PEM hydrolysis hydrogen production titanium metal bipolar plate and preparation method thereof

A technology for hydrogen production and titanium metal production by hydrolysis, used in metal processing equipment, non-precious metal oxide coatings, electrodes, etc., can solve the problems of poor forming process performance, reduced hydrogen production capacity, and high cost of bipolar plates The effect of fine and uniform organization, weight reduction and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

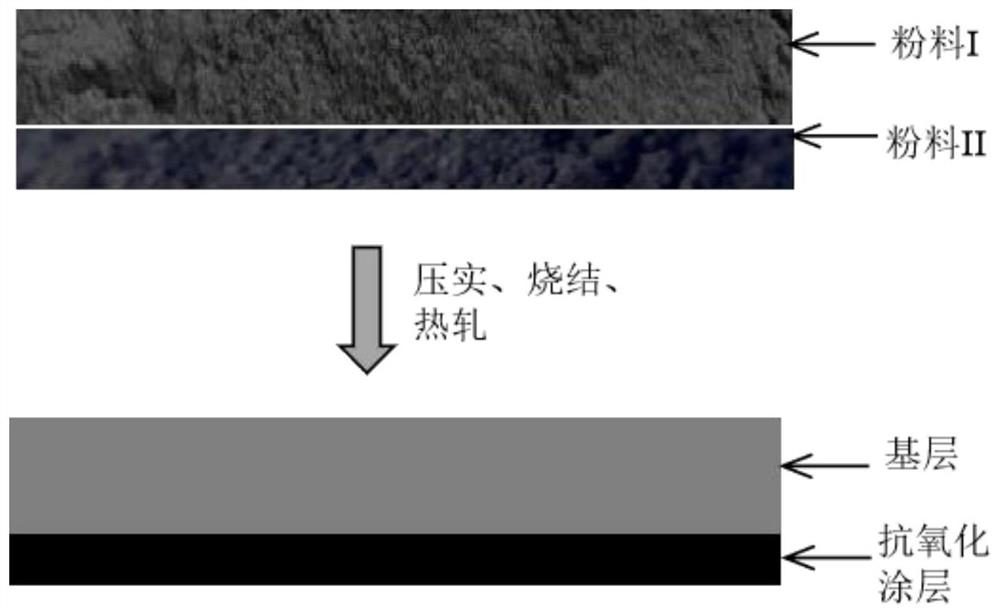

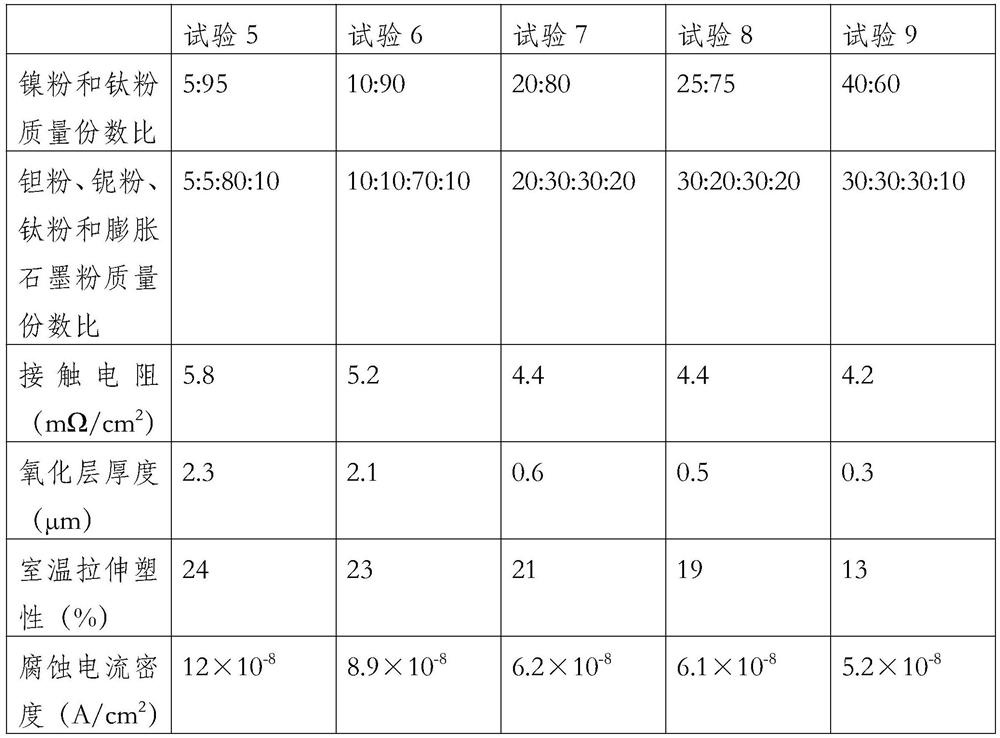

[0046] 1) Preparation of materials: Take commercial nickel powder, cobalt powder, pure titanium powder, metal tantalum and niobium powder; according to the mass ratio, take 15 parts of nickel powder and 85 parts of titanium powder for mixing, and then take 1% of cobalt by mass ratio, and mix them into powder Material Ⅰ;

[0047] According to the mass ratio, get 30 parts of metal tantalum powder, 30 parts of niobium powder, 30 parts of titanium powder and 10 parts of expanded graphite powder, then get 1% cobalt by mass ratio, and mix it into powder II;

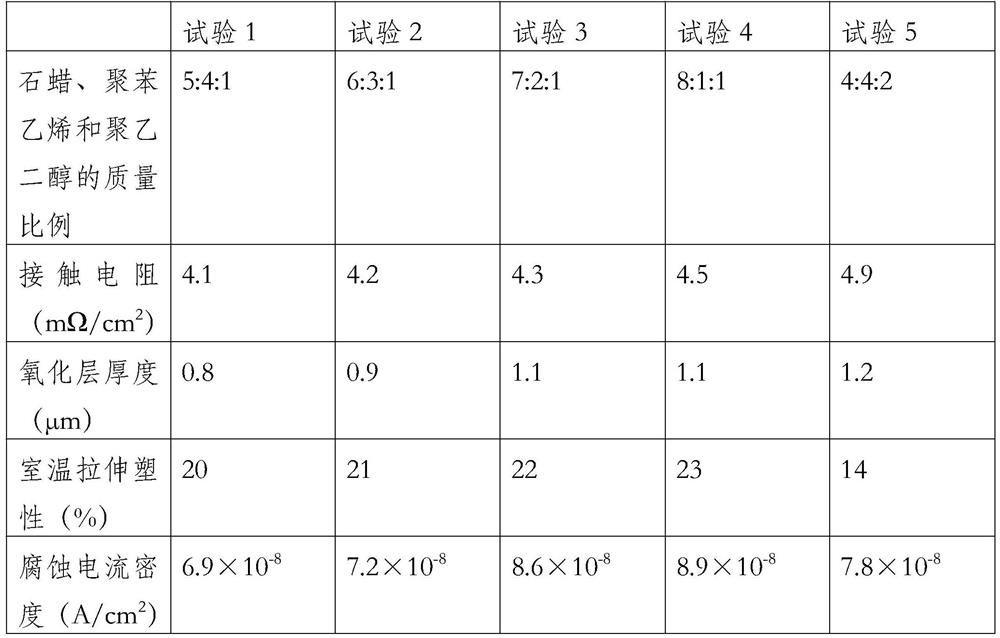

[0048] 2) Ball milling pretreatment: After powder I and powder II are mechanically alloyed separately in a ball mill, paraffin compound additives are added to powder I and powder II after mechanical alloying in a ball mill, and mixed evenly to obtain ball mill pretreated Powder I and Powder II; wherein, the amount of paraffin composite additives accounts for 3% of the mass ratio of the respective powders, the paraffin composite...

Embodiment 2

[0052] 1) Preparation of materials: Take commercial nickel powder, cobalt powder, pure titanium powder, metal tantalum and niobium powder; according to the mass ratio, take 10 parts of nickel powder and 90 parts of titanium powder for mixing, and then take 3% cobalt by mass ratio and mix them into powder Material Ⅰ;

[0053] According to the mass ratio, get 25 parts of metal tantalum powder, 25 parts of niobium powder, 30 parts of titanium powder and 20 parts of expanded graphite powder, get 2% cobalt of mass ratio again, mix into powder material II;

[0054] 2) Ball milling pretreatment: After powder I and powder II are mechanically alloyed separately in a ball mill, paraffin compound additives are added to powder I and powder II after mechanical alloying in a ball mill, and mixed evenly to obtain ball mill pretreated Powder Ⅰ and powder Ⅱ; the amount of paraffin compound added accounts for 4% of the mass ratio of the respective powders, the paraffin compound additive is comp...

Embodiment 3

[0058] 1) Preparation of materials: Take commercial nickel powder, cobalt powder, pure titanium powder, metal tantalum and niobium powder; according to the mass ratio, take 30 parts of nickel powder and 70 parts of titanium powder for mixing, and then take 1% cobalt by mass ratio, and mix them into powder Material Ⅰ;

[0059] According to the mass ratio, get 30 parts of metal tantalum powder, 25 parts of niobium powder, 30 parts of titanium powder and 15 parts of expanded graphite powder, then get 5% cobalt in mass ratio, and mix it into powder II;

[0060] 2) Ball milling pretreatment: After powder I and powder II are mechanically alloyed separately in a ball mill, paraffin compound additives are added to powder I and powder II after mechanical alloying in a ball mill, and mixed evenly to obtain ball mill pretreated Powder Ⅰ and powder Ⅱ; wherein, the amount of paraffin wax added accounts for 5% of the mass ratio of the respective powders, and the paraffin wax composite addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com