Formwork system and cast-in-place concrete floor

A technology of cast-in-place concrete floor slabs and reinforced concrete floor slabs, which is applied in the field of cast-in-place concrete floor slabs, can solve problems such as many disadvantages, and achieve the effects of low cost, light weight, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

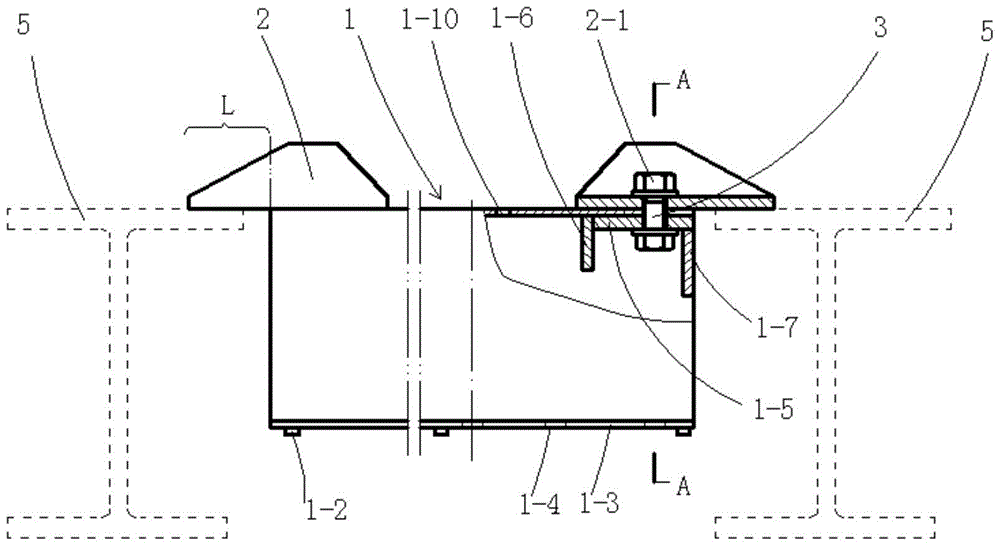

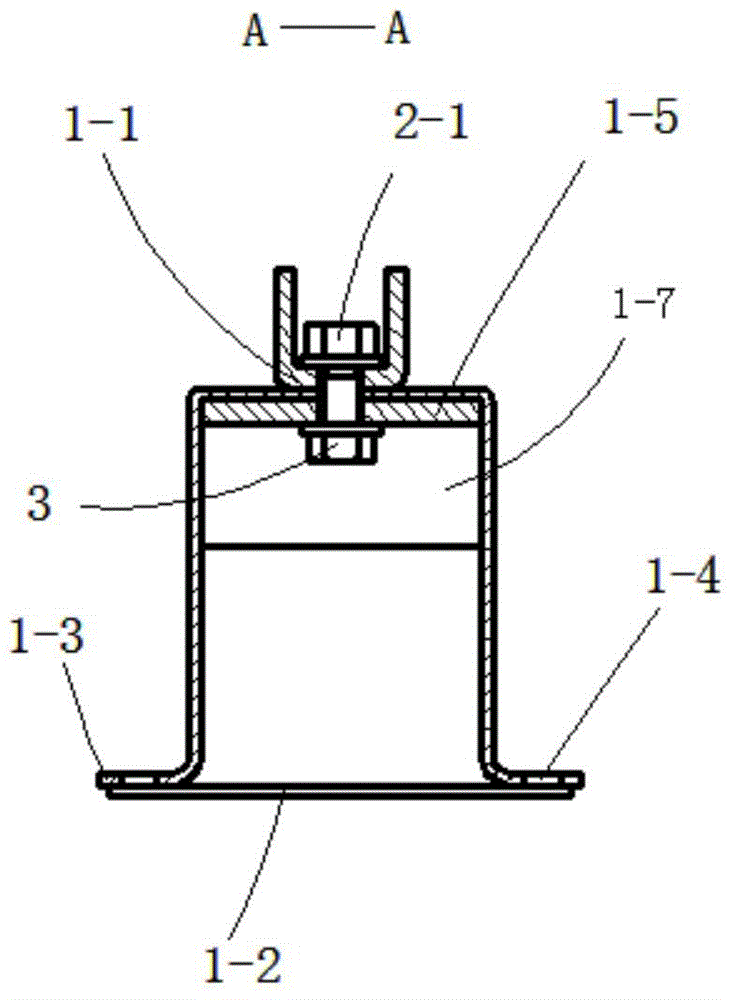

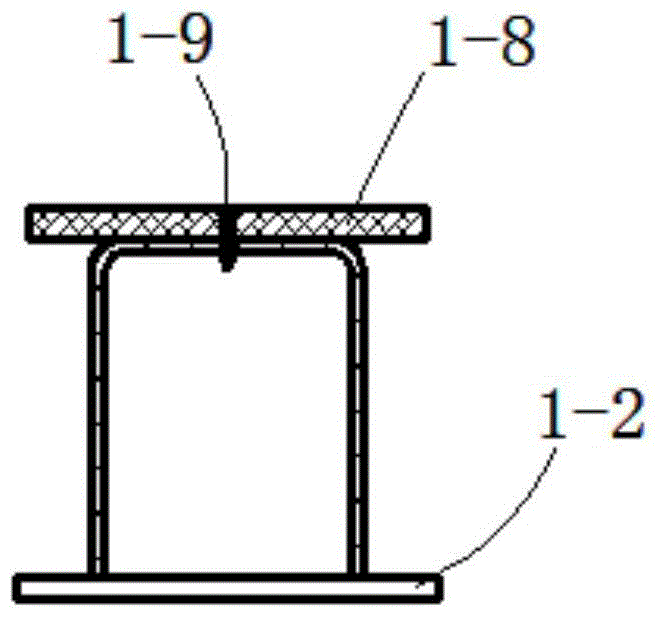

[0055] Template system embodiment 1, such as Figure 1-7 , including joist 1, template 6, figure 1 and figure 2 The joist 1 shown is a hat-shaped steel beam with a through hole 1-1 at the top, and the reinforcement structure at the end includes a reinforcement plate 1-5, a first reinforcement rib 1-6, and a second reinforcement rib 1-7 , horizontal bars 1-2 are arranged at intervals at the bottom; there are folded edges 1-3 at the lower part of the hat-shaped steel beam, and small holes a1-4 are arranged on the folded edges 1-3. The cantilever 2 is a U-shaped steel part, the two ends of the vertical bar are chamfered or chamfered, and there is an opening in the middle. The nut 2-1 is arranged on the opening, and the bolt 3 passes through the through hole 1-1, and the nut 2-1 1 Tighten the joist 1 and the cantilever 2, the bolt 3 can be di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com