A quick-loading and anti-bending tooling for thermally processed camshafts and a quick-loading and anti-bending method

A camshaft and thermal processing technology, applied in metal processing equipment, workpiece cooling devices, manufacturing tools, etc., can solve the problems of environmental and on-site equipment and personnel safety threats, high cost, etc., to improve product yield and turnover efficiency, loading The effect of large capacity and stable loading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

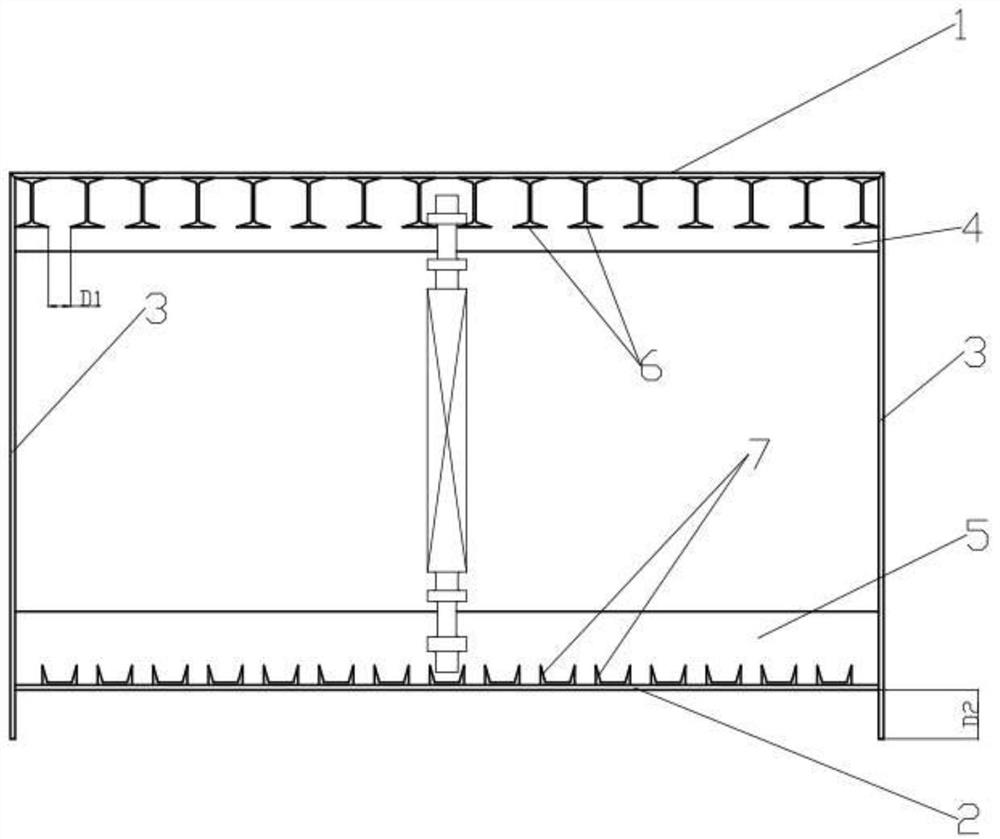

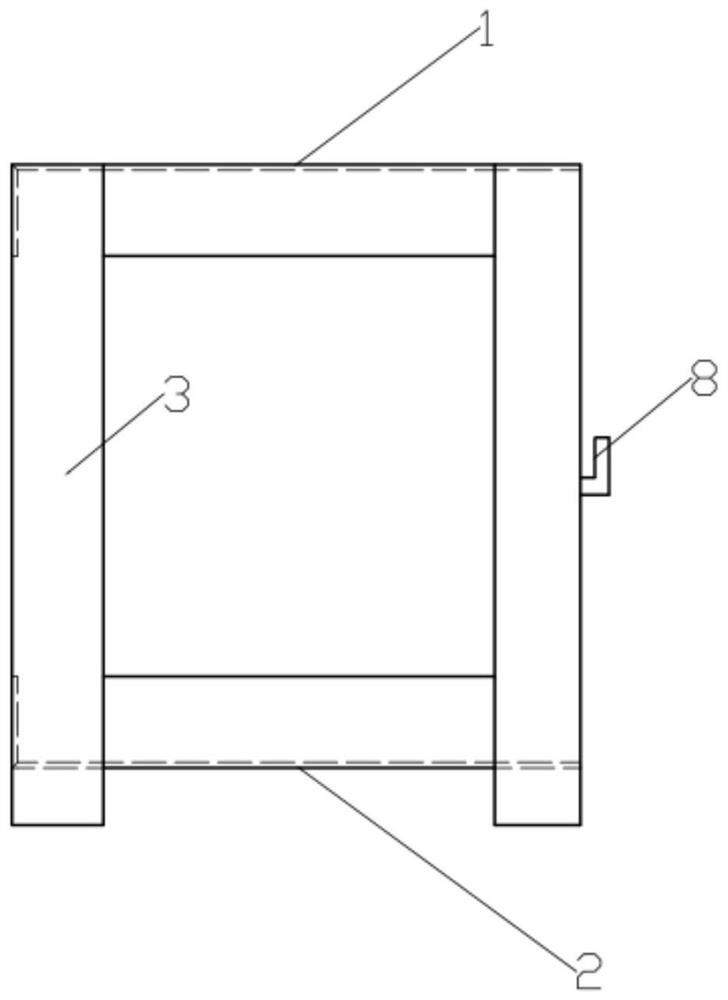

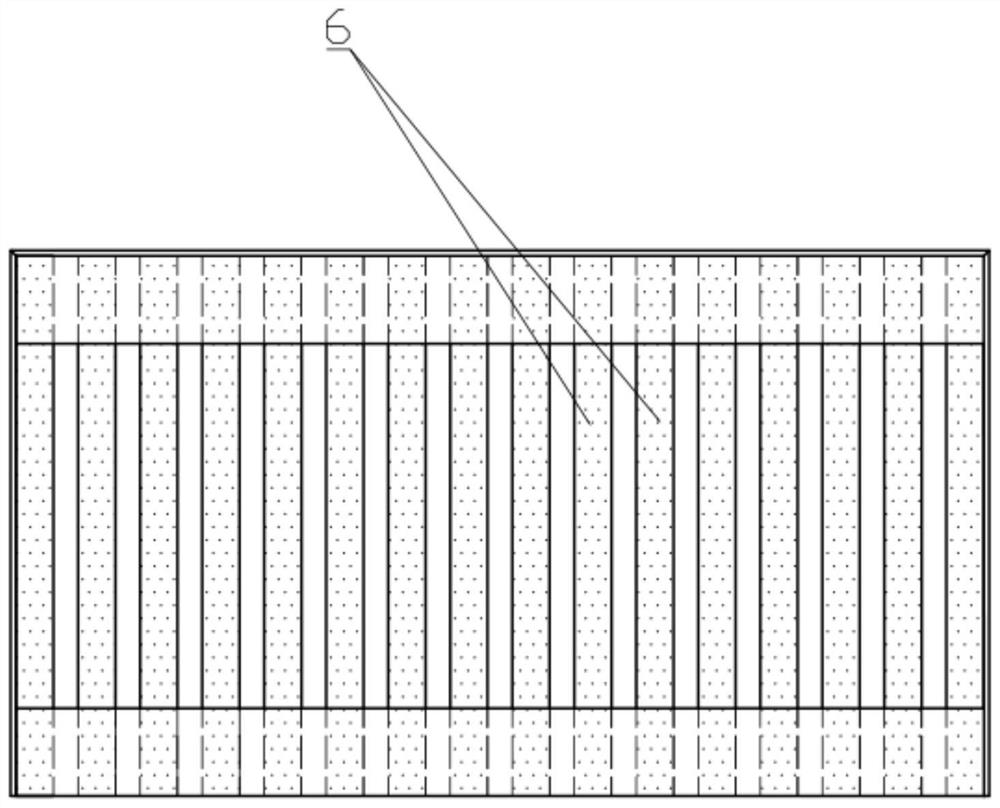

[0032] see Figure 1 ~ Figure 3 , Figure 1 ~ Figure 3 It is a diagram of various directions of a fast loading and anti-bending tooling for a thermally processed camshaft according to Embodiment 1 of the present invention.

[0033] A quick-loading and anti-bending tooling for thermally processed camshafts in this embodiment includes an upper support frame plate 1, a lower support frame plate 2, and a vertical support frame plate 3, and a plurality of the upper support frame plates 1 and lower support frame plates 2 Together with the vertical support frame plate 3, a rectangular parallelepiped frame is formed, and a plurality of I-beams or H-shaped steels 6 are welded on the bottom surface of the upper support frame plate 1. The vertical mode is welded on the bottom of the upper support frame plate 1 through the upper legs, and the plurality of I-beams or H-shaped steels 6 are arranged in parallel and spaced apart, and there is a gap between the edges of the lower legs of two ...

Embodiment 2

[0048] The scheme of embodiment 2 is as Figure 4 As shown, embodiment 2 provides an improved hot-worked camshaft rapid loading anti-bending tooling compared to embodiment 1, the improvement lies in the lower leg of the I-beam or H-beam 6 that will be in direct contact with the red-hot camshaft The part is reinforced, specifically, a reinforcing plate 9 is welded at the bottom end along the width direction of the lower leg, and the reinforcing plate 9 provides a higher resistance to thermal stress deformation for the lower leg of the I-beam or H-shaped steel 6, Ensure the service life of the entire tooling. Other technical features and effects not mentioned in this embodiment may be the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com