Grinding Center

A kind of grinding processing and grinding head technology, which is applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems that the CNC grinding equipment cannot meet the actual production needs, and achieve Improve machining accuracy and surface quality, compact structure, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

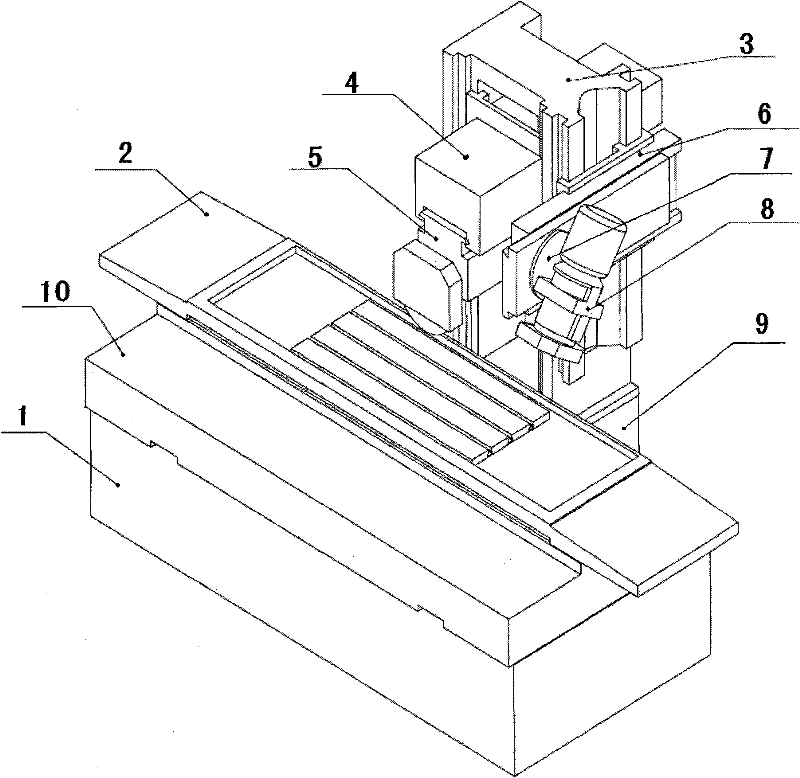

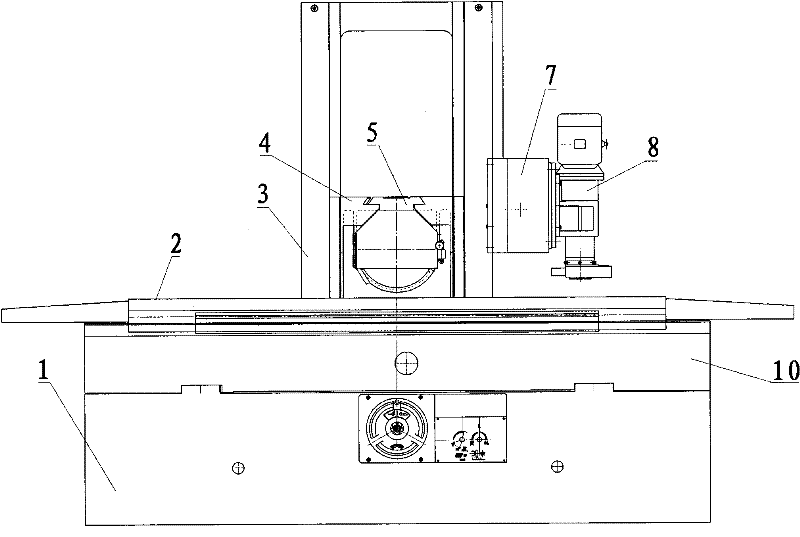

[0041] like Figure 1 to Figure 12, the present invention includes a bed, a large carriage, a workbench, a column, a horizontal grinding head assembly and a vertical grinding head assembly, a lubrication system, and a control system. The control system includes a computer numerical control system and a servo system. The bed is divided into a front bed 1 and a The rear bed 9, the door-shaped column 3 is arranged on the rear bed 9, the horizontal grinding head assembly is placed inside the door-shaped column 3, the vertical grinding head assembly is located on one side of the door-shaped column 3, and the large carriage 10 is arranged on the front On the bed 1, a workbench 2 is arranged on the large carriage 10, and this structure is called a memory external hanging type vertical and horizontal double grinding head structure.

[0042] The horizontal grinding head assembly includes a horizontal grinding head carriage 4 and a horizontal grinding head 5, the horizontal grinding hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com