Alternatively-operated efficient hydraulic machine and using method

A technology of alternate operation and hydraulic press, applied in the field of hydraulic pressure, can solve the problems of low forming efficiency, unfavorable rapid replacement of upper mold and lower mold, and inability to perform alternately, so as to achieve high forming efficiency, facilitate rapid hydraulic forming, and avoid uneven force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

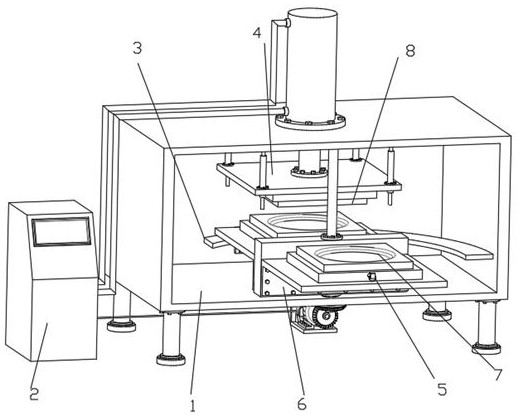

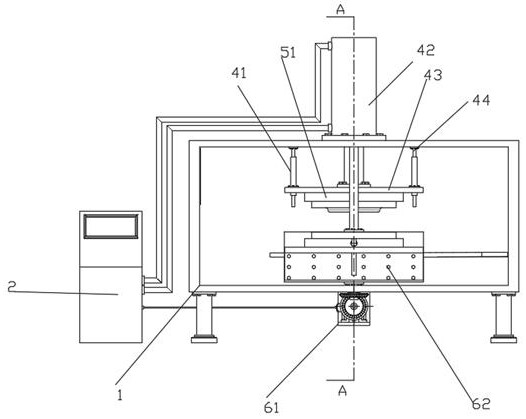

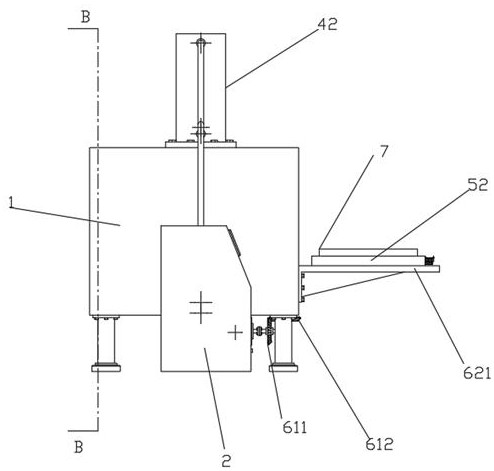

[0046] like Figure 1-7 As shown, a high-efficiency hydraulic press for alternating operation includes a chassis 1, a control box 2, a lower mold 7 and an upper mold 8, the control box 2 includes a control system and a hydraulic station, and the bottom front end of the chassis 1 is provided with alternate operation. The operation assembly 6, the alternate operation assembly 6 includes an intermittent rotation assembly 61 and a multi-station support assembly 62, the intermittent rotation assembly 61 is installed at the bottom of the chassis 1, the intermittent rotation assembly 61 is connected to the multi-station support assembly 62, and the multi-station support assembly 62. 62 is connected to the inner top of the chassis 1, the intermittent rotation component 61 is used for intermittent rotation of the multi-station support component 62, and the intermittently rotated multi-station support component 62 is used for alternate operation;

[0047] The intermittent rotation assem...

Embodiment 2

[0063] On the basis of Example 1, see Figure 11 As shown, the hydraulic assembly 4 is symmetrically provided with a lower mold position calibration assembly 9 for position calibration. The lower mold position calibration assembly 9 includes a calibration straight plate 91 and an arc guide plate 92. The left and right side walls of the mounting plate 43 are fixed with a calibration straight plate 91. An arc guide plate 92 is fixed at the bottom of the straight plate 91 , and the bottom of the arc guide plate 92 is set higher than the installation straight plate 623 and the top of the lower mold 7 when the hydraulic assembly 4 moves to the highest end.

[0064] The mounting plate 43 drives the arc guide plate 92 of the lower mold position calibration assembly 9 to move downward, the arc guide plate 92 moves to the outer side of the lower mold support plate 621, and the arc guide plate 92 moves to the lower mold support plate 621 and then calibrates The straight plate 91 clamps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com