Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Reduce labor output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

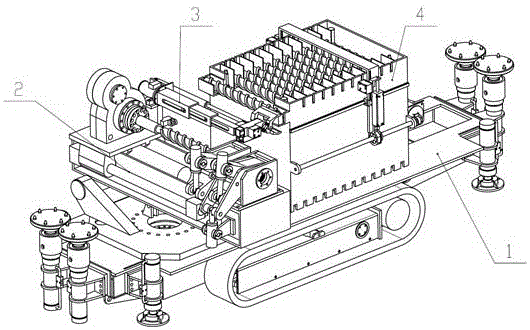

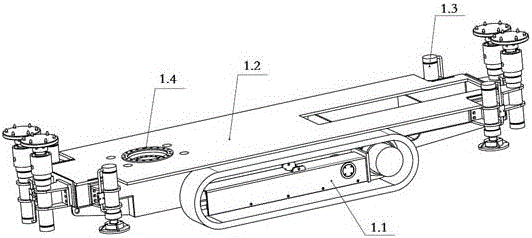

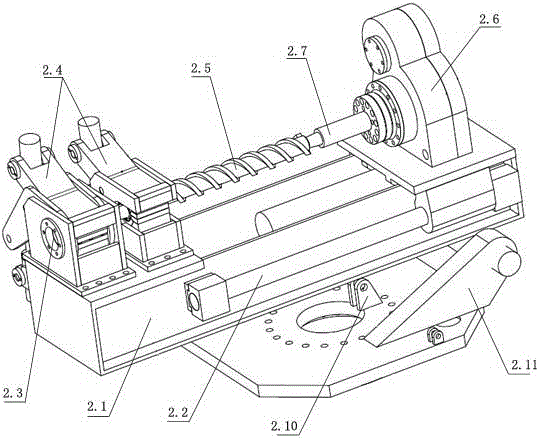

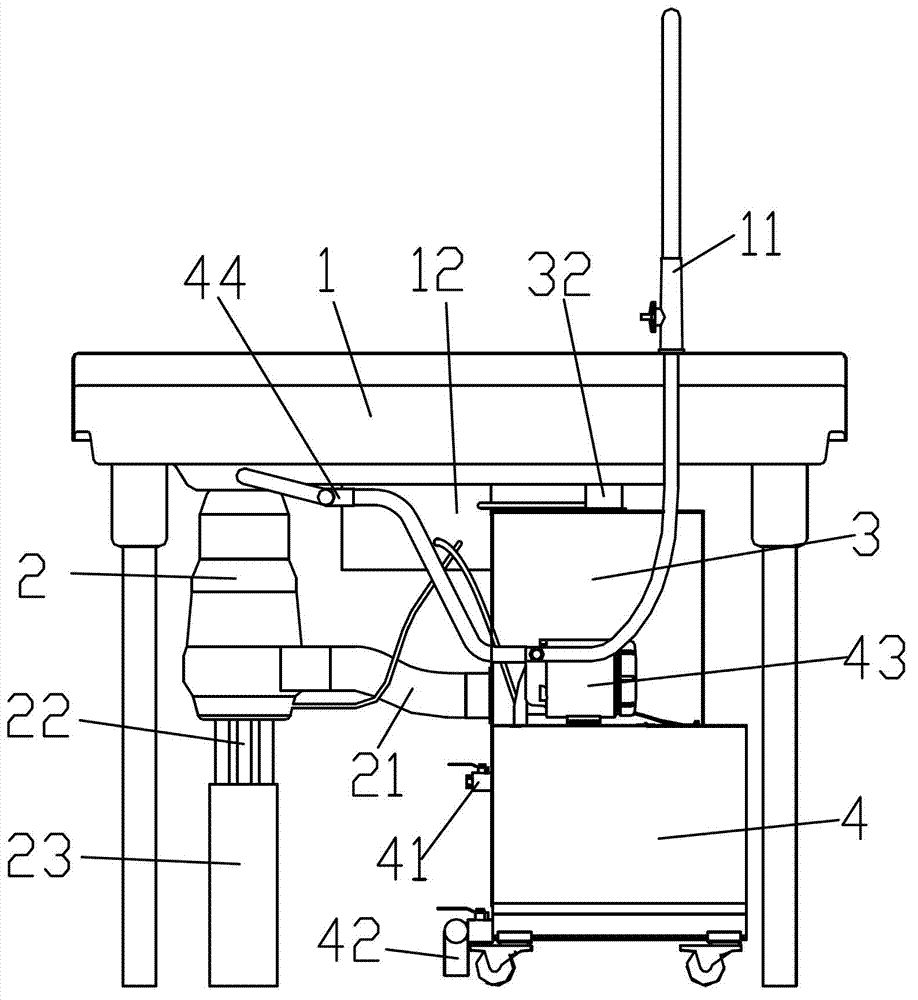

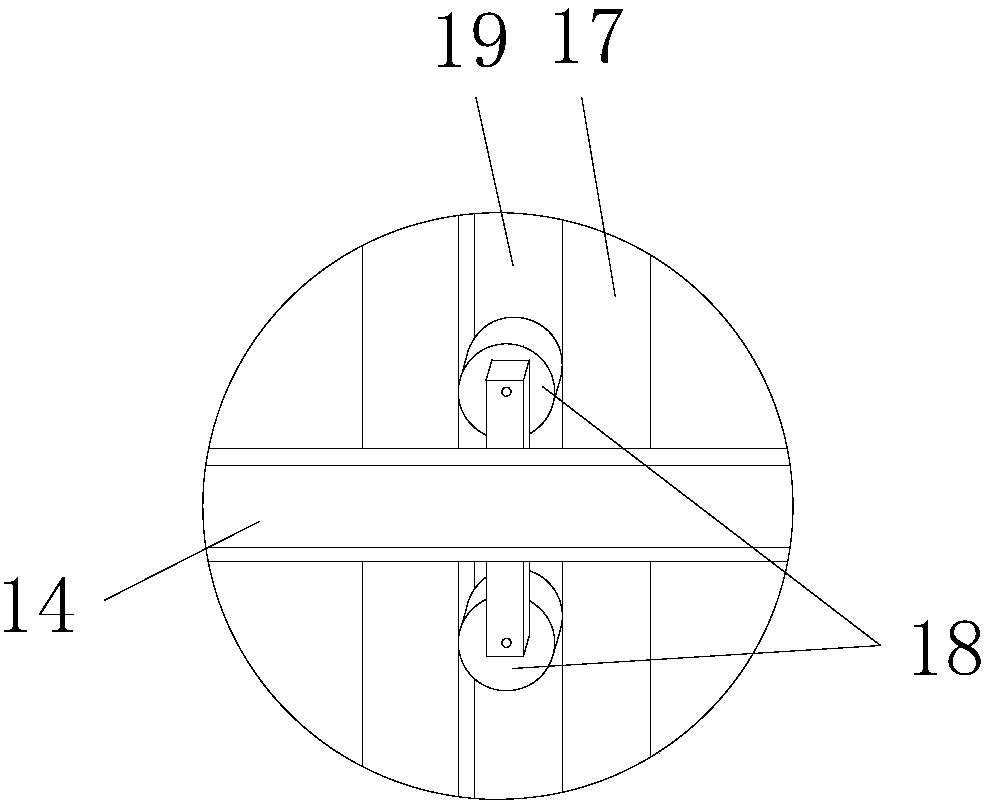

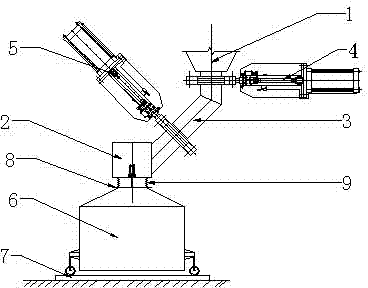

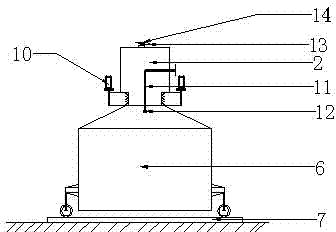

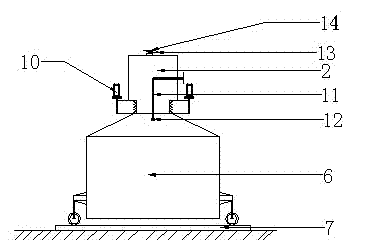

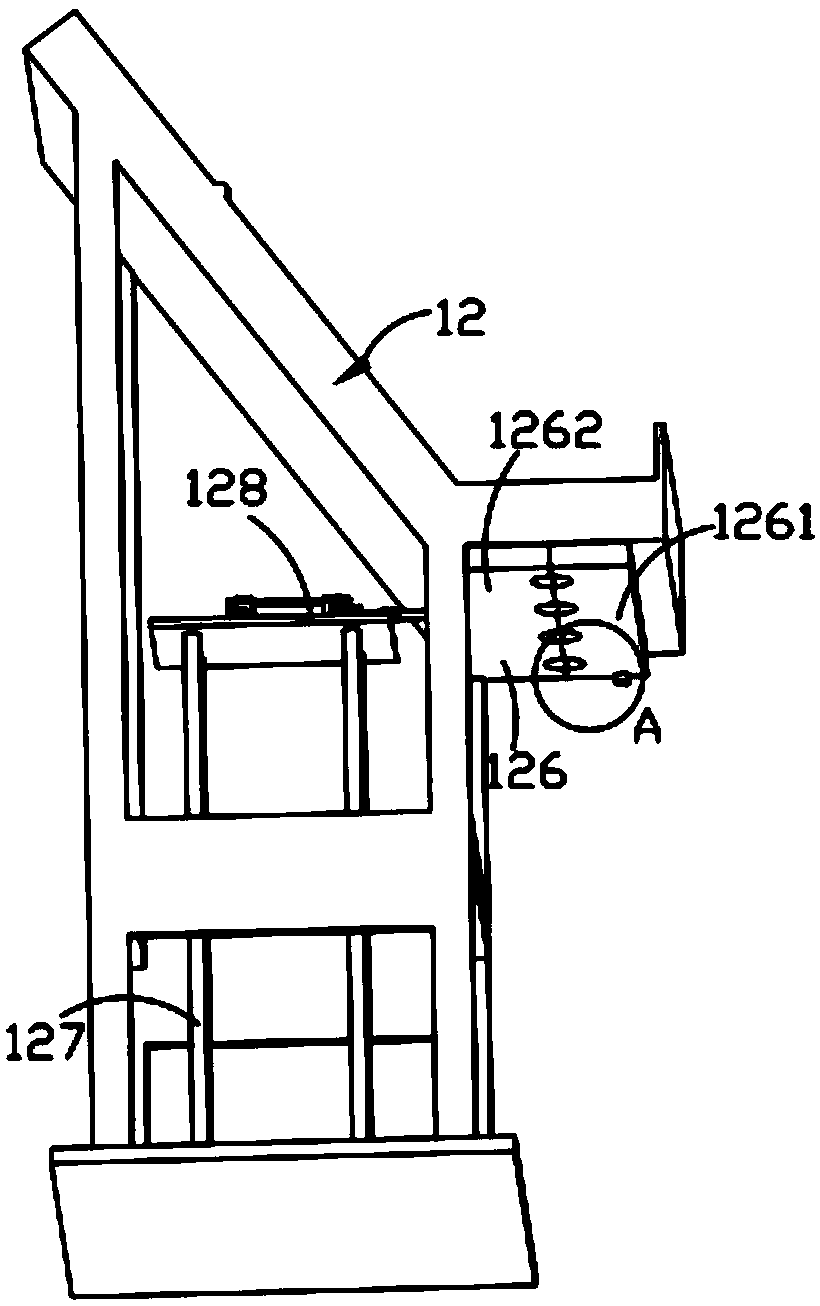

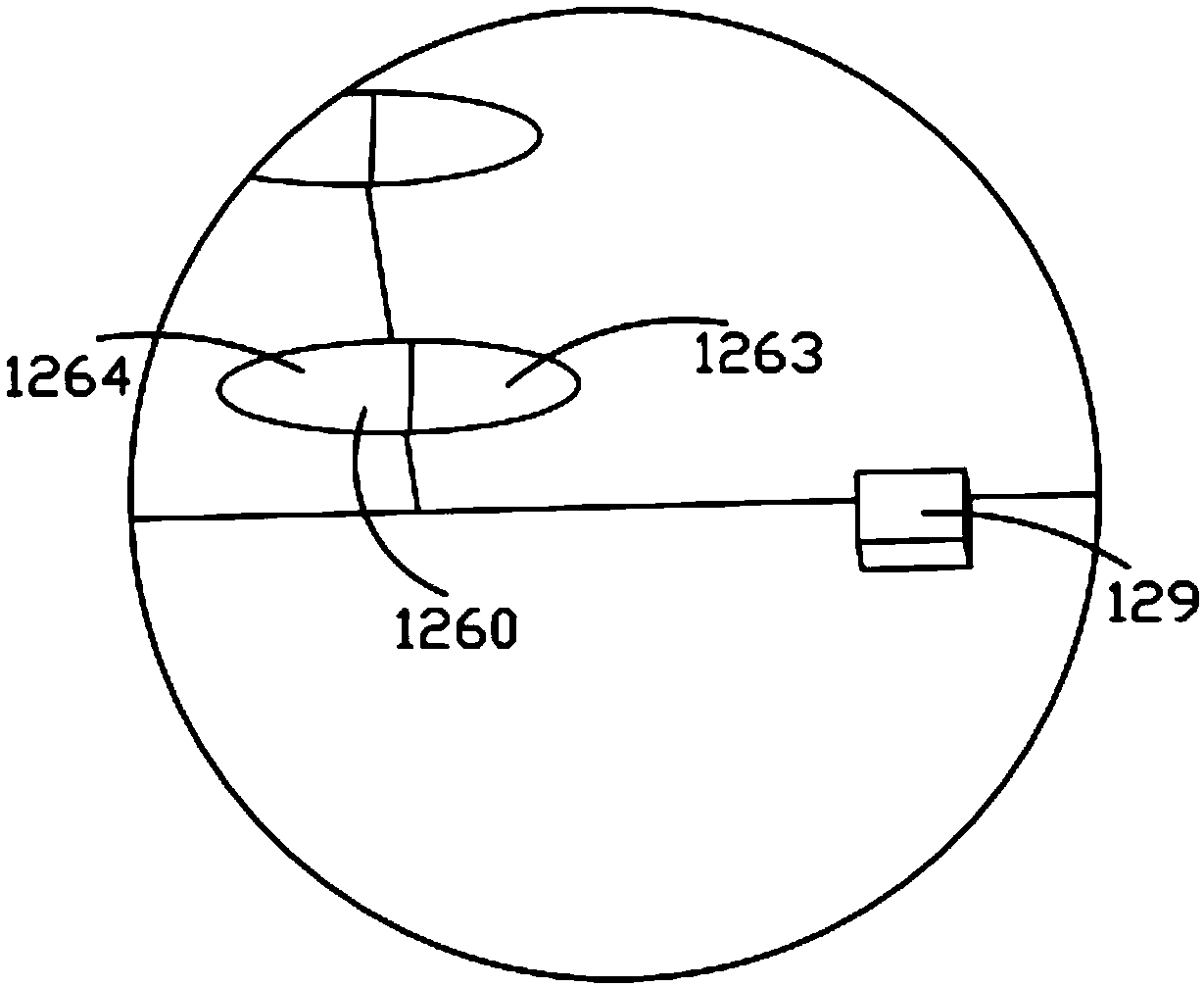

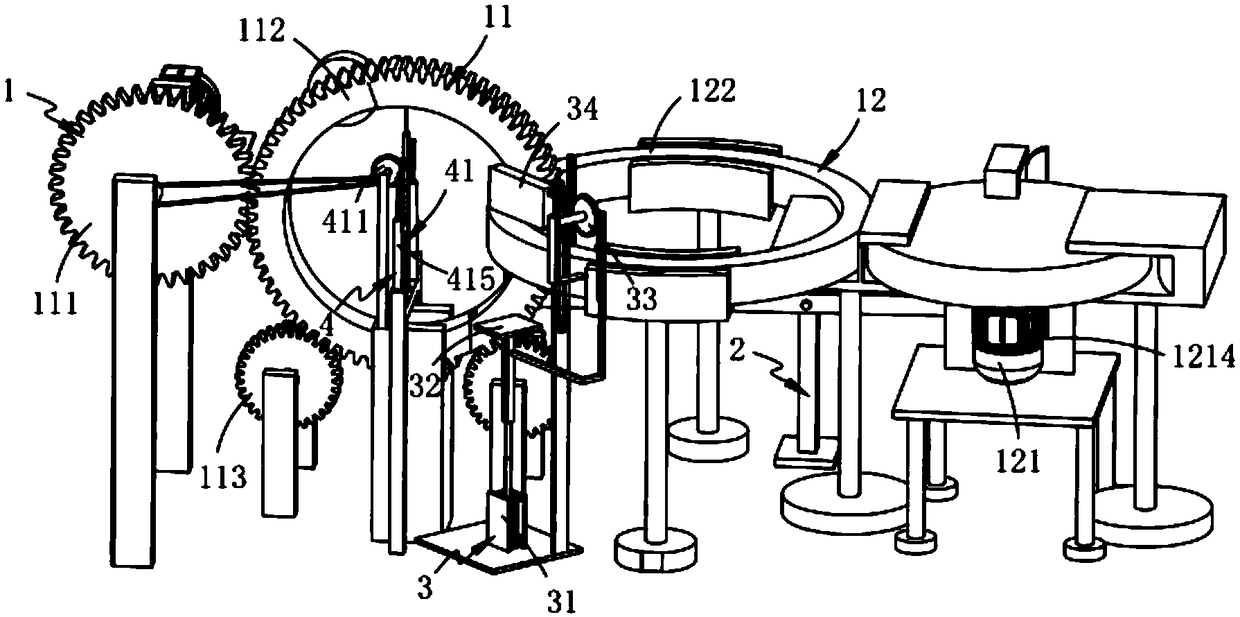

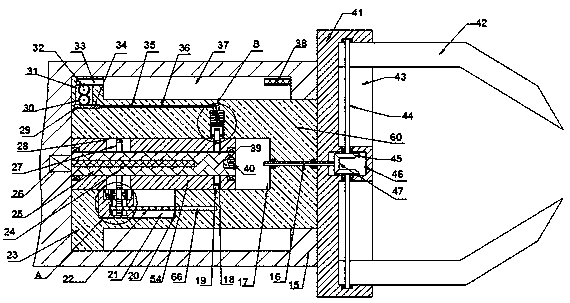

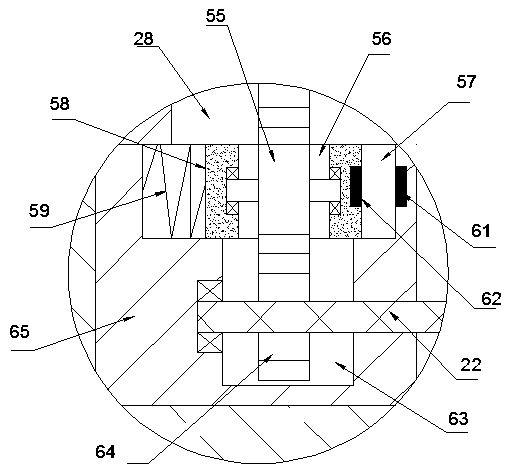

Automatic hydraulic drilling machine for coal mine

ActiveCN106677699AEasy to moveChange the disadvantage of not being able to moveDrilling rodsConstructionsControl systemHydraulic pump

An automatic hydraulic drilling machine for a coal mine comprises a drilling execution device, a manipulator, an automatic drill rod box and a caterpillar band travelling mechanism, wherein the caterpillar band travelling mechanism is used for supporting and moving the drilling execution device, the manipulator and the automatic drill rod box. The manipulating manipulator is controlled by a PLC programmable control system to extract drill rods from the automatic drill rod box and place the drill rods on the drilling execution device, and drilling operation is completed through the drilling execution device. According to the automatic hydraulic drilling machine for the coal mine, power is supplied to the drilling machine by a hydraulic pump and a motor; and through the PLC programmable control system, the automatic drill rod feeding and discharging function of the drill rod box of the drilling machine, the automatic drill rod disassembling function of the drilling execution device and the automatic drill rod grabbing function of the manipulator are achieved, so that labor intensity of workers is effectively lowered, operation and production efficiency is improved, and the personal safety coefficient of the workers is increased.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

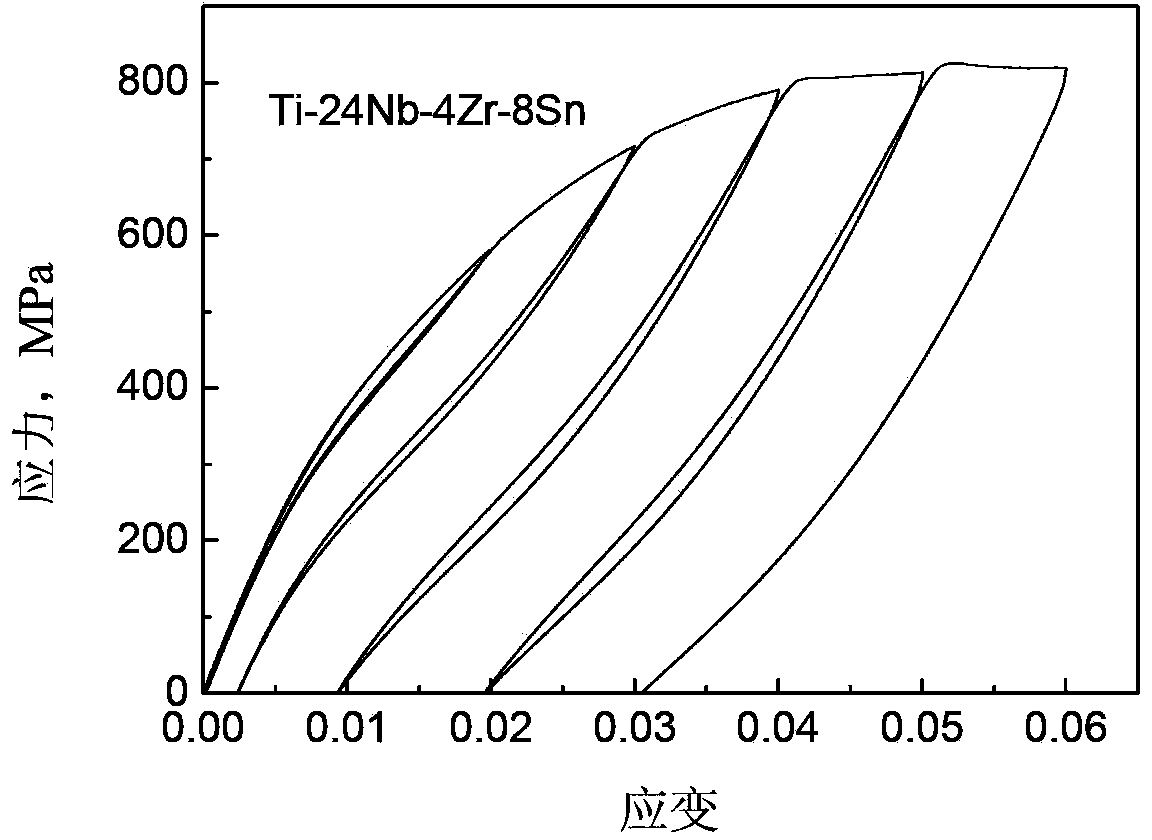

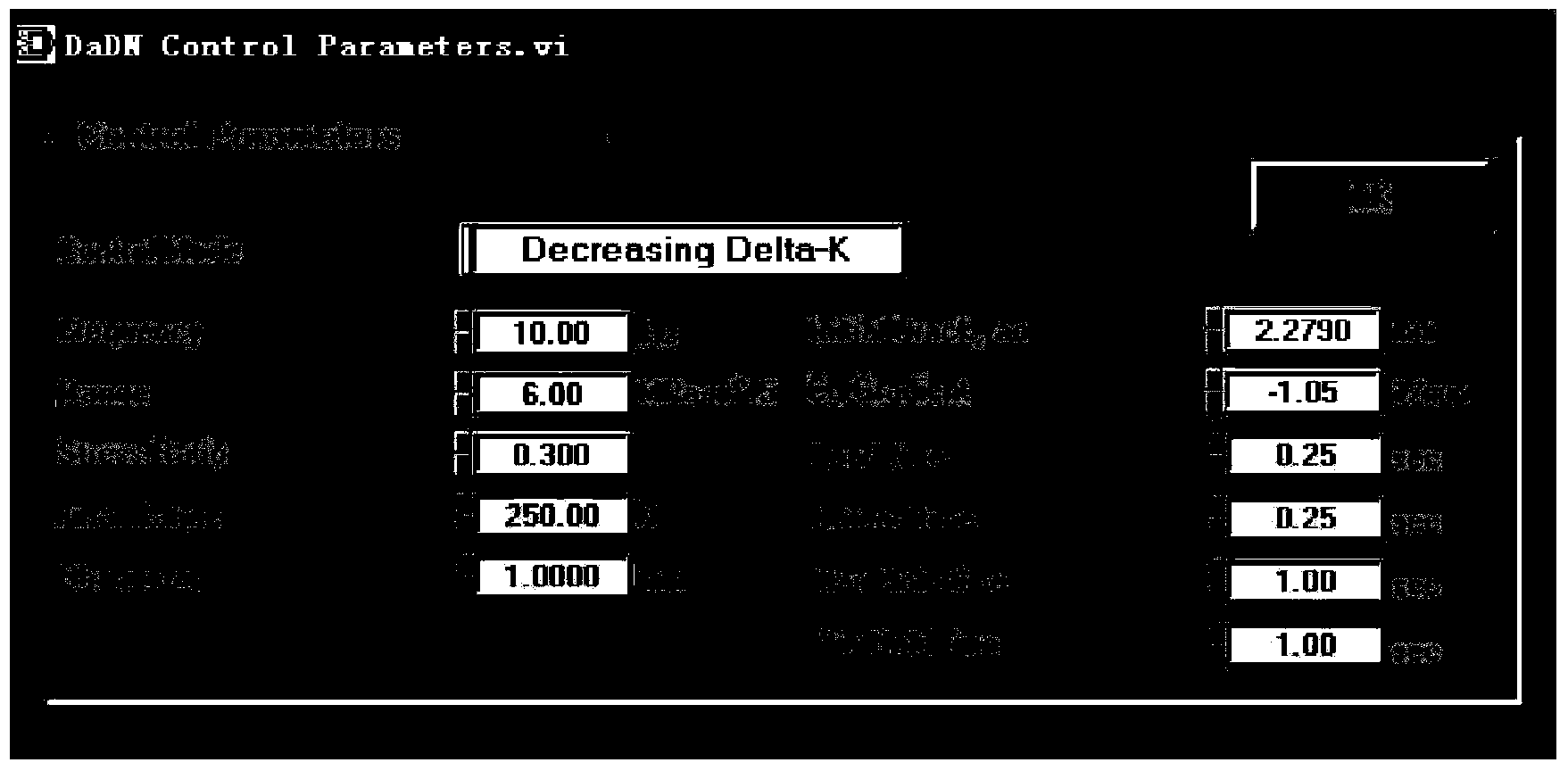

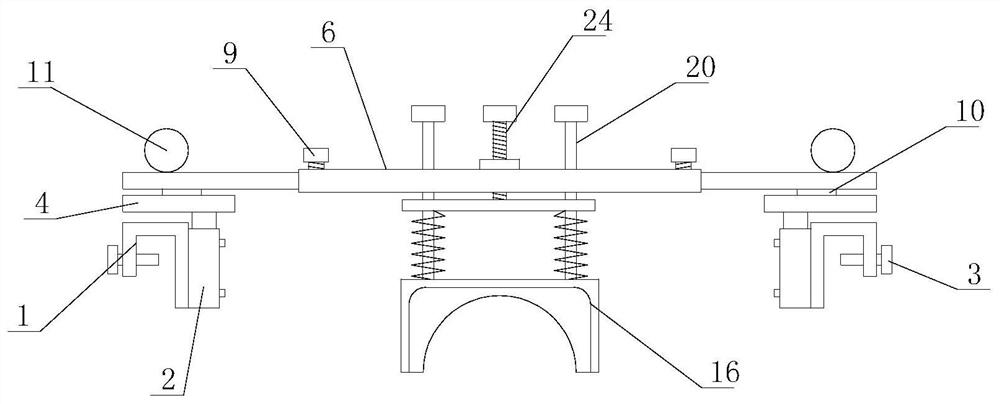

Simple method for measuring fatigue crack propagation threshold value of metal material

InactiveCN103454140ASimple test methodAvoid Overload HysteresisStrength propertiesSingle stageStress intensity factor

The invention relates to the technical field of fatigue crack propagation, in particular to a simple method for measuring fatigue crack propagation threshold value of a metal material. The simple method comprises the steps of estimating the initial stress intensity factor range delta K1 and the fatigue crack propagation threshold value delta Kth by referring to related documents or experimental data firstly; selecting whether to use a single-stage experiment or a multi-stage experiment according to the suggestion of the invention; substituting the delta K1 into the formula provided by the invention and calculating the c value and the delta a value; finally calculating the fatigue crack propagation threshold value delta Kt according to the experimental data. The method is suitable for the metal material, and the measured fatigue crack propagation threshold value is in accordance with the national standard GB / T 6398-2000; furthermore, the measurement method disclosed by the invention is simple and easy to use, and can quickly obtain the fatigue crack propagation threshold value of the metal material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

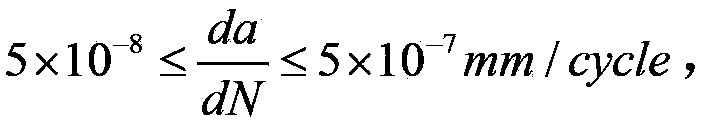

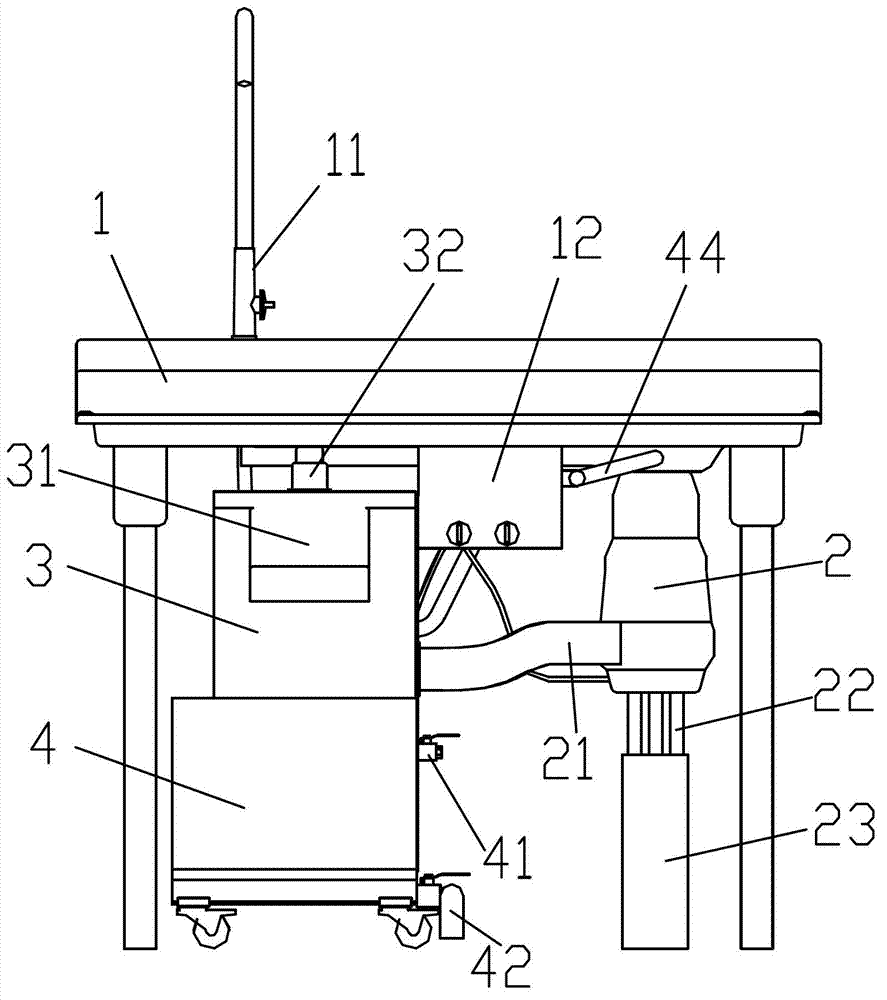

Food garbage treatment bench

The invention discloses a food garbage treatment bench. The food garbage treatment bench comprises a workbench, a garbage treater, a dewatering and slagging device and a water recovery device, wherein the garbage treater is fixed below the workbench, the dewatering and slagging device is arranged on the water recovery device and is communicated with the water recovery device, and a waste material pipe is arranged between the dewatering and slagging device and the garbage treater. Through the manner, the food garbage treatment bench has the advantages that the labor is reduced, the garbage transportation cost is reduced, the garbage treatment efficiency is increased, meanwhile, the waste of water resources is reduced, and the cost is reduced.

Owner:HANBOK KITCHEN ELECTRIC APPLIANCE TECH

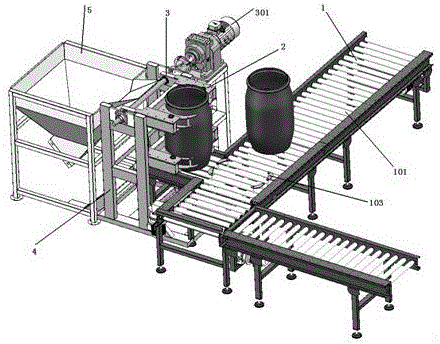

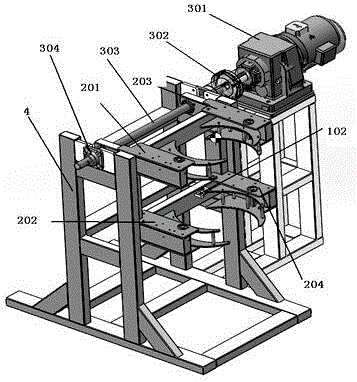

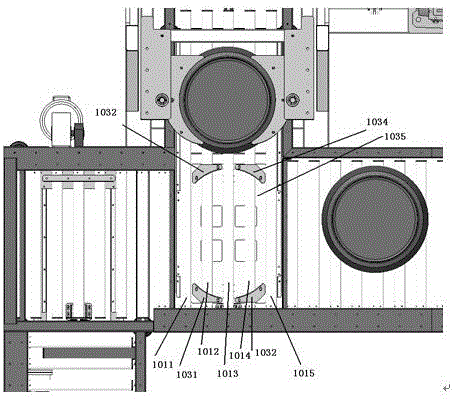

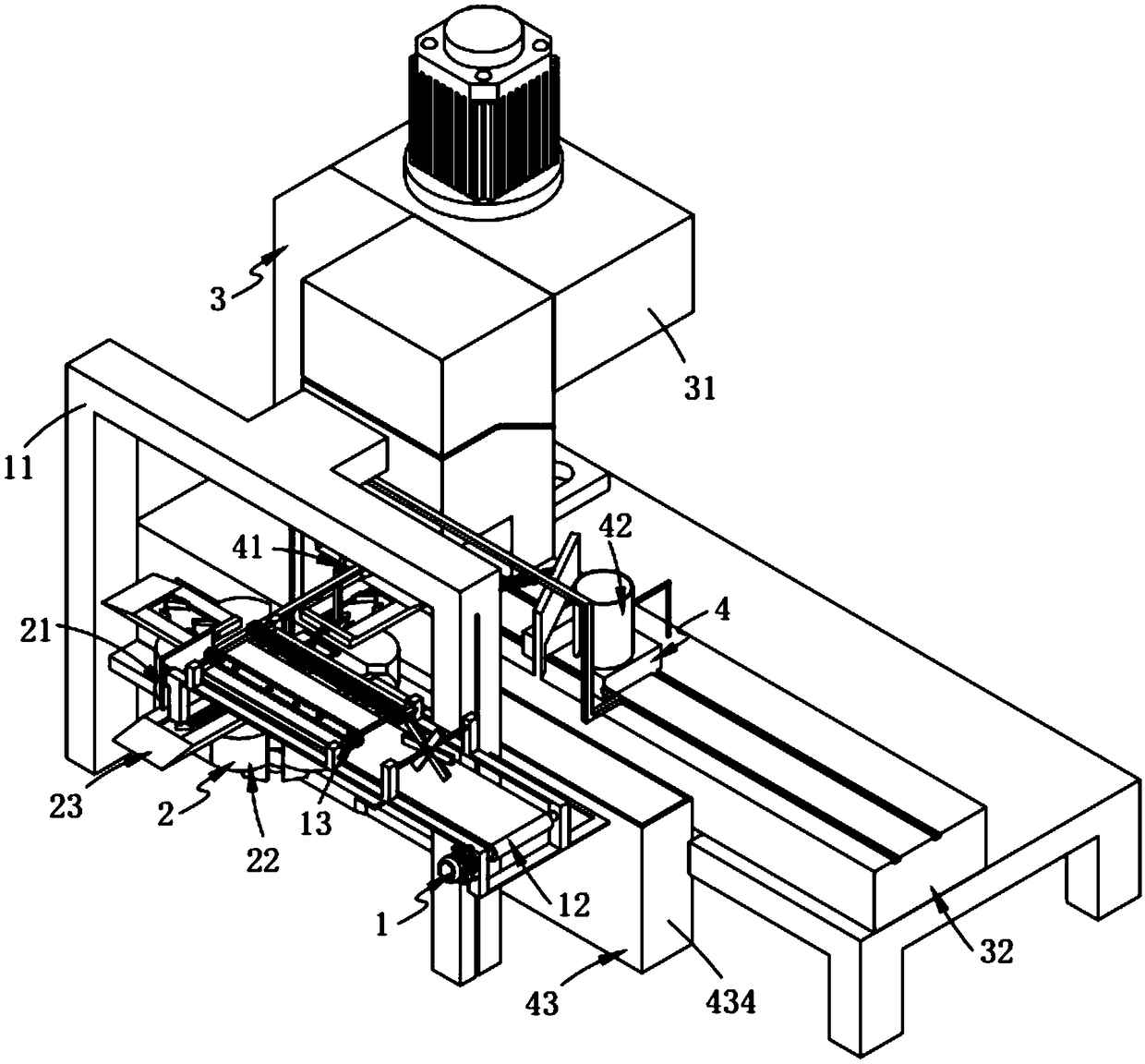

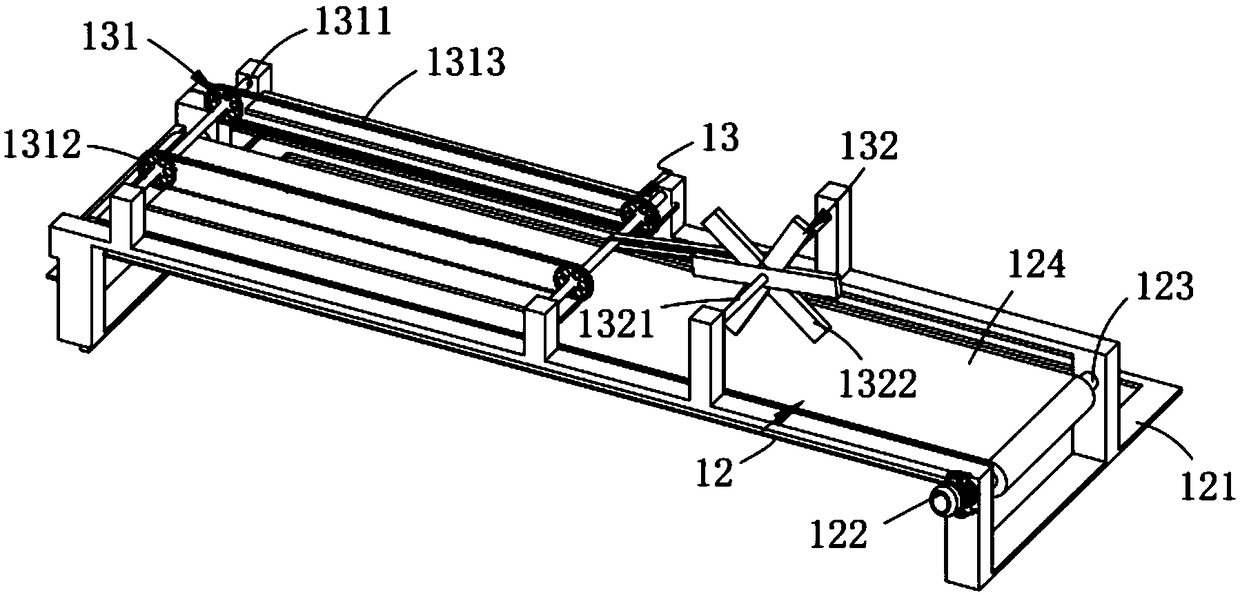

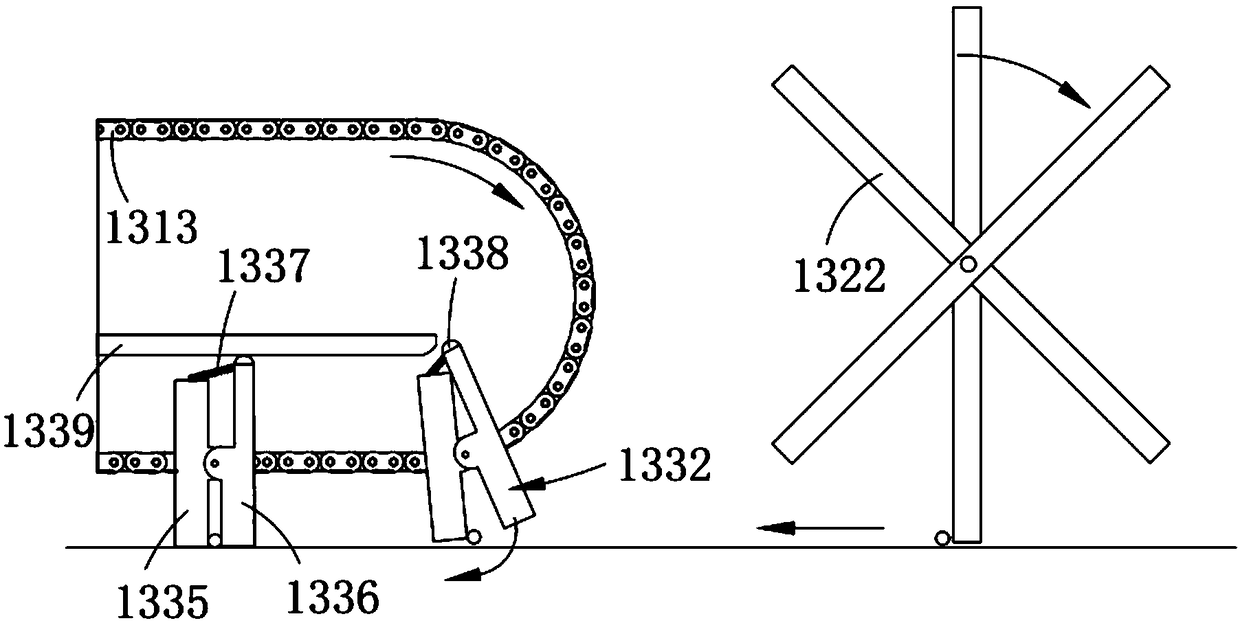

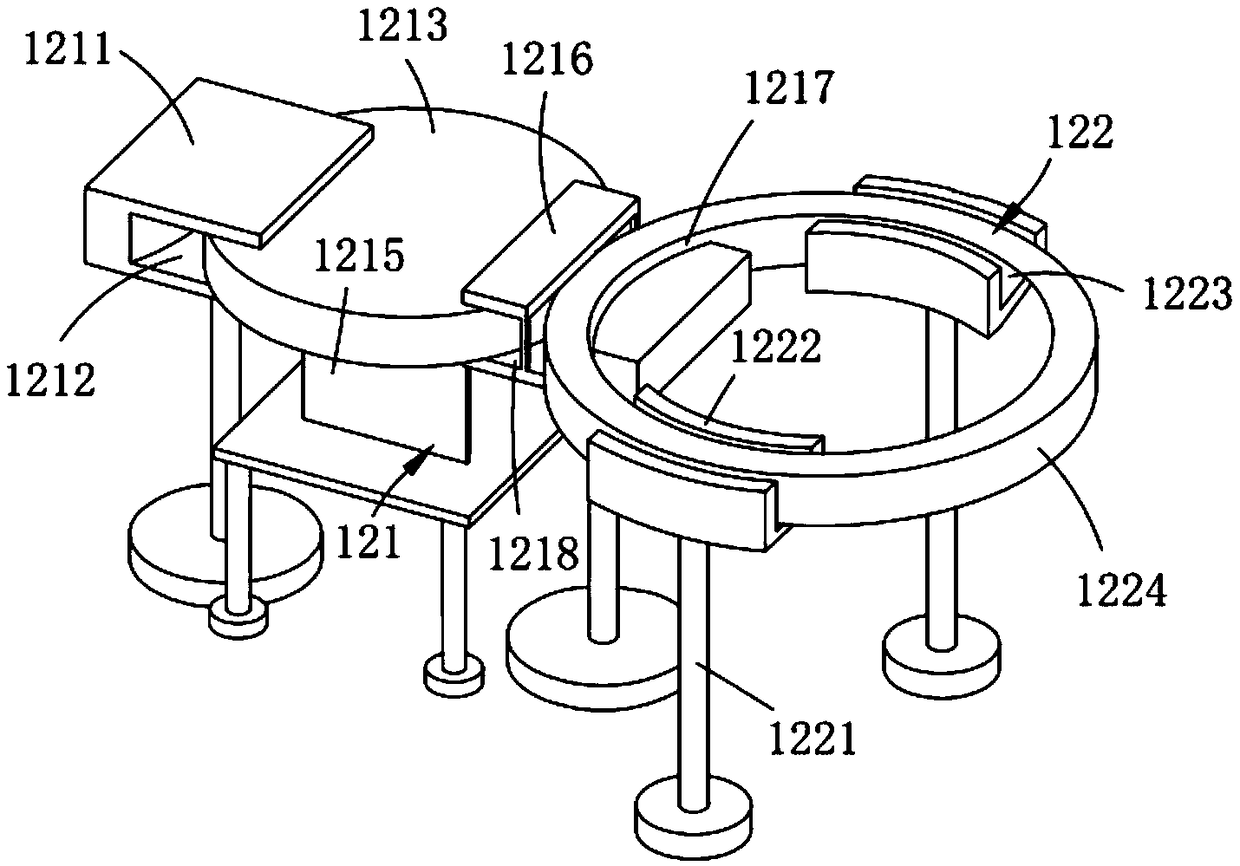

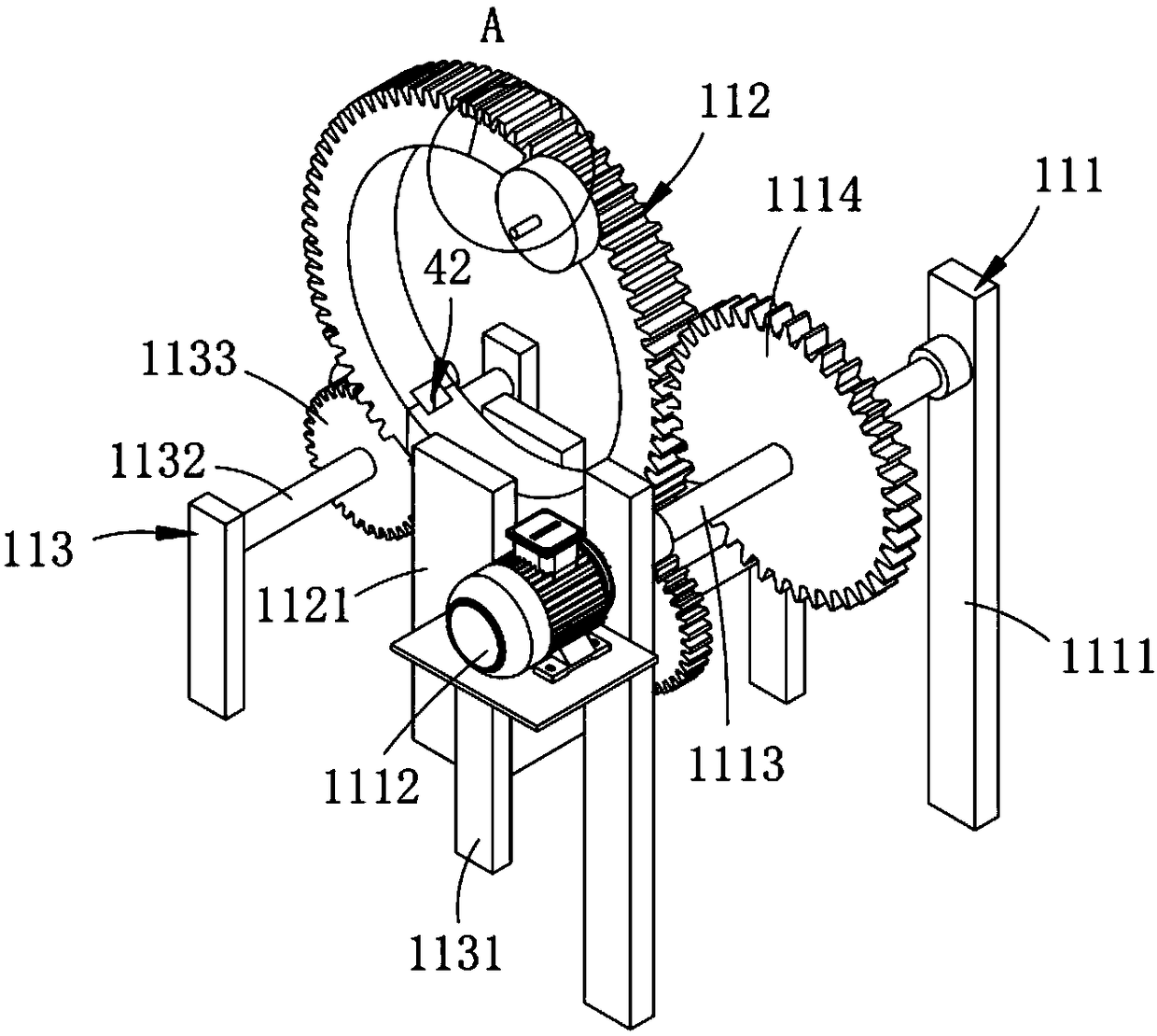

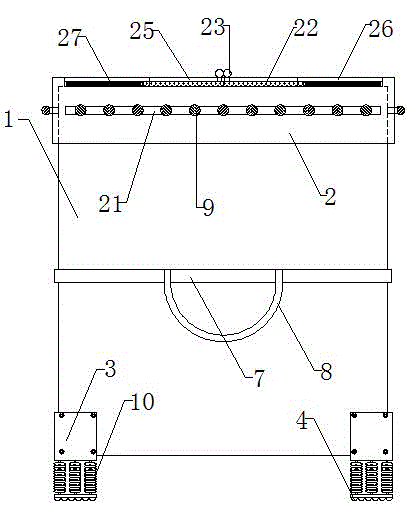

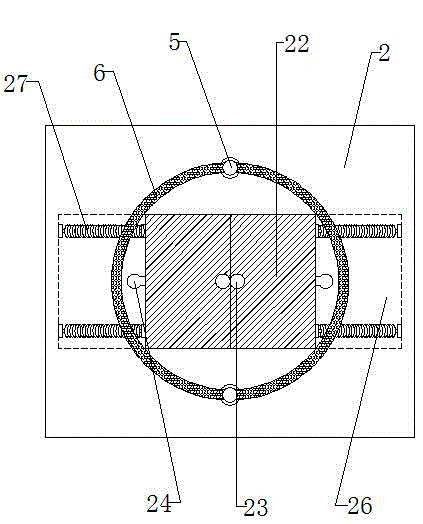

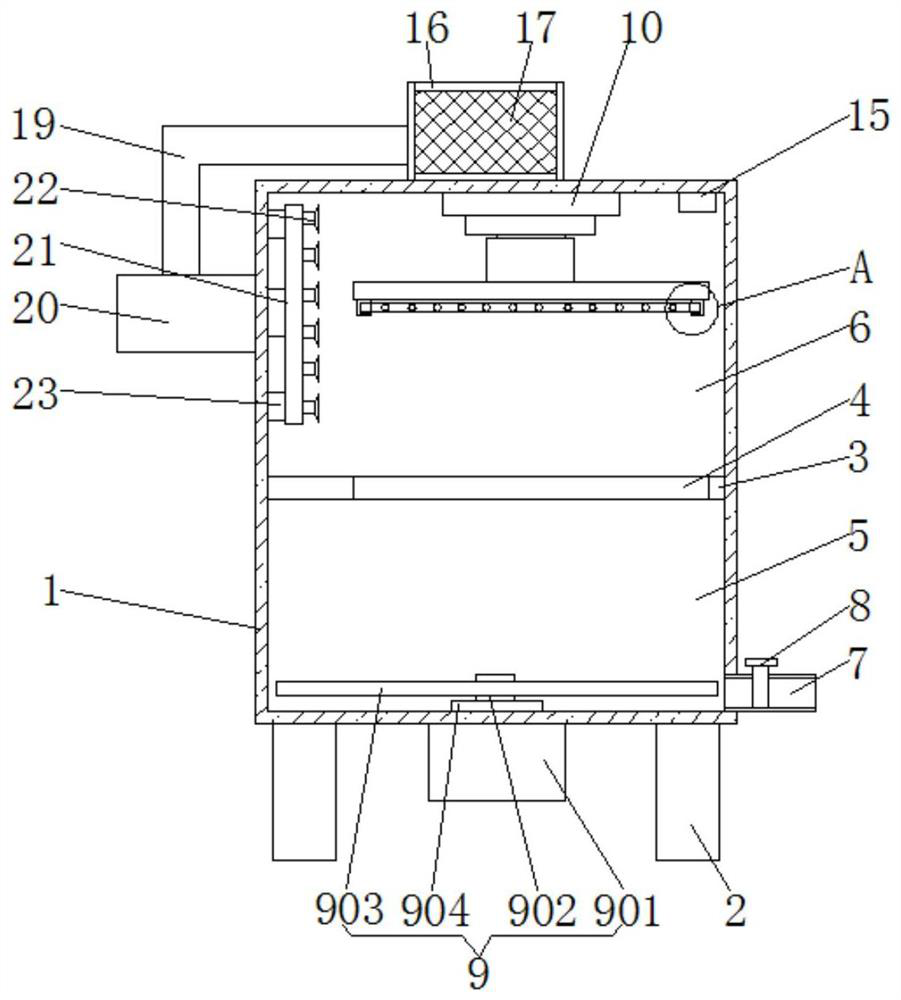

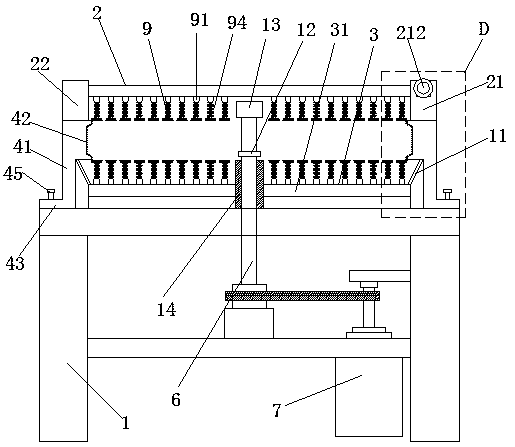

Full-automatic bucket turnover machine

ActiveCN106185358AImprove pouring efficiencySimple and fast operationBottle emptyingLoading/unloadingEngineeringElectric control

A full-automatic bucket turnover machine comprises an automatic bucket feeding device, a clamping and loosening device, a rotating device, a supporting device, a bearing device and an electric control device. The automatic bucket feeding device is connected with the clamping and loosening device. The clamping and loosening device is connected with the rotating device. The clamping and loosening device and the rotating device are mounted on the supporting device. The supporting device is connected with the bearing device. When a bucket containing materials is placed on rollers of the automatic bucket feeding device, the bucket is driven by the rollers to reach clamping jaw portions of the clamping and loosening device; after the bucket is clamped by clamping jaws, the clamping and loosening device clamping the bucket is driven by the rotating device to rotate; the clamping and loosening device rotates by a certain angle to dump the materials into a hopper of the bearing device; and after dumping is finished, the clamping and loosening device rotates reversely, the clamping jaws loosen the bucket, the empty bucket falls on a conveying roller, and the roller conveys the empty bucket to an empty bucket storage position. According to the full-automatic bucket turnover machine, the process can be completely and automatically completed in the discharging process, the material dumping efficiency is improved, and labor force output is saved; and operation is stable, and safety and high efficiency are achieved.

Owner:潍坊星美生物科技股份有限公司

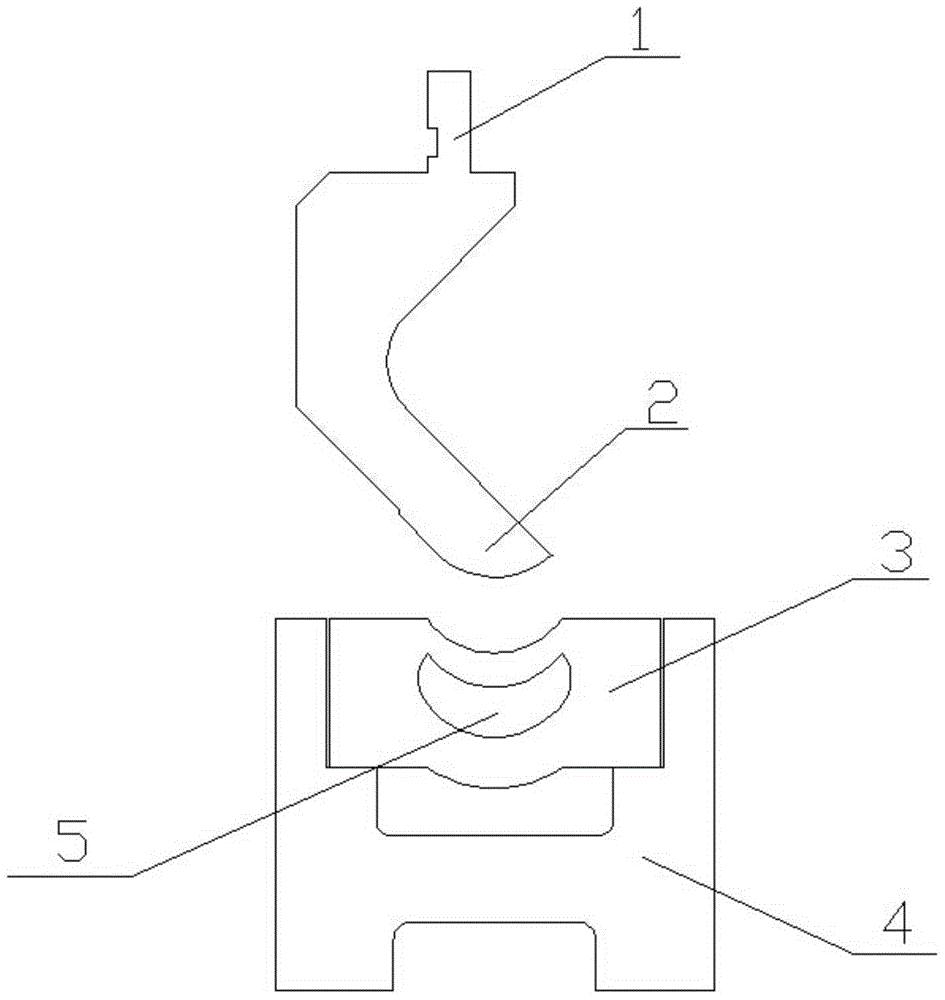

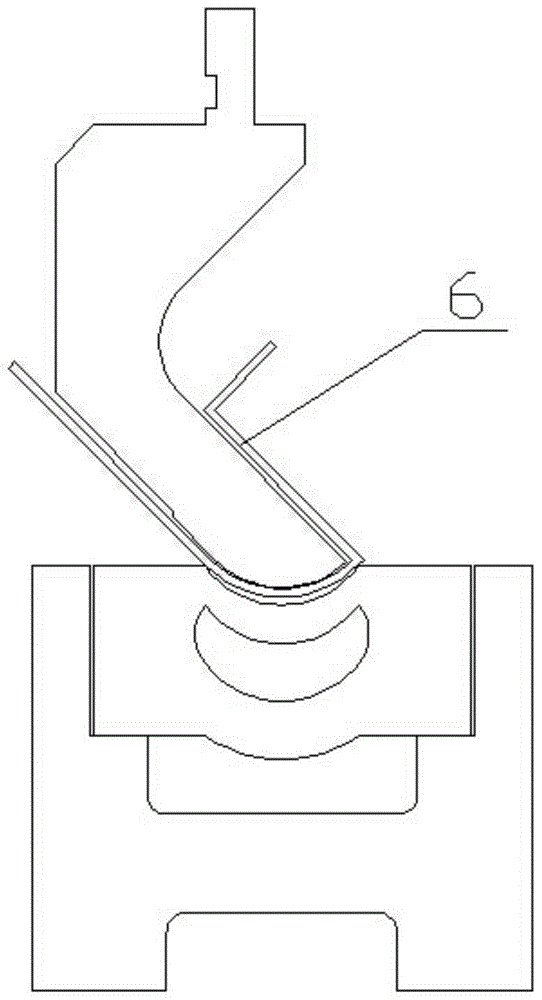

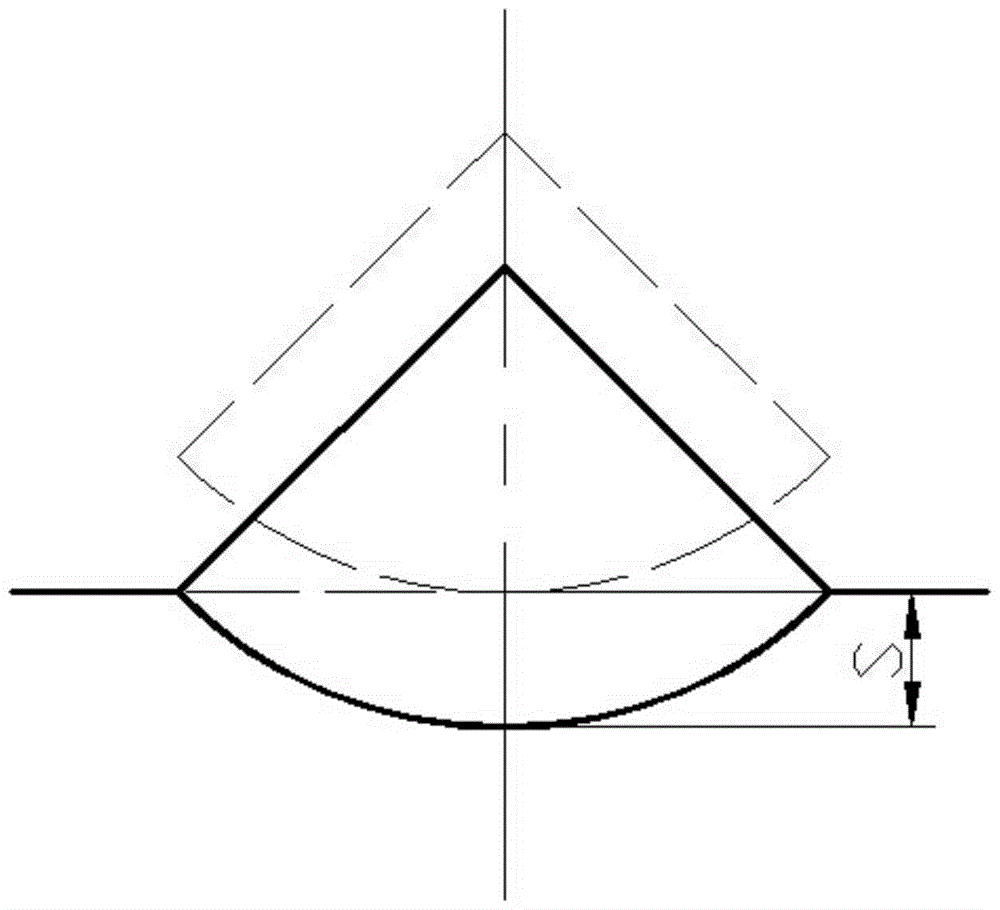

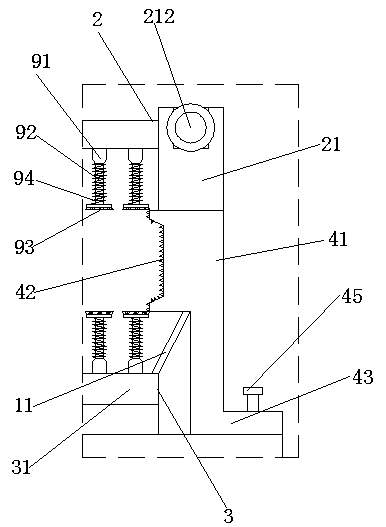

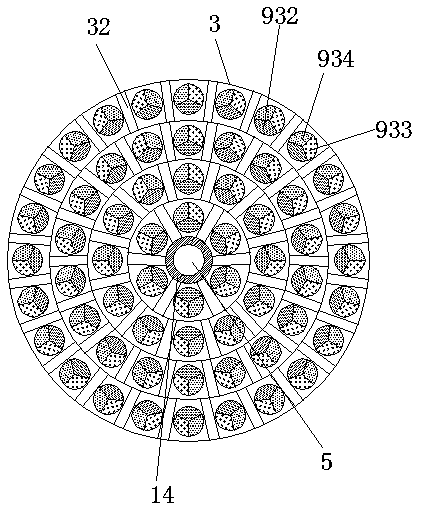

Application method of bending machine die capable of machining multi-radian circular face

ActiveCN105665532AImprove wear resistanceIncreased cushioning capacityShaping toolsCircular faceMachining

The invention discloses an application method of a bending machine die capable of machining a multi-radian circular face, and belongs to the field of bending machines. The application method solves the problem that an existing bending machine die cannot adapt to machining of workpieces of different sizes or the application range is narrow. The die comprises an upper die body and a lower die body. The upper die body comprises an upper die clamping part and an upper die cutter head. The lower die body comprises a lower die forming body and a lower die base. The cross section of the bottom of the upper die cutter head is in an arc shape. A first groove is formed in the lower die base, and a second groove is formed in the bottom of the first groove. The lower die forming body is arranged on the first groove. An arc groove is formed in the upper surface of the lower die forming body. A buffering cavity is formed in the middle portion of the lower die forming body, an arc protrusion is arranged on the lower surface of the lower die forming body, and the lower die forming body is made of polyurethane. A third groove concaved upwards is formed in the bottom of the lower die base. The application method can adapt to machining of workpieces with different radian radii, stability is good, the machining precision is high, and the workpiece surface quality is high.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

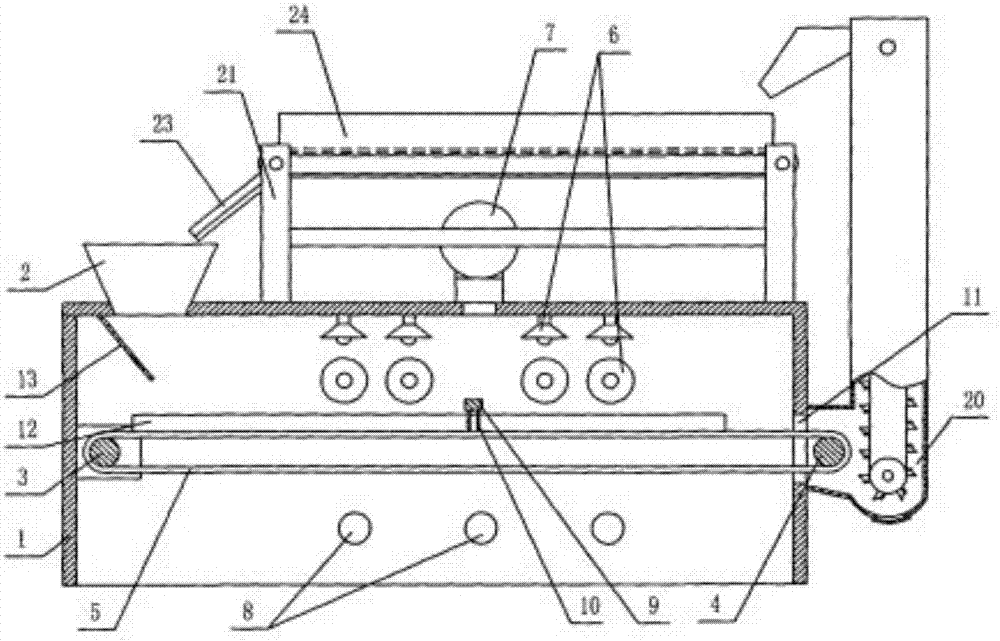

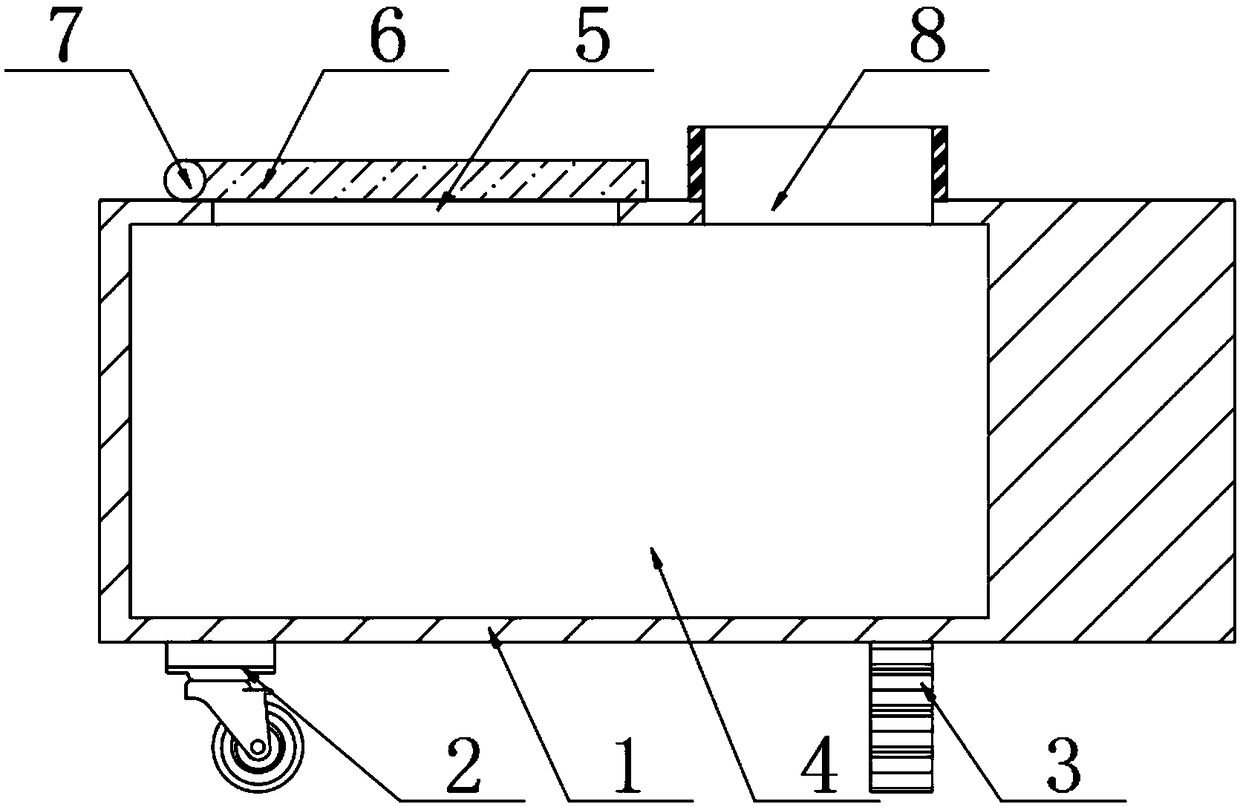

Grain dryer

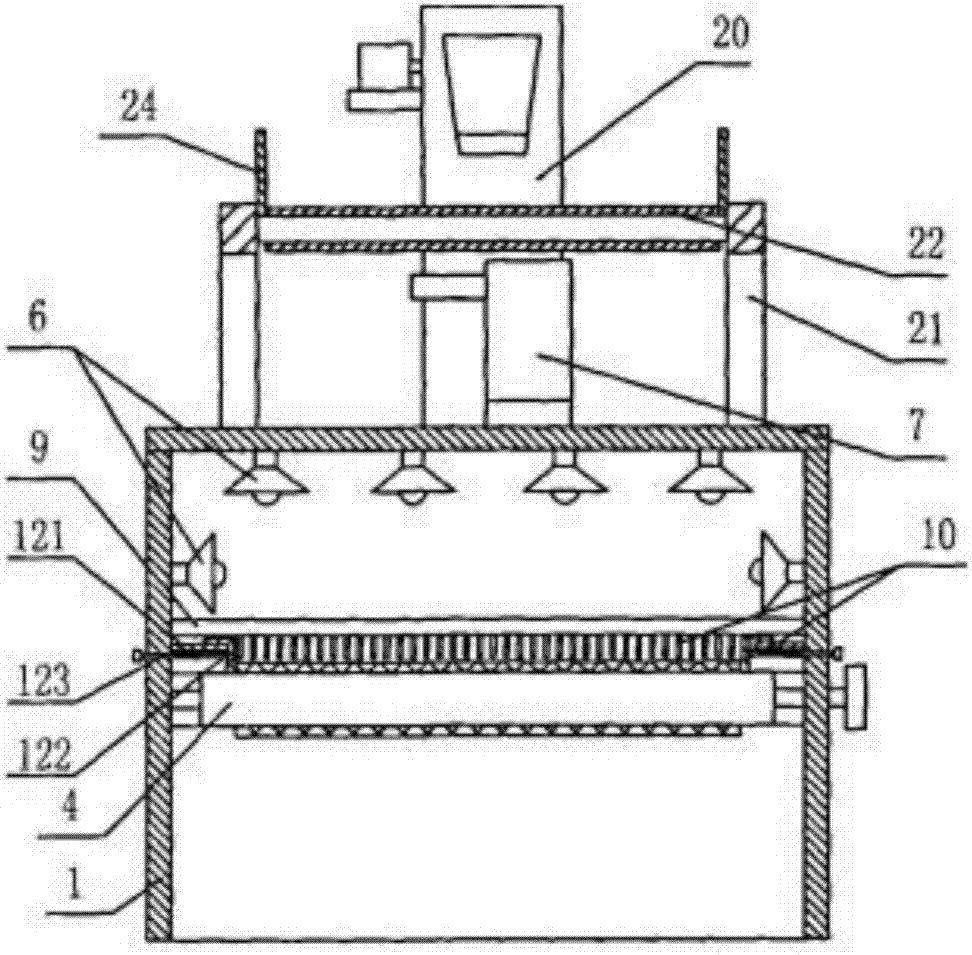

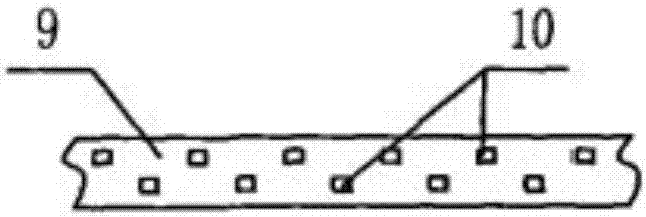

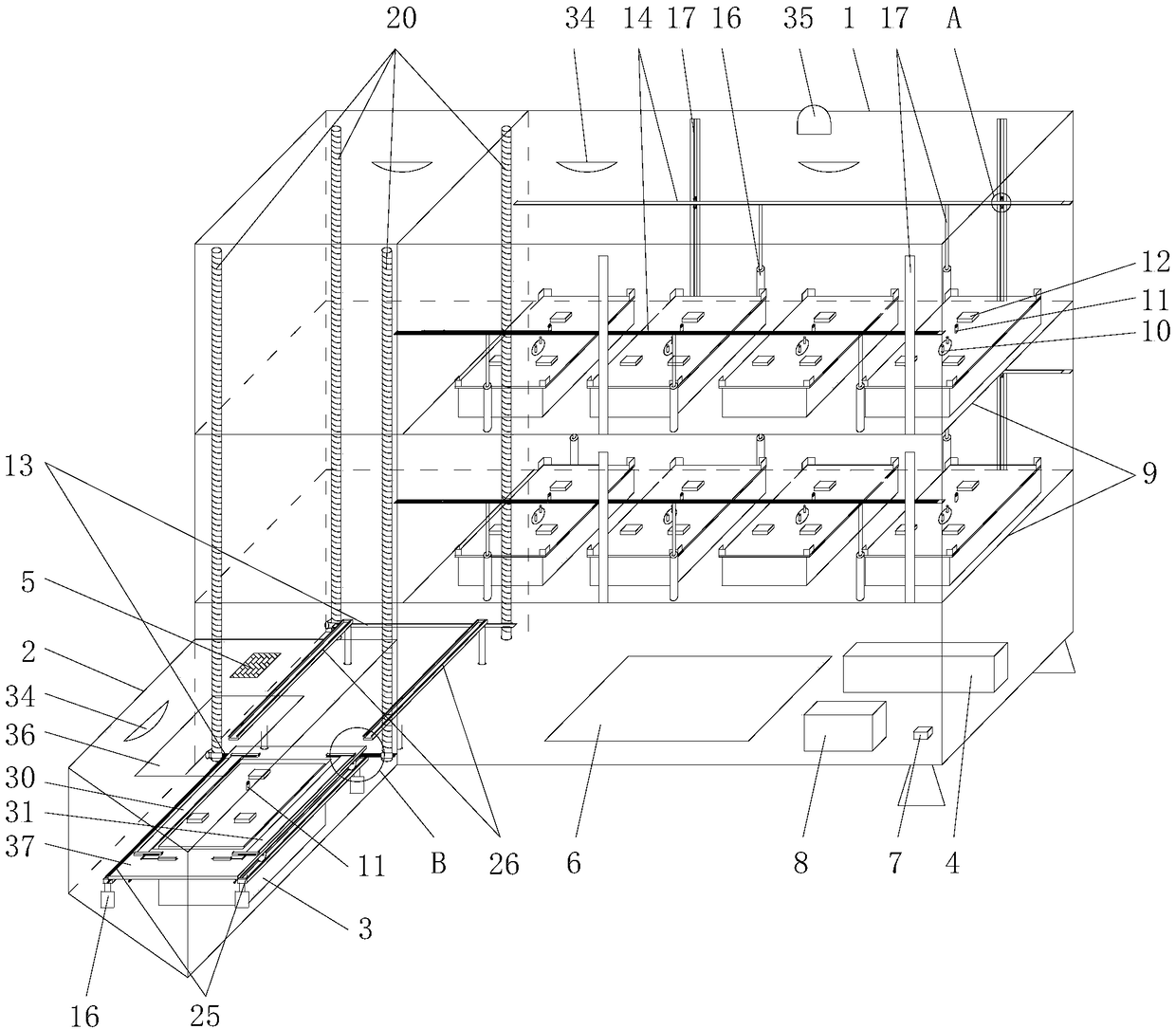

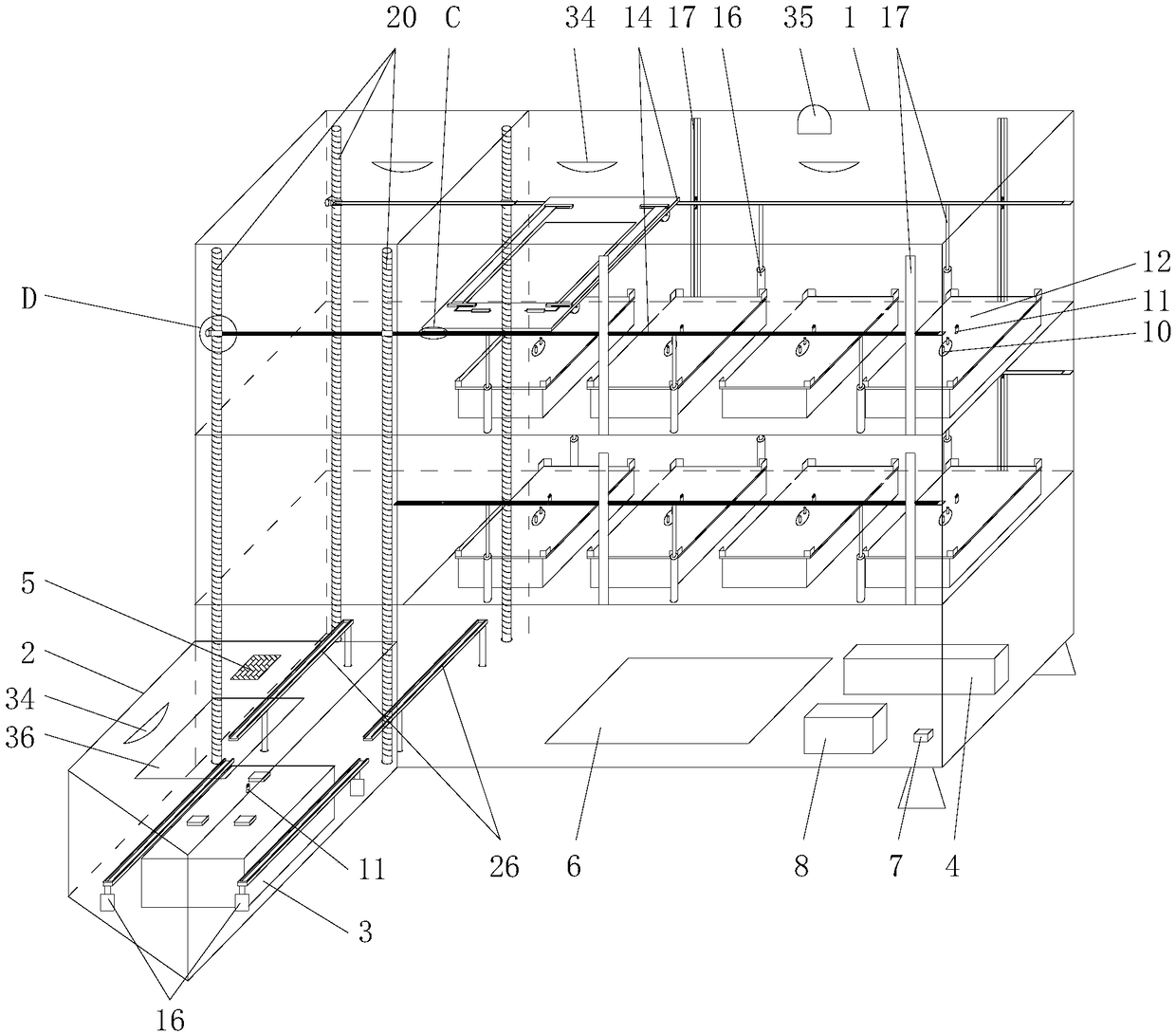

InactiveCN107202482ASpeed up dryingImprove drying effectDrying solid materials with heatDrying gas arrangementsEngineeringAgricultural machinery

The invention discloses a grain dryer, and relates to the technical field of agricultural machinery. The grain dryer comprises a drying machine box and a feeding hopper which is arranged at the front part of the top wall of the drying machine box; a driving roller and a driven roller which are driven by a power mechanism are correspondingly mounted in the front of the drying machine box and behind the drying machine box; a conveying mesh belt of which the two sides are attached to the inner surfaces of the side walls of the drying machine box is arranged between the driving roller and the driven roller in a wrapping manner; a material outlet which is formed corresponding to the rear part of the driven roller is also formed in the rear wall of the drying machine box; a lifting machine is mounted behind the drying machine box; a feeding cabin corresponding to the material outlet is arranged at the lower part of the lifting machine; and a material discharge door is arranged at the bottom of the feeding cabin. The grain dryer, disclosed by the invention, can automatically and repeatedly air and dry grain; moreover, the airing speed is high; the drying quality is high; the automation degree is high; the labor output is low; and the grain dryer is suitable to be popularized and applied.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

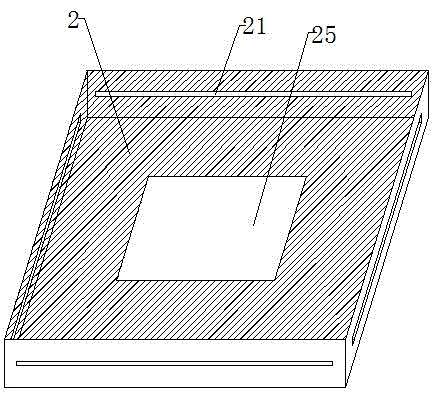

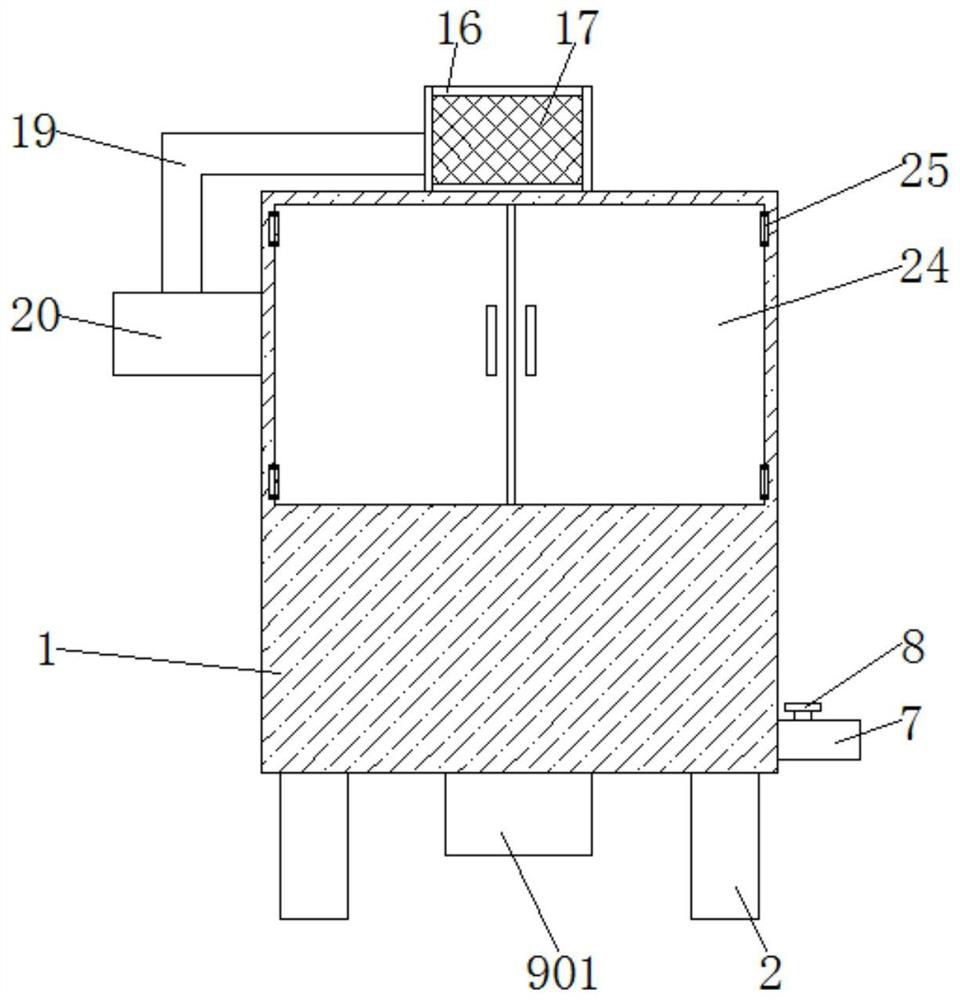

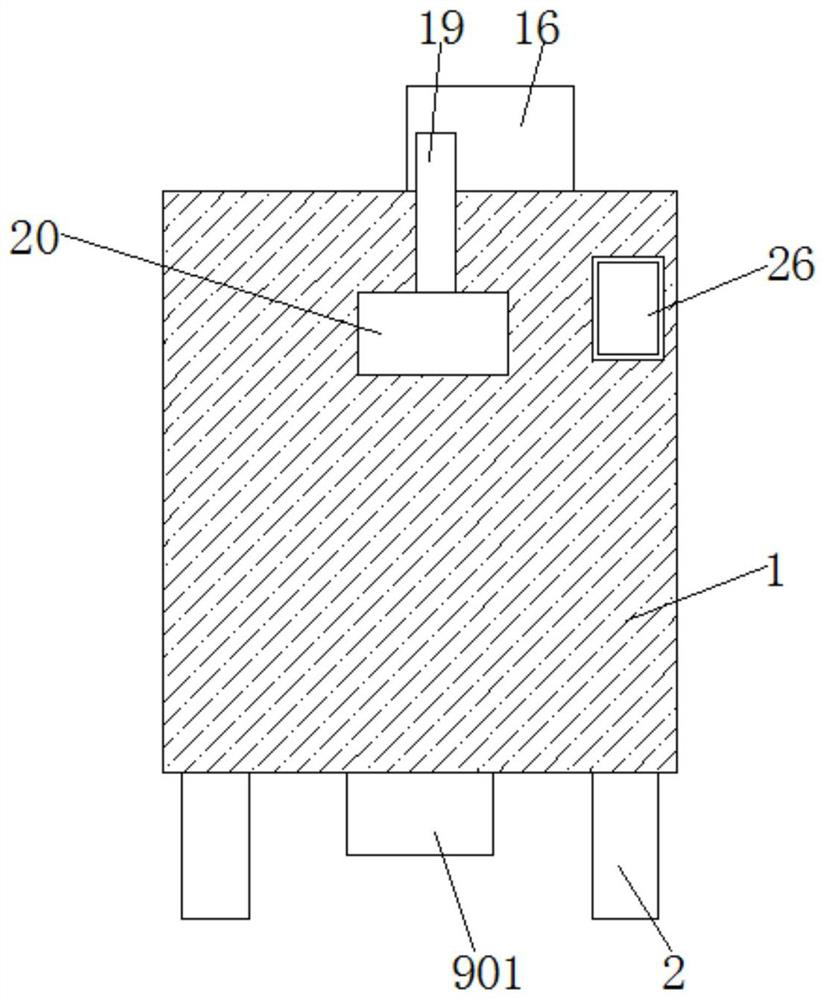

Intelligent charging equipment for shared new energy battery

ActiveCN108321913AReduce operating costsReduce labor outputMobile unit charging stationsApparatus for meter-controlled dispensingElectrical batteryElectricity

The invention discloses intelligent charging equipment for a shared new energy battery. The intelligent charging equipment for the shared new energy battery comprises a charging box, a quality inspection box, a quality inspection table, a storage battery, a display, a temperature difference electricity generating piece, a network communication module, a transmission mechanism and a controller; a plurality of layers of charging platforms are arranged on the right in the charging box, and each layer of the charging platform is provided with a charging table for charging the shared new energy battery; the storage battery, the temperature difference electricity generating piece, the network communication module and the controller are all mounted on the bottom wall of the charging box; a hot surface of the temperature difference electricity generating piece is positioned in the charging box, and the cold surface of the temperature difference electricity generating piece is positioned out ofthe charging box; the quality inspection table is fixedly mounted in the quality inspection box, and the quality inspection table is positioned right below a taking / placing opening of the quality inspection box; the display is mounted on the upper surface of the quality inspection box. The intelligent charging equipment for the shared new energy battery reduces the operating cost of the shared new energy battery, is beneficial to large-area popularization, and meanwhile, improves the intelligence of a charging process.

Owner:罗利高

Pebble coal sealing discharge device

InactiveCN102284341APrevent spontaneous combustionTimely dumpingGrain treatmentsSpontaneous combustionSlag

The invention discloses a pebble coal discharge mechanism of a coal mill, in particular a pebble coal sealing discharge device. It includes a pebble coal drop port and a sealing box, the pebble coal drop port and the seal box are connected together through a conveying pipeline, a primary shut-off valve and a secondary shut-off valve are set on the pipeline, and a storage and transportation bin is set at the lower end of the sealing device, and the storage and transportation small The lower end of the warehouse is equipped with a weighing device, and the outlet of the lower end of the sealed box is connected with a telescopic joint. The sealed box is also provided with a cylinder to control the telescopic movement of the telescopic joint. The edge of the material inlet is in sealing contact. After adopting the above-mentioned structure, the entire slag discharge process can be carried out under completely closed conditions to avoid dust and powder spraying; using a sealed slag discharge device plus negative pressure and water spraying treatment can further eliminate dust and coal gangue spontaneous combustion Occurrence; At the same time, load-bearing sensors are installed to completely avoid the accumulation of pebbles and coal. Dumping by special forklifts does not require manual handling and reduces labor output.

Owner:WEIYU POWER EQUIP YANGZHONG CITY

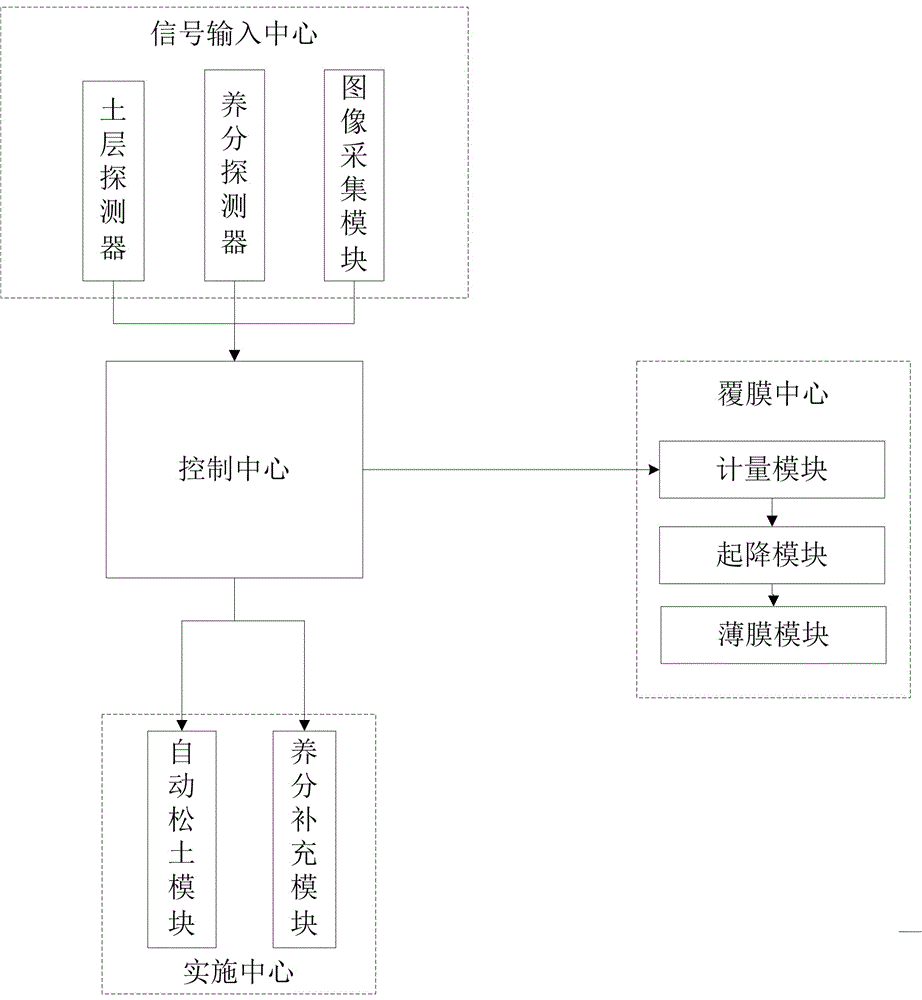

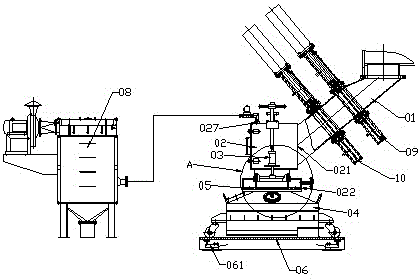

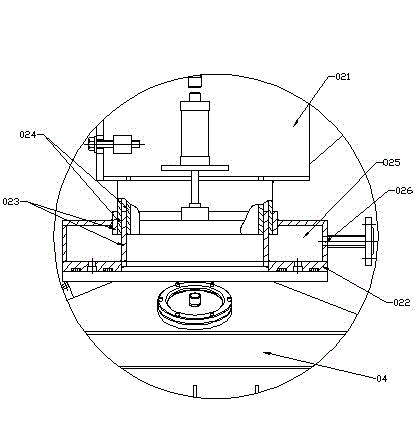

Ecological circulation improvement system built on basis of seedling automatic coverage culture

The invention discloses an ecological circulation improvement system built on the basis of seedling automatic coverage culture. The ecological circulation improvement system comprises a control center, a control center input end signal input center, an output end implementation center and a coverage center, wherein the signal input center comprises an image acquiring module, a nutrient detector and a soil layer detector; the image acquiring module is used for acquiring an image signal within a monitoring range; the nutrient detector is used for detecting a nutrient signal of soil within the monitoring range; the soil layer detector is used for detecting a density signal of the soil within the monitoring range, and all the signals are transmitted to the control center; the control center is used for receiving a signal of the signal input center; an operator transmits a coverage command to a film-coating center through the control center according to image information in the image signal, transmits a supplement command to a nutrient supplement module according to the nutrient signal, and transmits a soil-loosening command to an automatic soil-loosening module according to the density signal; the implementation center comprises a nutrient supplement module and an automatic soil-loosening module; the nutrient supplement module is used for receiving and processing the nutrient signal.

Owner:成都谭记胖哥农业服务有限公司

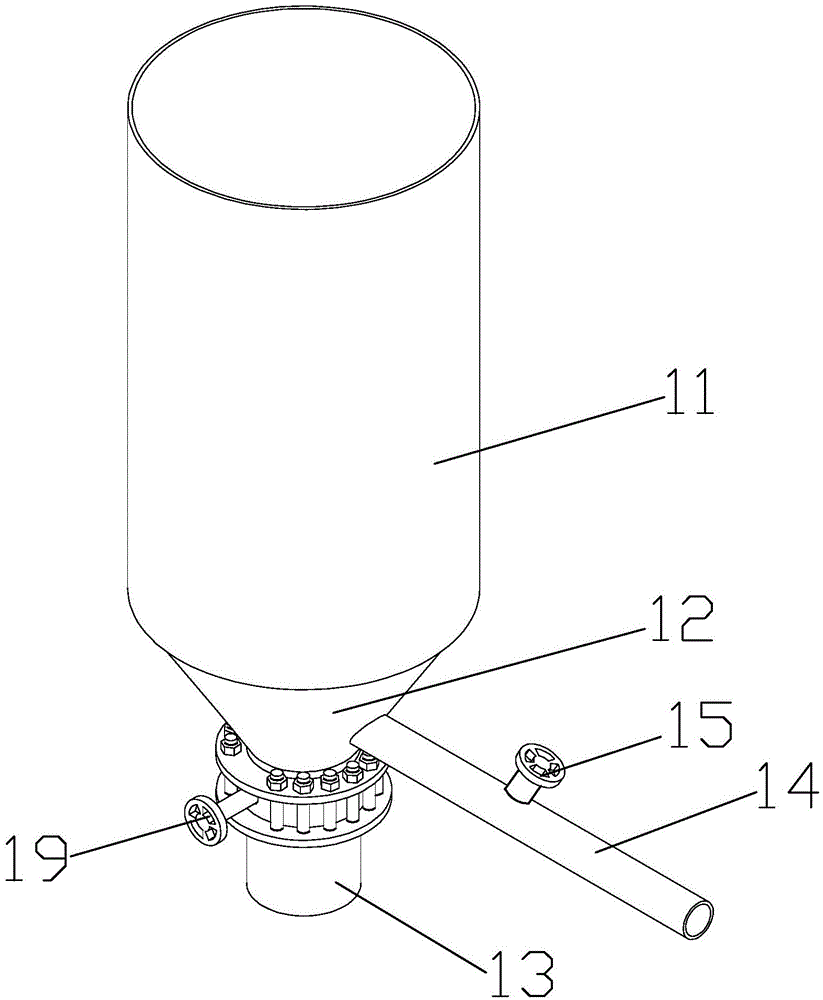

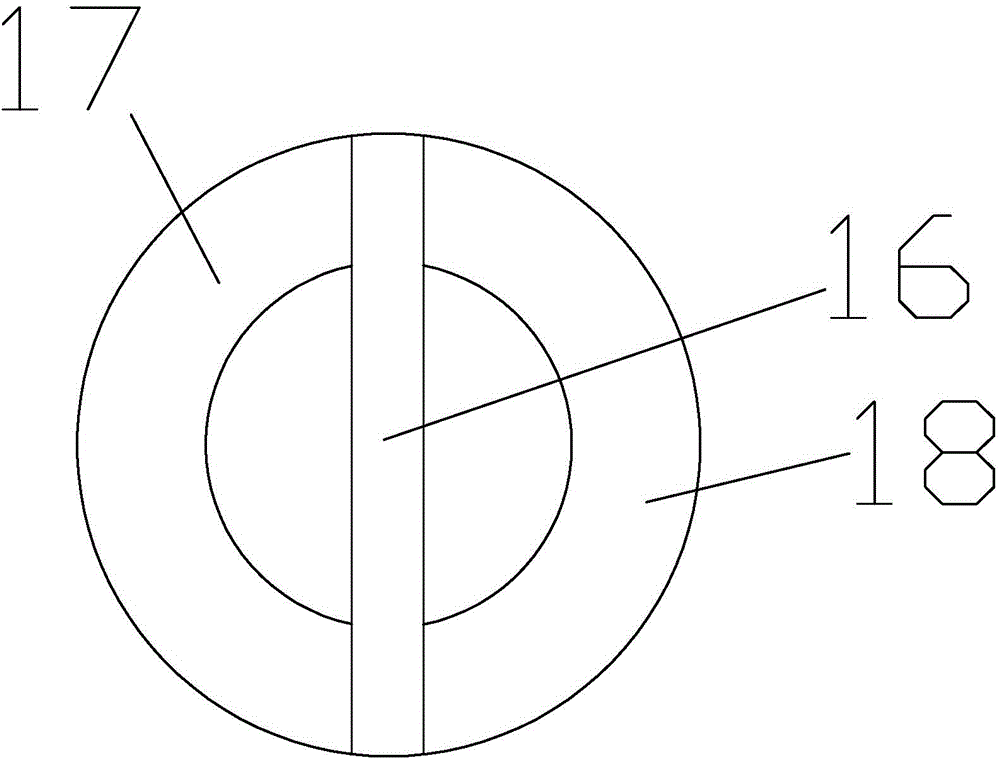

High efficient and environment-friendly pebble coal full-sealing discharge device

InactiveCN102942071ATimely dumpingEffectively judge the running status of dynamic and static ringsLarge containersLoading/unloadingElectricityWorking environment

The invention relates to equipment in a thermal power plant, and particularly relates to a high efficient and environment-friendly pebble coal full-sealing discharge device applied to a quick grinding pebble coal discharge system in a thermal power plant. The device comprises a transition pipeline, wherein the tail end of the transition pipeline is connected with a gas-tight silo; the gas-tight silo consists of a silo body and a sealing cover which is driven by a cylinder; a transferring box is arranged below the sealing cover; the top of the transferring box is provided with a feed port; a sealing ring is arranged between the edge of the feed port and the bottom surface of the sealing cover; the top of the sealing cover is provided with a lower shell; the lower opening of the silo body is provided with an upper shell; the upper shell and the lower shell are interlaced, sleeved and closed; the top of the sealing cover is also provided with a gas-tight cavity; the lower end of the joint gap between the upper shell and the lower shell is sealed in the gas-tight cavity; and the outer wall of the gas-tight cavity is provided with a sealed air inlet connected with a compressed air source. By adopting the high efficient and environment-friendly pebble coal full-sealing discharge device, dust pollution in a pebble coal working environment can be reduced, the labor intensity is lowered, and water and electricity consumption of auxiliary equipment are saved.

Owner:JIANGSU ZHONGNENG POWER EQUIP

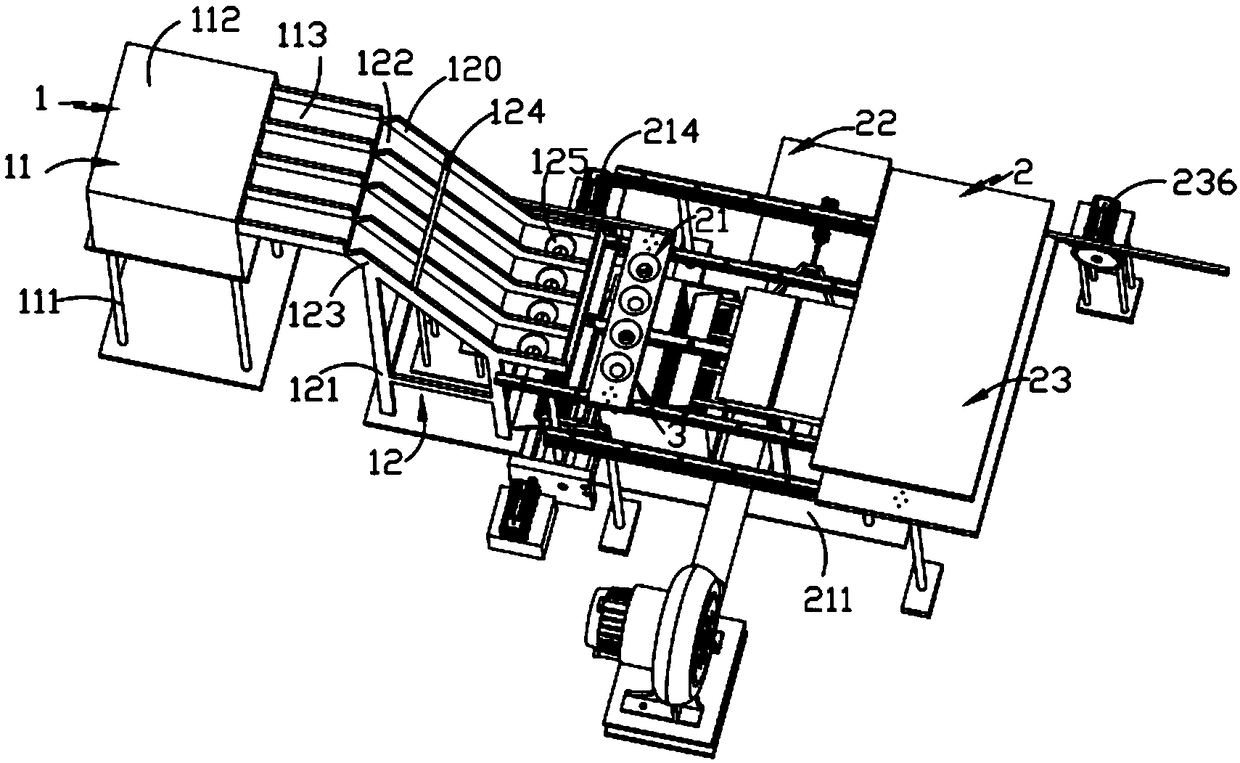

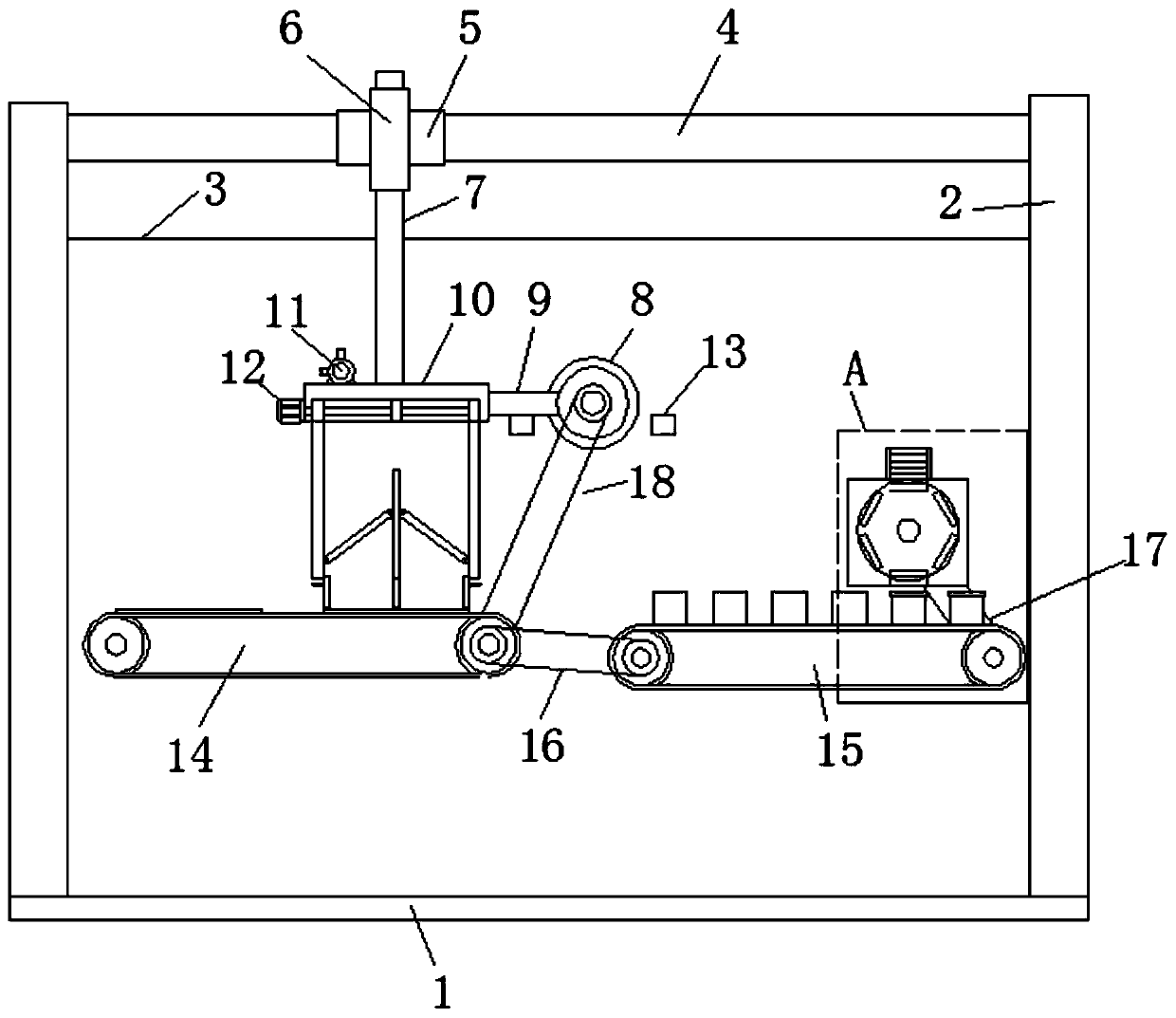

Garlic full-automatic processing and grinding production system and production technology

The invention provides a garlic full-automatic processing and grinding production system, which comprises a feed mechanism, a first processing mechanism and a second processing mechanism. The feed mechanism comprises a sorting component and a diverting component. The diverting component is arranged below the output end of the sorting component. The first processing mechanism is arranged at one side of the feed mechanism and comprises a feeding assembly, a shearing assembly and a grubbing assembly. The feeding assembly is located at one side of the diverting component. The shearing assembly islocated below the feeding assembly. The grubbing assembly is located above the feeding assembly. The second processing mechanism is disposed above the feeding assembly and comprises an elastic component, a peeling component, a drying component and a milling component. According to the invention, peeling, drying and milling of garlic can be integrated, and the problem that existing technologies aretime-consuming and labor-consuming and production efficiency is low in the prior art is solved.

Owner:临泉县超杰蔬菜脱水有限公司

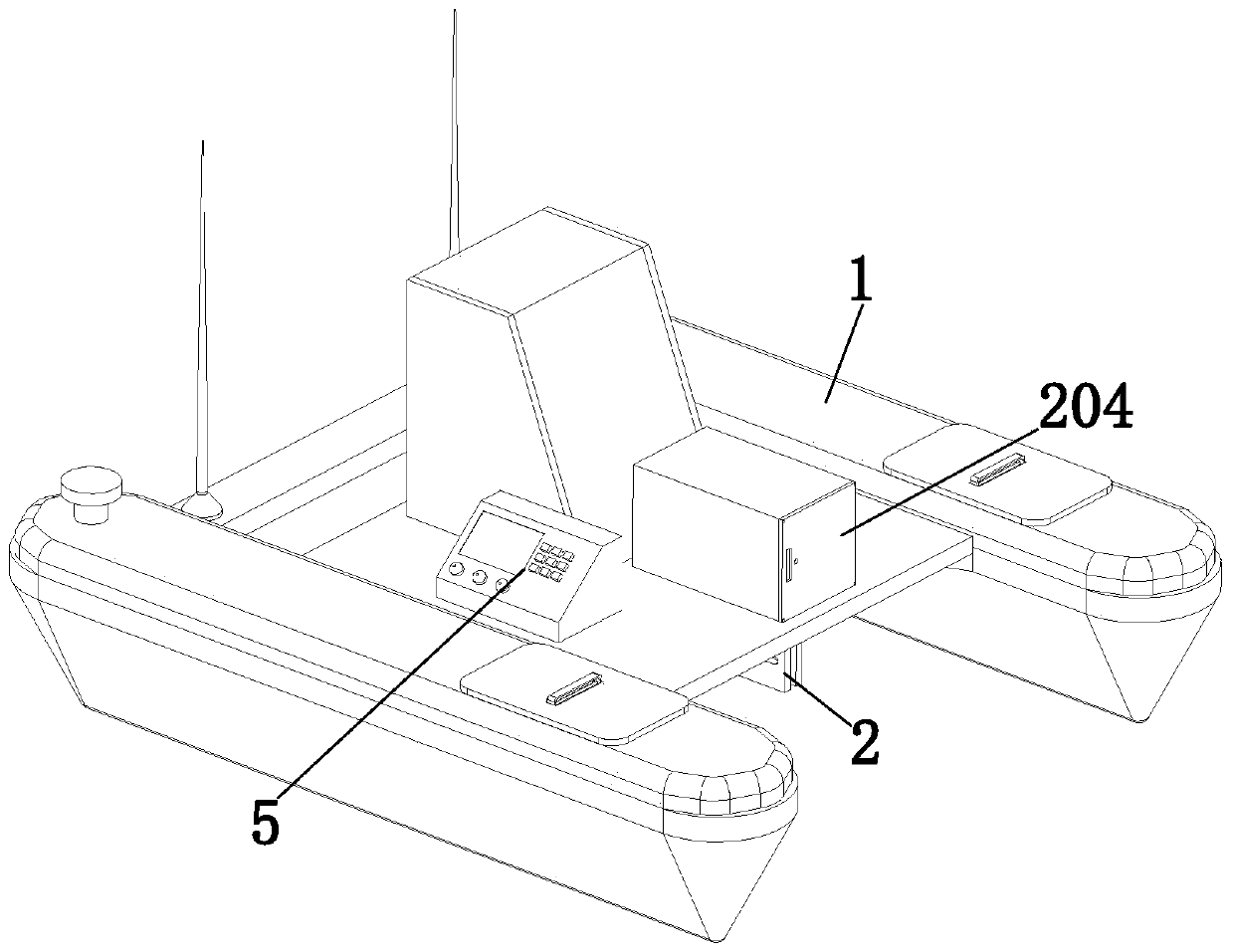

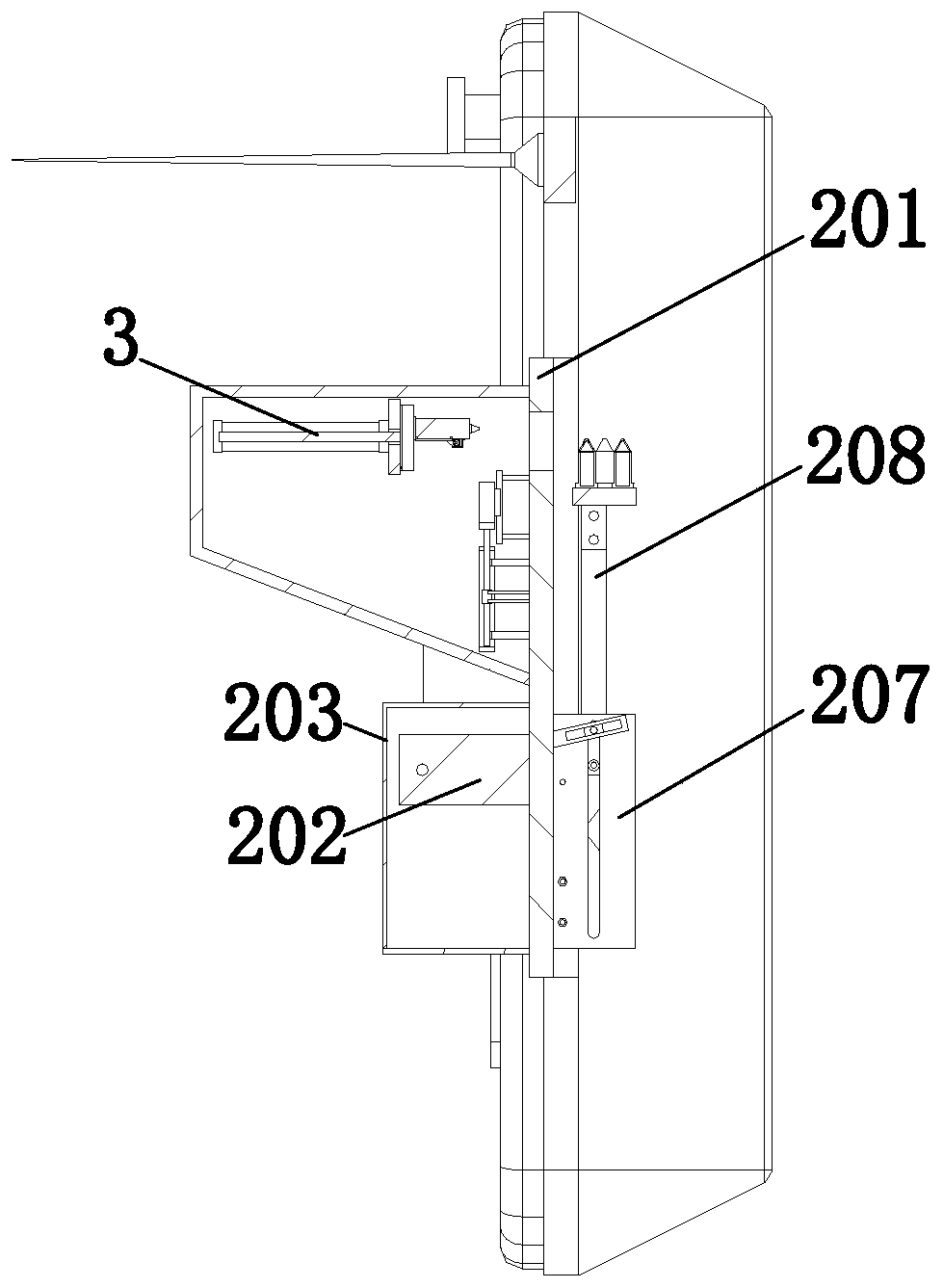

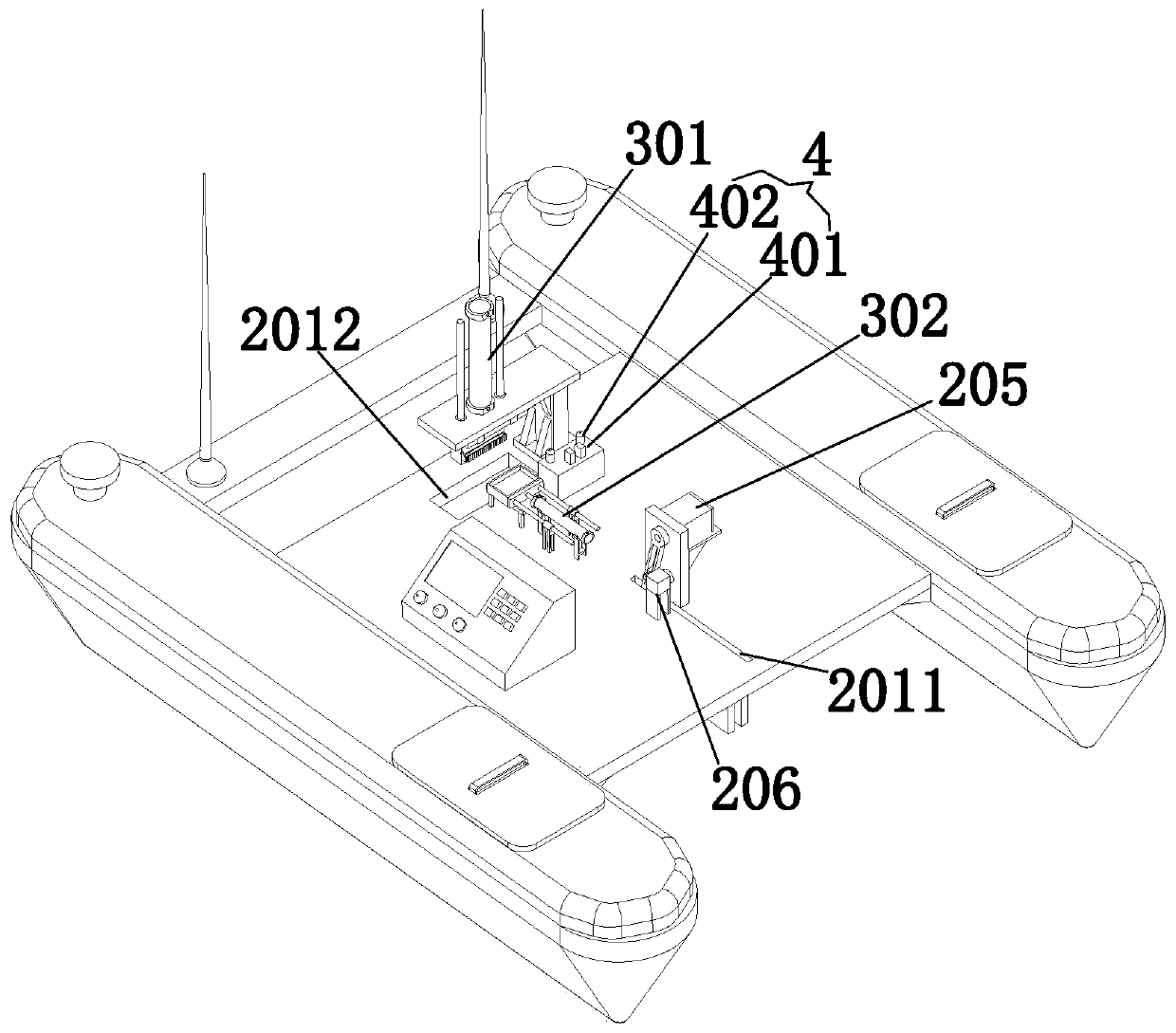

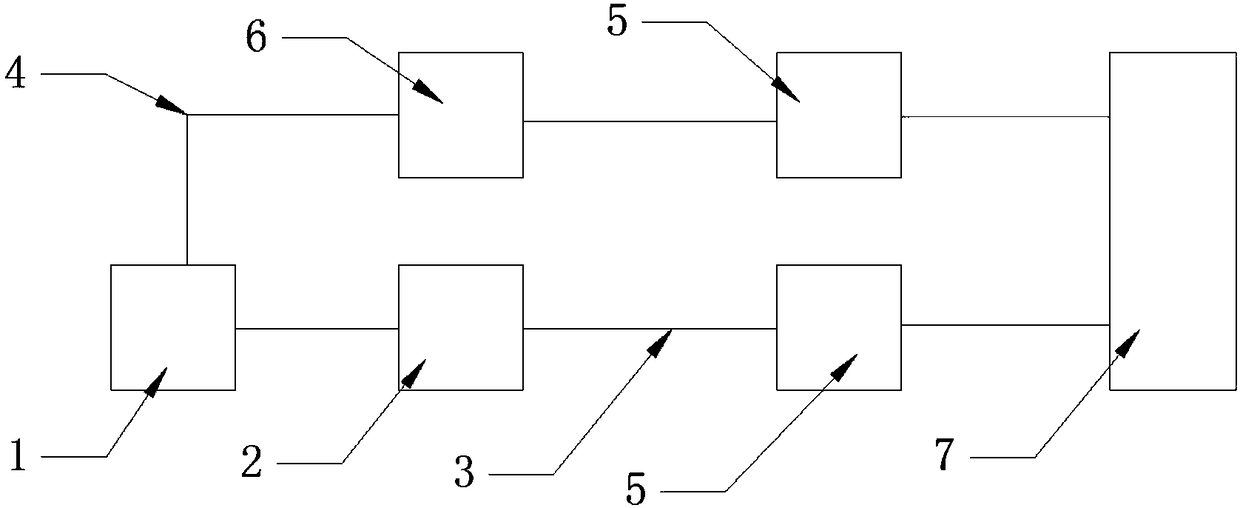

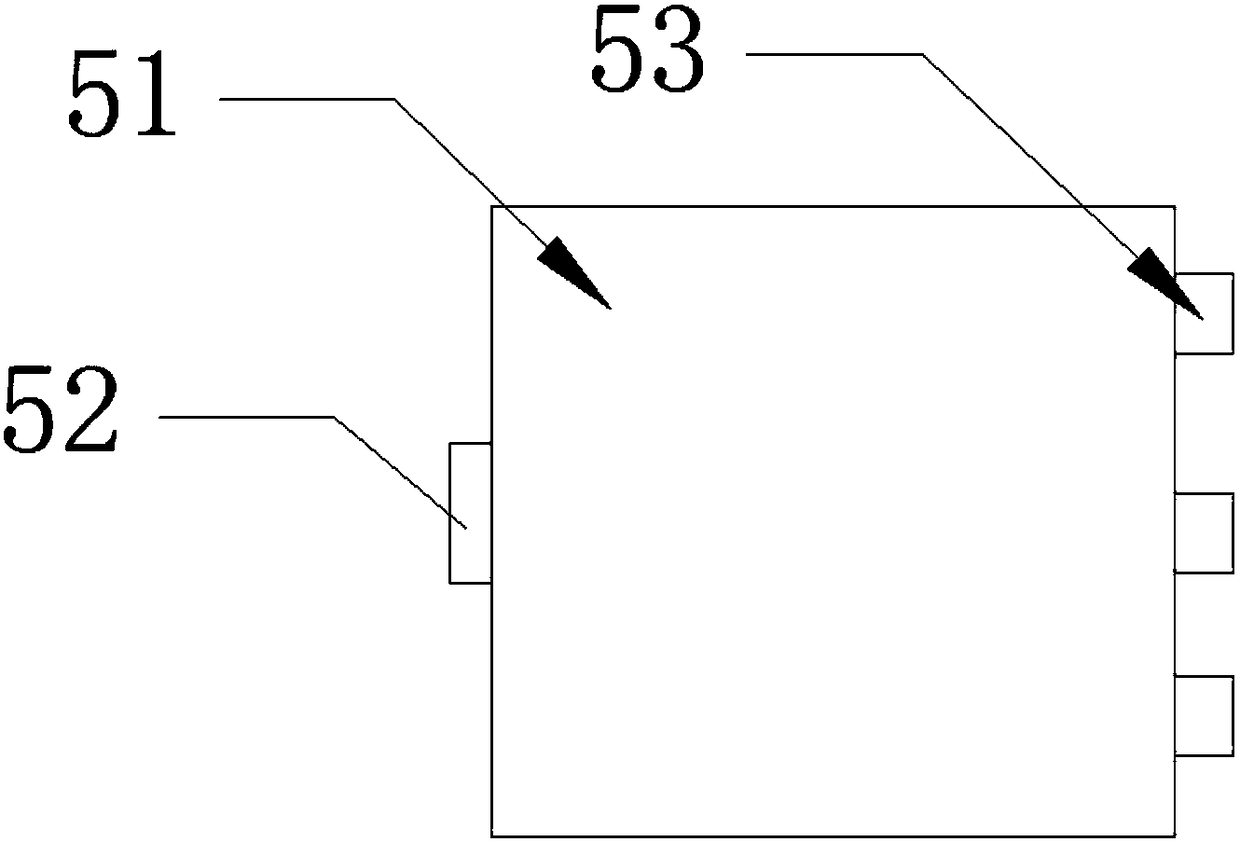

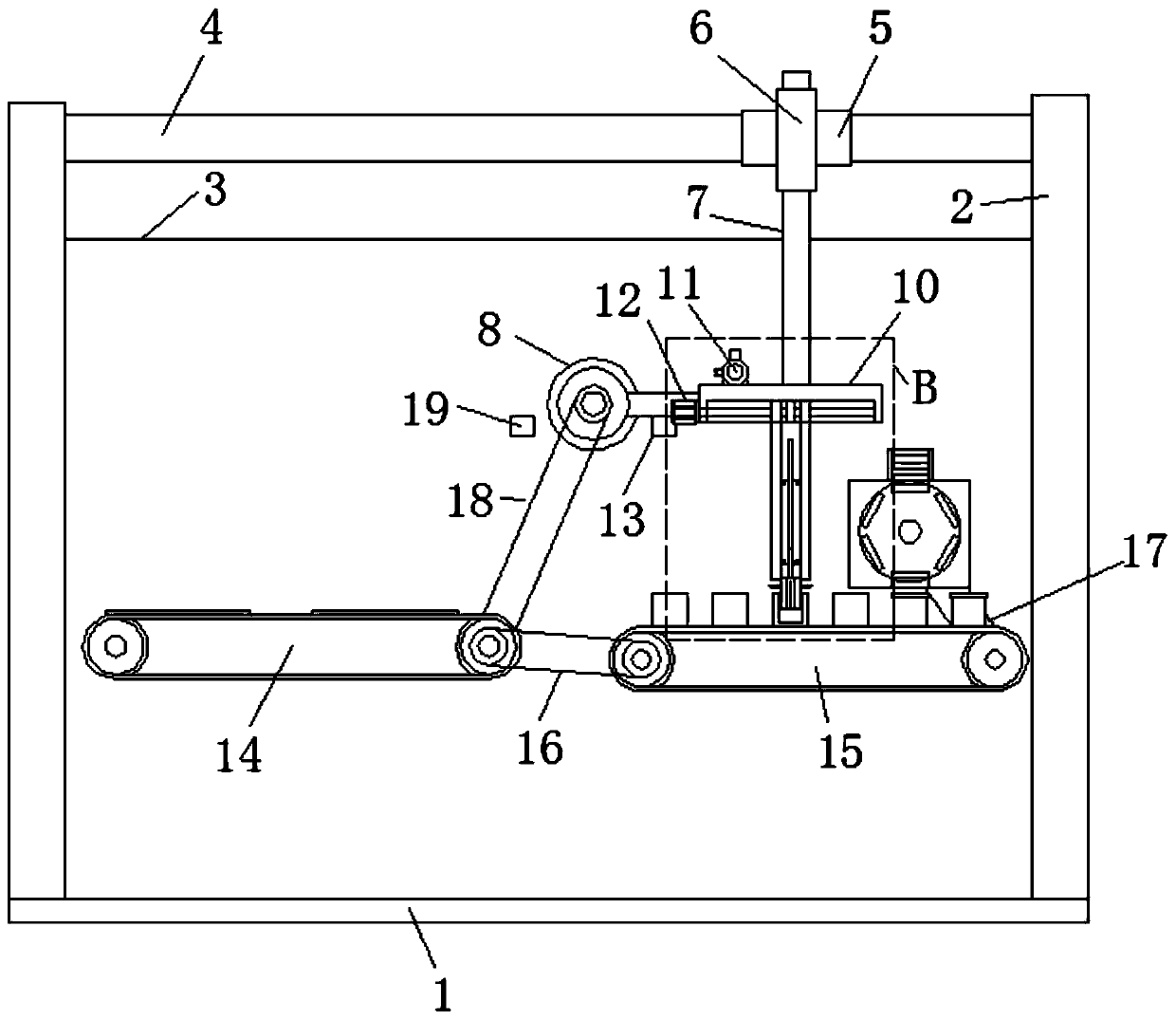

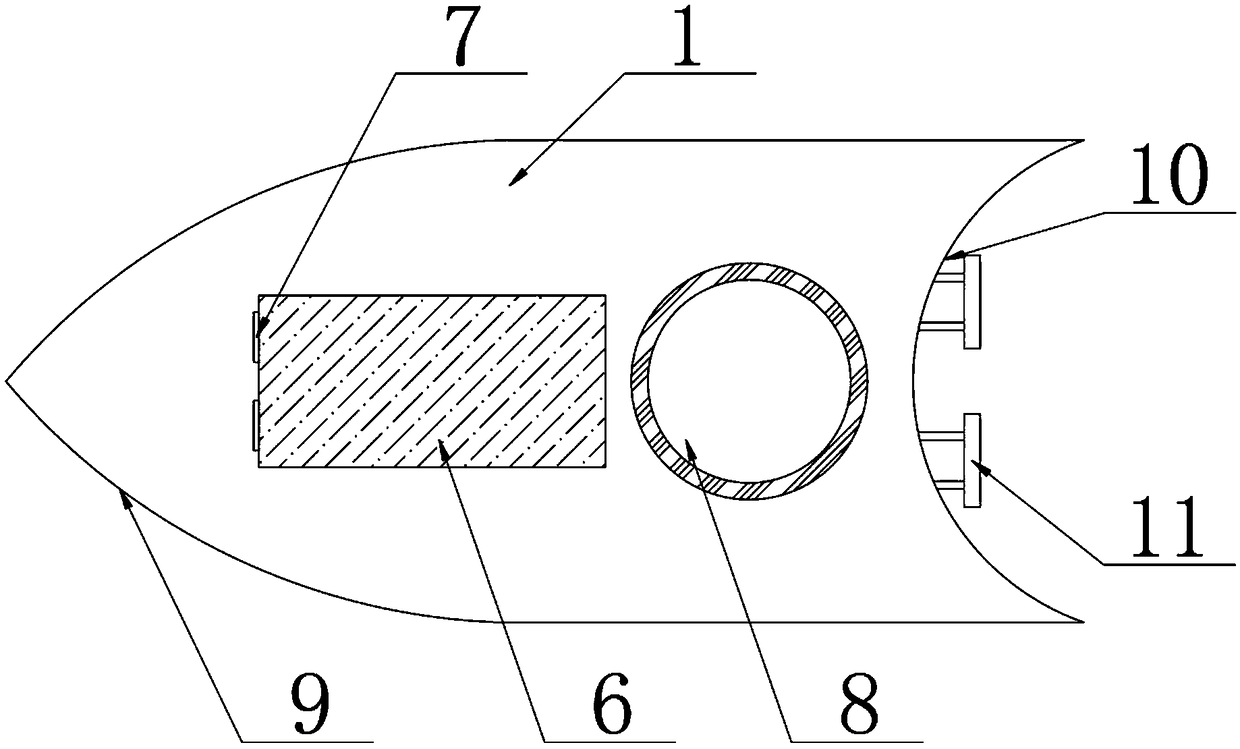

Unmanned ship for water quality detection

ActiveCN110104132AReduce labor outputRealize the collection operationWaterborne vesselsWithdrawing sample devicesMarine engineeringWater quality

The invention relates to the technical field of water quality detection, specifically to an unmanned ship for water quality detection. The unmanned ship for water quality detection comprises a hull body, a water sample taking device, a water sample transferring device, a water quality analysis device and a positioning control device; the water sample taking device comprises a positioning bearing plate and a positioning water taking part; the water sample transferring device comprises a vertical material taking part and a water sample loading part; a water taking end of the vertical material taking part can move in the vertical direction to be docked with a water inlet end of the positioning water taking part; the material taking end of the vertical material taking part is docked with a water loading end of the water sample loading part; the positioning water taking part, the vertical material taking part, the water sample loading part and the positioning control device are electricallyconnected with each other; and the positioning control device is electrically connected with the water quality analysis device. According to the unmanned ship for water quality detection, through automatic water taking, water passing, water through and water quality detection, water quality can be full-automatically detected to reduce the labor force output of a worker to water quality detection.

Owner:HEFEI UNIV

Mold cooling water pipeline dredging and cleaning device

The invention discloses a mold cooling water pipeline dredging and cleaning device, which comprises a water tank, a high-pressure device, a water inlet pipe and a water return pipe. The high-pressuredevice is connected with the water tank and is connected with one end of a mold cooling water pipeline through the water inlet pipe; the other end of the mold cooling water pipeline is connected withthe water tank through the water return pipe. The mold cooling water pipeline dredging and cleaning device provided by the invention is simple in structure, wide in application range, low in manufacturing cost, and capable of effectively dredging and cleaning the mold cooling water pipeline, so that the working efficiency is improved, and the labor output is reduced.

Owner:苏州梅克卡斯汽车科技有限公司

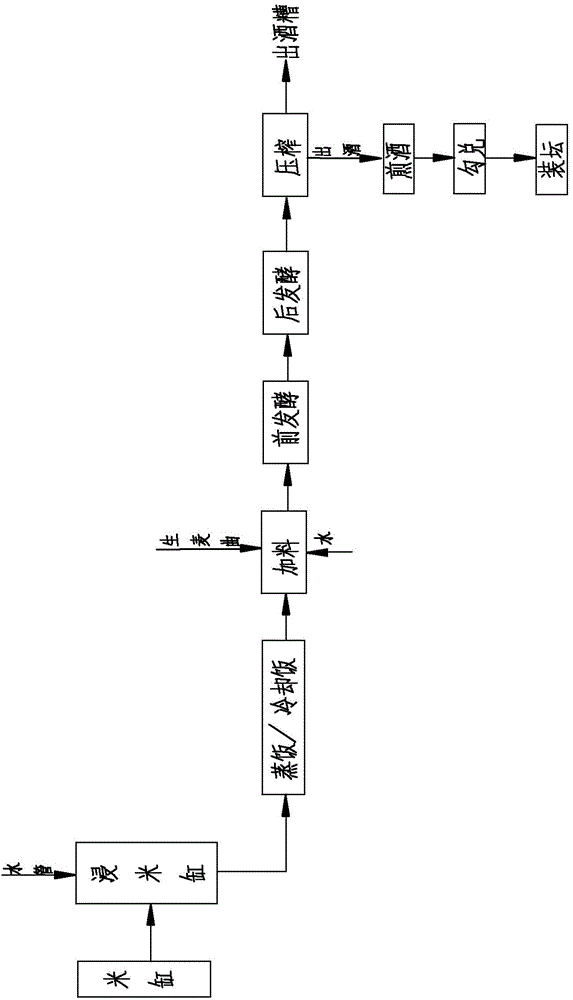

Automated yellow wine production process

ActiveCN104099212AReduce manual laborIncrease productivityAlcoholic beverage preparationProcess engineeringSteaming

The invention relates to a yellow wine production process, which comprises the steps of: (1) rice soaking; (2) rice steaming, cooling and charging; (3) primary fermentation: conveying the rice, raw wheat koji and water evenly mixed in step (2) into a primary fermentation cylinder together; (4) after fermentation: conveying the material subjected to primary fermentation in step (3) into an after fermentation cylinder through a pipeline to undergo after fermentation; (5) squeezing: conveying material subjected to after fermentation in step (4) into a squeezing workshop to undergo squeezing, conveying squeezed wine into a wine decoction workshop by a pipeline, and conveying the squeezed distillers' grains into a distillers' grain treatment pool through a yellow wine groove discharge conveying device to undergo treatment; (6) wine decoction and blending; and (7) jug filling: filling jugs with the well blended yellow wine. The whole production process involved in the invention realizes pipelining and automation, greatly reduces manual labor, improves the production efficiency, and also greatly improves the yellow wine production quality under the precondition of beautifying the workshop environment.

Owner:KUAIJISHAN SHAOXING WINE

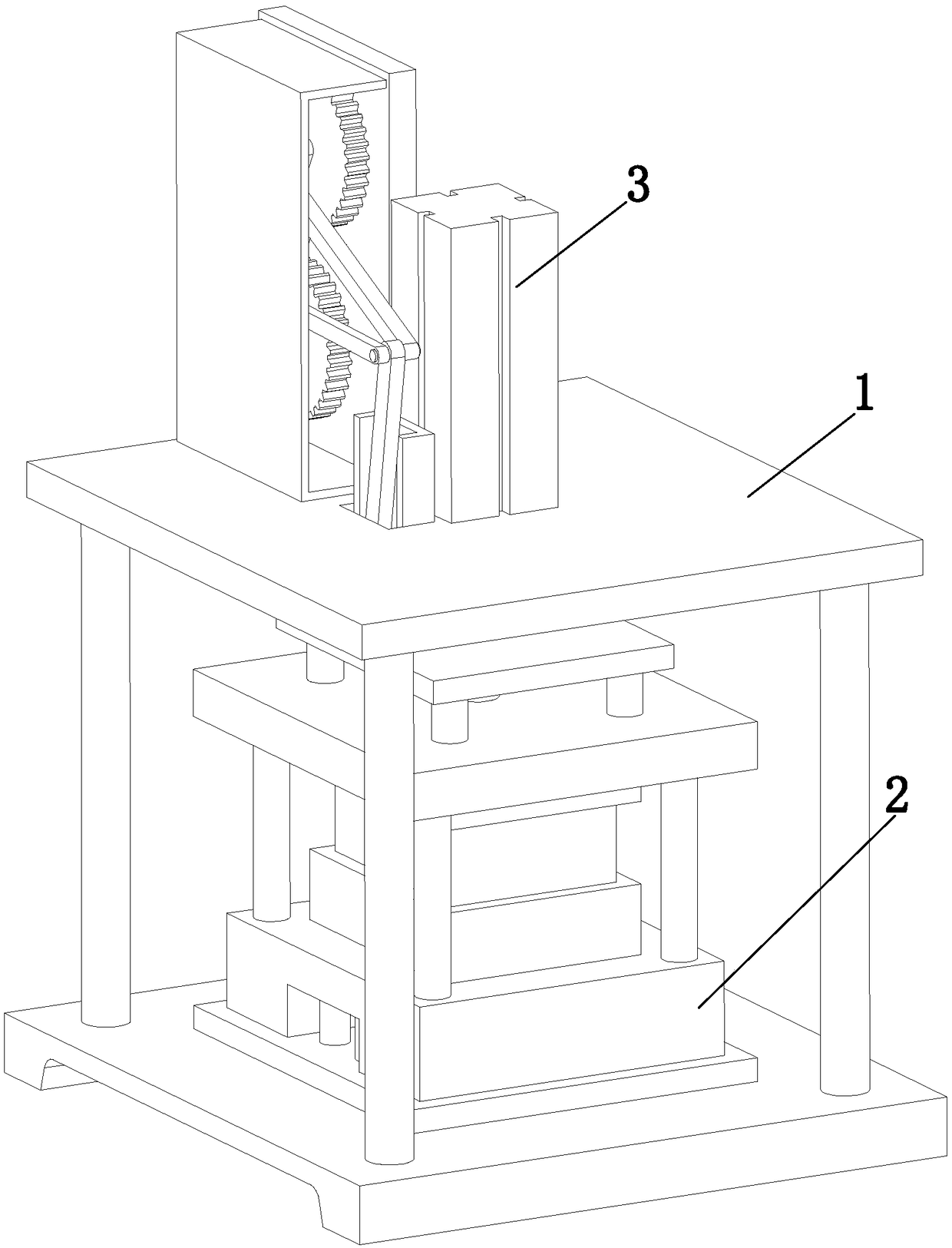

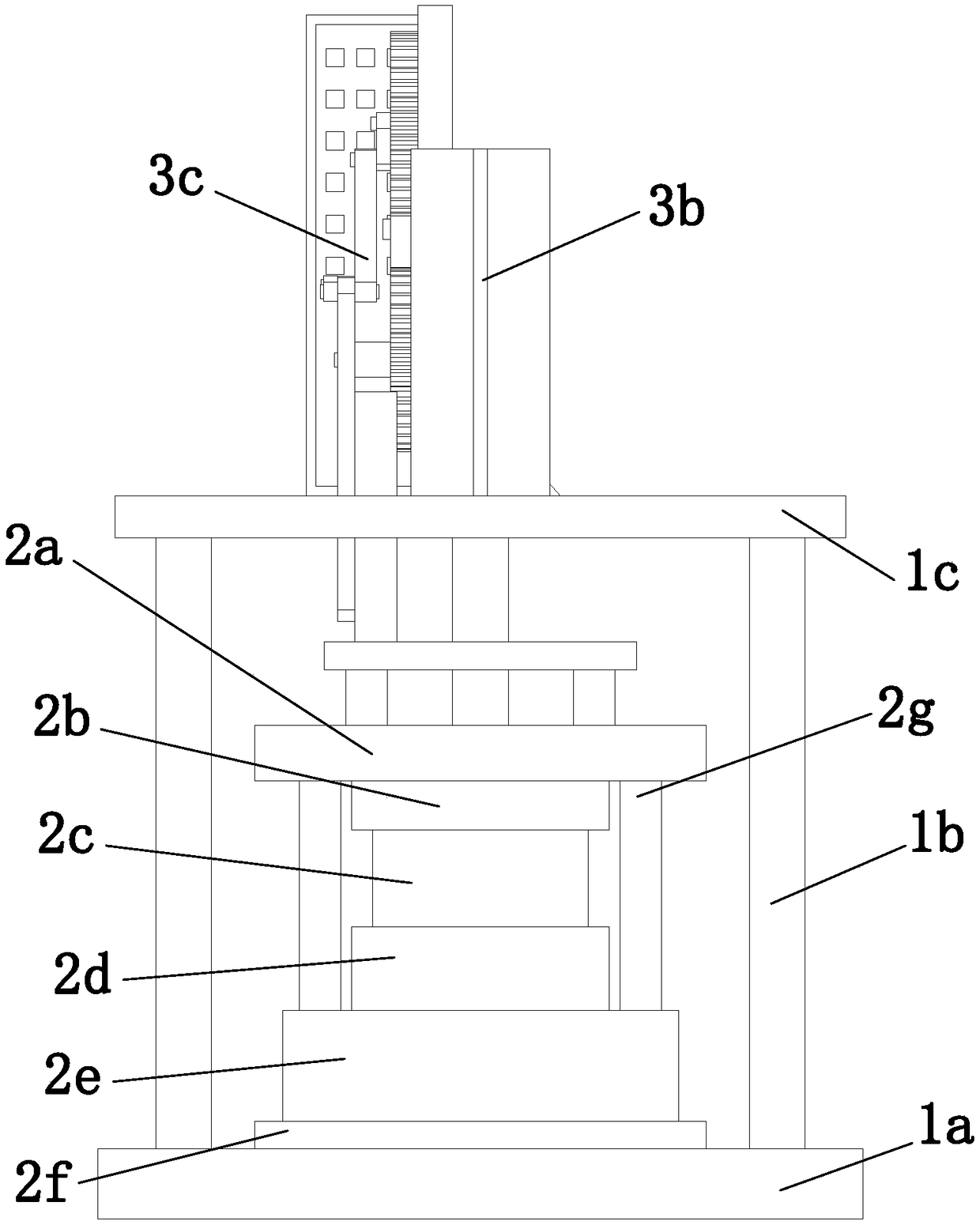

Automobile engine hood punching mold

The invention relates to the technical field of mold equipment, in particular to an automobile engine hood punching mold which comprises a positioning frame, a mold body and a drive device. The mold body comprises an upper mold seat, an upper mold plate, an upper mold core, a lower mold core, a lower mold plate, a lower mold seat and a plurality of connecting pillars. A holding cavity for storingproducts to be punched is formed between the upper mold core and the lower mold core; the drive device comprises a fixed frame, a drive part, and a linkage part arranged beside the drive part; the drive part and the linkage part are arranged on the positioning frame; and under the installation condition, the fixed frame is arranged on the top part of the upper mold plate, and the output ends of the linkage part and the drive part penetrate through the top part of the positioning frame and are connected with the top part of the fixed frame. According to the automobile engine hood punching moldprovided by the invention, under the drive of the drive assembly and the linkage assembly, the connecting assembly can upwards move slowly, so that the opening degree of the mold can be maximized, operating personnel can smoothly take out a product in the mold, and the labor output of the operating personnel is reduced.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

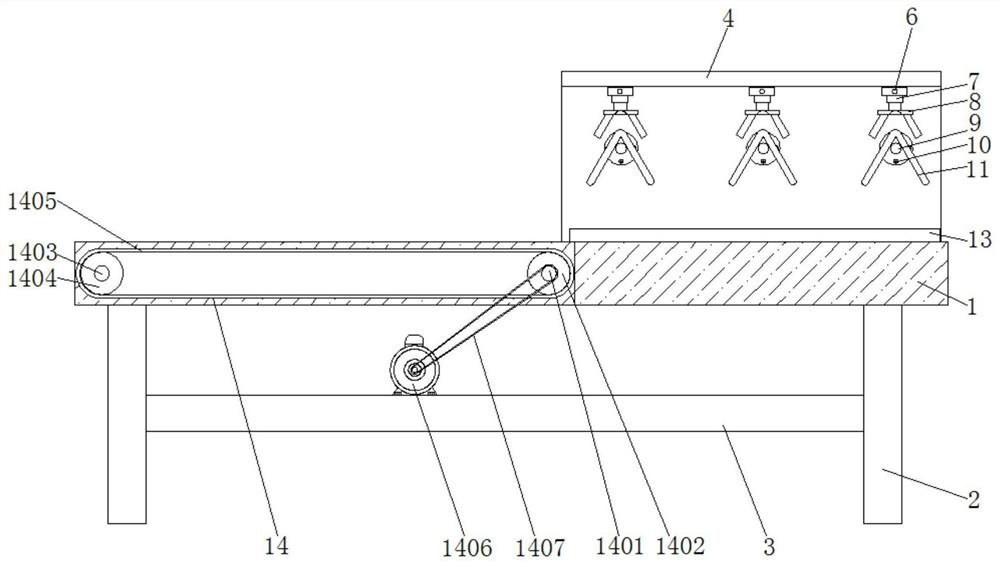

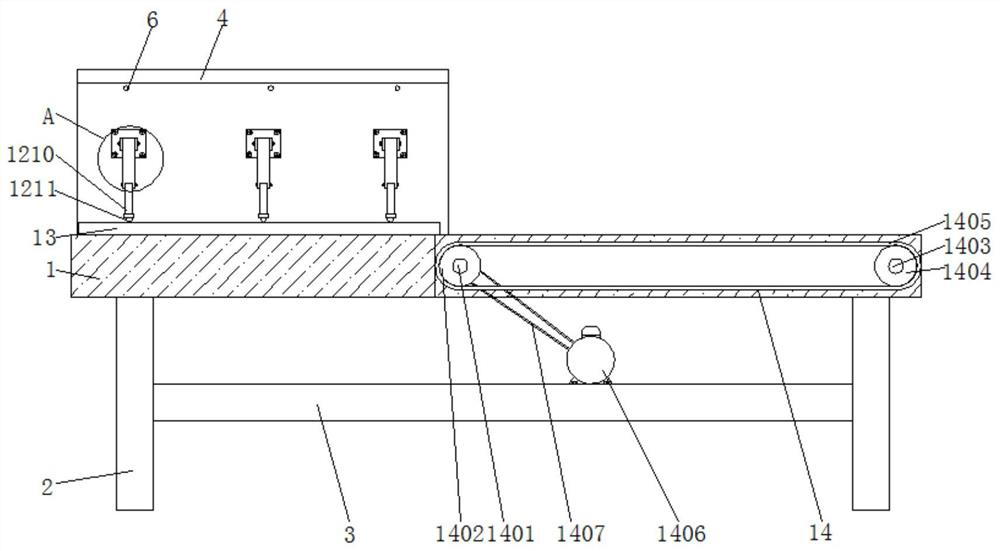

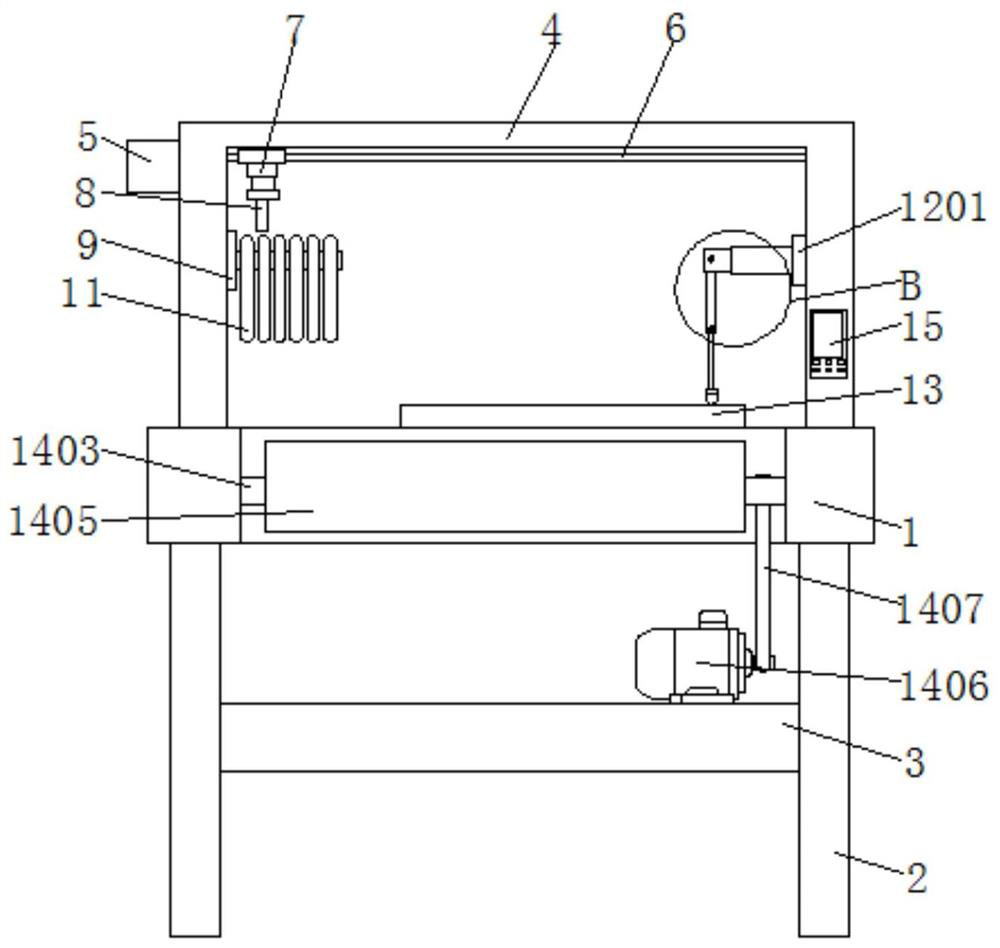

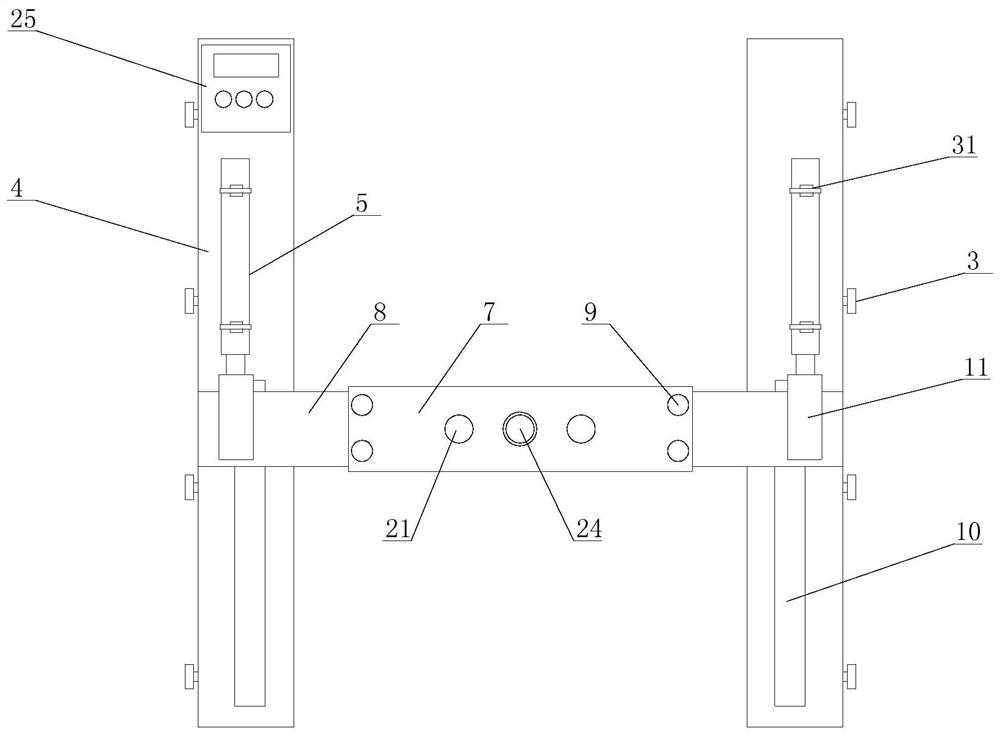

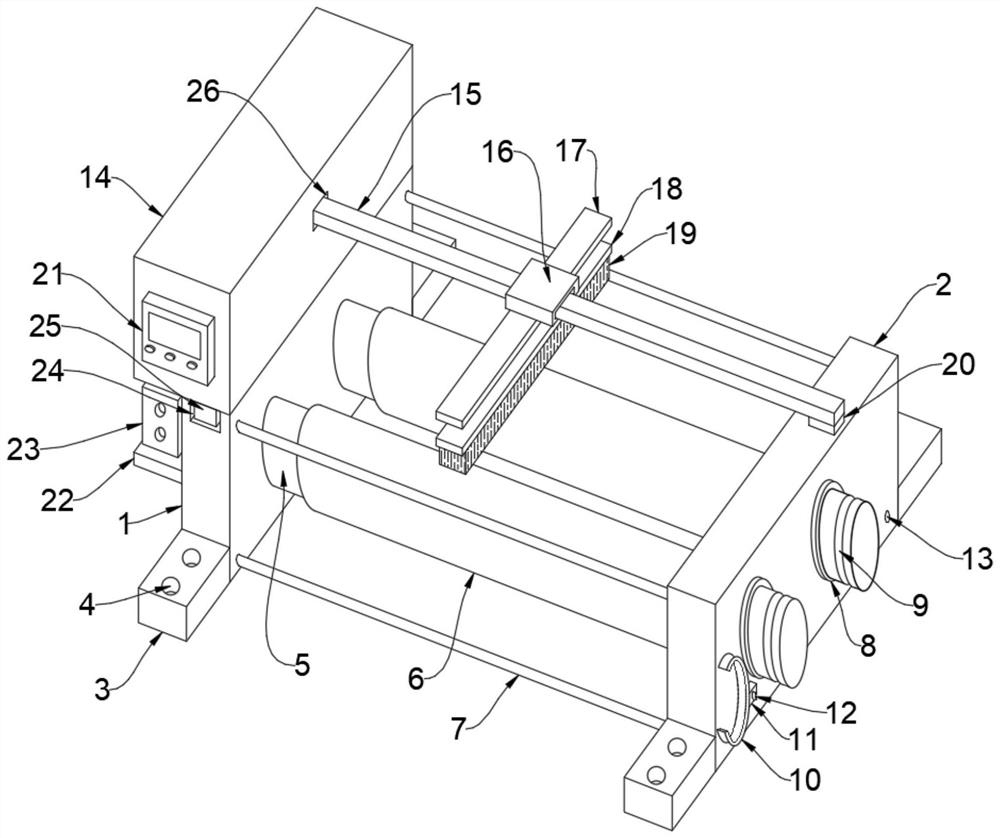

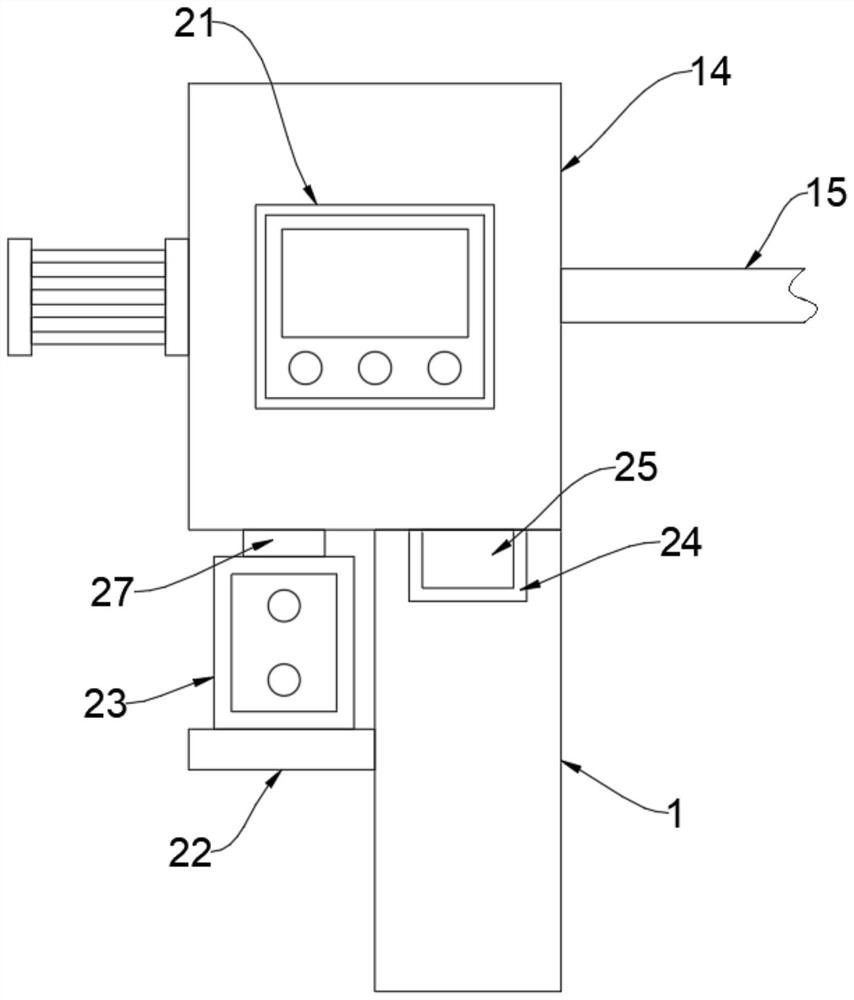

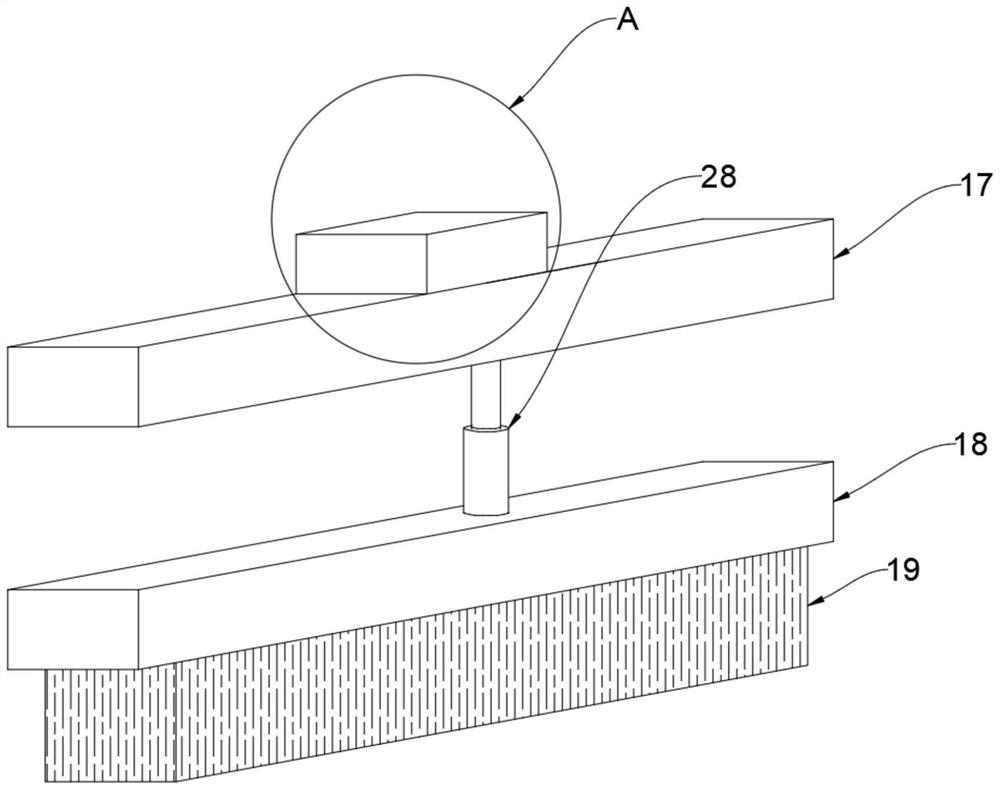

Welding device suitable for batch machining of steel bar truss floor support plates

InactiveCN113146088AEasy to moveImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRebarMachining

The invention discloses a welding device suitable for batch machining of steel bar truss floor support plates. The welding device comprises a workbench, a welding mechanism, a storage table and a conveying mechanism, supporting legs are arranged on the left side and the right side of the bottom of the workbench, a support is installed at the upper end of the right side of the workbench, a lead screw structure is installed at the upper end in the support, a clamping base is installed at the bottom of an electric telescopic rod, a fixing rod is arranged on the inner wall of the rear side of the support, the welding mechanism is installed on the inner wall of the front side of the support, the storage table is arranged at the upper end of the right side of the workbench, and the conveying mechanism is installed on the left side of the workbench. According to the welding device suitable for batch machining of the steel bar truss floor support plates, the welding mechanism is arranged, through matched use of a fixing base, a first supporting arm, a second supporting arm, a welding gun and a welding head, in the welding process of a steel bar truss, the welding gun does not need to be manually held for operation, meanwhile, the production efficiency of the steel bar truss floor support plates is improved, and welding automation is achieved.

Owner:徐州中煤汉泰建筑工业化有限公司

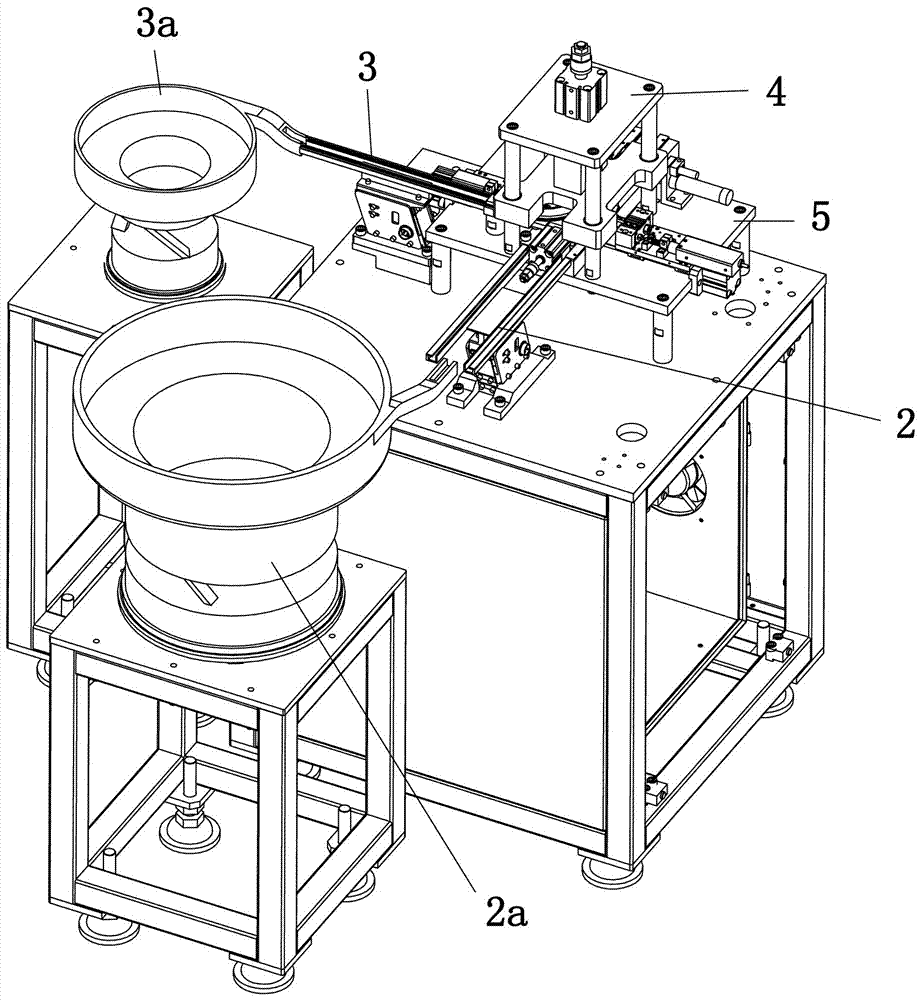

An inductor full-automatic and high-efficiency assembly device

The invention relates to an inductor full-automatic and high-efficiency assembly device, comprising: a wire flattening mechanism, comprising a frame, a conveying assembly arranged on the frame and anextension assembly mounted on the conveying assembly and positioned above the conveying assembly; a wire transfer mechanism including a wire crimping assembly disposed below an output end of the transfer assembly, a switching assembly positioned below the wire crimping assembly and rotatably disposed on a rack, and a plurality of holding assemblies disposed on the switching assembly and disposed along a circumference of the switching assembly; a wiring mechanism including a wire pressing machine and a support assembly fixedly connected with the wire pressing machine; and a coil conveying mechanism comprising a drive assembly mounted on a rack, an upper coil assembly having one end connected to the drive assembly and the other end slidably mounted on the support assembly, and a discharge assembly disposed at an output end of the support assembly, wherein the upper coil assembly is connected to the drive assembly and the other end is slidably mounted on the support assembly. The invention solves the technical problem that the conductor is bent and twisted when the wiring is connected, and the conductor is manually straightened in the back sequence.

Owner:阜阳汇中芯自动化技术有限公司

Folding packaging equipment for air cushion bed transportation and using method thereof

InactiveCN111232341AHigh degree of automationIncrease productivityPackagingStructural engineeringIndustrial engineering

The invention relates to the technical field of air cushion bed folding and packaging, in particular to folding packaging equipment for air cushion bed transportation and a using method thereof. The folding packaging equipment comprises a base, wherein vertical upward vertical frames are fixed to the left side and the right side of the base, a back plate is fixedly connected between the two vertical frames, a feeding mechanism used for conveying an air cushion bed is fixed on the back plate, and the feeding mechanism is in driving connection with a folding mechanism; and the back plate is further fixedly provided with a packaging mechanism used for packaging the folded air cushion bed, and the feeding mechanism is in driving connection with the packaging mechanism. According to the foldingpackaging equipment for air cushion bed transportation and the using method thereof, the air cushion bed is automatically conveyed through the feeding mechanism, the air cushion bed is folded throughthe folding mechanism, and is conveyed to the packaging mechanism for packaging treatment, the equipment investment cost and management difficulty are reduced, time and labor are saved, and the production efficiency is improved.

Owner:冯鸿儒

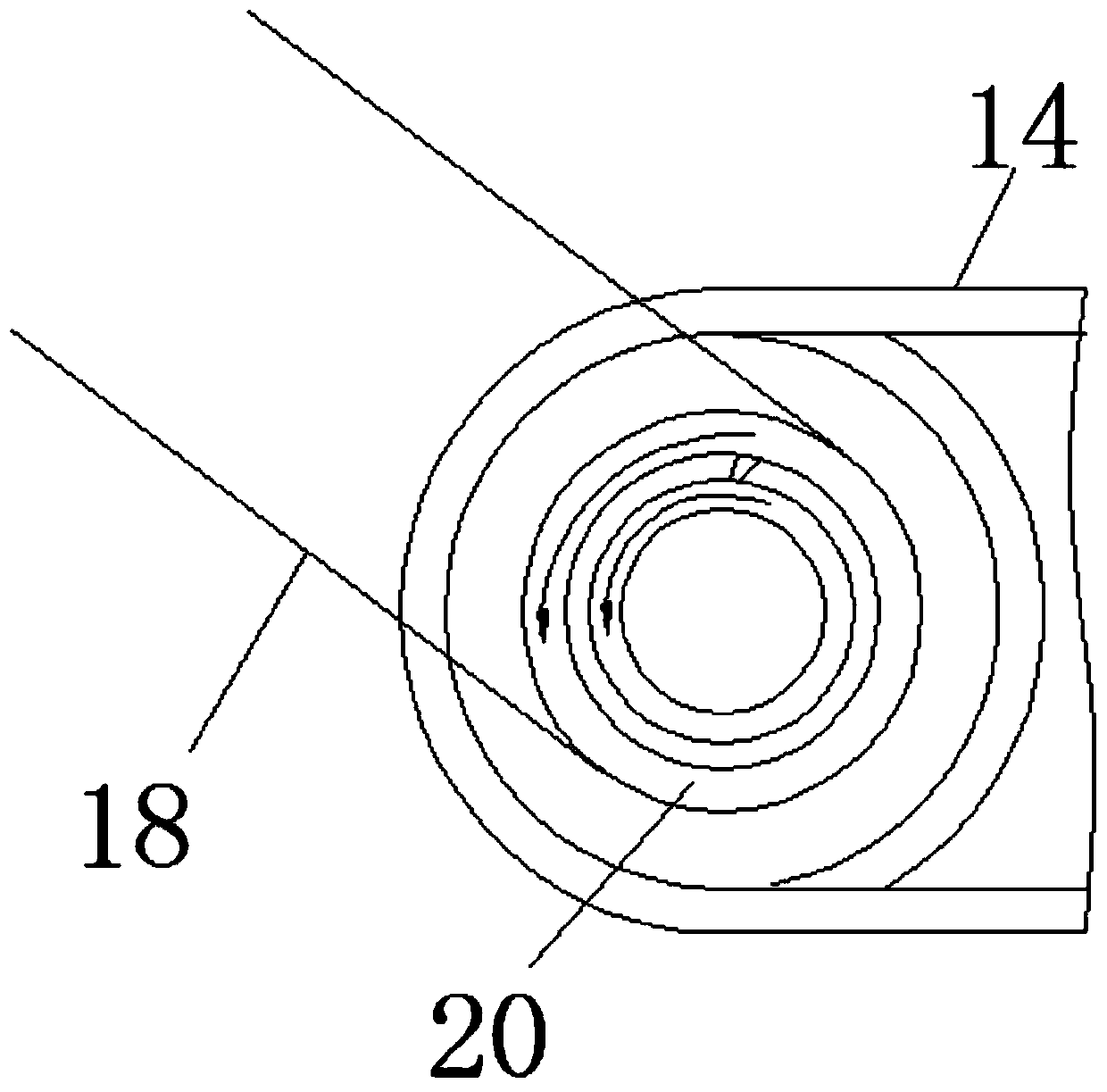

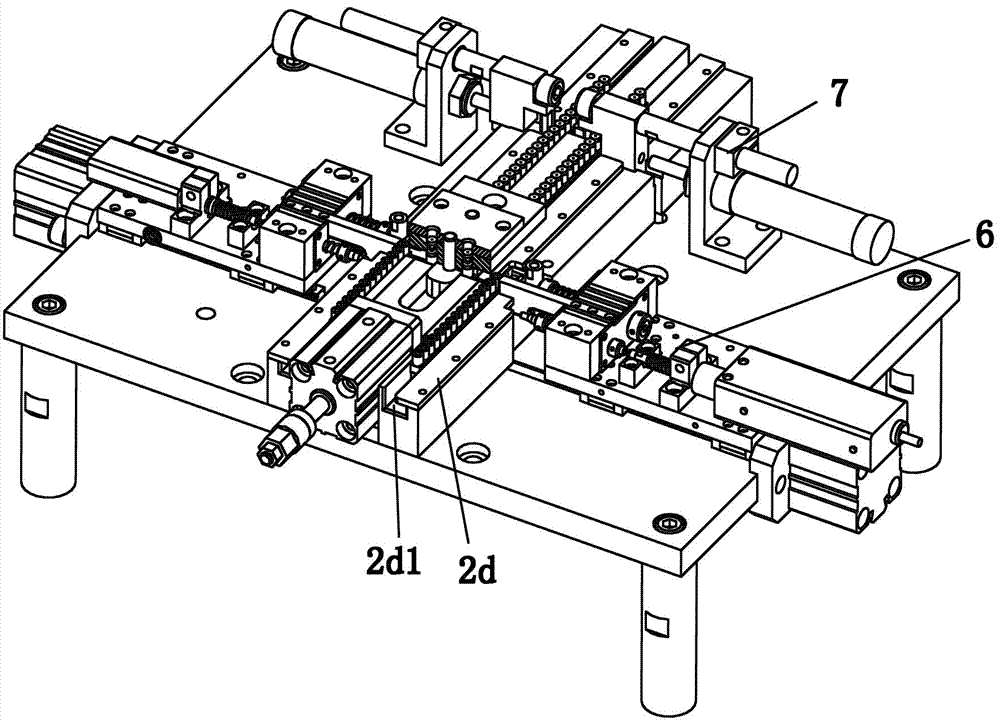

An electromagnetic clutch coil automatic cloth winding device

The invention relates to an electromagnetic clutch coil automatic cloth winding device, comprising a cloth winding mechanism which comprises an upper cloth assembly vertically arranged and a molding assembly arranged behind the upper cloth assembly and perpendicular to the upper cloth assembly; A gluing mechanism disposed on one side of the molding assembly and located at a lower end of the molding assembly; A cloth cutting mechanism disposed on the other side of the molding assembly with respect to the gluing mechanism; And a release mechanism arranged on the upper cloth assembly and comprising a control assembly moving up and down along the height direction of the upper cloth assembly and a flick assembly arranged in cooperation with the control assembly and mounted on the upper cloth assembly; The invention solves the technical problem that the insulation cloth needs to be cut manually and glued to be sealed in the winding process, and the degree of automation is not high.

Owner:阜阳运筹生产力促进中心有限公司

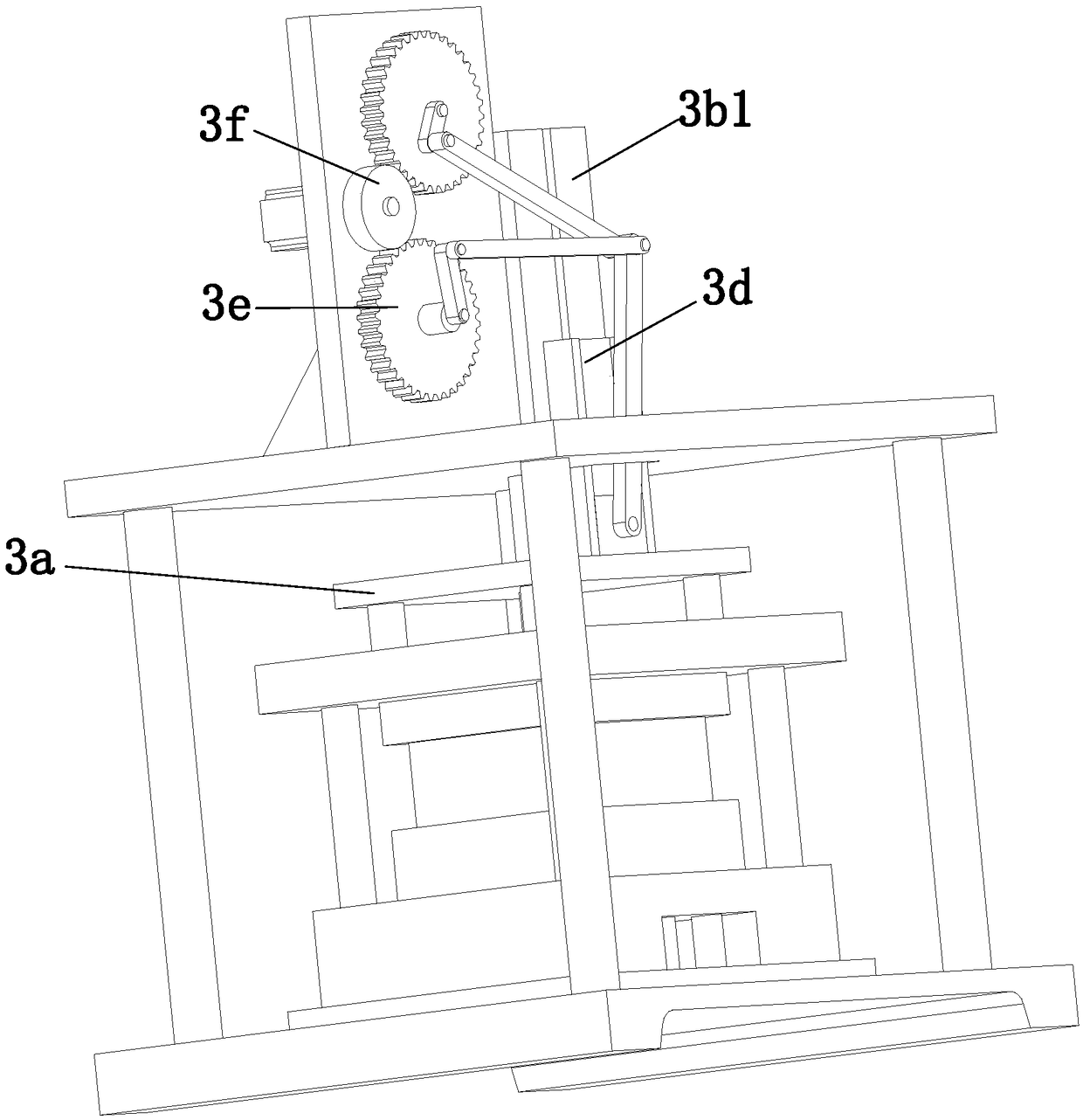

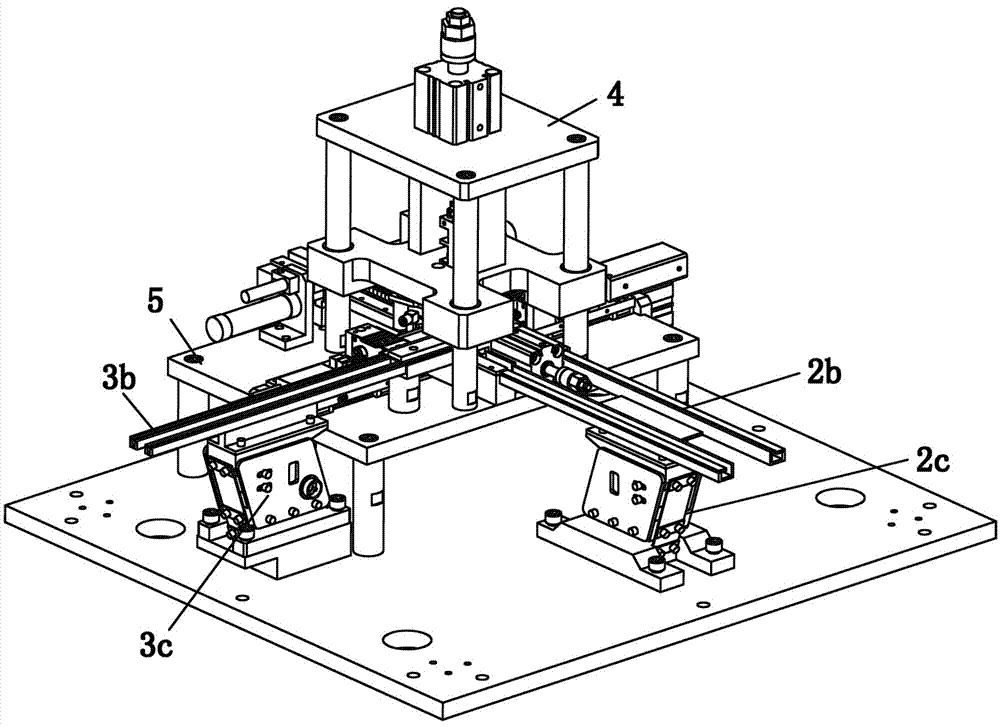

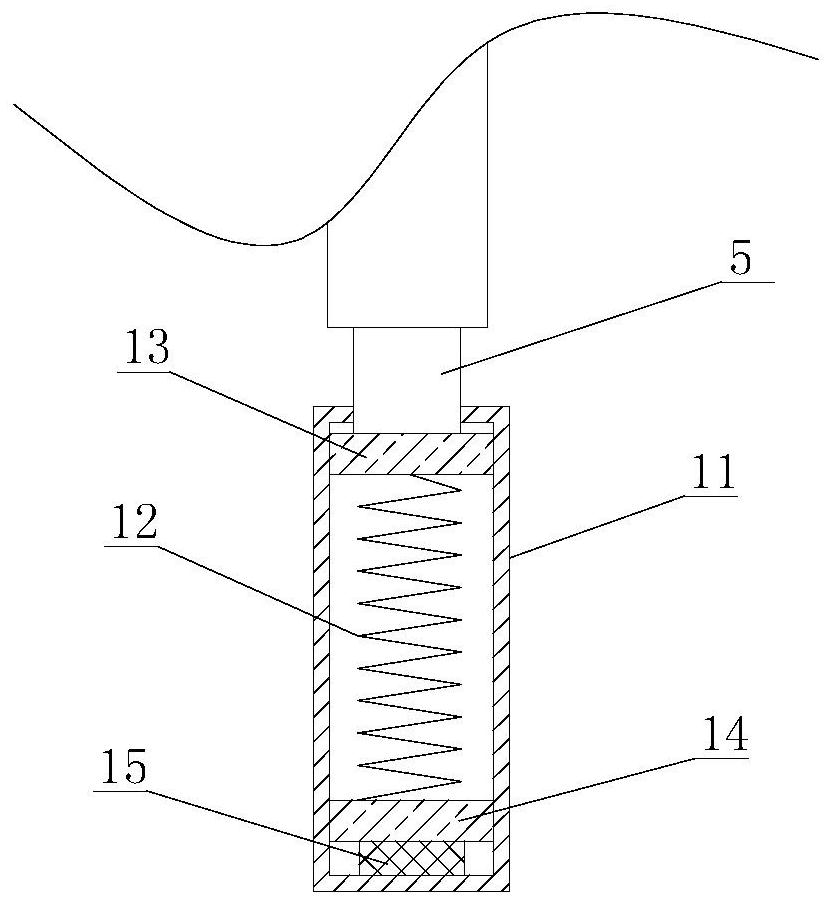

Press fitting mechanism of gas nipple assembly machine

ActiveCN107443051ARealize automatic pressingImprove assembly efficiencyMetal working apparatusAssembly machinePlunger

The invention relates to the field of automation equipment, in particular to a press fitting mechanism of a gas nipple assembly machine, which comprises a fixing plate, wherein the fixing plate is arranged above one assembly platform; four upright poles in rectangular distribution are arranged at the bottom of the fixing plate, bottoms of the four upright poles are fixed on the assembly platform, press plates in up-and-down sliding fit with the four upright poles are arranged on the four upright poles, a press pole is arranged at the bottom of the press plate, a press plate driving cylinder is mounted at the top of the fixing plate, and an output shaft of the press plate driving cylinder passes through the fixing plate and is fixedly connected with the top of the press plate; an arc support is mounted at the top of the press plate, the output shaft of the press plate driving cylinder is connected at the top of the arc support, and a first in-place detection device is mounted on one side inside the arc support; the first in-place detection device comprises a first spring plunger and a first pressure sensor arranged at the top of the first spring plunger. The press fitting mechanism can realize automatic press fitting, has the advantages of high assembly efficiency and good assembly effect, and can effectively reduce labor output.

Owner:惠东达声五金制品有限公司

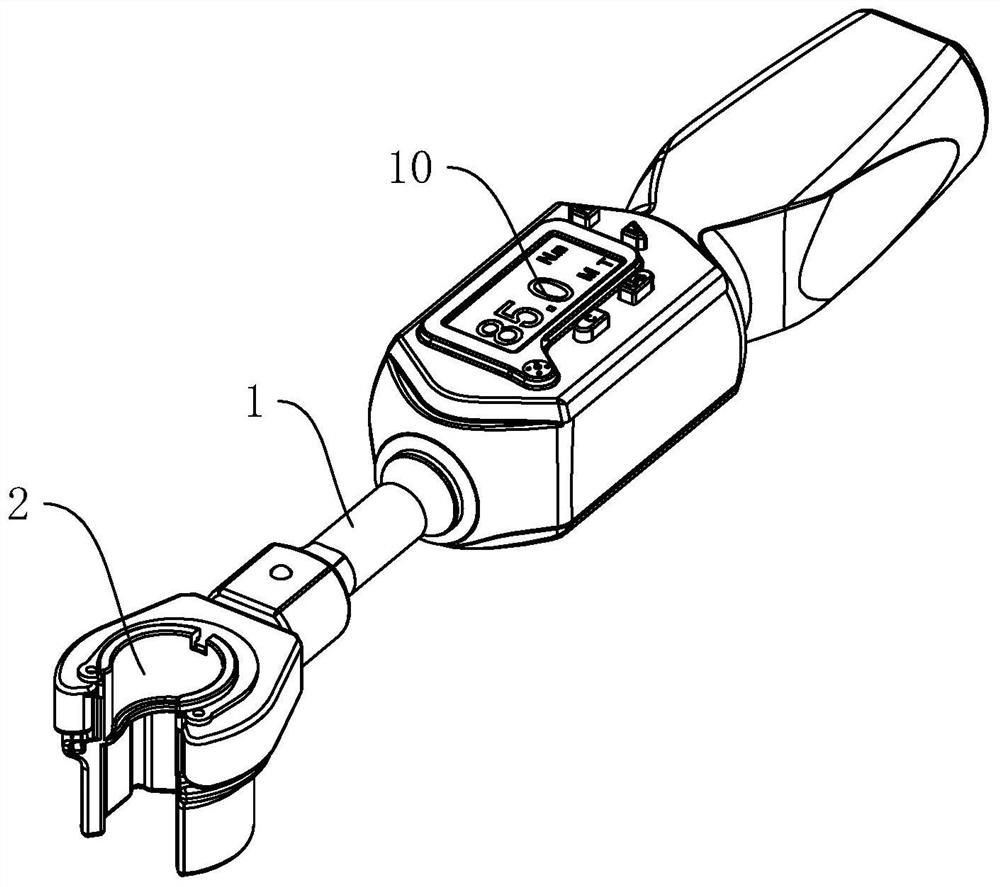

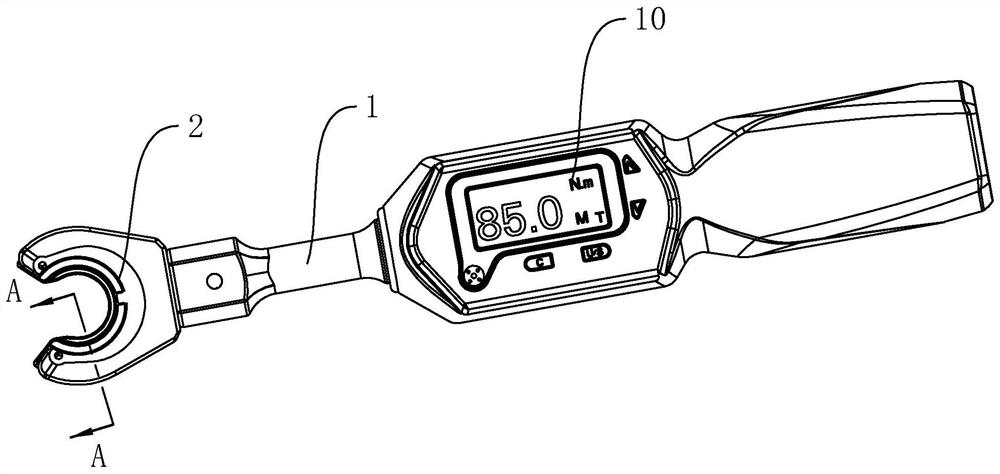

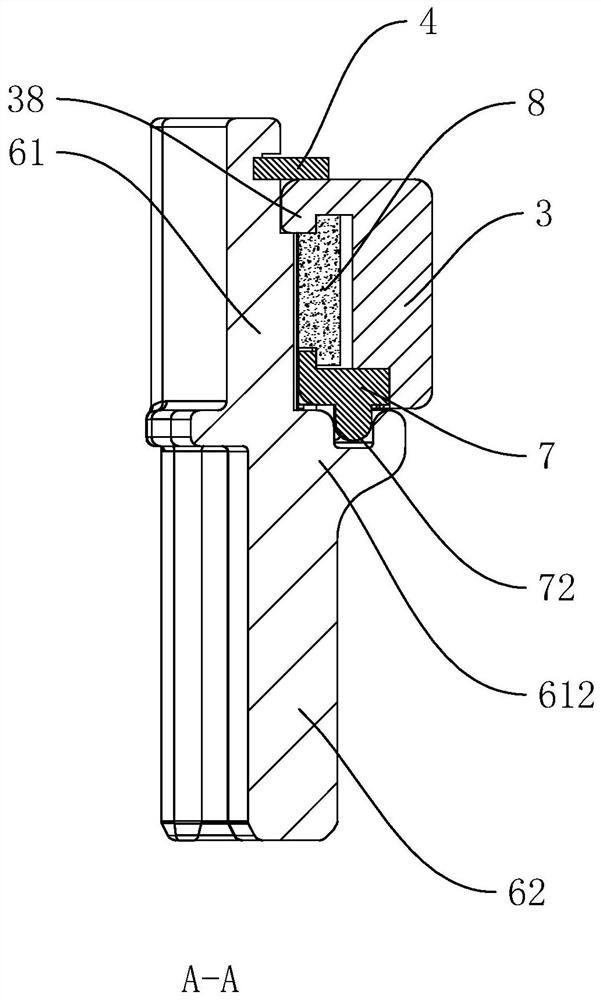

Manual digital display open spanner

The invention discloses a manual digital display open spanner. The manual digital display open spanner comprises a grab handle and a head with an opening. The head comprises a swing claw and a spanner head, the spanner head and the side wall of the swing claw are each provided with an inlet and outlet opening, the spanner head penetrates through the swing claw and is connected with the swing claw in a circumferential rotating mode, and a plurality of tooth grooves are formed in the side wall of the spanner head. A plurality of driving tooth pieces matched with the tooth grooves are arranged on the swing claw, a connecting block is arranged on the swing claw, a connecting groove allowing the connecting block to be inserted is formed in the grab handle, a screw is arranged on the connecting block, a spring bead is arranged at the end of the screw, and a limiting groove allowing the spring bead to be embedded is formed in the connecting groove. According to the manual digital display open spanner, the spanner is twisted in a manual mode, the spanner can avoid a cable, a connector with the cable can be conveniently installed, meanwhile, the spanner can be suitable for a very small connector space, the whole head can be replaced according to the size of the connector, and disassembly and assembly are convenient and fast.

Owner:JIAXING SHENG YANG ELECTRIC CO LTD

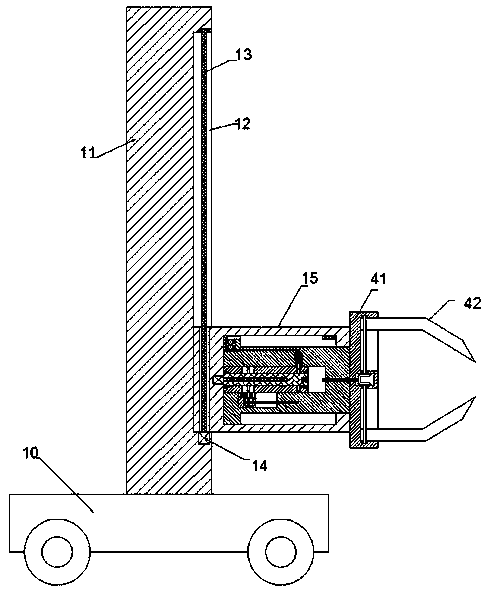

Machining technology for ladder type formwork platform

InactiveCN110641343AQuick handling operationHigh degree of automationLoading/unloading vehicle arrangmentTransportation itemsMachining processSupport plane

The invention relates to the field of formwork platform machining, in particular to a machining technology for a ladder type formwork platform. Machining equipment for the ladder type formwork platform comprises a formwork platform vehicle and a support frame which is fixedly arranged on the formwork platform vehicle and extends upwards, a lifting platform is arranged in the support frame througha lifting device in a vertical moving manner, a telescopic cavity with a rightward opening is arranged in the lifting platform, a telescopic column is slidably installed in the telescopic cavity, a clamping frame stretching out of the end face of the right side of the lifting platform is fixedly arranged on the end face of the right side of the telescopic column, and a clamping assembly used for clamping a formwork platform plate is arranged in the clamping frame. According to the machining technology for the ladder type formwork platform, quick carrying operation of the formwork platform plate can be achieved, and compared with a traditional manual carrying method, the machining technology for the ladder type formwork platform has the advantages that the automation degree is high, labor output can be greatly reduced, and the assembling efficiency is improved; and meanwhile, compared with existing formwork platform carrying equipment, the machining equipment for the ladder type formwork platform has the obvious advantages of being easy and convenient to operate and low in using cost and is suitable for being used and popularized.

Owner:河北蓝堡住宅工业有限公司

Improved damp-proof carton box easy to open

The invention discloses an improved damp-proof carton box easy to open. The improved damp-proof carton box easy to open comprises a box body and a cuboid-shaped cover plate. The upper end of each side face of the box body is transversely provided with a row of elastic protrusions. Each side face of the cover plate is provided with a clamping groove in clamping connection with the corresponding row of elastic protrusions. Each corner of the bottom of the box body is provided with three damp-proof plates, buffering devices are arranged on the lower faces of the three damp-proof plates at each corner, and rolling balls are arranged on the bottom faces of the buffering devices. An article taking opening is formed in a top plate of the cover plate, two opposite inner side faces formed by the article taking opening are each provided with an extension groove, at least one flexible spring is arranged in each extension groove, and the end of each flexible spring is fixedly connected with a transparent plastic plate capable of moving leftwards and rightwards. A shifting block is arranged on each transparent plastic plate, and the top plate of the cover plate is provided with round notches in clamping connection with the shifting blocks correspondingly in a matched mode. The improved damp-proof carton box easy to open has the beneficial effects that firstly, the problem that carbon boxes are prone to damp is solved; secondly, the problems that it is difficult to carry carbon boxes, and part of articles are damaged since carbon boxes are prone to vibration in the carrying process are solved; and the problems that carbon boxes are inconvenient to disassemble and it is inconvenient to take articles from carton boxes are solved.

Owner:丹阳市华丰精密配件厂

Delivery boosting device

InactiveCN111839688AReduce labor outputImprove work efficiencyOperating tablesObstetrical instrumentsPhysical medicine and rehabilitationEngineering

The invention discloses a delivery boosting device, which belongs to the technical field of delivery assisting tools, and comprises a pushing mechanism, a compression mechanism and a control box, wherein the pushing mechanism comprises two supporting frames, a transverse plate and two electric control telescopic rods, and the two supporting frames are used for being fixed to two guardrails of a delivery sickbed and have the lifting function; the compression mechanism comprises a compression block, two movable rods, two first springs, a pressure adjusting plate and an adjusting screw rod; the compression mechanism is used for being clamped on the belly of a puerpera and exerting certain pressure on the belly of the puerpera; and a controller is arranged in the control box. When the device works, the controller firstly controls the electric control telescopic rod to drive the compression mechanism to push forwards to assist a fetus in a puerpera to move forwards slowly, and then controlsthe compression mechanism to reset, and circulation is conducted in sequence; the problem that in the prior art, medical staff need to consume large physical strength due to the fact that no specialdelivery boosting device exists is solved.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

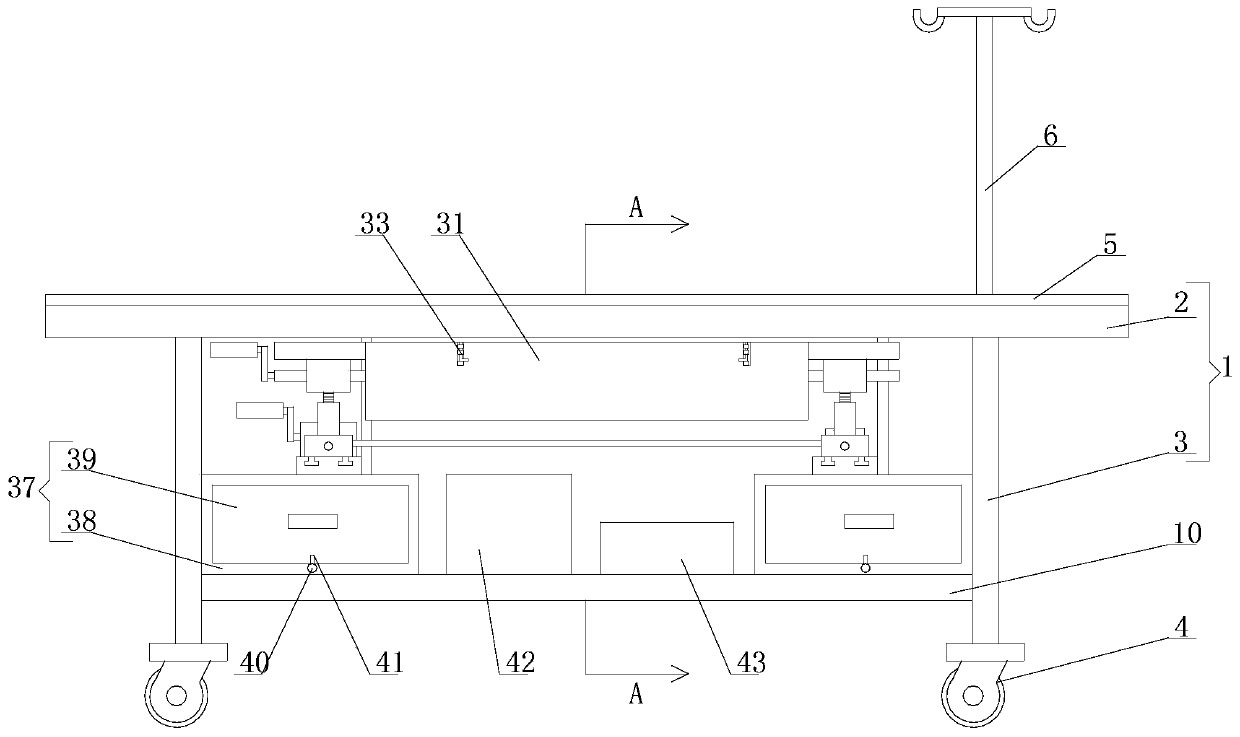

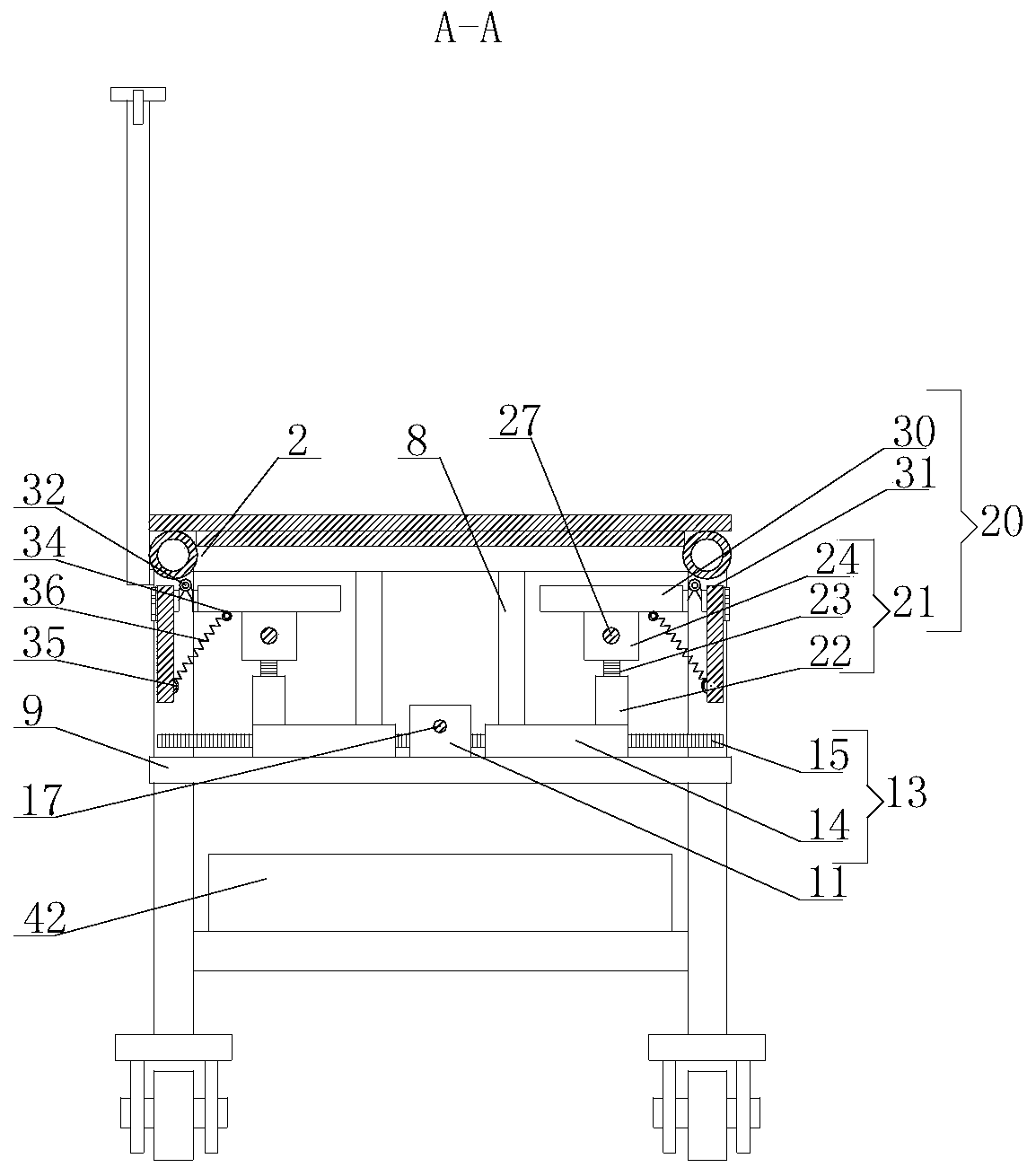

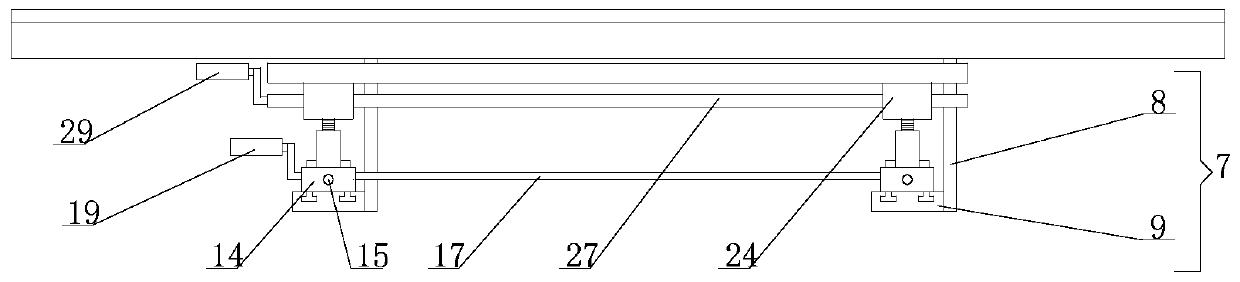

Improved platform trailer

PendingCN109893350AWill not affect normal trafficIncrease the areaStretcherNursing bedsVehicle frameEngineering

The invention discloses an improved platform trailer, and belongs to the technical field of medical auxiliary tools. The platform trailer comprises a trailer frame, a platform and an infusion rod, wherein the trailer frame comprises a support frame and four support legs, wheels are arranged on the support legs, two hand supporting devices which can be movably accommodated under the support frame and a driving device for driving the two hand supporting devices to move horizontally are arranged on the trailer frame; the driving device comprises two mounting frames, two driving assemblies, a first driving shaft and a first driving handle; the two mounting frames are arranged at the bottom of the support frame at intervals, the two driving assemblies are respectively arranged on the two mounting frames, and horizontally move under the driving of the first driving shaft and the first driving handle; the two hand supporting devices are respectively transversely arranged on the two driving assemblies and symmetrically arranged left and right, and the hand supporting devices have the function of height adjustment. The improved platform trailer solves the problem that the arm of the patienteasily slides off from the platform trailer and an accident is caused due to the narrow body of the existing platform trailer when transfusion is carried out.

Owner:柳州市柳铁中心医院

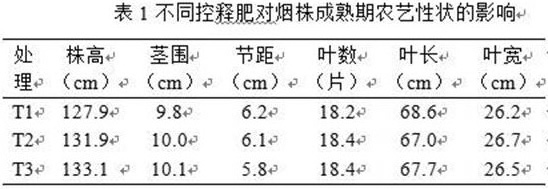

Blended controlled-release fertilizer for flue-cured tobacco in southwest Hubei province, and preparation method and application thereof

PendingCN112159282AImprove qualityReduce labor outputCalcareous fertilisersAlkali orthophosphate fertiliserCoated ureaSoil science

The invention discloses a blended controlled-release fertilizer for flue-cured tobacco in southwest Hubei province. The blended controlled-release fertilizer is composed of a coated nitrogen-potassiumcompound fertilizer with a controlled-release period of 50-70 days, coated urea with a controlled-release period of 30 days, a quick-acting ternary compound fertilizer, granular diammonium phosphateand granular potassium sulfate in a mass ratio of (14-28): (2.3-5.5): (33.5-41): (8-10): (23-33.5). The coated nitrogen-potassium compound fertilizer with the controlled release period of 50-70 days is prepared by the following steps: mixing urea, potassium chloride and stone powder in a mass ratio of (28-32): (58-62): (8-12) to form a raw material mixture, water vapor is introduced, and the mixture is granulated, and then is coated with polyurethane. The compound fertilizer with different release periods provided by the invention can ensure sufficient supply of nutritional ingredients of tobaccos in the early stage, the middle stage and the later stage, the quality of the tobaccos is improved, and the labor output of later topdressing is reduced; and through reasonable matching of the nutrient elements and control of the release period, unnecessary loss of the nutrient elements is reduced, the utilization rate of the fertilizer is increased, environmental pollution is reduced, and theproduction cost is reduced.

Owner:HUBEI CHINA TOBACCO IND

Dyeing device with drying function for cotton yarn processing

PendingCN113322609AWith drying functionEasy to placeTextile treatment machine arrangementsTextile treatment cleaning apparatusYarnPolymer science

The invention discloses a dyeing device with a drying function for cotton yarn processing. The dyeing device comprises a box body, a stirring device, an electric telescopic rod and an air inlet pipe; supporting legs are mounted on the left and right sides of the bottom of the lower end of the box body; the stirring device is mounted in the middle of the bottom of the box body and extends into a dyeing cavity; the electric telescopic rod is mounted at the upper end of the interior of the drying cavity; a placing frame is arranged on two clamping blocks; a fan is arranged on the rear side of the interior of the air inlet pipe; and a plurality of air outlets are formed in a vertical pipe. The dyeing device with the drying function for cotton yarn processing is provided with a partition plate, a through hole, the dyeing cavity and a drying cavity; the box body is divided into the dyeing cavity and the drying cavity through the partition plate, so that the device can complete dyeing and drying in the box body, and the processing time is saved; and through the through hole, cotton yarn can be conveniently placed in the dyeing cavity for dyeing, then the cotton yarn is conveniently taken out of the dyeing cavity during drying, and dye in the dyeing cavity is not easily brought to the outside, so that the practicability of the device is improved.

Owner:宿迁至诚纺织品股份有限公司

Motorbike hub surface deburring device convenient to open and close

ActiveCN108972214AImprove deburring efficiencyReduce labor outputEdge grinding machinesGrinding drivesDrive motorEngineering

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Agricultural picking carrying cart

The invention discloses an agricultural picking carrying cart which comprises a cart body. A roller is arranged at one end of the bottom of the cart body. A supporting rod is arranged at the other endof the bottom of the cart body, a storage cavity is formed inside the cart body, a discharging outlet is formed between the cart body and the storage cavity, a cover plate is arranged at one side ofthe discharging outlet, a hinge is arranged between the cart body and one end of the cover plate, a feeding cylinder is arranged at one side of the discharging outlet, a road breaking front plate is arranged at one end of the cart body, a standing groove is formed in the other end of the cart body, and a handheld handle is arranged at the inner wall of the standing groove. By arranging the road breaking front plate and the standing groove, a user stands inside the standing groove, the cart body is lifted through the handheld handle, the supporting rod is separated from the ground, the cart body moves forwards through rolling of the roller by pushing the handheld handle while the road breaking front plate opens the front road in cotton planting gaps, the user stands inside the standing groove, the user is protected by the cart body against bruising.

Owner:HEFEI CHUANQIU ECOLOGICAL AGRI TECH DEV CO LTD

Double-screw conveying high-hardness granulator compression roller mechanism

InactiveCN112915920AEasy to moveEasy to useGranulation by pressingClassical mechanicsStructural engineering

The invention discloses a double-screw conveying high-hardness granulator compression roller mechanism, relates to the technical field of compression rollers of granulators, and aims to solve the problem that the existing compression rollers of the granulator need to be manually cleaned by personnel after being used for a long time and the labor force is wasted. A rear fixing plate is arranged on one side of the front fixing plate, rotating shafts are arranged between the front fixing plate and the rear fixing plate, compression rollers are arranged outside the rotating shafts and fixedly connected with the rotating shafts, there are two rotating shafts and two compression rollers, and grooves are formed in the outer walls of one end of the rotating shafts. A moving base is arranged at the upper end of the front fixing plate, an electric sliding rail mechanism is arranged on one side of the moving base, a top plate is arranged below the electric sliding rail mechanism, a bottom plate is arranged below the top plate, a brush is arranged at the lower end of the bottom plate, and an air cylinder mechanism is arranged on the other side of the front fixing plate. A fixing ring is arranged on one side of the rear fixing plate.

Owner:扬州首佳机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com