Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Satisfy sensory needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

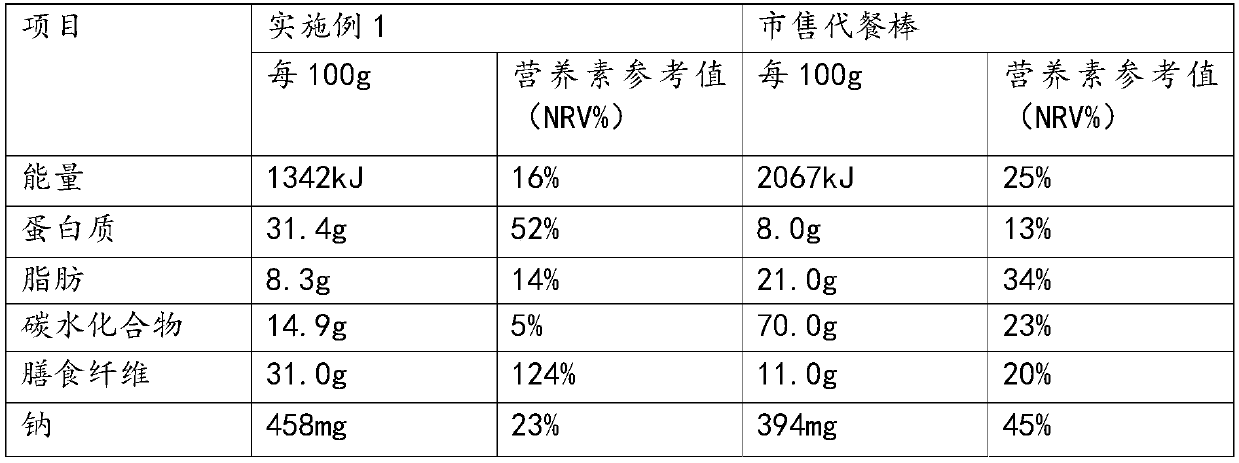

Low-GI meal replacement rod for diabetes patients and preparation method and applications thereof

InactiveCN109527396AIncrease satietyReduce hungerSugar food ingredientsFood ingredient functionsMeal replacementWater soluble

The invention provides a low-GI meal replacement rod for diabetes patients and a preparation method and applications thereof. The low-GI meal replacement rod is mainly prepared from following raw materials: dietary fibers, proteins, sugar alcohols, cereal grains, oil, and optional condiments; wherein dietary fibers comprise water soluble dietary fibers and insoluble dietary fibers. The main raw materials are all low-GI materials, at the same time, soluble and insoluble dietary fibers are added, through scientific blending, the meal replacement rod has a characteristic of low GI (glycemic index), and moreover, raw materials that are rich in dietary fibers such as chia seeds, oatmeal, quinoa, konjak, and the like, are added to effectively reduce the increasing of GI after meals. The low-GI raw material and raw materials rich in dietary fibers cooperate with each other, the satiety is enhanced, the hungry feeling is reduced, and the blood glucose fluctuation is reduced.

Owner:玛士撒拉(上海)医疗科技有限公司

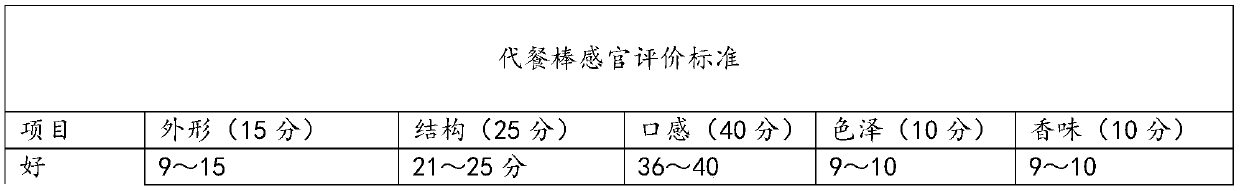

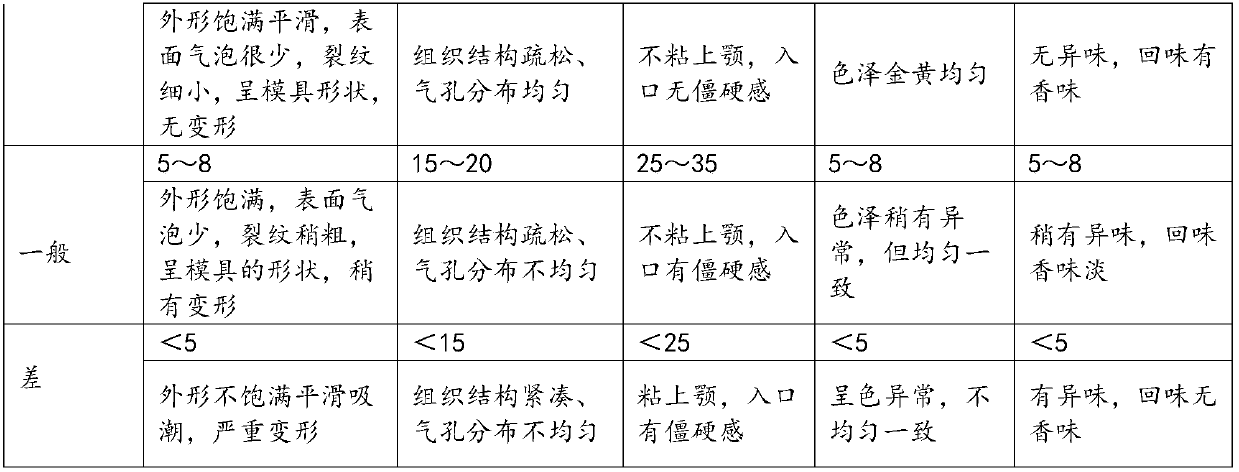

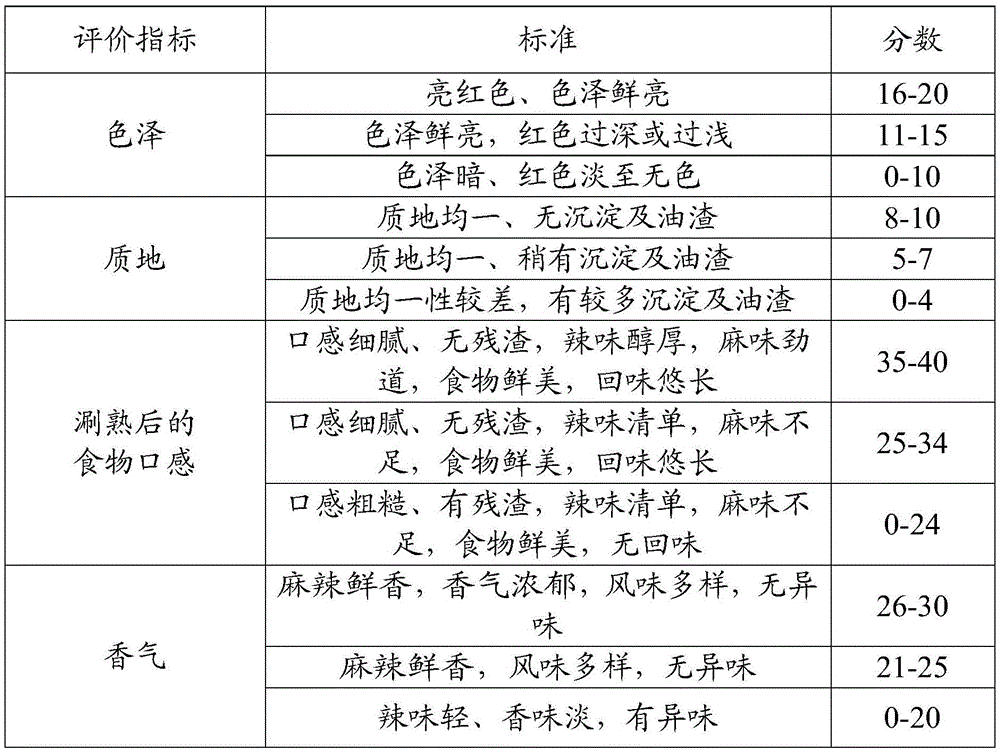

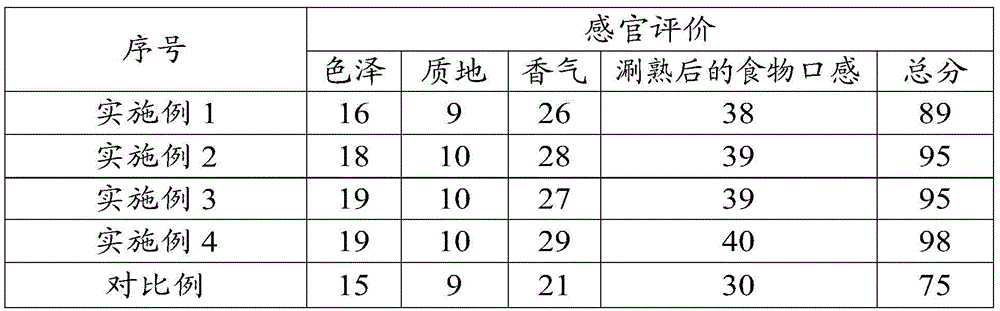

Hotpot condiment and preparation method thereof

ActiveCN105661454ASatisfy sensory needsGreat tasteFood processesFood ingredient functionsMonosodium glutamateAllium sativum

The invention provides a hotpot condiment and a preparation method thereof. The hotpot condiment is prepared from the following components in parts by weight: 60-150 parts of animal oil, 30-50 parts of vegetable oil, 2-6 parts of garlic, 1-5 parts of thick broad-bean sauce, 1-5 parts of fresh gingers, 0.5-2 parts of cloves, 2-6 parts of cinnamons, 2-6 parts of anises, 0.1-1 part of pepper, 0.5-2 parts of cardamoms, 0.5-2 parts of white wine, 0.5-2 parts of fermented glutinous rice, 60-80 parts of chilies, 2-10 parts of Chinese prickly ash, 10-20 parts of chicken essence, 1-10 parts of monosodium glutamate and 1-5 parts of rocky candies. The hotpot condiment provided by the invention has the advantages of being spicy and delicious, having a good taste and the like, and also has the effects of nourishing stomach, protecting stomach and promoting digestion. The preparation method of the hotpot condiment, provided by the invention, adopts a supercritical CO2 extraction method so that oil and residues are separated; the preparation method has the advantages of convenience, simplicity, easiness of operation and the like; and the hotpot condiment produced by the method has a relatively good taste, and is relatively pure and sanitary.

Owner:重庆汤嫂食品有限公司

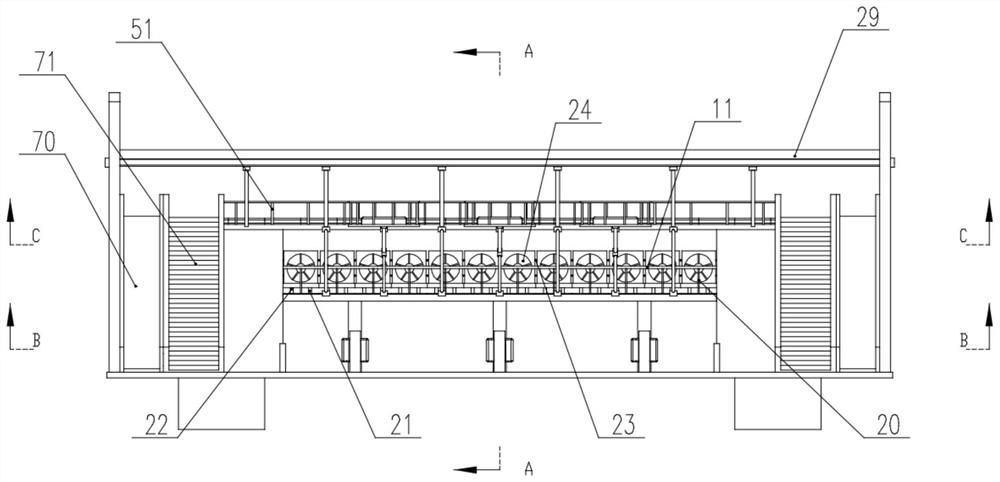

Blowing rate adjusting device of railway vehicle

ActiveCN104118444ASatisfy sensory needsThe air volume will not changeRailway heating/coolingSpace heating and ventilation safety systemsMechanical engineeringEngineering

Owner:CRRC QINGDAO SIFANG CO LTD

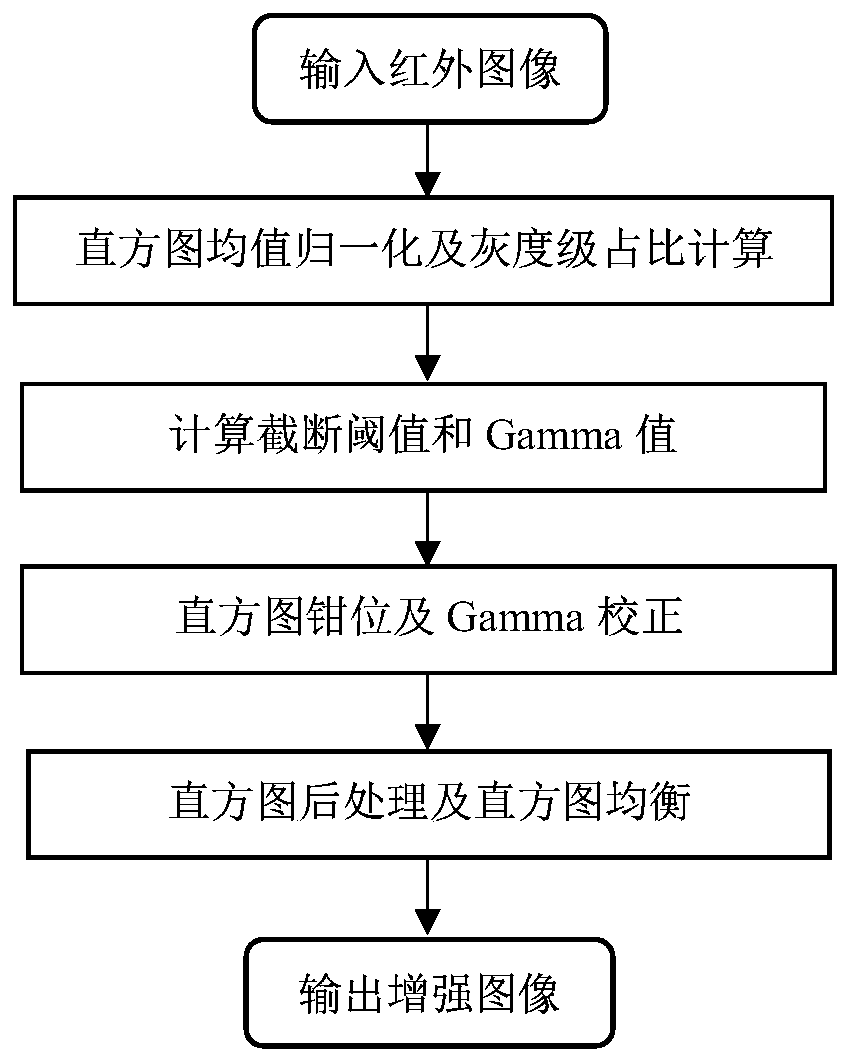

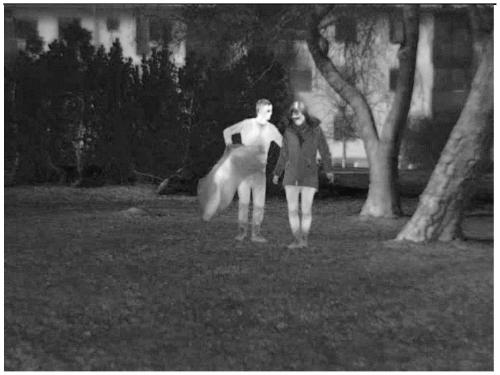

Histogram double-control infrared image contrast enhancement method

ActiveCN111127343ASimple calculationIncrease contrastImage enhancementImage analysisAlgorithmImage contrast

The invention discloses a histogram double-control infrared image contrast enhancement method, and the technical scheme comprises the steps: firstly carrying out the mean normalization preprocessing of a histogram, and then calculating the proportion of effective gray levels in the histogram; setting a histogram truncation threshold value according to the effective gray scale proportion, wherein the truncation threshold value is directly proportional to the proportion value, and numerical protection processing is carried out; solving a correction parameter Gamma value, wherein the Gamma valueis inversely proportional to the truncation threshold; performing clamping processing on the histogram, and then performing Gamma correction processing on part of data; and performing post-processingon the histogram data and performing classic histogram equalization operation, and finally outputting an infrared image with enhanced contrast. The histogram of the whole image needs to be counted; other operations adopt a point processing algorithm; therefore, the processing efficiency is high, few resources are occupied; the real-time performance is good; the method is simple in calculation, direct processing of histograms. Compared with the prior art, operation and internal self-adaptive control on each pixel point of each image are not needed, a better contrast enhancement effect can be achieved by adopting default parameters, the control mode is flexible, and manual control parameters can be set according to personal visual perception differences, so that sensory requirements of different users are met, and the flexibility of the algorithm is improved.

Owner:HUAQIAO UNIVERSITY

Dough fermentation method for producing fermented dough products

ActiveCN106070420AIncrease specific volumeUniform internal structurePre-baking dough treatmentSpecific volumeUltrasonic technology

The invention discloses a dough fermentation method for producing fermented dough products and belongs to the technical field of fermented dough products. The dough fermentation method comprises the step of ultrasonically processing the to-be-fermented dough for 5-50 min under ultrasonic power of 50-1000 W and ultrasonic frequency of 20-100 kHz. According to the invention, compared with common fermentation box for fermenting or natural fermentation, the ultrasonic technology adopted for fermenting the dough can increase the specific volume of the dough products and can enable the internal structure to be more uniform and compact. A test proves that the steamed bun prepared by adopting the ultrasonic technology for fermenting has higher specific volume, higher elasticity and lower hardness than the common steamed bun; the steamed bun tastes soft and dense, is chewy and can meet the sense organ requirements of people living in northern area and taking the steamed bun as staple food.

Owner:HENAN UNIV OF SCI & TECH

Novel areca-nut type chewing tobacco product

The invention discloses a novel areca-nut type chewing tobacco product which is obtained by marinating dried areca-nuts in edible areca-nut brine. The edible areca-nut brine comprises 5-20 parts of slaked lime, 10-70 parts of maltose, 5-40 parts of white granulated sugar, 1-15 parts of tobacco extractives, 0.1-2 parts of glycerinum, 0.1-2 parts of gelatin, 0.2-2 parts of acidity regulators, 0.01-2 parts of auxiliary materials and water, and the sum of all the components is 100 parts; the ratio of the slaked lime to the maltose is 1 to 2 to 1 to5; the weight of each dried areca-nut is 2.5-3.0 g; the nicotinic content, meeting each dried areca-nut, of marinating of each time is 0.01-1.5 mg. According to the product, areca-nut products consistent in taste are obtained by limiting the weight of the dried areca-nuts, the taste is good, viscosity is appropriate, safety of consumers can be guaranteed, and the sense requirement of the consumers is met.

Owner:CHINA TOBACCO JIANGSU INDAL

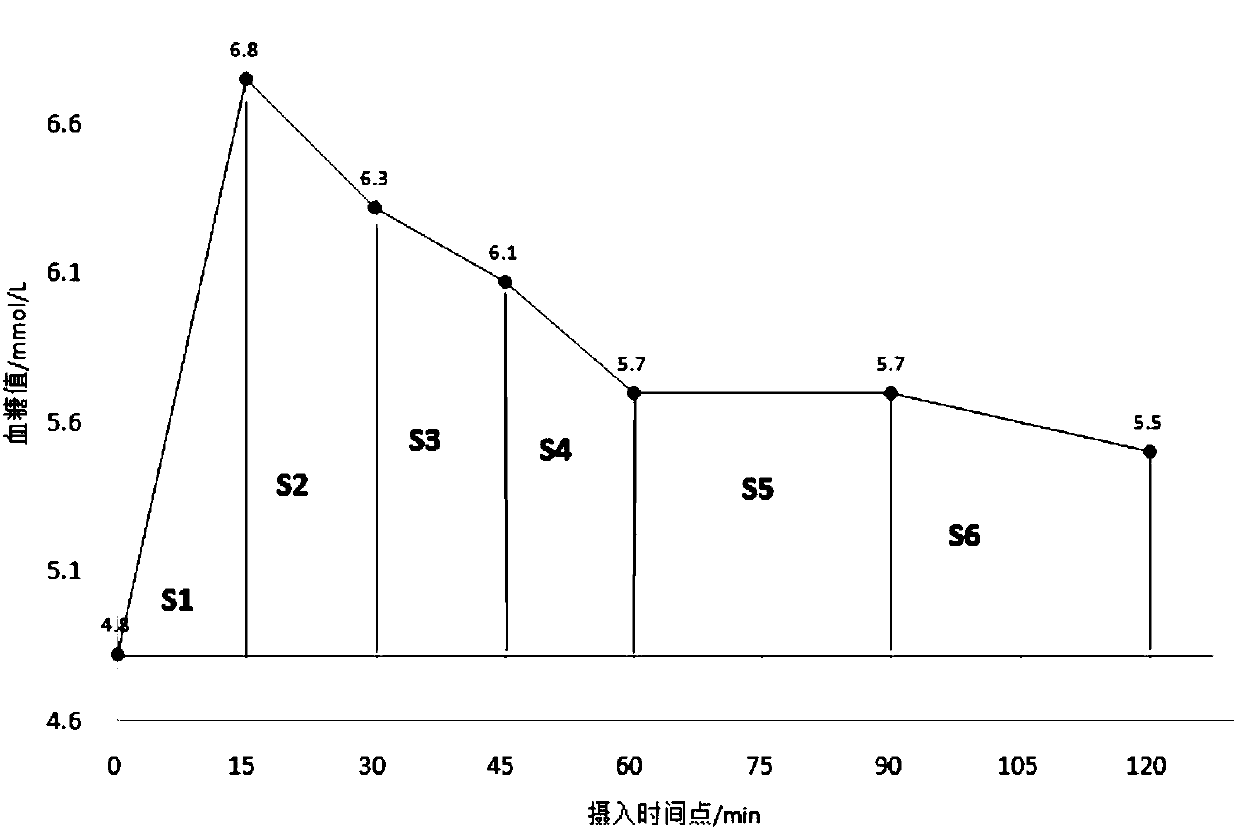

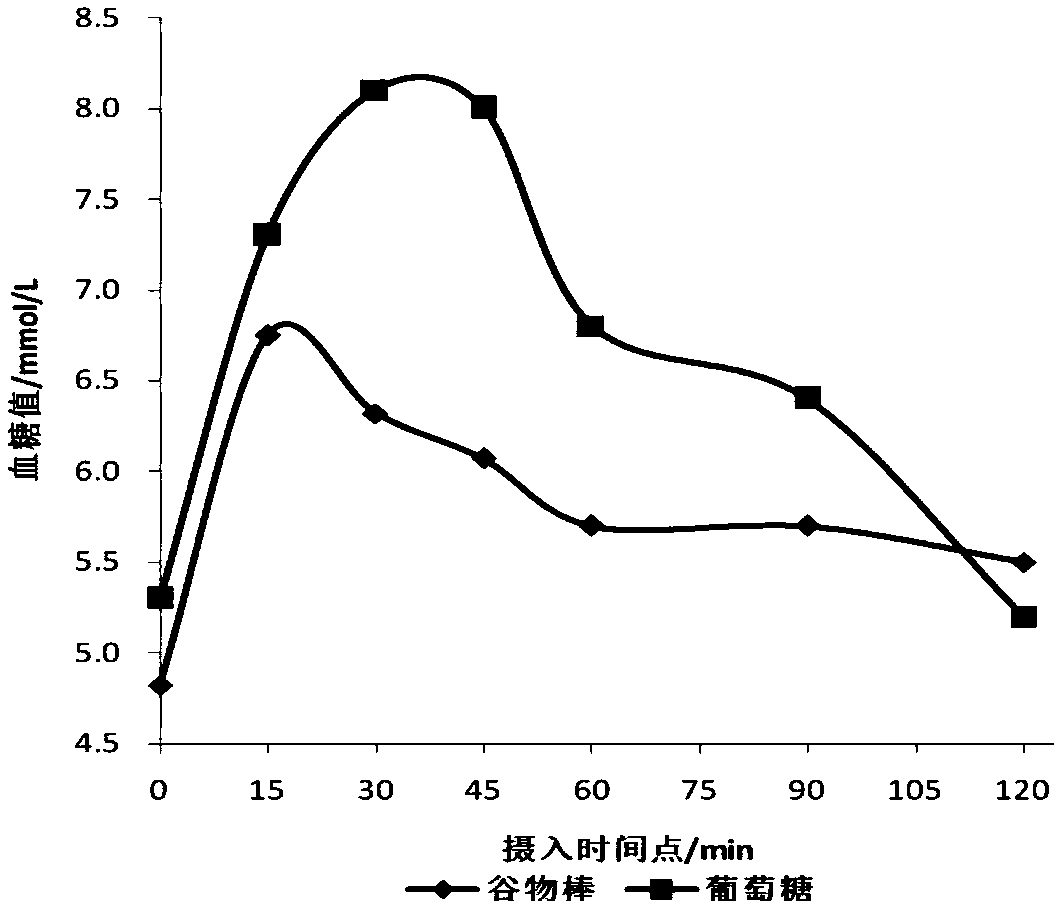

Low-GI cereal bars and preparation method thereof

PendingCN108041116AHigh protein contentMeet intakeDough treatmentBakery productsAmerican cranberryWhey protein powder

The invention discloses low-GI cereal bars and a preparation method thereof. The low-GI cereal bars are prepared from almonds, crisp red beans, compound syrup, dried cranberries and concentrated wheyprotein powder. The low-GI cereal bars provided by the invention are verified by performing testing experiments on people. The raw material components selected by the preparation method realize the beneficial effects of low-GI and smooth postprandial blood sugar by mutual collaboration. The low-GI cereal bars provided by the invention provide sufficient calories, protein and dietary fibers while generating satiety easily, provide a low-GI staple food capable of maintaining smooth postprandial blood sugar for diabetic patients and ensure nutrient intake of the diabetic patients while avoiding suffering from hunger.

Owner:美安康质量检测技术(上海)有限公司

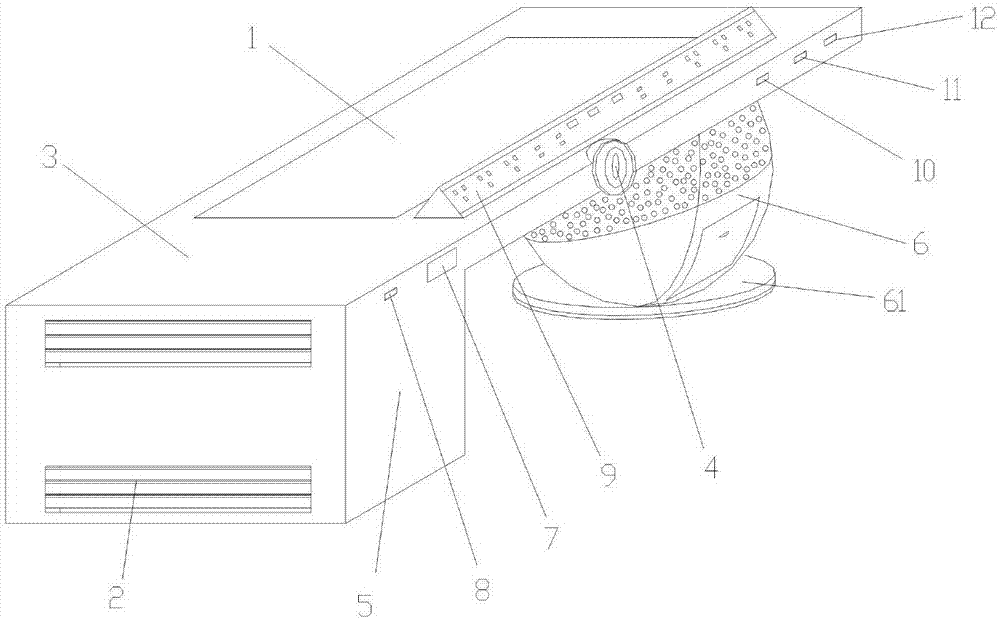

New type touch control tea table

PendingCN107374044AFunction increaseEnhance the sense of immersionMechanical apparatusSpace heating and ventilation safety systemsTransceiverSpherical shaped

The invention discloses a new type touch control tea table. The new type touch control tea table comprises a touch screen, an air purifying device, an air detecting device, a power strip, an ARM processor, a tea table platform, a projector, a subwoofer, a supporting body, a supporting column, a signal transceiver and a circuit master switch; the supporting body and the supporting column are arranged on the two sides below the tea table platform correspondingly and are used for supporting the tea table platform; the supporting column is in a spherical shape, a floor mat is arranged below the supporting column, and the subwoofer is arranged in the supporting column; the supporting body is of a cuboid-shaped structure, both the ARM processor and the air detecting device are arranged in the supporting body; and a rectangular groove is formed in the middle of the upper portion of the tea table platform, the touch screen connected with the ARM processor is mounted in the groove, the projector is mounted on the middle of one side face of the tea table platform. The new type touch control tea table is complete in function, convenient to use, high in intellectualization degree, attractive and harmonious in shape and greatly convenient for life of people.

Owner:成都方寸家居有限公司

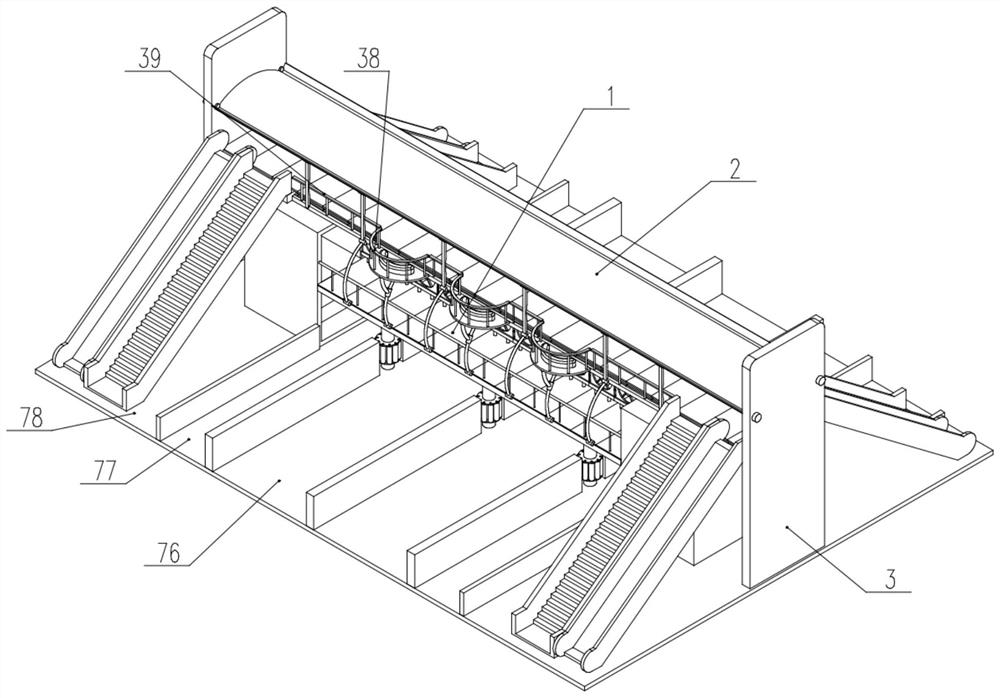

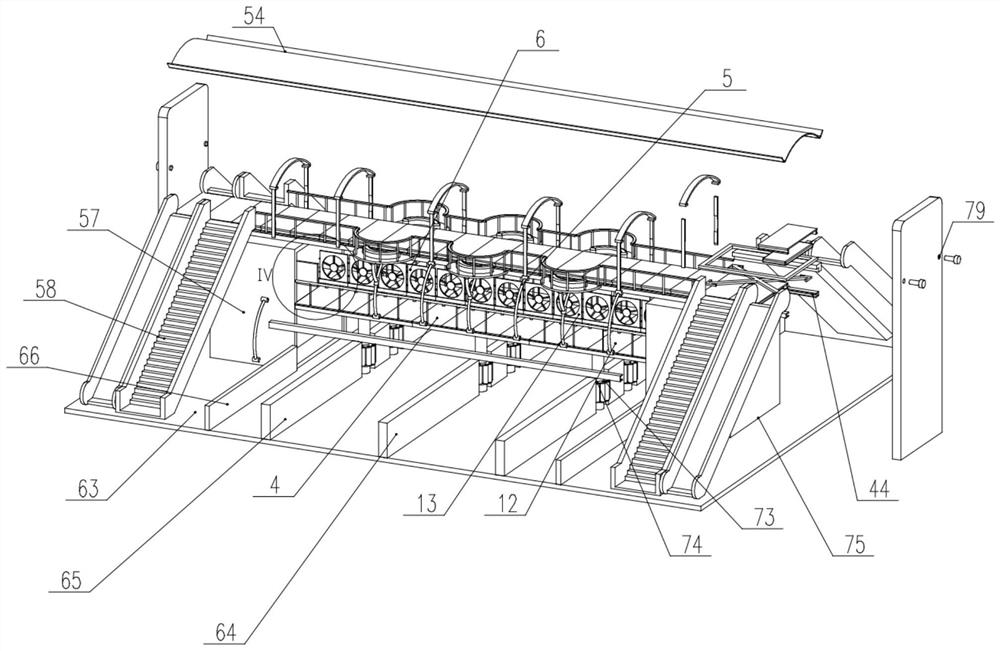

Novel assembly type green pedestrian overpass and using method thereof

PendingCN113481814AOptimize locationEasy to viewRoof coveringRoadwaysMechanical engineeringPedestrian overpass

The invention discloses a novel assembly type green pedestrian overpass which comprises a two-way separation type non-motor vehicle running layer, a green side viewing type pedestrian layer and an overpass upper and lower supporting assembly; the two-way separation type non-motor vehicle running layer is arranged on the overpass upper and lower supporting assembly; and the green side view type pedestrian layer is arranged on the two-way separation type non-motor vehicle running layer. The invention relates to the technical field of overpass, in particular to the novel assembly type green pedestrian overpass and the using method thereof. The design of double-layer passage, people-vehicle separation and the like is adopted, passage efficiency and convenience are improved on the premise of guaranteeing safety, temperature changes of the overbridge and a passage area are reduced through the water tank arranged in the interlayer, so that deformation of the steel structure is reduced, and the leisure and entertainment requirements of people are met through the viewing platform; impact force caused by non-frontal collision of vehicles is transferred through a rotary force unloading roller, damage to the vehicles and the bridge piers is reduced, and the problem that an existing common overbridge can only be used for pedestrians to pass is effectively solved.

Owner:HUNAN WANGXIN CONSTR GROUP +1

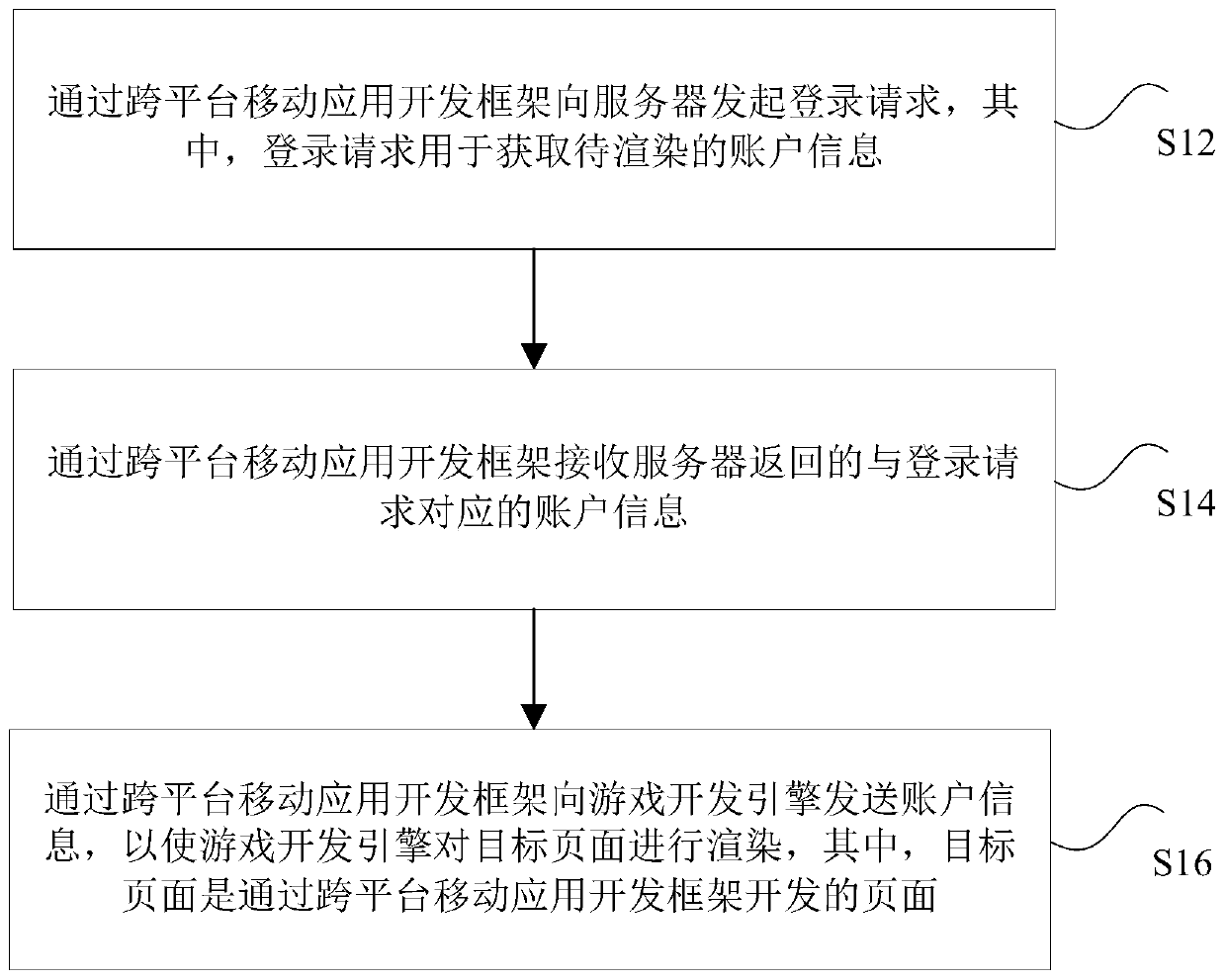

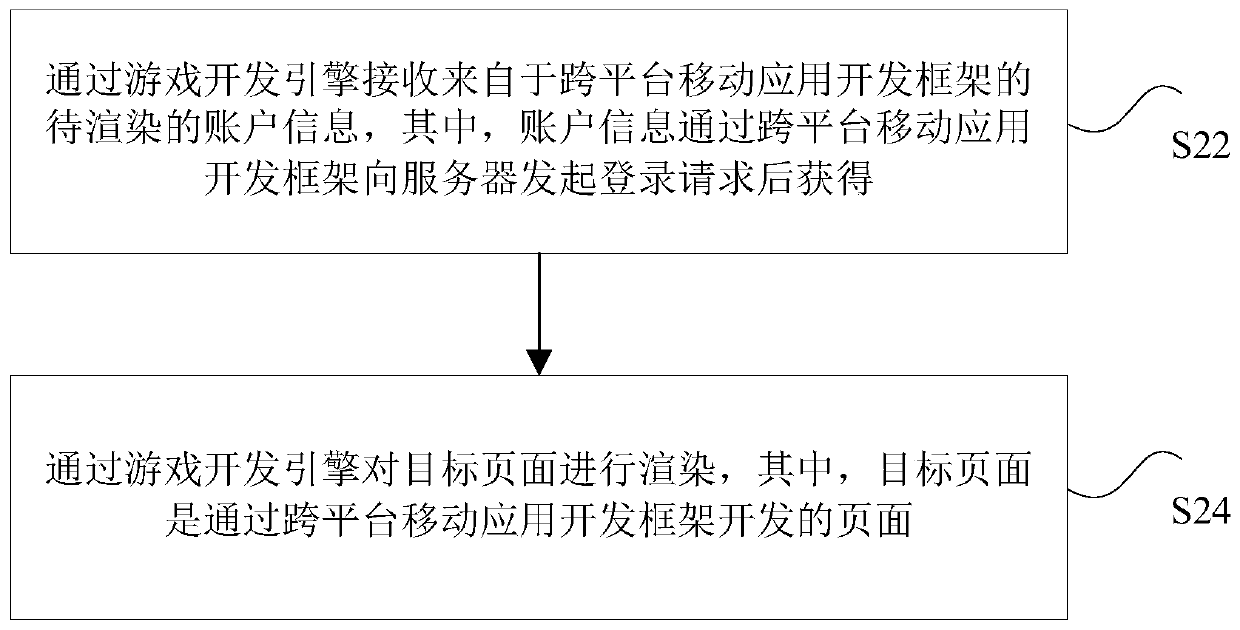

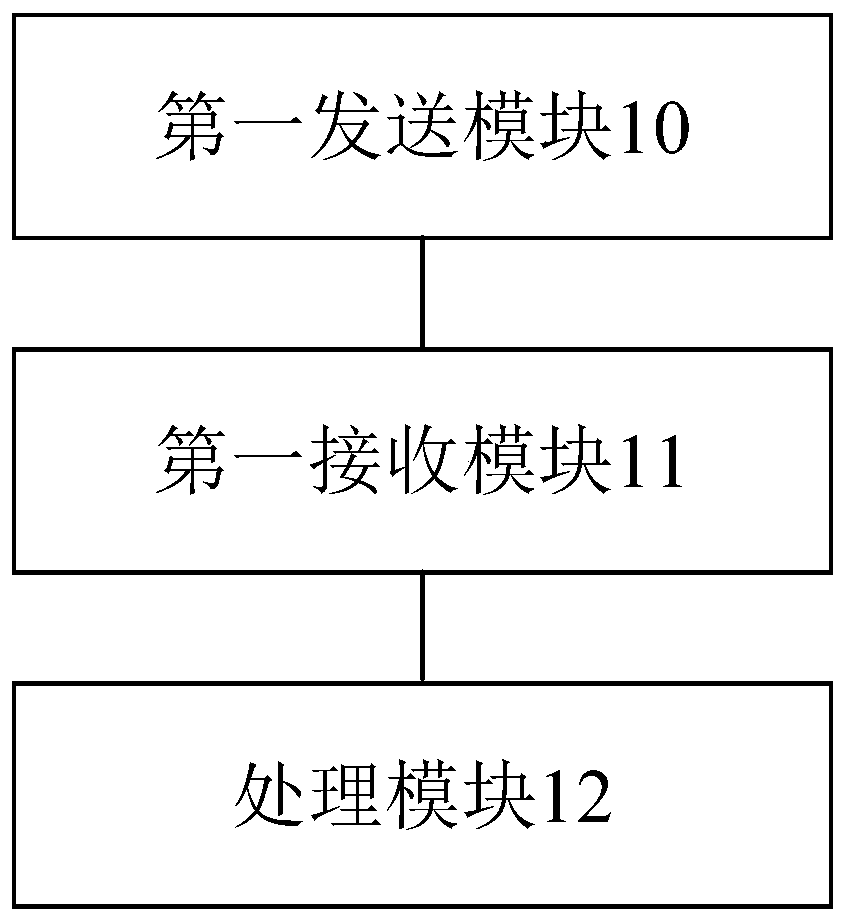

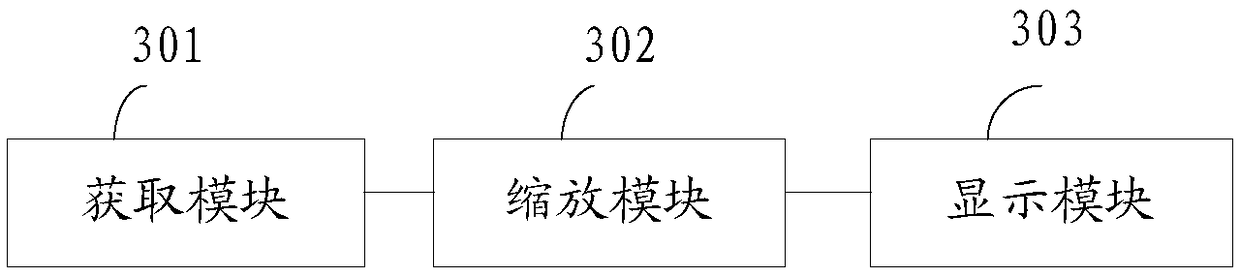

Page rendering method and device, storage medium, processor and electronic device

The invention discloses a page rendering method and device, a storage medium, a processor and an electronic device. The method comprises the steps of initiating a login request to a server through a cross-platform mobile application development framework, and the login request is used for obtaining account information to be rendered; receiving account information corresponding to the login requestreturned by the server through a cross-platform mobile application development framework; and sending account information to a game development engine through the cross-platform mobile application development framework, so that the game development engine renders the target page, and the target page is a page developed through the cross-platform mobile application development framework. Accordingto the method and the device, the technical problems that React Native provided in related technologies has obvious defects in the aspect of 3D rendering capability and cannot meet sensory requirements of users are solved.

Owner:北京代码乾坤科技有限公司

Method for preparing tobacco base material high in smoke loading capacity and incombustible after heating

The invention provides a method for preparing a tobacco base material high in smoke loading capacity and incombustible after heating. Water is added into cigarette waste tobacco, standby slurry is formed through pulping after stirring and soaking, then needlebush pulp and hardwood pulp are prepared, the standby slurry with the weight accounting for 40-60% that of over-dried substances is added into a slurry mixing tank, then the needlebush pulp with the weight accounting for 20-30% that of over-dried substances and the hardwood pulp with the weight accounting for 10-30% that of over-dried substances are added, the materials are stirred to obtain mixed slurry, the mixed slurry is diluted, then diatomite, activated carbon and guar gum are added, and formed slurry is obtained; a base material with the over-dry weight being 40-60 g / m<2> is obtained after the formed slurry is formed by a former and dehydrated, the base material is dried, cut and coiled, and the tobacco base material is obtained. The prepared incombustible tobacco base material can absorb a large number of low-temperature volatile flavoring components extracted from tobacco, and can generate a large amount of tobacco flavor under the combustion-free low-temperature heating condition, and compared with traditional combustion-smoking type cigarettes, the base material is good in similarity in the aspect of smoke and taste, sufficient in fragrance and good in coordination.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

A kind of betel nut type chewing tobacco product

The invention discloses a novel areca-nut type chewing tobacco product which is obtained by marinating dried areca-nuts in edible areca-nut brine. The edible areca-nut brine comprises 5-20 parts of slaked lime, 10-70 parts of maltose, 5-40 parts of white granulated sugar, 1-15 parts of tobacco extractives, 0.1-2 parts of glycerinum, 0.1-2 parts of gelatin, 0.2-2 parts of acidity regulators, 0.01-2 parts of auxiliary materials and water, and the sum of all the components is 100 parts; the ratio of the slaked lime to the maltose is 1 to 2 to 1 to5; the weight of each dried areca-nut is 2.5-3.0 g; the nicotinic content, meeting each dried areca-nut, of marinating of each time is 0.01-1.5 mg. According to the product, areca-nut products consistent in taste are obtained by limiting the weight of the dried areca-nuts, the taste is good, viscosity is appropriate, safety of consumers can be guaranteed, and the sense requirement of the consumers is met.

Owner:CHINA TOBACCO JIANGSU INDAL

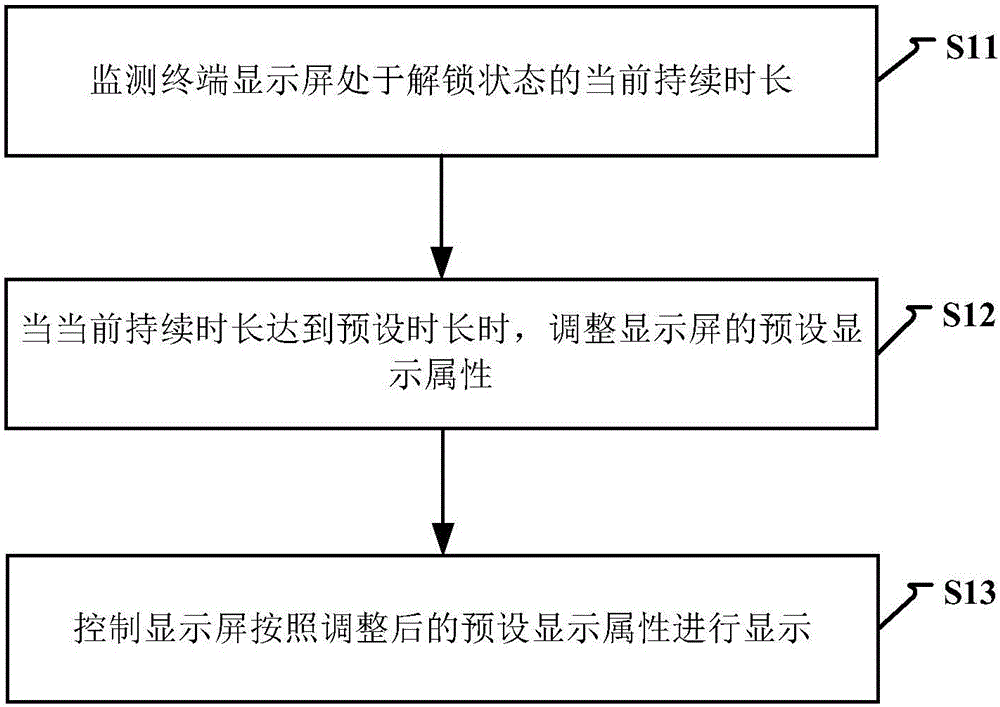

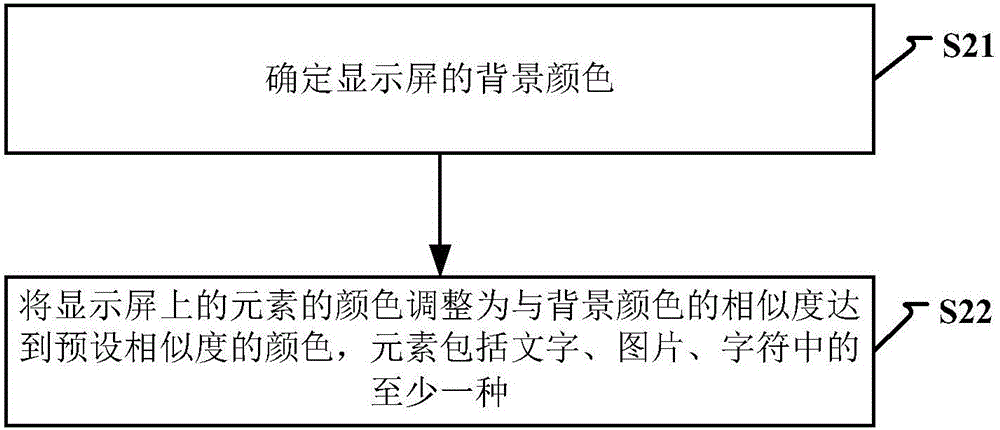

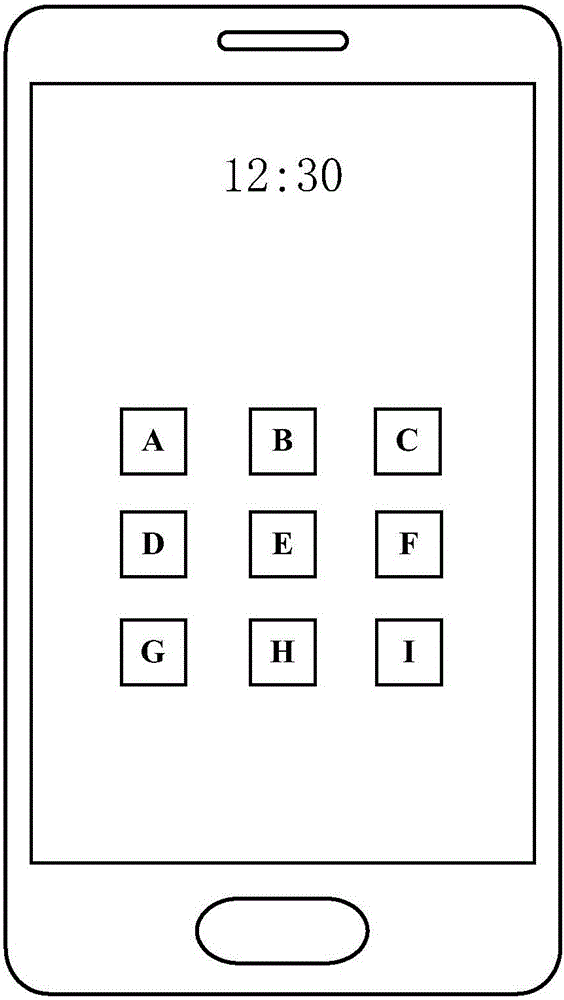

Method and device for display of terminal display screen

InactiveCN105912210AImprove user experienceSatisfy sensory needsInput/output processes for data processingSystem levelComputer engineering

The invention discloses a method and device for display of a terminal display screen. The method comprises the steps that current continuous duration for the terminal display screen to stay at an unlocking state is monitored; when the current continuous duration reaches preset duration, preset display attributes of the display screen can be adjusted; and the display screen is controlled to carry out display according to adjusted preset display attributes. The technical scheme has the advantages that a terminal can prevent a user from using the terminal for a long time by a display state of the display screen rather than limit the user by settings of application program, so that the user's terminal use is limited on a system level, and real limiting effects are reached.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Roxburgh rose beverage formula

PendingCN110623072APreserve Flavor and NutritionSolve sournessMilk preparationOther dairy technologyBeta-CaroteneSodium citrate

The present invention discloses technical field of beverages and particularly discloses a roxburgh rose beverage formula. The formula comprises the following raw materials: 90-100 parts of white granulated sugar, 5-12 parts of Alfonso mango puree, 15-25 parts of apple juice concentrate, 1-5 parts of skim milk powder, 15-25 parts of roxburgh rose juice concentrate, 1-3 parts of probiotics, 2-6 parts of a compound thickener, 0.5-1.5 parts of sodium citrate, 1.3-1.8 parts of citric acid, 0.1-0.5 part of beta-carotene, 0.1-0.3 part of wild roxburgh rose essence and 800-850 parts of purified water.The roxburgh rose beverage is smooth and silky in mouthfeel, pleasant in fragrance, and clear in liquid, satisfies sensory needs of human body to the greatest extent from appearance to mouthfeel, isrich in nutrients and suitable for use of a variety of consumer populations, and can bring pleasant sensory stimulation and spiritual enjoyment for consumers during drinking.

Owner:贵州初好农业科技开发有限公司

Chinese yam cream formula and preparation method thereof

InactiveCN108576639AEasy to prepareModerate sweetnessCream substitutesFood ingredient as mouthfeel improving agentMedicineCoconut oil

The invention provides a Chinese yam cream formula and a preparation method thereof. The Chinese yam cream formula comprises the following components in parts by mass: 10-90 parts of Chinese Yam mud,1-9 parts of honey, 0.1-5 parts of coconut milk, 1-9 parts of condensed milk, and 0.1-6 parts of milk; the above raw materials are uniformly stirred according to the mass part to obtain the preliminarily prepared Chinese yam cream, and the preliminarily prepared Chinese yam cream passes through a 60-100-mesh sieve to obtain the finished product Chinese yam cream. The Chinese yam cream can substitute traditional cream for piping, cake coating or being used as a sandwich. The Chinese yam cream formula has the advantages that by adjusting the proportion of Chinese yam and honey, coconut milk, condensed milk and milk as well as improving the preparation method of the Chinese yam cream, the Chinese yam cream has the characteristics of moderate sweet degree and fine mouthfeel, can satisfy sensory requirements, and has health-caring effect and abundant nutrition.

Owner:何蔚

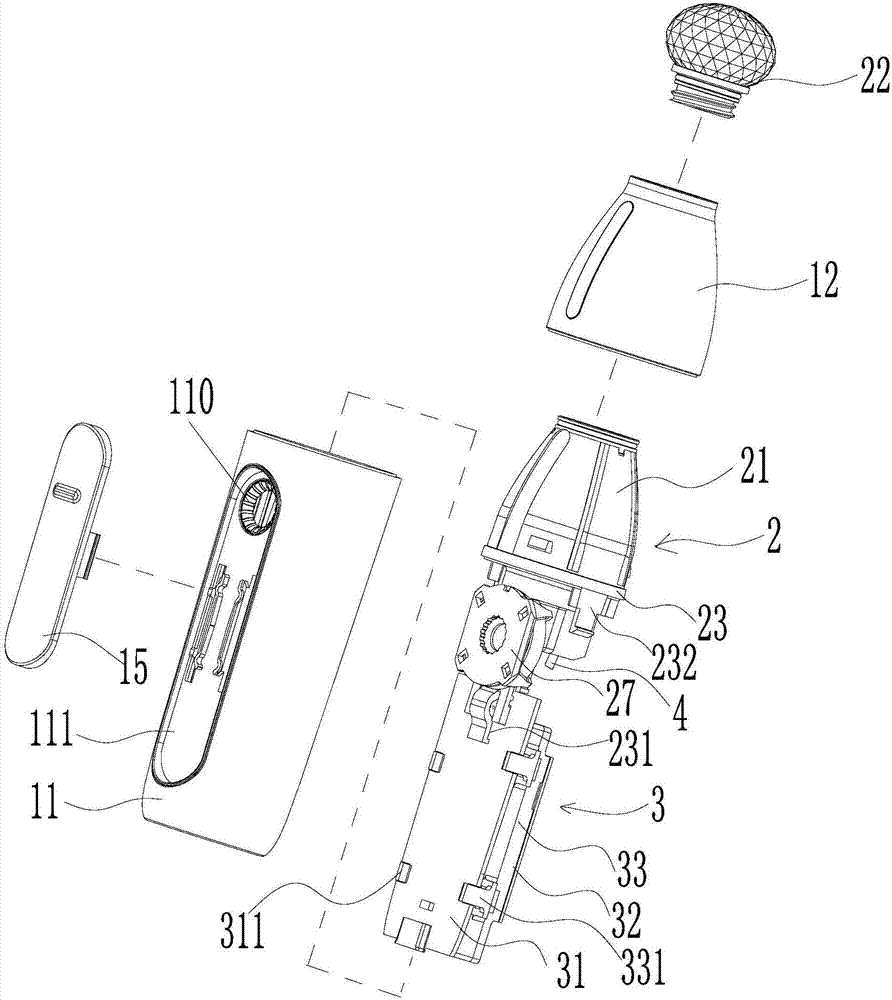

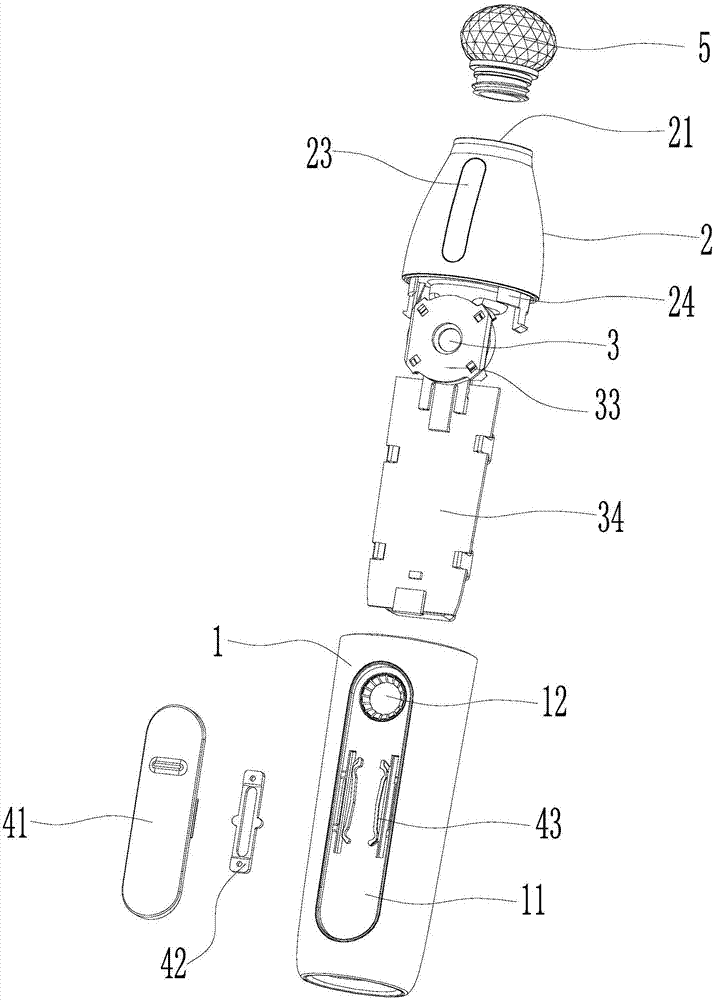

Water supplementing instrument with lighting effect

PendingCN107982045AAddressing Structural ComplexitySolve needsBathing devicesMedical applicatorsWater storageBaseboard

The invention discloses a water supplementing instrument with a lighting effect. The water supplementing instrument comprises a lighttight shell, a water storage assembly, an electric-control assembly, a light-emitting element and a light-transmitting ornament, wherein the shell comprises a lower shell body and an upper shell body, a mist outlet is formed in the side wall of the lower shell body,the water storage assembly is arranged in the upper shell body and comprises a light-transmitting water tank, a water tank baseboard which is connected with the bottom of the light-transmitting watertank, and a micropore atomization sheet fixed to a water outlet and communicated with the mist outlet; the light-emitting element is arranged below the bottom of the light-transmitting water tank, theelectric-control assembly is arranged in the lower shell body, and both the micropore atomization sheet and the light-emitting element are electrically connected with the electric-control assembly; the light-transmitting ornament is used for propagating lamplight light given out by the light-emitting element to generate an attractive lamplight effect. The water supplementing instrument generatesan attractive lighting effect during use, has the function of water supplying, and has the advantages of being simple in structure, easy to assemble, convenient to use and carry and the like.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

Electronic cigarette smoke solution solvent and electronic cigarette smoke solution

The invention discloses an electronic cigarette smoke solution solvent which comprises phytic acid, namely inositol hexaphosphoric acid. The phytic acid is independently used as the solvent of the electronic cigarette smoke solution, or is used as the solvent of the electronic cigarette smoke solution together with polyhydric alcohol, through the function of the phytic acid, the electronic cigarette smoke solution prepared by the electronic cigarette smoke solution solvent provided by the invention is thick and full in smoking experience and not oily, has no foreign flavor, is large in smoke amount, and has a relatively high smoking comfort level. The phytic acid is a nutriment beneficial to human bodies per se, and meanwhile has freshness retaining efficacy, so that the solvent not only can meet the sense requirement of a smoker, but also has the functions of nourishing, resisting aging and protecting mouth health.

Owner:CHINA TOBACCO JIANGSU INDAL

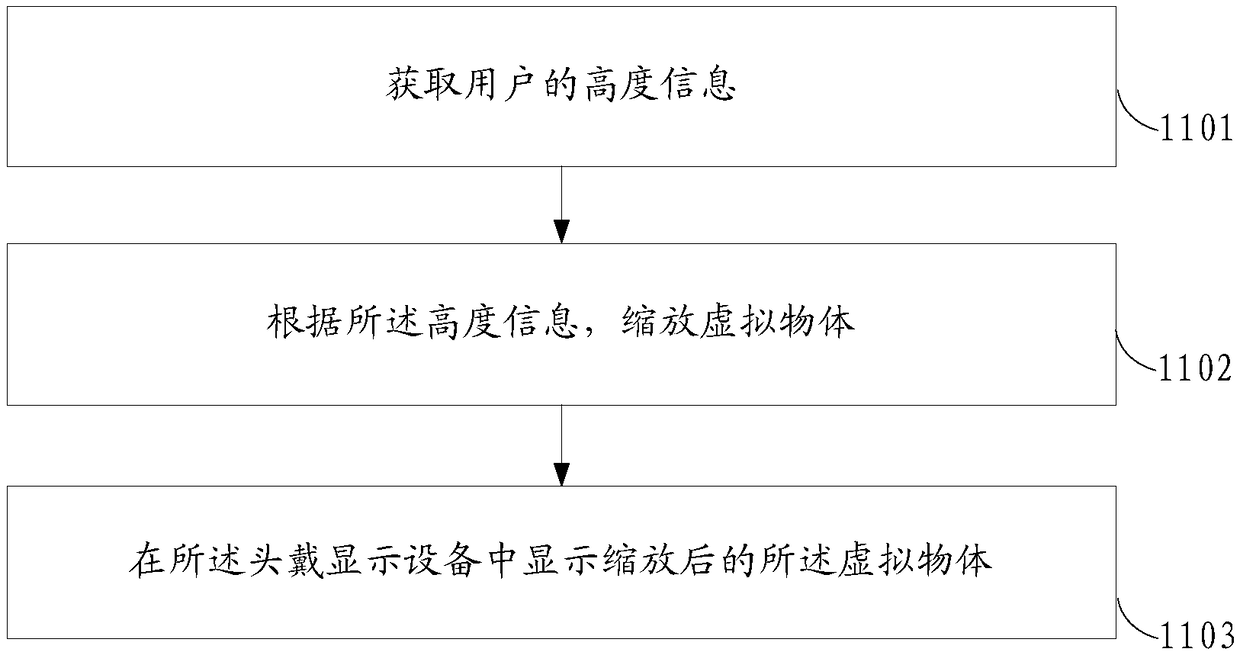

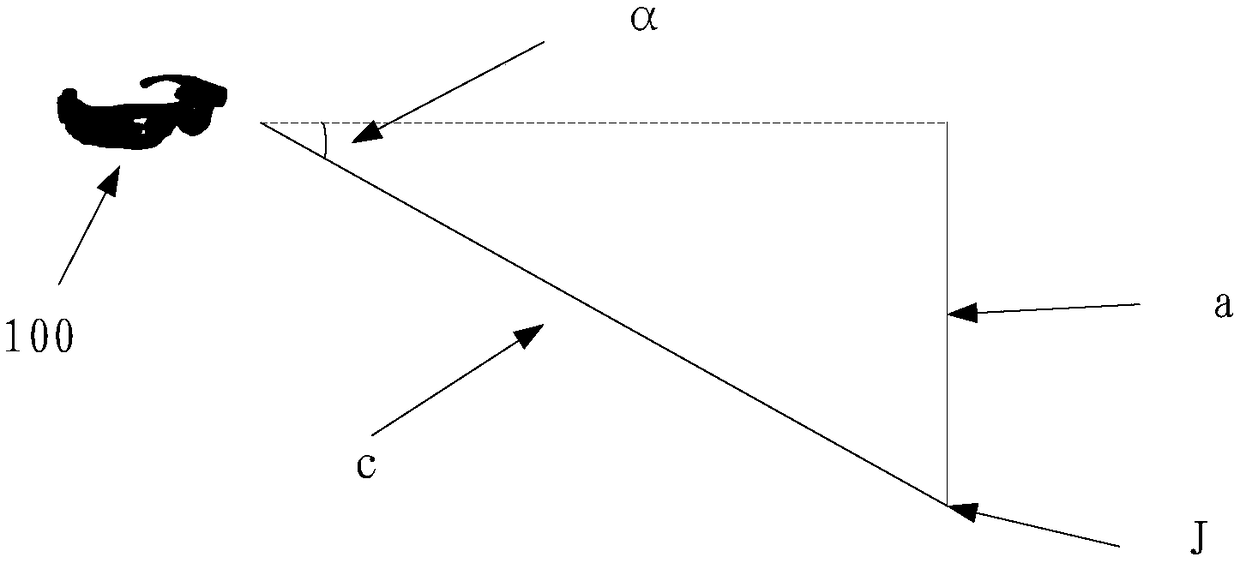

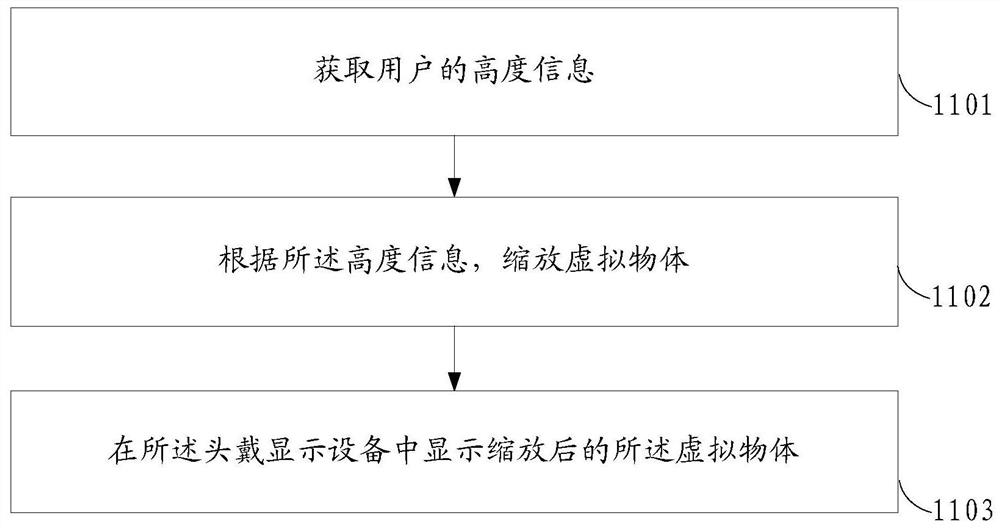

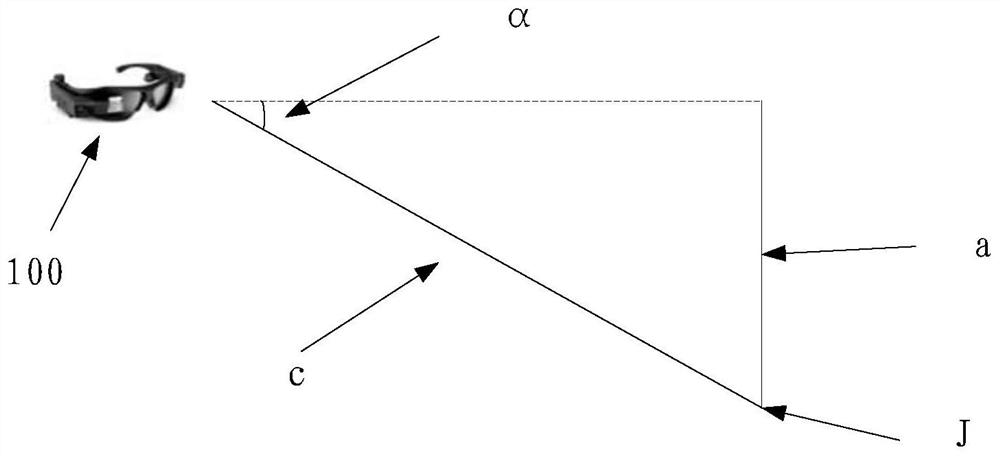

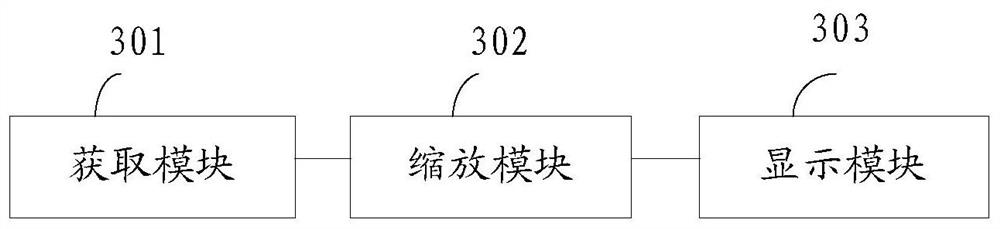

Display method, apparatus and device for head-mounted display device

ActiveCN109408011ASatisfy sensory needsMeet experience needsDigital output to display deviceOptical elementsDisplay deviceHuman–computer interaction

Embodiments of the present application provide a display method, apparatus, and device for a head mounted display device. The method comprises the following steps: acquiring the height information ofthe user; scaling the virtual object according to the altitude information; displaying the scaled virtual object in the headset display device. The technical proposal provided by the embodiment of theapplication can meet the experience needs of users of different heights, so that users of different heights can experience better visual effects.

Owner:GEER TECH CO LTD

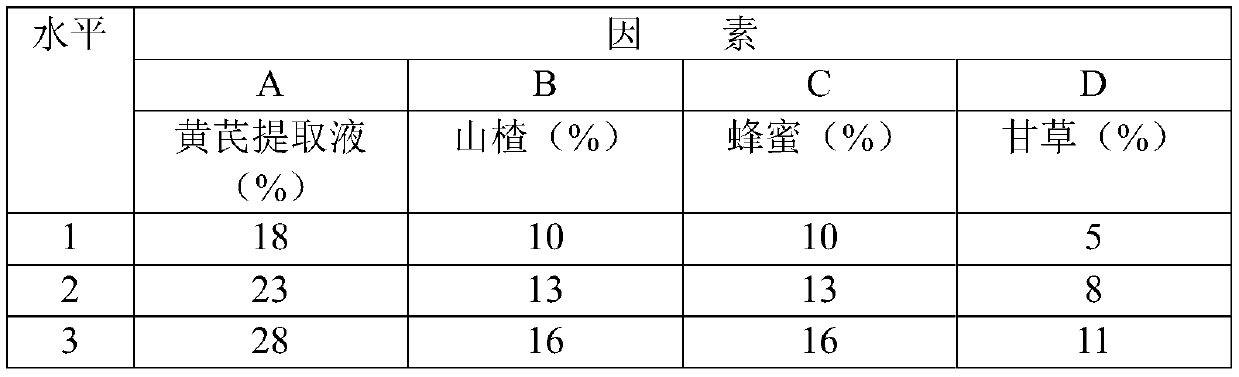

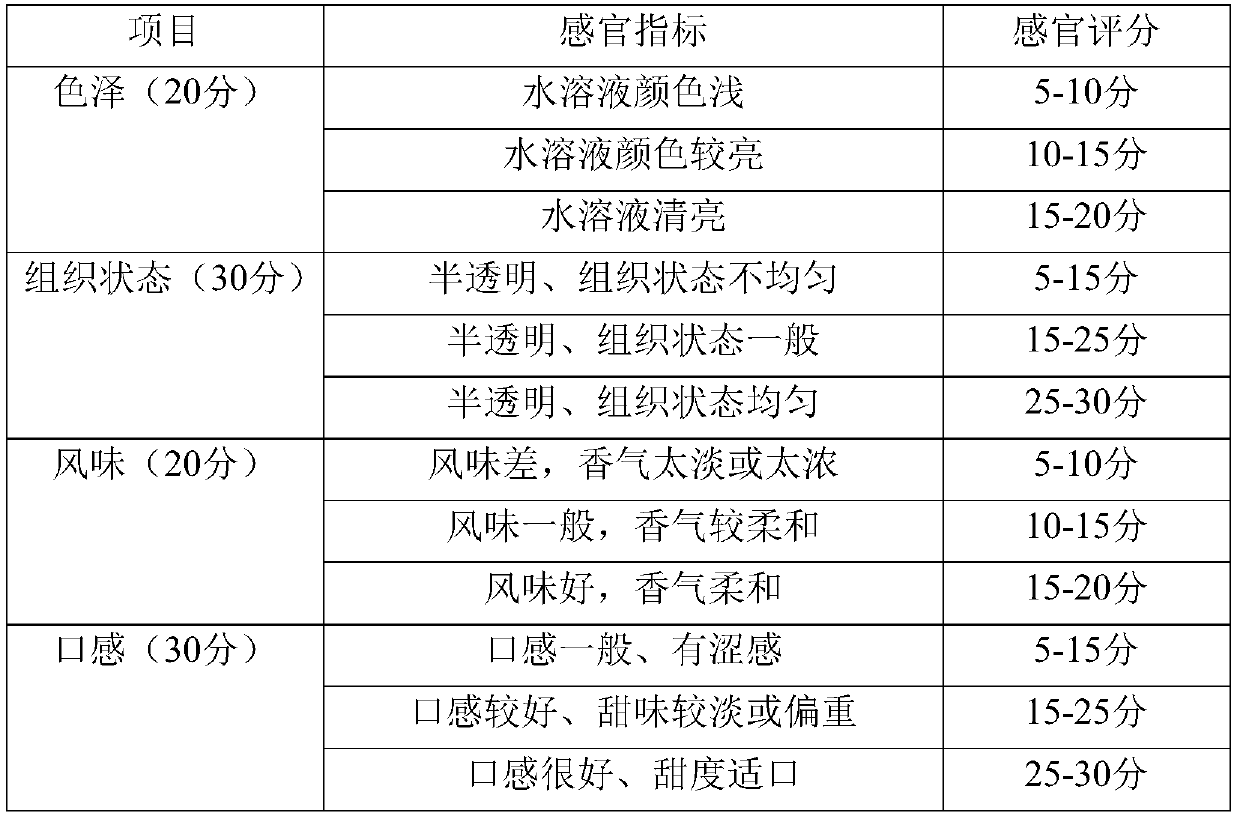

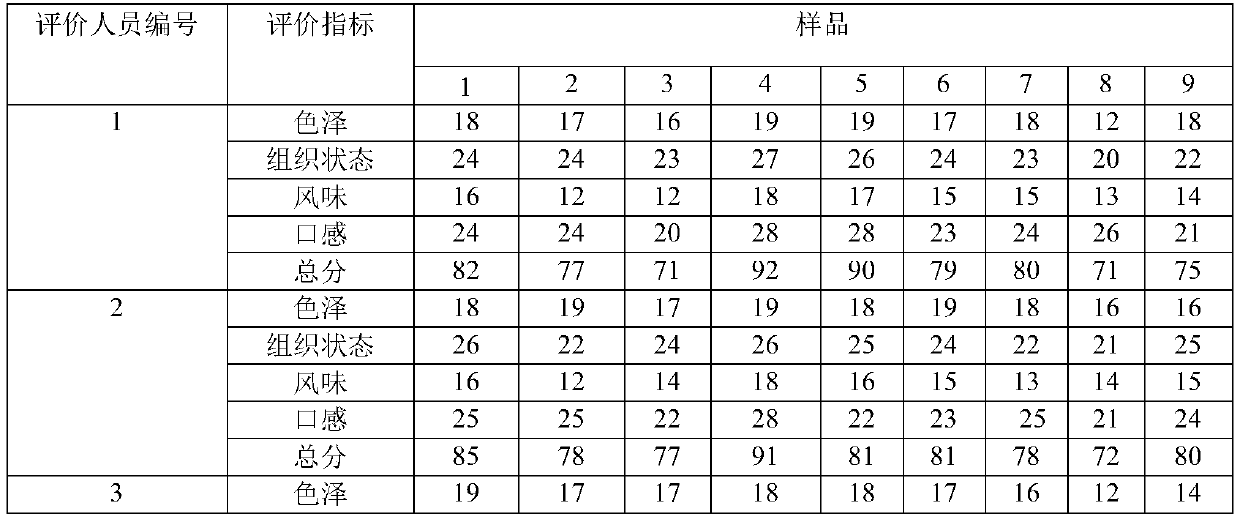

Honey composite health-care solid beverage and preparation method thereof

InactiveCN110934245AGood instant solubilityEasy to carryFood ingredient as flavour affecting agentNatural extract food ingredientsBiotechnologyRadix Astragali seu Hedysari

The invention discloses a honey composite health-care solid beverage and a preparation method thereof. The health-care solid beverage is prepared from the following components in parts by weight: 18 to 28 parts of a radix astragali extract, 10 to 16 parts of hawthorn, 10 to 16 parts of honey and 5 to 11 parts of liquorice. In the process of preparing the health-care solid beverage, firstly, radixastragali is extracted, hawthorn is pulped into juice, then the juice is mixed with honey and liquorice, and finally a mixture and water are uniformly mixed according to a certain proportion and thensterilized to obtain the health-care solid beverage. The prepared health-care solid beverage is natural in components, and does not contain artificially synthesized additives, artificial pigments andessences; all the components play a synergistic effect, play a role in tonifying qi, tonifying kidney, reducing blood pressure, detoxifying, protecting liver and improving immunity of a human body, and also have an appetizing function; moreover, the solid beverage is good in instant solubility, can be drunk after being brewed with water, is convenient to carry, and provides a new thought for development and utilization of honey products.

Owner:CHONGQING ACAD OF ANIMAL SCI

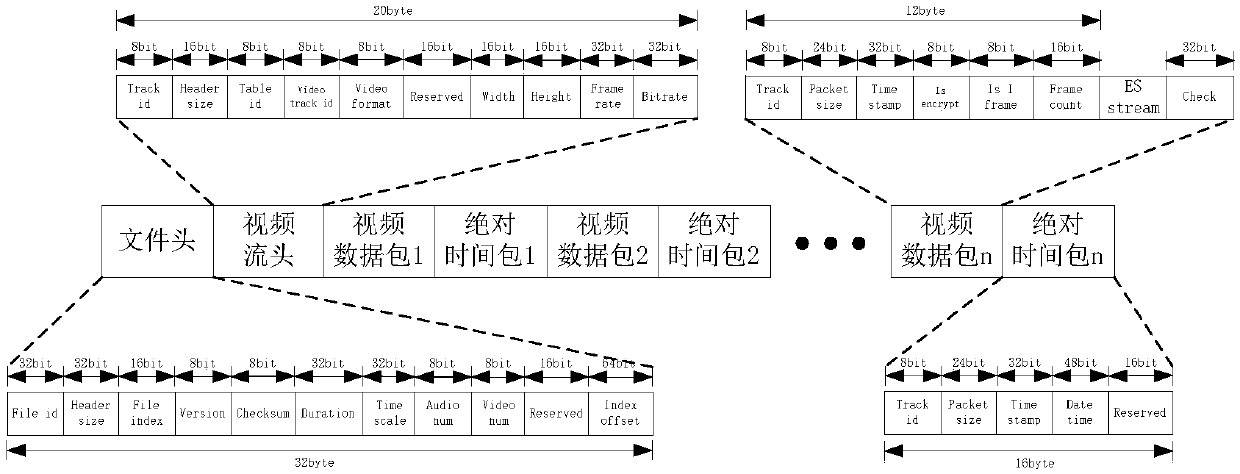

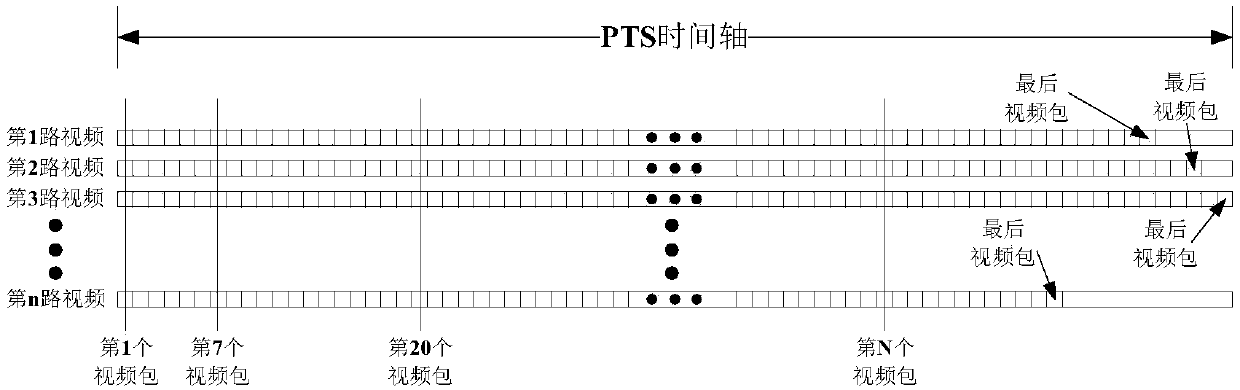

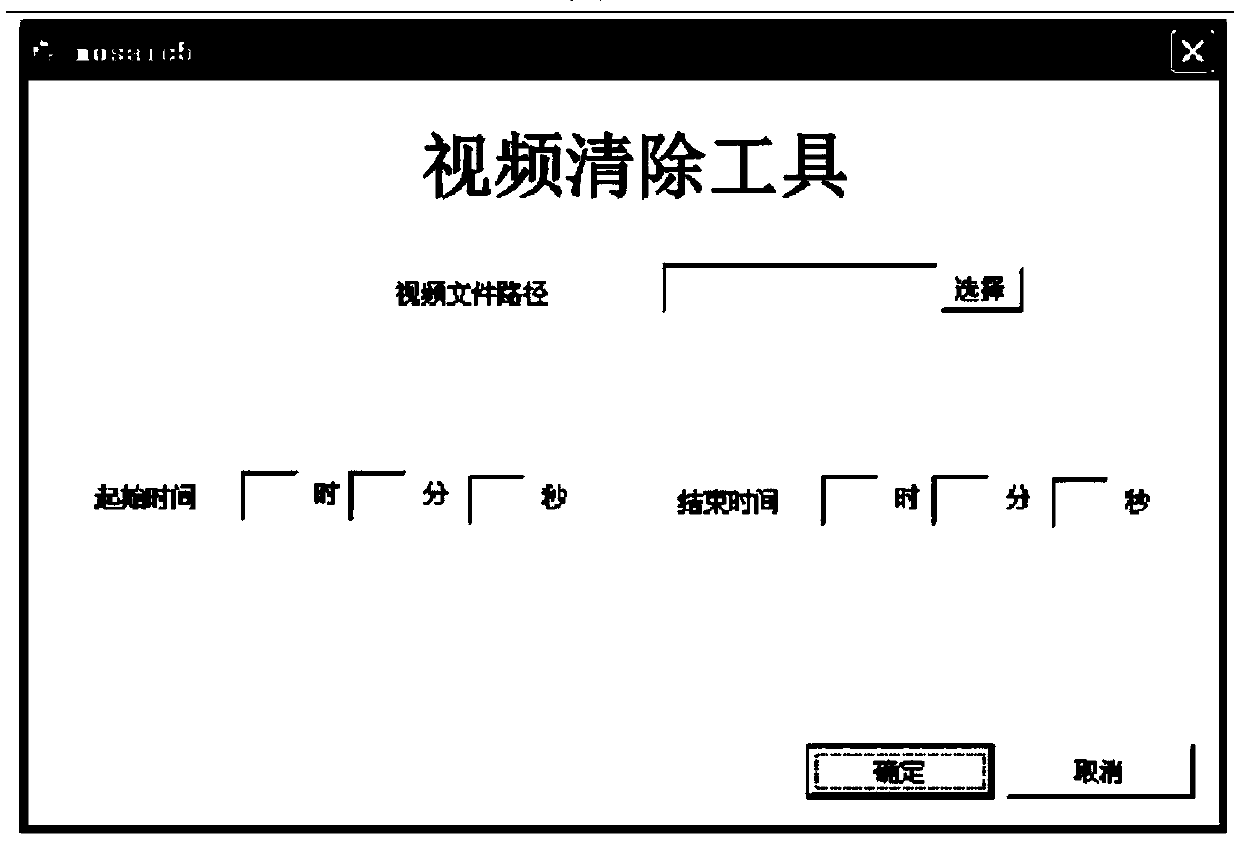

Organization method, synchronous playing method and segmentation clearance method of video encoding data

ActiveCN109547865AImprove efficiencySatisfy sensory needsSelective content distributionTime informationStreaming data

The invention discloses an organization method of video encoding data. The method comprises the following program steps: step A.1, generating a file header and a video stream header according to customization rules and known information; step A.2, carrying out packaging processing on ES code stream data after encoding to form a video data packet, wherein a packet header of the video data packet includes PTS time information; step A.3, generating an absolute time packet according to received calendar time or default time; and step A.4, adding a series of video data packets and absolute time packets after the video header and the video stream header to form a video file. The video file provided by the method can enable a dedicated player to carry out multi-path simultaneous synchronous playing according to the PTS time information in a code stream, can enable a video data clearance tool to quickly rewrite original data in the code stream with PTS time as parameter input, and satisfies needs of certain special application occasions.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

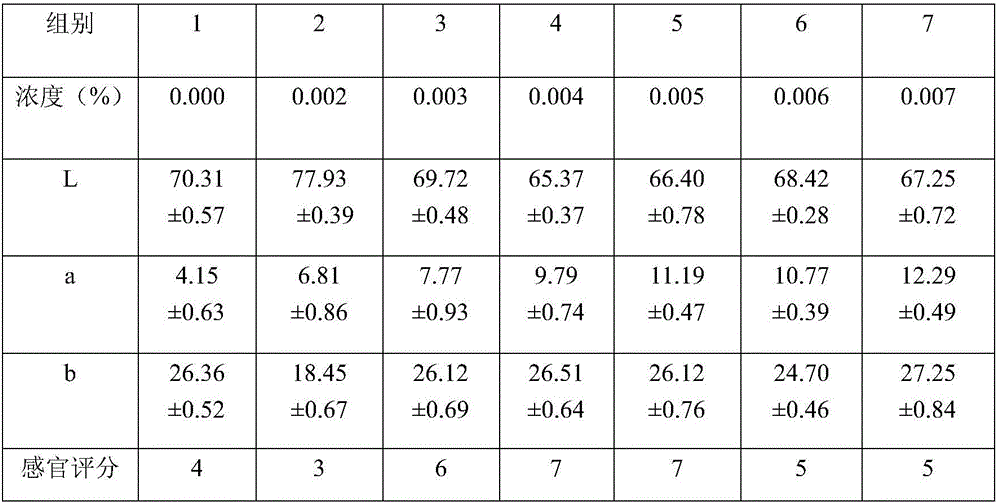

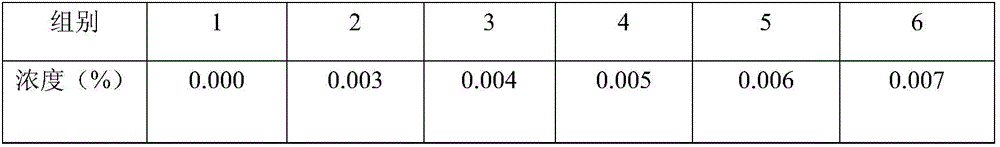

Stable and natural compound pigment special for chicken meat and application method thereof

ActiveCN107518252AGood colorSatisfy sensory needsFood ingredient as antioxidantFood ingredient as emulsifierMonoglycerideCochineal red

The present invention relates to a stable and natural compound pigment special for chicken meat and an application method thereof. The compound pigment comprises the following raw materials: a compound pigment, a compound emulsifier and a compound antioxidant. A monascus red pigment and monoglyceride are dissolved with ethanol to obtain a solution A; a cochineal red pigment, sodium alginate and sucrose fatty acid ester are dissolved with hot alkaline water to obtain a solution B; a gardenia yellow pigment, sodium erythorbate, tea polyphenols and vitamin E are dissolved with deionized water to obtain a solution C; and the completely dissolved solution A , solution B and solution C are evenly mixed, water is added to a constant volume, and the stable and natural compound pigment special for the chicken meat is prepared. Chicken meat products and the compound pigment solution special for the chicken meat are combined, and a pre-cooking and coloring are conducted. Advantages are as follows: the pure natural pigments are selected and combined, so that the compound pigment improves food colors, meets human sense needs, is also safer and plays a supporting function and an antioxidant function of nutrition strengthening.

Owner:BOHAI UNIV

Tobacco extract containing candy food

InactiveCN105076629AHarm reductionReduce inhalationConfectioneryTobacco devicesFood gradeTobacco product

The present invention discloses a tobacco extract containing candy food. The tobacco extract is added in the surface layer or interlayer or stuffing of the candy, and the addition amount of the tobacco extract is 0.01-2% of the surface layer or the interlayer or the stuffing of the candy by weight ratio. The tobacco extract containing candy food can not only satisfy the needs of tobacco consumer population, but also reduce the damage of smoking to health, avoid the damage of smoking to environment, reduce the possibility of secondhand smoking for non-smokers, and make smoking to be free of environment population, thereby being a safer, new and environmentally friendly tobacco product for tobacco consumers, and also being a food-grade tobacco alternative for traditional cigarettes.

Owner:云南拓宝科技有限公司

Preparation method for nutrition egg powder

ActiveCN105029412AImprove economic efficiencyFull of nutritionFood ingredient functionsFood preparationFlavorPre treatment

The invention discloses a preparation method for nutrition egg powder, and relates to the field of agricultural product deep processing. Selected Chinese yam, hawthorns, purple sweet potatoes, red dates and quail eggs are preprocessed and then compounded in proportion to form a compound nutrient solution, and the product is obtained after sterilization, homogenization and centrifugal drying are conducted on the compound nutrient solution. The preparation method effectively solves the problems that due to the fact that only eggs are adopted for main raw materials of traditional egg powder, the market is simplex, nutritional ingredient is not rich, and heath care effects are not comprehensive. By means of the preparation method, the application field of quail eggs is widened, the economic value is improved, and nutrient ingredient of the product is effectively increased, the health care effect is enhanced, the requirements of people for nutrition and health care are met, and meanwhile the nutrition egg powder has good quality indexes such as appearance, flavor, colors, luster, granularity and dissolving ability and has the advantages of being rich in nutrition and suitable for people of all ages.

Owner:北京家康葆科技发展有限公司

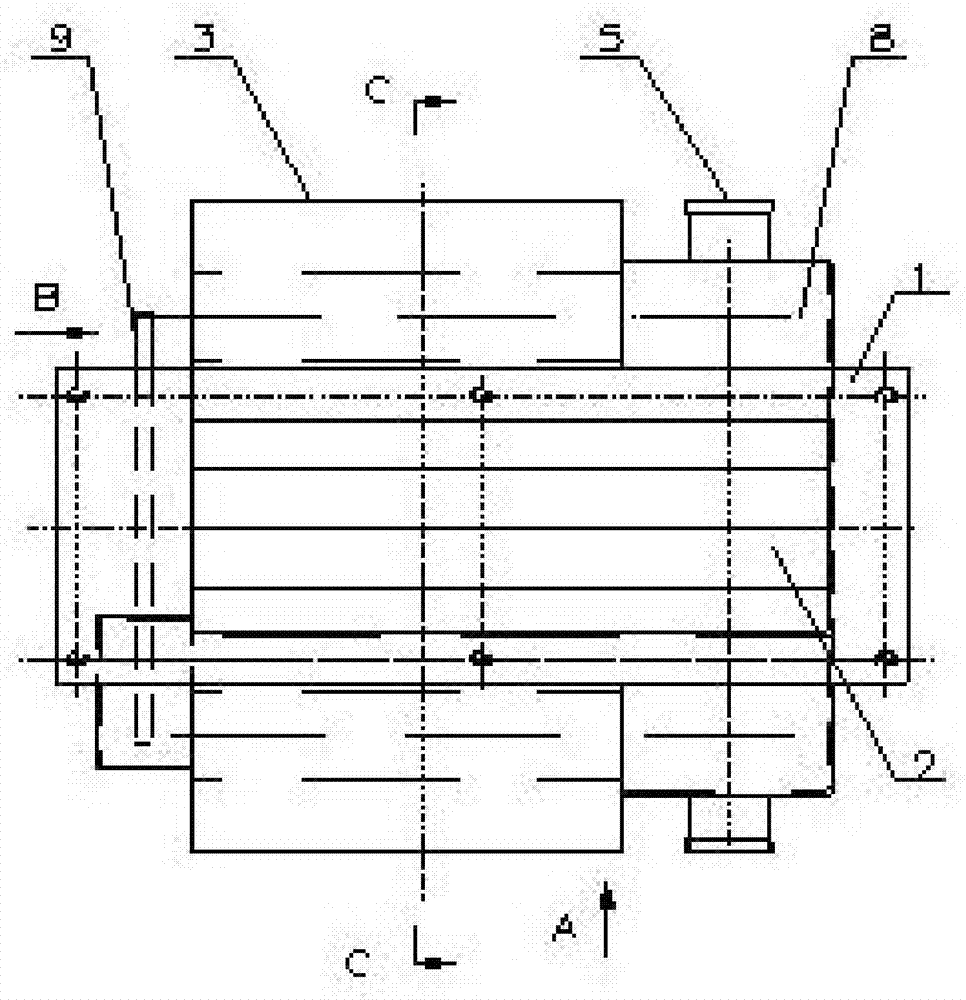

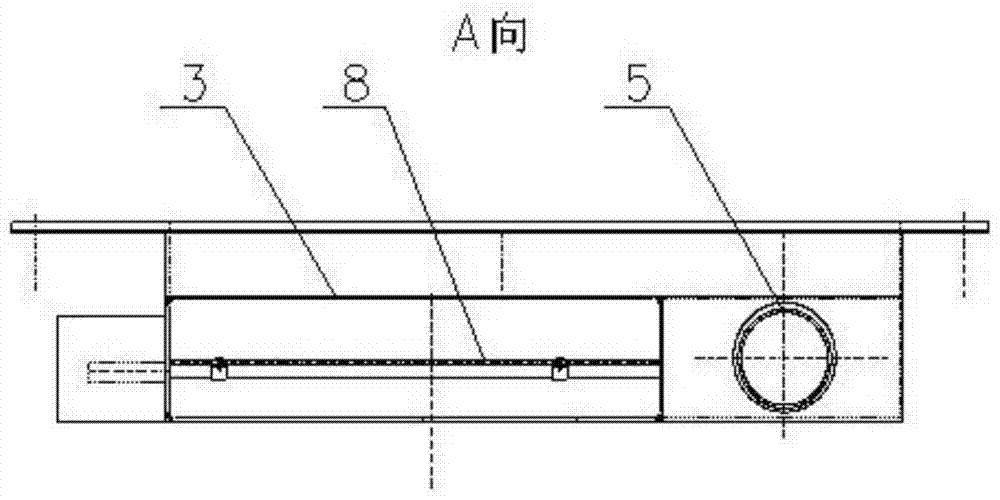

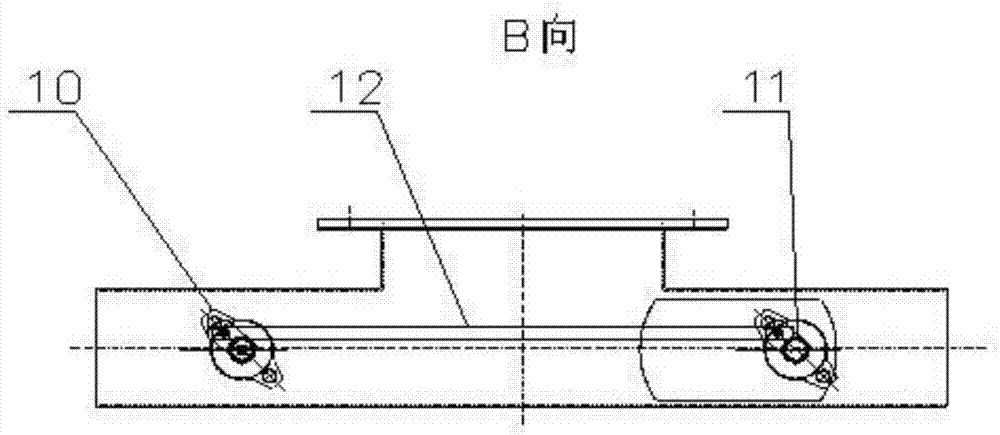

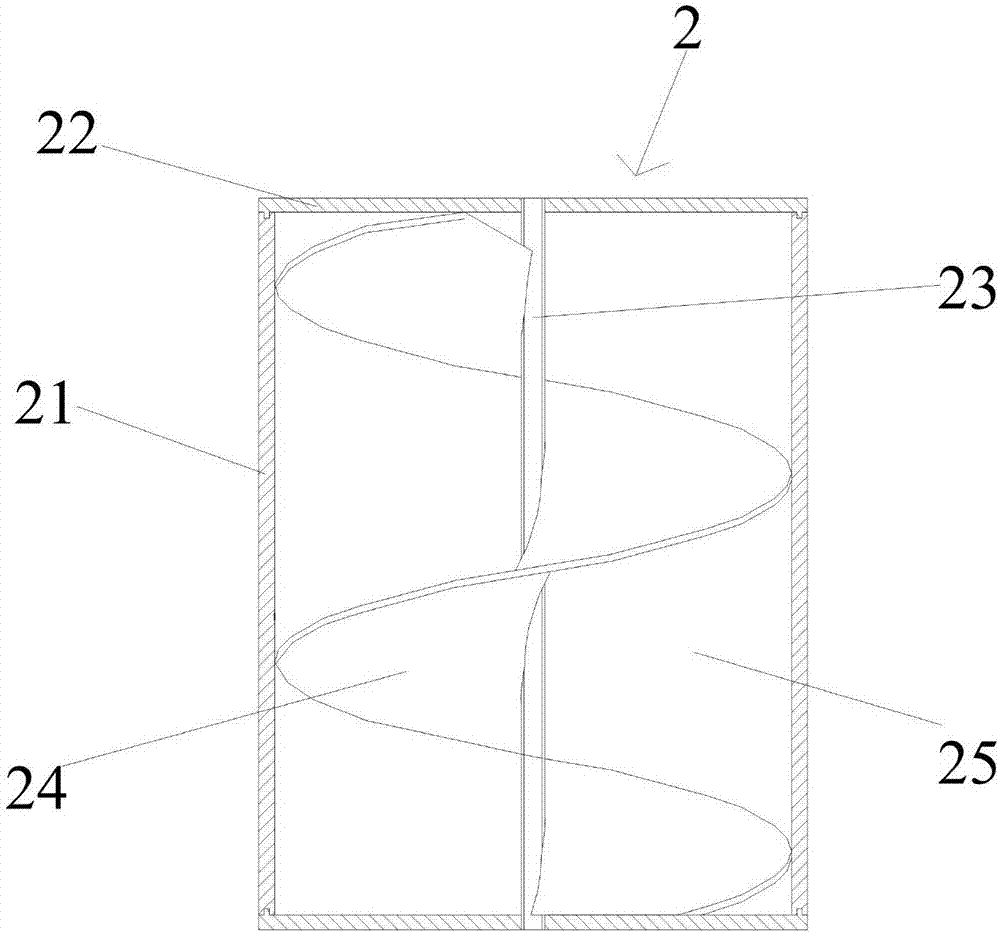

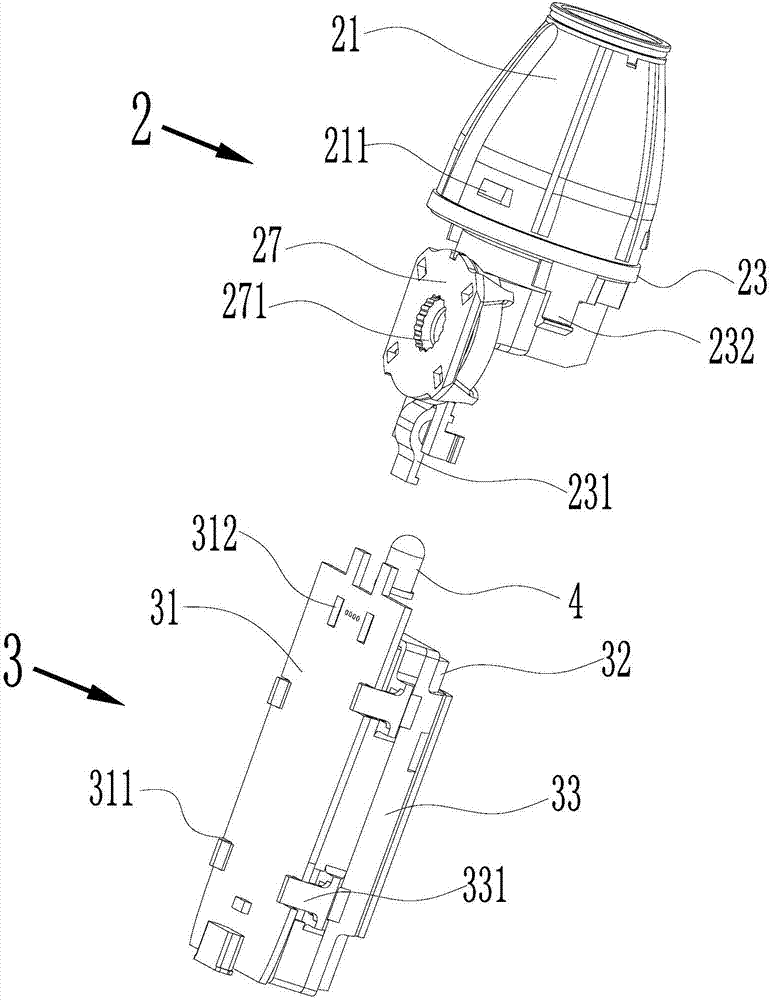

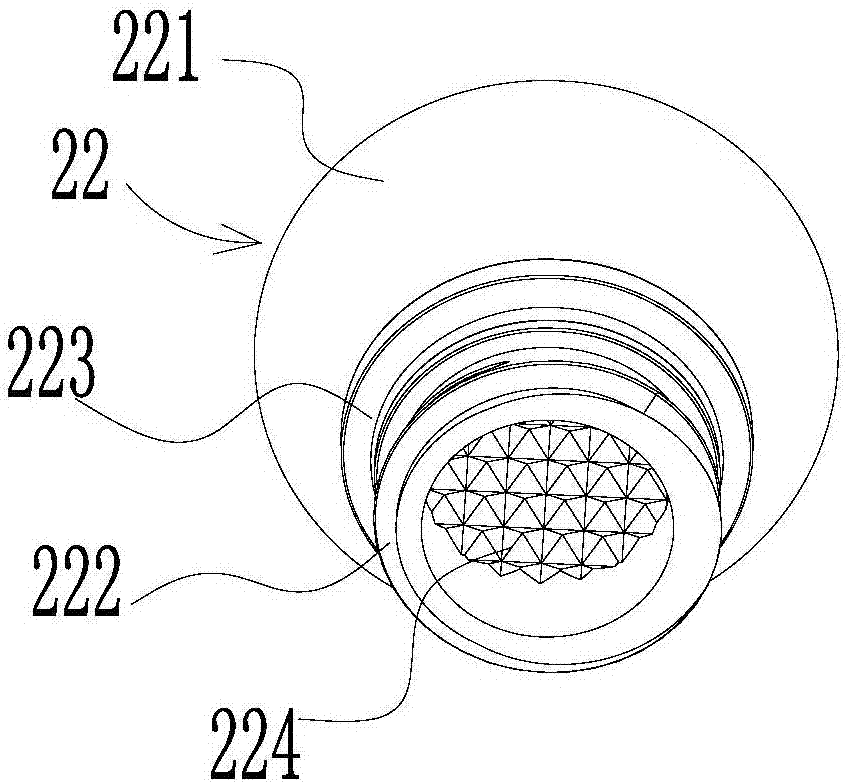

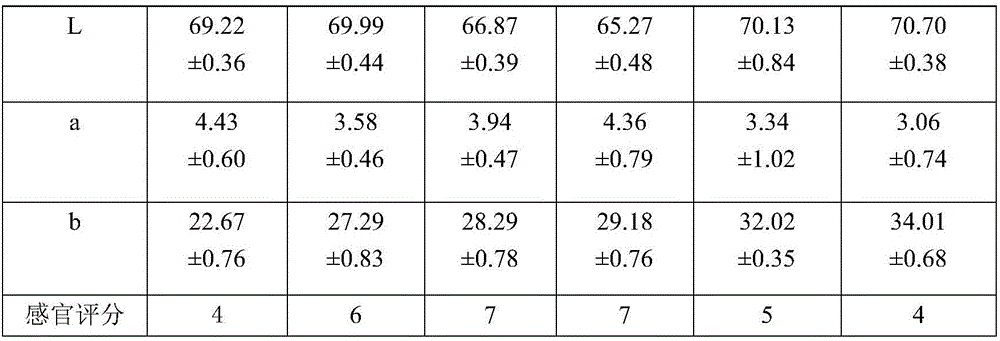

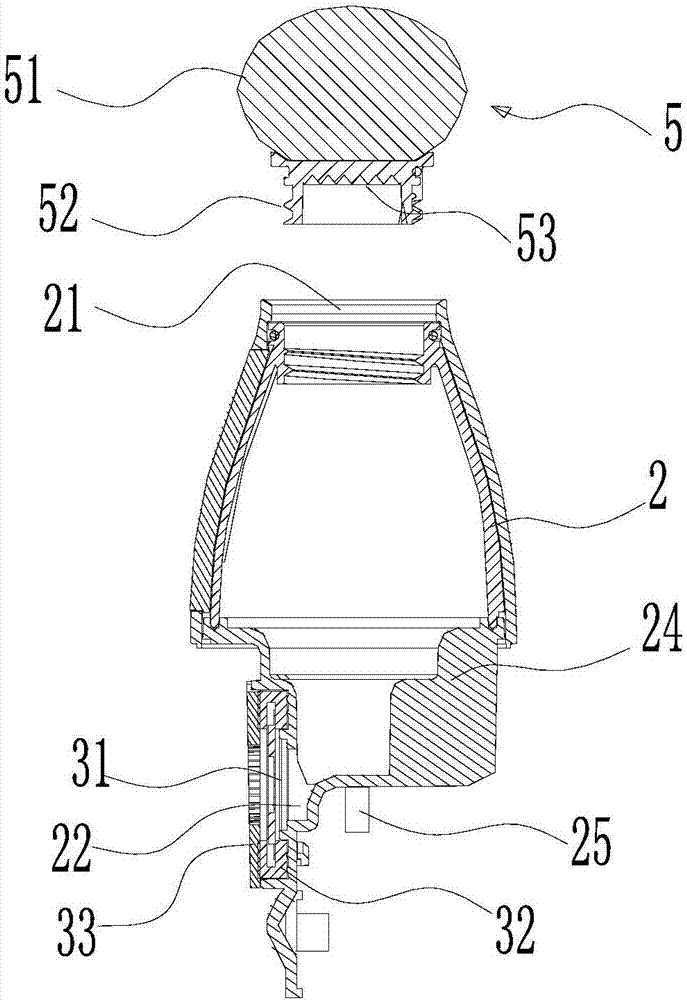

Water supply instrument and switching device

PendingCN107981516AImprove reliabilityNo malfunctionElectric switchesPackaging toiletriesWater storage tankAgricultural engineering

The invention discloses a water supply instrument and a switching device. The water supply instrument comprises a case (1), a water storage tank (2) and the switching device, and a switch fixing groove (11) and a mist outlet (12) are formed in the case (1); a water adding opening (21) is formed in the top of the water storage tank (2), a water outlet (22) is formed in the bottom of the water storage tank (2), and an atomization device is arranged in the case (1) and is communicated with the mist outlet (12); the switching device comprises a switch push plate (41), a gear plate (42) and a limiting plate (43). The switch push plate (41) is slidably arranged in the switch fixing groove (11). The limiting plate (43) is fixed to the groove wall of the switch fixing groove (43). The switching device is simple in structure, convenient for users to operate and high in reliability.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

An electronic cigarette liquid

ActiveCN104172463BRich review experienceReview and suck experience is fullTobacco treatmentLiquid smokePhytic acid

The invention discloses an electronic cigarette smoke solution solvent which comprises phytic acid, namely inositol hexaphosphoric acid. The phytic acid is independently used as the solvent of the electronic cigarette smoke solution, or is used as the solvent of the electronic cigarette smoke solution together with polyhydric alcohol, through the function of the phytic acid, the electronic cigarette smoke solution prepared by the electronic cigarette smoke solution solvent provided by the invention is thick and full in smoking experience and not oily, has no foreign flavor, is large in smoke amount, and has a relatively high smoking comfort level. The phytic acid is a nutriment beneficial to human bodies per se, and meanwhile has freshness retaining efficacy, so that the solvent not only can meet the sense requirement of a smoker, but also has the functions of nourishing, resisting aging and protecting mouth health.

Owner:CHINA TOBACCO JIANGSU INDAL

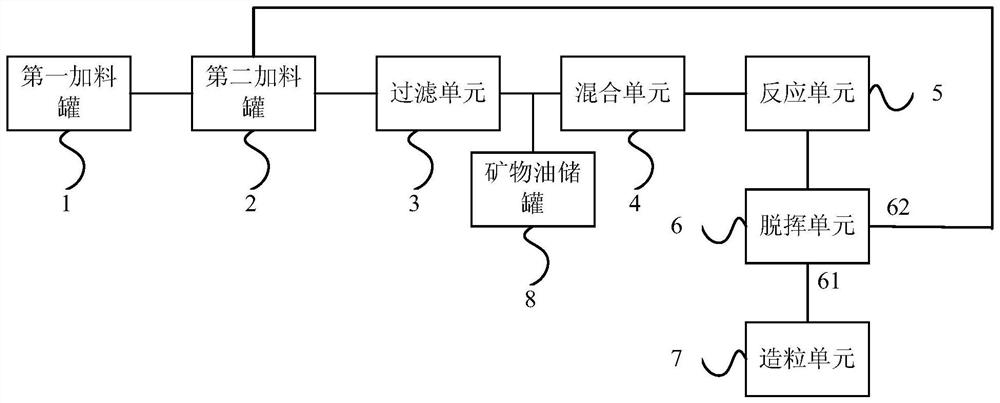

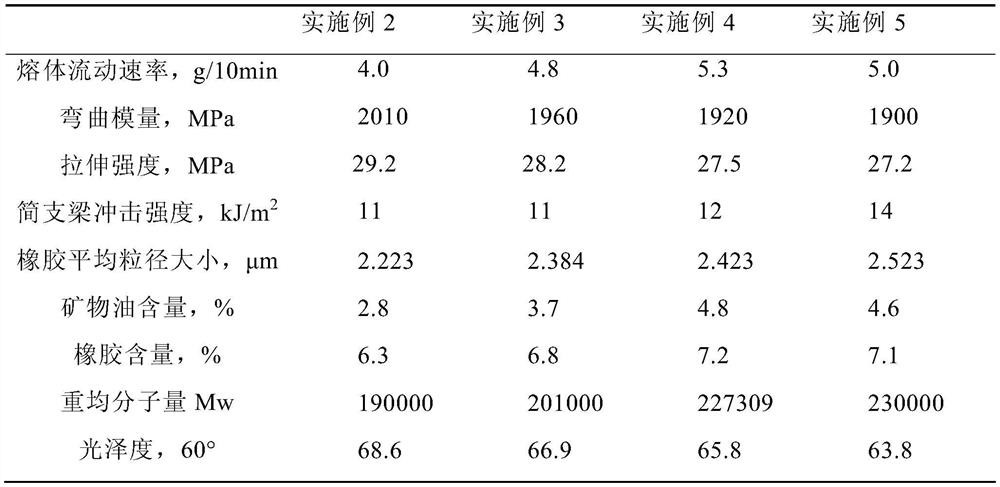

Yoghurt cup sheet raw material and preparation method thereof

The invention provides a yoghurt cup sheet raw material and a preparation method thereof. The yoghurt cup sheet raw material comprises the following components by weight: 6-7.5 parts of polybutadienerubber, 3-5 parts of mineral oil, 0.05-0.1 part of an antioxidant, and 87.4-90.95 parts of polystyrene. Specifically, the polybutadiene rubber has a particle size distribution of 1-8micron unimodal distribution. The yoghurt cup sheet raw material has a weight-average molecular weight of 19000-230000, impact resistance of 11-14kJ / m<2>, and tensile strength of 27-30Mpa. The yoghurt cup sheet raw material provided by the invention is HIPS with special strength properties, has good processability, rigidity and impact resistance, can be directly used as yoghurt packaging material, and has no need for adding rubber products, thereby further avoiding the phenomena of yellow spots and black spots caused by uneven mixing of rubber and HIPS.

Owner:PETROCHINA CO LTD

Display method, device and equipment of head-mounted display device

ActiveCN109408011BSatisfy sensory needsMeet experience needsDigital output to display deviceOptical elementsComputer hardwareComputer graphics (images)

Embodiments of the present application provide a display method, device, and device for a head-mounted display device. Wherein, the method includes the following steps: acquiring height information of the user; scaling the virtual object according to the height information; and displaying the scaled virtual object on the head-mounted display device. The technical solutions provided by the embodiments of the present application can meet the experience requirements of users of different heights, so that users of different heights can experience better visual effects.

Owner:GEER TECH CO LTD

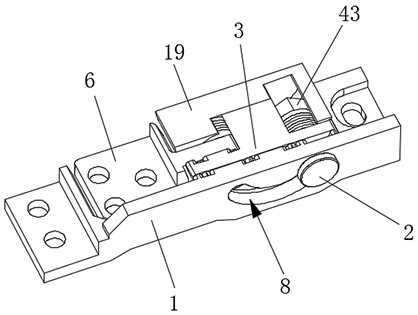

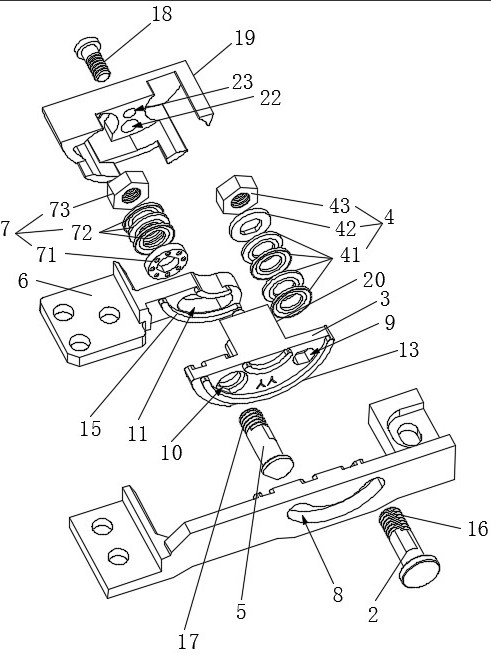

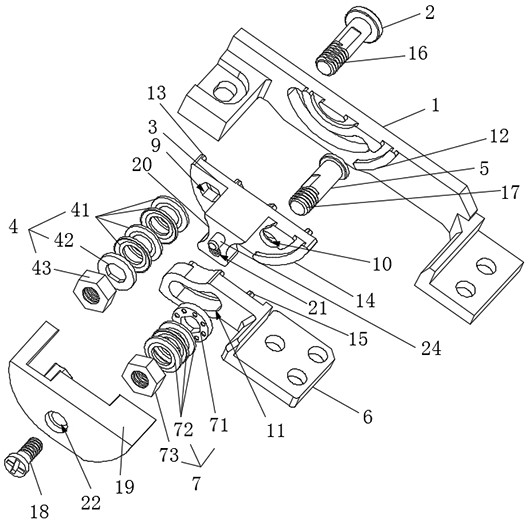

Flip type rotating shaft

PendingCN112814994ASatisfy sensory needsAvoid restricting the flap angleDetails for portable computersPivotal connectionsFixed frameDual axis

The invention relates to the technical field of hinge rotating shafts, in particular to a flip type rotating shaft. A fixed frame, a first connecting shaft, a rotary connecting piece, a first tensioning adjusting assembly, a second connecting shaft, a movable frame and a second tensioning adjusting assembly are adopted to cooperate with each other, the first connecting shaft sequentially penetrates through a first guide groove and a first through hole and is connected with the first tensioning adjusting assembly, and the second connecting shaft sequentially penetrates through a second through hole and a second guide groove and is connected with the second tensioning adjusting assembly. In the actual operation process, the relative position of the fixed frame and the rotary connecting piece and the relative position of the rotary connecting piece and the movable frame are changed, and the movable frame is turned over at multiple angles. When the flip type rotating shaft is applied to a flip product, a certain gap can be formed between the edges of a lower cover and an upper cover by means of the double-shaft linkage structure of the flip type rotating shaft, the situation that the flip angle is limited due to the fact that the edges of the lower cover and the upper cover are clamped after the flip type rotating shaft is turned over by a certain angle is avoided, and the perception requirement of consumers can be better met.

Owner:东莞市毅洋精密科技有限公司

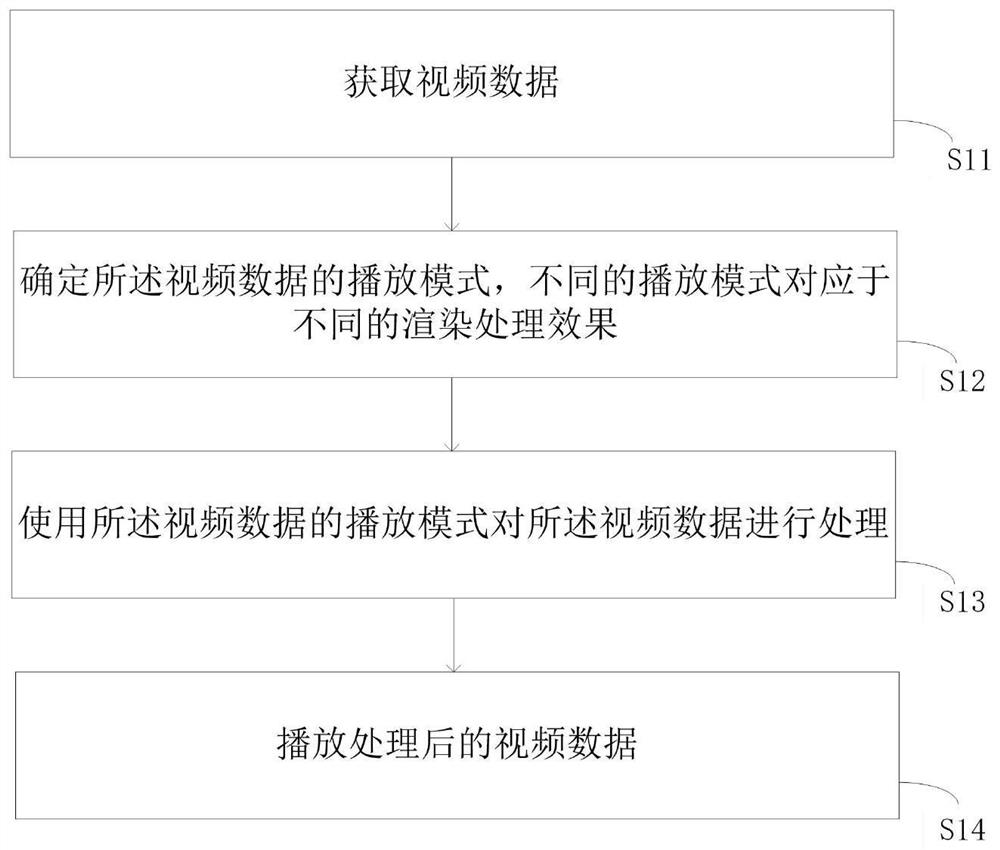

Video playing method and device and medium

PendingCN113365144ASatisfy sensory needsImprove user experienceSelective content distributionComputer graphics (images)Multimedia

The invention provides a video playing method and device and a medium. The method comprises the following steps: acquiring video data; determining playing modes of the video data, wherein different playing modes correspond to different rendering processing effects; processing the video data by using the playing mode of the video data; and playing the processed video data. According to the invention, different playing modes are set to provide different playing effects for the user in different scenes, so that the perception requirements of the user in different scenes are met, and the user experience is effectively improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Yogurt cup sheet raw material and preparation method thereof

The invention provides a yogurt cup sheet material and a preparation method thereof. The yogurt cup sheet material comprises the following components in parts by weight: 6-7.5 parts of polybutadiene rubber, 3-5 parts of mineral oil, and 0.05-5 parts of antioxidant 0.1 part, 87.4-90.95 parts of polystyrene; wherein, the particle size distribution of the polybutadiene rubber is a unimodal distribution of 1-8 μm; the weight-average molecular weight of the yogurt cup sheet material is 190,000-230,000 The impact performance is 11~14kJ / m 2 , The tensile strength is 27 ~ 30Mpa. The raw material of the yogurt cup sheet of the present invention is HIPS with special strength properties, which has good processing performance, rigidity and impact resistance, and can be directly used as packaging materials for yogurt without adding rubber products to it, thereby further avoiding It eliminates the phenomenon of macula and black spots due to uneven mixing of rubber and HIPS.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com