Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduced risk of bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

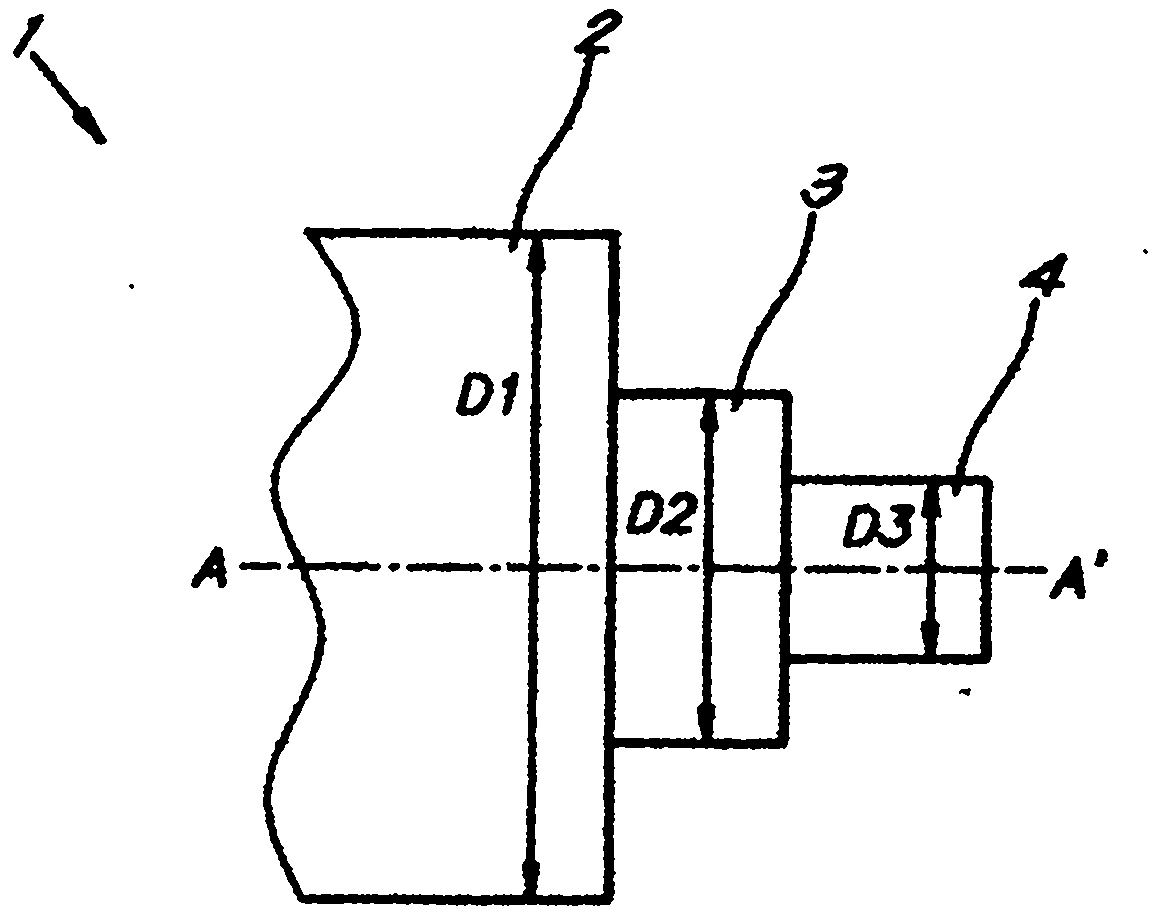

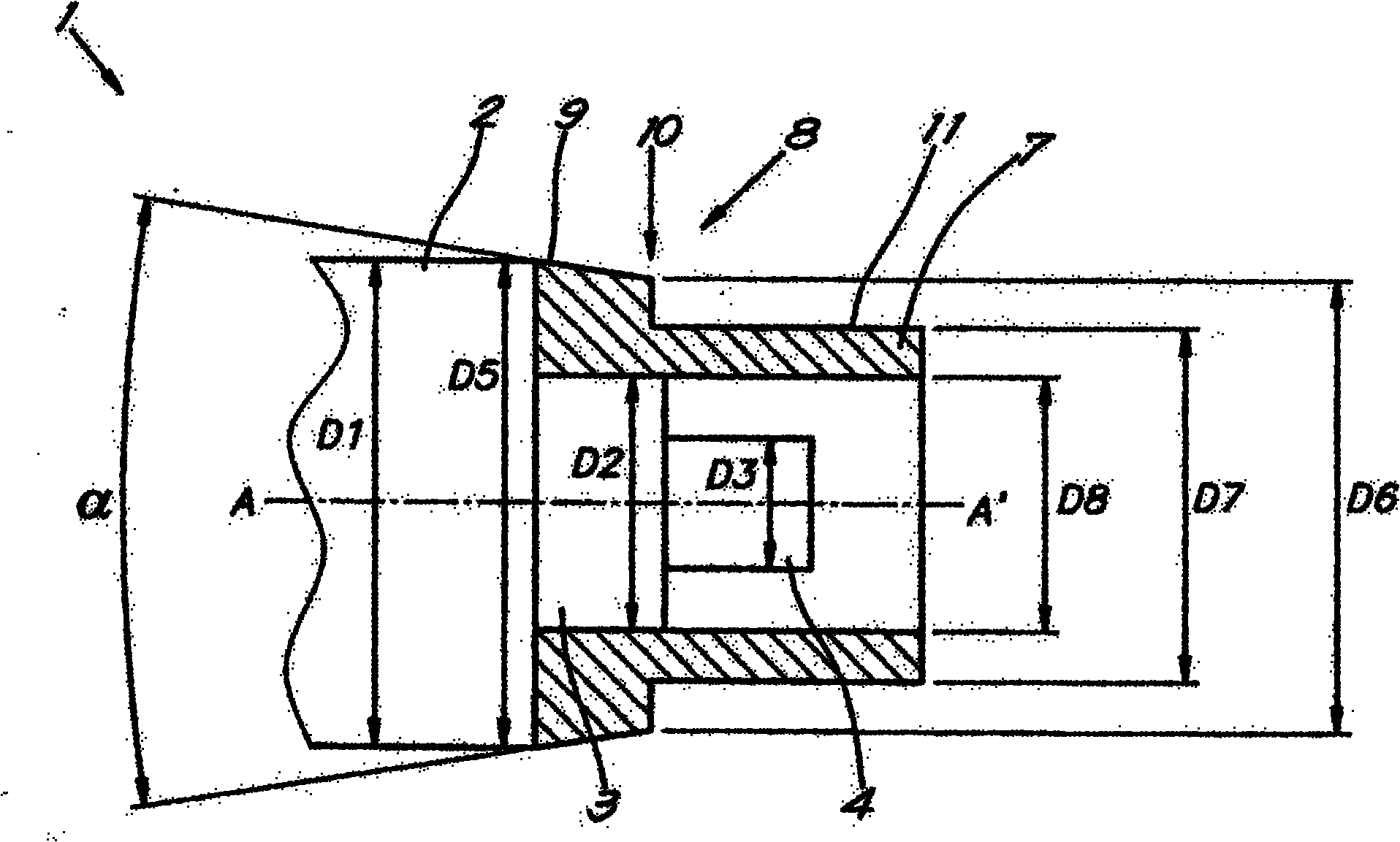

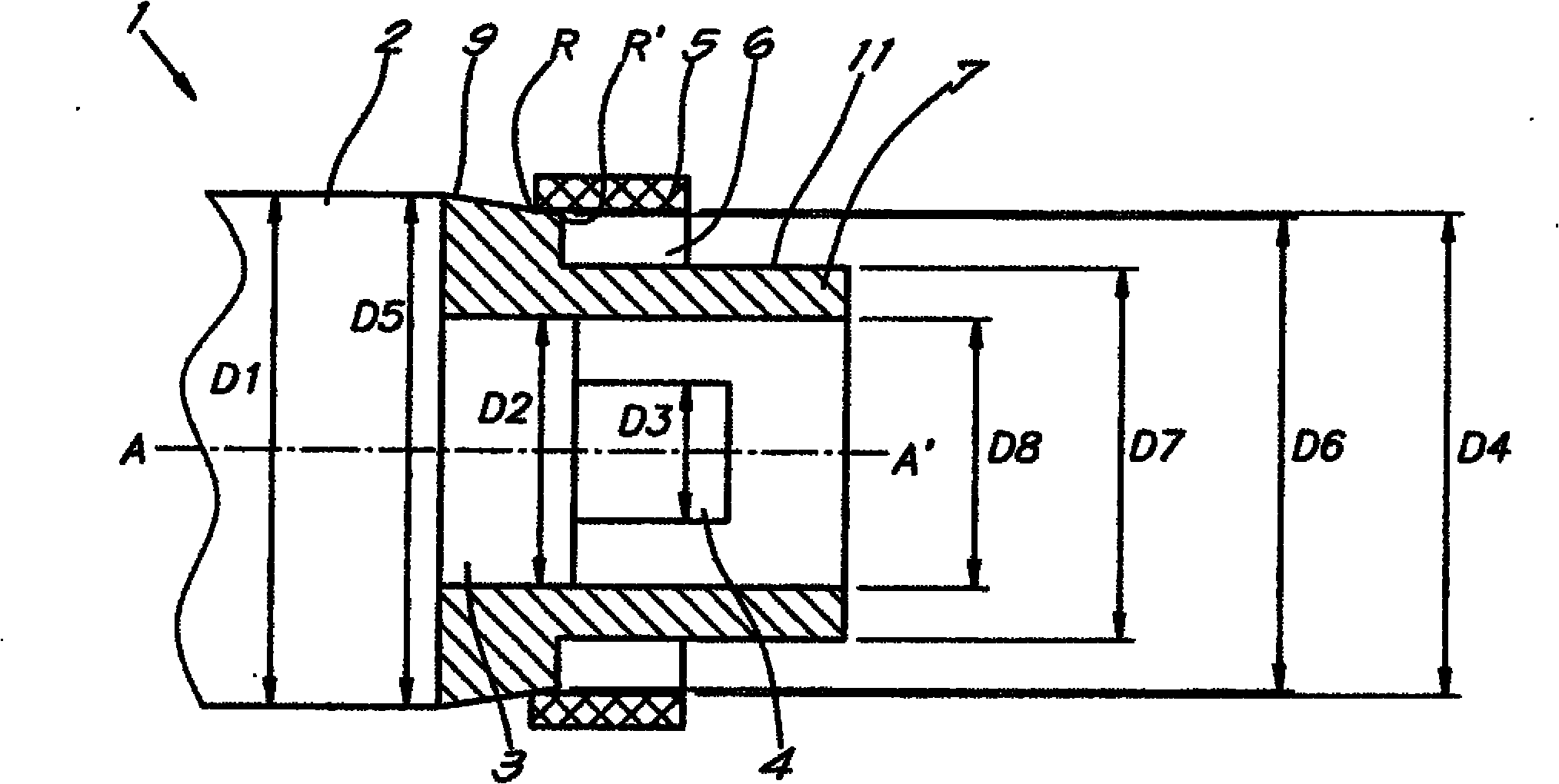

Method for mounting a bush around a part of a shaft by means of a tight fitting

ActiveCN102067417ANo risk of damageIncrease the lengthClutchesRotary bearingsInterference fitClassical mechanics

Owner:ATLAS COPCO AIRPOWER NV

Machining method of slender shaft made of17-4PH stainless steel material

The invention belongs to the technical field of material machining and particularly relates to a machining method of a slender shaft made of a 17-4PH stainless steel material. The machining method of the slender shaft made of the 17-4PH stainless steel material at least includes the steps of firstly, stress relief annealing heat treatment, secondly, slender shaft end face machining and drilling, thirdly, determination of the grinding benchmark of the slender shaft, fourthly, rough turning, semi-finish turning and penetration flaw detection, fifthly, solid solution and aging thermal treatment, sixthly, grinding treatment, seventhly, surface quenching and annealing heat treatment and eighthly, obtainment of the slender shaft, wherein the slender shaft obtained in the seventh step is subjected to finish grinding, a plug is removed, the following conventional shaft end fine dressing or end cut-off is conducted, and the finished slender shaft is obtained. By the adoption of the method, the defect that the machining rejection rate of the slender shaft made of the 17-4 PH stainless steel material is high at present can be effectively overcome, the high-precision shape of the slender shaft and the surface roughness machining of the slender shaft are guaranteed, the machining efficiency of the slender shaft is improved, and the yield is increased.

Owner:HEFEI UNIV OF TECH +1

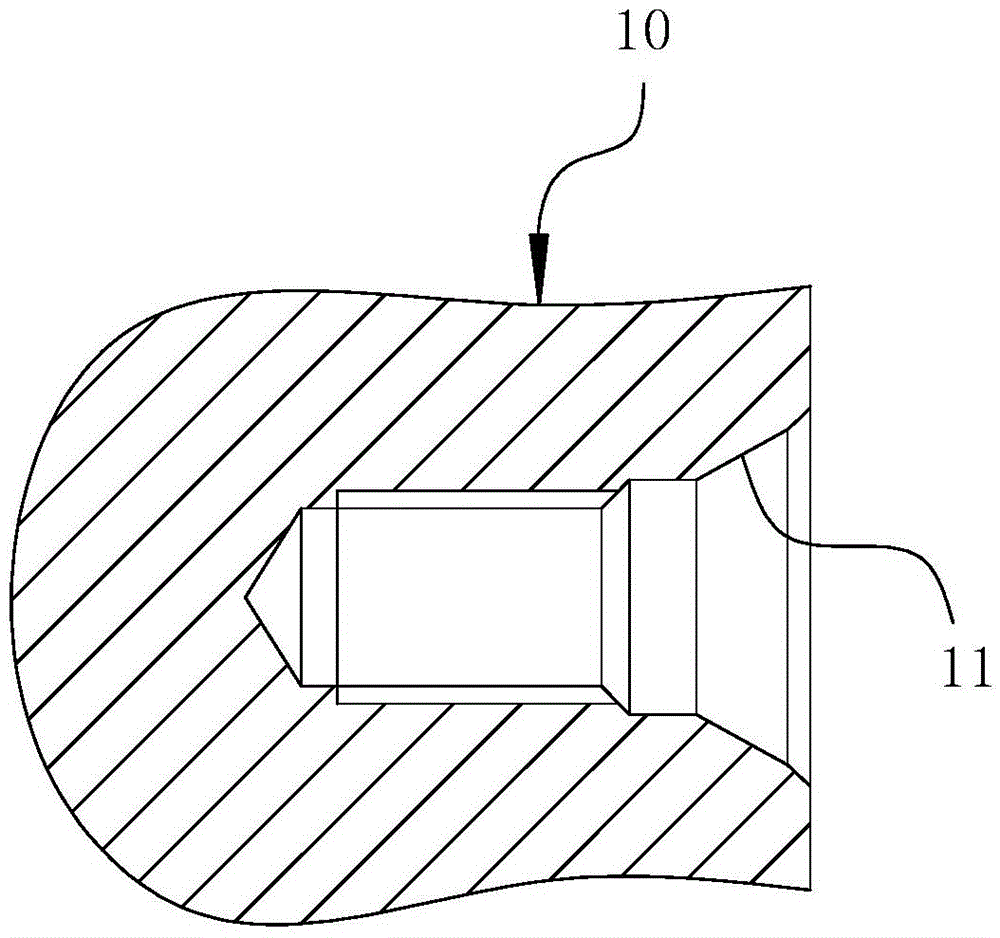

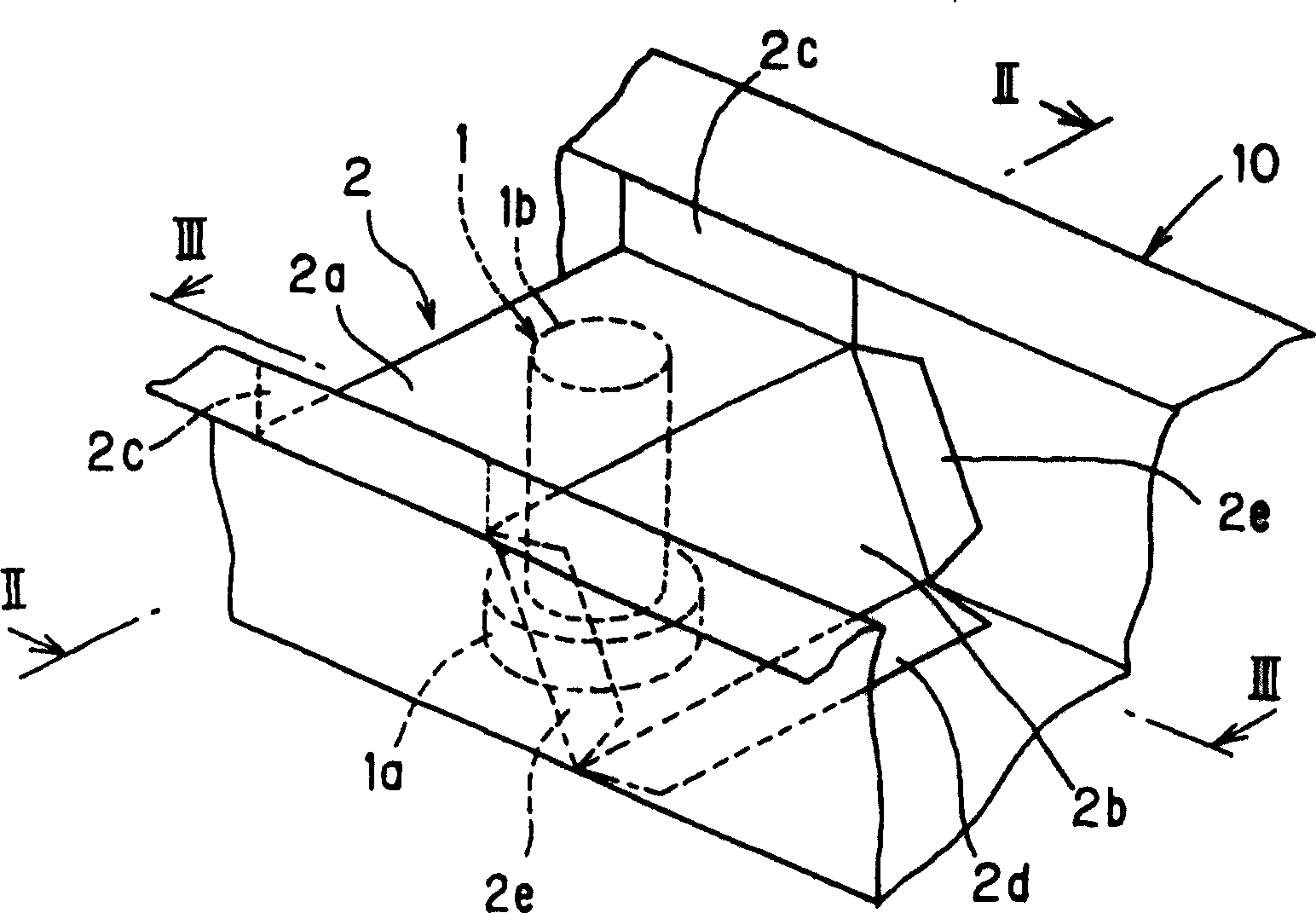

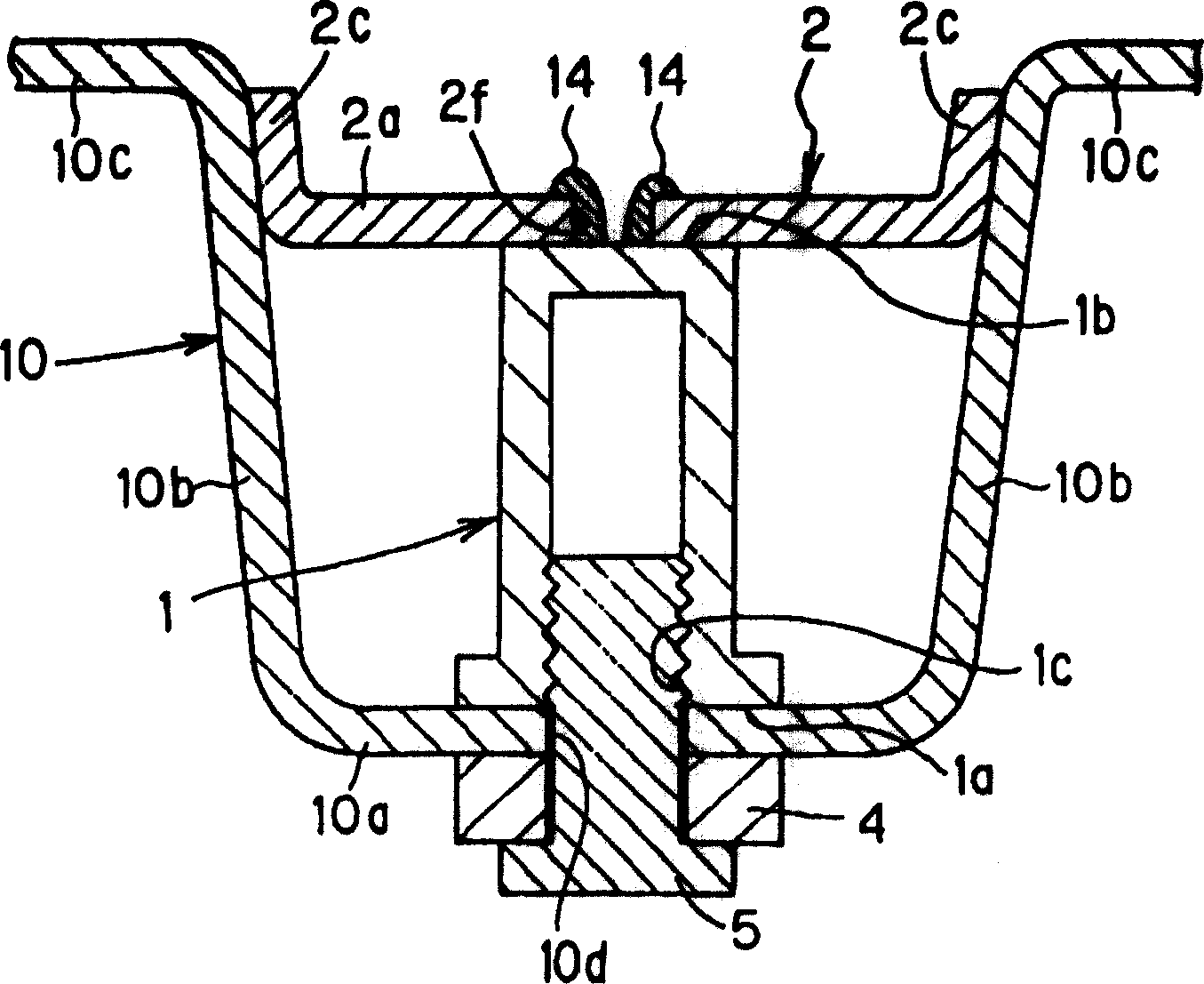

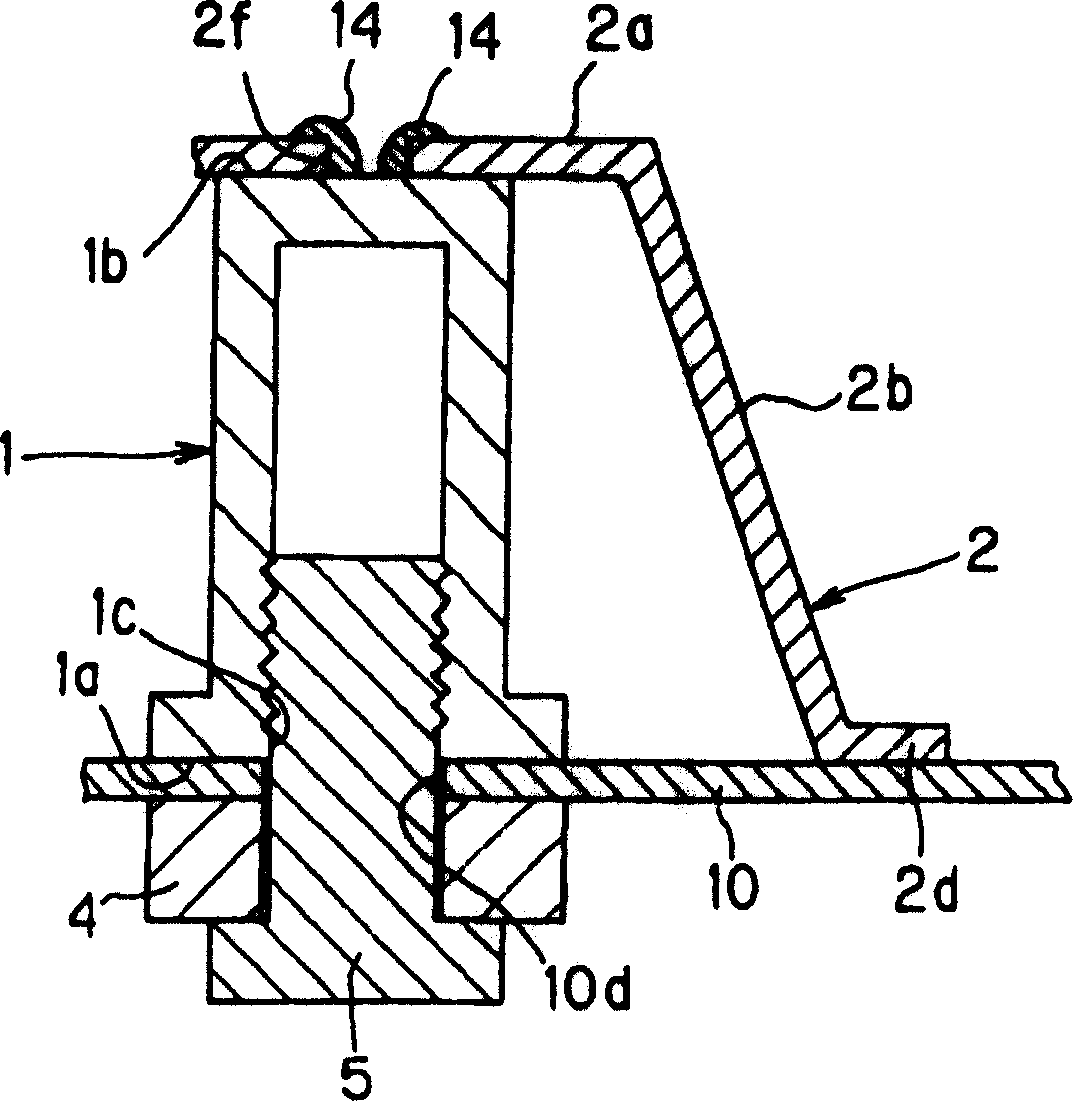

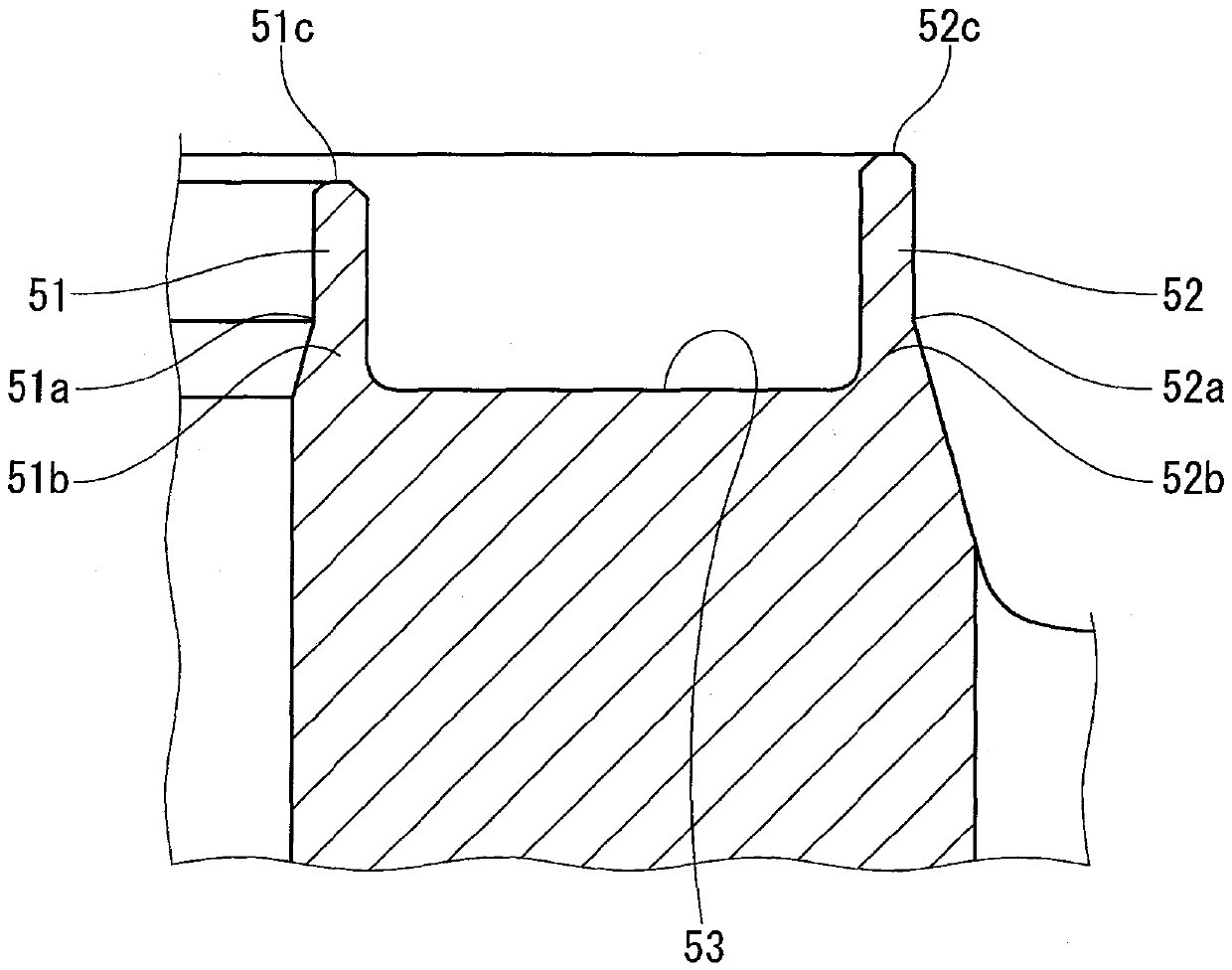

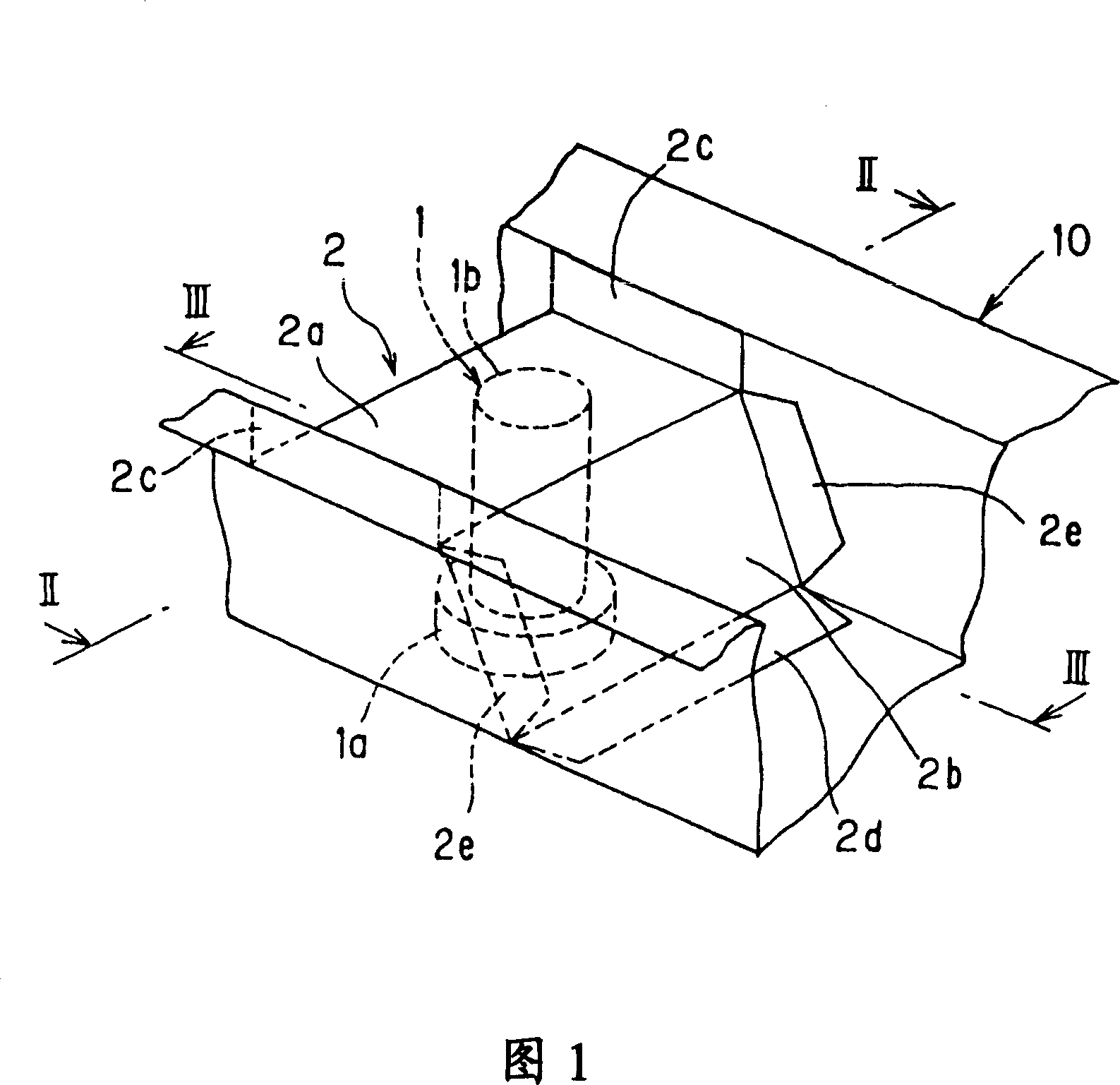

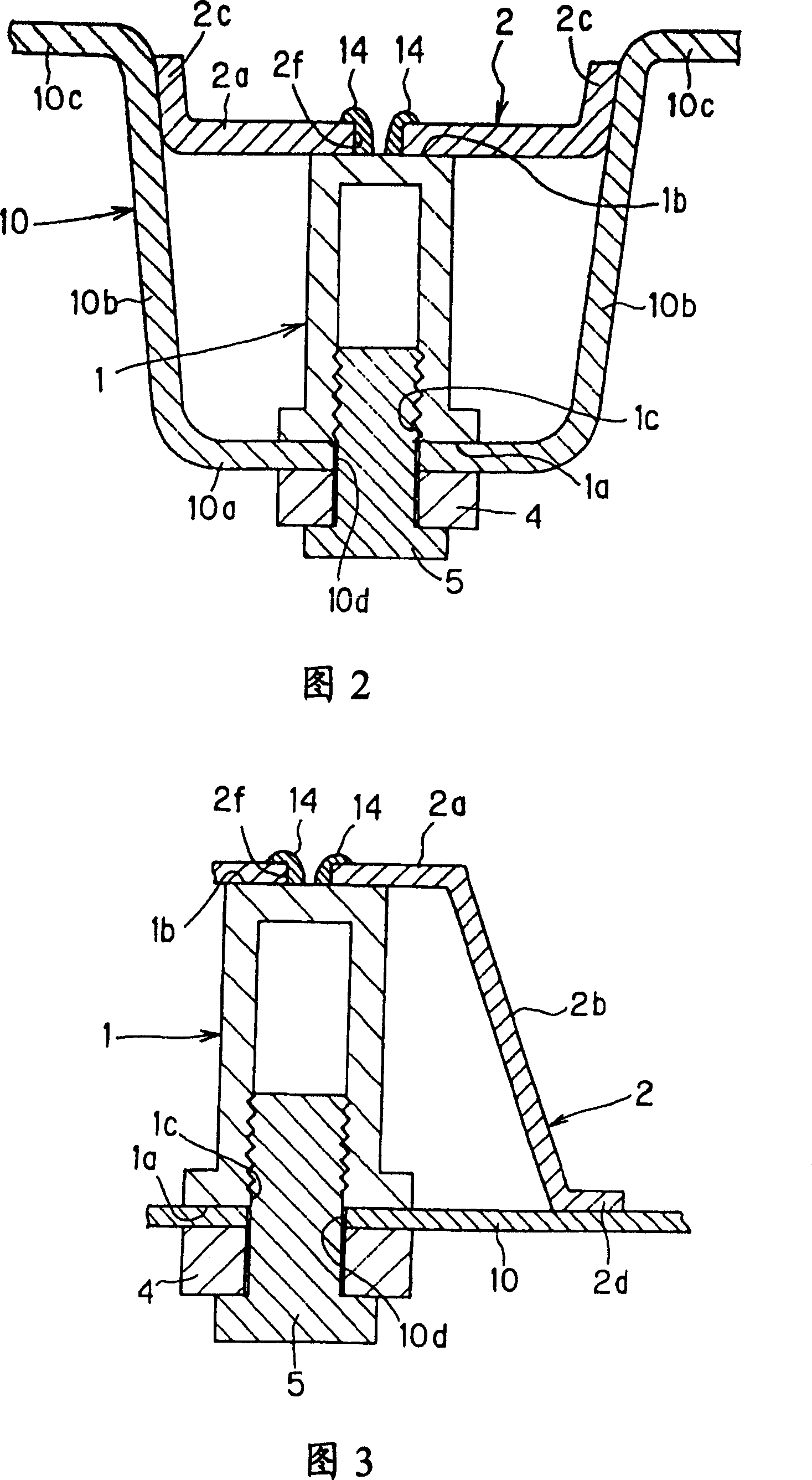

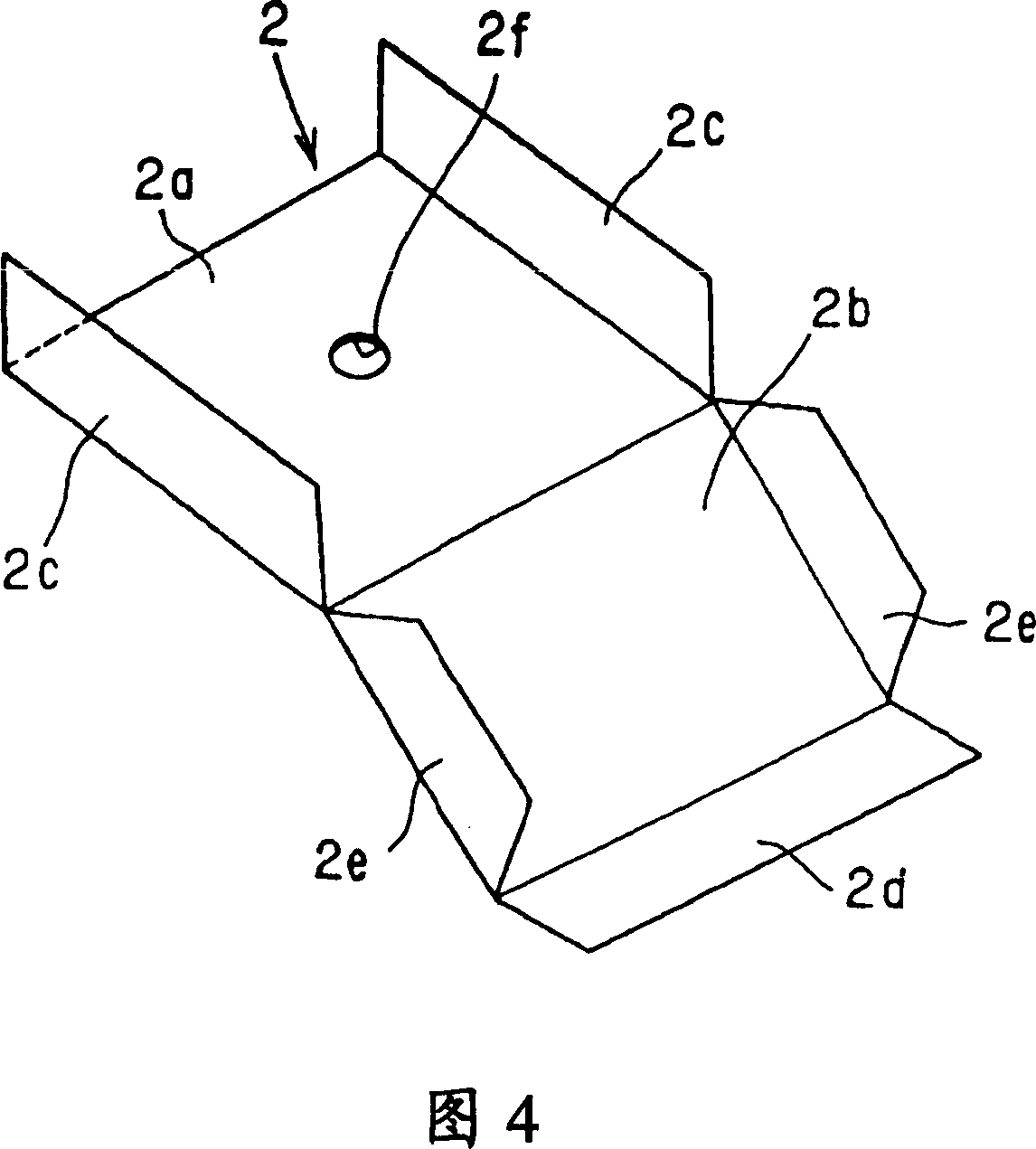

Pipe nut supporting structure

ActiveCN1640750AEasy to fixEasy to assembleUnderstructuresSuperstructure subunitsVehicle frameBody frame

Provided is support structure of a pipe nut improving assemblability. The structure comprises a pipe nut 1 where one end side 1a is supported by matching to a hole part of a vehicle body frame 10, a bolt which is fastened to the pipe nut 1 through the hole part and supports a supported body to the vehicle body frame 10, and a reinforcing member 2 which is fixed to the vehicle body frame 10 and contacted to the other end surface 1b of the other end part of the pipe nut 1, and constituted so as to be mounted by welding the other end surface 1b of the pipe nut 1 and the reinforcing member 2.

Owner:MITSUBISHI MOTORS CORP

Looping tool strickle and its manufacturing method

Owner:KARL MAYER TEXTILMASCHFAB GMBH

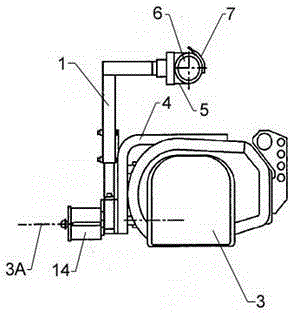

Printing press cylinder

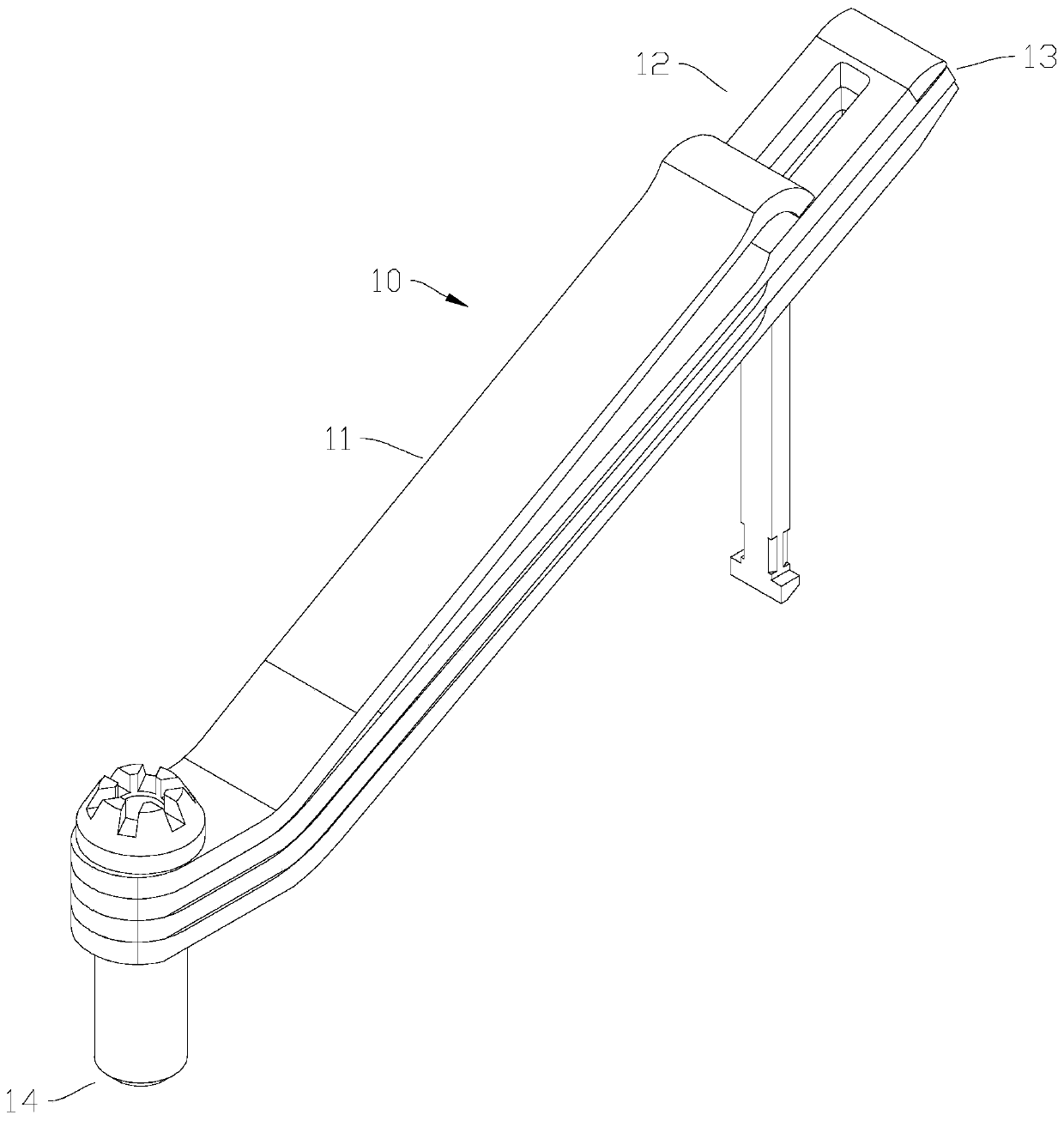

InactiveCN101310976AImproved shape stabilityReduced risk of bendingPrinting roller shellsRotary pressesCardboardFiber

The invention relates to a printing machine roller (10) with a roller basal body (11) and a function layer forming an outer surface of the printing machine. According to the invention, the roller basal body (11) is made of textile fabric or hardboard soaked by phenolic resin.

Owner:M A N ROLAND DRUCKMASCHINEN AG

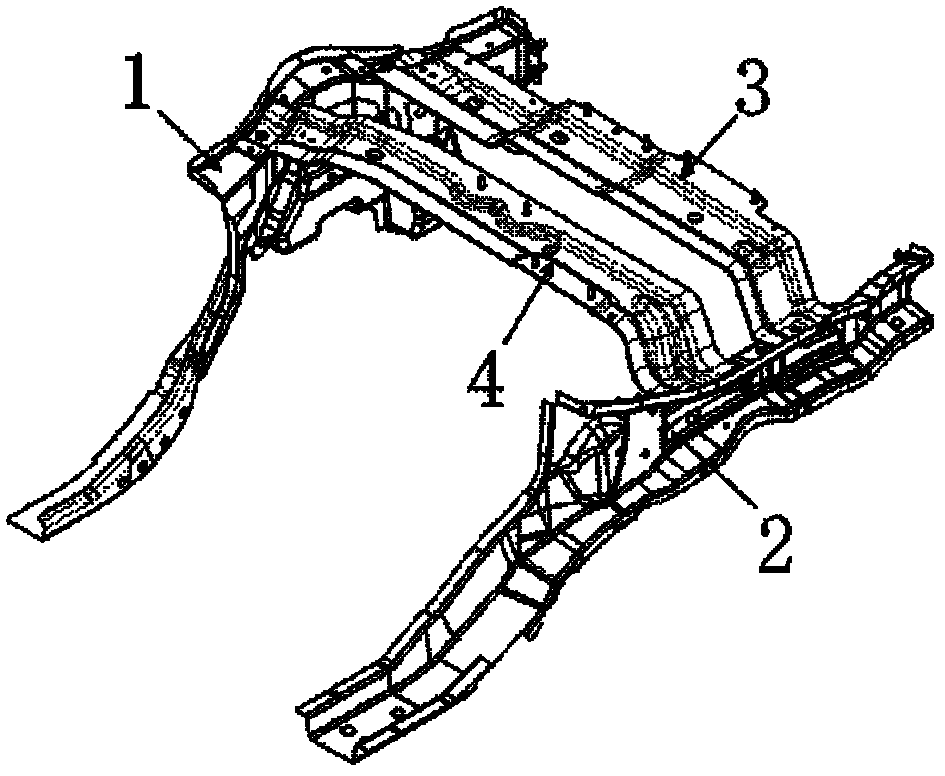

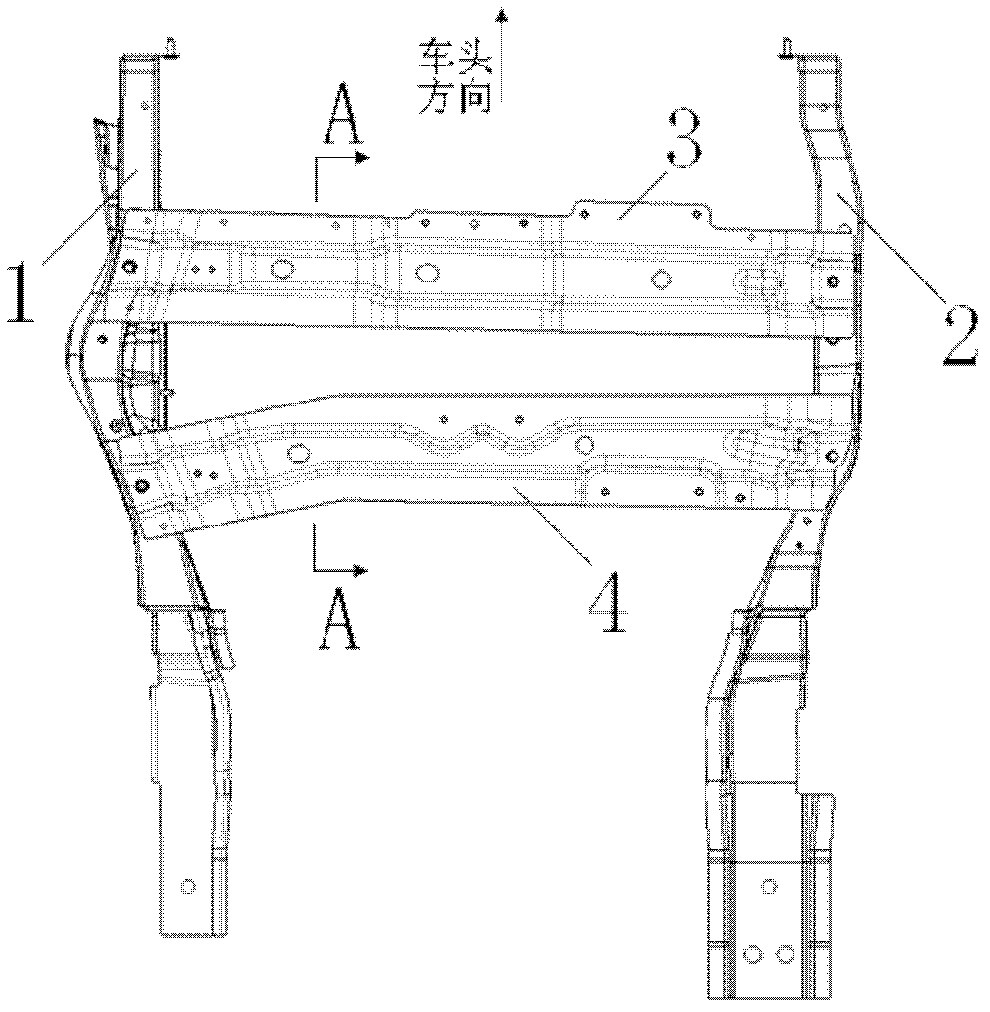

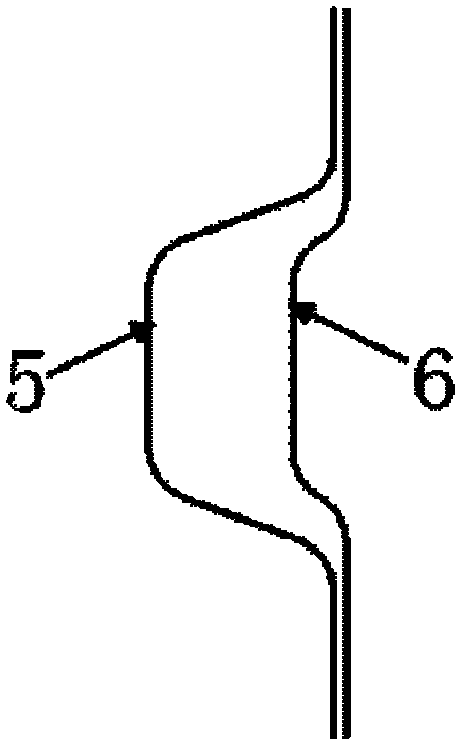

Front cabin element fixing structure for electric vehicle

InactiveCN102358250AFirmly connectedHigh strengthElectric propulsion mountingElectric/fluid circuitEngineeringElectric vehicle

The invention discloses a front cabin element fixing structure for an electric vehicle. The front cabin element fixing structure for the electric vehicle comprises a left longitudinal beam assembly and a right longitudinal beam assembly arranged on the two sides of a front cabin; and a front-cabin front inner beam assembly and a front-cabin back inner beam assembly which are used for fixing elements in the front cabin are arranged between the left longitudinal beam assembly and the right longitudinal beam assembly. Therefore, the connectivity of the left longitudinal beam assembly and the right longitudinal beam assembly is enhanced and the rigidity of an overall vehicle, particularly the front cabin, is improved. The two beams are made into a cavity structure by adopting two layers of plates, so that the strength and the rigidity of an overall beam are effectively improved, the risk of bending the beam is reduced, and the Z-directional precision of an installation point can be ensured. A plurality of connecting pieces are reduced, so that the weight and the cost of the overall vehicle are reduced favorably, and further the performance and the competitive power of the overall vehicle are further increased.

Owner:CHERY AUTOMOBILE CO LTD

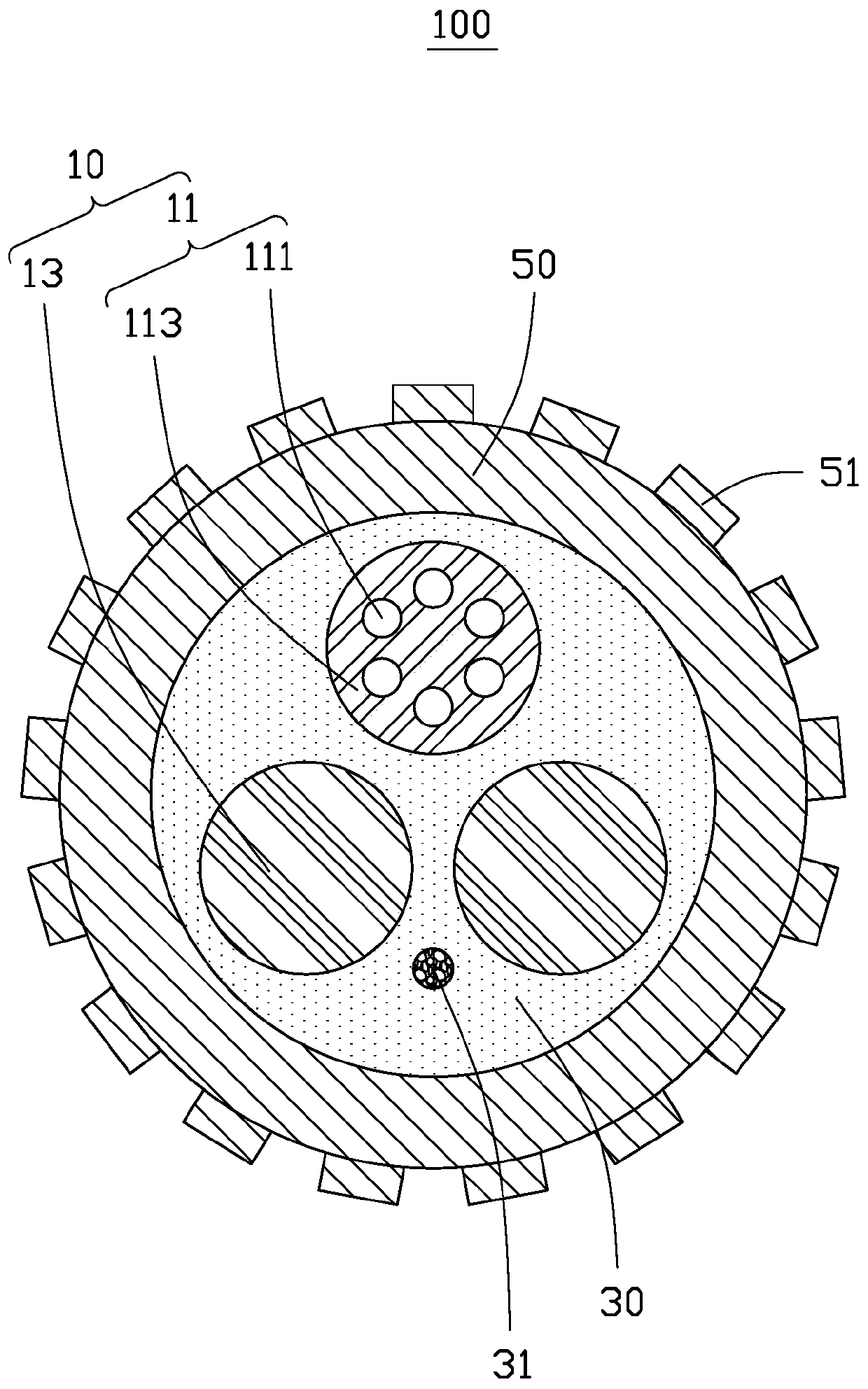

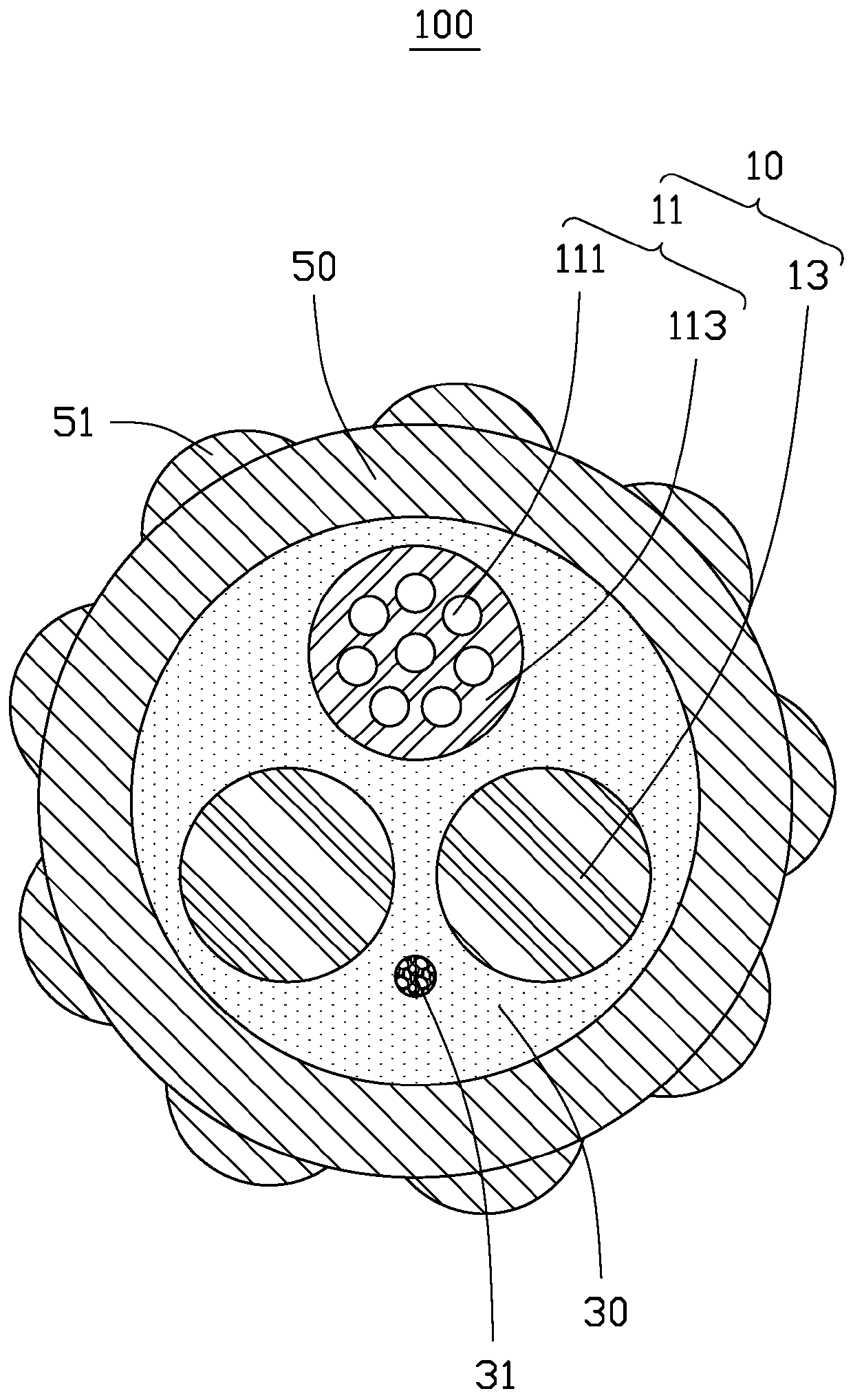

Air-blowing micro-cable and preparation method thereof

InactiveCN111596427AImprove rigidityHigh tensile strengthFibre mechanical structuresMechanical engineeringCore (optical fiber)

The invention discloses an air-blowing micro-cable and a preparation method thereof; the air-blowing micro-cable is provided with an outer sheath and a cable core arranged in the outer sheath; the cable core comprises three optical fiber units and three reinforcing units, the optical fiber units and the reinforcing units are arranged in a stranded mode, the optical fiber units and the reinforcingunits are stranded in a one-way S mode, and the periphery of the cable core is coated with a reinforcing layer. The invention provides the air-blowing micro cable. Compared with a traditional air-blowing optical fiber unit, the optical fiber unit cured through resin and the reinforcing unit are adopted for twisting the cable core, the rigidity of the optical cable is effectively improved, the reinforcing layer is coated, the tensile strength of the air-blowing micro-cable is further improved, and the bending risk of the air-blowing micro-cable is reduced; the air-blowing micro-cable is suitable for rapid long-distance air-blowing laying, and the construction laying efficiency is improved.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

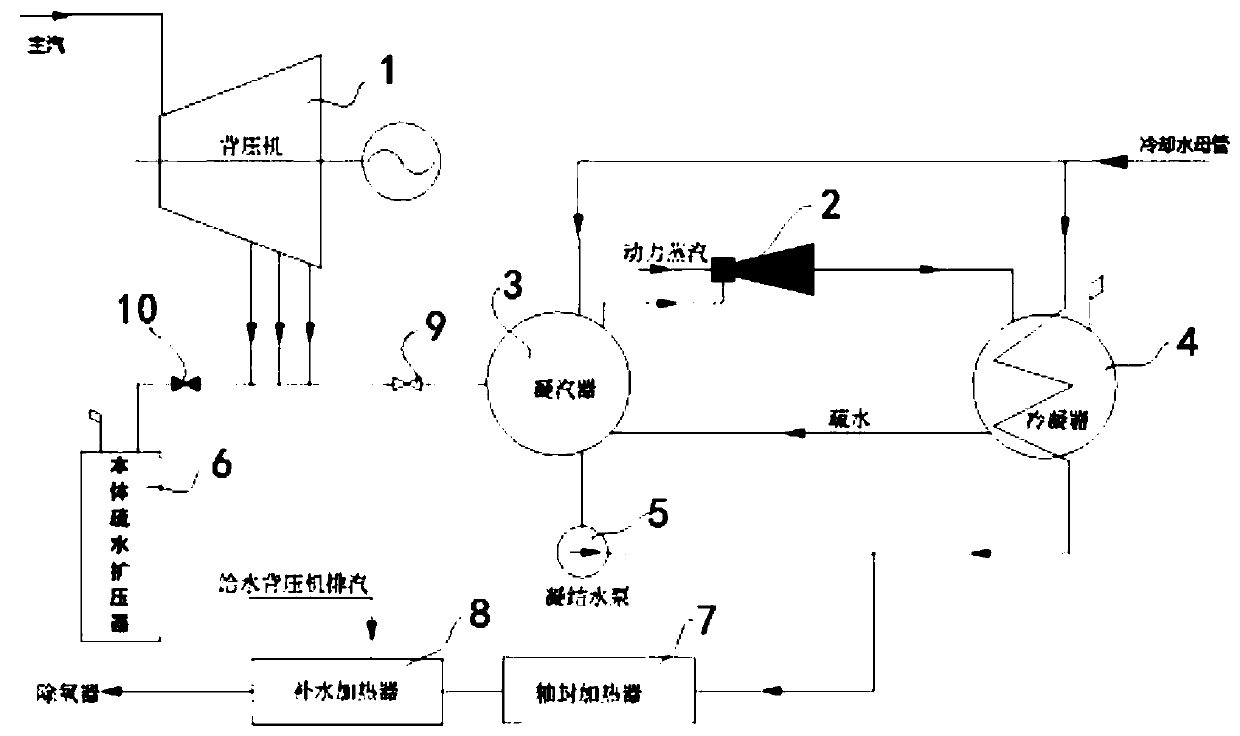

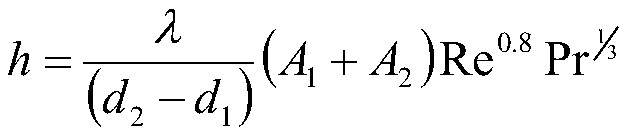

Back pressure type steam turbine rapid starting method based on cold end optimization

InactiveCN110410161AHydrophobic exhaust increasedImprove the heating effectMachines/enginesEngine startersEnd systemEngineering

The invention discloses a back pressure type steam turbine rapid starting method based on cold end optimization. The back pressure type steam turbine comprises a negative pressure cold end system, thenegative pressure cold end system comprises a back pressure machine and a cooling water main pipe, one side of an output end of the back pressure machine is connected with a body hydrophobic expansion container, and the other end of the output end of the back pressure machine is connected with a steam condenser. The steam condenser is connected with a condensate pump and a steam-jetting steam extractor, and an outlet of the steam-jetting stream extractor is connected with a condenser. When back pressure type steam turbine is used, the heating speed of a steam cylinder can be increased, the temperature difference between an upper and lower cylinders of the steam turbine is reduced, the risk of dynamic and static collision grinding and large shaft bending is reduced, the steam turbine is safer and more stable, the safety of a power plant is improved, meanwhile, emission of carbon dioxide, sulfur dioxide, nitrogen oxide and the like can be reduced, the steam exhaust and hydrophobic heatof the back pressure machine is recycled, meanwhile, the outward steam supply amount of the power plant is increased, and the economical efficiency of the power plant is improved. The method is suitable for starting processes of various back-pressure steam turbines and is suitable for popularization and use.

Owner:程琛

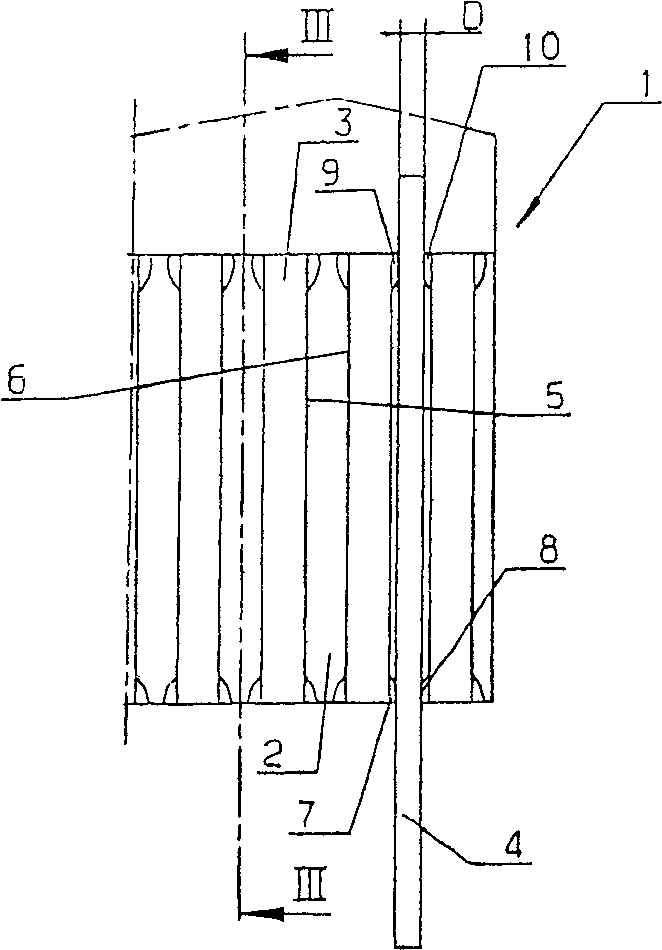

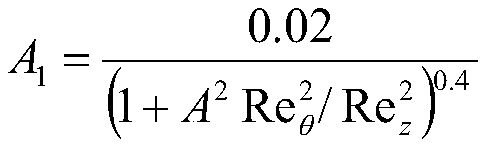

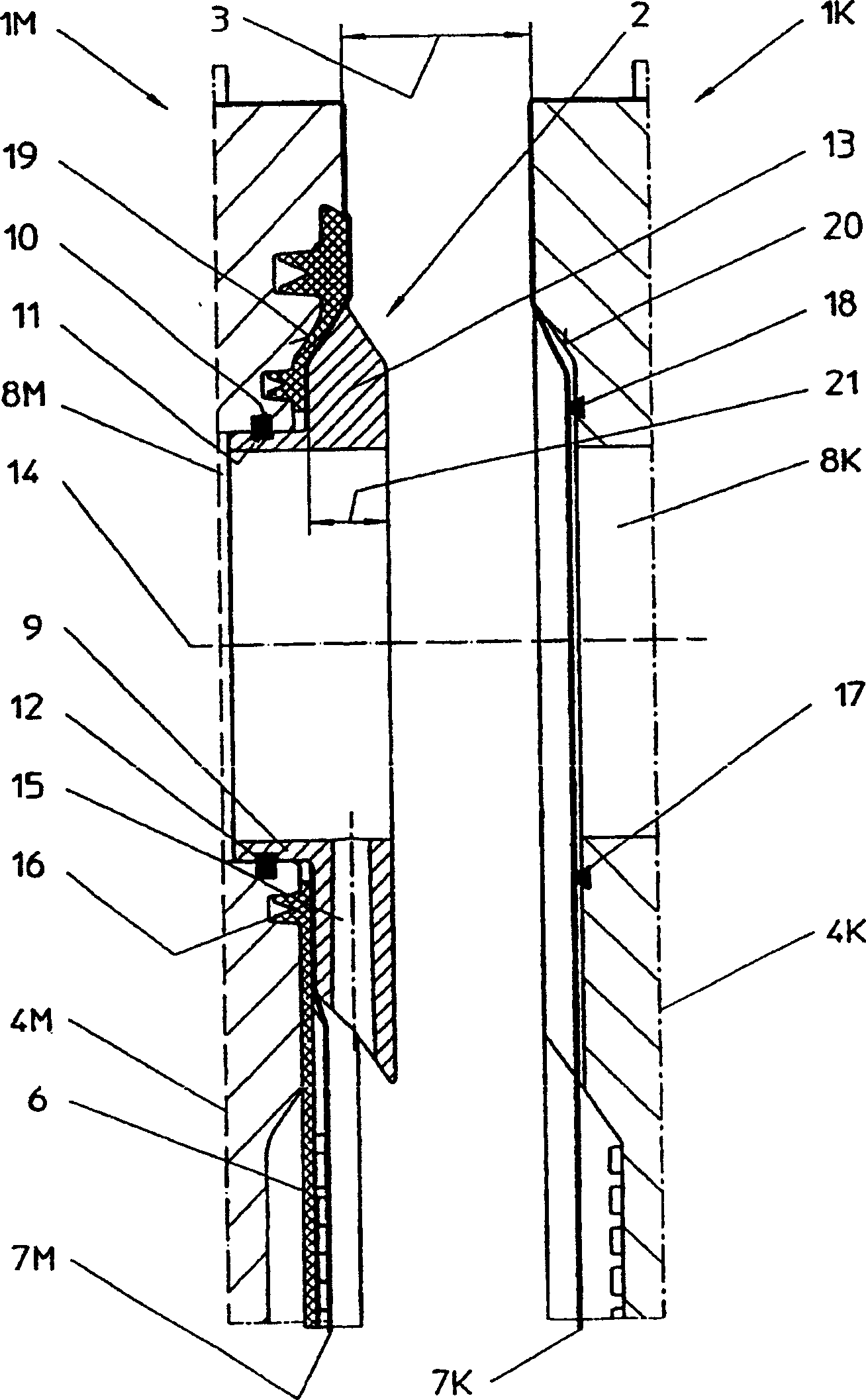

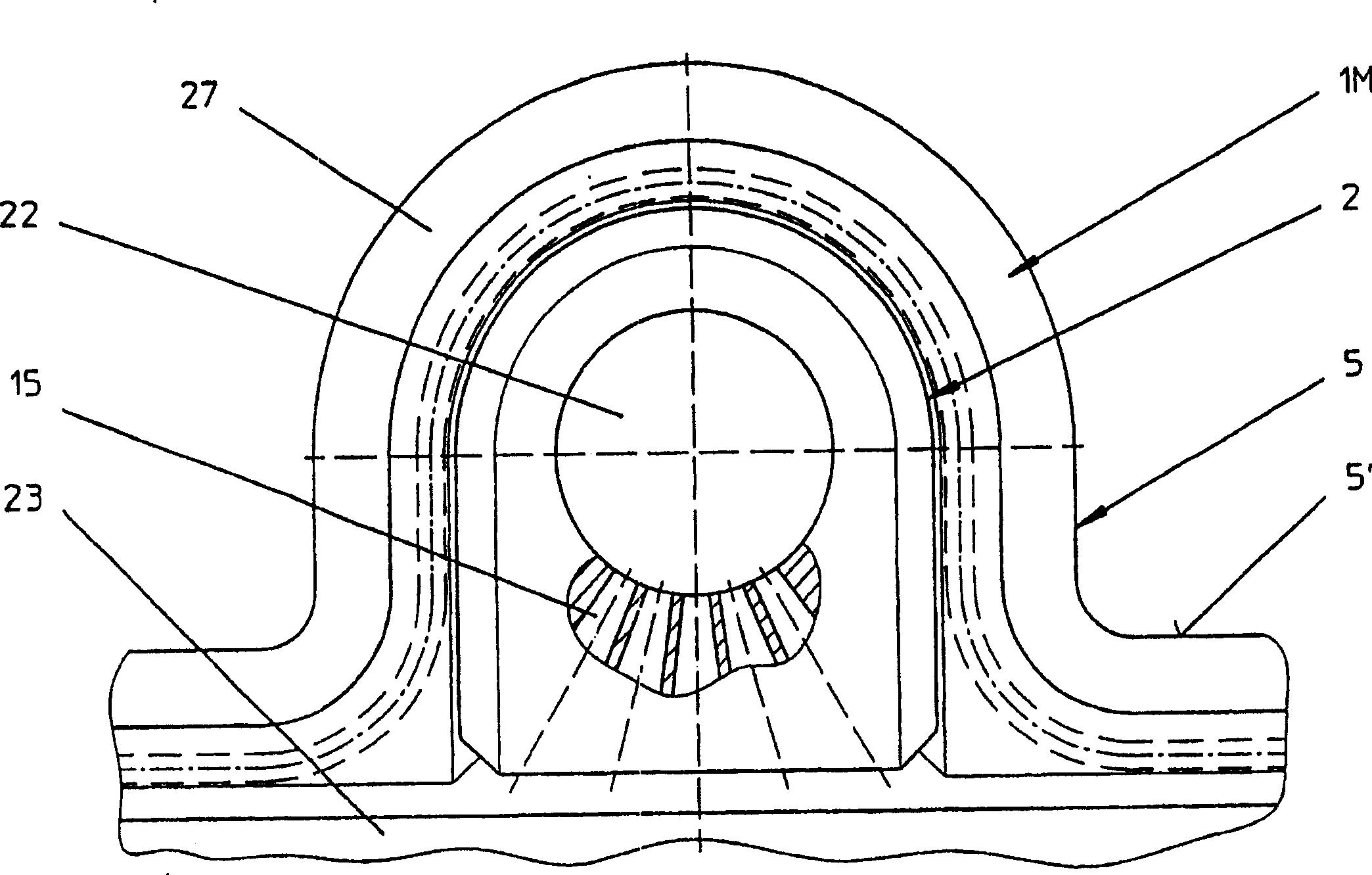

Filter plate of filter press

InactiveCN1160143CReduce manufacturing costReduce maintenanceFiltration separationEngineeringFilter press

The invention relates to a filter press (1) for filtering suspensions that comprises a plurality of filter plates (1M, 1K) that can be displaced in parallel with respect to one another. In a filtering position, said filter plates can be compressed to a package that comprises a filter chamber (23) between respective two filter plates (1M, 1K), said chamber being provided with at least one filter cloth (7M, 7K). In a discharge position, adjoining filter plates (1M, 1K) can be moved apart by a discharge distance (3) so that the filter cake adhering to the filter cloth (7K) can be discharged. Every filter chamber (3) is correlated with at least one filling element (2) for feeding the suspension to the filter chamber (23). The aim of the invention is to prevent leakages in the zone of the peripheral sealing edge, to guarantee an unimpaired filter capacity during feeding and to facilitate operation of the filter press without an external supply line and outgoing connection lines. To this end, the filling element (2) is disposed on a joining piece (5) that extends outside a plate level and within a sealing edge (27) on the periphery of the filter plates (1M, 1K) and that can be linked with a filter plate (1M). In the filtering position, the filling elements (2) form a suspension supply channel (22) that extends through the filter plate package and are sealingly wedged between adjoining filter plates (1M, 1K).

Owner:OUTOKUMPU OY

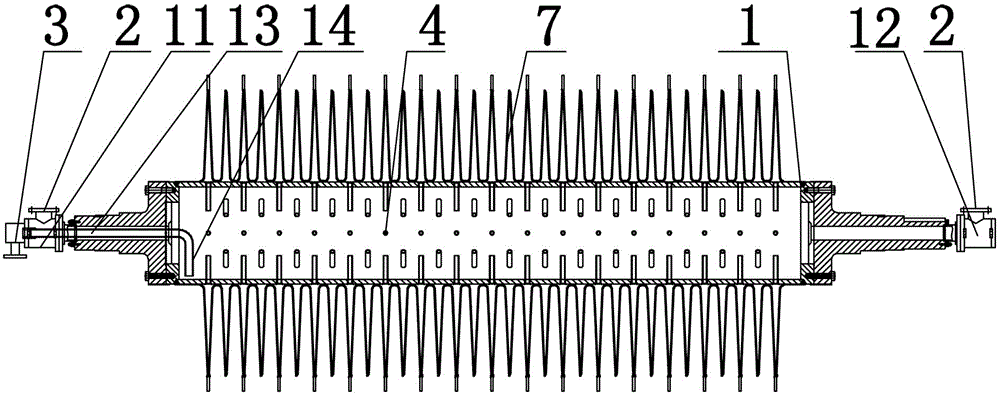

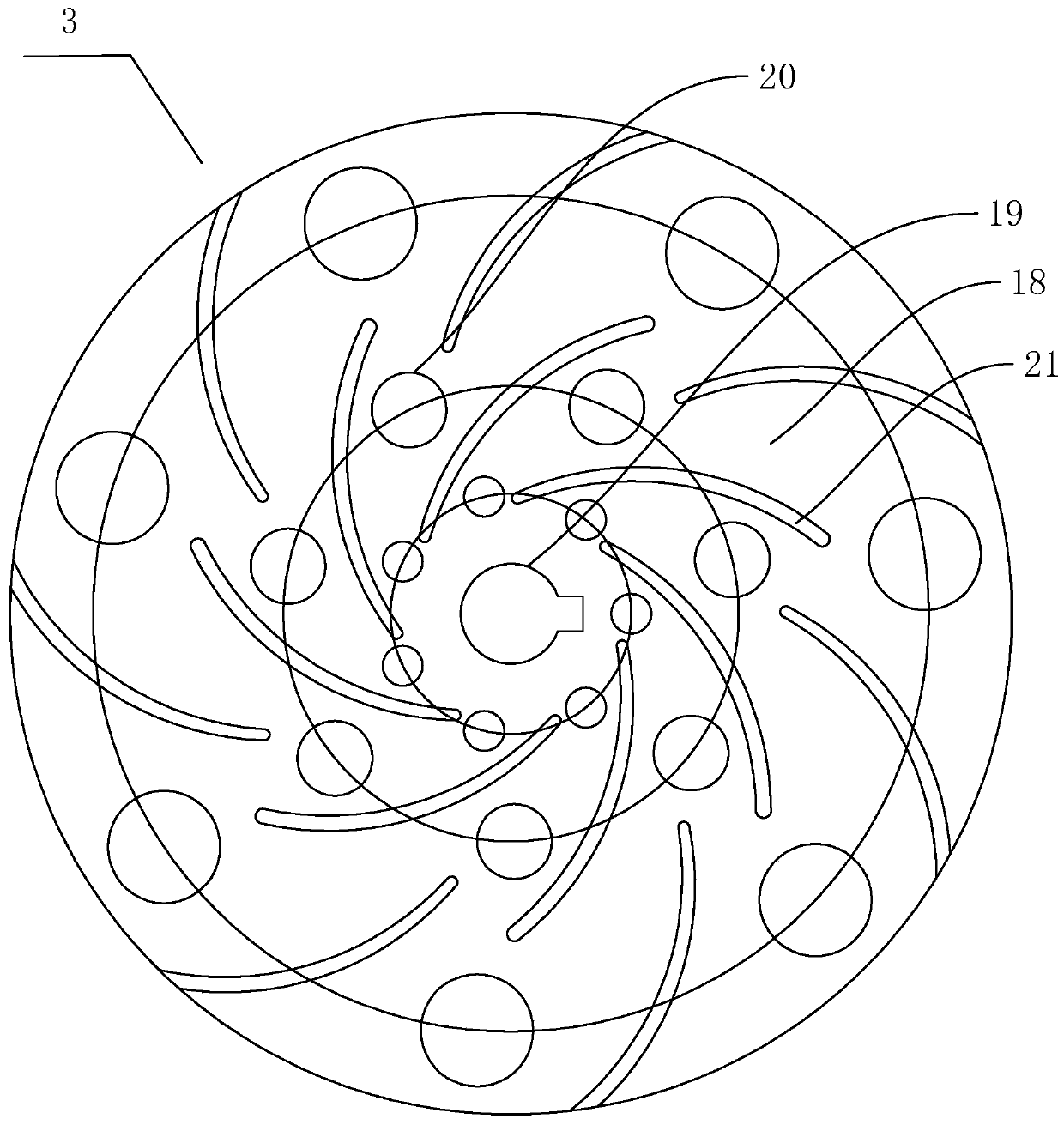

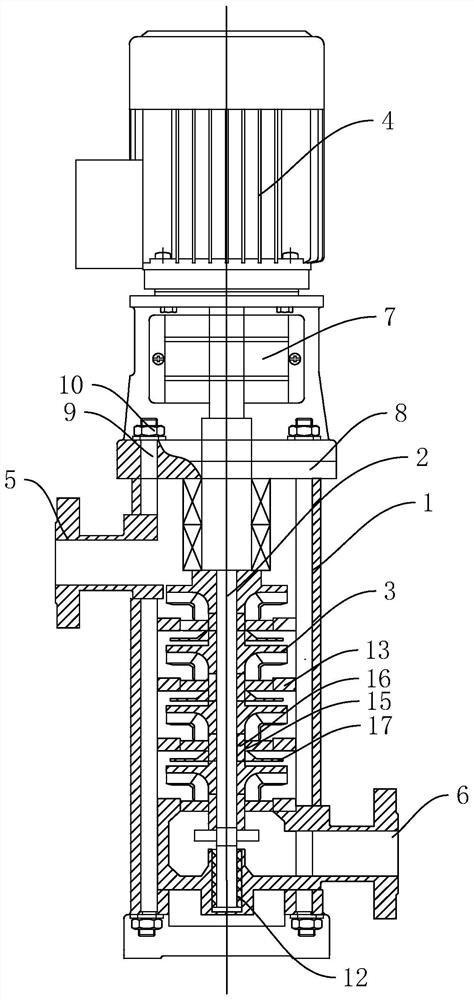

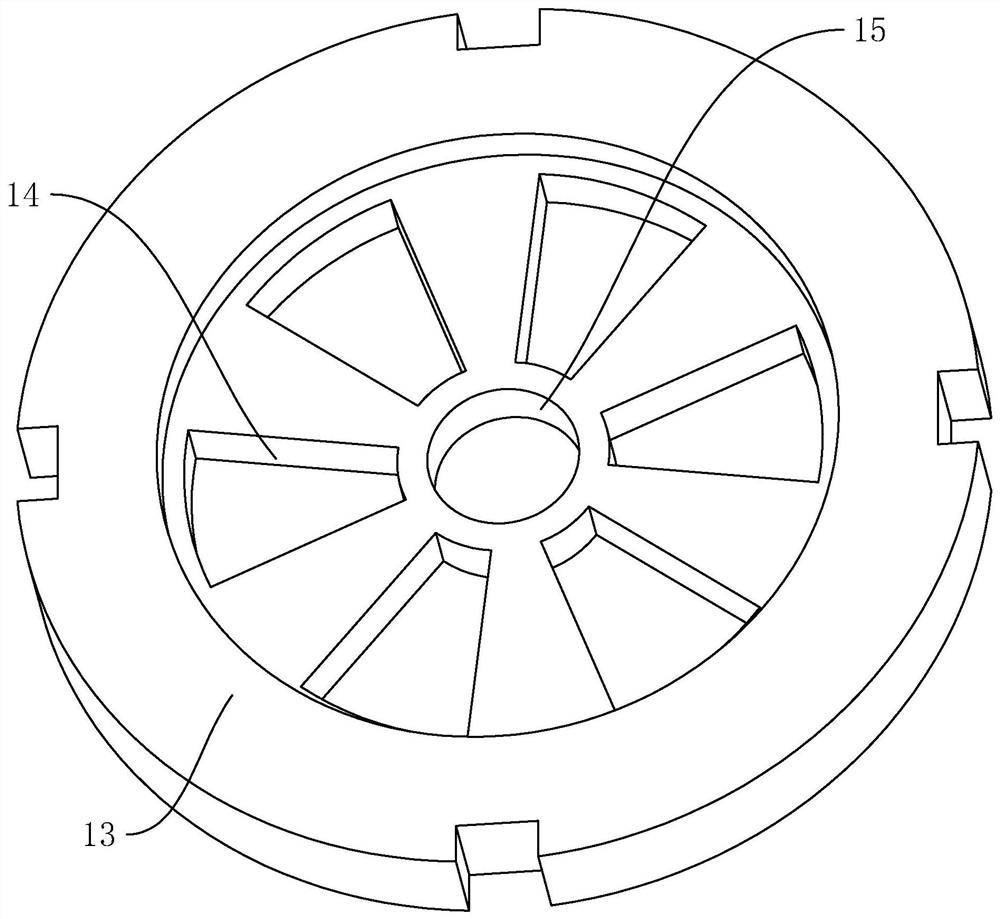

Disc type drier

ActiveCN103395958BEfficient drying operationExtended service lifeSludge treatment by de-watering/drying/thickeningEngineeringWater hammer

The invention relates to a disc type drier. The disc type drier comprises a machine shell and a drying mechanism arranged in the machine shell, wherein the drying mechanism comprises a shaft rod and shaft heads sleeved at the two ends of the shaft rod, and the shaft heads are provided with steam inlets and condensate outlets; a plurality of guiding pipe groups are uniformly distributed on the shaft rod, guiding pipes of each guiding pipe group are uniformly distributed on the same shaft section of the shaft rod, and each guiding pipe group comprises a plurality of condensate water guiding pipes and a plurality of steam guiding pipes; heat transfer discs are sleeved on the shaft rod by corresponding to the guiding pipe groups one by one, and the heat transfer discs are formed by welding two disc-shaped pieces in an opposite manner; a radial gap formed by the two disc-shaped pieces is internally provided with a plurality of guiding plate groups, and the guiding plate groups are arranged in match with the condensate water guiding pipes. The disc type drier provided by the invention has the advantages that large amount of condensate water in the heat transfer discs can be rapidly discharged through the condensate water guiding pipes, and the heat exchange efficiency is high; the guiding pipe groups and the heat transfer discs are uniform to distribute and drain, a water hammer effect is unlikely to cause, the damage risk of the shaft rod is reduced, the service life of the drier is prolonged, the driving energy consumption is reduced, and the maintenance cost is reduced.

Owner:天通新环境技术有限公司

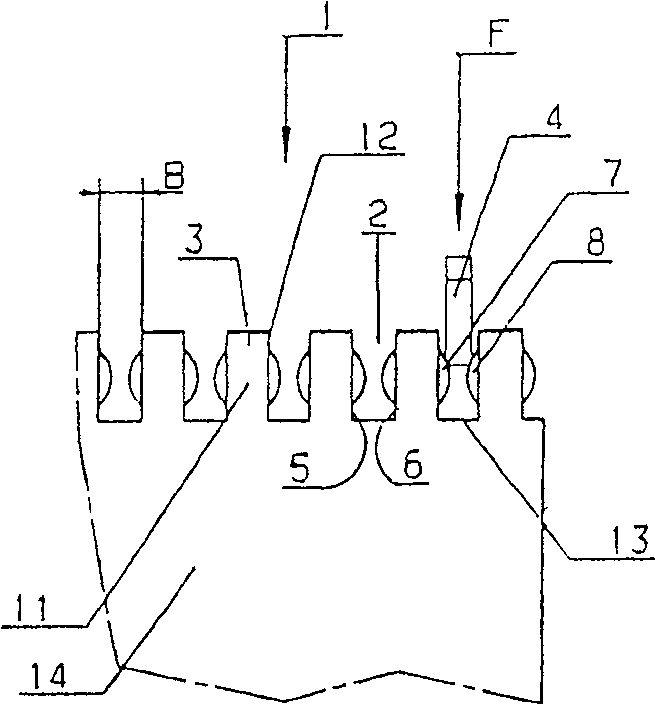

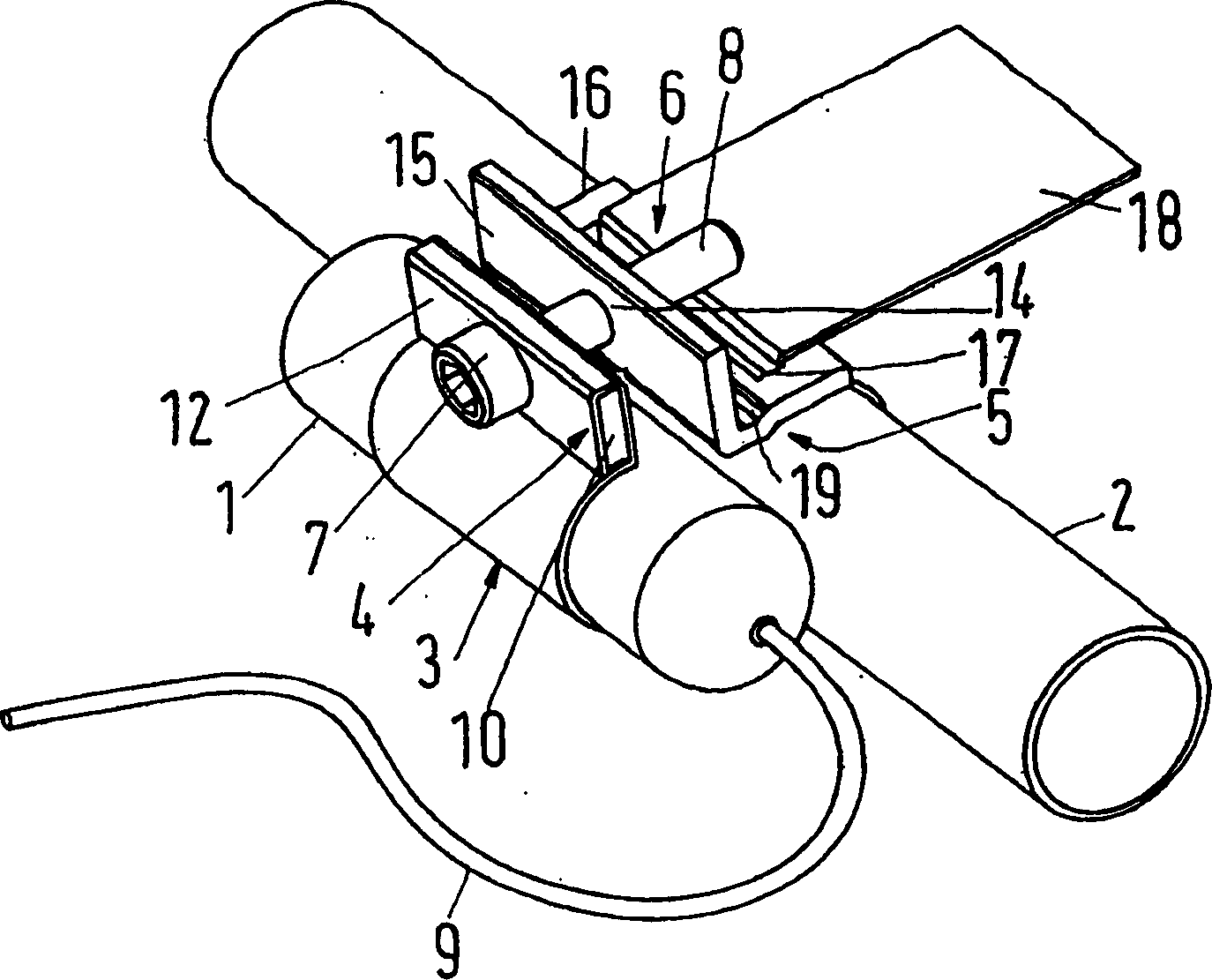

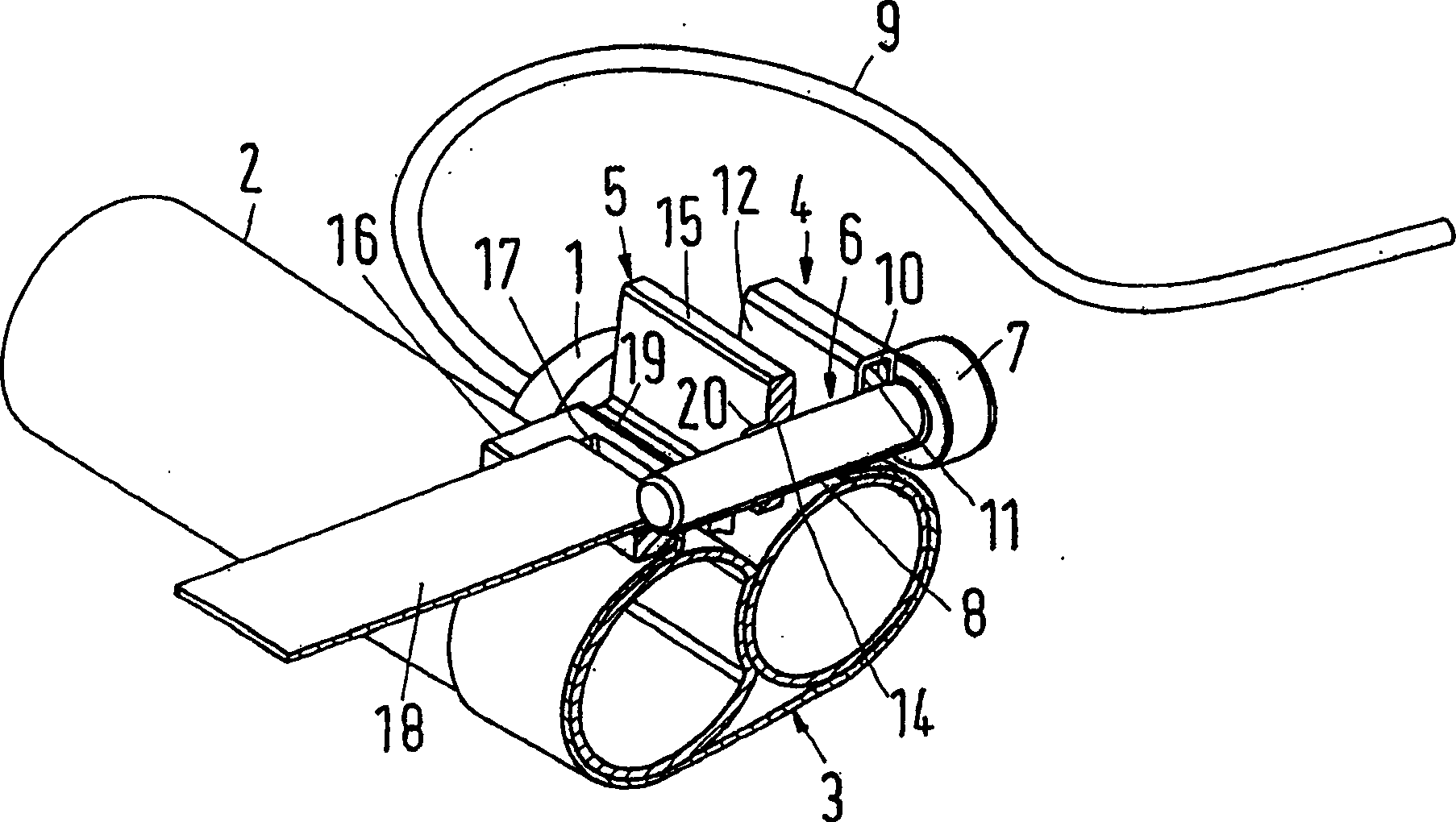

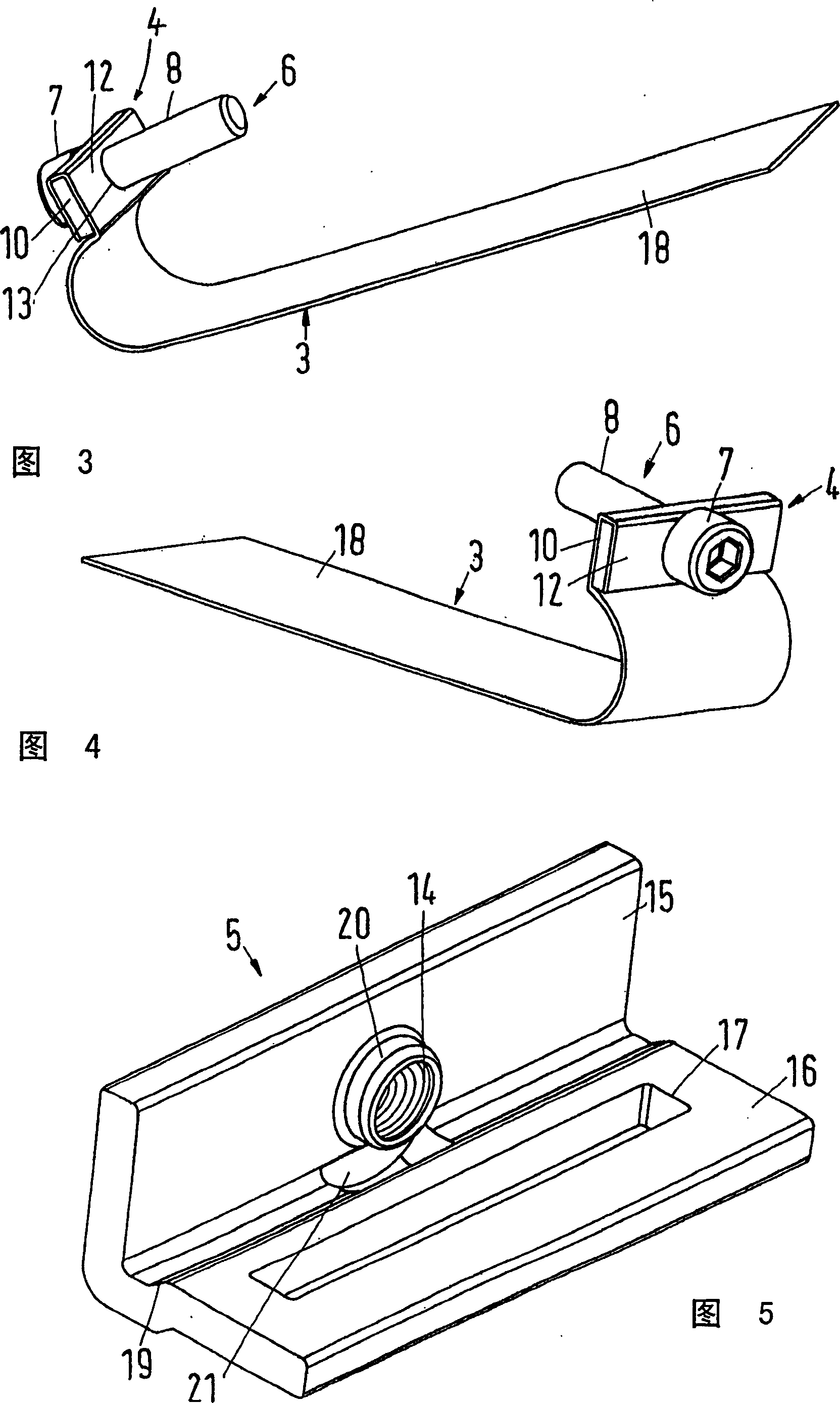

Clamp capable of axial parallelly connecting cylinder shape temp sensor with pipe

InactiveCN1246656CReduce heat transfer resistanceReduce stressThermometer detailsPipe supportsEngineeringScrew thread

A clamp for connecting a cylindrical temperature sensor 1 axis-parallel with a tube 2 has a bendable metallic tension band 3 which tension band on its one end portion 12 has a first jaw 4 and at its other end section 18 is shapewise connectable with a second jaw 5, and which clamp also has a tension screw 6. The tension screw 6 is inserted through a bore 11 in the first jaw 4 and is threaded through a threaded bore 14 in the second jaw 5. To be able to connect the sensor 1 and tube 2 rigidly with little heat transfer resistance the second jaw 5 has a bent plate with two legs 15, 16. The first leg 15 is provided with the threaded bore 14 and the second leg 16 with a slot 17 through which the other end section 18 can be passed. The tension band length is so chosen that the other end section 18 after the wrapping of the tension band 3 around the temperature sensor 1 and the tube 2 as well as its being passed through the slot 17 is bendable down onto the second leg 16. The tension screw length is so chosen that after its tightening it lies on the bent down end section 18.

Owner:DANFOSS AS

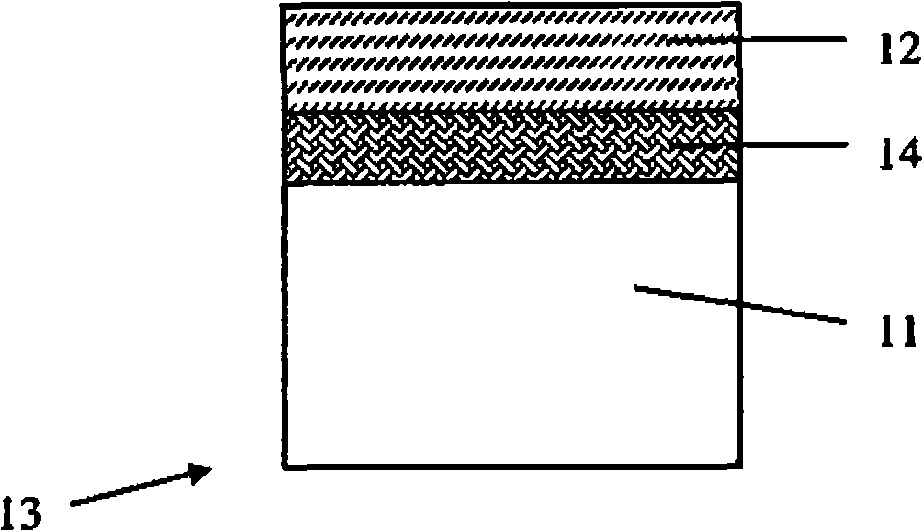

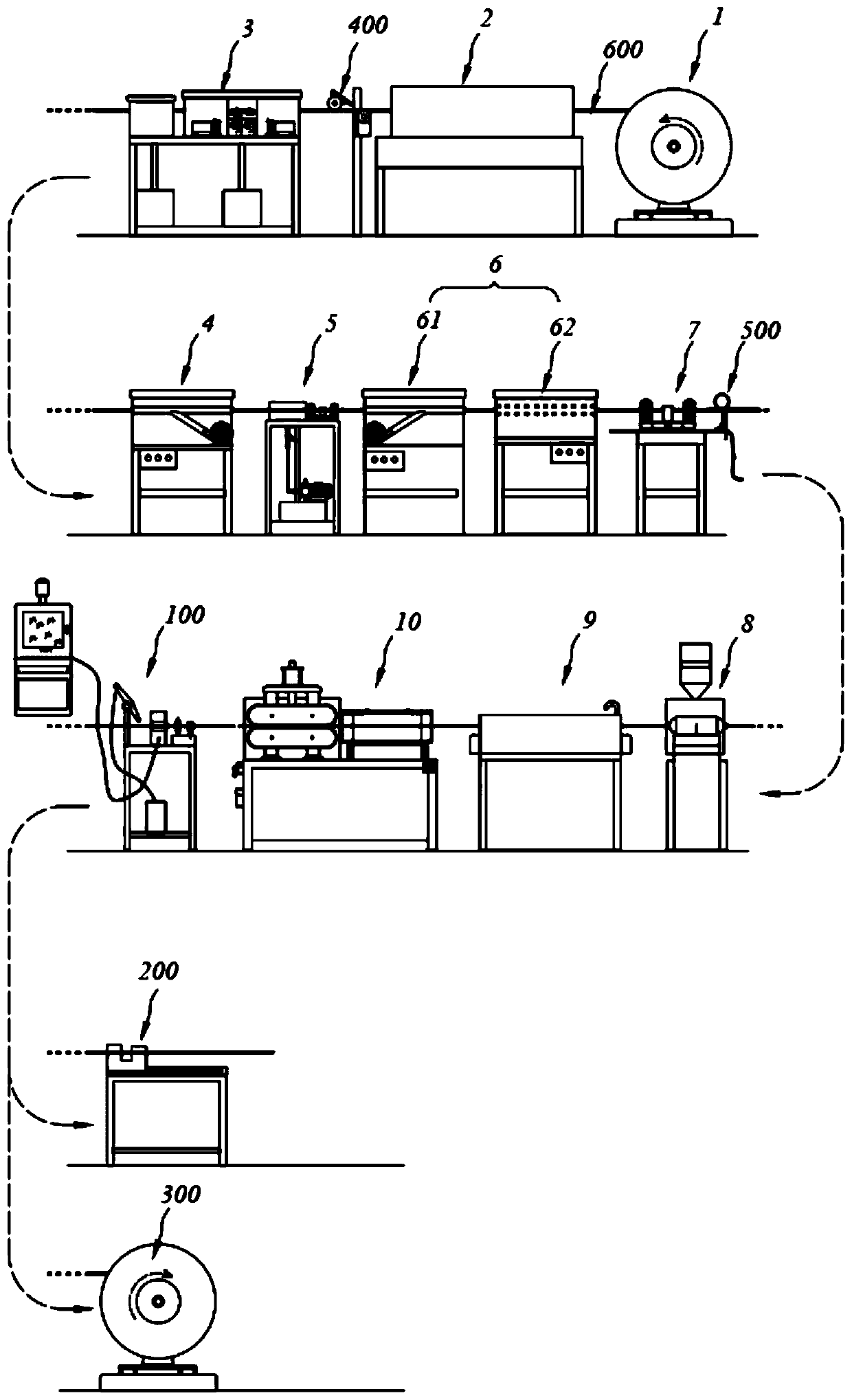

Aluminum pipe surface resin coating system

InactiveCN110802002AReduced risk of bendingReduce the risk of being stretchedShaping toolsHollow article cleaningComposite materialCooling Units

The invention relates to an aluminum pipe surface resin coating system. A discharging unit, a cleaning unit, a drying unit, a gluing unit, a heating unit, a resin coating unit, a cooling unit, a traction unit and a collecting unit are sequentially arranged in the advancing direction of an aluminum pipe, wherein a pipe diameter correcting unit is arranged between the discharging unit and the cleaning unit; and the discharging unit adjusts the position and speed of the aluminum pipe discharged by the discharging unit according to the position of the aluminum pipe at the pipe diameter correctingunit, so that the aluminum pipe discharged by the discharging unit and the aluminum pipe at the pipe diameter correcting unit are coaxial and the speed is the same. By moving the discharging unit, thecenter axis of the aluminum pipe and the center axis of the aluminum pipe on a production line are coaxial in the discharging process, and the bending risk is reduced; and meanwhile, the dischargingspeed of the aluminum pipe is controlled, the speed of the aluminum pipe in the discharging process and the speed of the aluminum pipe on the production line are kept consistent, the risk that the aluminum pipe is stretched can be reduced, the production quality of the aluminum pipe is improved, and unqualified products are reduced.

Owner:NINGBO INTELLIGENCE INNOVATIVE MATERIALS TECH CO LTD +1

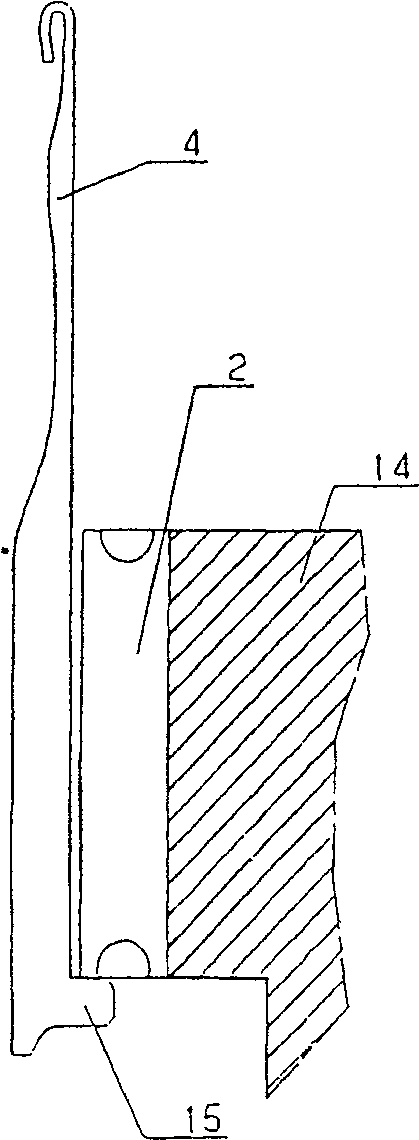

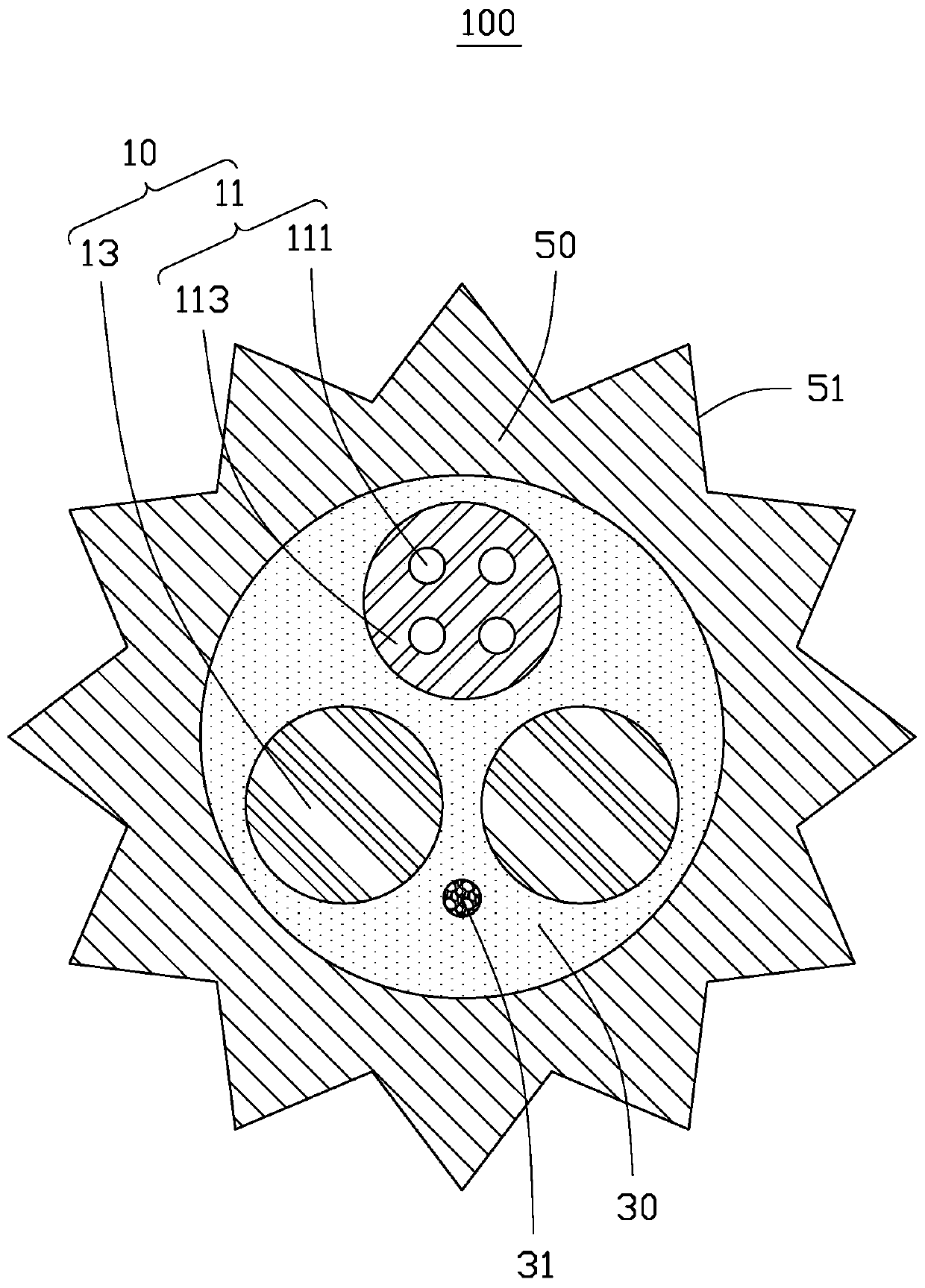

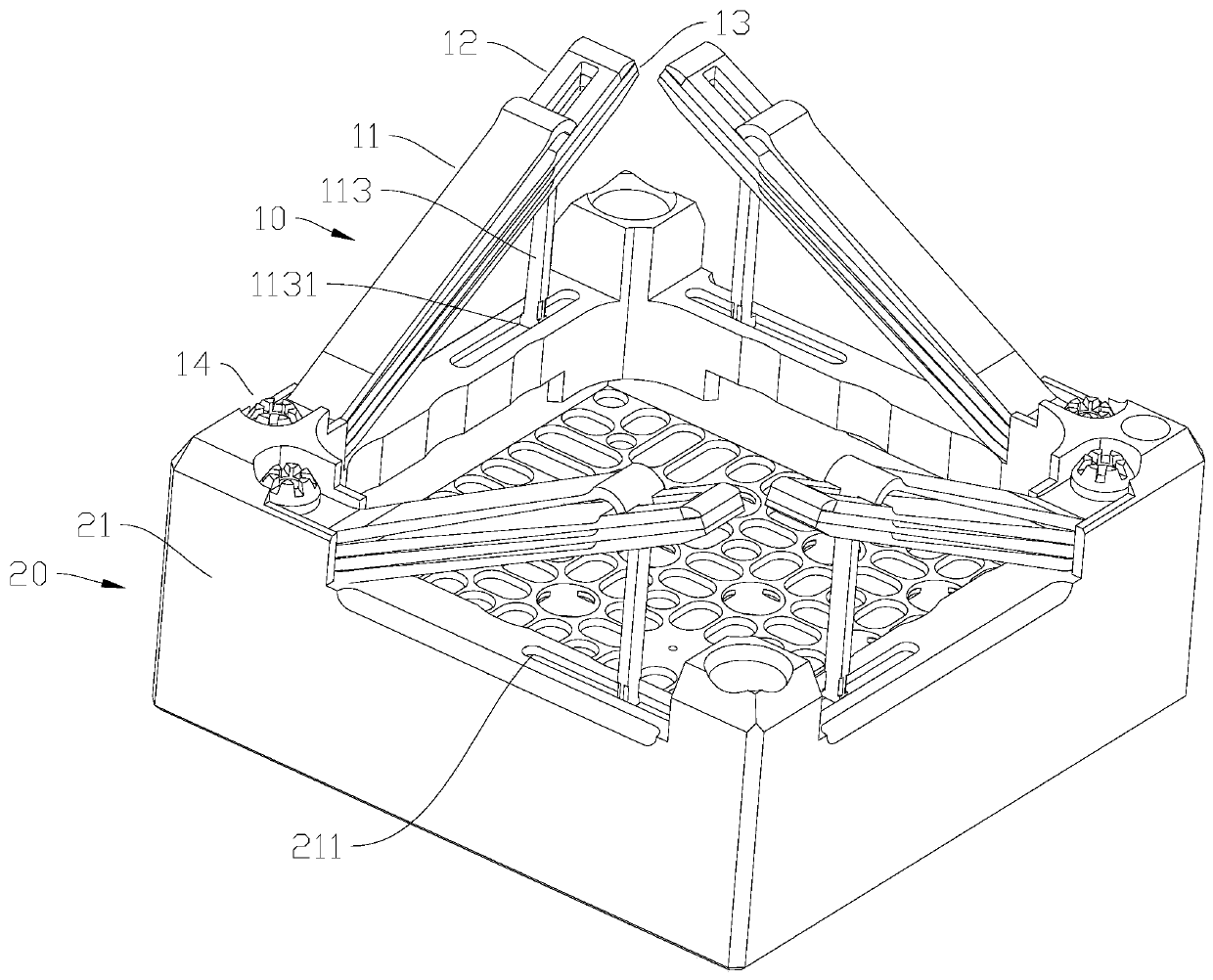

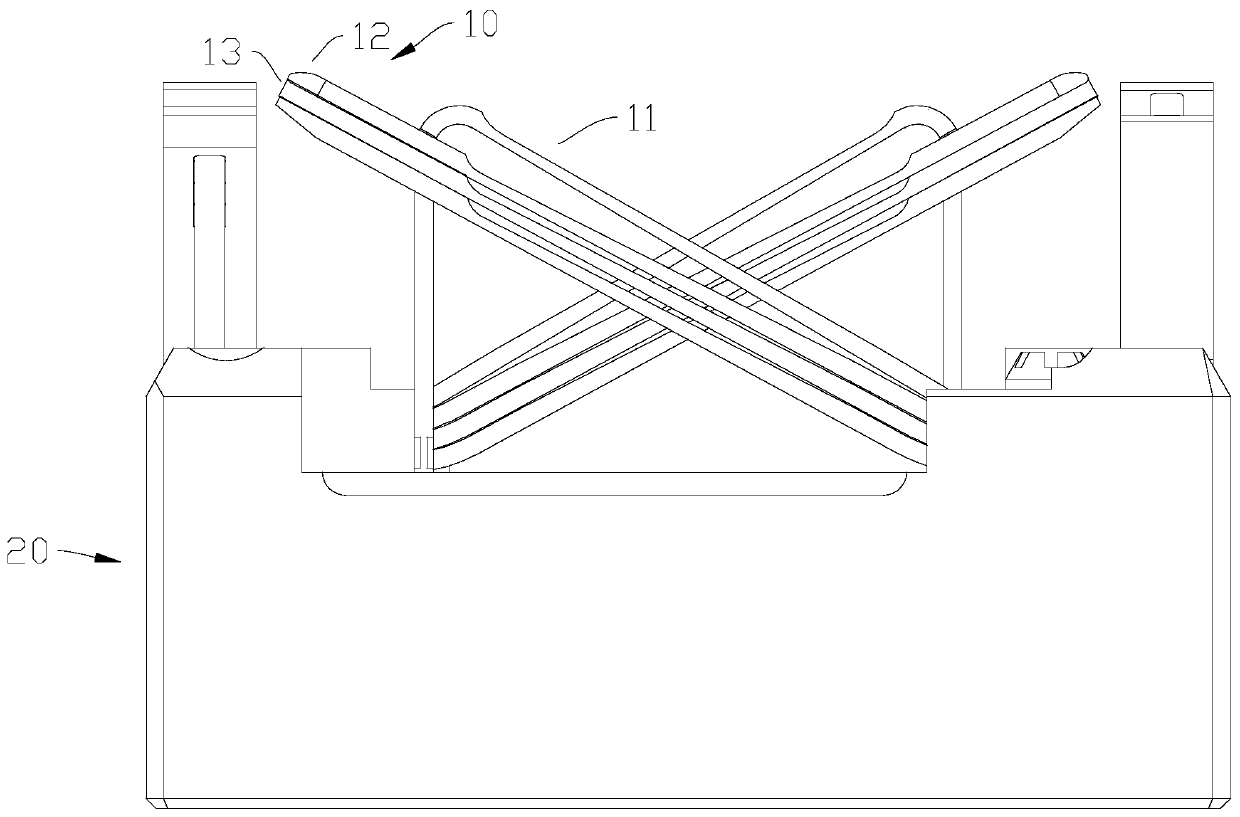

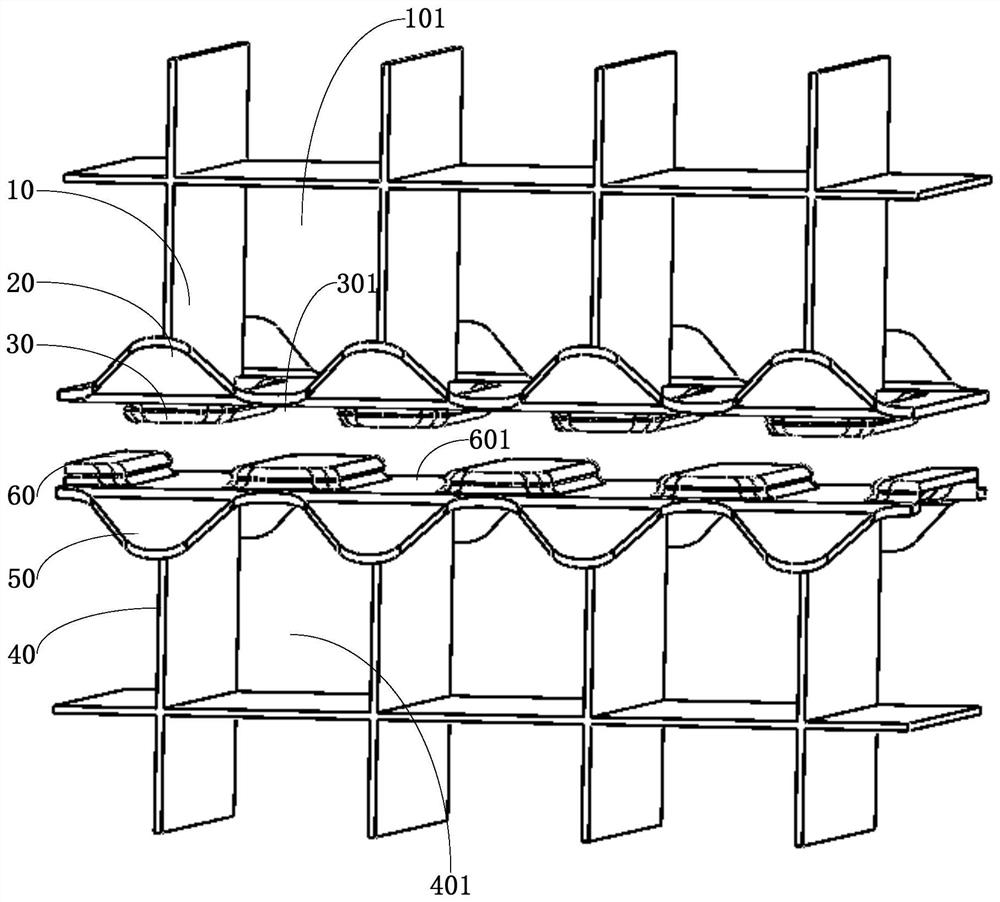

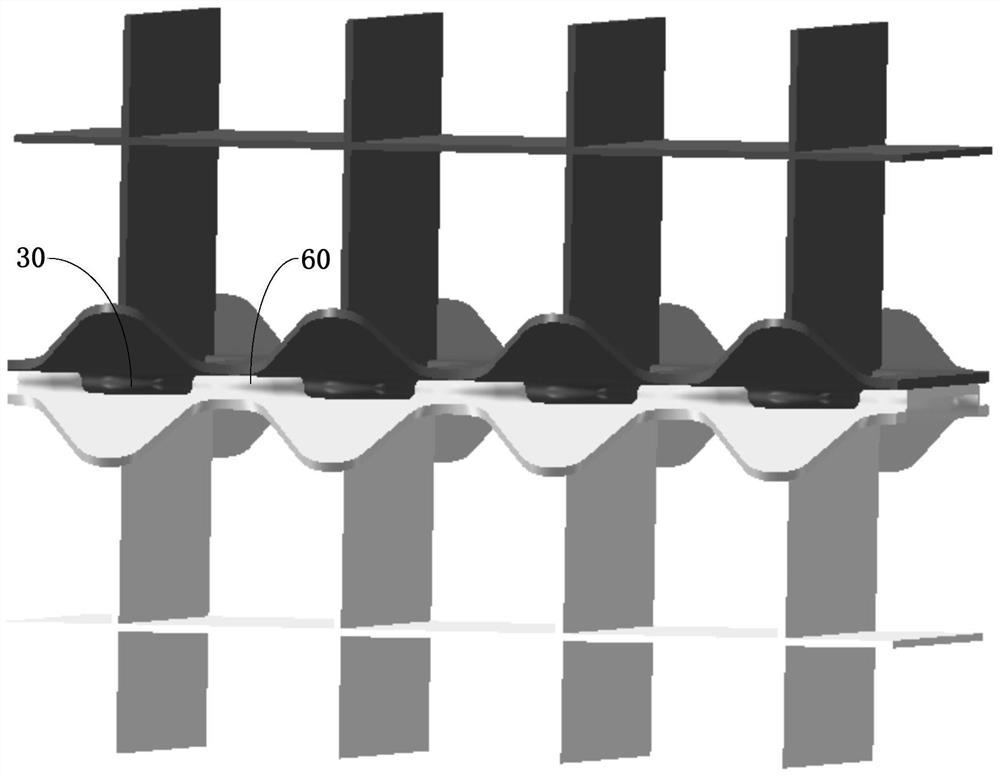

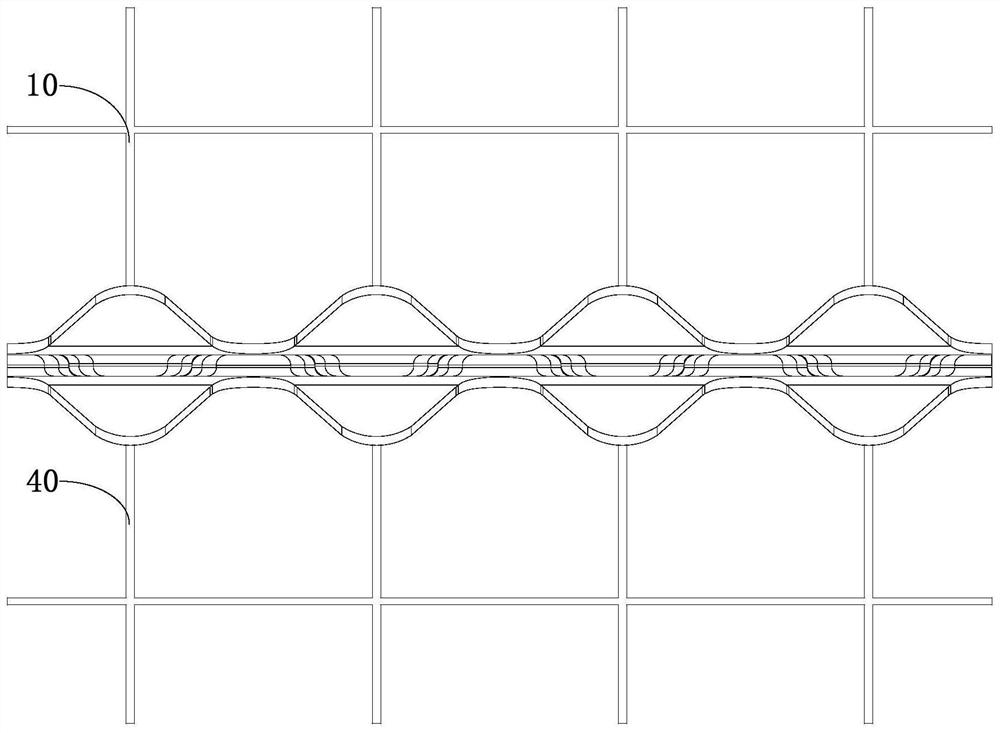

Nuclear fuel assembly and variable-rigidity pressing device

ActiveCN110993127AReduced risk of bendingReduce creep relaxationNuclear energy generationFuel element assembliesStructural engineeringMechanical engineering

The invention relates to a nuclear fuel assembly and a variable-rigidity pressing device. The variable-rigidity pressing device comprises a plurality of pressing units. Each pressing unit comprises afirst plate spring and a second plate spring which are sequentially arranged in a stacked mode from top to bottom. The first plate spring comprises a first connecting arm, a first inclined arm obliquely extending at one end of the first connecting arm and a vertical arm arranged at the end, away from the first connecting arm, of the first inclined arm. The second plate spring comprises a second connecting arm and a second inclined arm obliquely extending at one end of the second connecting arm and stacked with the first inclined arm. A first window allowing the vertical arm to penetrate through is arranged in the section, away from the second connecting arm, of the second inclined arm, and the length of the second inclined arm is greater than that of the first inclined arm so that the highest point of the second inclined arm is higher than that of the first inclined arm. According to the variable-rigidity pressing device, plastic deformation of the plate spring can be reduced or eliminated, the bending risk of the fuel assembly can be reduced and irradiation stress creep relaxation can be reduced.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

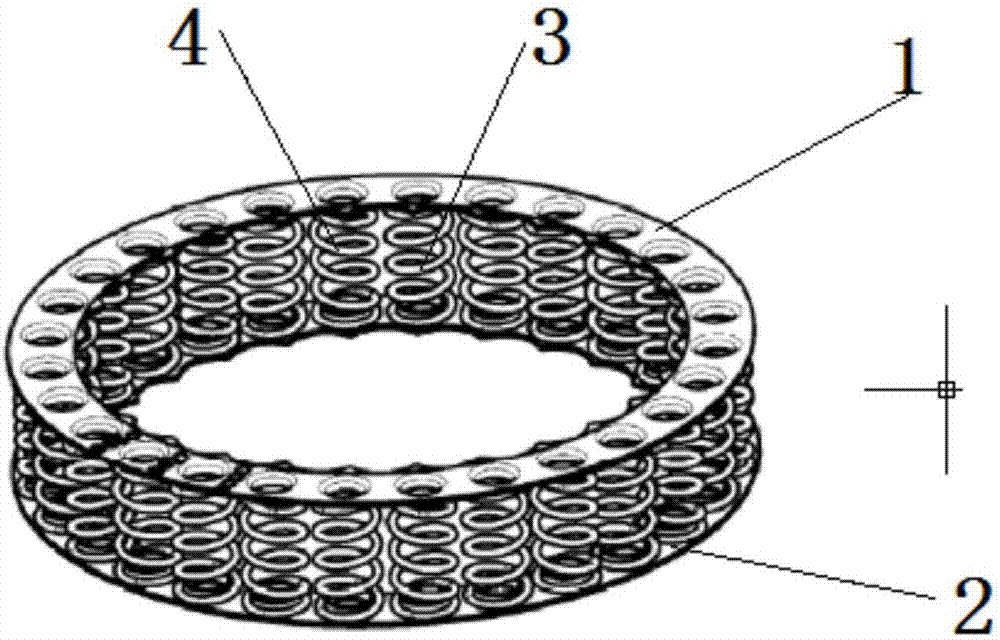

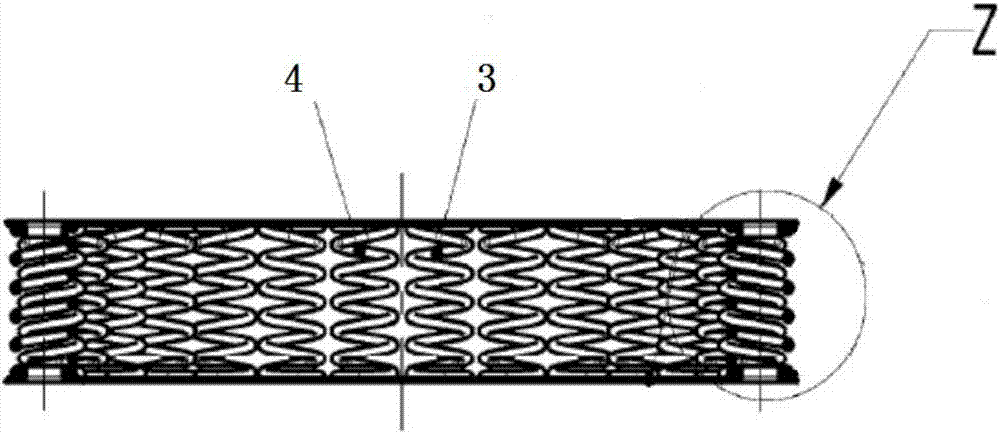

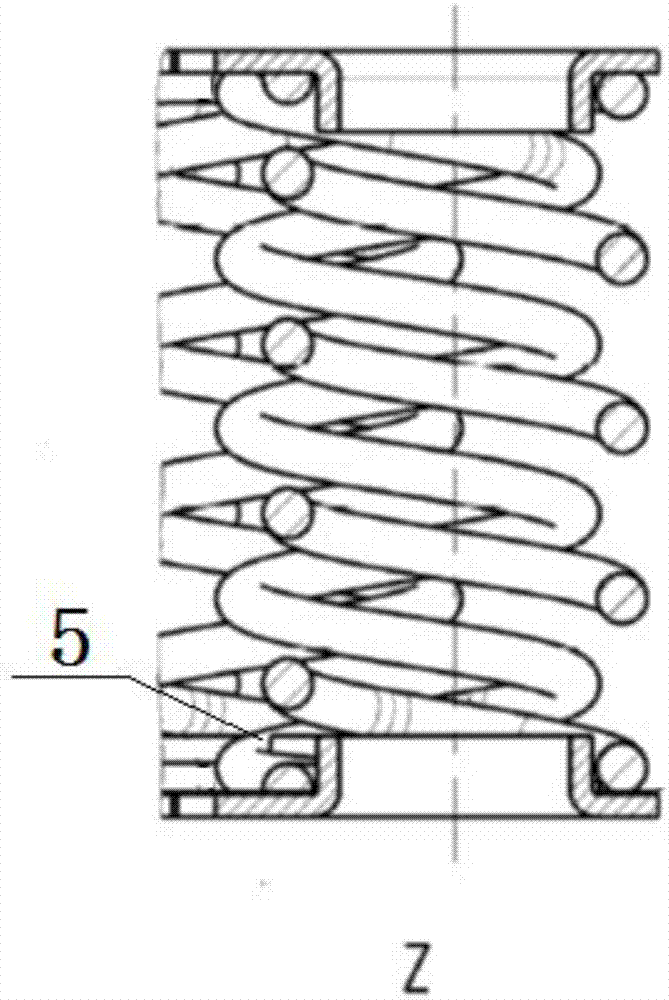

Spring set

PendingCN107355502ACause bendingReduce chafingLow internal friction springsMechanical engineeringPhysics

The invention discloses a spring set. The spring set comprises an upper steel disc, a lower steel disc and a plurality of springs. The upper steel disc and the lower steel disc are arranged in parallel. The upper ends of the springs are fixed to the lower portion of the upper steel disc, the lower ends of the springs are fixed to the upper portion of the lower steel disc, the number of the springs is an even number, the turning directions of every two adjacent springs are different, the number of total coils and the tail coils of the springs are set to be 0.5, the left-hand springs and the right-hand springs are the same in number, height, coil number and other ordinary parameters, and the middle external diameter of each spring is larger than the external diameters of the two ends. The spring set has the beneficial effects that the problems that a spring is bent easily and a spring set is poor in stability and short in service life are solved, and the service life is prolonged.

Owner:安庆谢德尔汽车零部件有限公司

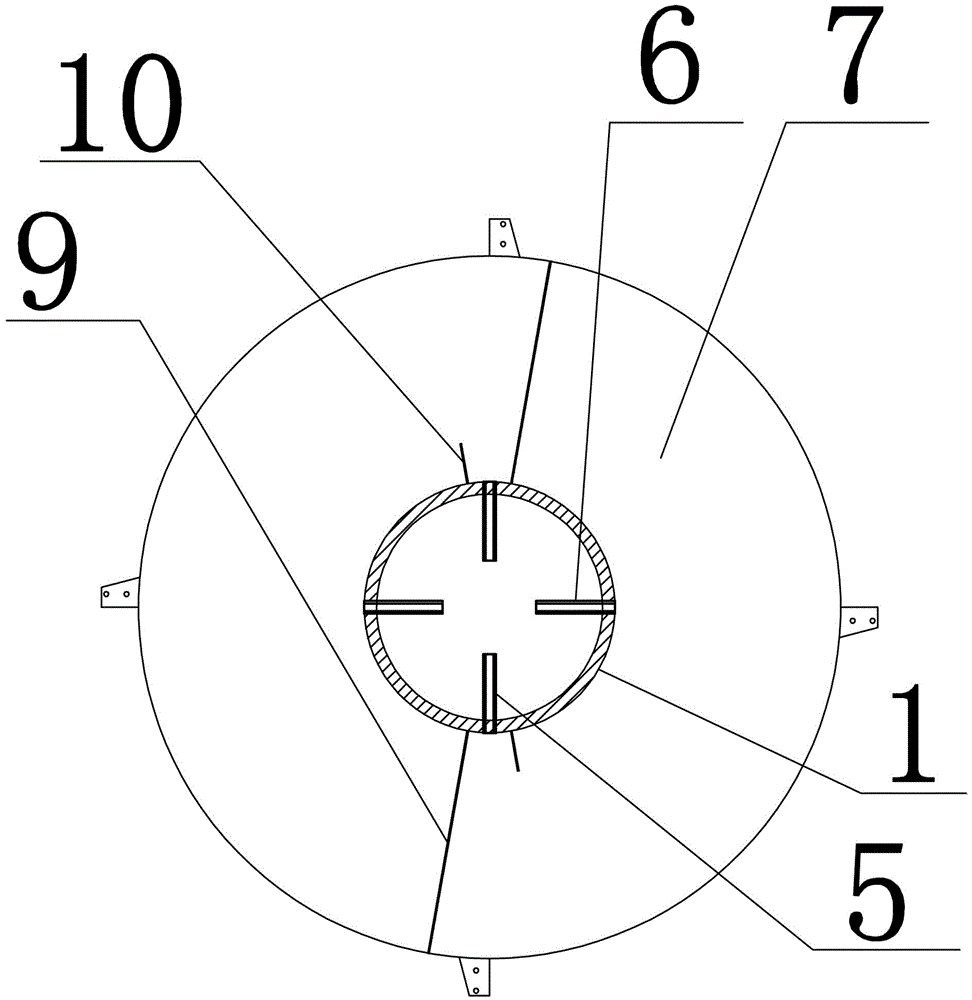

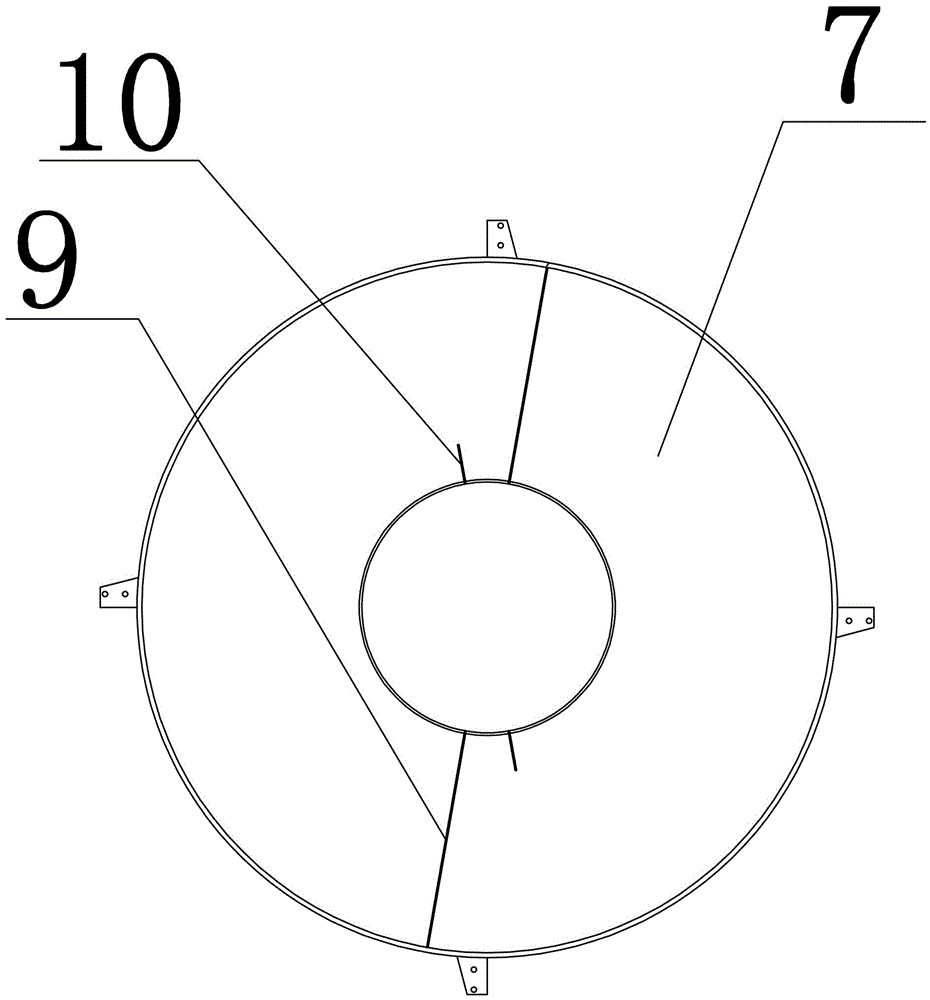

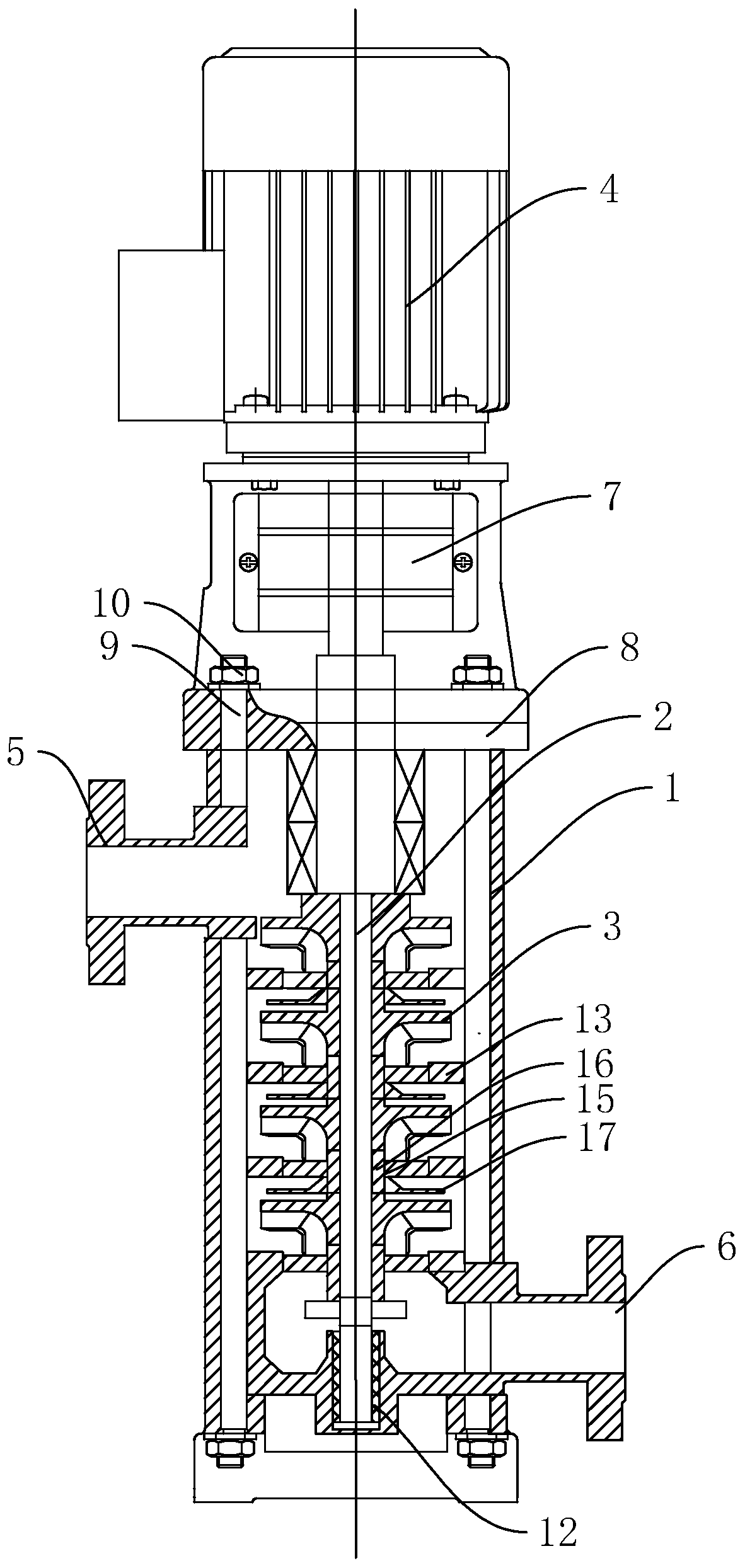

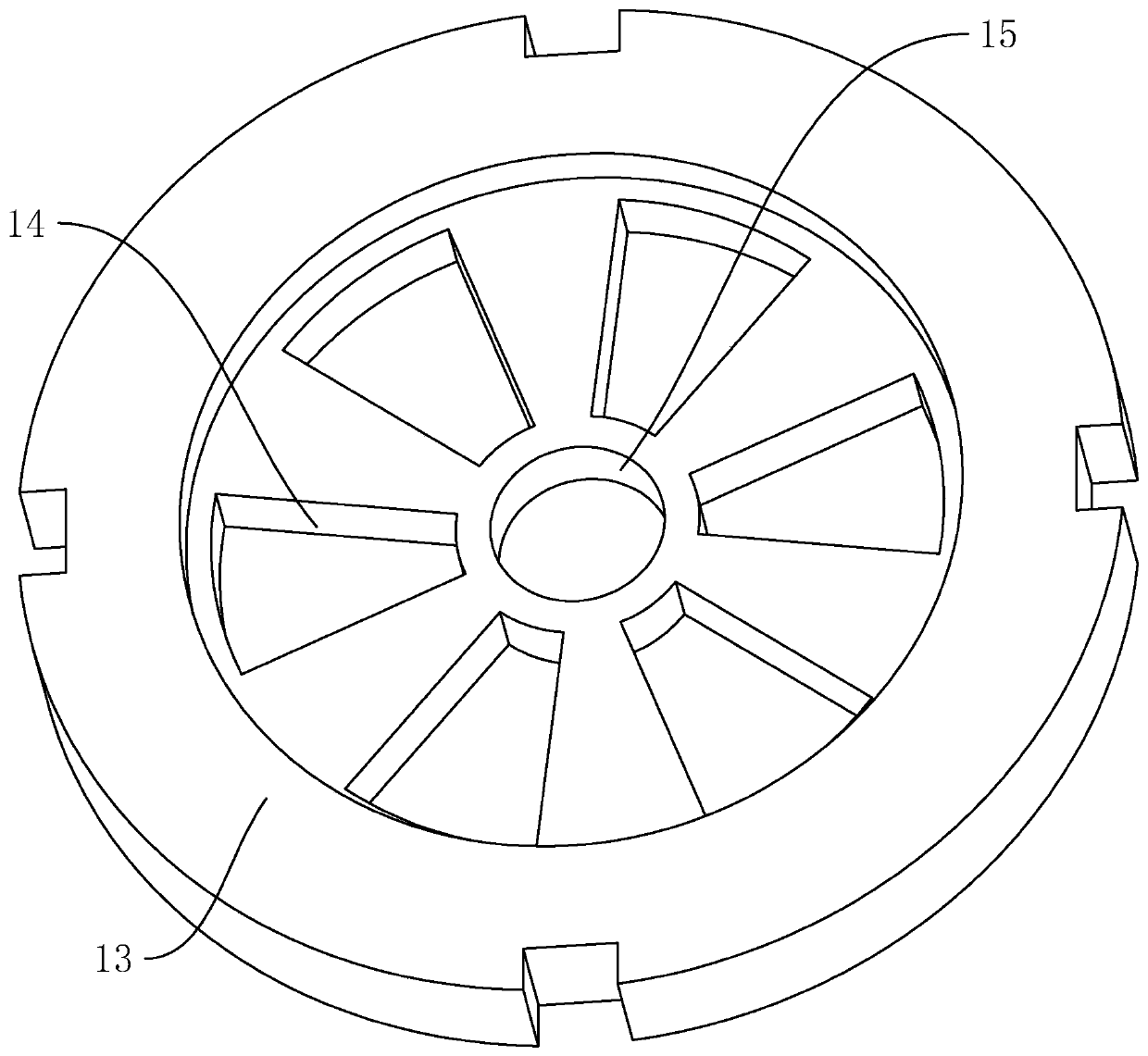

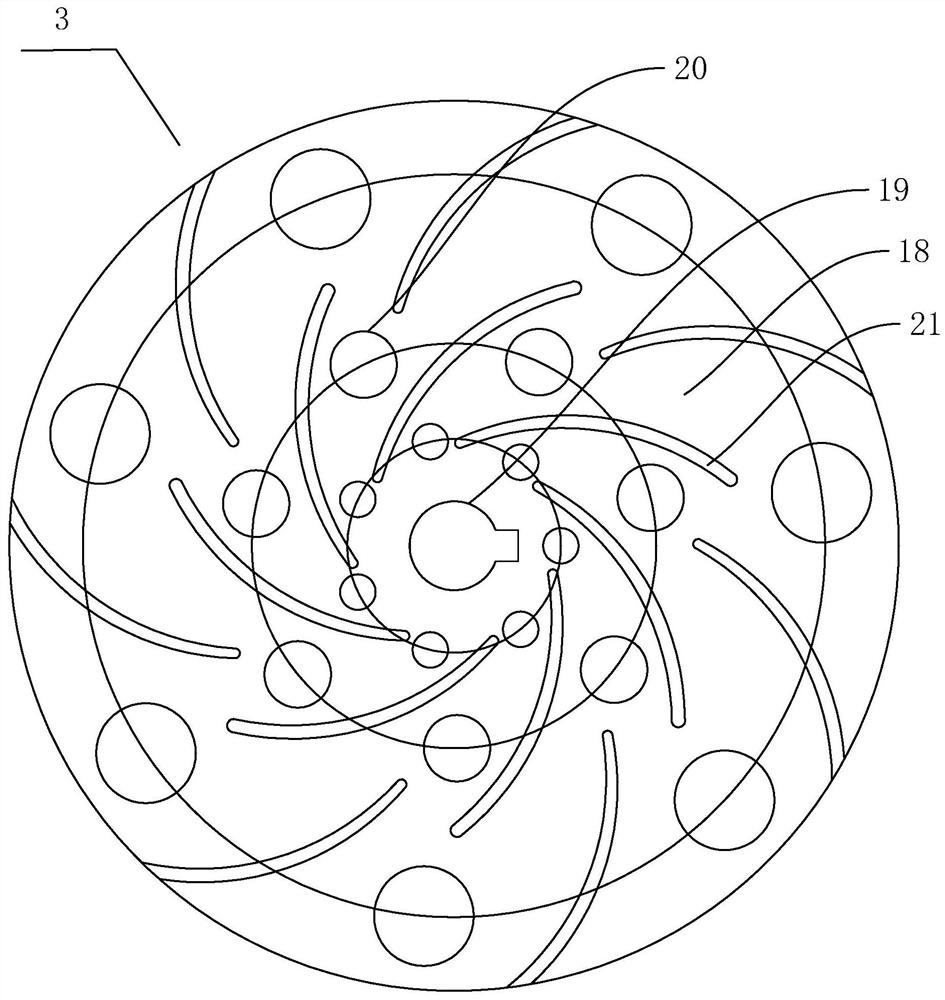

Cyclone extraction device and separation system using same

ActiveCN111467837AReduce the risk of bendingAchieve horizontal supportLiquid solutions solvent extractionProcess efficiency improvementElectric machineryEngineering

The invention discloses a cyclone extraction device, relates to metal melting, and aims to solve the problem that the extraction mass transfer efficiency is low. The device is characterized in that: the device comprises a cylindrical shell, a main shaft arranged along the central axis of the shell, at least four cyclone reaction discs coaxially fixed on the main shaft, and a cyclone extraction motor used for driving the main shaft, wherein a liquid inlet and a liquid outlet are formed in the upper end and the lower end of the circumferential outer wall of the cylindrical shell respectively, aconnector is arranged between the top end of the shell and the cyclone extraction motor, and the cyclone reaction discs are arranged at equal intervals in the length direction of the main shaft. The cyclone extraction device provided by the invention assists in extraction or back extraction, effectively improves the mass transfer efficiency, and effectively reduces the influence of mass transfer reaction heat.

Owner:浙江科菲科技股份有限公司

Fluid control valve and fluid control valve assembling method

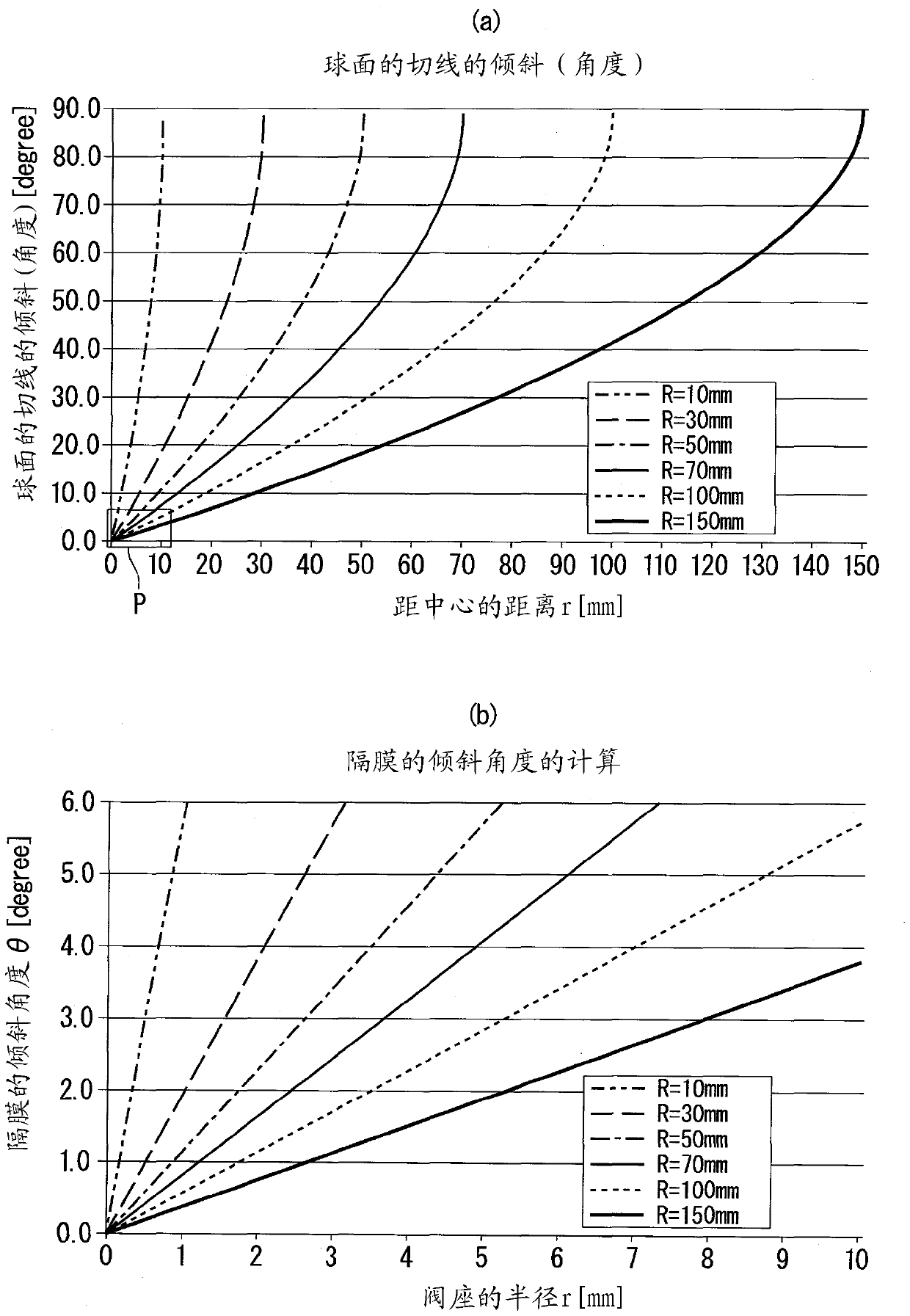

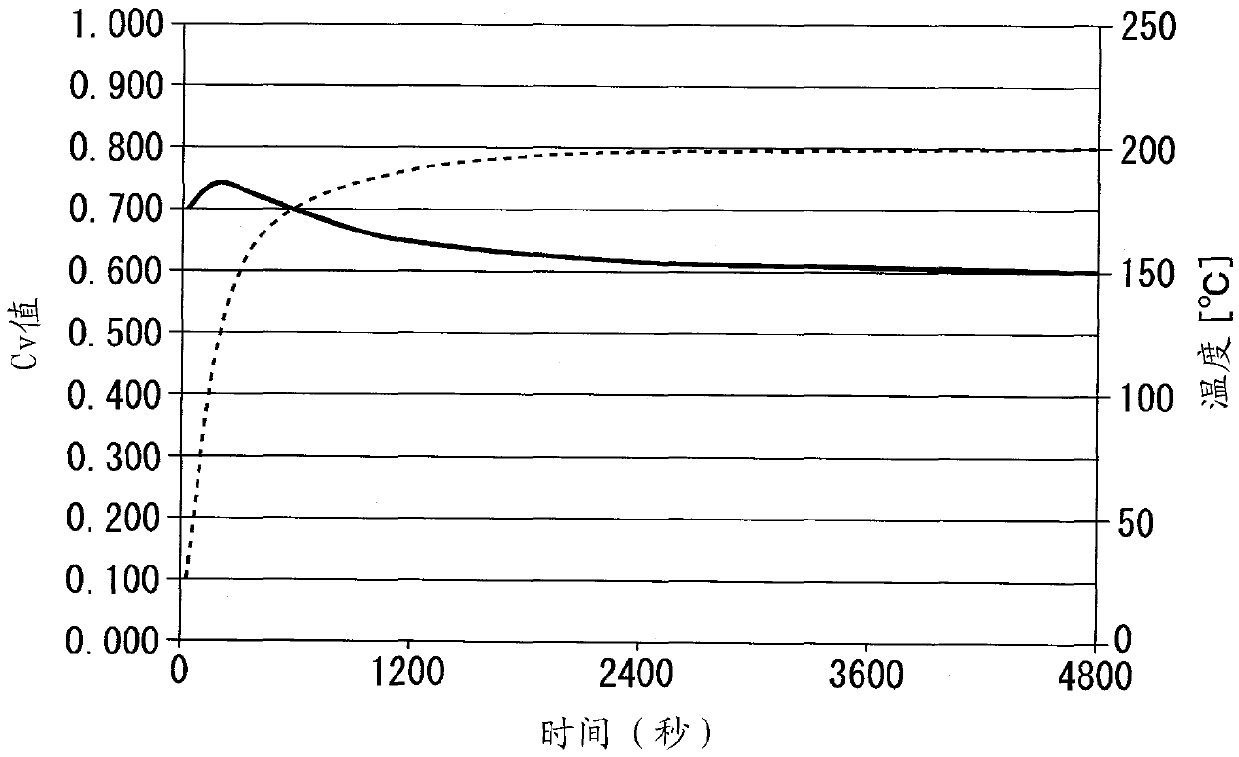

ActiveCN109899555AAvoid deformationIncreased durabilityDiaphragm valvesOperating means/releasing devices for valvesFluid controlControl valves

The object of the invention is to provide a fluid control valve for use under high-temperature conditions and capable of achieving high durability and Cv value stability even with many operations, anda method of assembling the fluid control valve. The fluid control valve includes an annular valve seat provided inside a body having an inflow port and an outflow port and a diaphragm opposed to theannular valve seat to be in contact therewith or away therefrom by an ascending / descending motion of an actuator rod or a manual rod. A contact surface, which is an upper surface of the annular valveseat, has a tapered surface formed along a centripetal direction of the annular valve seat.

Owner:KAISHI SCT CO LTD

Fuel assembly positioning grillwork, fuel assembly and reactor core

ActiveCN113450931AHigh lateral bending stiffnessReduce crackingNuclear energy generationFuel element assembliesStructural engineeringProcess engineering

The invention relates to a fuel assembly positioning grillwork, a fuel assembly and a reactor core, the fuel assembly positioning grillwork comprises: fuel rod positioning grids; interlocking assemblies which are arranged on the outer strips of the fuel rod positioning grids wherein the adjacent fuel rod positioning grids can be mutually locked through the interlocking assemblies. According to the scheme provided by the invention, after the fuel assemblies are arranged in the reactor core, the bulges on the fuel assembly positioning grillwork on each fuel assembly are matched with the grooves in the fuel assembly positioning grillwork on the adjacent fuel assembly so that the adjacent fuel assemblies can be mutually locked and positioned through the structure; therefore, the fuel assemblies in the whole reactor core are interlocked into a whole, the transverse bending rigidity of the whole structure is obviously higher than that of a single fuel assembly, and the possibility that the SiC composite cladding cracks due to bending can be effectively reduced by applying the fuel rod based on the SiC composite cladding on the basis of the structure.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

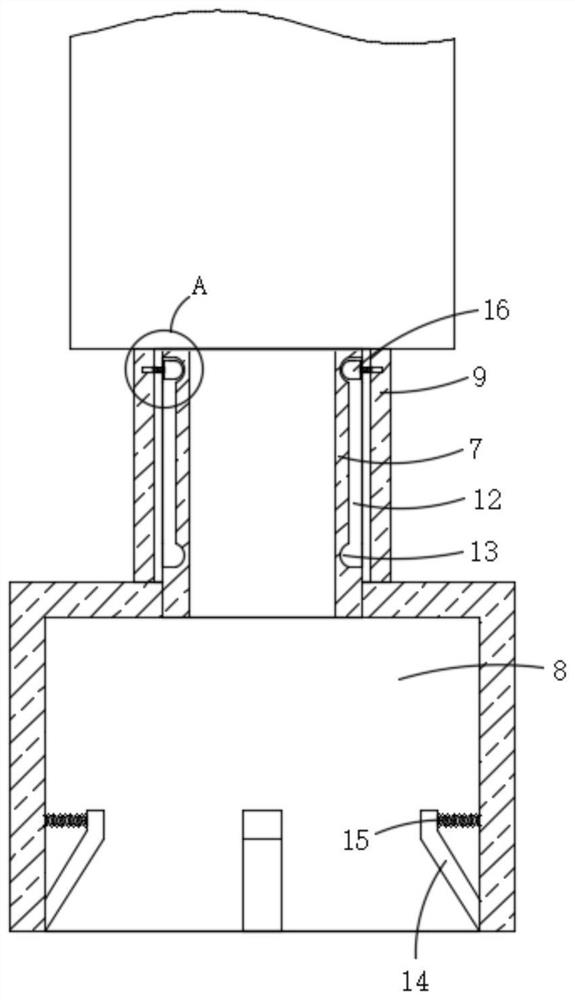

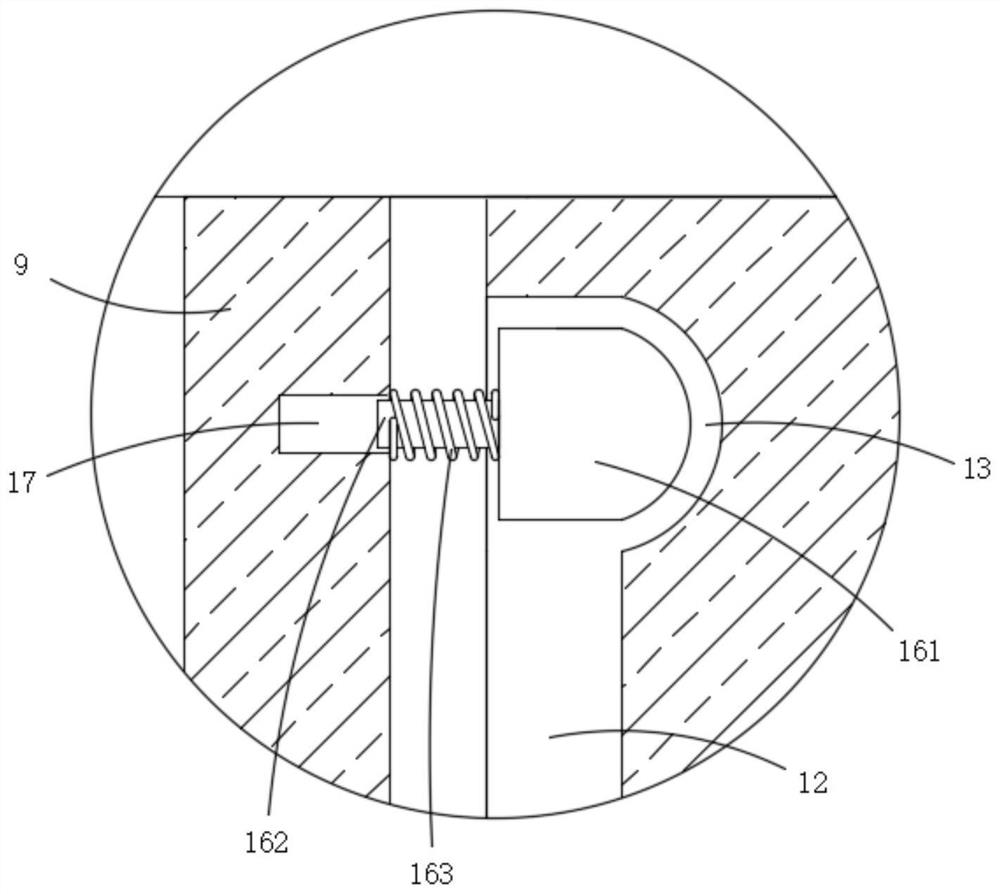

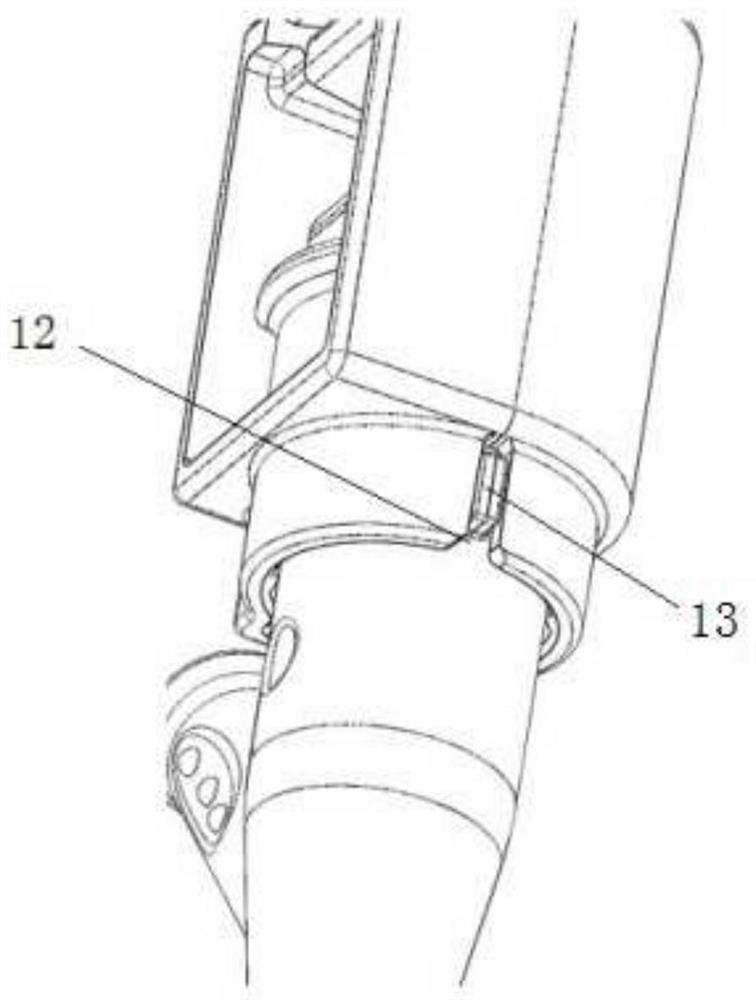

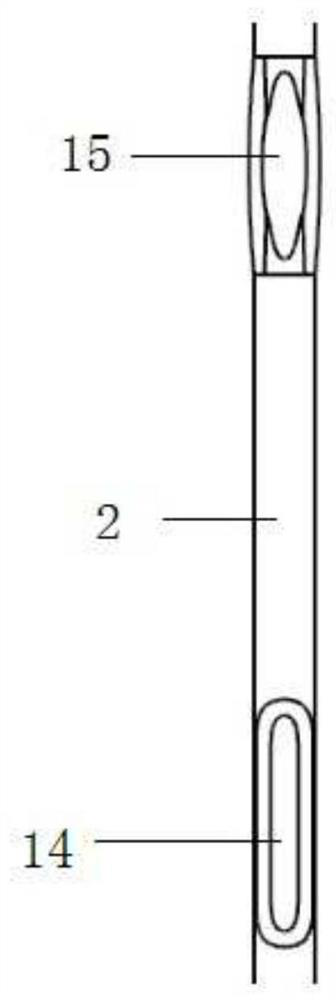

Push button system, and timepiece comprising same

ActiveCN111983910AIncrease guide lengthNot super staticMechanical unknown time interval measurementElectromechanical unknown time interval measurementStructural engineeringActuator

The invention relates to a push button system for activating an actuation member, the system including a button head, a pusher actuator integral with the button head, a first hollow guide member, thepusher actuator being mounted to slide inside the first hollow guide member, the first hollow guide member being intended to be secured to a fixed element relative to the button head and to the pusheractuator, a second hollow guide member arranged in the button head, and a pin mounted to slide inside the second hollow member, and intended to be secured to the fixed element. The pusher actuator has an upper portion provided on the periphery thereof with a collar intended to cooperate with an internal face of the first hollow guide member to guide the pusher inside the member.

Owner:MECO SA

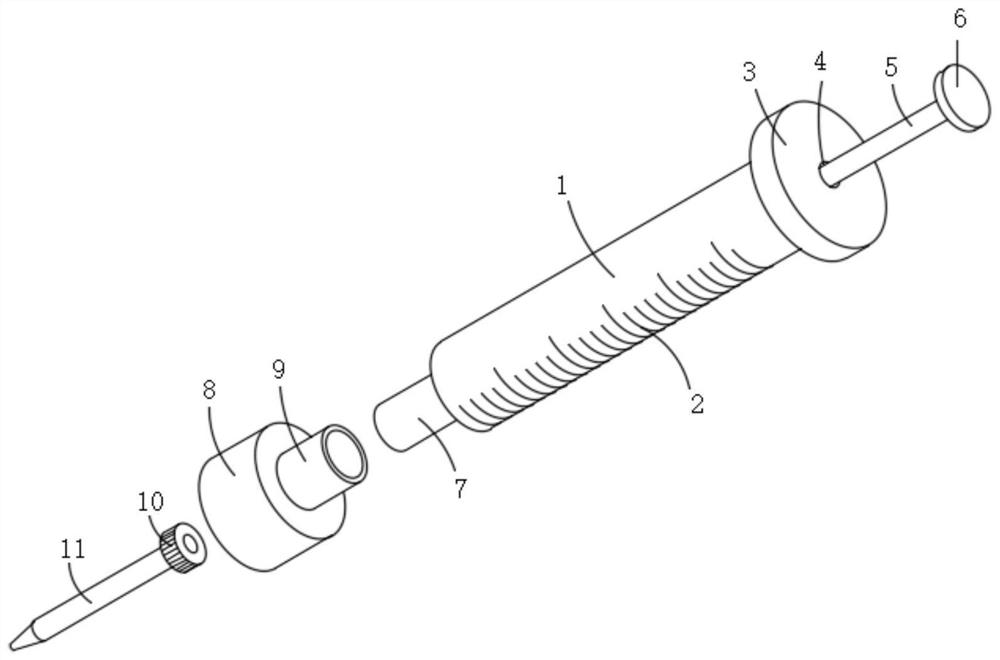

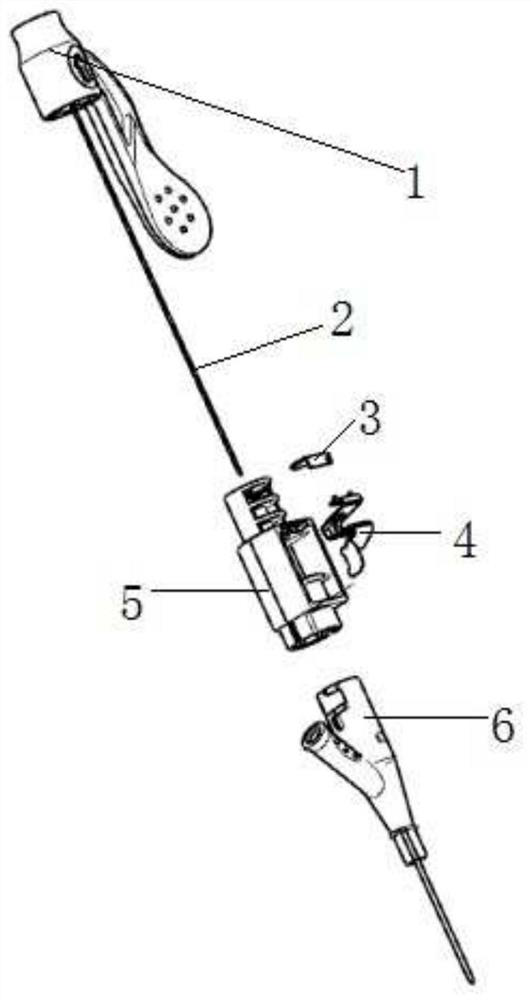

Instrument sampling device of novel gas chromatograph

PendingCN114705795AReduced risk of bendingExtended service lifeComponent separationHollow article cleaningPhysicsMechanical engineering

The invention discloses a novel gas chromatograph instrument sample introduction device, which comprises a needle cylinder, a push rod is vertically and movably arranged in the needle cylinder, the push rod can extract liquid when moving upwards, the push rod can release liquid when moving downwards, the lower end of the needle cylinder is fixedly connected with a liquid outlet cylinder, and a needle head is installed at the lower end of the liquid outlet cylinder in a threaded manner. A limiting cylinder is clamped to the outer wall of the liquid outlet cylinder through a fixing assembly, the position of the limiting cylinder on the liquid outlet cylinder is adjustable, and the lower end of the limiting cylinder is connected with a positioning sleeve. Before a solution is extracted, the needle cylinder and the liquid outlet of the container can be connected, the stability of connection between the needle cylinder and the liquid outlet of the container is kept, and the operation is convenient. The risk of needle head bending is reduced, the accuracy of liquid suction quantification is improved, the test error is reduced, the service life of the needle head is further prolonged, the interior of the needle head can be timely and rapidly cleaned, the risk of needle head blocking is reduced, and the working efficiency is further improved.

Owner:宁波中盛产品检测有限公司 +2

Anti-needling assembly

The invention provides an anti-needling assembly, which comprises a needle tip protection sleeve and a needle return prevention structure, the needle tip protection sleeve is provided with a puncture channel allowing a needle tube to pass through, and the needle return prevention structure is arranged at the puncture channel to achieve communication / closing of the puncture channel. The anti-needling assembly has the advantages that the repeated puncture frequency can be reduced, a user is effectively prevented from making contact with the needle tip after the catheter is inserted into the blood vessel of a patient and the needle tube is pulled out of the catheter base, the user is prevented from making contact with residues on the needle tip, and medical staff can use the anti-needling assembly conveniently.

Owner:天津迪玛克医疗器械有限公司

Pipe nut supporting structure

ActiveCN100366494CEasy to fixEasy to assembleUnderstructuresSuperstructure subunitsVehicle frameEngineering

Provided is support structure of a pipe nut improving assemblability. The structure comprises a pipe nut 1 where one end side 1a is supported by matching to a hole part of a vehicle body frame 10, a bolt which is fastened to the pipe nut 1 through the hole part and supports a supported body to the vehicle body frame 10, and a reinforcing member 2 which is fixed to the vehicle body frame 10 and contacted to the other end surface 1b of the other end part of the pipe nut 1, and constituted so as to be mounted by welding the other end surface 1b of the pipe nut 1 and the reinforcing member 2.

Owner:MITSUBISHI MOTORS CORP

Push button system and timepiece including the push button system

ActiveCN111983910BIncrease guide lengthNot super staticMechanical unknown time interval measurementElectromechanical unknown time interval measurementPhysicsPush-button

The invention relates to a button system for activating an actuating member, the system comprising a button head, a pusher integral with the button head, a first hollow guide member, the pusher mounted to slide inside the first hollow guide member, The first hollow guide member is for fixing to the fixing element relative to the button head and the pusher, the second hollow guiding member is arranged in the button head, and the pin is mounted to slide inside the second hollow member and for fixing to the fixing element superior. According to the invention, the pusher has an upper part provided on its periphery with a flange intended to cooperate with the inner surface of the first hollow guide member to guide the pusher within said member.

Owner:MECO SA

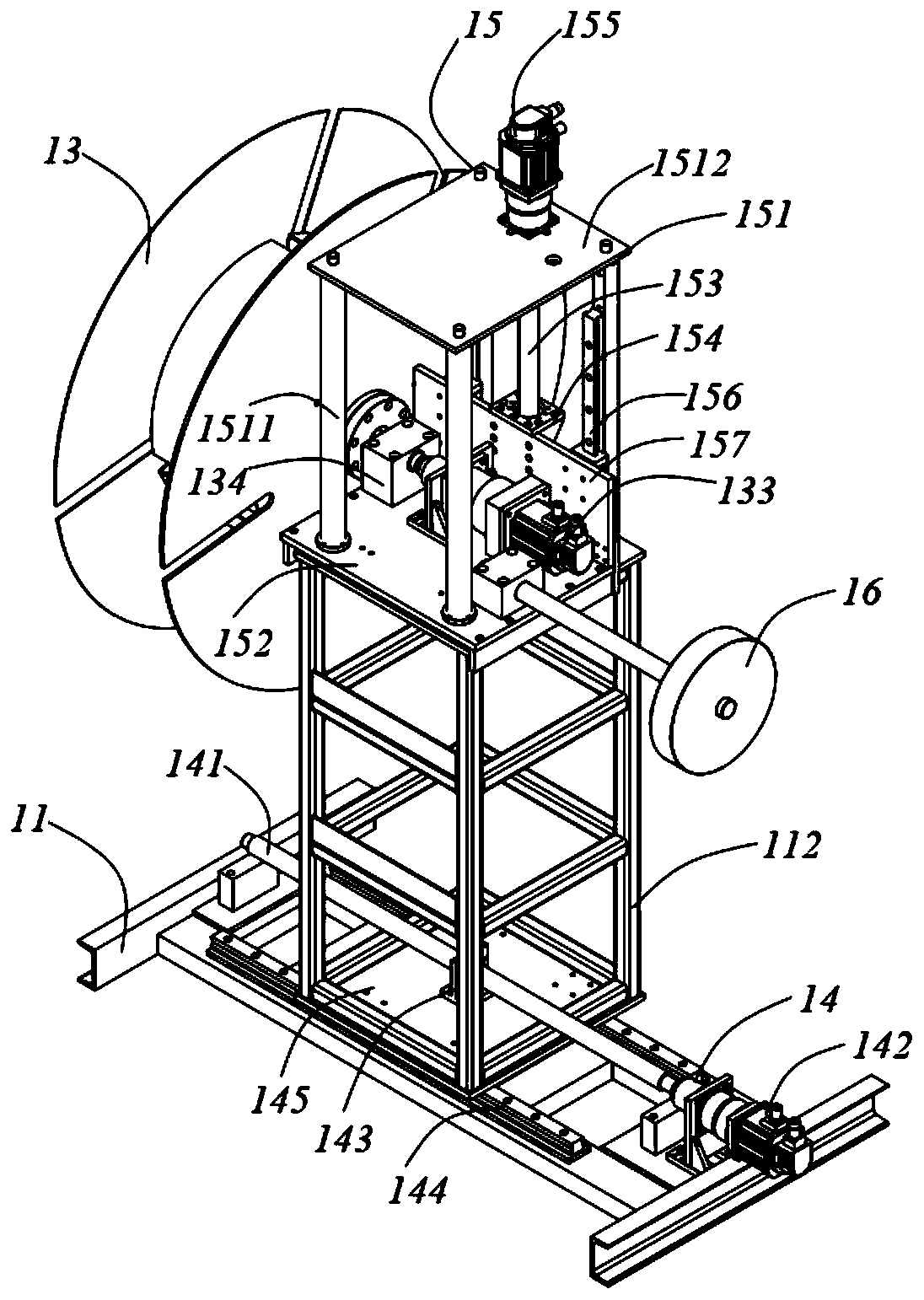

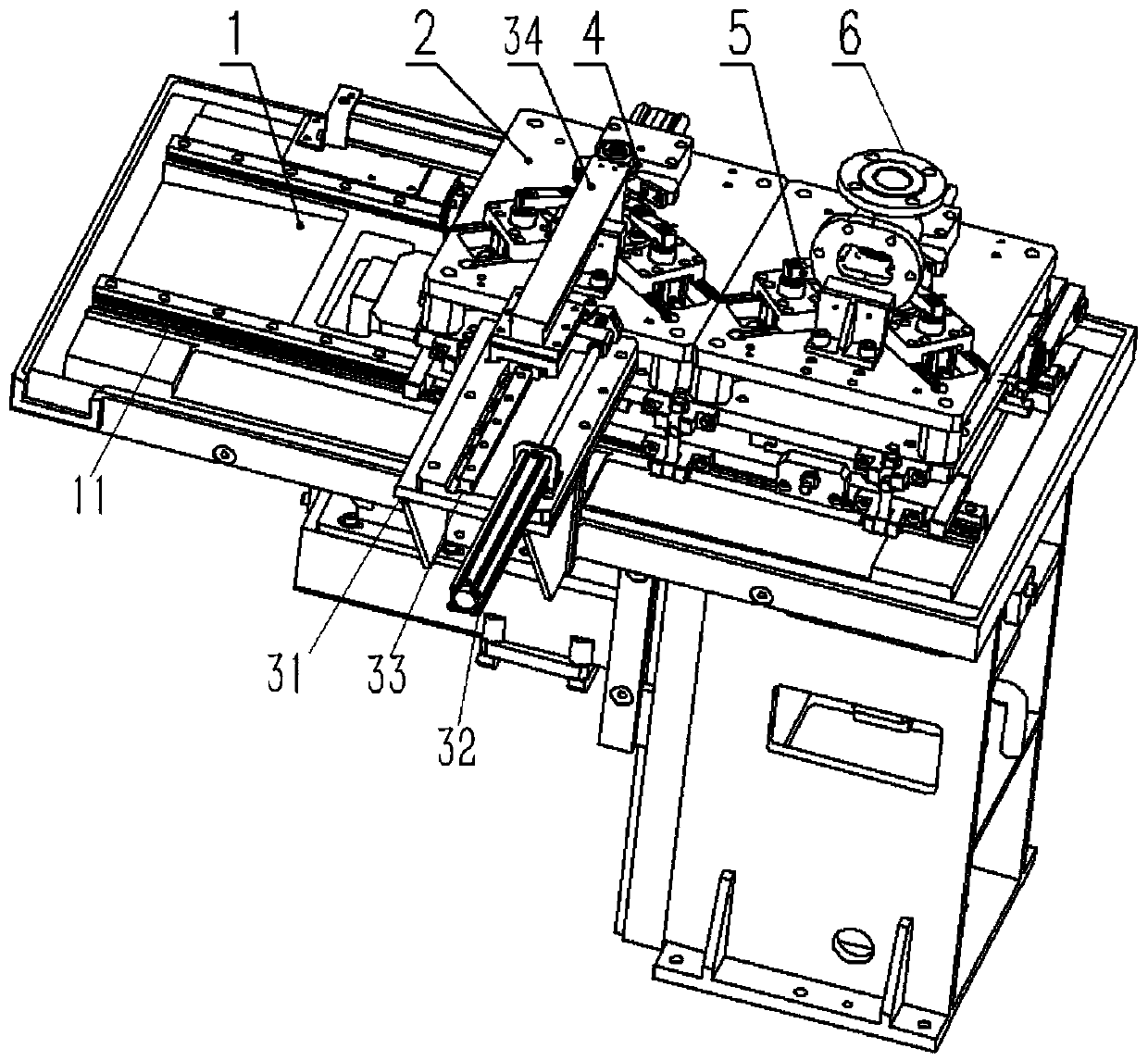

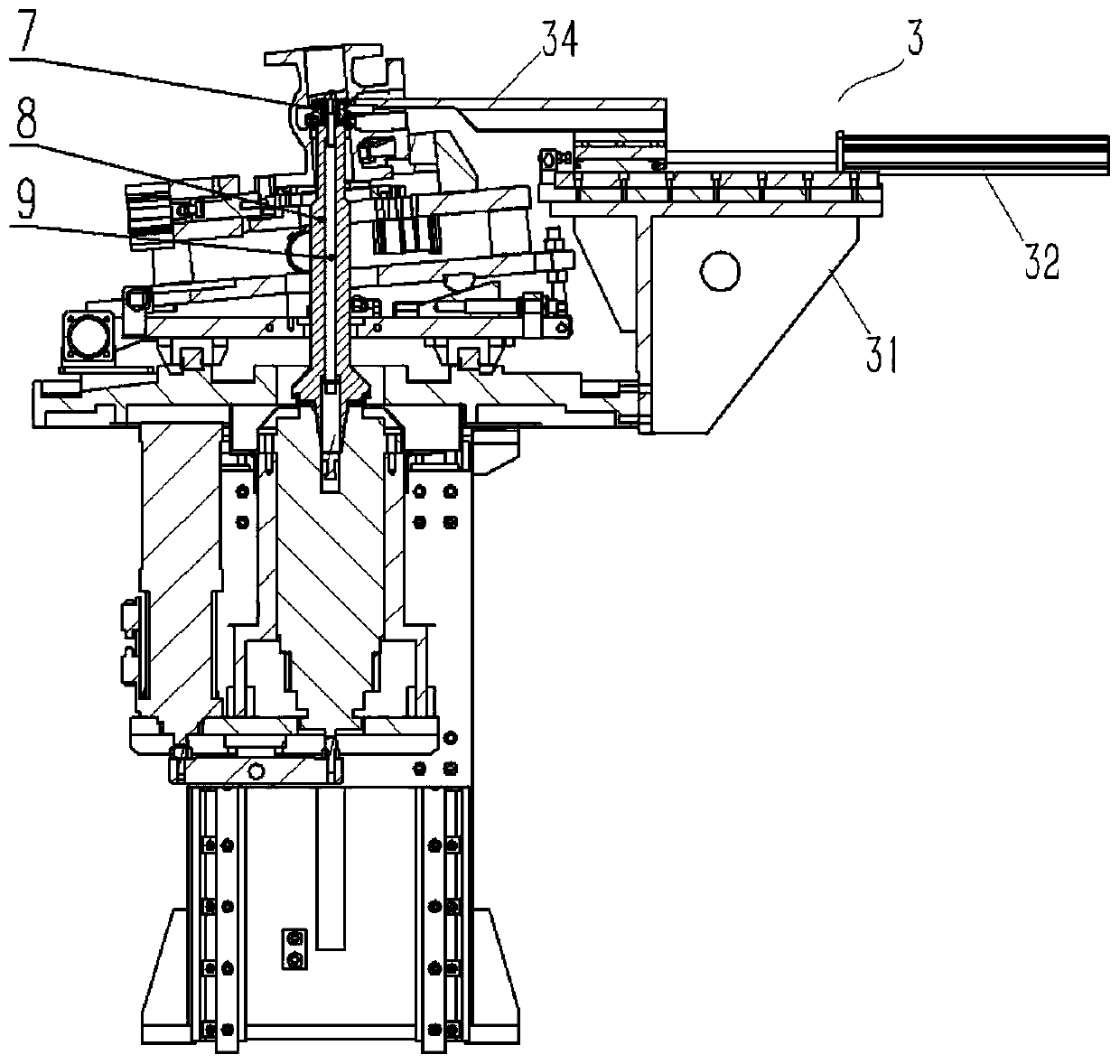

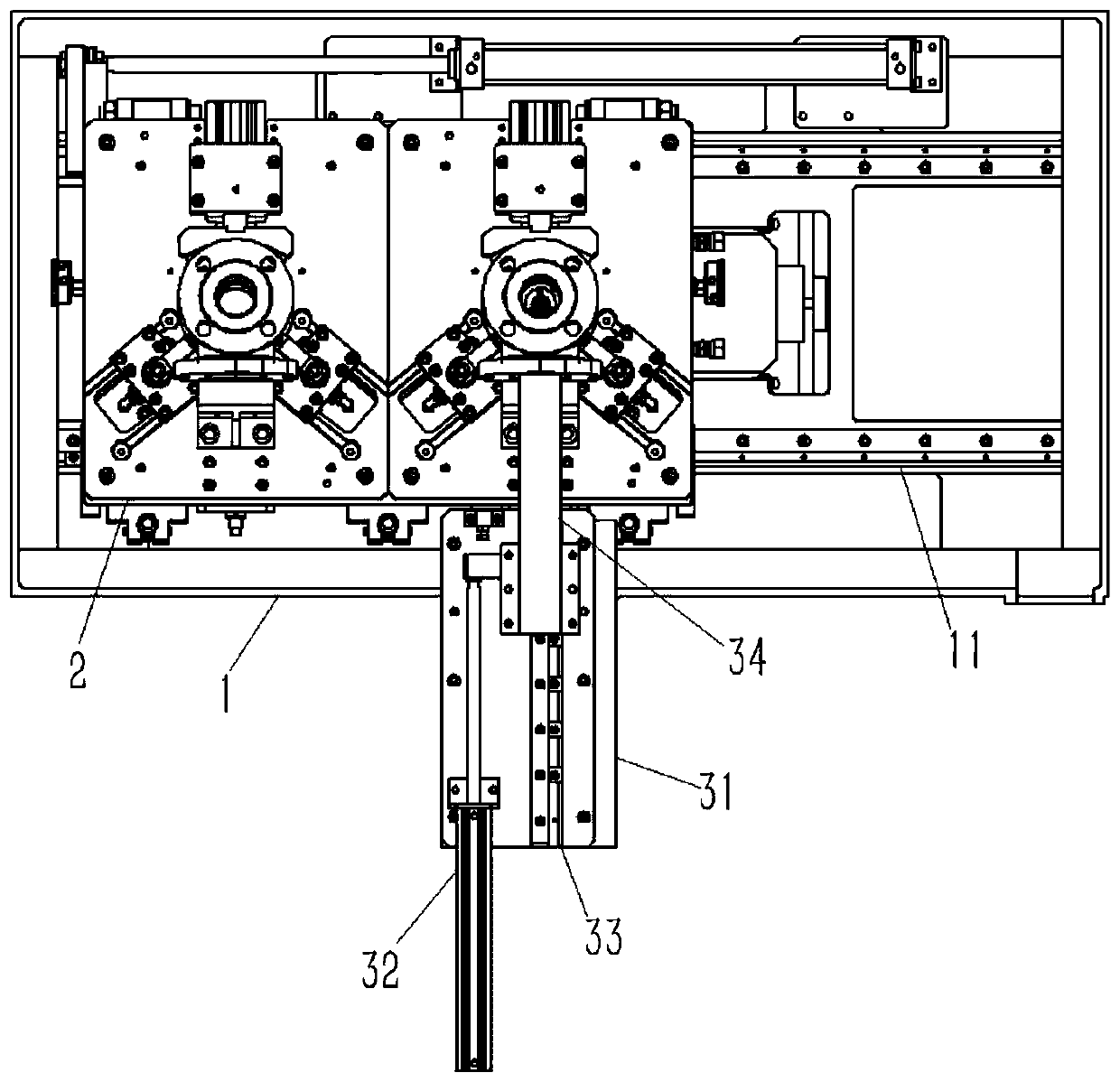

Grinding system and grinding method

ActiveCN109746790BShort tripEasy loading and unloadingGrinding carriagesSeat surface grinding machinesRobot handPull force

Owner:NEWAY VALVE SUZHOU

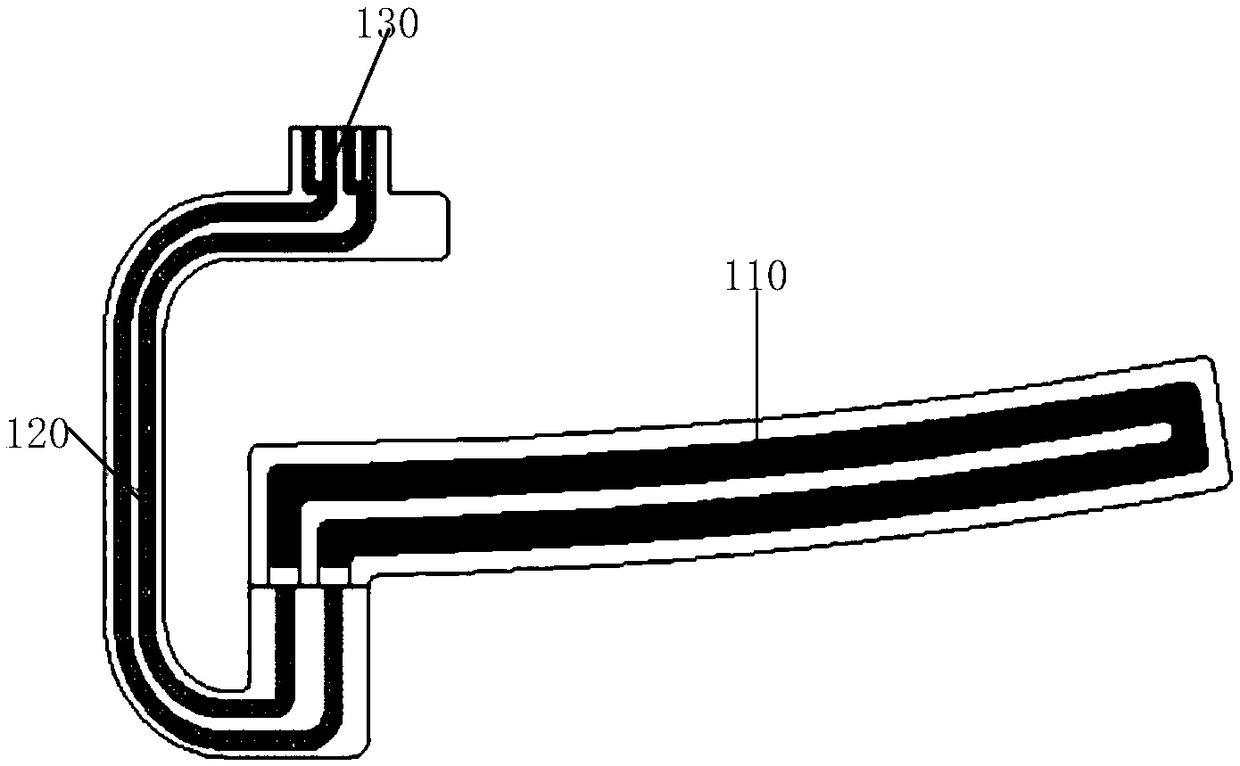

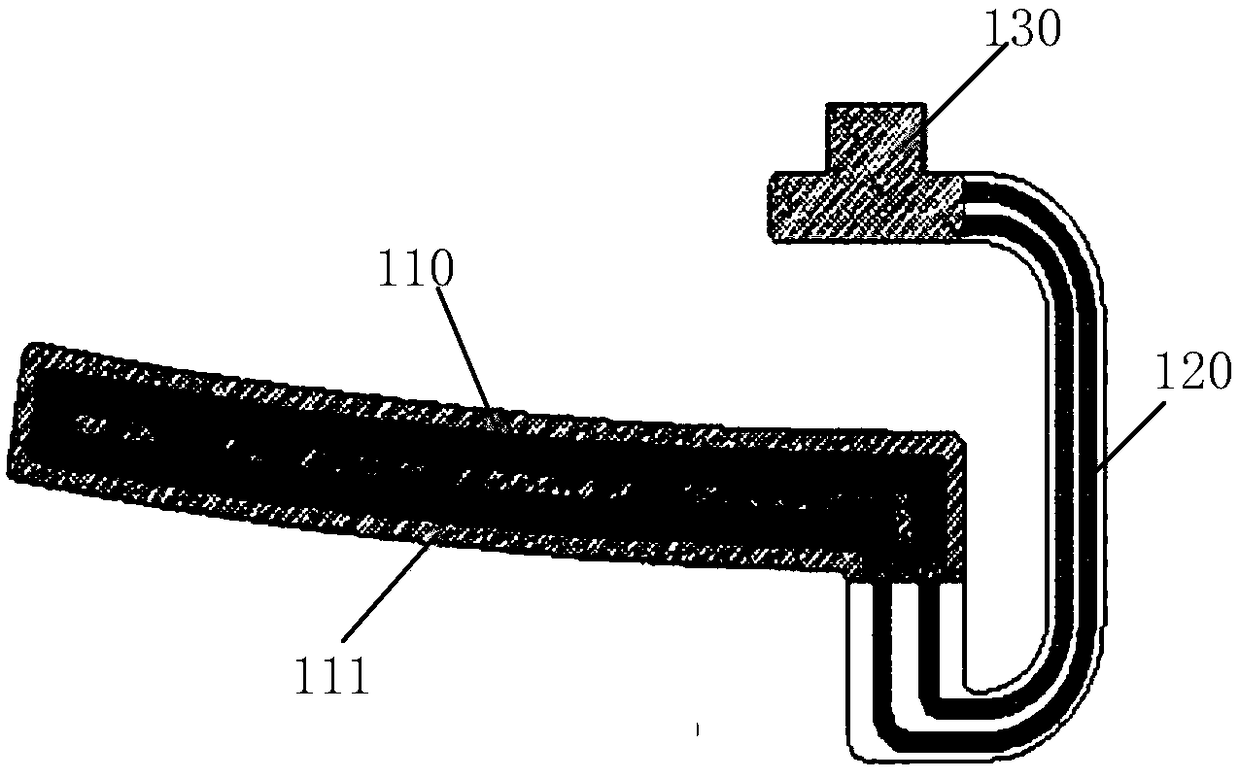

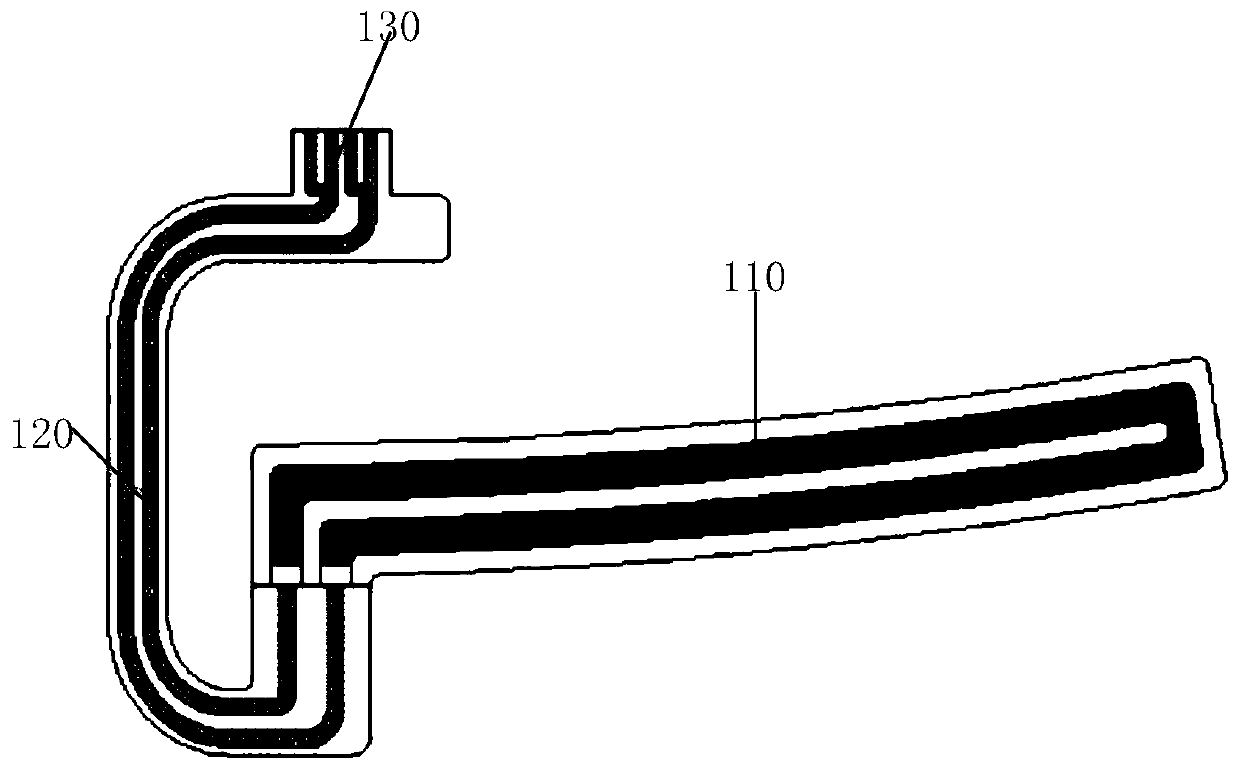

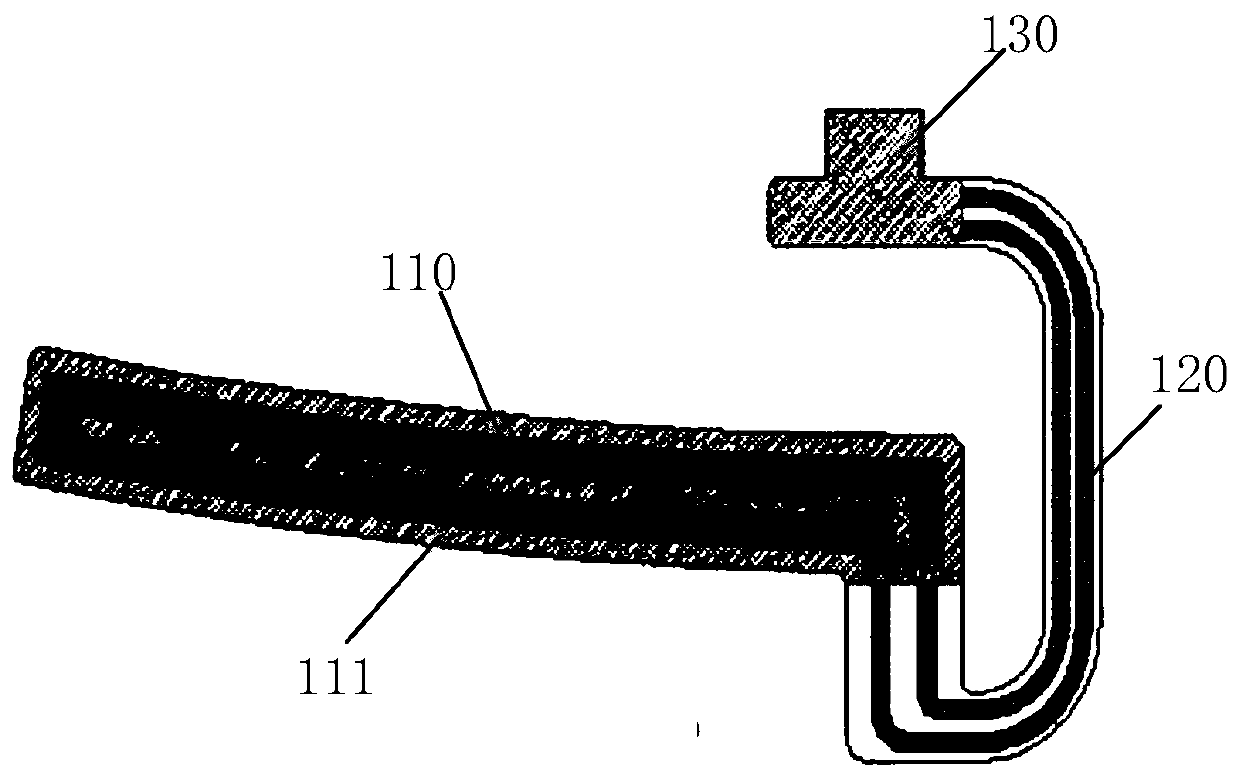

A heating fitting and a photographing apparatus for a photographing apparatus

ActiveCN108989650AEasy to assembleReduced risk of bendingTelevision system detailsColor television detailsElectrical and Electronics engineeringEngineering

The invention provides a heating fitting for a photographing apparatus and a photographing apparatus. The heating fitting is applied to heating the photographing apparatus, and comprising a heating part, a power supply line and a power supply connection part. The heating part is connected to the power supply connecting part through the power supply line; the heating part is integrally in the shapeof a strip, and is used for heating the photographing device; the plugging / unplugging direction of the power supply connection part is perpendicular to the bar-shaped direction of the heating portion. Compared with the prior art, the heating part of the heating fitting in the prior art has the same orientation as the power supply connection part, so that the heating part and the power supply connection part can be combined with the photographing equipment only by bending the power supply line in practical application, so that the invention can reduce the bending risk of the power supply line,facilitates the assembly of the heating fitting, and is conducive to improving the working efficiency.

Owner:TRULY OPTO ELECTRONICS

Cyclone extraction device and separation system using the same

ActiveCN111467837BIncrease profitGuaranteed reuseLiquid solutions solvent extractionProcess efficiency improvementElectric machineMechanical engineering

The invention discloses a swirling extraction device, which relates to metal smelting and aims to solve the problem of low extraction and mass transfer efficiency. The main shaft, the swirl reaction disk coaxially fixed on the main shaft, and the swirl extraction motor used to drive the main shaft, the upper and lower ends of the cylindrical outer wall of the cylindrical shell are respectively provided with a liquid inlet and a liquid outlet. A connector is provided between the top end and the swirl extraction motor, and the number of the swirl reaction discs is at least four, and they are arranged at equal intervals along the length direction of the main shaft. The cyclone extraction device of the present invention assists in extraction or stripping, effectively improves mass transfer efficiency, and effectively reduces the influence of mass transfer reaction heat.

Owner:浙江科菲科技股份有限公司

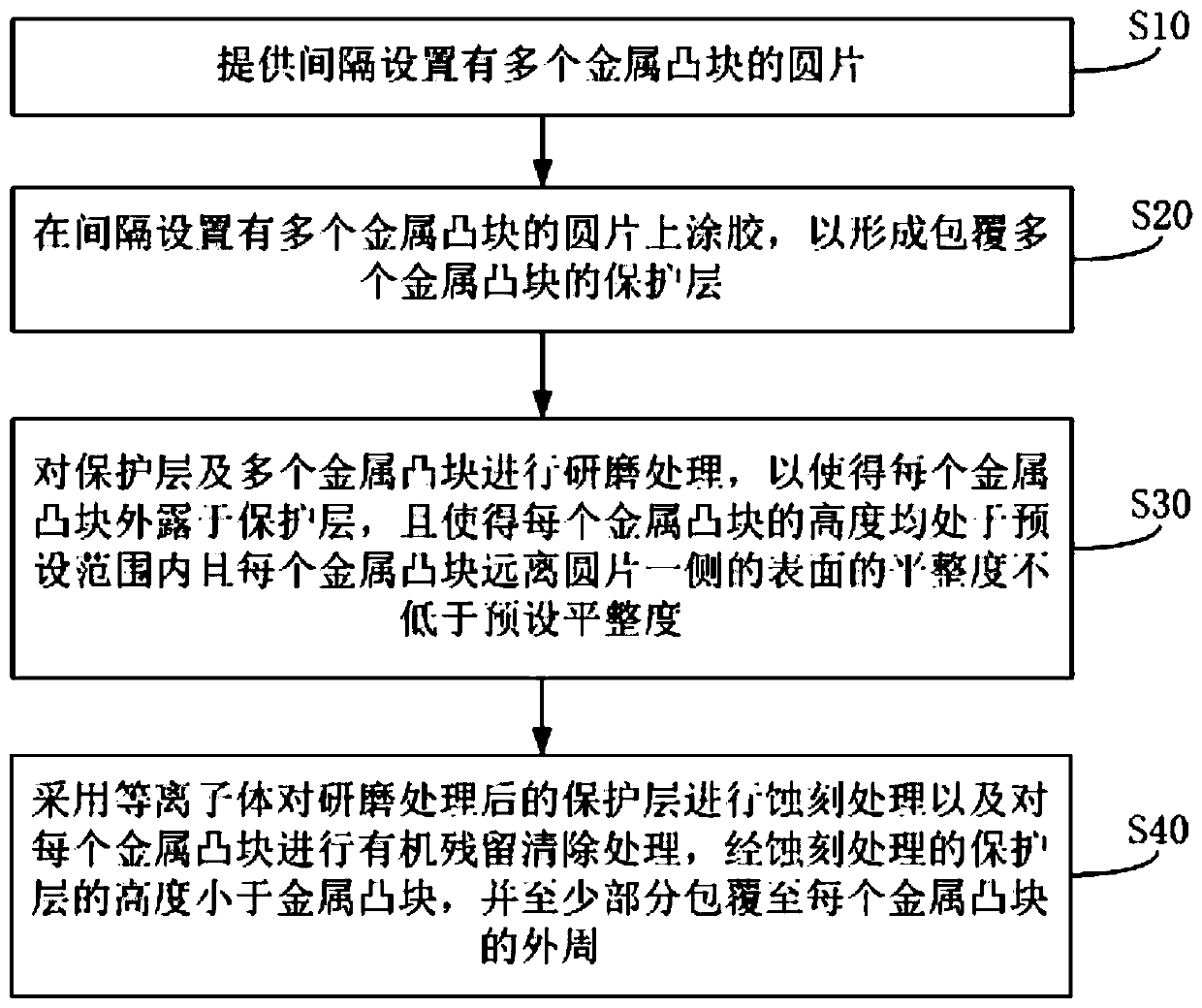

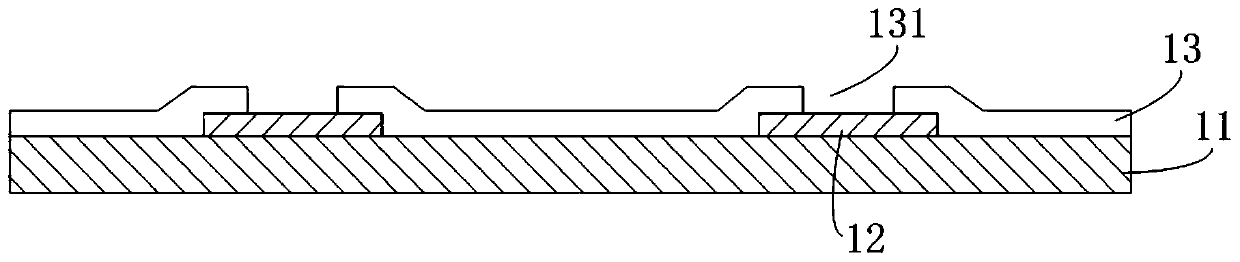

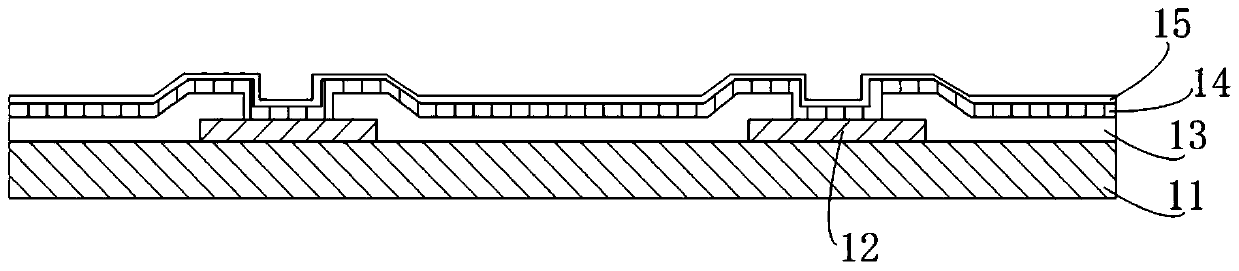

Wafer and manufacturing method thereof

InactiveCN110335822AUniform heightHigh surface flatnessSemiconductor/solid-state device detailsSolid-state devicesMetallurgyMaterials science

The invention discloses a wafer and a manufacturing method thereof. The manufacturing method comprises the steps of: providing a wafer provided with a plurality of metal bumps at intervals; coating glue on the wafer provided with the plurality of metal bumps at intervals to form a protective layer for coating the plurality of metal bumps; and grinding the protective layer and the metal bumps to expose each metal bump out of the protective layer, wherein the height of each metal bump is in a preset range, and the flatness of the surface of one side of each metal bump far away from the wafer isnot lower than a preset flatness. In this way, the surface evenness of the metal bumps can be improved, the heights of different metal bumps are uniform, and the risk that the metal bumps are bent dueto external force can be reduced.

Owner:厦门通富微电子有限公司

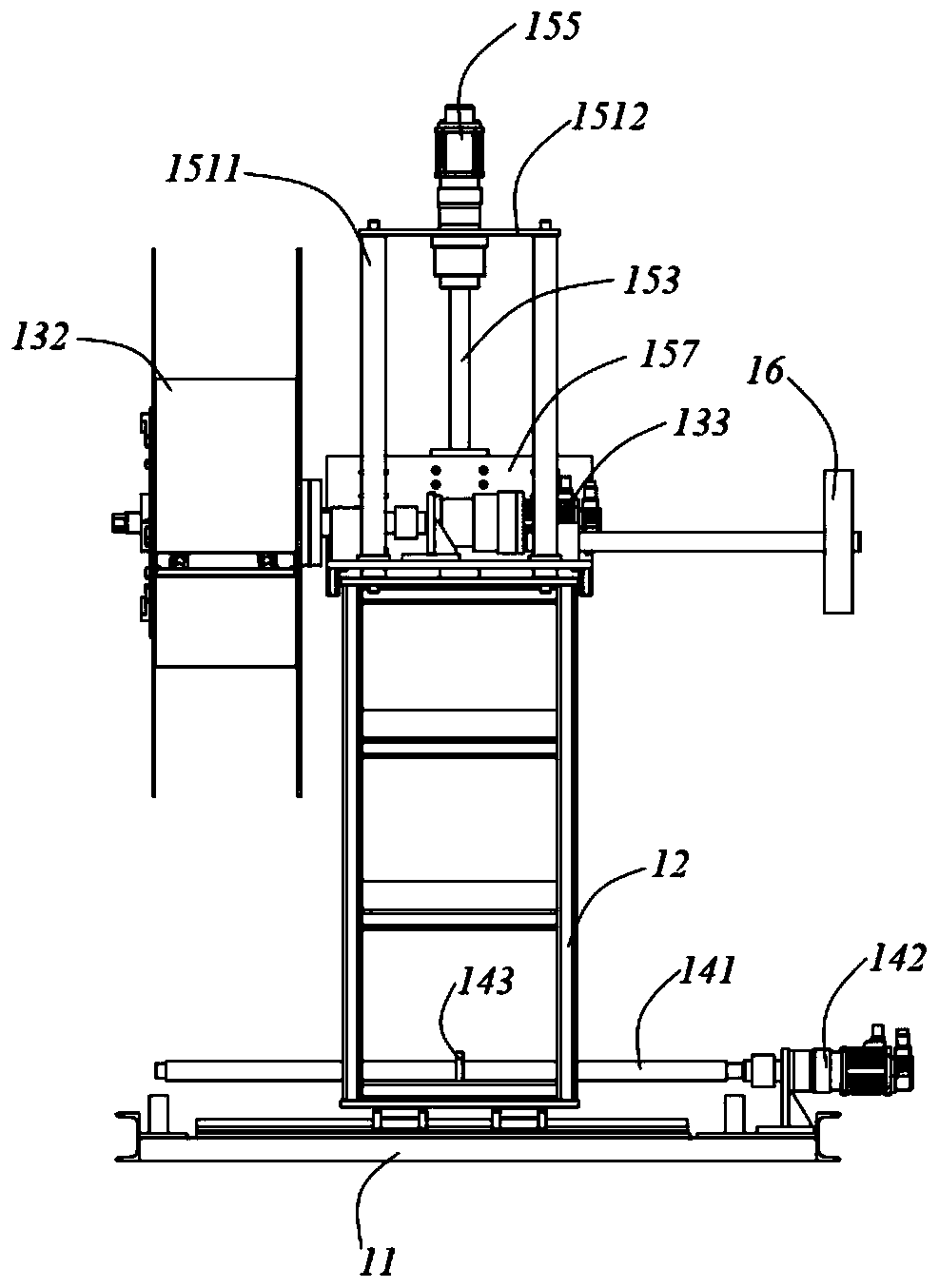

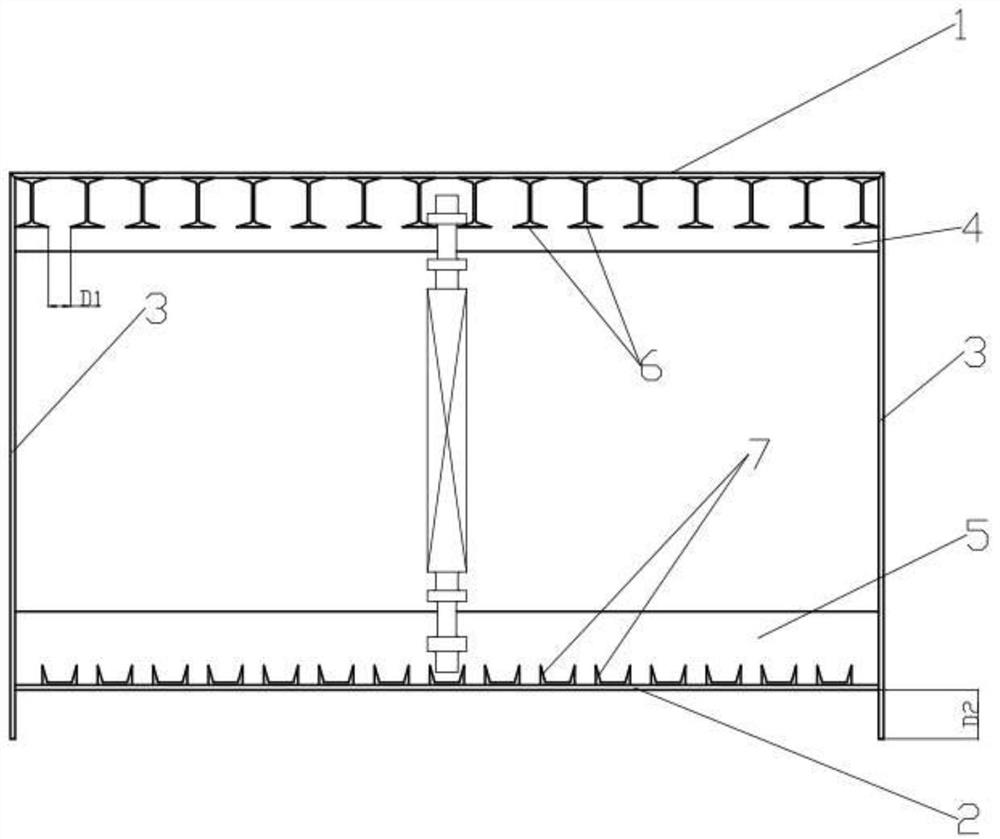

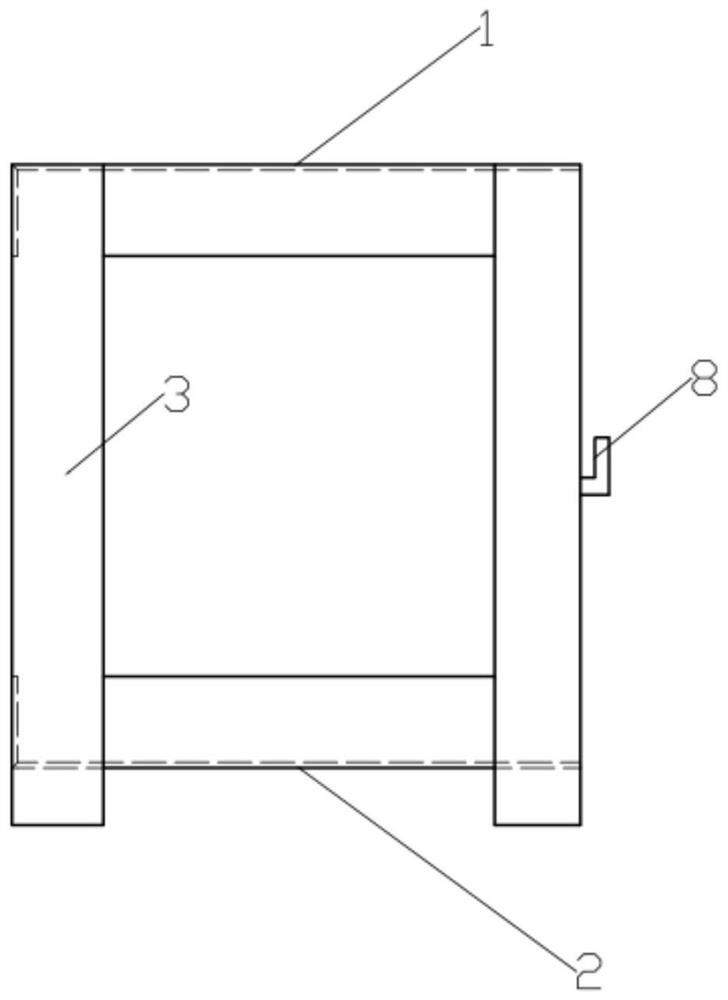

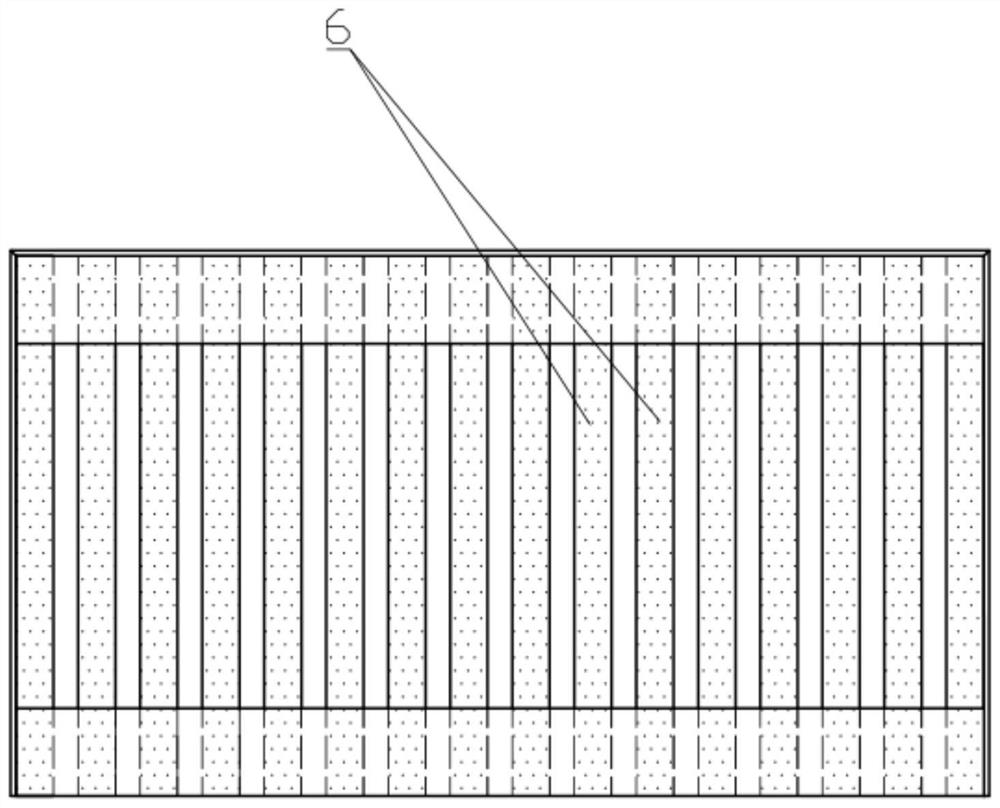

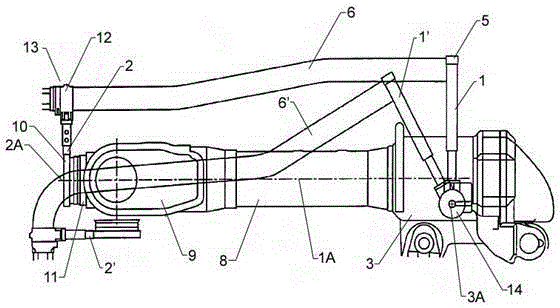

A quick-loading and anti-bending tooling for thermally processed camshafts and a quick-loading and anti-bending method

ActiveCN110773581BFast loadingAvoid accumulationWork cooling devicesMetal rolling arrangementsThermal stateHot work

A thermally processed camshaft quick-loading anti-bending tooling, comprising a cube or cuboid frame jointly surrounded by a plurality of upper support frame plates (1), lower support frame plates (2) and vertical support frame plates (3). The bottom surface of the support frame plate (1) is fixedly connected with a plurality of I-beams or H-shaped steels (6), and the top surface of the lower support frame plate (2) is fixedly connected with a plurality of channel steels (7). The red hot camshaft can The gap between two adjacent I-beams or H-beams (6) is loaded and snapped between the lower legs of two adjacent I-beams or H-beams (6), and part of the shaft section at the lower end of the camshaft can Stretch into the gap space between the channel steel (7) two legs. The hot-processed camshaft fast loading anti-bending tooling and corresponding method of the present invention can quickly load the red-hot camshaft, prevent bending caused by traditional horizontal placement and boxing, and have a large capacity, and can quickly calculate the loading amount, comprehensively Improve product yield and turnover efficiency.

Owner:QILU INST OF TECH

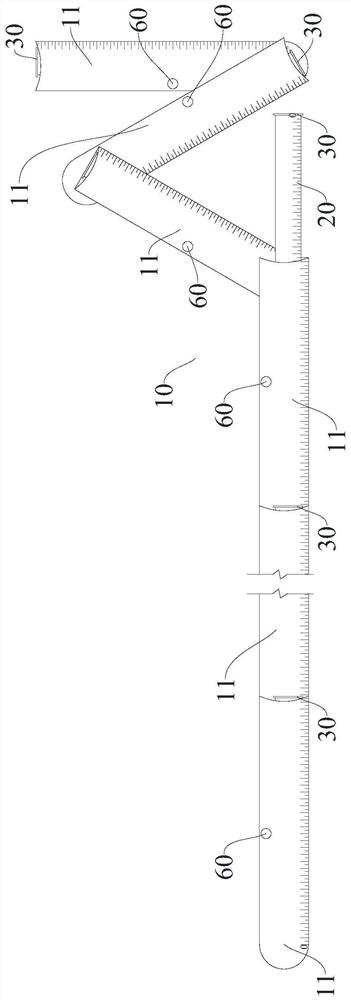

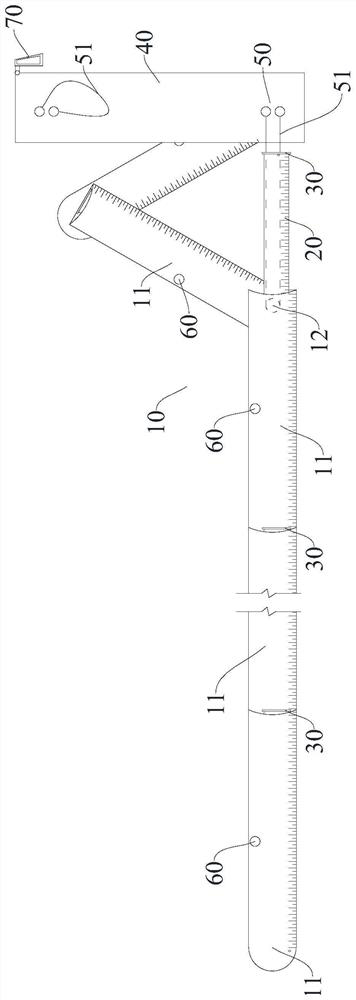

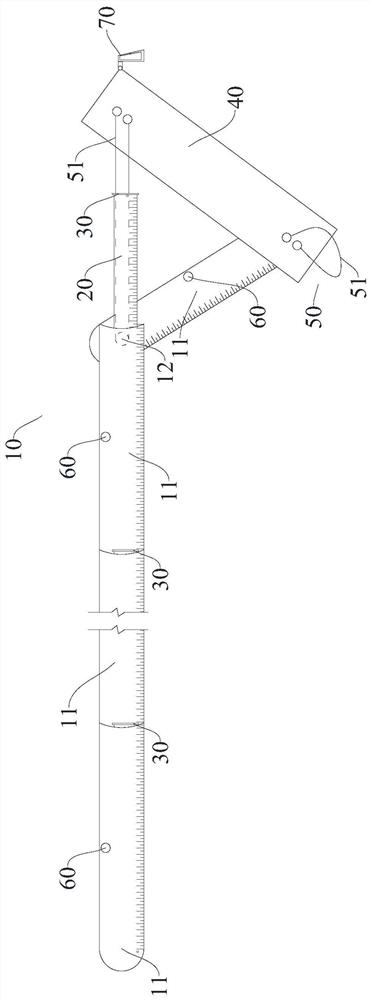

Distance measuring device for electric power construction

ActiveCN109506547BReduced risk of bendingGuaranteed accuracyMechanical measuring arrangementsStructural engineeringElectric shock

The invention provides a distance measuring device for electric construction, which belongs to the technical field of electric construction tools. One end is set on the back of the tail end of the previous ruler section, the other end of the connecting rod is set on the front of the head end of the latter ruler section, and the ruler section is provided with a cavity with an opening facing the tail end of the ruler section; and a built-in ruler section, which is inserted in the It is in the cavity and used to extend outside the tail end of the ruler segment along the long axis of the ruler segment; the ruler segment, the connecting rod and the built-in ruler segment are respectively insulating material components. The distance measuring device for electric construction provided by the present invention aims to solve the problem that the current measuring tape measure is used to measure the installation position of electric power fittings, the ruler body is prone to bending during measurement, which affects the accuracy of the measurement data, and the technology that is prone to electric shock is used on live cables. question.

Owner:STATE GRID CORP OF CHINA +2

Supporting device for manipulator

The invention discloses a supporting device for a manipulator. The supporting device for the manipulator comprises a supporting arm and an auxiliary arm, wherein the supporting arm is connected to a support on a rear arm part of an upper arm of the manipulator and rotates around a third shaft. The supporting arm comprises a first connecting piece, and the first connecting piece comprises a sealing piece used for mounting and dismounting a cable. The auxiliary arm is connected with a front arm part, the front arm part is mounted on the rear arm part, rotates around a first shaft and is provided with a wrist, and a hand connected with a steering wheel is mounted on the wrist. The steering wheel rotates around a second shaft. The auxiliary arm comprises a second connecting piece, and the second connecting piece is provided with a sealing piece. A spiral spring is arranged on the third shaft of the supporting arm, and a protective sleeve is arranged outside the spiral spring. The cable is arranged between the supporting arm and the auxiliary arm. The supporting device for the manipulator has the beneficial effects that damage to the cable is avoided, and the cable can be allowed to move in the smallest space; and by arranging the connecting pieces, the cable can be allowed to be mounted and dismounted rapidly, the cable bending risk is lowered, the design is simple, and the cost effectiveness is low.

Owner:TIANJIN SANXIN SUNSHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com