Cyclone extraction device and separation system using same

An extraction device and separation system technology, which is applied in separation methods, solvent extraction, liquid solution solvent extraction, etc., can solve the problems of low extraction and mass transfer efficiency, and the inability to fully mix the organic phase and the aqueous phase, so as to improve the rotation stability , Reduce the impact of mass transfer reaction heat, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

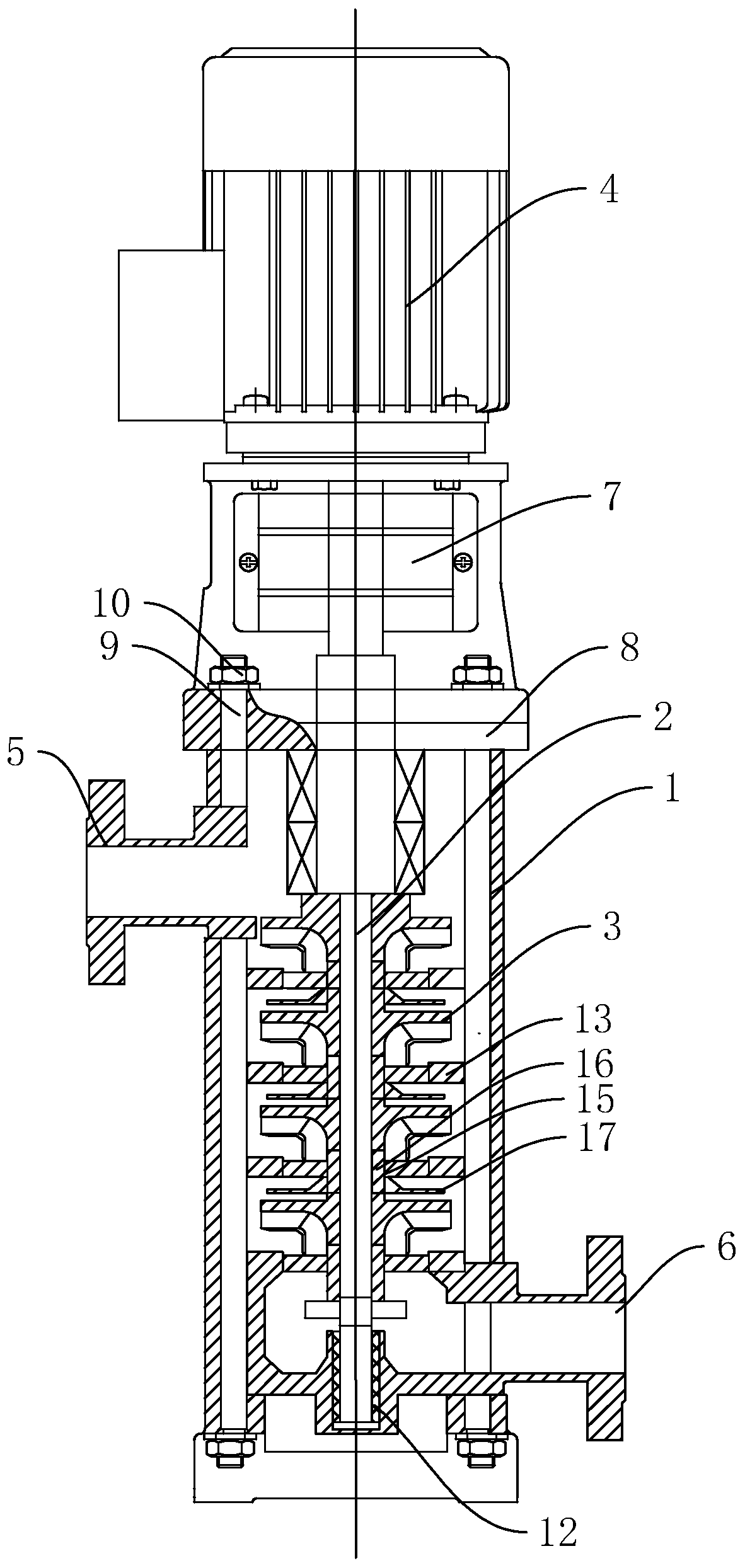

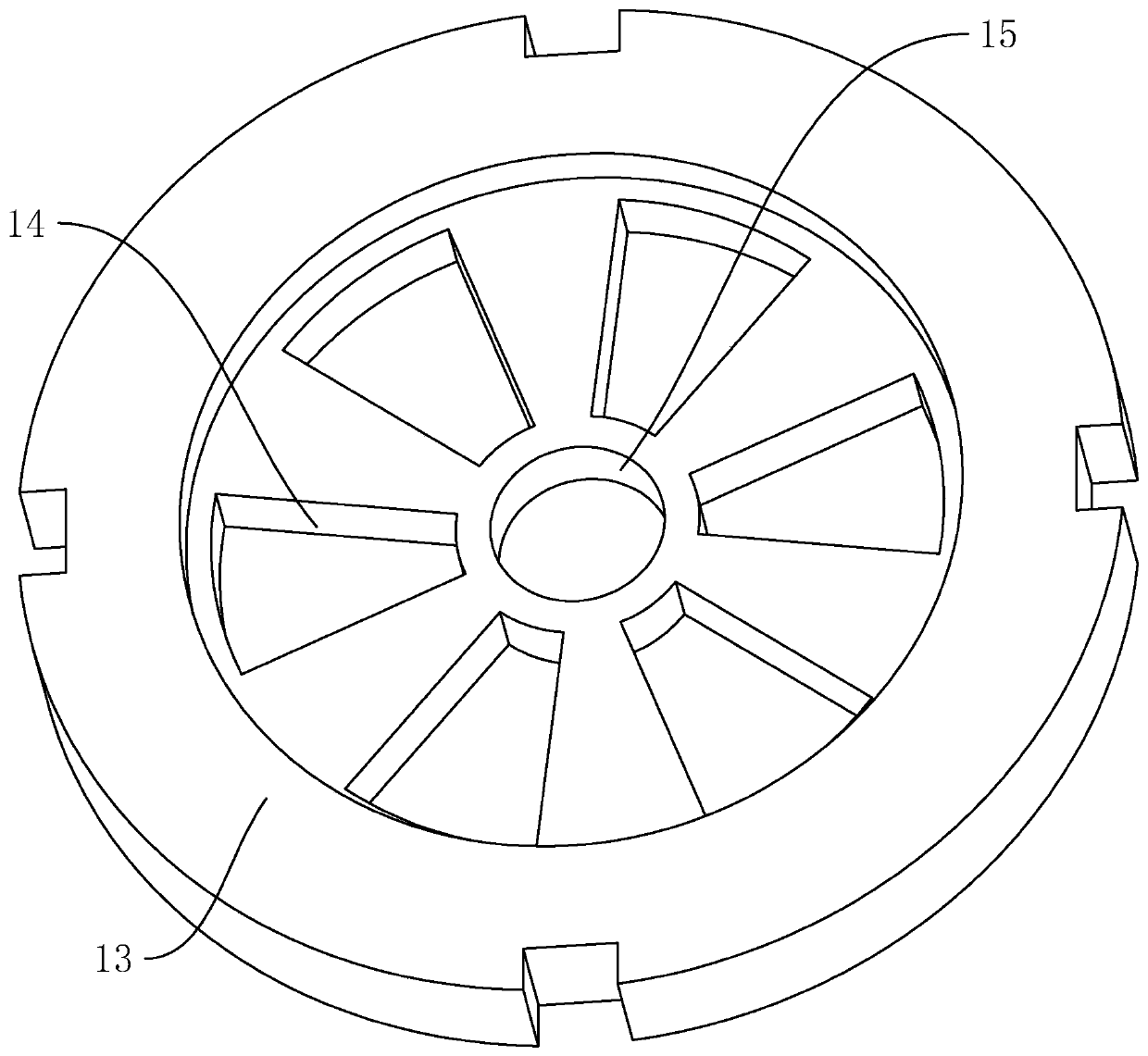

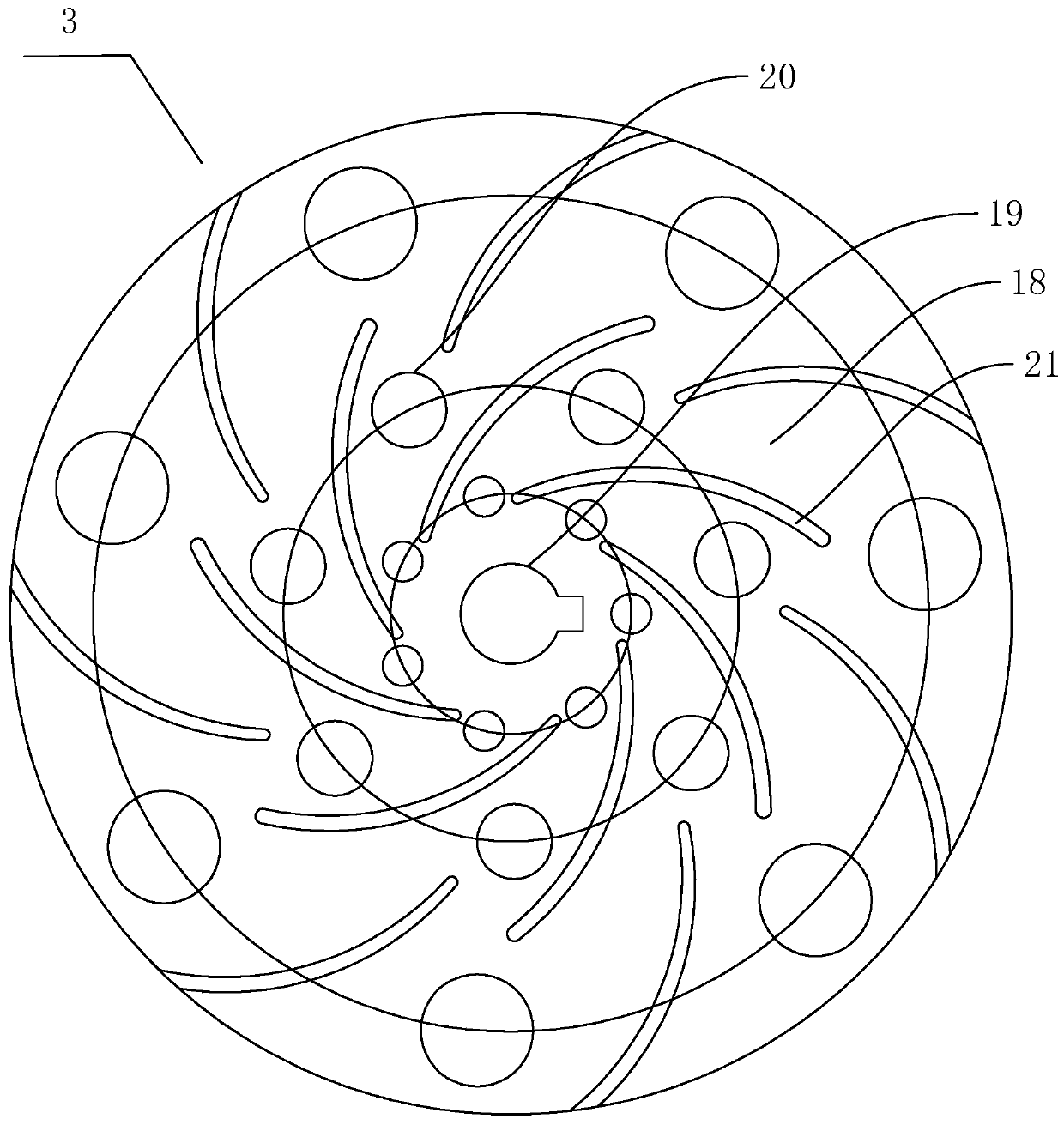

[0042] Embodiment one: cyclone extraction device, such as figure 1 As shown, it includes a cylindrical shell 1, a main shaft 2 rotatably connected along the central axis of the shell 1, a swirl reaction disc 3 coaxially fixed to the main shaft 2, and a swirl extraction motor 4 for driving the main shaft 2. The cylindrical shell 1 A liquid inlet 5 and a liquid outlet 6 are respectively integrally formed at the upper and lower ends of the outer wall of the circumference, and a connector 7 is installed between the top of the shell 1 and the swirl extraction motor 4, and the number of swirl reaction discs 3 is at least four. In the embodiment, the specific number of swirling flow reaction discs 3 is three, and they are arranged at equal intervals along the length direction of the main shaft 2 .

[0043] When the cyclone extraction device is used for extraction or stripping, the two-phase feed liquid enters the shell 1 through the liquid inlet 5, and flows from top to bottom along ...

Embodiment 2

[0049] Embodiment two: utilize the separation system of cyclone extraction device, as Figure 4 As shown, including extraction system A, extraction system B, extraction system C, extraction system D, stripping cobalt system A, stripping cobalt system B, stripping copper system A, stripping copper system B, stripping iron system A, Iron stripping system B, raw material liquid storage tank 22, organic storage tank after extraction 23, organic storage tank after copper washing 24, extraction raffinate storage tank 25, cobalt sulfate storage tank 26, reverse cobalt acid storage tank 27, after iron washing Organic storage tank 28, refined sulfuric acid tank 29, refined liquid alkali tank 30, pure water tank 31, saponification tank 32, sodium sulfate liquid tank 33, copper washing acid solution preparation tank 34, anti-cobalt acid preparation tank 35, anti-ferric zinc acid preparation Tank 36; extraction system A, extraction system B, extraction system C, extraction system D, strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com