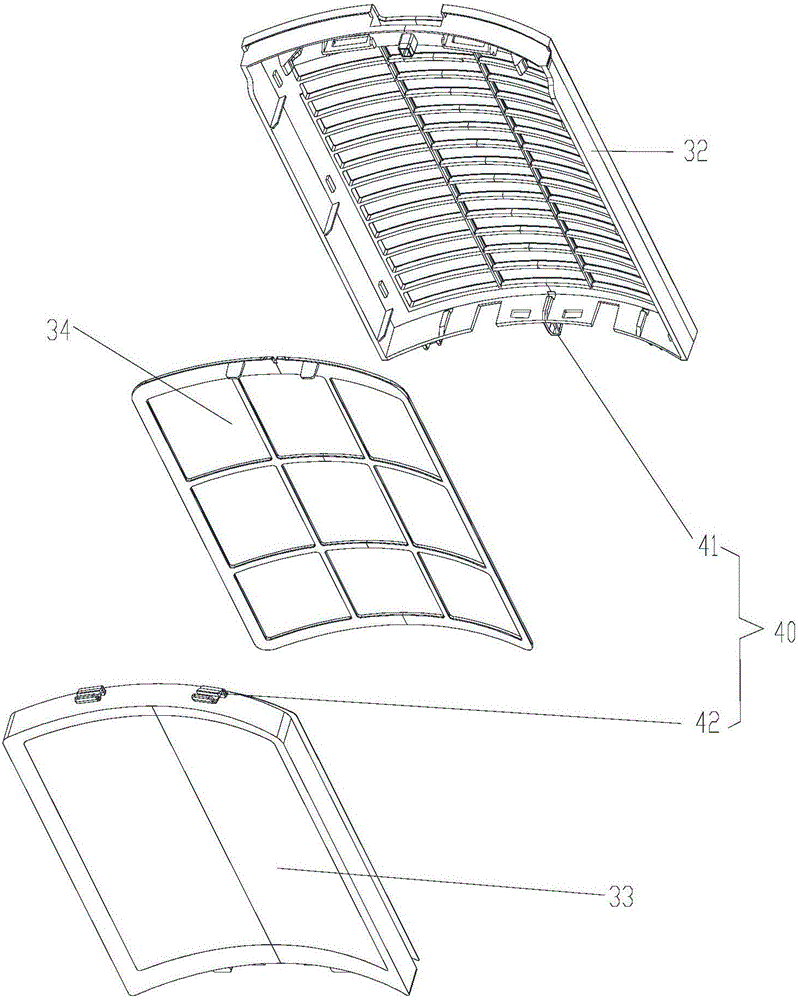

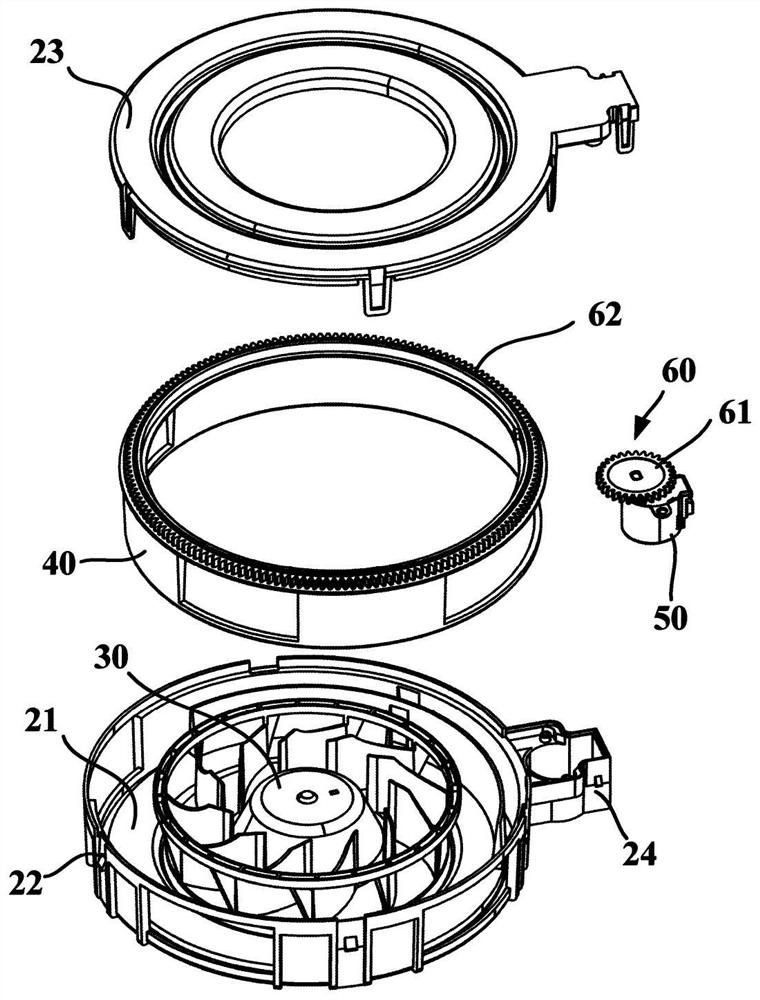

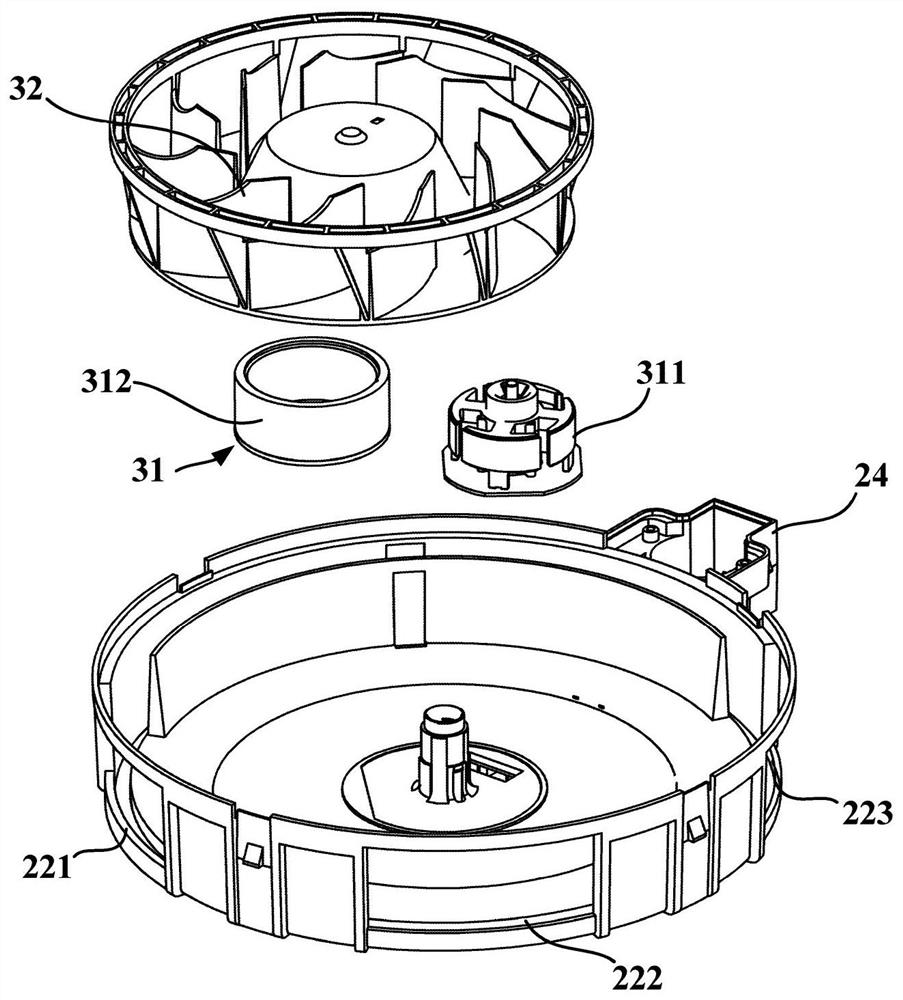

centrifugal fan

ActiveCN106286327BRealize reasonable air supplySmooth air supplyPump componentsPump controlAir volumeEngineering

A centrifugal fan comprises a housing (20) having an air inlet provided on a cover portion (23) thereof and a plurality sets of air outlets provided on a peripheral wall portion (22) thereof; a wind wheel (30) configured to urge the air flow flowing into the housing (20) via the air inlet and out of the housing (20) via one or more of the plurality of the air outlets; a plurality groups of damper blocking plates (40), each of the damper blocking plates (40) being movably mounted to an air outlet and configured to be controllably moved to a different obstructing position to completely shield, partially shield, or fully expose the air outlet so as to adjust the air blowing area of the air outlet; a rotating member (50) rotatably mounted on the housing (20); and a transmission mechanism configured to transmit the rotational movement of the rotating member (50) to the plurality of damper blocking plates (40). In the centrifugal fan, the blocking plates (40) can be moved by rotating the rotating member (50) to controllably shield the plurality of air outlets so as to achieve blowing air in multiple directions at the same time and to achieve a reasonable air supply by choosing air blowing directions and adjusting air volume of each outlet.

Owner:QINGDAO HAIER SPECIAL REFRIGERATION ELECTRIC APPLIANCE CO LTD +1

Air conditioner

ActiveCN114688614AReduce sizeReduce manufacturing costsLighting and heating apparatusHeating and ventilation casings/coversRotational axisEngineering

An air conditioner is provided with: a case having a suction port formed in the rear surface thereof and a front discharge port formed in the front surface thereof; a heat exchanger that exchanges heat between the air flowing into the suction port and the refrigerant; an air supply fan which has a rotation axis extending from the front surface of the box body to the back surface of the box body, and which sucks in the heat-exchanged air; a discharge guide having a front discharge port formed at the front end thereof and having a discharge flow path formed therein for guiding the air discharged from the blower fan to the front discharge port; and a front door portion provided between the forefront position and the rearmost position so as to be movable in a direction parallel to the rotation axis, the outer peripheral surface of the front door portion forming the discharge flow path together with the discharge guide having a first inclined surface, the first inclined surface gradually rising toward the front in the direction parallel to the rotation axis, and the first inclined surface gradually rising toward the rear in the direction parallel to the rotation axis. When the front door part moves to the forefront position, a part of the first inclined surface protrudes to the outer side of the box body through the front discharge port.

Owner:LG ELECTRONICS INC

Making method of siphonic air incrementer

InactiveCN106321529AGuaranteed to proceed normallyEasy to makeDucting arrangementsJet pumpsAir exchangeExhaust pipe

The invention discloses a siphonic air incrementer. The tail end of an air inlet pipe is connected with the front end of an air exhaust pipe, an airflow pipe cavity of the air inlet pipe and an airflow pipe cavity of the air exhaust pipe are connected to form an airflow channel, and the tail end of the air inlet pipe is provided with a positioning concave cavity which is internally provided with an outwards convex connection air tap; the front end of the air exhaust pipe is provided with a connection end socket which is installed in the mode of being matched with the inner wall face of the positioning concave cavity; an airflow pipe cavity of the connection end socket surrounds the periphery of the connection air tap, and an air excitation gap is reserved between the airflow pipe cavity of the connection end socket and the connection air tap; and the air inlet end of the air excitation gap receives an airflow output by an external compressed air source supply device, and the air outlet end of the air excitation gap is arranged to face the airflow direction of the airflow pipe cavity. Meanwhile, the invention discloses a making method of the air incrementer and a breathing air exchange shoe or pipeline air supply system with the air incrementer. The air incrementer and the making method thereof and the breathing air exchange shoe or pipeline air supply system with the air incrementer have the advantages that the structure is simple, the cost is low, and making is convenient and easy.

Owner:许嘉乐

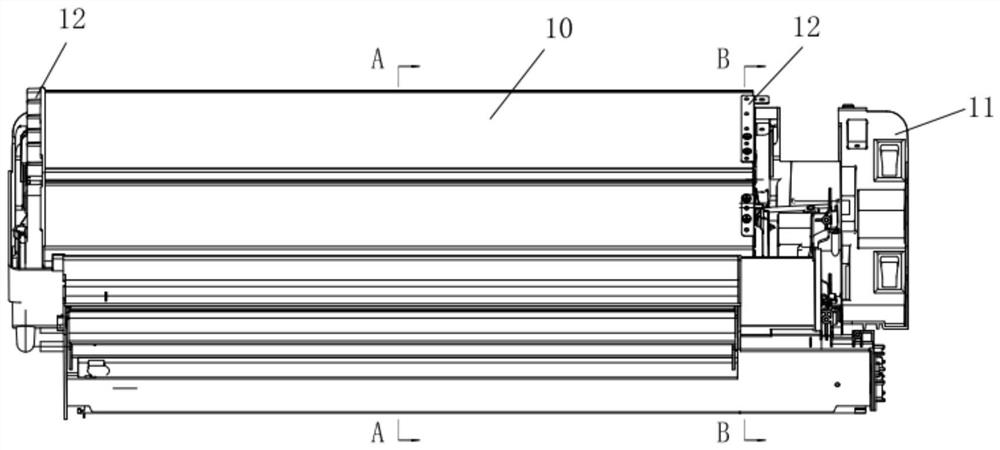

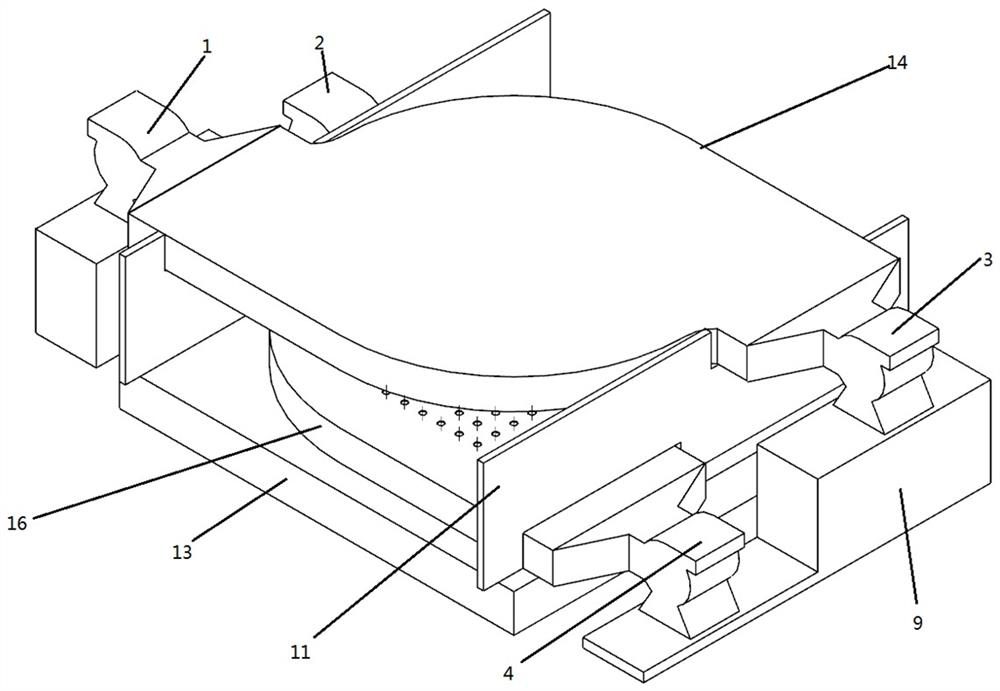

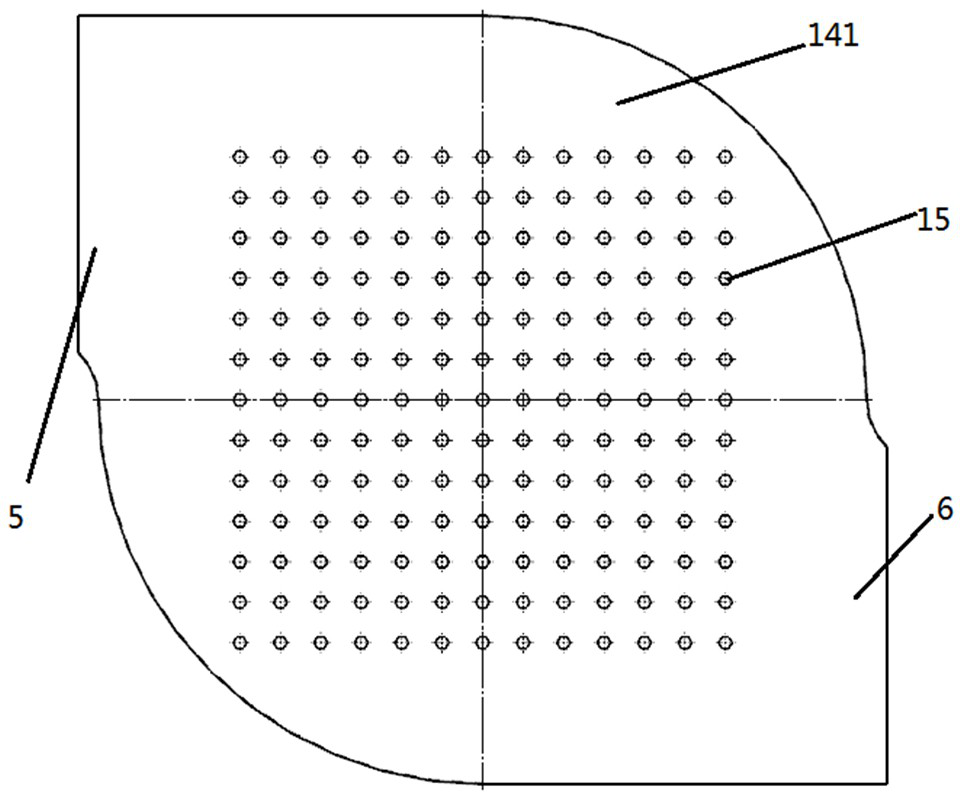

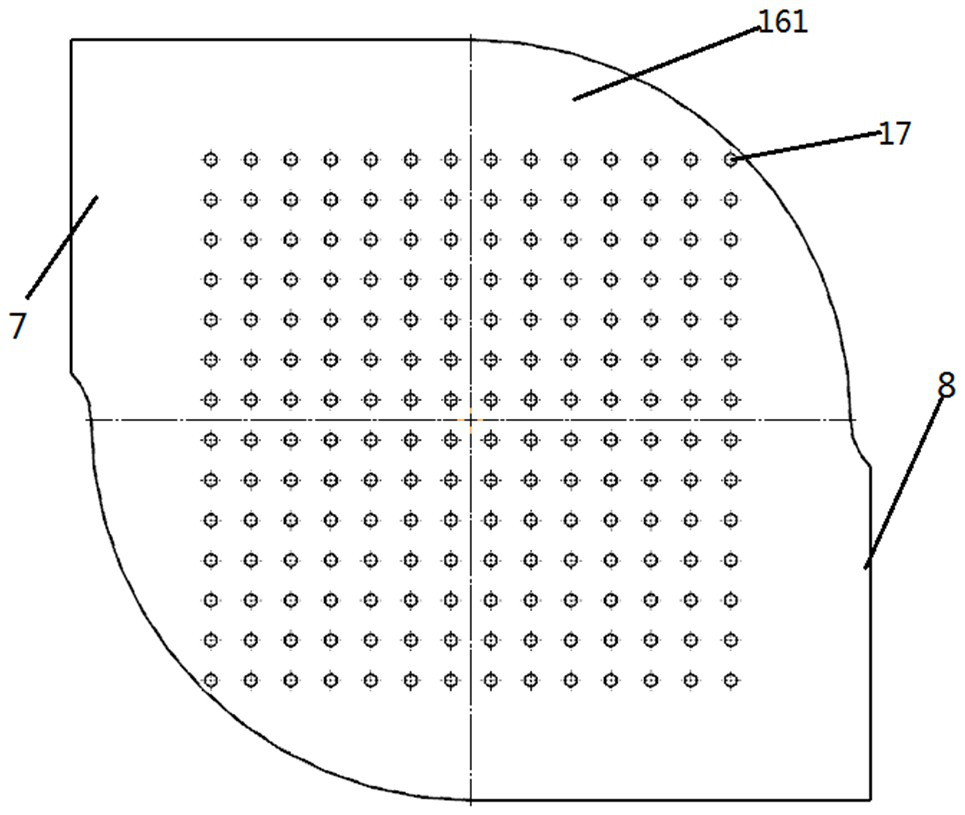

A uniform heating device for a biaxially stretched film horizontal stretching machine

The invention discloses a uniform heating device for a biaxially stretched film cross drawing machine. The device comprises two static pressure boxes arranged in parallel in the vertical direction andorthogonally and four hot-air blowers, wherein the two static pressure boxes are the upper static pressure box and the lower static pressure box, and the two static pressure boxes are hollow and discoid boxes with same shapes and same structures; two sides of each static pressure box in the radial direction are each provided with an air intake channel, and the two air intake channels at two sidesare parallel to each other; the space between the upper working surface of the upper static pressure box and the lower working surface of the lower static pressure box is of a heating area; upper airoutlet holes and lower air outlet holes are correspondingly arranged on the upper working surface and the lower working surface; the upper air outlet holes and the lower air outlet holes are arrangedalternately; and the four hot-air blowers are correspondingly arranged at air inlets of the upper static pressure box and the lower static pressure box. The hot air in the upper static pressure box and in the lower static pressure box reach pressure balance in working; the upper air outlet holes and the lower air outlet holes are arranged alternately, so that the direct face of the discharged gasis avoided. Uniform heating temperature in a working area is ensured by the three key designs.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com