Manual making technique of green tea

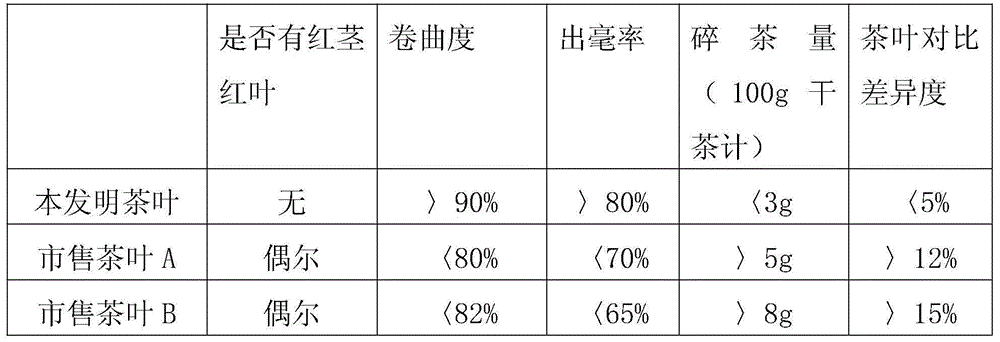

A craft and manual technology, applied in the field of green tea hand-made tea technology, can solve the problems of unsustainable aroma, uneven curl, smelly paste, etc., and achieve the effect of uniform fluffy pekoe, uniform curl, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 of the present invention: a kind of manual tea-making process of green tea, is made according to the following steps: A, fix green, B, knead, C, shape, D, extract millet, E, enhance fragrance, F, dry. The whole process is carried out in an iron pot with a diameter of 60-70 cm, and the gestures of stewing, turning, grasping, throwing, shaking and kneading are continuously operated, and the whole process takes about 45 minutes.

[0028] A completed:

[0029] 1. High temperature finishing, first high and then low.

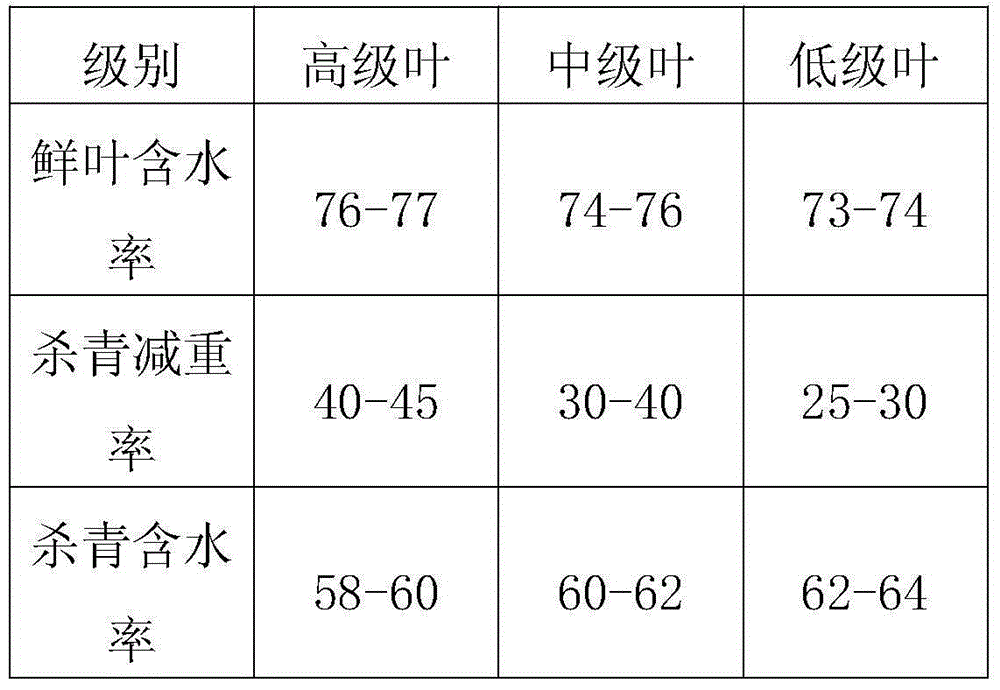

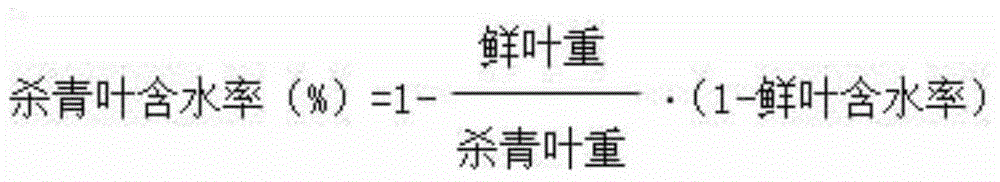

[0030] High temperature mainly refers to the pot temperature, that is, the pot temperature should be high at the beginning of finishing, and the pot temperature should be low in the later stage of finishing. The so-called "high temperature finishing" does not mean that the higher the better, otherwise the green leaves are easy to burn, resulting in smoke and burnt gas. Gray, seriously reduce the quality of tea, of course, the pot temperature is to...

Embodiment 2

[0065] Embodiment 2 of the present invention: a kind of hand-made tea-making process of green tea, make according to following steps: A, clear green, B, knead, C, shaping, D, extract millet, E, enhance fragrance, F, dry. The whole process is carried out in an iron pot with a diameter of 60-70 cm, and the gestures of stewing, turning, grasping, throwing, shaking and kneading are continuously operated, and the whole process takes about 45 minutes.

[0066] A completed:

[0067] 1. High temperature finishing, first high and then low.

[0068] High temperature mainly refers to the pot temperature, that is, the pot temperature should be high at the beginning of finishing, and the pot temperature should be low in the later stage of finishing. The so-called "high temperature finishing" does not mean that the higher the better, otherwise the green leaves are easy to burn, resulting in smoke and burnt gas. Gray, seriously reduce the quality of tea, of course, the pot temperature is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com