Blended controlled-release fertilizer for flue-cured tobacco in southwest Hubei province, and preparation method and application thereof

A technology of controlled-release fertilizer and mixed control, which is applied in the field of blended controlled-release fertilizer and its preparation of flue-cured tobacco in Southwest Hubei, can solve the problems of unsuitable for large-scale promotion, unfavorable plant growth, slow nutrient release, etc., to prevent rapid release, The effect of reducing labor output and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

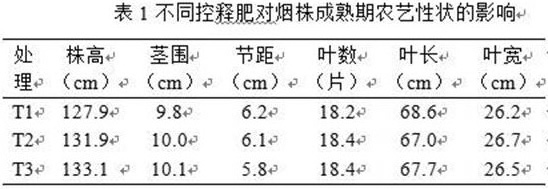

Image

Examples

Embodiment 1

[0044] Embodiment 1 of the present invention provides a kind of preparation method that is used in the preparation method of the blending controlled-release fertilizer of flue-cured tobacco in southwest Hubei, and the specific process is as follows:

[0045] Step 1: Prepare the outer film, mix 20 parts of ring-opening epoxy soybean oil and 50 parts of isocyanate, add 10 parts of pyrethroid insecticides, stir evenly, and obtain the outer film coating solution; prepare the inner film, Mix 20 parts of sodium alginate, 1 part of agar, 0.5 part of glycerin, 0.08 part of paraffin, and 3 parts of calcium chloride at 60°C to obtain the inner membrane coating solution;

[0046] Step 2: Prepare a coated compound fertilizer with a controlled release period of 50-70 days, urea (Guangxi Liuzhou Yixuan Chemical Co., Ltd., item number 1225-6), potassium chloride (Jiangsu Zidong Food Co., Ltd.) and stone powder (Lingshou County Tianlong Mineral Products Processing Factory) mixed into a raw ma...

Embodiment 2

[0051] Embodiment 2 of the present invention provides a kind of preparation method that is used for the blending controlled-release fertilizer of flue-cured tobacco in southwest Hubei, and the specific process is as follows:

[0052] Step 1: Prepare the outer film, mix 25 parts of ring-opening epoxy soybean oil and 55 parts of isocyanate, add 15 parts of pyrethroid insecticides, stir evenly to obtain the outer film coating liquid; prepare the inner film, Mix 25 parts of sodium alginate, 5 parts of agar, 1.25 parts of glycerin, 0.12 parts of paraffin, and 4 parts of calcium chloride at 60°C to obtain the inner membrane coating solution;

[0053] Step 2: Prepare a coated compound fertilizer with a controlled release period of 50-70 days, urea (Guangxi Liuzhou Yixuan Chemical Co., Ltd., item number 1225-6), potassium chloride (Jiangsu Zidong Food Co., Ltd.) and stone powder (Lingshou County Tianlong Mineral Products Processing Factory) mixed into a raw material mixture in the for...

Embodiment 3

[0058] Embodiment 3 of the present invention provides a kind of preparation method that is used for the blending controlled-release fertilizer of flue-cured tobacco in southwest Hubei, and the specific process is as follows:

[0059] Step 1: To prepare the outer film, mix 30 parts of ring-opening epoxy soybean oil and 60 parts of isocyanate, add 20 parts of insecticide, and stir evenly to obtain the outer film coating solution; to prepare the inner film, mix 30 parts of seaweed Sodium bicarbonate, 10 parts of agar, 2 parts of glycerin, 0.16 parts of paraffin, and 5 parts of calcium chloride were mixed uniformly at 60°C to obtain the inner membrane coating solution;

[0060]Step 2: Prepare a coated compound fertilizer with a controlled release period of 50-70 days, urea (Guangxi Liuzhou Yixuan Chemical Co., Ltd., item number 1225-6), potassium chloride (Jiangsu Zidong Food Co., Ltd.) and stone powder (Lingshou County Tianlong Mineral Products Processing Factory) mixed into a ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com