Looping tool strickle and its manufacturing method

A technology of loop forming tool and manufacturing method, which is applied in textiles and papermaking, knitting, warp knitting, etc., and can solve the problems of increasing manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

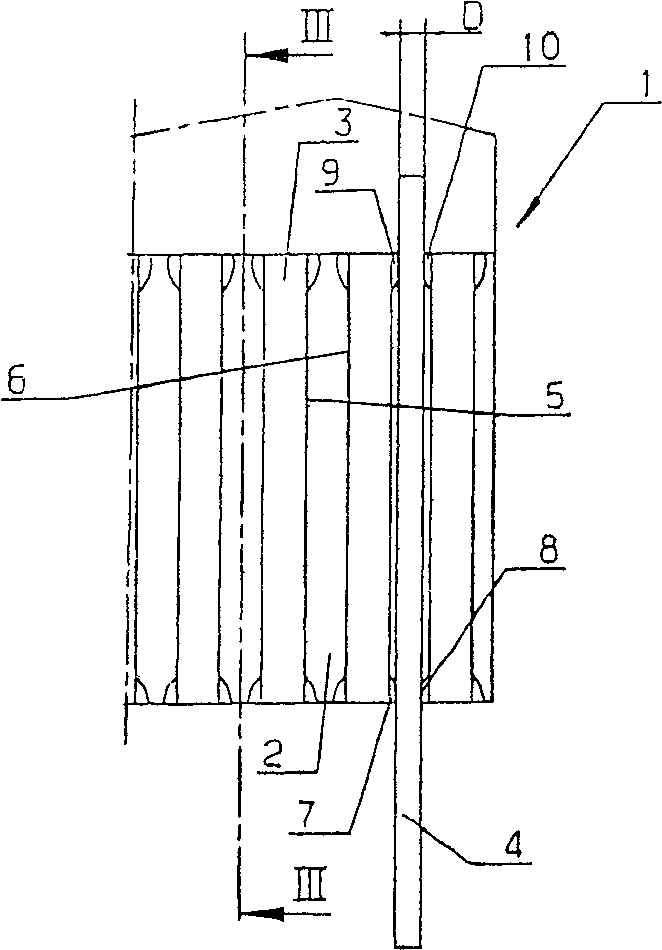

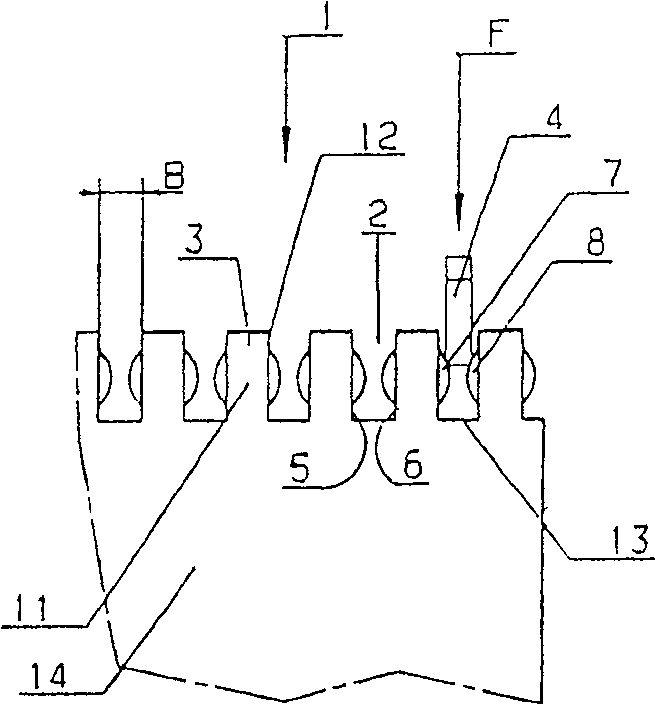

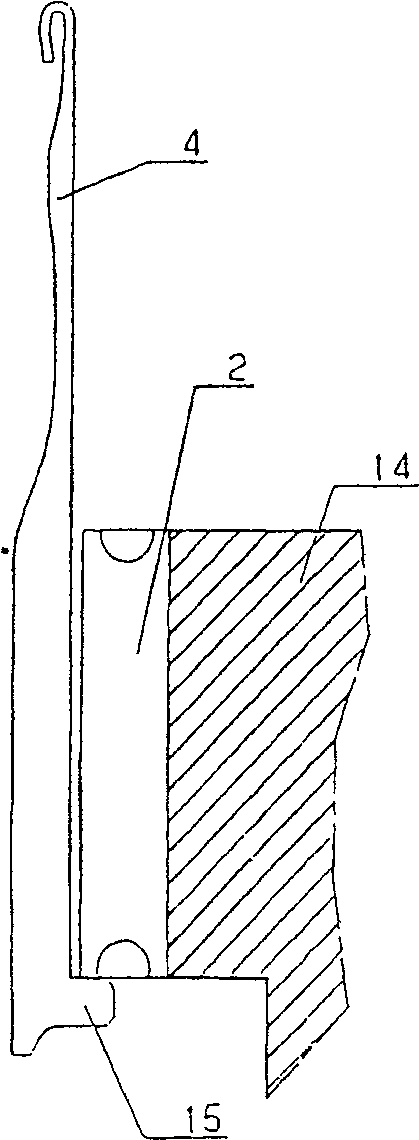

[0030] A looping tool bar 1 has a plurality of grooves 2 separated from one another by webs 3 . The slots 2 are used for accommodating knitting tools, a crochet needle 4 being inserted here as an example into a slot.

[0031] Each groove 2 has two side walls 5 , 6 , wherein the side walls 5 , 6 form the sides of the web 3 .

[0032] as by figure 1 with 2 It can be seen that the thickness D of the hook 4 is smaller than the width B of the groove 2 .

[0033] In order to be able to hold the hooks 4 in their grooves 2 virtually without play, the webs 3 have formed parts 7 - 10 on their two front sides. These shaped parts 7-10 are formed by upsetting of the material. For this purpose, a tool-in the simplest case is a continuous flat material on the length of the looping tool bar 1, its height is less than the height of the spacer 3-attached to each end face of the spacer 3, A predetermined force is then applied, for example by impact. A cutout 11 is now formed at the end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com