How to use pins for semiconductor coating equipment with different heights

A kind of coating equipment and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of unequal pin height, achieve the effect of low precision parts, horizontal support, and good performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

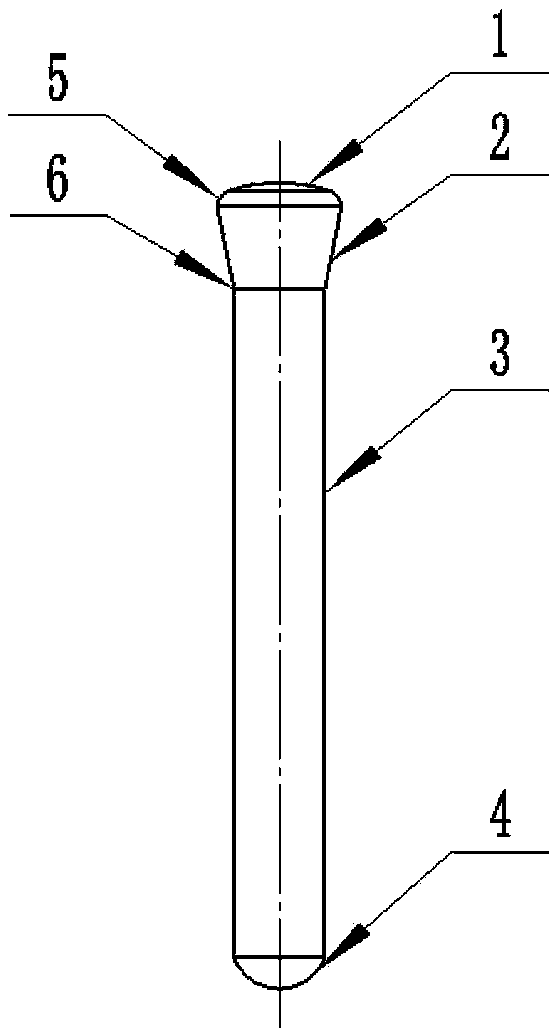

[0010] refer to figure 1 , The method of using pins for semiconductor coating equipment with different heights, the pins have multiple different heights. The height of the pin is set according to its reference value. Two height values are set at the top and bottom respectively. According to the actual height, it is divided into 5 height values. The height value difference is set as the upper and lower height differences. 0.3mm range. The top surface 1 of the pin adopts a spherical structure, and this part is the part that is in direct contact with the wafer. Ensure that the pins and wafers are always in a tangential state, and there will be no adhesion due to external factors such as high temperature and process tests. The upper end portion 2 of the pin adopts a conical structure, which is more conducive to the smooth running of the pin when it contacts the heating plate during the lifting process. The main part 3 of the pin is a cylindrical structure, and it has a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com