Testing machine for testing crane scale and method for disassembling and assembling weight thereof

A verification test and weight technology, applied in the field of measurement verification, can solve the problems of measurement accuracy and measurement result error, and achieve the effects of convenient acquisition, high work efficiency and high work precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

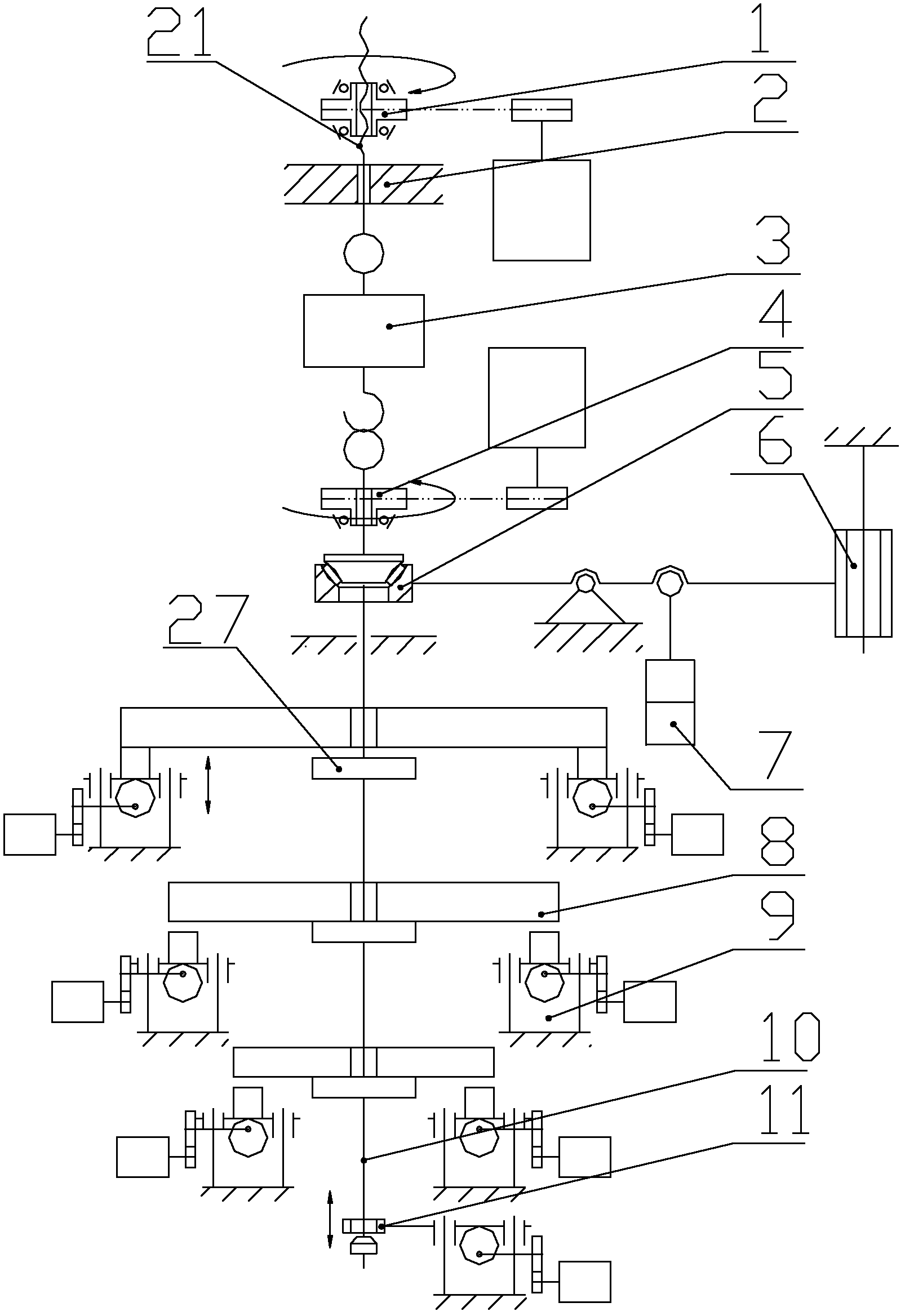

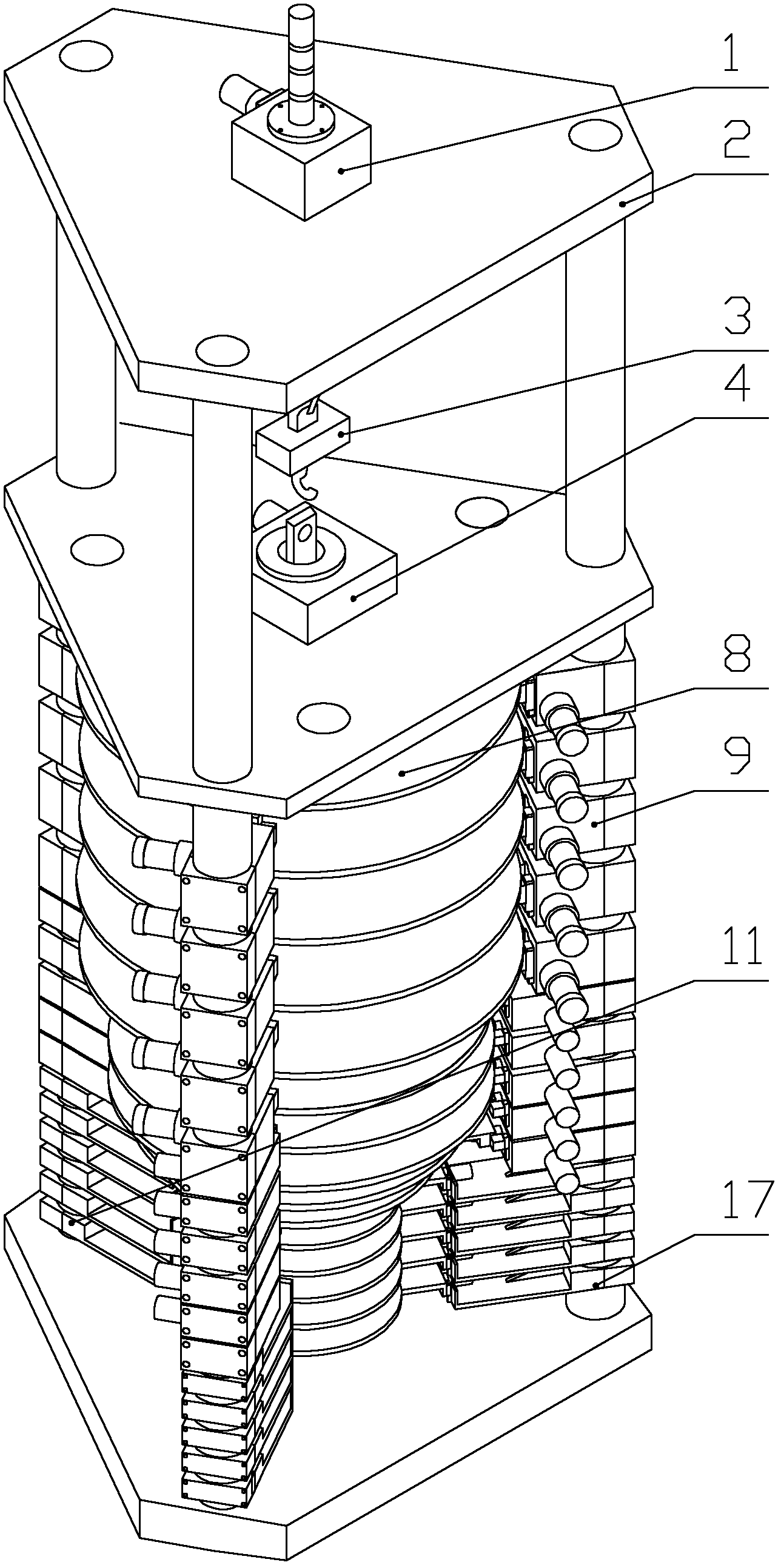

[0126] Embodiment——30t Specification Crane Scale Verification Testing Machine

[0127] 30t crane scale verification testing machine structure:

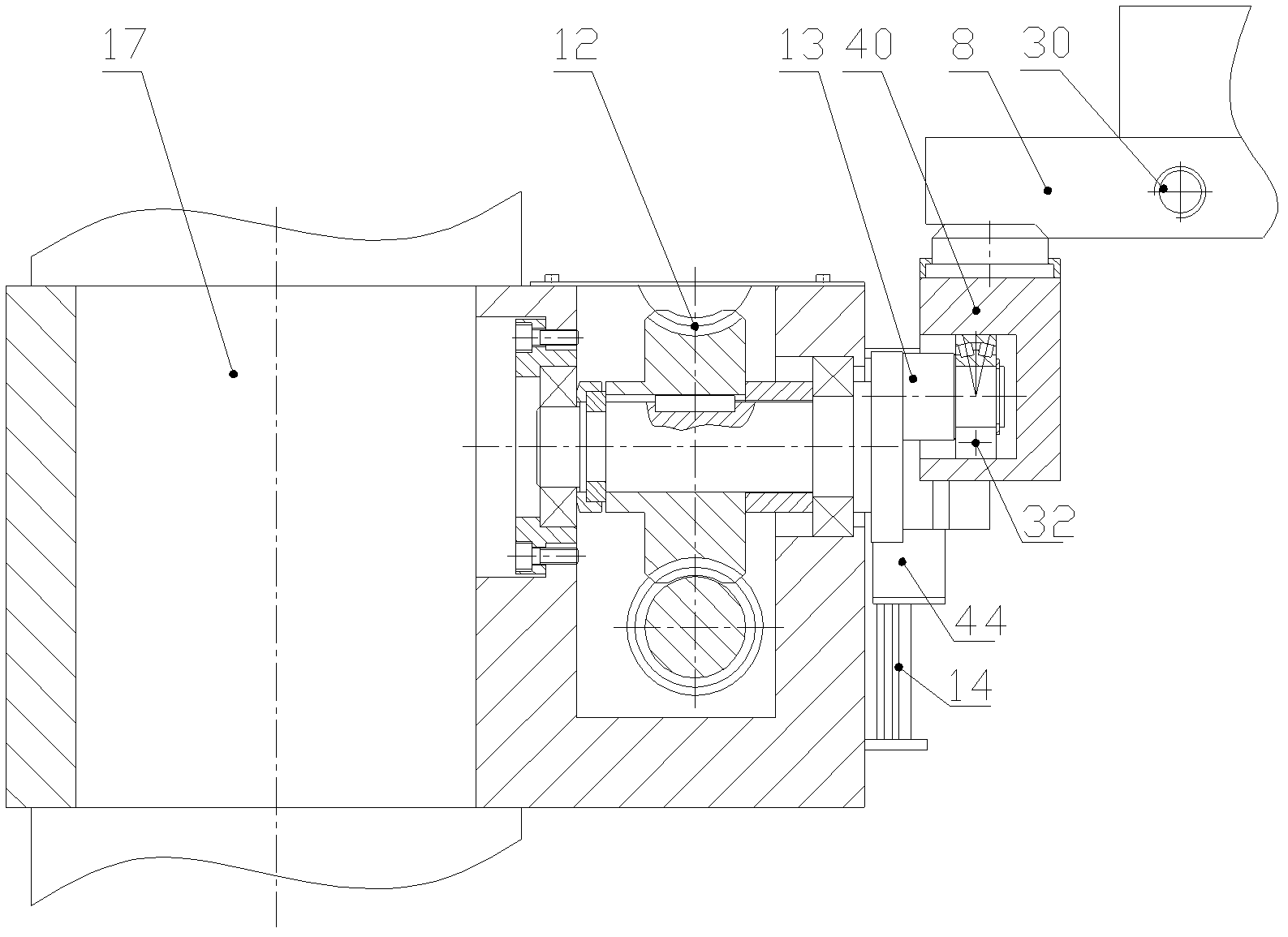

[0128] refer to figure 2 ,in accordance with figure 1 The composition principle of the mechanism is shown, and the design of the mechanical structure is as follows: figure 2 The crane scale verification testing machine shown. Wherein: the frame 2 is composed of three columns 17 with the same structure and a triangular upper beam, middle beam and lower beam, the weight driving mechanism 9 is fixed on the column 17, and each weight 8 is composed of three weights with the same structure The driving mechanism 9 drives and supports. The weight driving mechanism 9 is structurally designed in a split assembly form, installed in the annular groove of the column 17, and fastened with screws 16. When the screw 16 is loosened, the weight driving mechanism 9 as a whole can rotate around the center line of the column 17 . The crane scale 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com