Preparation method of high-quality black tea extract

A technology for high-quality, black tea, applied in the field of preparation of high-quality black tea tea paste, can solve the problems of poor color, bitter taste of tea soup, less black tea tea paste, etc., and achieves shortening the fixing time, improving the cell fragmentation rate, and having a good taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

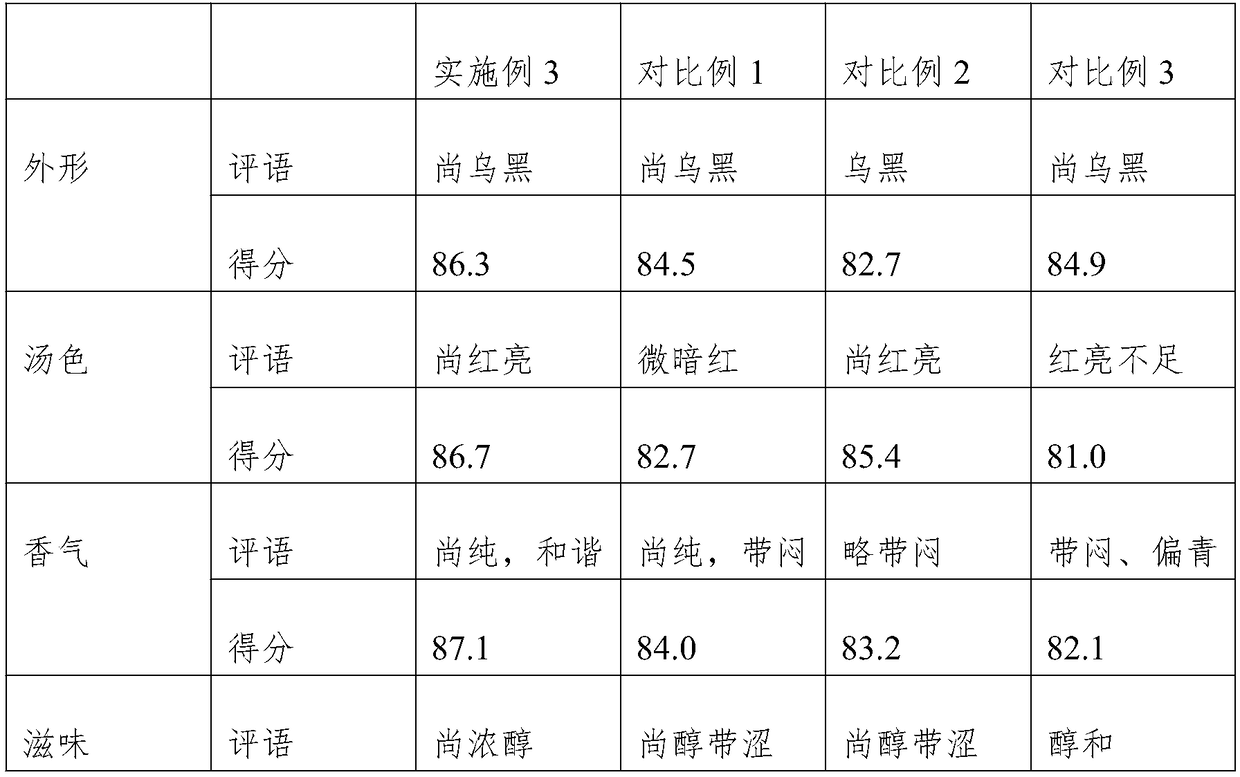

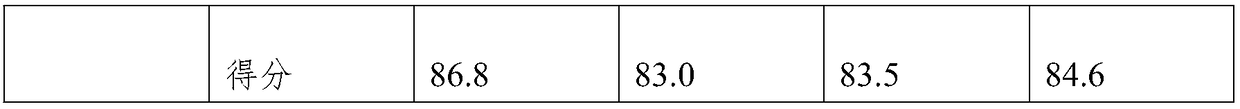

Examples

Embodiment 1

[0027] A preparation method of high-quality black tea paste, comprising the steps of:

[0028] S1 takes lotus leaves and sterilizes them with high-temperature steam, and then kills them at a temperature of 340°C until the water content is 15%;

[0029] S2 Take the green lotus leaves and black tea and put them into the kneading machine at a weight ratio of 7:1, and knead them again for 15 minutes at a temperature of 50°C;

[0030] S3 put the twisted lotus leaf and black tea in a fermenter, spray 0.05% of the total weight of the lotus leaf and black tea fermentation bacteria liquid, and ferment for 12 hours at a temperature of 40-48°C and a humidity of 82-88%;

[0031] S4 Add distilled water 5 times its weight to the fermented product in step S3, heat up and decoct for 1.5h, after decocting, concentrate under reduced pressure to 1 / 3 of the original volume, then add xylitol and Mix 40% glucose evenly to get tea cream;

[0032] S5 Drying and Sterilization: Put the tea paste into...

Embodiment 2

[0041] A preparation method of high-quality black tea paste, comprising the steps of:

[0042] S1 takes lotus leaves and sterilizes them with high-temperature steam, and then kills them at a temperature of 228°C until the water content is 10%;

[0043] S2 Take the green lotus leaves and black tea and put them into the kneading machine at a weight ratio of 4:1, and knead them again for 10 minutes at a temperature of 35°C;

[0044] S3 put the twisted lotus leaf and black tea in a fermenter, spray the lotus leaf and black tea with 0.02% of the total weight of the fermented bacteria liquid, place the temperature at 40 ° C, and ferment for 10 hours under the condition of 82% humidity;

[0045] S4 Add distilled water 3 times its weight to the fermented product in step S3, heat up and decoct for 1.2h, after decocting, concentrate under reduced pressure to 1 / 3 of the original volume, then add xylitol and Mix 20% glucose evenly to get tea cream;

[0046] S5 Drying and Sterilization: ...

Embodiment 3

[0055] A preparation method of high-quality black tea paste, comprising the steps of:

[0056] S1 lotus leaves are sterilized by high-temperature steam, and then killed at a temperature of 300°C until the water content is 12%;

[0057] S2 Take the green lotus leaves and black tea and put them into the kneading machine at a weight ratio of 5:1, and knead them again for 12 minutes at a temperature of 45°C;

[0058] S3 put the twisted lotus leaf and black tea in a fermenter, spray the lotus leaf and black tea with 0.03% of the total weight of fermentation bacteria liquid, place the temperature at 45°C, and ferment for 11 hours under the condition of 85% humidity;

[0059] S4 Add distilled water (3-5) times its weight to the fermented product in step S3, heat up and decoct for 1.3h, after the decoction is completed, concentrate under reduced pressure to 1 / 3 of the original volume, and then add 5% of the weight of the concentrate Xylitol and 30% glucose are mixed evenly to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com