Back pressure type steam turbine rapid starting method based on cold end optimization

A fast-start, back-pressure technology, applied in the direction of engine starting, machine/engine, mechanical equipment, etc., can solve the problems of large positive expansion difference of the unit, lengthening the warm-up time, affecting the safety of the unit, etc., to reduce the number of upper and lower cylinders. The effect of temperature difference, increasing the amount of steam supplied to the outside, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

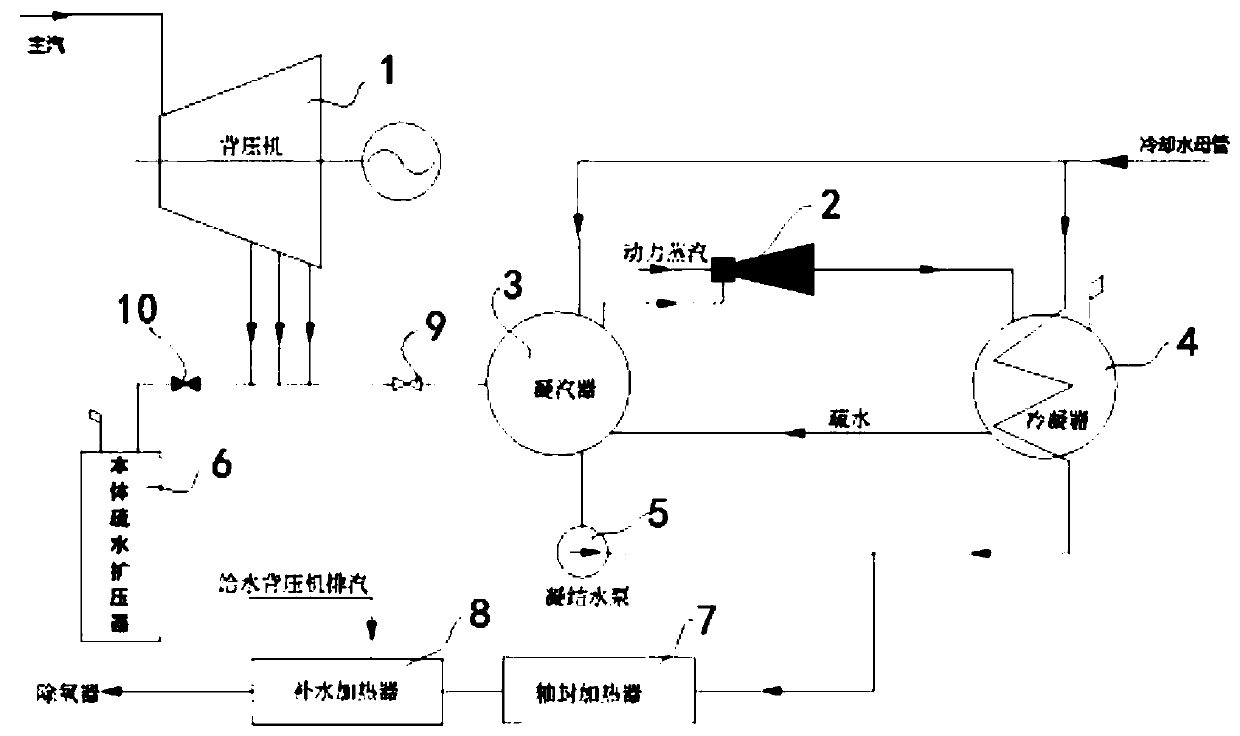

[0046] A method for quick start-up of a back pressure steam turbine based on cold end optimization. The working process is as follows: establish a negative pressure cold end, introduce the main body drainage of the back pressure machine 1 into it, make the exhaust steam condense in it, reduce the drainage, discharge At the same time, use the steam ejector 2 and the condensate pump 5 to maintain the vacuum at the cold end of the negative pressure. One side of the output end of the back pressure machine 1 is connected to the main body hydrophobic expander 6, and the other end is connected to the condenser 3, and the condenser 3 The condensate pump 5 is connected, the outlet of the steam ejector 3 is connected to the condenser 4, one end of the cooling water pipe is connected to the condenser 3, and the other end is connected to the condenser 4, and the cooled water in the condenser 4 returns to the condensate In the condenser 3, it returns to the cooling water system after being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com