High-aroma Maojian and processing technology thereof

A processing technology and high-fragrance hair tip technology, which is applied in the field of high-fragrance hair tip and its processing technology, can solve the problems of opacity, bursting point, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

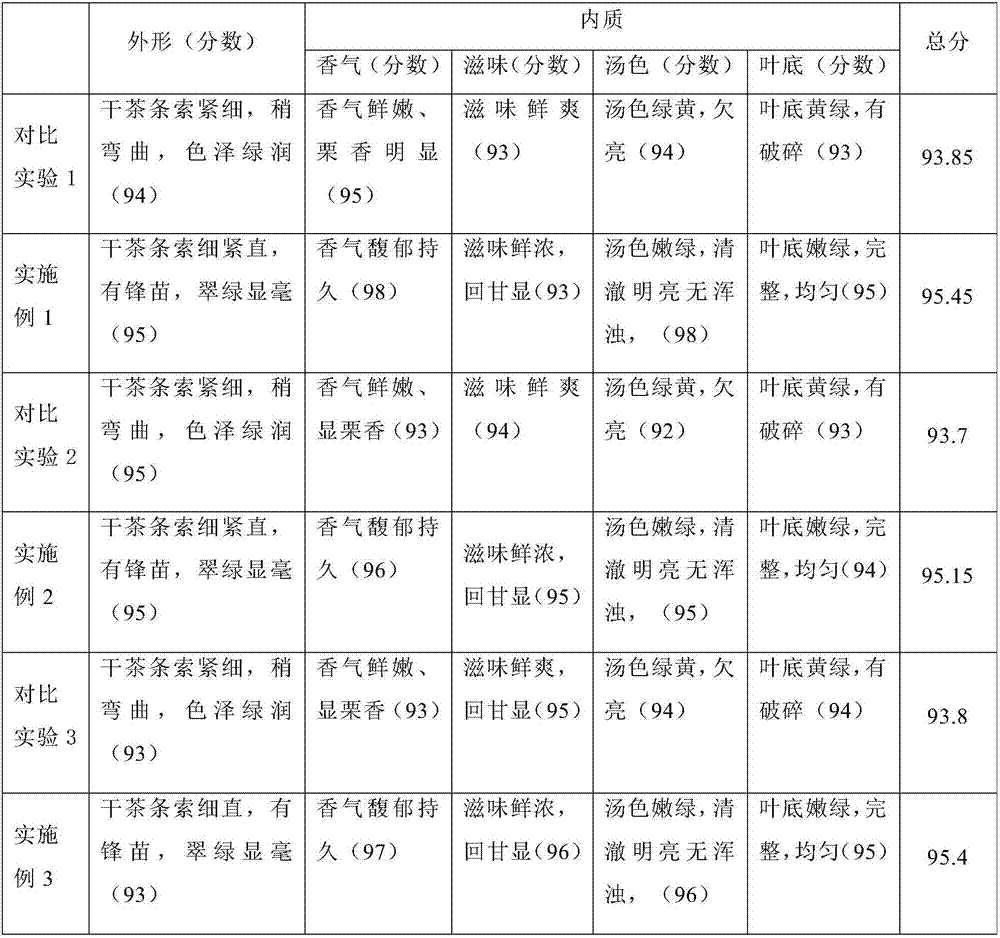

Examples

Embodiment 1

[0025] A kind of high-fragrance hair tip processing technology, it comprises the following steps:

[0026] Spread airing at 25-30°C, spread 50kg of Maojian fresh leaves to a thickness of 8cm, and spread them in the air for 5 hours to obtain air-dried leaves with a water content of 70%; wherein, the Maojian fresh leaves are selected from Xinyang City tea demonstration The fresh leaves of the first-grade tea from the Xinyang group are taken from the garden;

[0027] Shake blue and green leaves by shaking green and green machine to carry out shaking green and green processing to described airing leaf, shake green and green 5min for the first time, spread and air 30min, shake green and green 5min again, obtain shaking green leaves;

[0028] Under the condition of 265°C, use a roller fixer to fix the shaken green leaves for 80s to obtain the semi-finished finished leaves with a water content of 60%; wherein, the outlet leaf temperature of the roller fixer is 110°C; The leaf semi-f...

Embodiment 2

[0037] A kind of high-fragrance hair tip processing technology, it comprises the following steps:

[0038] Spread airing at 25-30°C, spread 40kg of fresh leaves of Maojian to a thickness of 7cm, and spread them in air for 4 hours to obtain air-dried leaves with a water content of 68%; wherein, the fresh leaves of Maojian are selected from Shihe, Xinyang City Baiyun Village, Shihegang Town, District takes the first-class fresh leaves of Xinyang Group;

[0039] Shake the blue and green leaves by shaking the blue and green machine to carry out the green and green processing to the described air-dried leaves, shake the blue and green leaves for the first time for 4 minutes, spread and air for 20 minutes, and shake the green and green leaves for 4 minutes again to obtain shake green leaves;

[0040] Under the condition of 250°C, use a roller fixer to fix the shaken green leaves for 90s to obtain the semi-finished finished leaves with a moisture content of 55%; wherein, the outlet l...

Embodiment 3

[0049] A kind of high-fragrance hair tip processing technology, it comprises the following steps:

[0050] Spread airing at 25-30°C, spread 25kg of fresh leaves of Maojian to a thickness of 6cm, and spread them in air for 3 hours to obtain air-dried leaves with a water content of 69%; wherein, the fresh leaves of Maojian are selected from Guangshan County, Xinyang City Wenshu Township Zhushanquan Village Chengxin Industrial Co., Ltd. takes the fresh leaves of the first-class tea from Xinyang Group;

[0051] Shake blue and green leaves by shaking green and green machine to carry out shaking green and green treatment to described air-drying leaves, shake green and green 3min for the first time, spread and air 40min, shake green and green 3min again, obtain shaking green leaves;

[0052] Under the condition of 245°C, use a roller fixing machine to fix the shake green leaves for 100s to obtain the semi-finished finished leaves with a moisture content of 58%; wherein, the outlet le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com