Clamp capable of axial parallelly connecting cylinder shape temp sensor with pipe

A temperature sensor, axially parallel technology, used in thermometer parts, thermometers, pipes/pipe joints/fittings, etc., can solve the problem of high heat conduction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

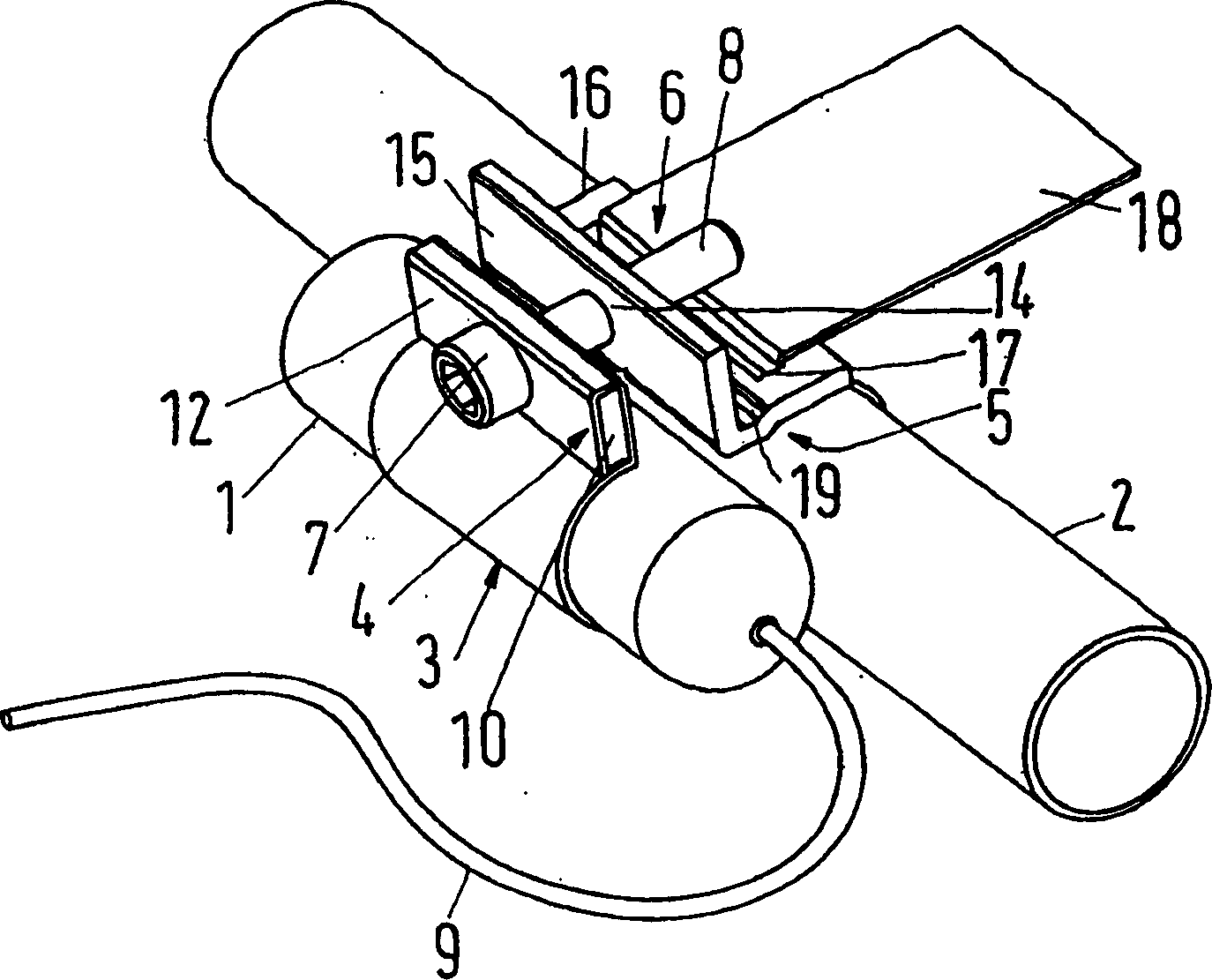

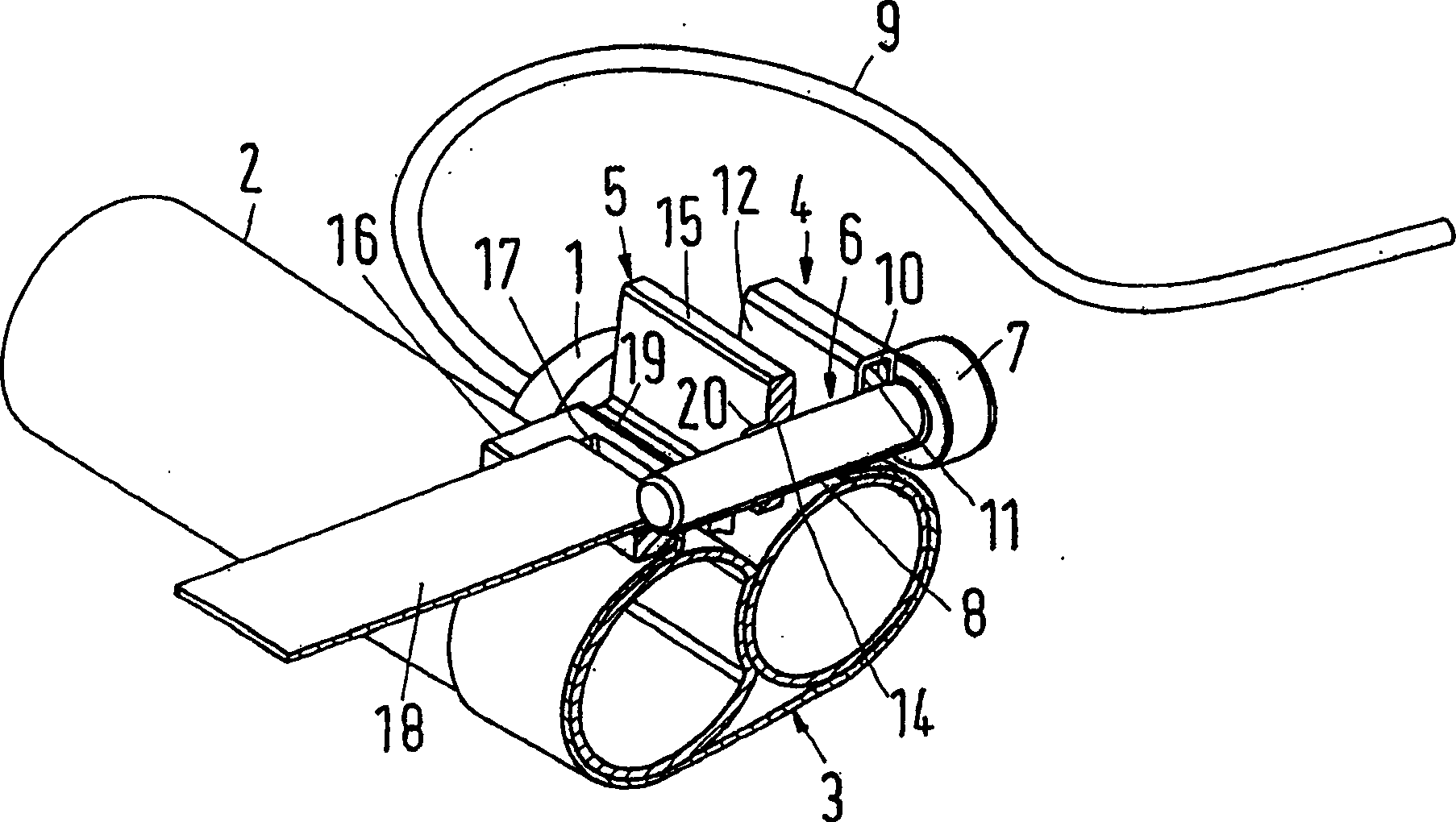

[0018] The clip shown is used to connect a cylindrical temperature sensor 1 of an expansion valve of a refrigeration plant or cooling unit to a tube 2 at the outlet of the evaporator of a refrigeration plant or cooling unit and to make the temperature sensor 1 and the tube 2 axial. touch each other in parallel.

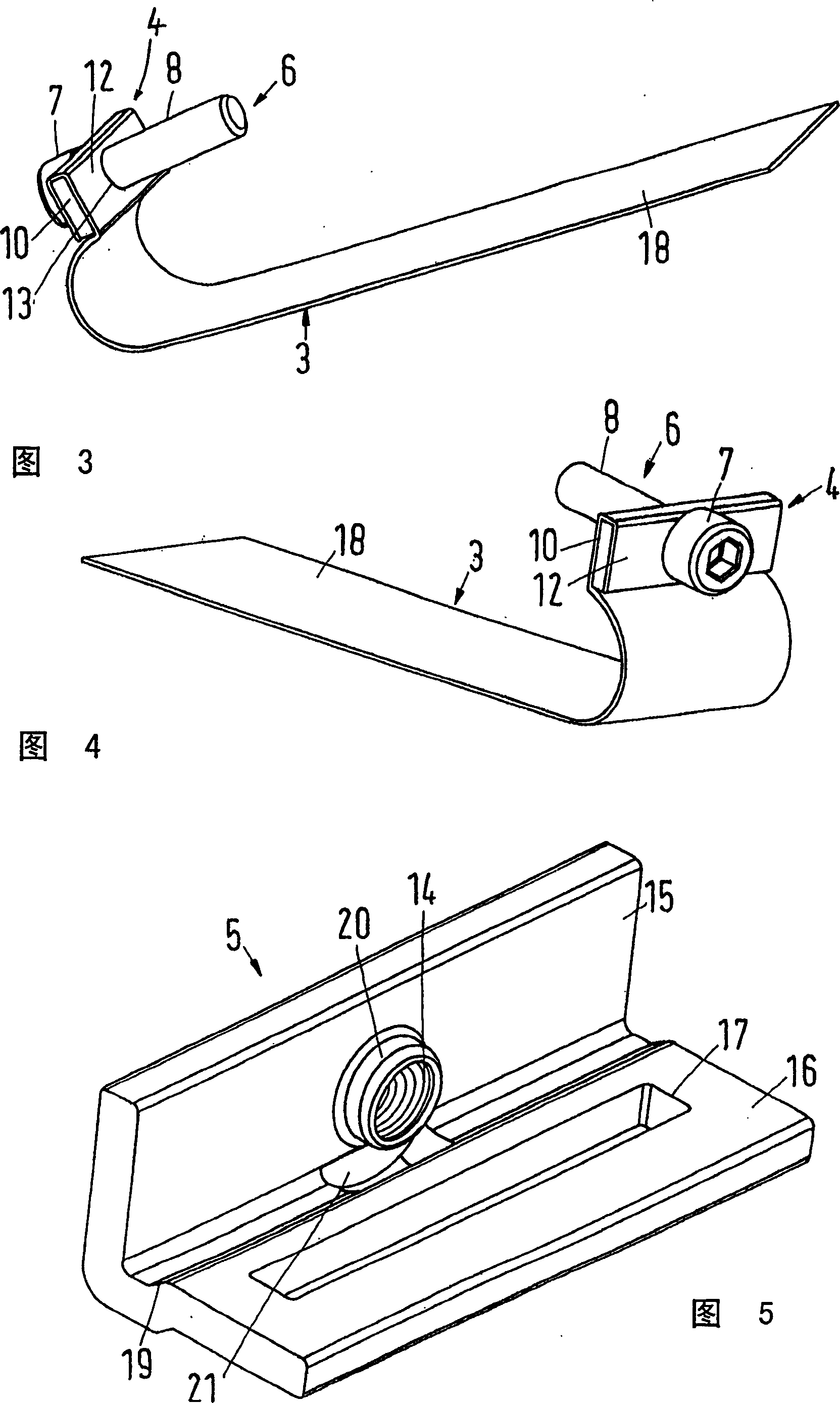

[0019] The clip shown comprises a bendable clamping collar 3 made of metal and preferably copper, a first jaw 4, a second jaw 5 in the form of a metal strip bent approximately 90°, and a metal strip with a Fastening bolt 6 with head 7 and threaded rod 8 .

[0020] The temperature sensor 1 is connected via a capillary 9 to the expansion valve (not shown).

[0021] Jaw 4 comprises a plate 10 with an unthreaded hole 11 . The first end 12 of the clamping jaw 3 is bent around the plate 10 so that it rests on both sides of the plate 10 . The first end 12 of the jaw 3 has a hole 13 on either side of the plate 10 (FIG. 3). The hole 13 is aligned with the unthreaded hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com