Printing press cylinder

A technology for printing presses and cylinders, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of temperature rise, bending, adverse effects on printing quality, etc., to reduce the risk of bending, high stability, and reduce local Dangerous effects of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention relates to a printing press cylinder of a printing press, in particular a rotary printing press.

[0011] The printing press cylinder according to the invention may be a plate cylinder, a transfer cylinder or also a planetary cylinder. Furthermore, the printing press cylinder according to the invention may also be an inking roller, a dampening roller or also a sheet feeding roller.

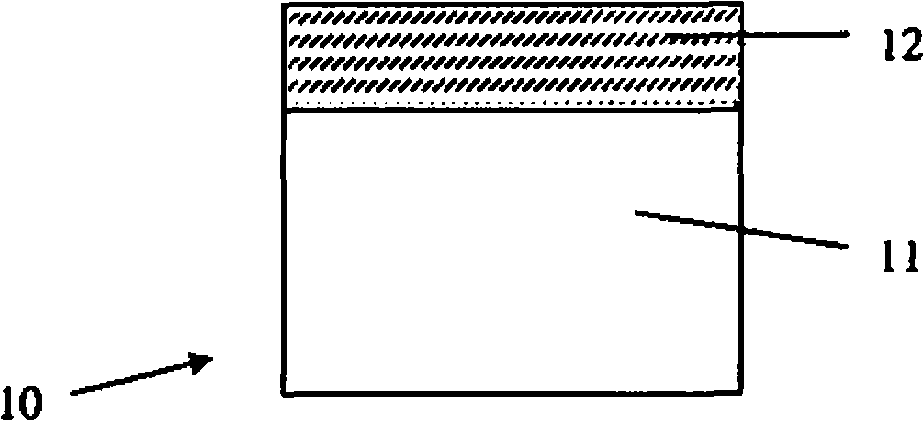

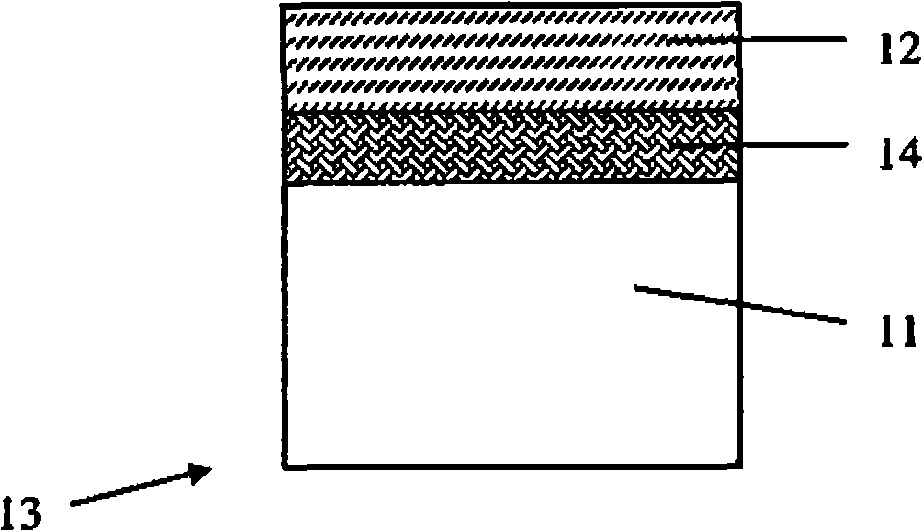

[0012] FIG. 1 shows a section through a part of a printing press cylinder 10 according to the invention, wherein the printing press cylinder 10 according to FIG. 1 has a cylinder base body 11 and a functional layer 12 applied to the cylinder base body. The functional layer 12 forms the outer surface of the printing press cylinder 10 .

[0013] In the sense of the invention, the drum base body 11 is formed from textile fibers impregnated with phenolic resin. Alternatively, the drum base 11 may also be formed of cardboard. A drum base body 11 formed of phenolic resin-impregna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com