An electromagnetic clutch coil automatic cloth winding device

An electromagnetic clutch and automatic technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of cutting short insulation cloth and low degree of automation, so as to achieve convenient take-out work, reduce labor output, and high-efficiency leak prevention effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

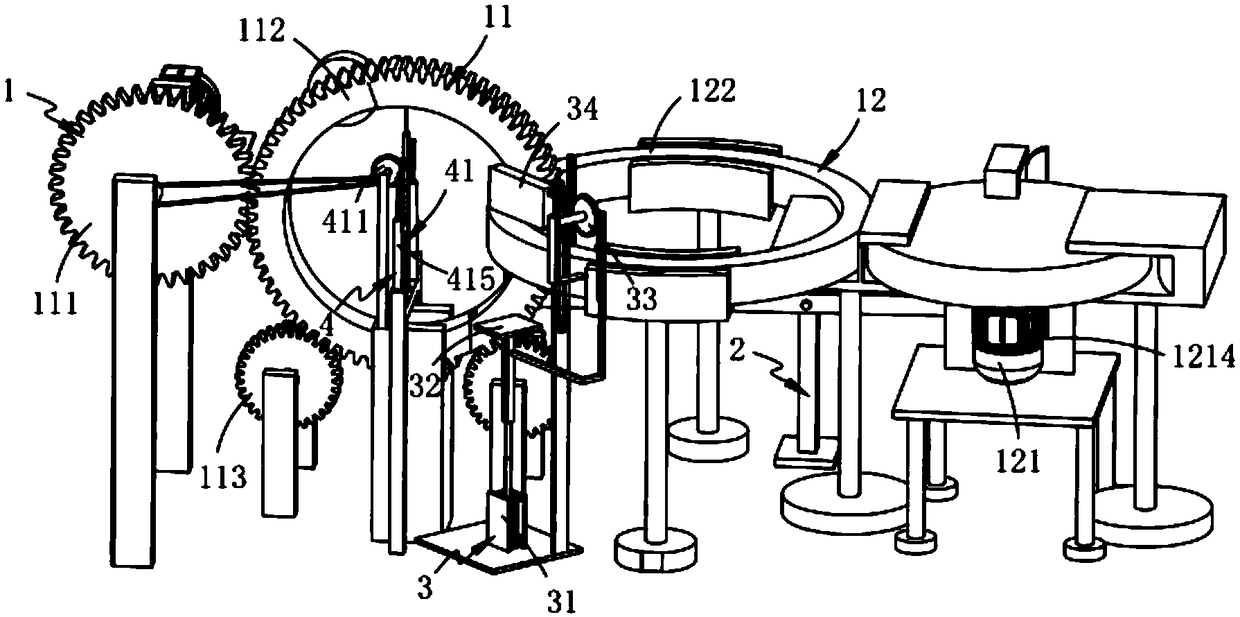

[0081] Such as figure 1 As shown, an electromagnetic clutch coil automatic winding device, including:

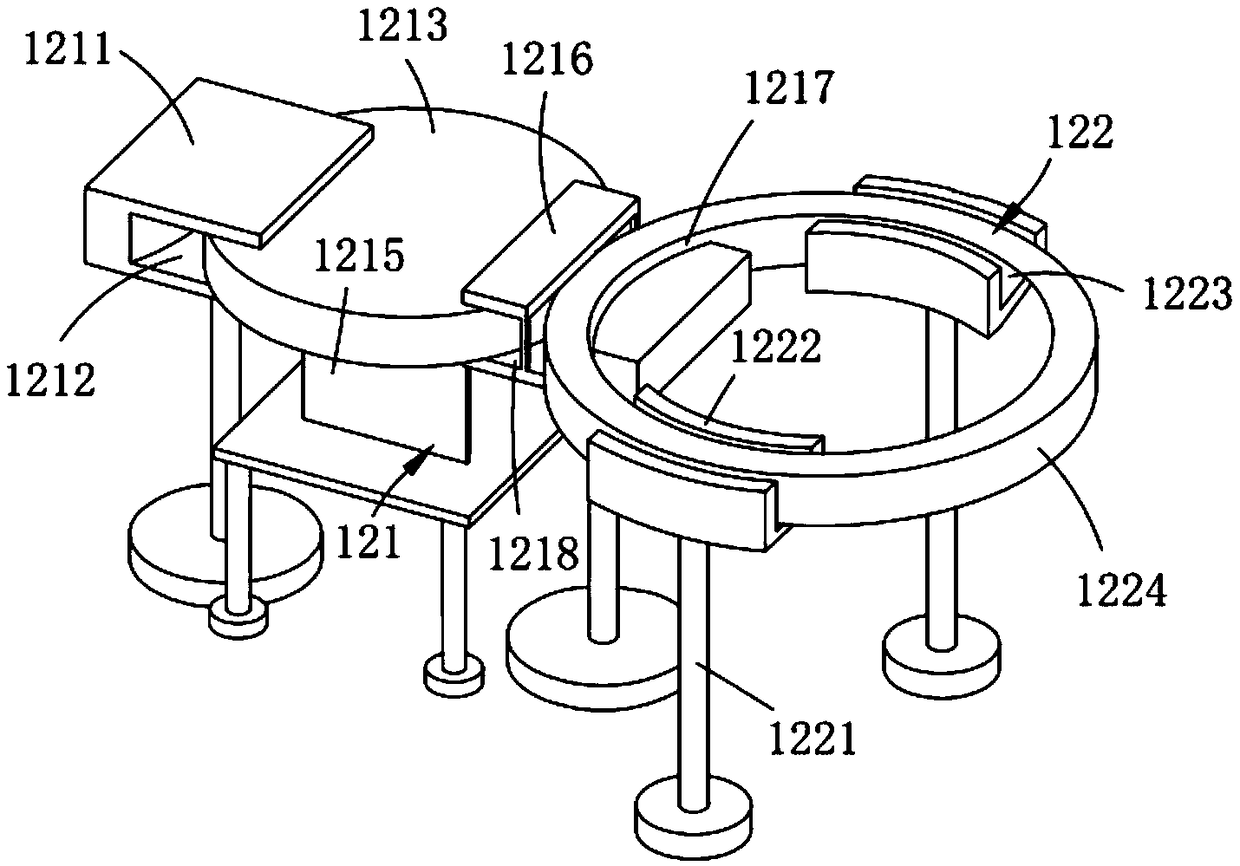

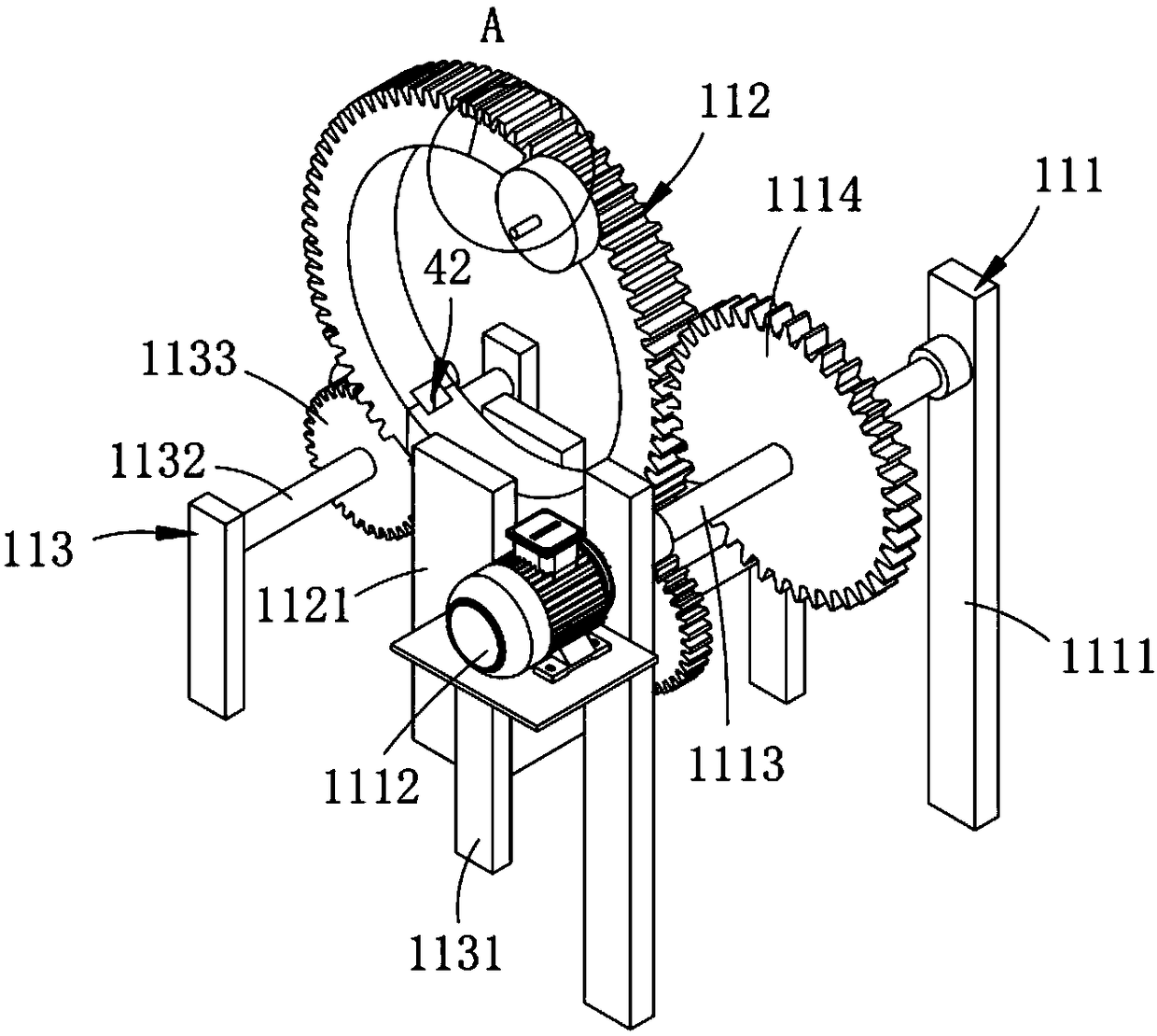

[0082] Cloth winding mechanism 1, said cloth winding mechanism 1 comprises a vertically placed upper cloth assembly 11 and a forming assembly 12 arranged behind said upper cloth assembly 11 and perpendicular to said upper cloth assembly 11;

[0083] A glue-fixing mechanism 2, the glue-fixing mechanism 2 is arranged on one side of the molding assembly 12 and is located at the lower end of the molding assembly 12;

[0084] Cloth cutting mechanism 3, the cloth cutting mechanism 3 is arranged on the other side of the forming assembly 12 relative to the glue fixing mechanism 2; and

[0085] The release mechanism 4, the release mechanism 4 is arranged on the upper cloth assembly 11, which includes a control assembly 41 that moves up and down along the height direction of the upper cloth assembly 11 and is arranged in cooperation with the control assembly 41 and installed on the u...

Embodiment 2

[0147] Such as Figure 7 , Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0148] further, such as Figure 7 , Figure 8 Shown, described glue solid mechanism 2 comprises:

[0149] A control unit a21, the control unit a21 includes a protruding rod 211 fixedly arranged on the upper surface of the edge of the turntable 1213 and an upper pressure block 212 fixedly arranged at the end of the protruding rod 211 and located below;

[0150] The base rod 22, the base rod 22 is located between the turntable 1213 and the induction coil 1224 and is arranged vertically upward;

[0151]The control unit b23, the control unit b23 includes a tilting rod 231 hinged to the base rod 22, a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com