A uniform heating device for a biaxially stretched film horizontal stretching machine

A uniform heating and biaxial stretching technology, applied in the field of biaxial stretching film production equipment, can solve the problems of low heating efficiency, uneven temperature distribution, and reduced heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described through examples below in conjunction with the accompanying drawings.

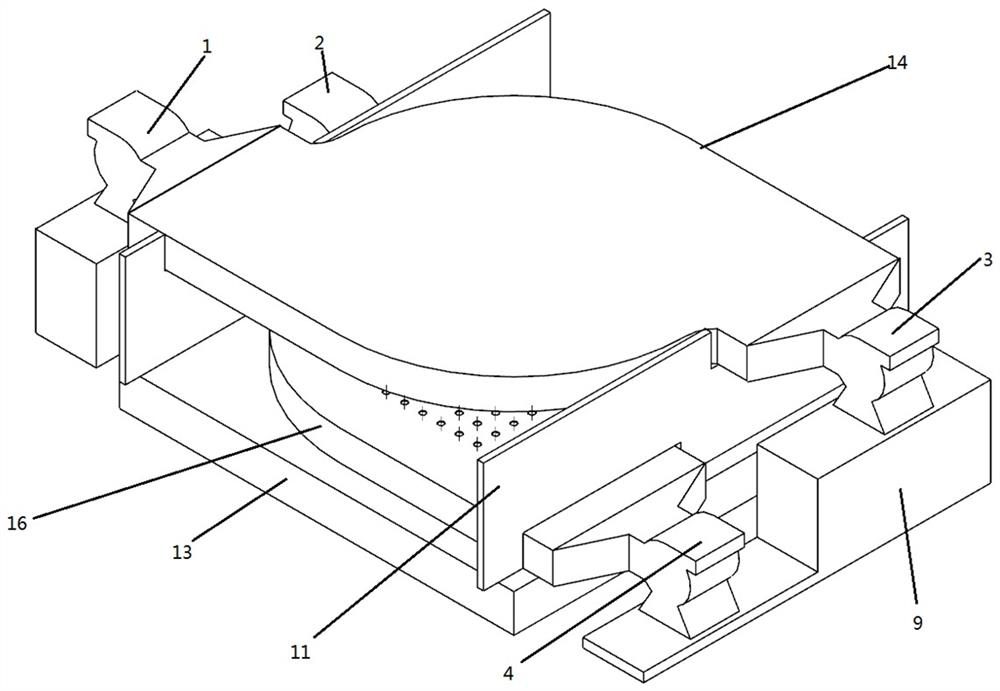

[0025] see figure 1 A uniform heating device for a biaxially stretched film horizontal stretching machine includes a pair of static pressure boxes arranged in parallel and orthogonally up and down, four hot air blowers and a supporting mechanism.

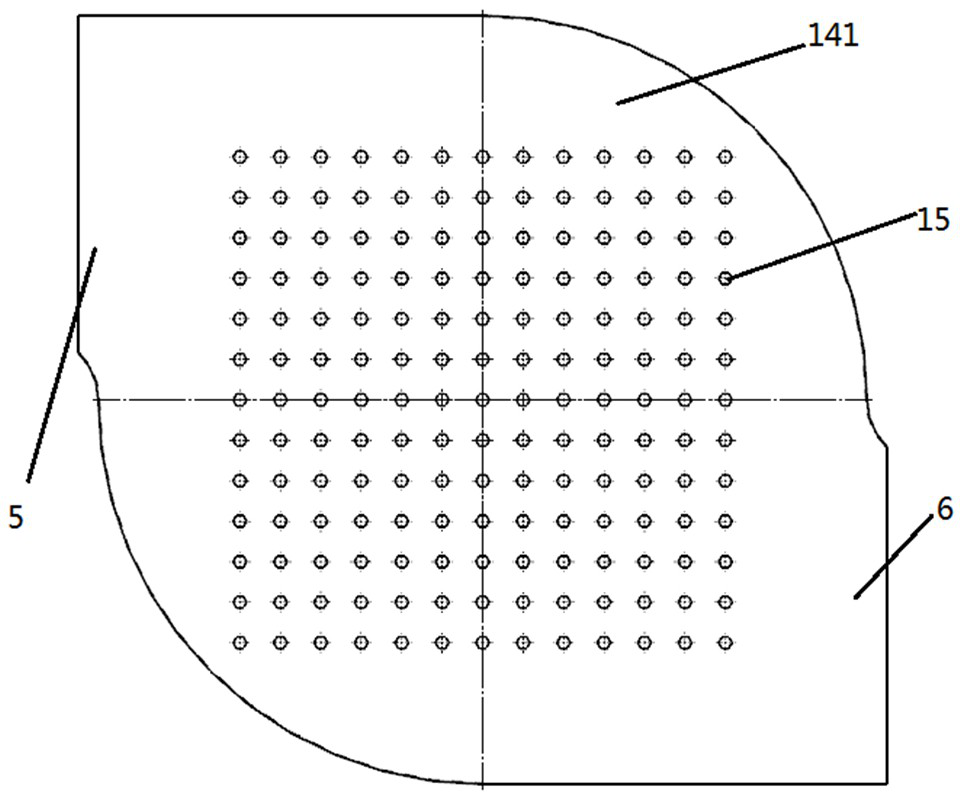

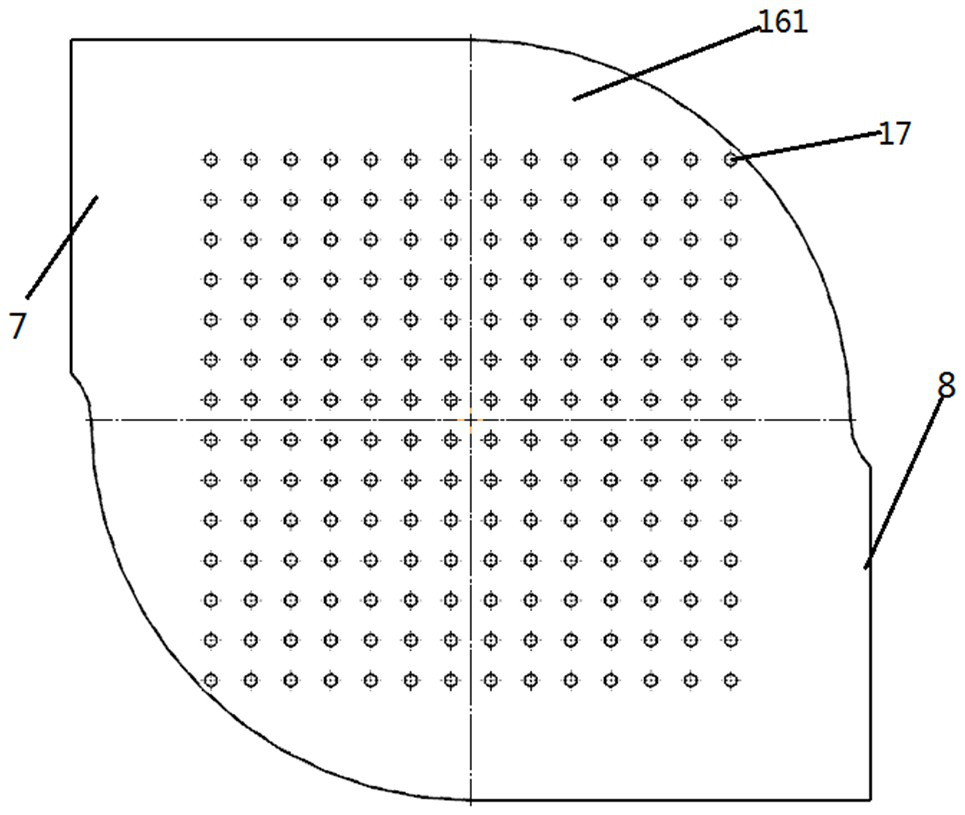

[0026] A pair of plenums are an upper plenum 14 and a lower plenum 16, the upper plenum 14 and the lower plenum 16 have the same shape and structure, and are hollow disk-shaped boxes; the upper plenum 14 and the lower plenum The box 16 has a diameter of 1400 mm and a thickness of 100 mm. The upper first air inlet 5 and the upper second air inlet 6 are arranged tangentially on both sides of the upper plenum 14 in the circumferential direction, and the upper first air inlet 5 and the upper second air inlet 6 are symmetrical in opposite directions. Parallel state; the two sides of the lower plenum 16 are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com