Method for preparing tea bag by oriental blueberry leaf

A technology for making black rice leaves and tea bags, which is applied in the fields of agricultural products and food processing, can solve the problems of destroying the activity of tea oxidase, destroying nutrients, and large equipment investment, and achieves improved utilization value, improved leaf temperature, and small equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

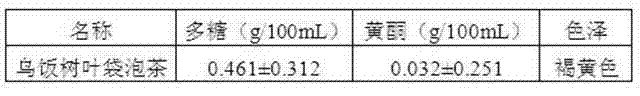

Examples

Embodiment 1

[0020] A, pulverization: the black rice leaves are pulverized by a universal pulverizer, the sieve aperture is 8 mm, and the pulverization time is 3 minutes, and then pulverized by a traditional Chinese medicine pulverizer, and the pulverization time is 3 minutes;

[0021] B. Soaking: Mix the crushed black rice leaves with water, the ratio of material to water is 1:10 (W / V, g / mL), and the soaking time is 15 minutes;

[0022] C, suction filtration: realize the separation of slag liquid by the suction filtration method, obtain the black rice leaf after soaking;

[0023] D. Fixing: the soaked black rice leaves are fixed by steam, the fixing temperature is 100°C, and the fixing time is 10 minutes;

[0024] E. Drying and sterilization: Dry and sterilize the dried black rice leaves by circulating hot air, the drying temperature is 60°C, the drying time is 10 minutes, and the moisture content is below 7%;

[0025] F, bagging and packaging: the dried and sterilized black rice leaf te...

Embodiment 2

[0027] A, pulverization: the black rice leaves are pulverized by a universal pulverizer, the sieve aperture is 8mm, and the pulverization time is 4min, and then pulverized by a traditional Chinese medicine pulverizer, and the pulverization time is 2min;

[0028] B. Soaking: Mix the pulverized black rice leaves with water, the ratio of material to water is 1:12 (W / V, g / mL), and the soaking time is 13 minutes;

[0029] C, suction filtration: realize the separation of slag liquid by the suction filtration method, obtain the black rice leaf after soaking;

[0030] D. Fixing: The soaked black rice leaves are fixed by steam, the fixing temperature is 120°C, and the fixing time is 9 minutes;

[0031] E. Drying and sterilization: Dry and sterilize the dried black rice leaves by circulating hot air, the drying temperature is 70°C, the drying time is 8 minutes, and the moisture content is below 6%;

[0032] F, bagging and packaging: the dried and sterilized black rice leaf tea is bagge...

Embodiment 3

[0034] A. Pulverization: the leaves of black rice are pulverized by a universal pulverizer, the sieve aperture is 8mm, and the pulverization time is 5min, and then pulverized by a traditional Chinese medicine pulverizer, and the pulverization time is 1min;

[0035] B. Soaking: Mix the pulverized black rice leaves with water, the ratio of material to water is 1:15 (W / V, g / mL), and the soaking time is 10 minutes;

[0036] C, suction filtration: realize the separation of slag liquid by the suction filtration method, obtain the black rice leaf after soaking;

[0037] D. Fixing: the soaked black rice leaves are fixed by steam, the fixing temperature is 130°C, and the fixing time is 8 minutes;

[0038] E. Drying and sterilization: Dry and sterilize the dried black rice leaves by circulating hot air, the drying temperature is 80°C, the drying time is 6 minutes, and the moisture content is below 5%;

[0039] F, bagging and packaging: the dried and sterilized black rice leaf tea is ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com