Method for preparing compact metal oxide ceramic film based on in situ reaction

A technology of oxide ceramics and dense metals, which is applied in the field of metal oxide ceramic thin films, can solve the problems of many closed pores, limit the use of membrane materials, and it is difficult to obtain dense ceramic thin films, so as to simplify the process steps and make the carrier gas environment friendly , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

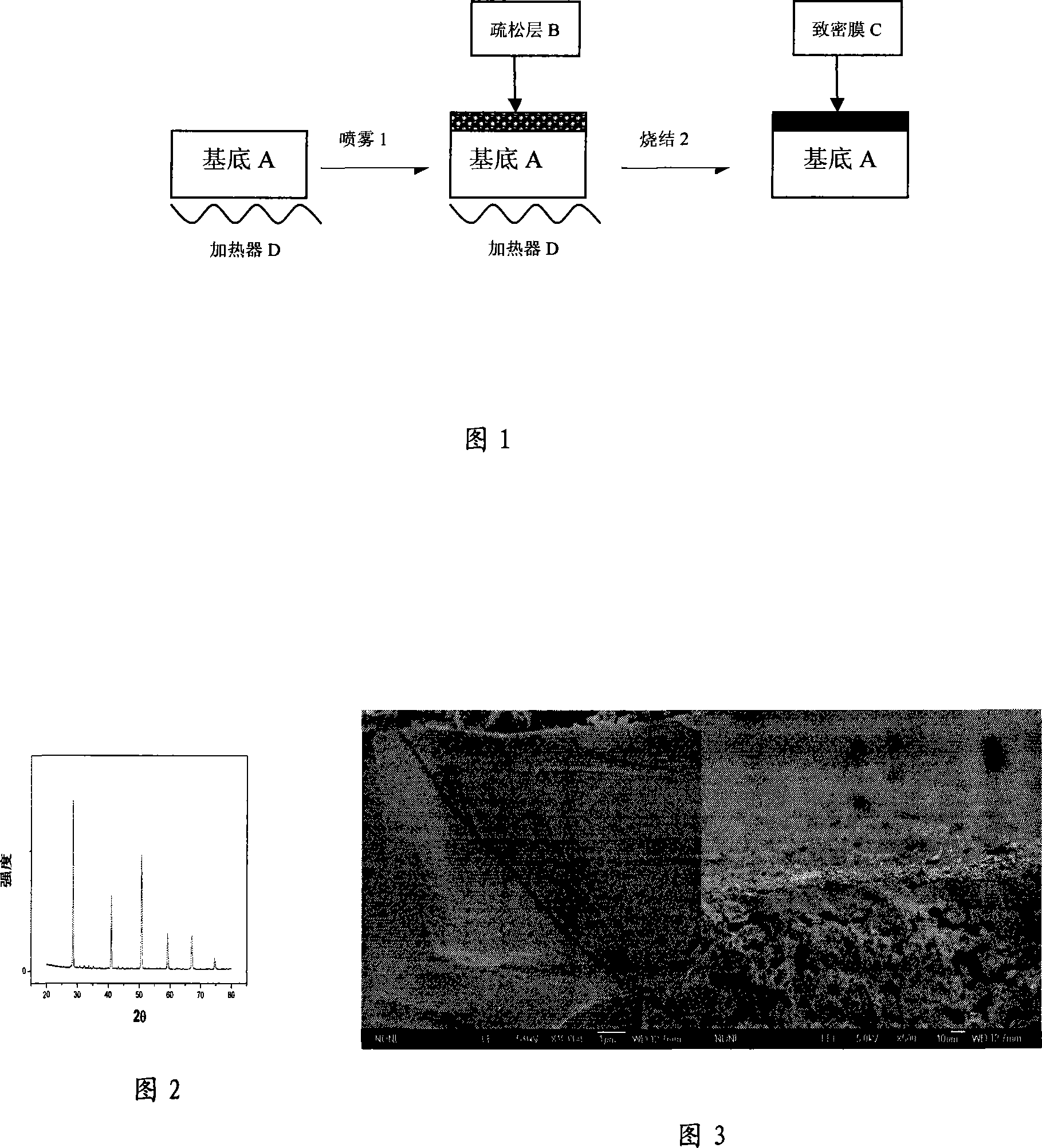

Method used

Image

Examples

Embodiment 1

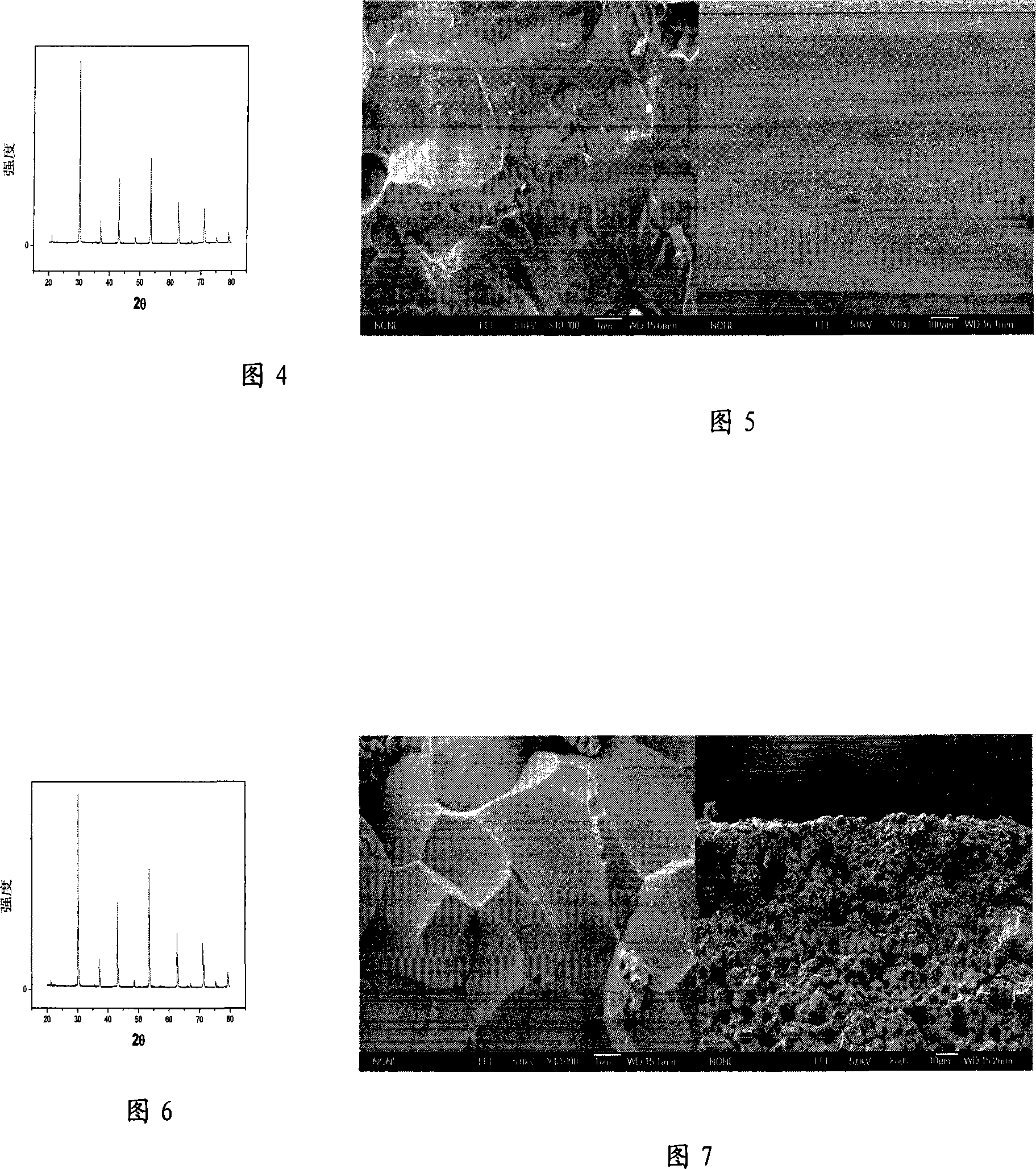

[0013] Example 1: On NiO-BaCe 0.8 SM 0.2 o 2.9 Preparation of BaCe on substrate 0.8 SM 0.2 o 2.9 film

[0014] Formulating BaCe 0.8 SM 0.2 o 2.9 Slurry: Weigh the raw material BaCO 3 , CeO 2 and Sm 2 o 3 , so that the ratio of the amount of raw materials (molar ratio) is BaCO 3 : CeO 2 :Sm 2 o 3 =1:0.8:0.1, using absolute ethanol as solvent, the rare earth metal oxide CeO 2 and Sm 2 o 3 Alkaline earth metal carbonate BaCO 3 Powder: absolute ethanol: triethanolamine mixed uniformly according to the mass ratio of 8:100:0.5, ball milled for 24 hours; then add polyethylene glycol and dibutyl phthalate according to the mass ratio of 0.5:0.5:0.2 and polyvinyl butyral, and then ball milled for 24 hours to form a slurry; the slurry prepared above was sprayed with a sprayer using nitrogen as a carrier gas, and heated to a temperature of 200°C-300°C and kept at this temperature with A thin layer of loose metal oxides and metal carbonates is formed on the surface of t...

Embodiment 2

[0018] Example 2: On NiO-BaCe 0.8 SM 0.2 o 2.9 Preparation of Ba on the substrate 3 Ca 1.18 Nb 1.82 o 9-σ film

[0019] Prepare Ba 3 Ca 1.18 Nb 1.82 o 9-σ Slurry: Weigh the raw material BaCO 3 , CaCO 3 and Nb 2 o 5 , so that the ratio of the amount of raw materials (molar ratio) is BaCO 3 : CaCO 3 : Nb 2 o 5 =3:1.18:0.91, using absolute ethanol as solvent, the transition metal oxide Nb 2 o 5 and alkaline earth metal carbonate BaCO 3 and CaCO 3 Powder: absolute ethanol: triethanolamine is mixed uniformly according to the mass ratio of 6:100:0.5, ball milled for 24 hours; then add polyethylene glycol and dibutyl phthalate according to the mass ratio of 0.5:0.5:0.25 and polyvinyl butyral, and then ball milled for 24 hours to form a slurry; use a sprayer to spray the prepared slurry with air as the carrier gas, and heat it to a temperature of 200°C-300°C and keep it at this temperature. A layer of loose metal oxide and metal carbonate layer is formed on the s...

Embodiment 3

[0023] Example 3: On NiO-BaCe 0.8 SM 0.2 o 2.9 Preparation of Ba on the substrate 3 Ca 1.18 Nb 1.82 o 9-σ film

[0024] Prepare Ba 3 Ca 1.18 Nb 1.82 o 9-σ Slurry: Weigh the raw material BaCO 3 , CaCO 3 and Nb 2 o 5 , so that the ratio of the amount of raw materials (molar ratio) is BaCO 3 : CaCO 3 : Nb 2 o 5 =3:1.18:0.91, using absolute ethanol as solvent, the transition metal oxide Nb 2 o 5 and alkaline earth metal carbonate BaCO 3 and CaCO 3 Powder: absolute ethanol: triethanolamine according to the mass ratio of 15:100:1, mix evenly, ball mill for 24 hours; then add polyethylene glycol and dibutyl phthalate according to the mass ratio of 1:1:0.5 and polyvinyl butyral, and then ball milled for 24 hours to form a slurry; the slurry prepared above was sprayed with a sprayer using air as the carrier gas, and heated to a temperature of 200°C-300°C and kept at the temperature. A layer of loose metal oxide and metal carbonate layer is formed on the surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com