Driving structure of supporting arm for stacking hollow building blocks

A hollow block and drive structure technology, applied in the field of hollow block stacking, can solve the problems of poor buffering effect, loose arms and cylinders, easy damage, etc., to meet the needs of use, increase service life, and reduce inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

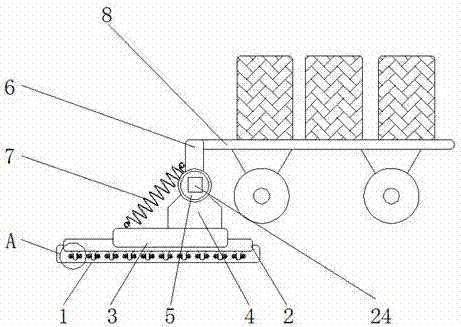

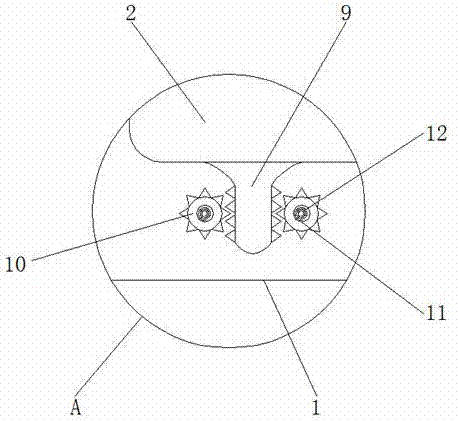

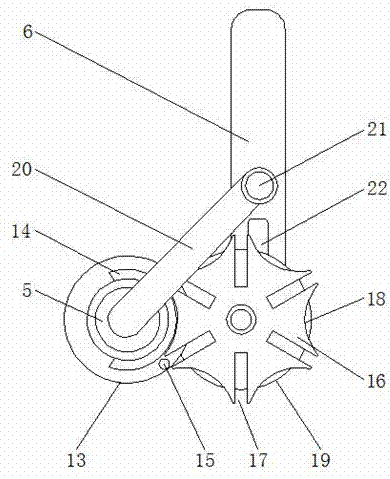

[0017] Example 1: Please refer to Figure 1-4 , the present invention provides a technical solution: a driving structure for the upper support arm of hollow block stacking, including a support base 1, a connecting shaft 11 is connected inside the supporting base 1, and a flat vortex is installed inside the connecting shaft 11 Spring 12, the outer side of connecting shaft 11 is connected with turning roller 10, and between turning roller 10 is connected by damping rod 9, and the upper end of damping rod 9 is connected with connecting plate 2, and connecting plate 2 is provided with slide plate 3 and The support platform 4, the left and right sides of the damping rod 9 are connected with the rollers 10 by meshing, and the number of the rollers 10 is twice the number of rows of the damping rods 9, which can facilitate the up and down movement of the damping rods 9 The movement drives the rotating roller 10 to rotate, and facilitates the stable up and down movement of the damping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com